Heat supply equipment

The technology of heating equipment and mixer is applied in the field of heating equipment for high-temperature hot water, which can solve the problems of increased power consumption, loss of thermal energy and pressure of thermal stations, and consumption of human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

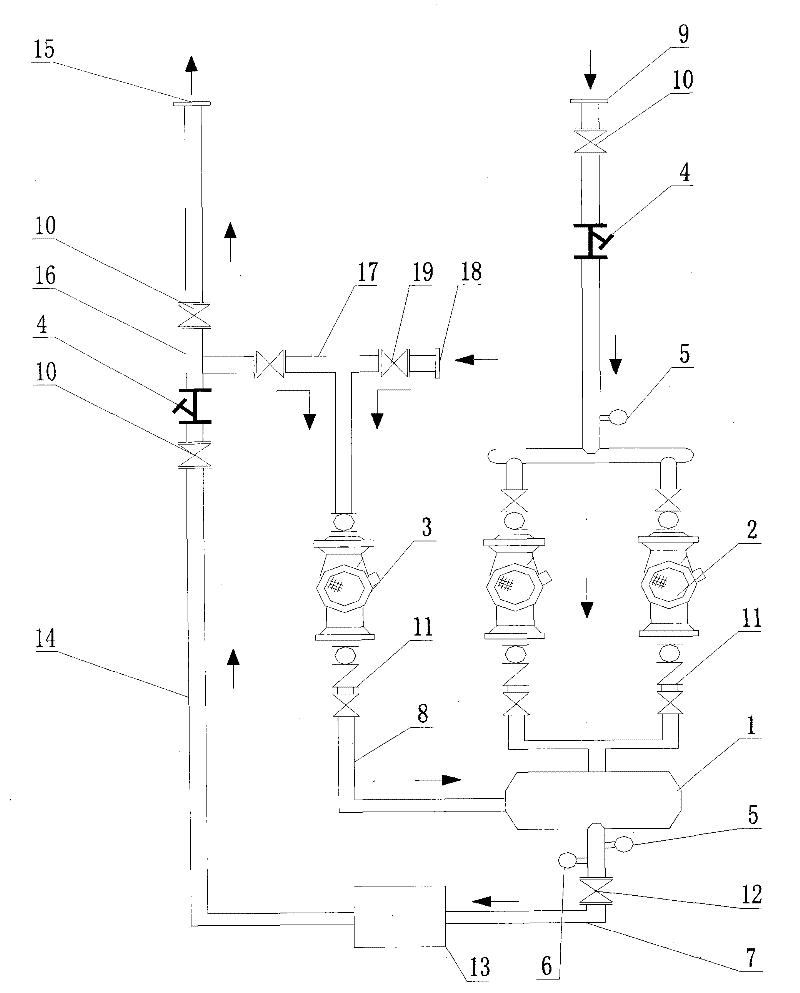

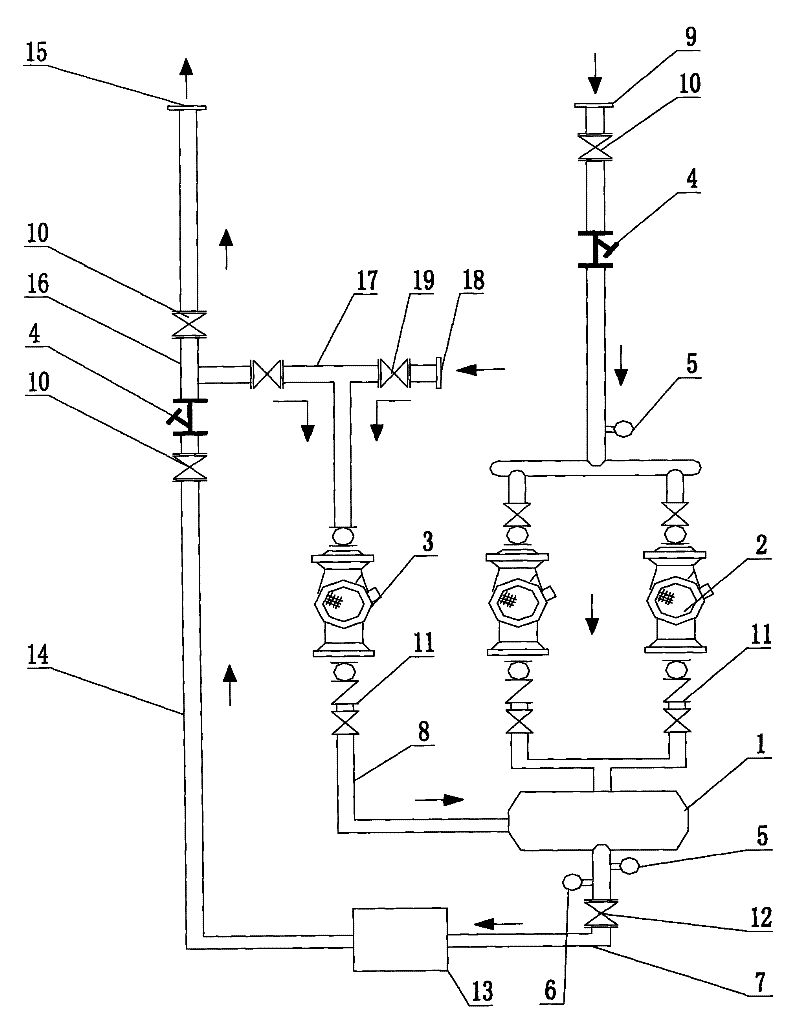

[0007] like figure 1 The shown heating equipment is composed of a mixer 1, a circulating pump 2, a temperature regulating pump 3, a filter 4, a pressure sensor 5, a temperature sensor 6, connecting pipes and the like. The high-temperature water source of the thermal station is connected to the inlet of the circulation pump 2 through the nozzle 9, the valve 10, and the filter 4. The outlet of the circulation pump 2 is connected to the mixer 1 after passing through the valve group 11, and the outlet of the mixer 1 is connected to the valve 12. The connecting pipe 7 is connected with the heat load 13 for the user, so that heat can be supplied to the heat load for the user. The low-temperature return water of the heat load 13 for the user passes through the return pipe 14. A valve 10 and a filter 4 are installed, and a There is a nozzle 15 connected to the recovery pipe network of the heat station, the return pipe 14 is connected to the water inlet of the temperature regulating pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com