Heat pipe heat dissipation structure

a heat dissipation structure and heat pipe technology, applied in indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of internal capillaries, internal capillaries, sintered metal powder or mesh capillaries, etc., to improve heat dissipation efficiency, reduce interface thermal resistance, and improve anti-gravity ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

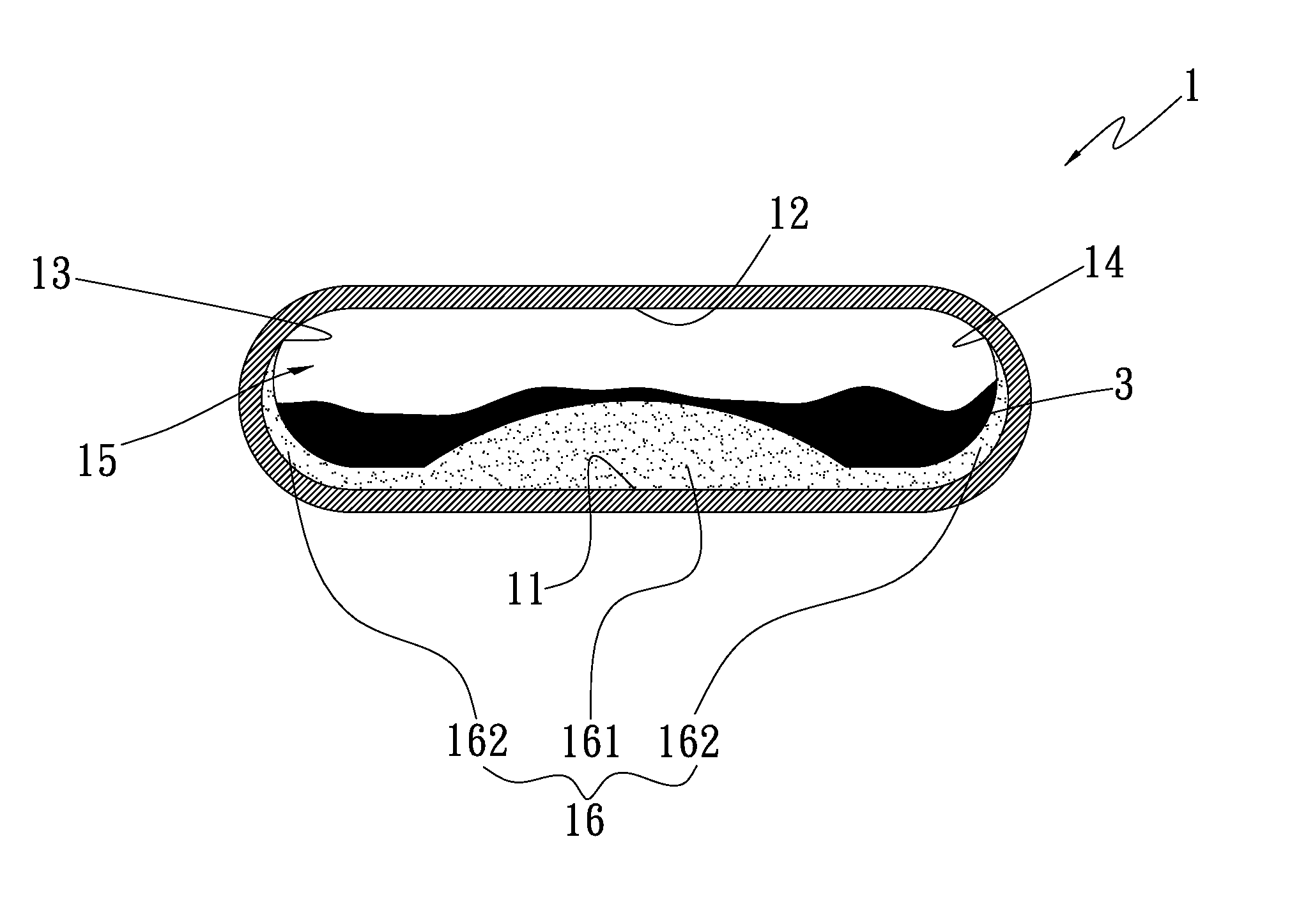

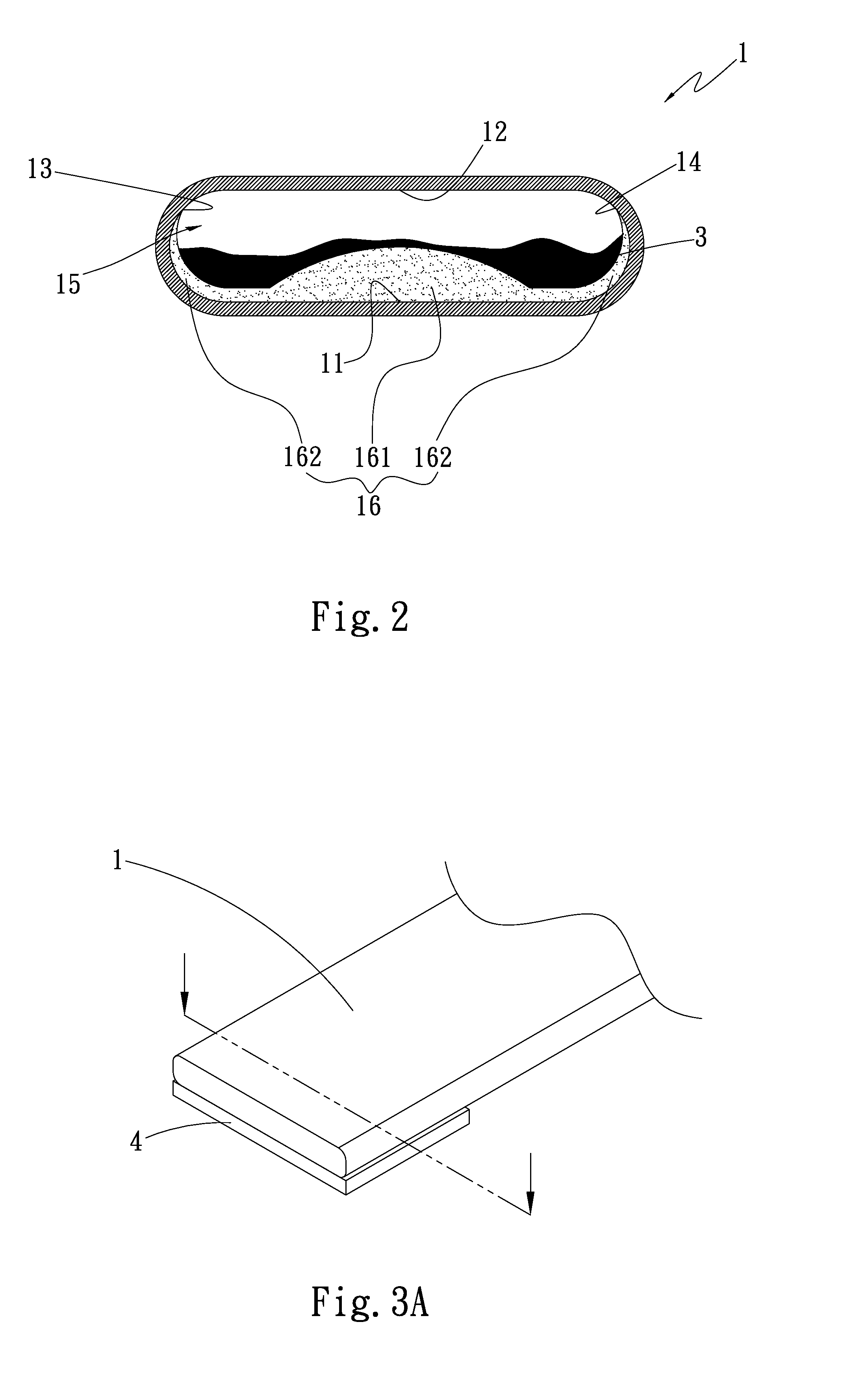

[0025]Please refer to FIGS. 1 and 2. FIG. 1 is a perspective view of a first embodiment of the heat pipe heat dissipation structure of the present invention. FIG. 2 is a sectional view of the first embodiment of the heat pipe heat dissipation structure of the present invention. According to the first embodiment, the heat pipe heat dissipation structure of the present invention includes a main body 1 and at least one first capillary structure 16. The main body 1 has a first inner side 11, a second inner side 12, a third inner side 13, a fourth inner side 14 and at least one chamber 15. The first inner side 11 is opposite to the second inner side 12, while the third inner side 13 is opposite to the fourth inner side 14. The first, second, third and fourth inner sides 11, 12, 13, 14 together define the chamber 15. A working fluid is filled in the chamber 15. The working fluid is selected from a group consisting of pure water, inorganic compound, alcohol, ketone, liquid metal, coolant a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com