Separable tank container movable heating plant with high stored energy

A technology for separating tanks and containers, applied in the field of high-energy-storage separable tank-type container mobile heating stations, can solve the problems of long charging and discharging time, low heat storage capacity, low heat storage temperature, etc. The effect of large heat storage capacity and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

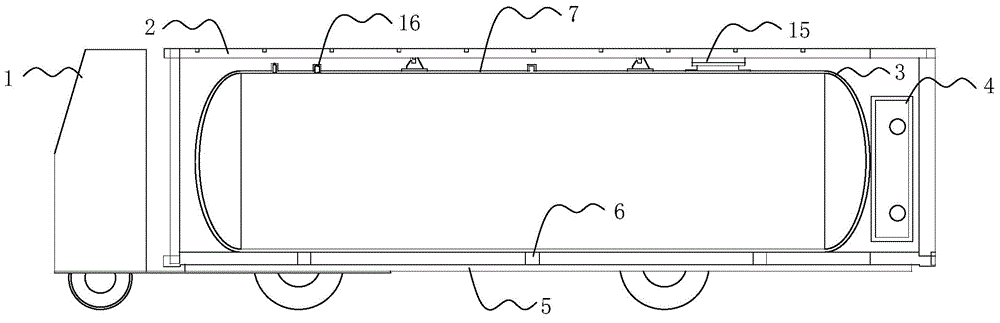

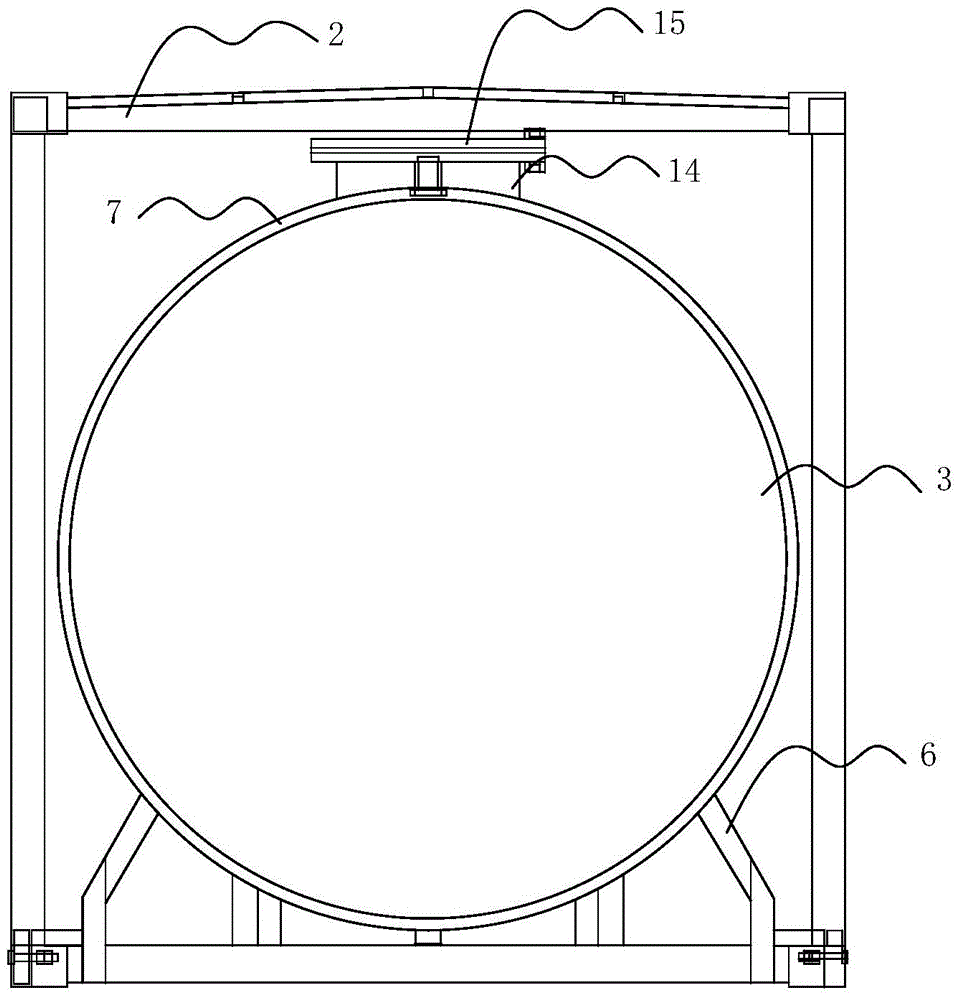

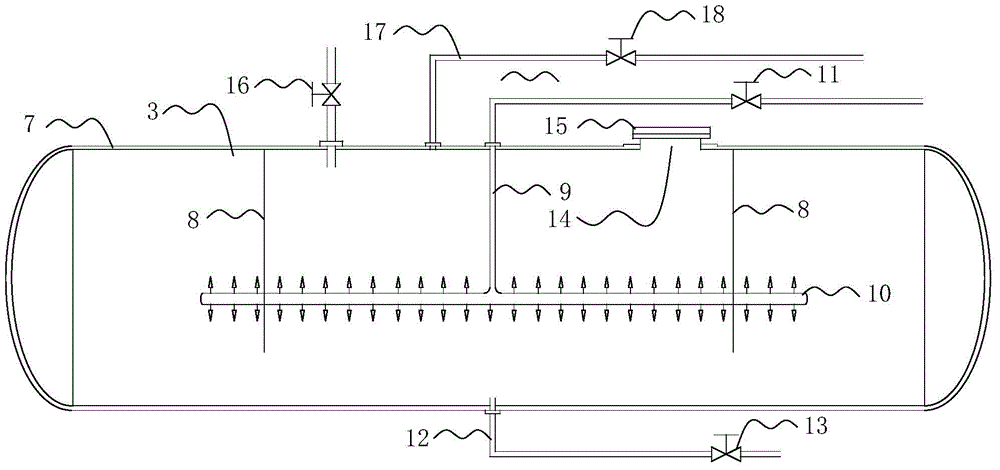

[0019] Embodiment 1, combining Figure 1 to Figure 3 , a high-energy-storage detachable tank-type container mobile heating station, including a tractor 1, a steel structure frame 2, a heat storage tank 3 and an operation control box 4, a trailer 5 is connected to the rear of the tractor 1, and a steel The structural frame 2 is installed on the trailer 5, and the heat storage tank 3 is installed in the steel structure frame 2 through the support 6 arranged at the bottom of the steel structure frame 2, and the heat storage tank 3 and the steel structure frame 2 can be separated. The cross-section of the heat storage tank 3 is preferably cylindrical or elliptical, and other shapes such as a square can also be adopted. The front and rear ends of the heat storage tank 3 adopt an outwardly protruding arc structure. Made of high-quality metal materials, such as high-quality Q235B carbon steel, Q245R, 345R manganese steel, S30408 or S31608 stainless steel. The filler in the heat st...

Embodiment 2

[0022] Example 2, combined with figure 1 , figure 2 and Figure 4 , a high-energy-storage detachable tank-type container mobile heating station, including a tractor 1, a steel structure frame 2, a heat storage tank 3 and an operation control box 4, a trailer 5 is connected to the rear of the tractor 1, and a steel The structural frame 2 is installed on the trailer 5, and the heat storage tank 3 is installed in the steel structure frame 2 through the support 6 arranged at the bottom of the steel structure frame 2, and the heat storage tank 3 and the steel structure frame 2 can be separated. The cross-section of the heat storage tank 3 is preferably cylindrical or elliptical, and other shapes such as a square can also be adopted. The front and rear ends of the heat storage tank 3 adopt an outwardly protruding arc structure. Made of high-quality metal materials, such as high-quality Q235B carbon steel, Q245R, 345R manganese steel, S30408 or S31608 stainless steel. The fille...

Embodiment 3

[0025] Example 3, combined with figure 1 , figure 2 and Figure 5 , a high-energy-storage detachable tank-type container mobile heating station, including a tractor 1, a steel structure frame 2, a heat storage tank 3 and an operation control box 4, a trailer 5 is connected to the rear of the tractor 1, and a steel The structural frame 2 is installed on the trailer 5, and the heat storage tank 3 is installed in the steel structure frame 2 through the support 6 arranged at the bottom of the steel structure frame 2, and the heat storage tank 3 and the steel structure frame 2 can be separated. The cross-section of the heat storage tank 3 is preferably cylindrical or elliptical, and other shapes such as a square can also be adopted. The front and rear ends of the heat storage tank 3 adopt an outwardly protruding arc structure. Made of high-quality metal materials, such as high-quality Q235B carbon steel, Q245R, 345R manganese steel, S30408 or S31608 stainless steel. The fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com