Method for generating power by gasifying integrated straws in supercritical coal-fired generator set

A generator set, supercritical technology, applied in combustion engines, internal combustion piston engines, granular/powdered fuel gasification, etc., can solve the problems of auger feeding equipment stuck, core components damaged, etc., to facilitate the storage and transportation of raw materials, Reduce the floor area and avoid the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

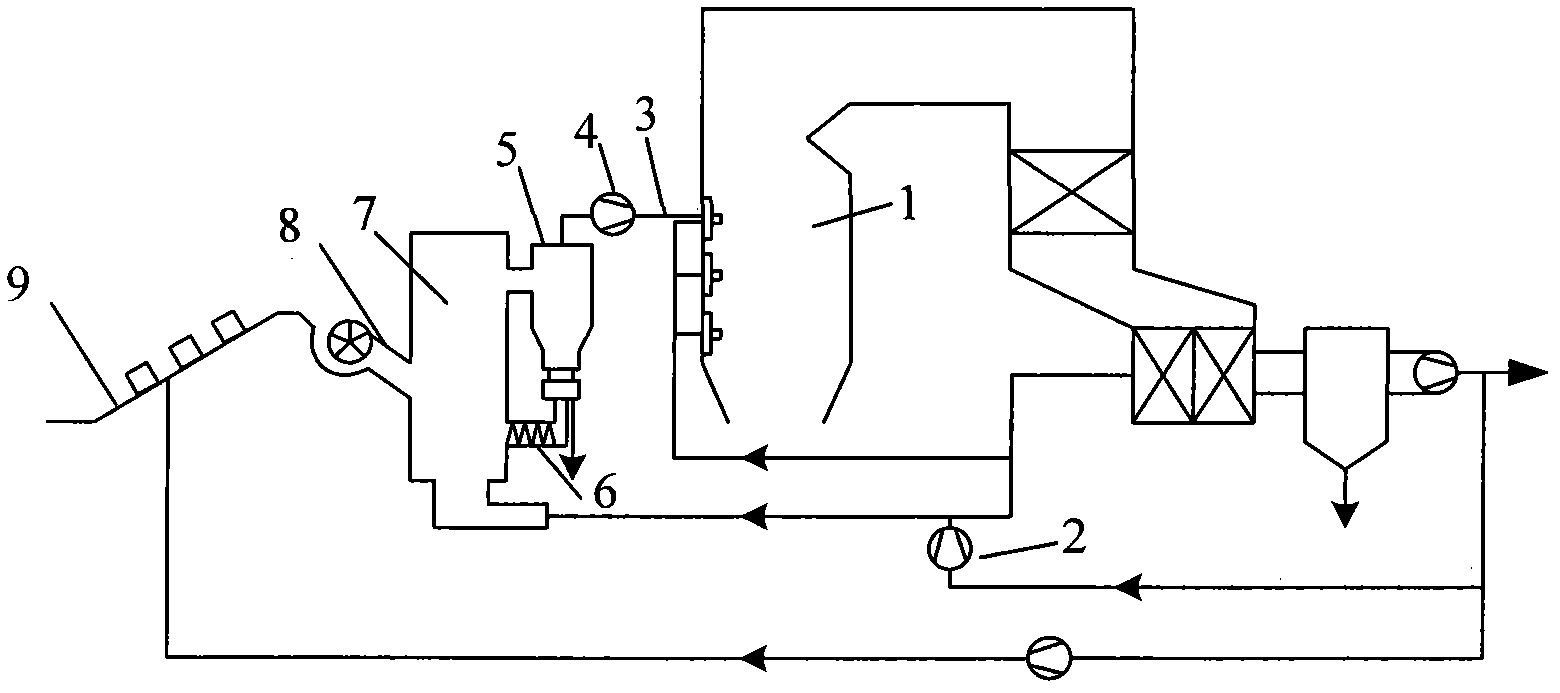

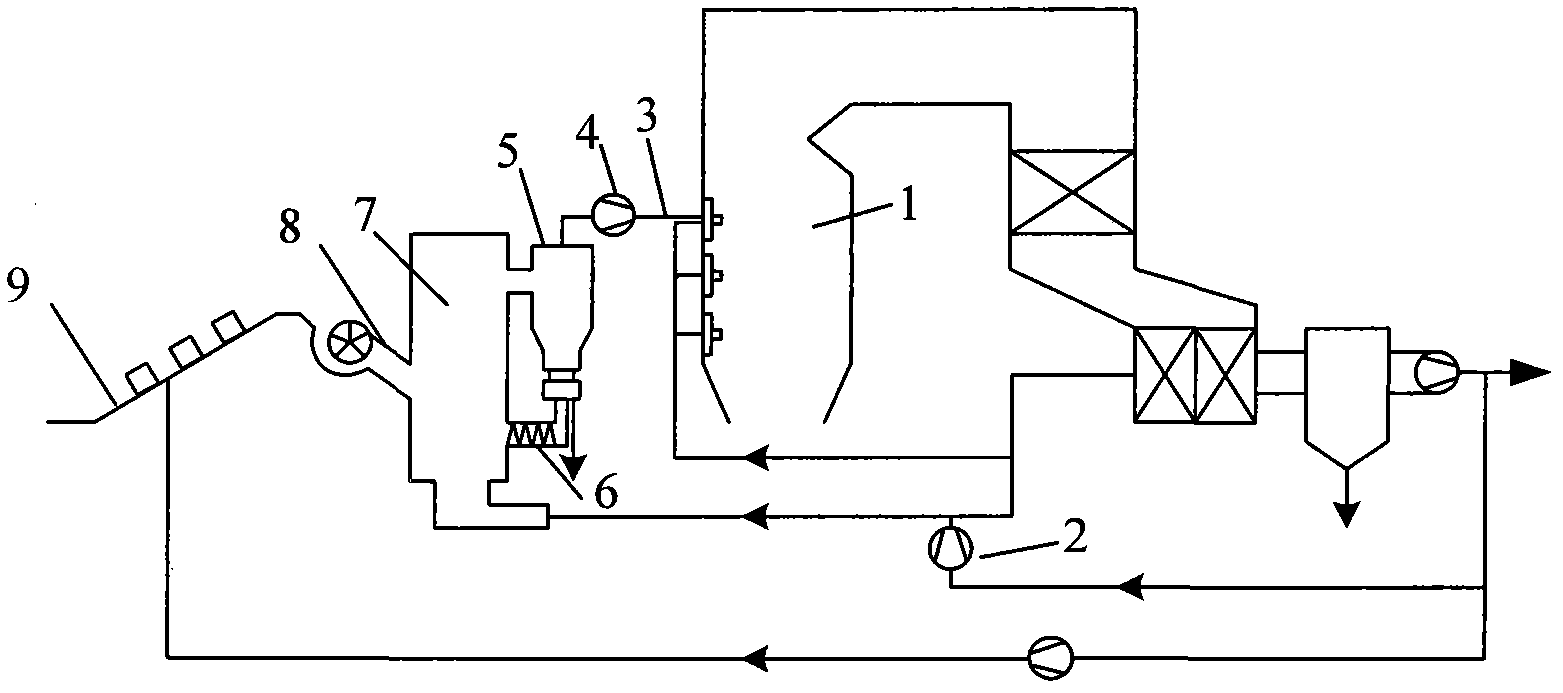

[0028] The entire pulverized coal power generation unit integrated straw gasification power generation system operates in the mode of one pulverized coal furnace and one or more gasifiers. In this example, it is a belt-one mode, such as figure 1 shown.

[0029] In view of the possibility that the moisture content of the biomass package may be too high, the belt drying conveyor adopted in this embodiment also has a drying function. After the biomass straw bag is transported to the site, it is broken up by the belt drying conveyor 9 through the straw bag breaking device 8 and thrown into the gasifier 7 for gasification. Packing density is about 200kg / m 3 , The size of the material bag is determined by the size of the gasifier, and the section of a single material bag is generally not more than 50% of the bed area of the gasifier. A part of exhaust gas from the boiler tail (about 100°C) is used as a desiccant, and the hot flue gas is dried on the way of the conveying section....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com