Waste comprehensive treatment process and equipment for solid fuel generating station

A comprehensive treatment and solid fuel technology, applied in waste treatment, solid waste removal, gas treatment, etc., can solve the problems of increased unsafe factors, easy damage to the deep sea ecological environment, and far-reaching practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

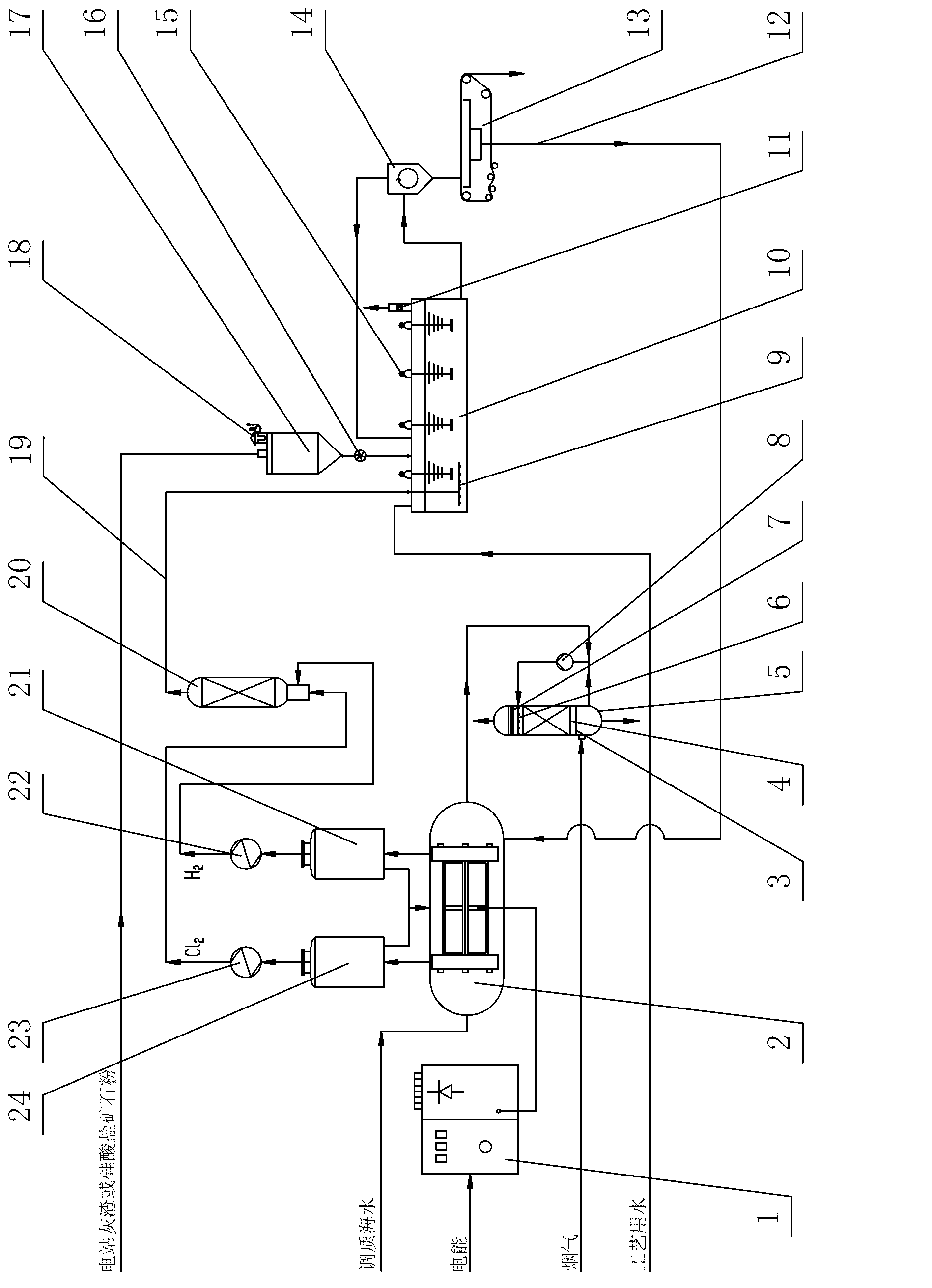

[0044] The process and equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The solid fuel power station waste comprehensive treatment equipment shown in the figure mainly consists of a voltage transformation and rectification device 1, an electrolysis device 2, a carbon dioxide absorption tower 5, a hydrogen chloride synthesis tower 20, a silicate powder silo 17, and a silicate reaction Device 10, cyclone separator 14 and vacuum belt conveyor 13 and other components. in:

[0046] The output end of the transformer and rectifier device 1 is connected to the power interface of the electrolysis device 2 . The cathode hydrogen outlet of the electrolysis device 2 is connected to the hydrogen input end of the hydrogen chloride synthesis tower 20 through the hydrogen separator 21 and the hydrogen cooler 22 successively, and the anode chlorine outlet of the electrolysis device 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com