Patents

Literature

187results about How to "Realize waste heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

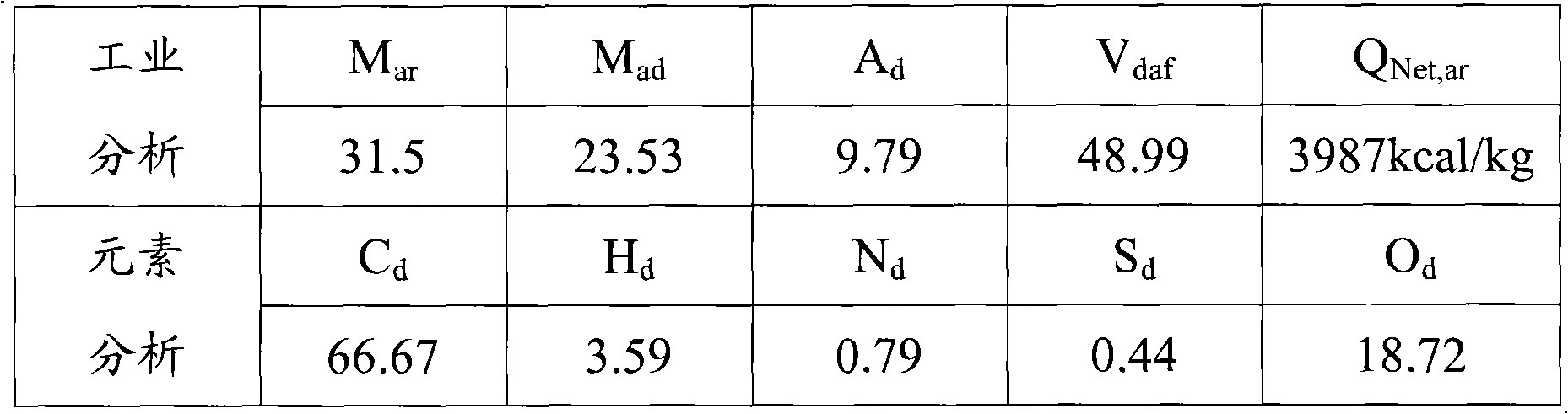

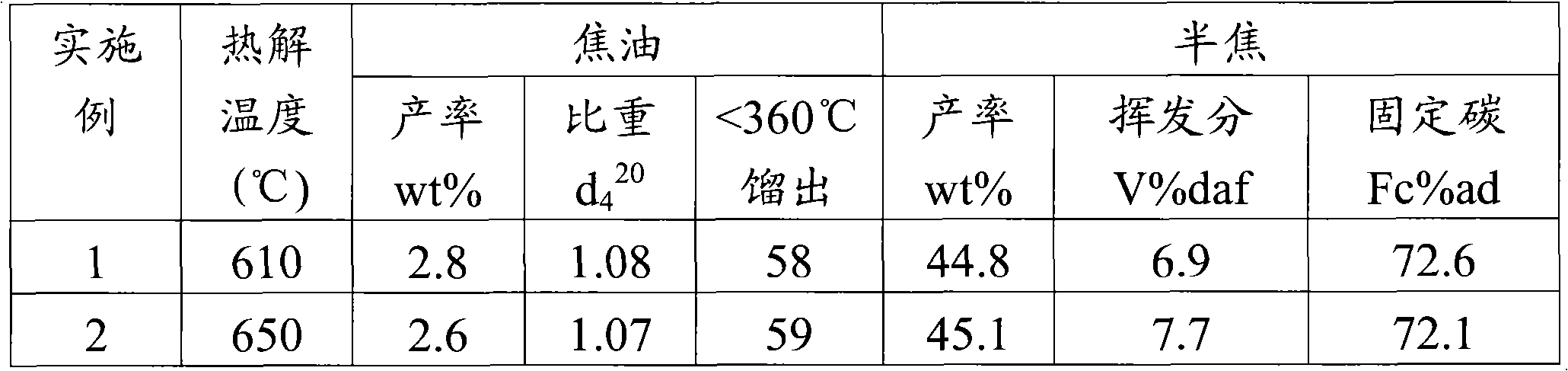

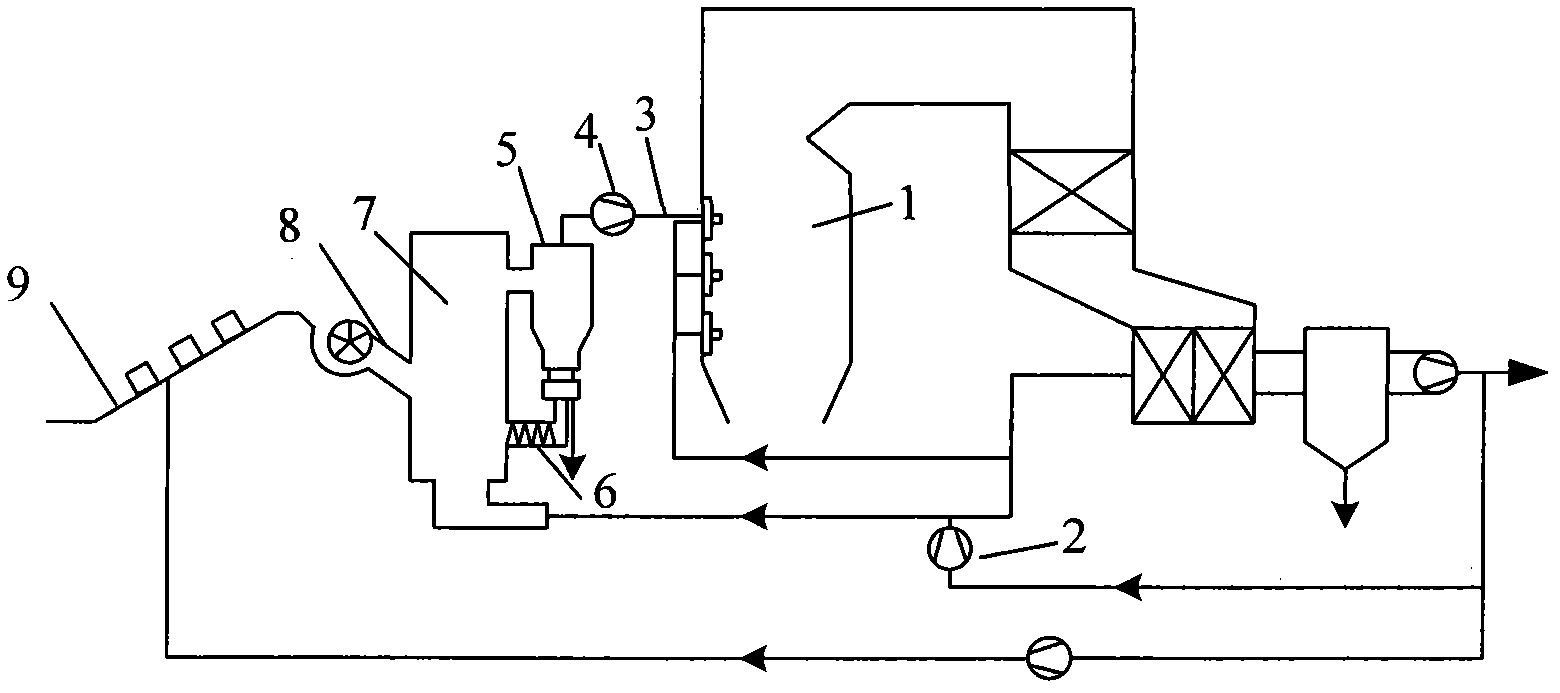

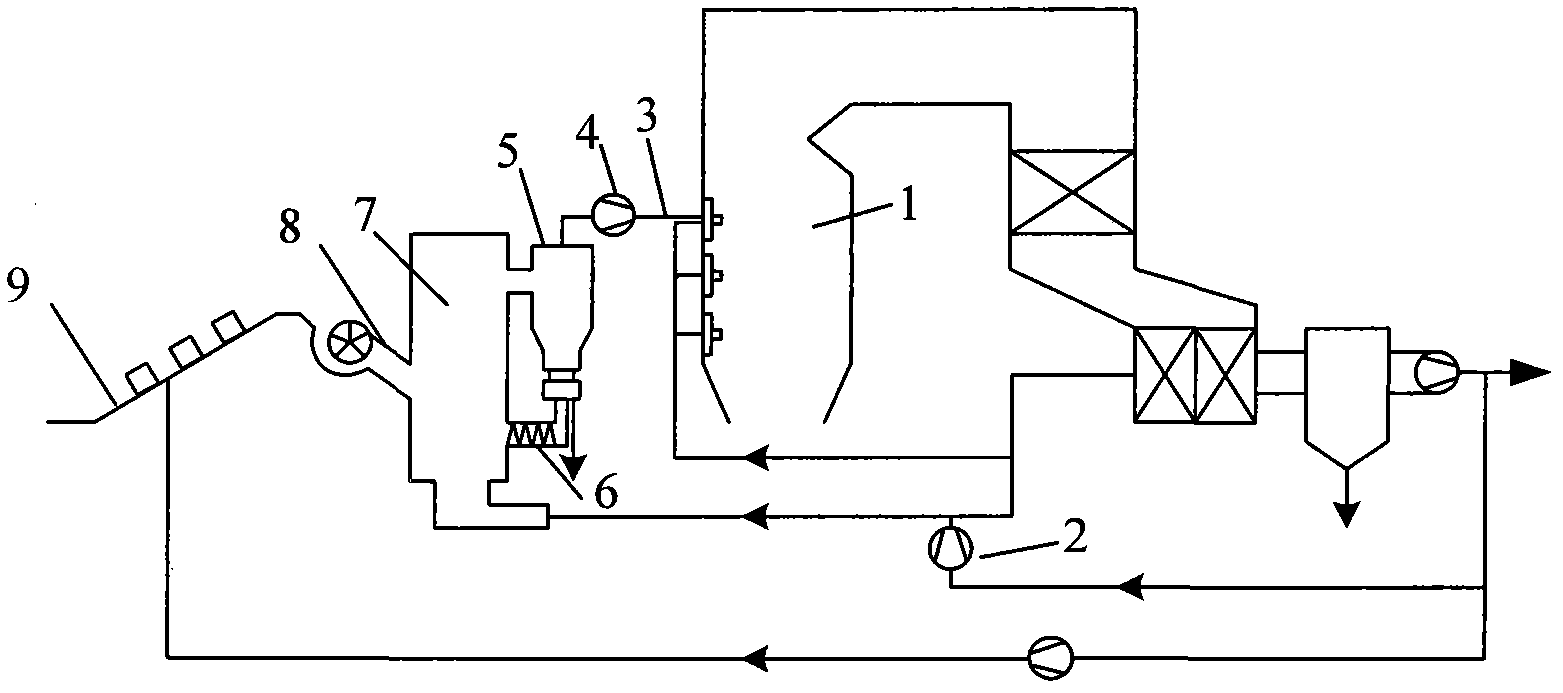

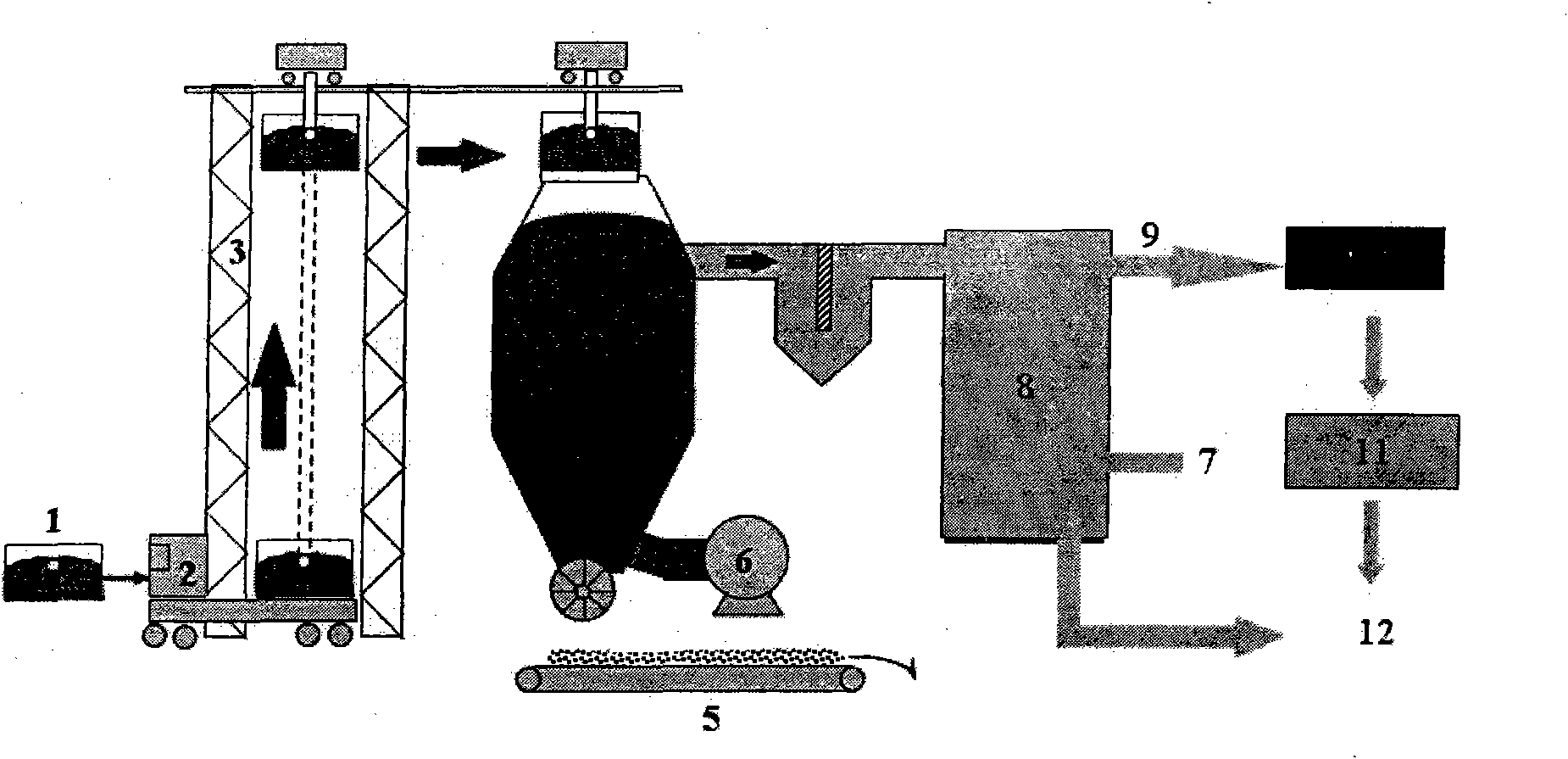

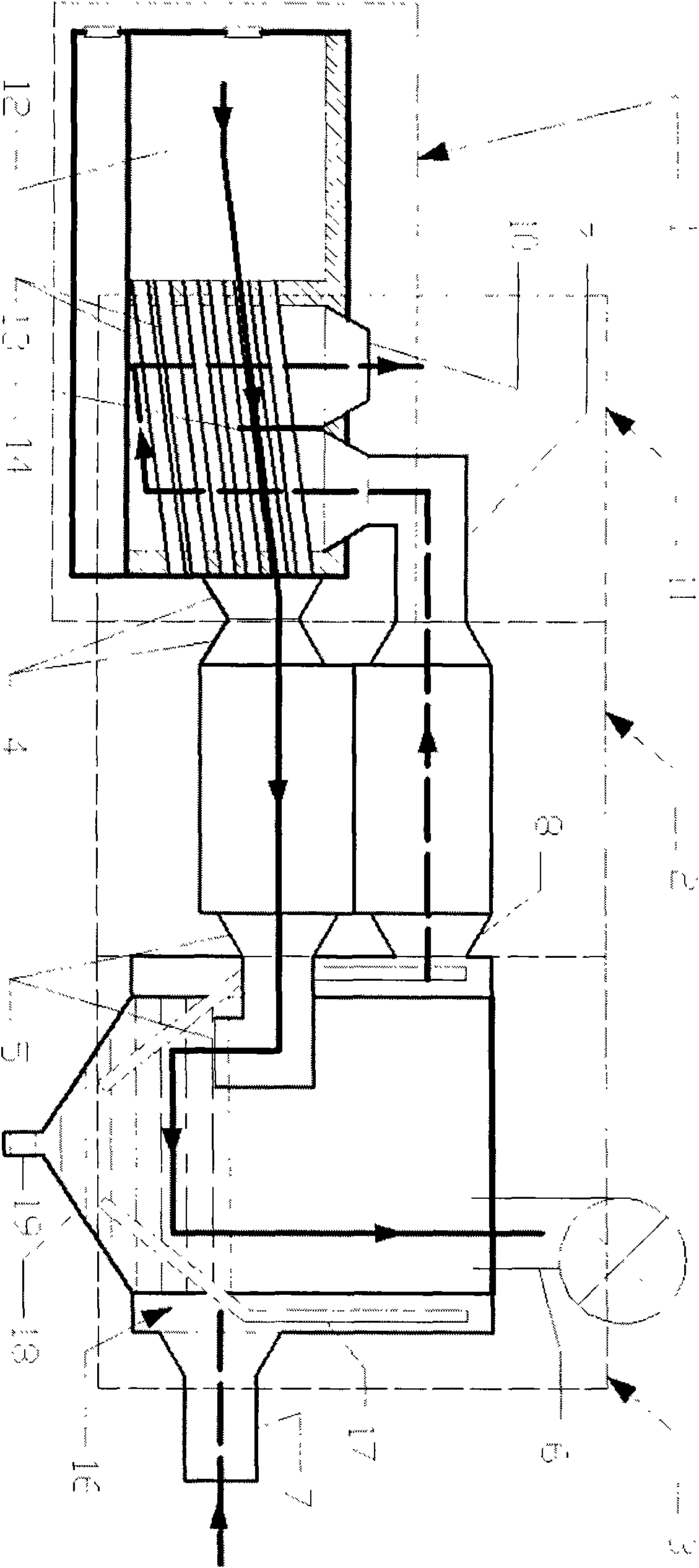

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

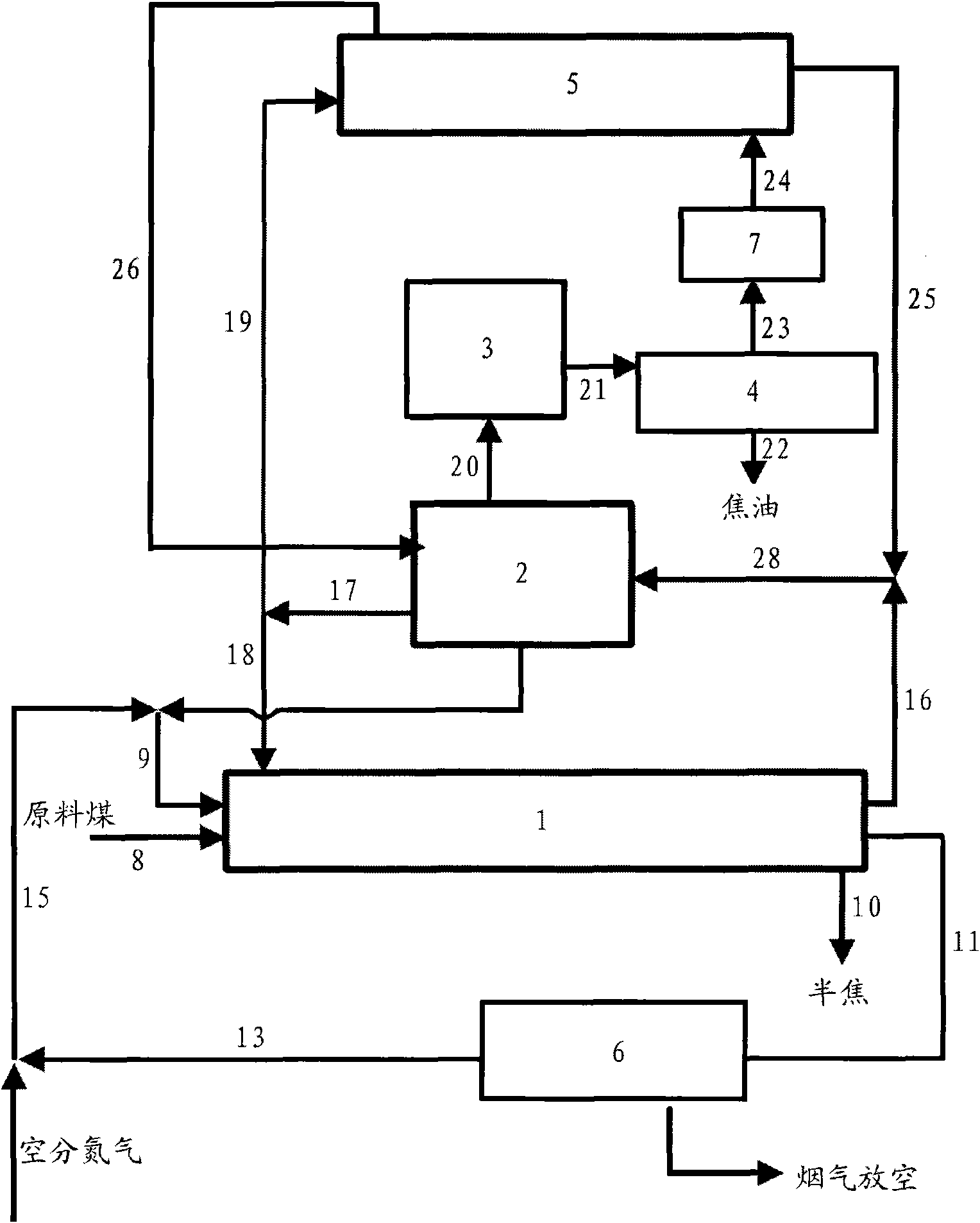

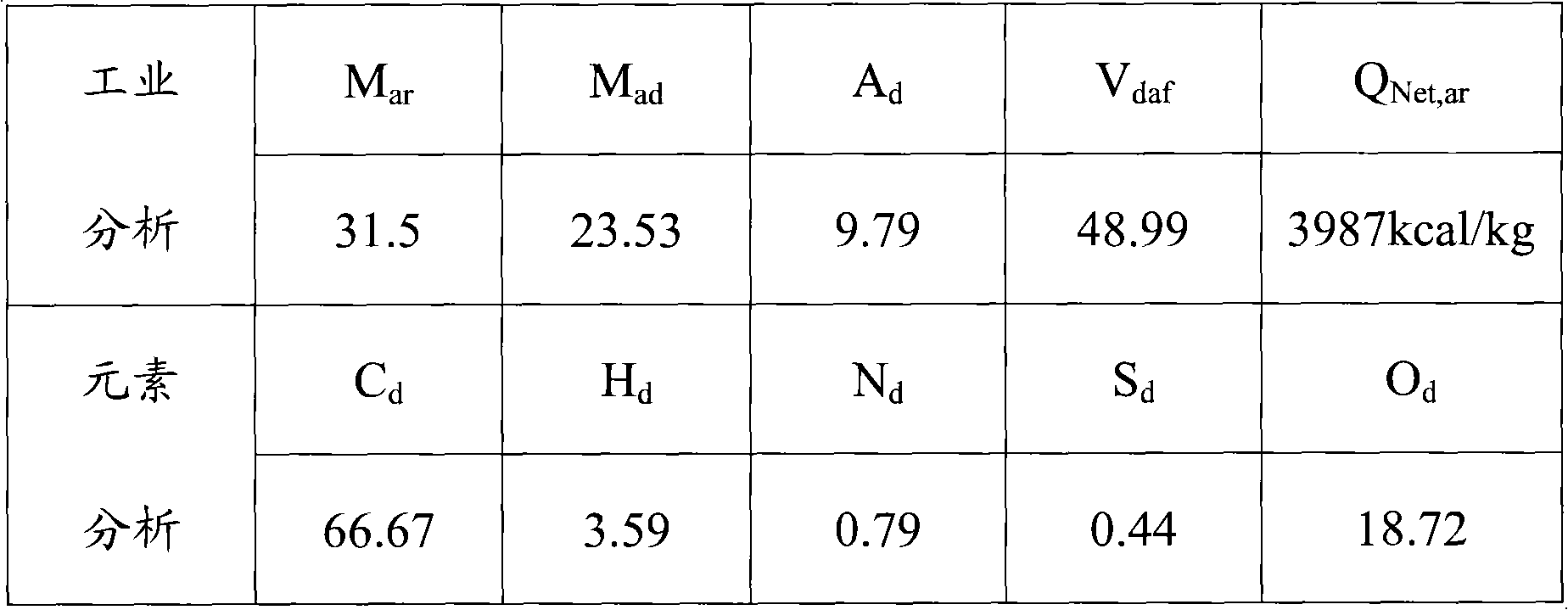

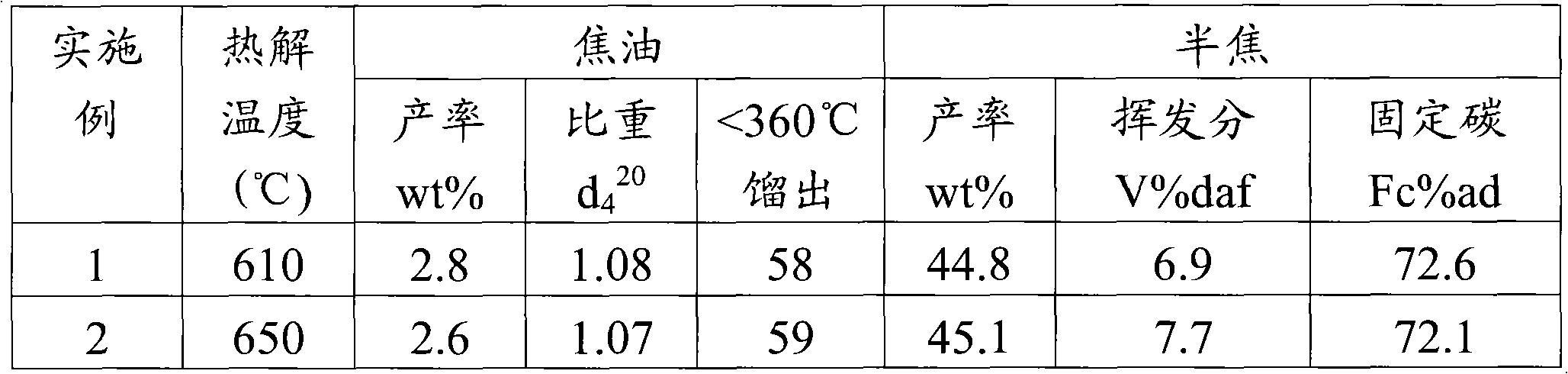

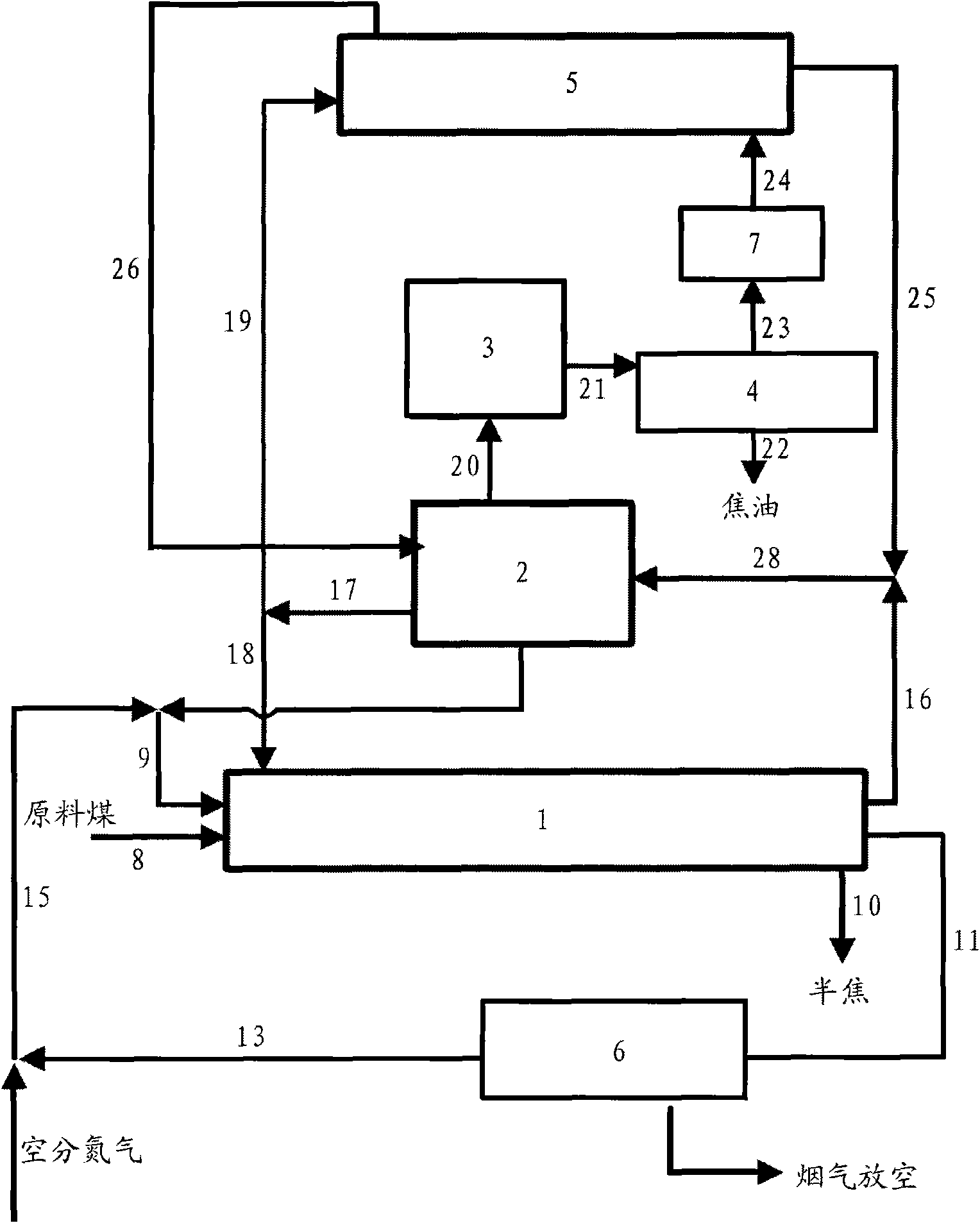

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

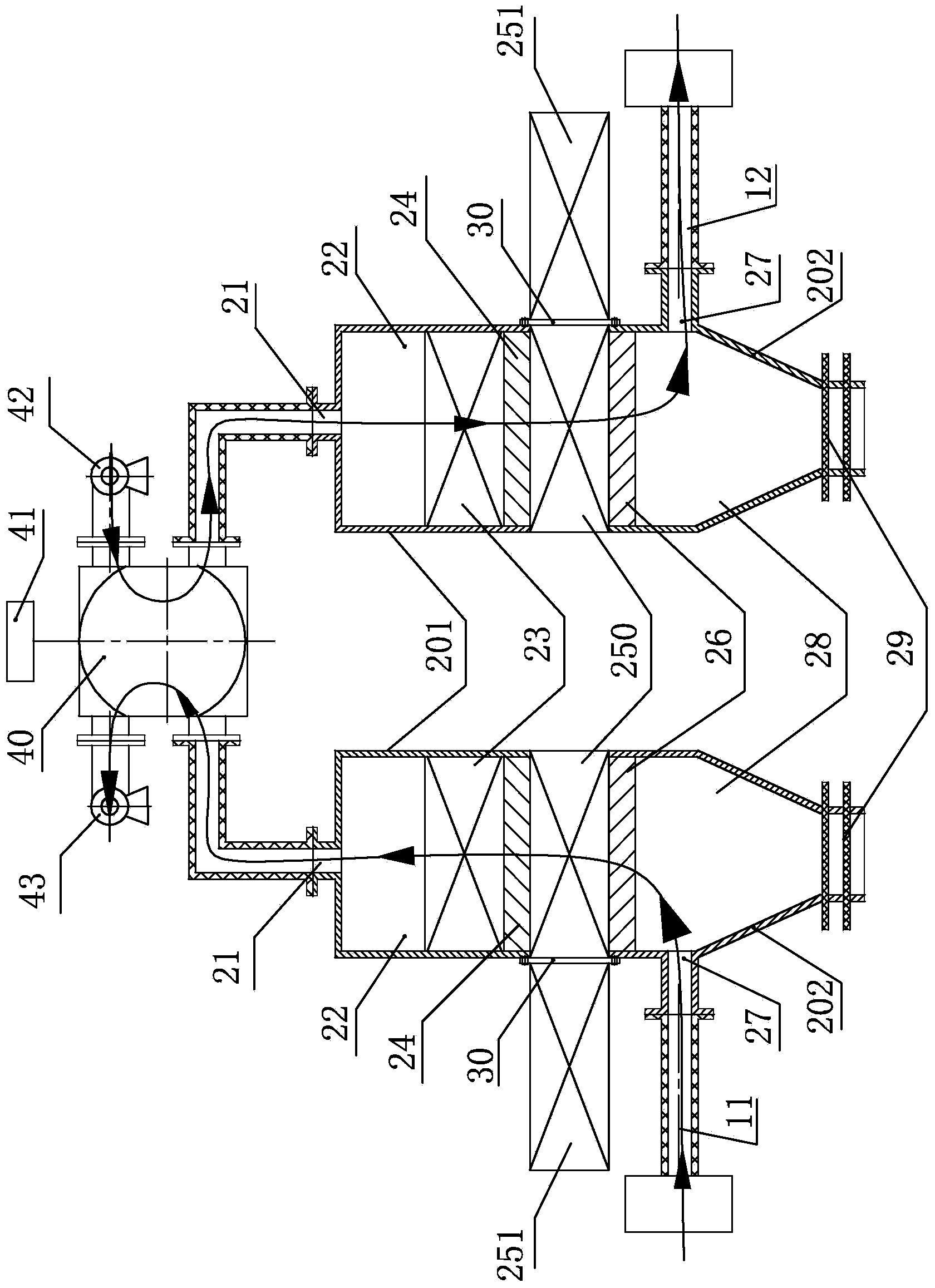

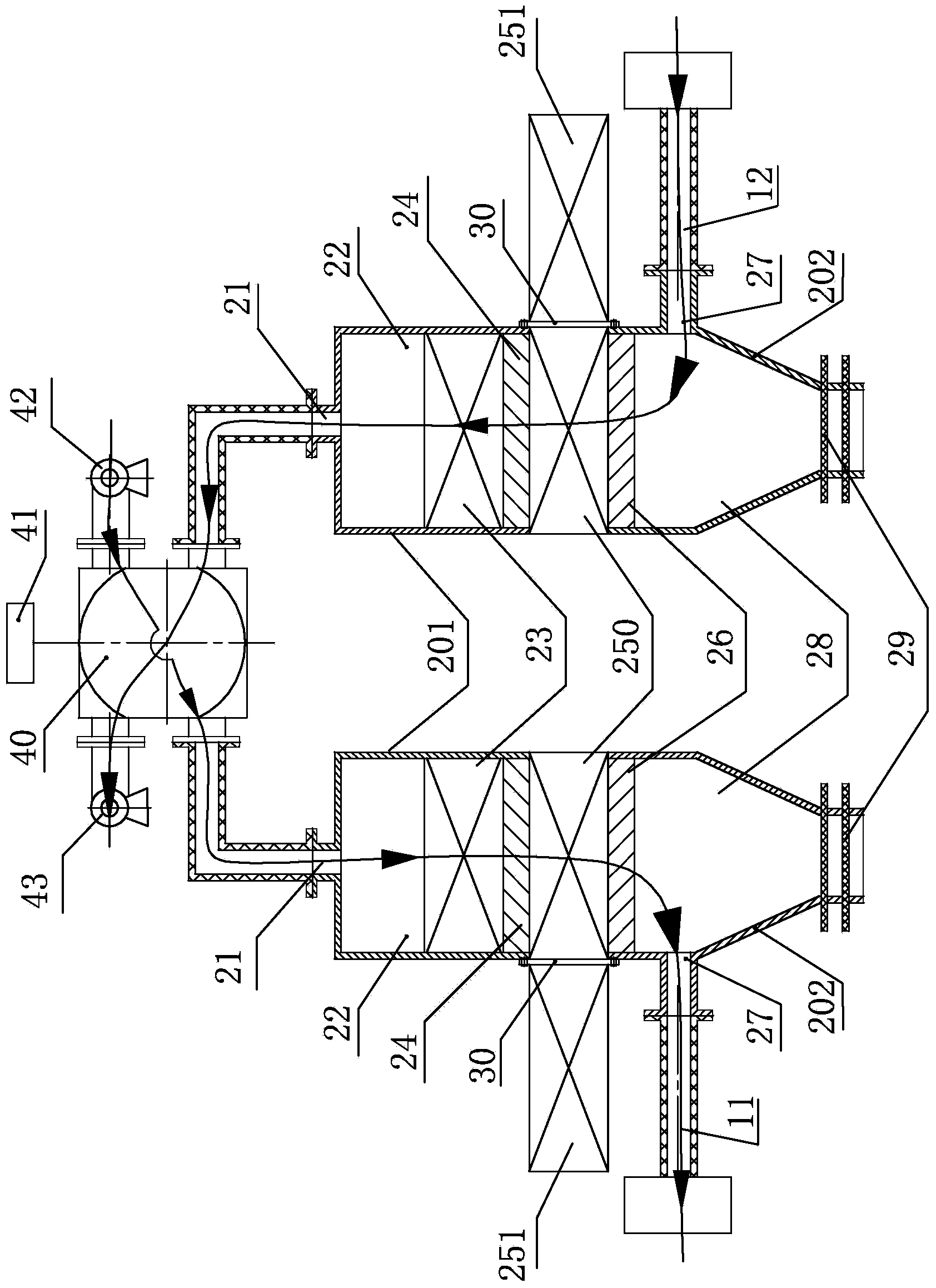

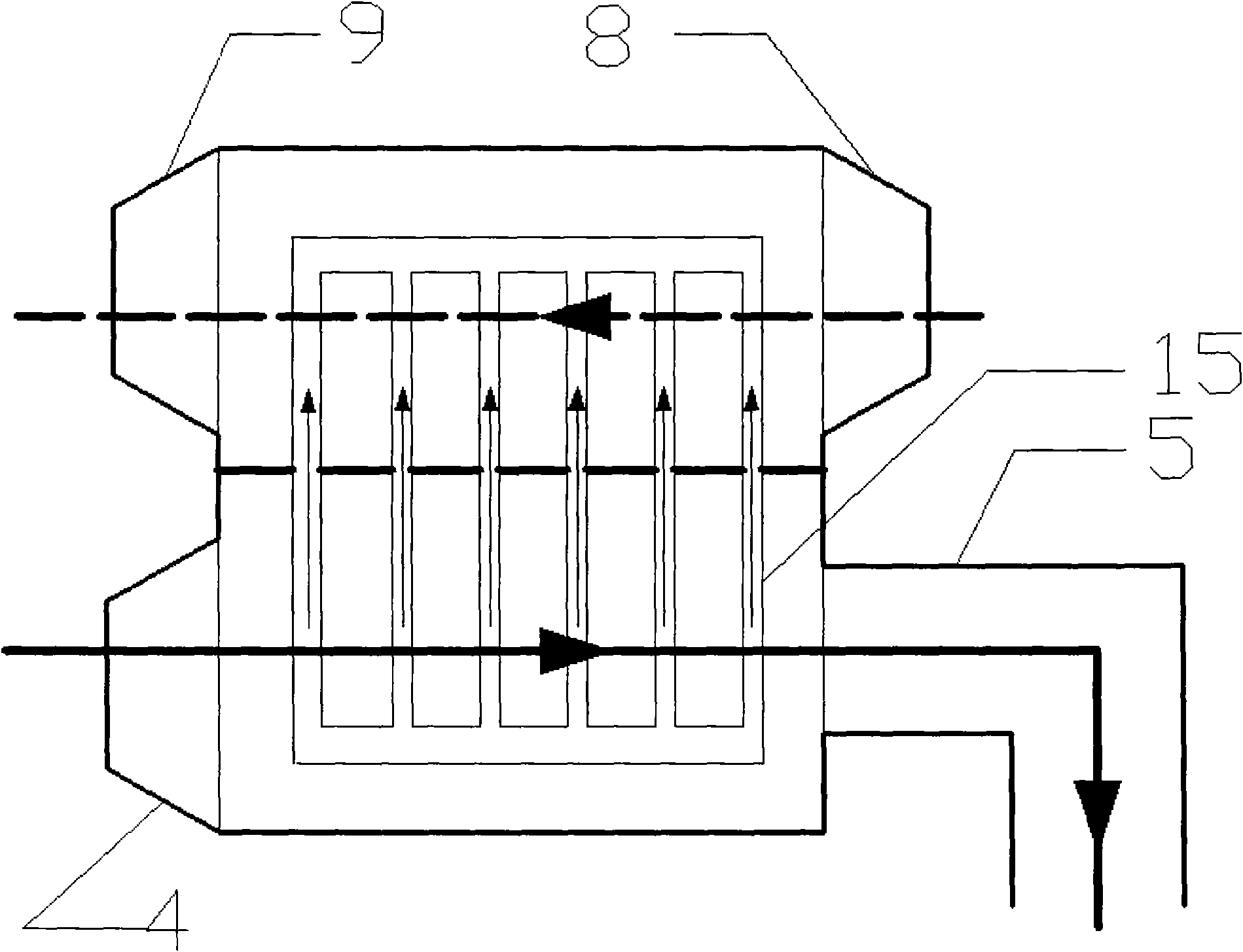

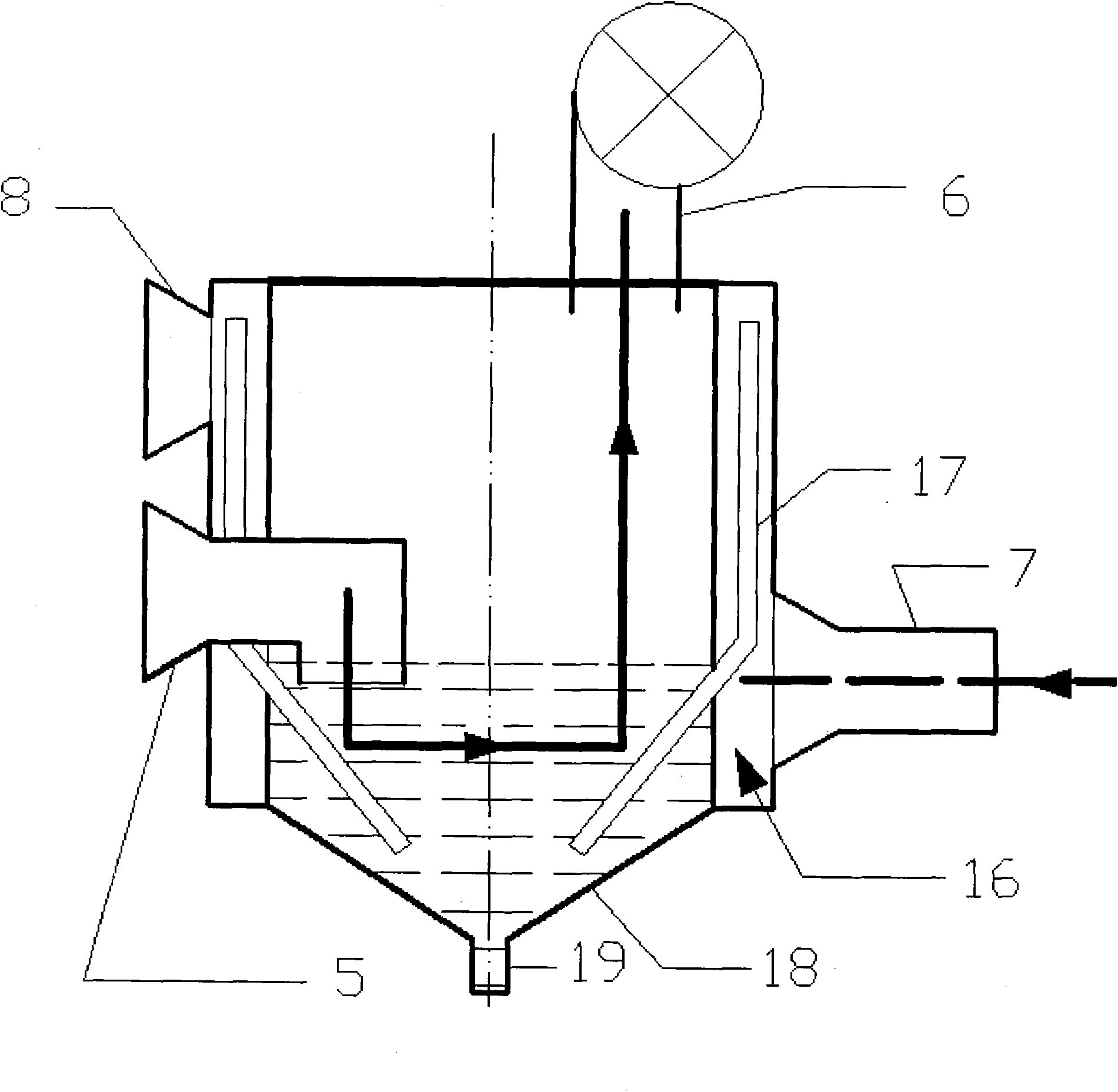

Device for improving quality of coal by pyrolysis

ActiveCN101608126AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a device for improving the quality of the coal by pyrolysis, comprising a rotary drier, a pyrolyzer and a heating rotary kiln. The rotary drier is used for receiving and drying raw coal with granularity being less than and equal to 30mm, and is provided with a sleeve structure to directly change heat between the raw coal and the hot flue gas and indirectly change heat between the raw coal and hot semicoke; the pyrolyzer receives mixture of the dried raw coal and the high-temperature semicoke by a feed line of solid material, directly changes heat between the raw coal and the hot semicoke, pyrolyzes the mixture, and is further provided with a heat clamping sleeve accompanied with high-temperature flue gas; and the heating rotary kiln is used for receiving the hot semicoke from the pyrolyzer and processing the hot semicoke by the means of heating. The device for improving the quality of the coal by pyrolysis has flexible operation, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

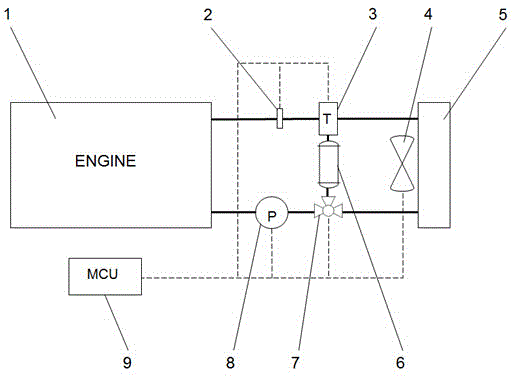

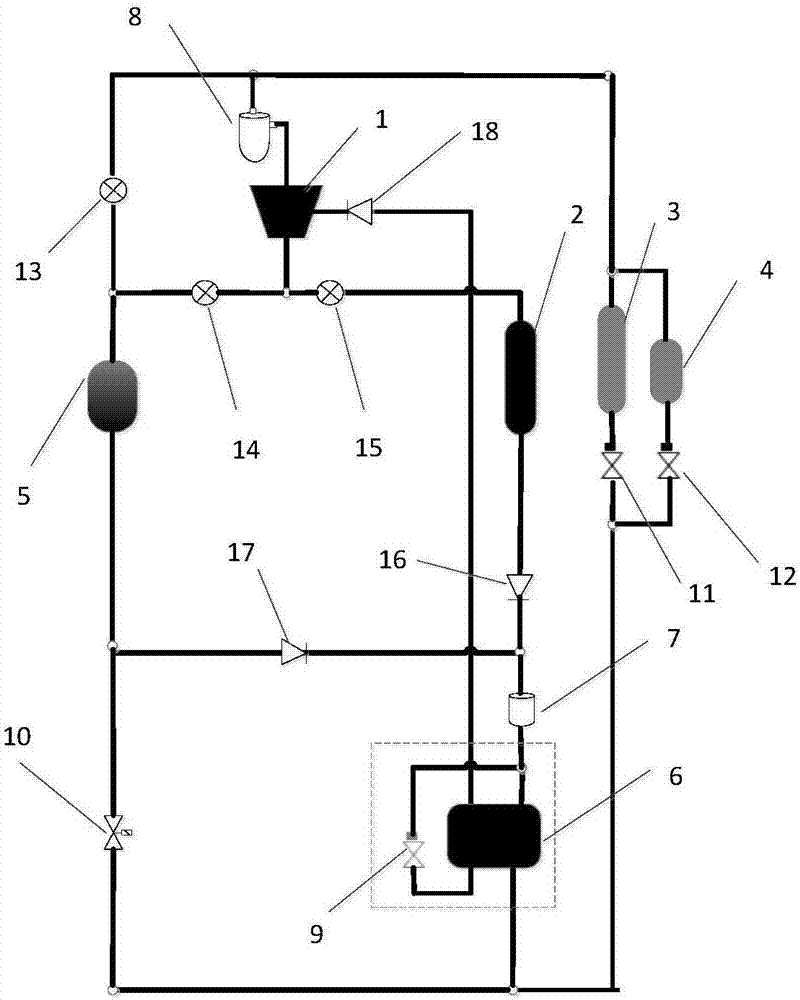

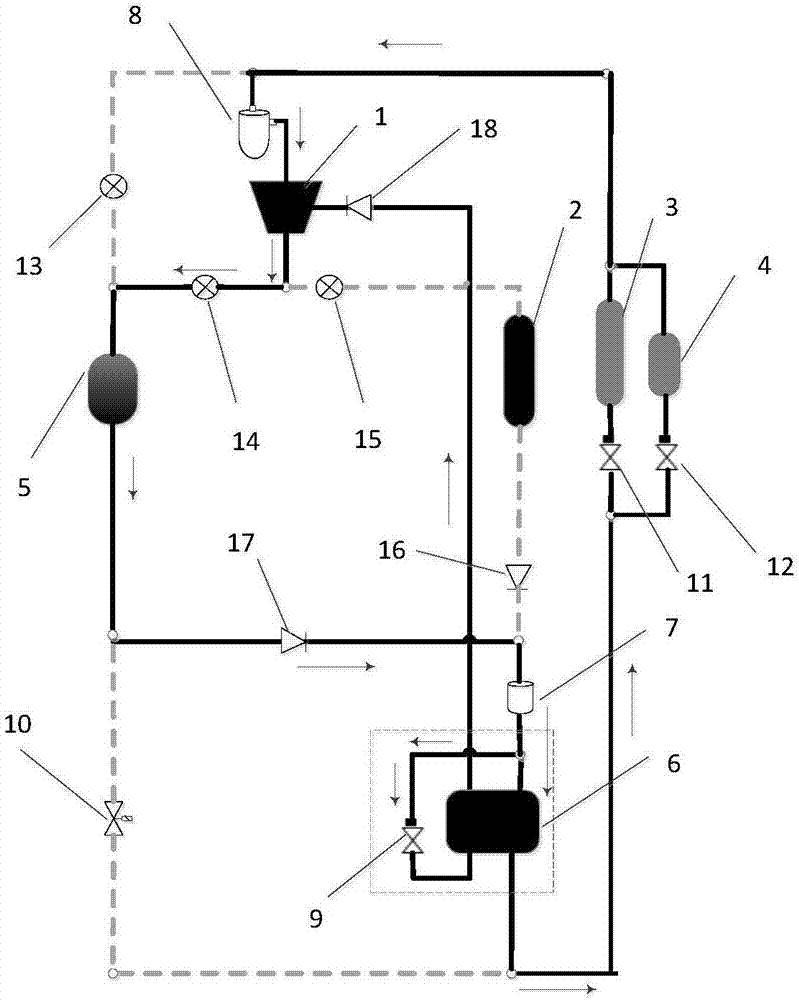

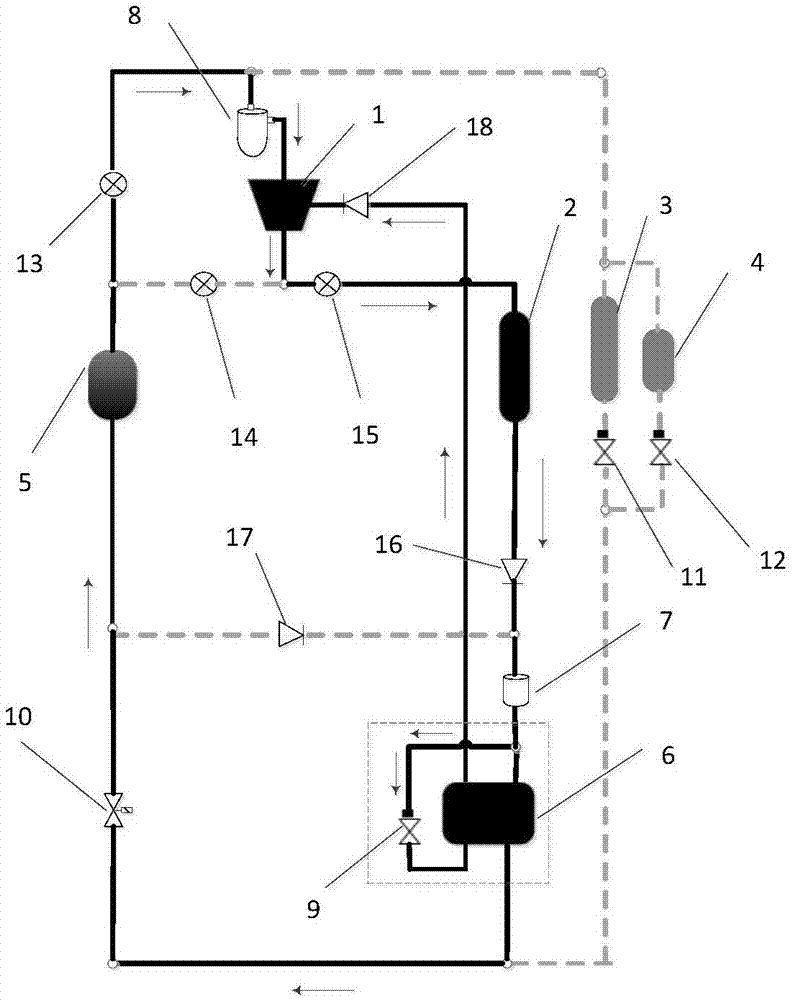

Engine coolant waste heat utilization engine warming system adopting solid-liquid phase change heat reservoir and method of engine coolant waste heat utilization engine warming system

ActiveCN104989548AImprove waste heat utilizationSolve the problem of waste heat utilizationCoolant flow controlInternal combustion piston enginesEnergy preservationCoolant flow

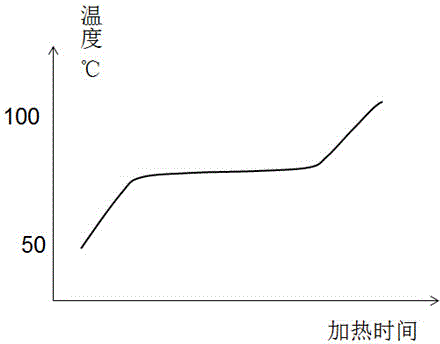

The invention discloses an engine coolant waste heat utilization engine warming system adopting a solid-liquid phase change heat reservoir and a method of the engine coolant waste heat utilization engine warming system. The system comprises a temperature sensor, an electronic thermostat, an electronic fan, a radiator, the solid-liquid phase change heat reservoir, an electronic three-way valve and an MCU. Coolant flows through the phase change heat reservoir to heat phase change materials. The phase change happens to the phase change materials, the phase change materials absorb a large amount of latent heat, and residual heat of an engine is transferred into the phase change heat reservoir to be stored and used for starting engine warming. The electronic thermostat and the electronic three-way valve are controlled by the MCU and kept running synchronously all the time. The premise that normal work of an engine cooling system is not influenced is ensured. After the engine stops, large circulation is closed through the electronic thermostat and the electronic three-way valve. The phase change heat reservoir is sealed and enters the energy preservation state. Thus, under the condition that the existing engine power consumption is hardly increased, waste heat recycle is achieved. The engine warming starting process is achieved under the condition that the engine power consumption is not increased.

Owner:ZHEJIANG UNIV +1

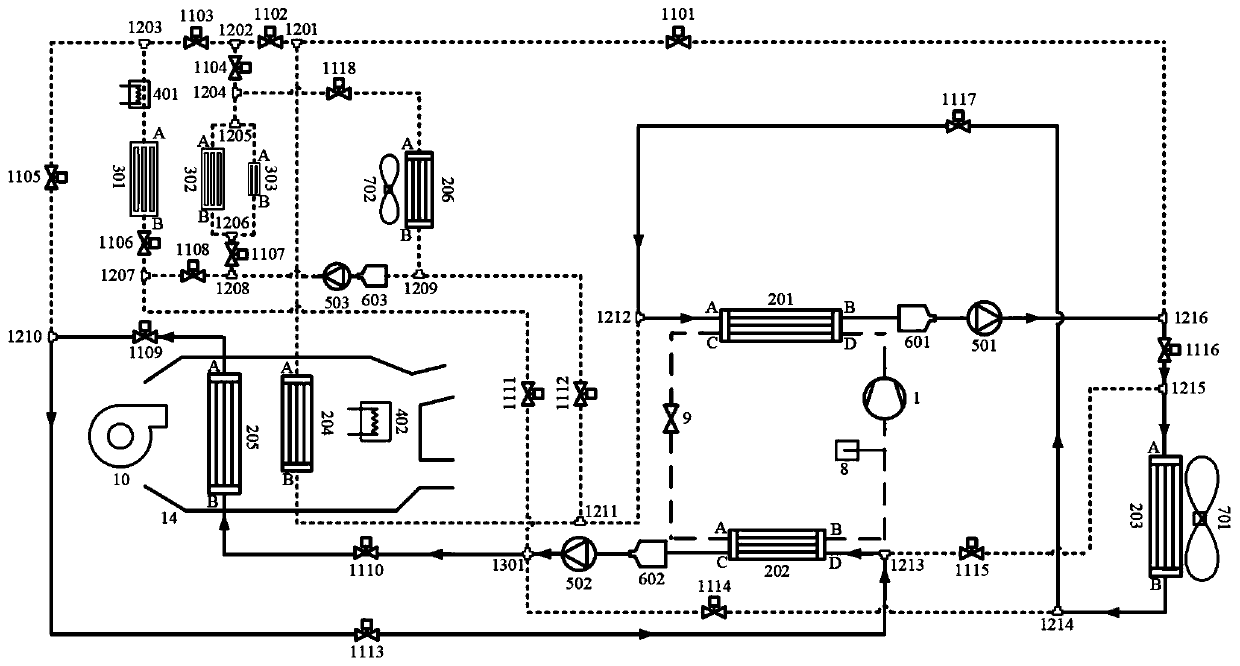

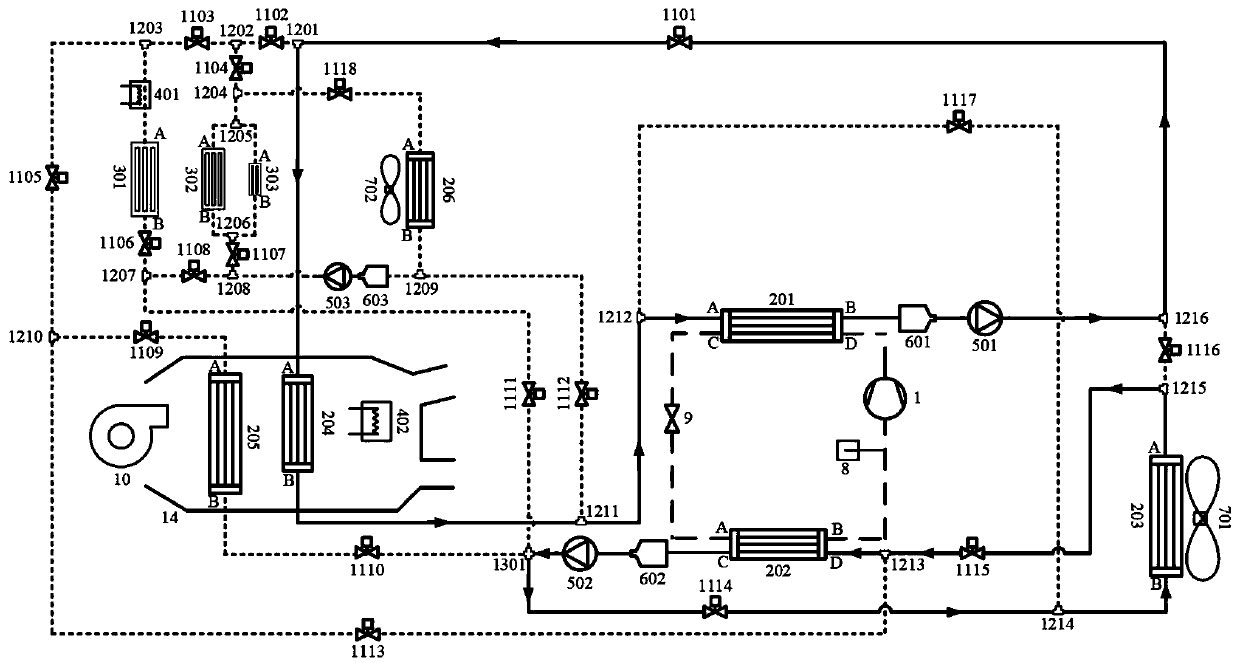

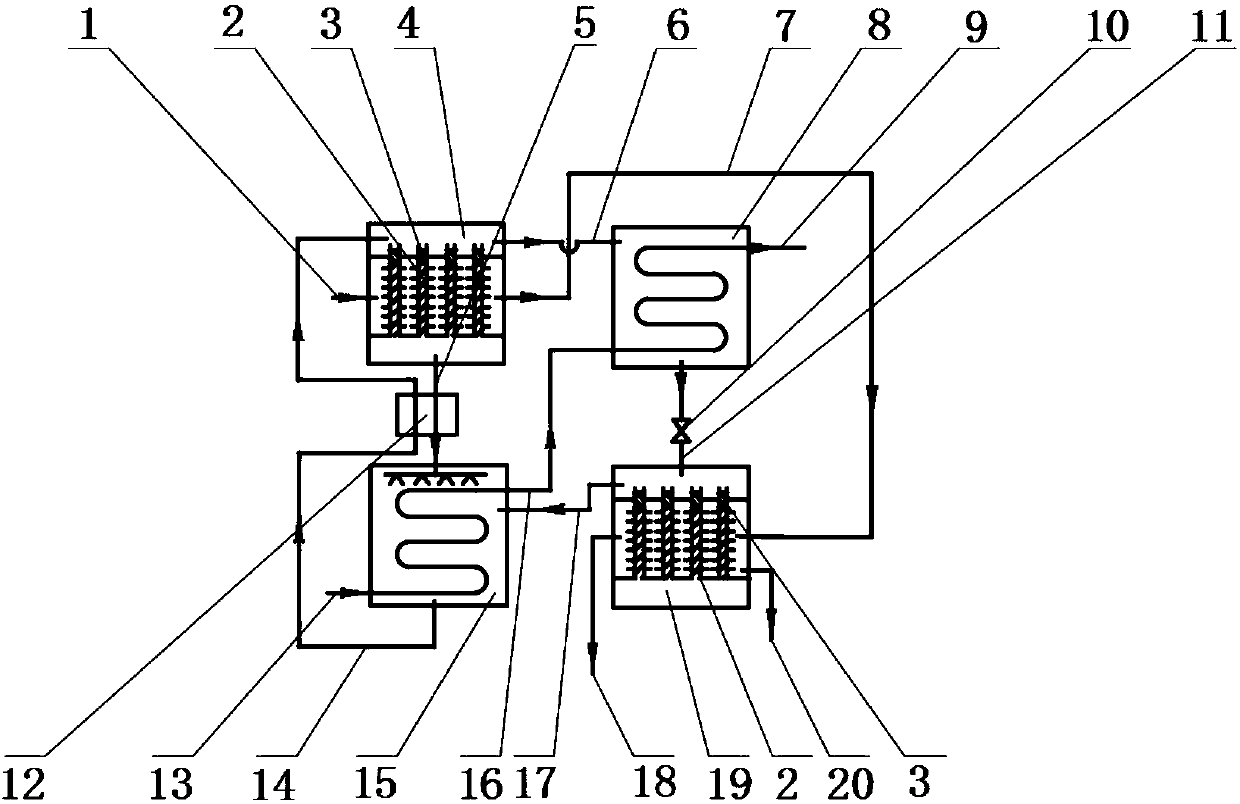

Whole-vehicle thermal management system of electric vehicle and control method of whole-vehicle thermal management system

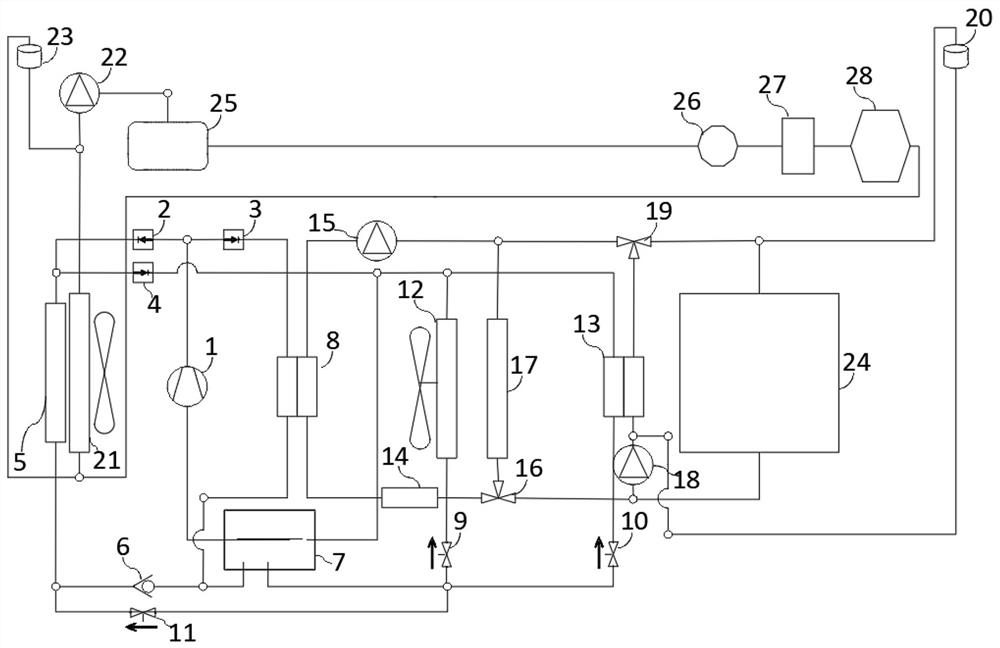

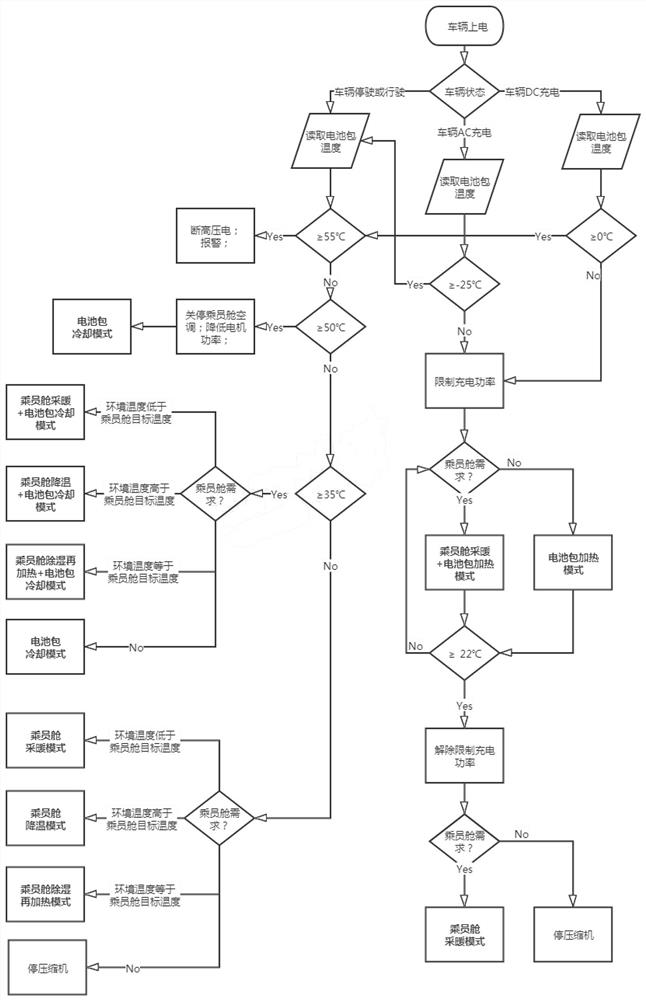

PendingCN112848842ARealize managementImprove thermal management efficiencyAir-treating devicesElectric propulsion mountingElectrical batteryElectric cars

The invention discloses an electric vehicle thermal management system and a control method thereof, and relates to the technical field of electric vehicle thermal management. The system comprises a heat pump air conditioner loop, a battery pack heat management loop and a motor electric control cooling loop; in theheat pump air conditioner loopa heating loop is used for heating a passenger compartment and a battery pack of the electric automobile, and an electric heater is communicated with a water cooling condenser; the battery pack heat management loop is used for adjusting the temperature of a battery pack in the electric vehicle, and the battery pack heat management loop is communicated with the heating loop; and the motor electric control cooling loop is used for cooling a driving motor of the electric vehicle. The heat pump air conditioner loop, thebattery pack heat management loop and the heat management loop of the passenger compartment are integrated, the purpose of overall management of heat in the passenger compartment and the battery pack is achieved, and the heat management efficiency of the whole vehicle is improved.

Owner:广州高澜创新科技有限公司

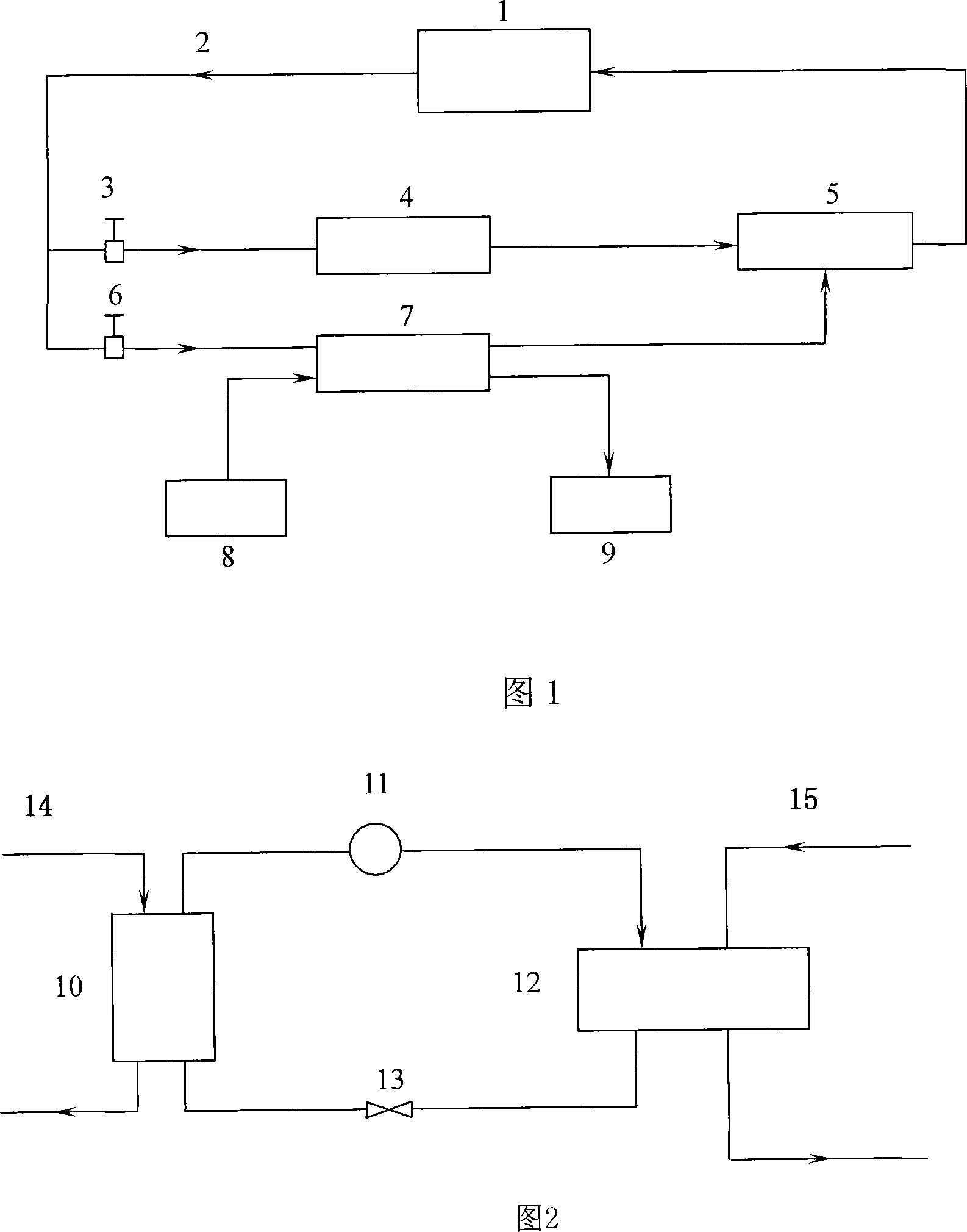

New energy automobile secondary circuit passenger compartment and battery motor electric control thermal management system

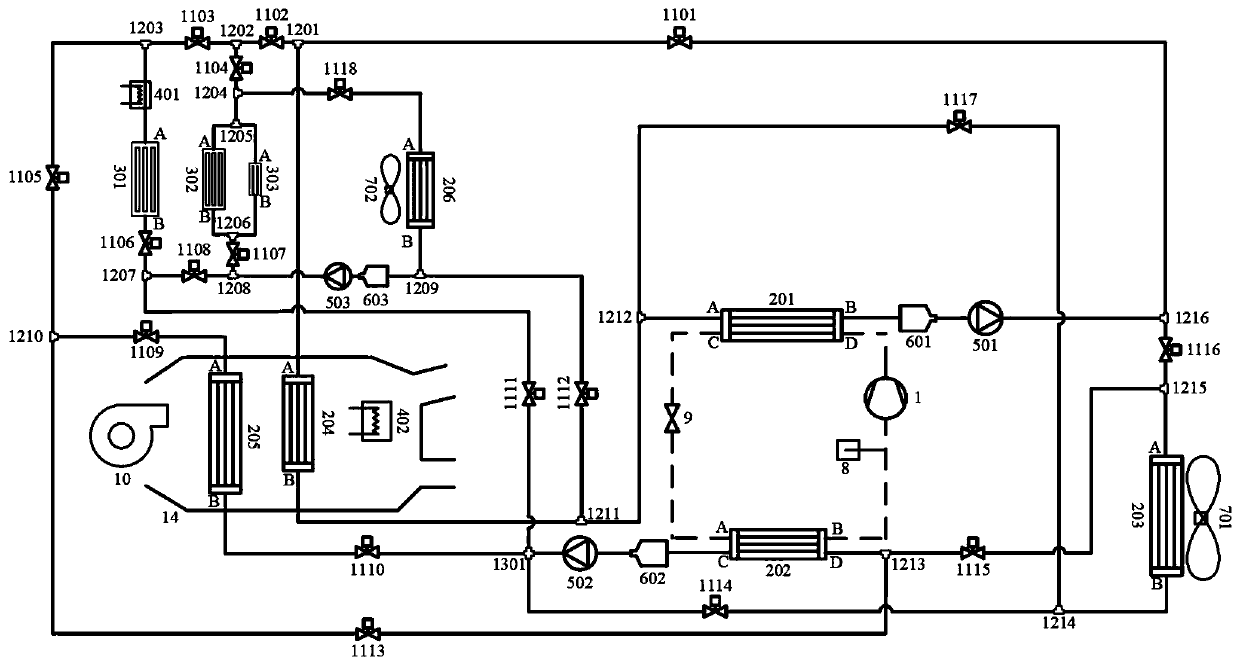

ActiveCN110525168AReduce in quantitySimple structureAir-treating devicesVehicle heating/cooling devicesVapor–liquid separatorNew energy

The invention provides a new energy automobile secondary circuit passenger compartment and battery motor electric control thermal management system. The system is composed of a refrigerant loop and acooling liquid loop. The refrigerant loop is composed of a compressor, a condenser, a throttling valve, an evaporator and a gas-liquid separator, so that a complete refrigeration cycle is formed. Thecooling liquid loop is divided into three parts of an outdoor heat exchanger unit, a battery motor electric control equipment heat dissipation and battery heating unit, and a passenger cabin heating and cooling unit. When the system runs, a water pump supplies power for the cooling liquid loop, and pumps the cooling liquid into each branch to realize the functions of refrigeration, heating and thelike. For the passenger compartment, the cooling liquid is used for exchanging heat with the interior, and the risk of refrigerant leakage is avoided. The cooling liquid loop is used for cooling or heating the passenger compartment, and the thermal management for battery, motor and electric control equipment in different modes is realized through opening or closing of an electromagnetic valve.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

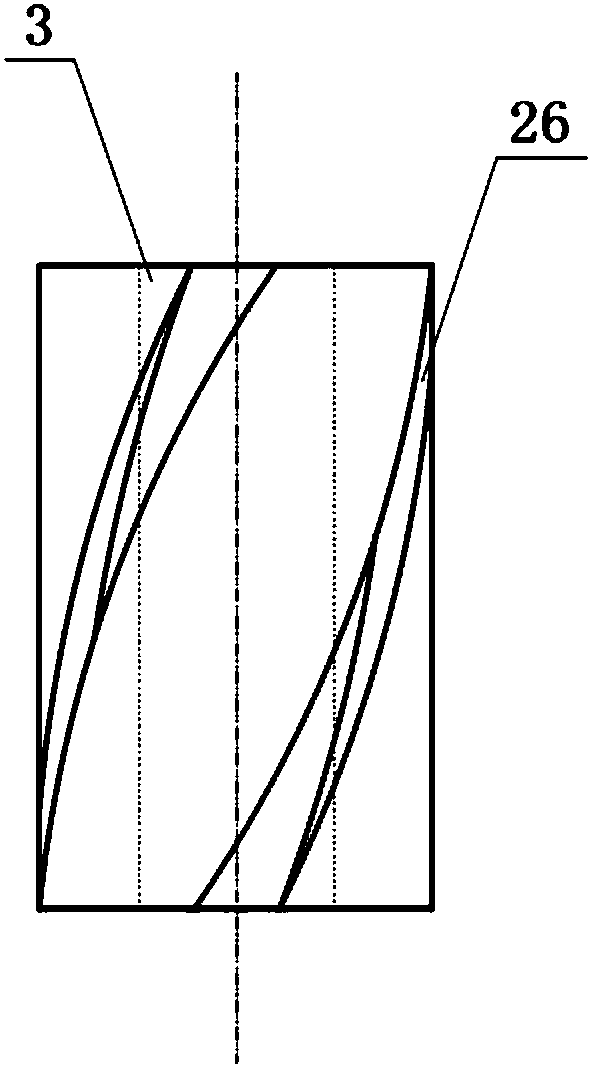

Electric car heat pump air conditioning system

PendingCN107512150ASolve the problem of charge adjustmentFlexible realization of waste heat recoveryAir-treating devicesVehicle heating/cooling devicesVapor–liquid separatorEngineering

The invention provides an electric car heat pump air conditioning system. The air conditioning system includes a compressor with middle gas compensation, an external heat exchanger, an internal condenser, an internal evaporator, a battery cooler and a gas compensation module, wherein an outlet of the compressor is connected with a first port of the external heat exchanger and an input end of the internal condenser, an inlet of the compressor is connected with the output end of a gas-liquid separator, the input end of the gas-liquid separator is connected with the first port of the external heat exchanger and the output end of the internal evaporator respectively, a high-pressure output end of the gas compensation module is connected with a second port of the external heat exchanger and the input end of the internal evaporator respectively, and a gas compensation output end of the gas compensation module is connected with a middle gas compensation mouth of the compressor. The electric car heat pump air conditioning system can be adapted to low temperature working conditions, the effect that the refrigeration mode and the heating mode share the same liquid storage is achieved, and subdivision functions of refrigeration, dehumidification and heating dehumidification can be achieved, and defrosting and battery waste heat recovery of part of heating operating conditions are achieved.

Owner:空调国际(上海)有限公司

Method and device for recycling residual heat of blast furnace low-temperature recirculated water with heat pump technology

This invention relates to a recovery process and method of waste heat of blast furnace circulating water in the steel production, which installs heat pump unit on the pipeline to recover the waste heat in the of 40-50deg.C with the low-boiling working substance in the heat pump unit, and the cooled blast furnace circulating soft water enters the blast furnace circulating water system directly; the heat exchanger is installed on the water replenishing pipe of the steam boiler to provide the heat in the low-boiling working substance with waste heat and the driving heat of heat pump working to the fresh boiler water in the pipeline network beside the heat exchanger to increase the temperature to 70-80deg.C; the fresh boiler water through the heat exchanger is imported to the boiler system. This invention realizes the recovery of the waste heat in the blast furnace low-temperature circulating water by the installation of heat pump unit and heat exchanger without big alteration and applies the heat on the preheating of the fresh water in the steam boiler to save the needed steam and energy.

Owner:LAIWU IRON & STEEL GRP

Method for generating power by gasifying integrated straws in supercritical coal-fired generator set

InactiveCN102010757AEasy to storeSmall footprintInternal combustion piston enginesEnergy inputBiomass gasifierBubbling fluidized bed

The invention discloses a method for generating power by gasifying integrated straws in a supercritical coal-fired generator set. The method comprises the following steps of: packing and forming biomass straws serving as a gasification raw material of a gasifier of a bubbling fluidized bed, wherein primary wind-heat air surplus in a power station and tail gas fume of a boiler are used as gasifying agents. A biomass gasifier is effectively integrated by simply modifying the conventional supercritical unit to make biomass gasified, combusted and generate power, so that the defect that the biomass is directly blended and combusted is effectively overcome, the influence of biomass ash on fly ash is avoided, and the problem that the conventional auger feeding equipment is easy to damage is solved; therefore, biomass energy can be efficiently utilized and pollutant emission of coal-fired power stations is further reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

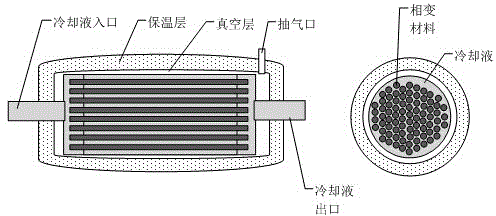

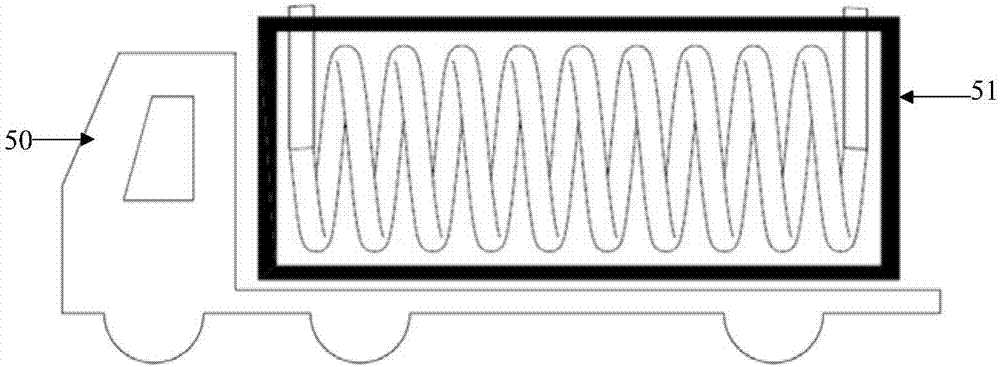

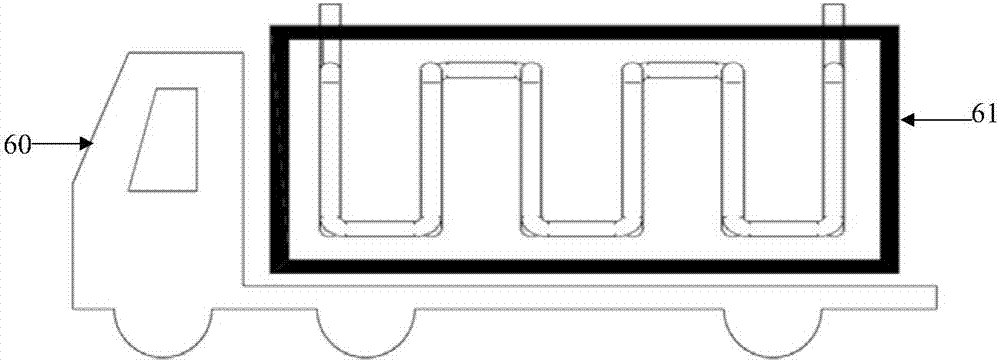

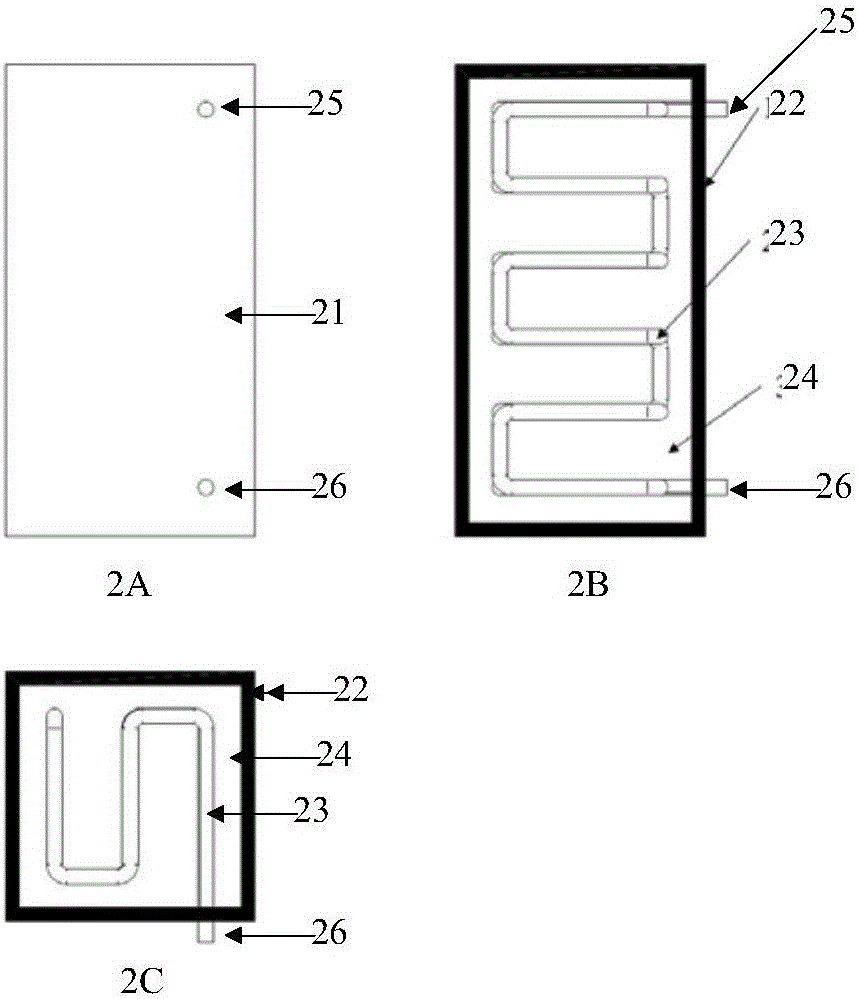

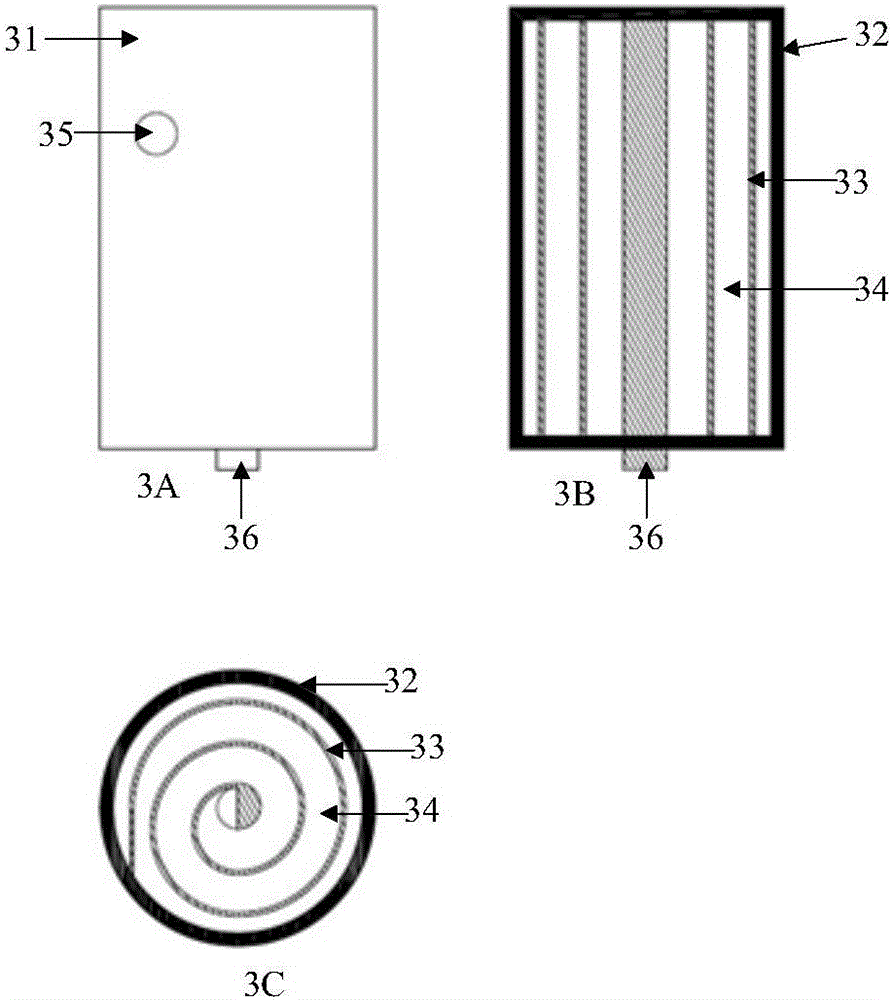

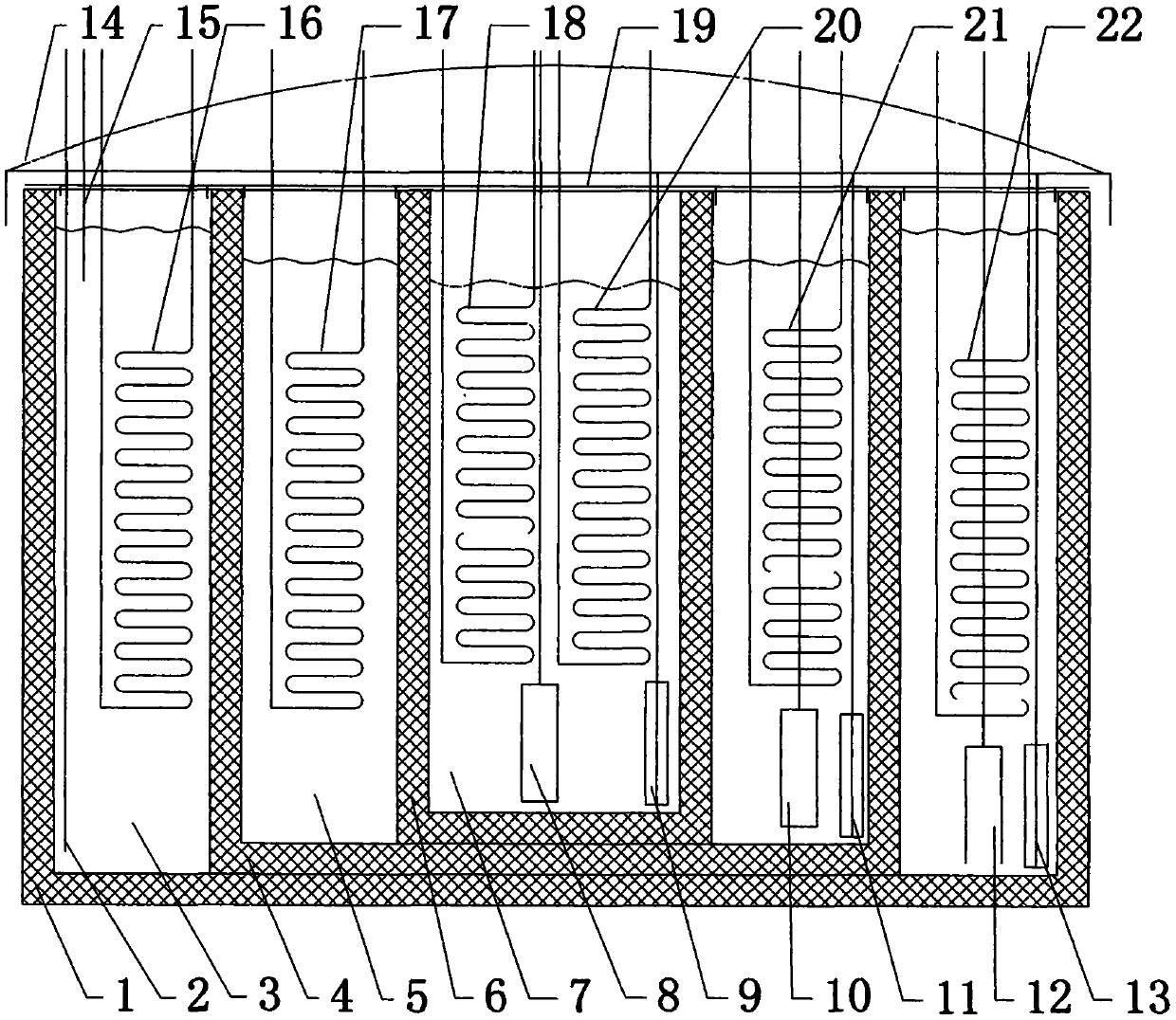

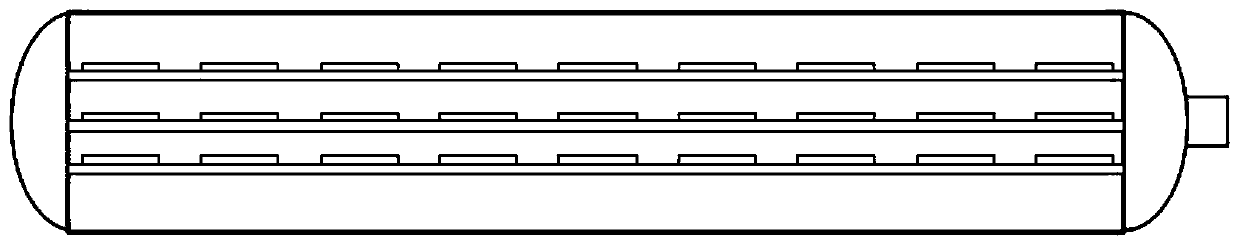

Mobile heat storage vehicle based on phase-change materials

PendingCN106985724ASimple structureEasy to manufactureHeat storage plantsItem transportation vehiclesControl systemPhase change

The invention relates to a mobile heat storage vehicle based on phase-change materials. The mobile heat storage vehicle comprises a transport device, a heat storage device and a control system, wherein the heat storage device is fixed to the transport device in an operating mode, and the control system can display in time or monitor in time the situation selected from the flow rate, temperature, pressure, heat storage capacity, GPS positioning, travel speed and / or operating mileage; and the heat storage device comprises a housing, heat conduction phase-change materials and a heat exchange device, wherein the heat conduction phase-change materials and the heat exchange device are filled in the housing. The mobile heat storage vehicle is filled with a large amount of high performance phase-change materials to serve as heat storage mediums, the heat storage mediums, belongs to heat transfer between heat source ends and client ends rather than the transfer with no medium, and is obviously superior to the heat storage performance of the mobile heat storage vehicle which uses water mediums of the hot source ends or is filled with a small amount of phase-change materials; the control system can realize real-time monitoring and background monitoring; and the heat storage device can further comprise a heated fluid pipeline independent of a heating fluid pipeline, the waste heat recovery for non-clean high temperature flow is achieved, and using of lone time does not produce pollutions such as water pipes.

Owner:齐齐哈尔市丰华节能环保发展有限公司 +1

Method for recovering waste heat of electrically fused magnesium fused weight

The invention relates to a method for breaking an electrically fused magnesium fused weight and simultaneously recovering waste heat by a dry quenching method, which belongs to the field of electrically fused magnesium smelting and provides an energy-saving technology for recycling the waste heat in the cooling process of the magnesium fused weight. The heat energy of the high-temperature magnesium fused weight is recovered by the dry quenching method in the cooling process of the magnesium fused weight, steam is generated through a heat exchanger by heat circulating gas which is obtained by adopting a direct countercurrent flow method of the air and the high-temperature magnesium fused weight, the steam is utilized for generating electricity, and the invention is used for the magnesite smelting process, achieves the purpose of energy saving, is beneficial to reducing the energy consumption level of electrically fused magnesium, achieves the coupling optimization of waste heat utilization and electrically fused magnesium quality improvement and has remarkable economic and social benefits.

Owner:PEKING UNIV

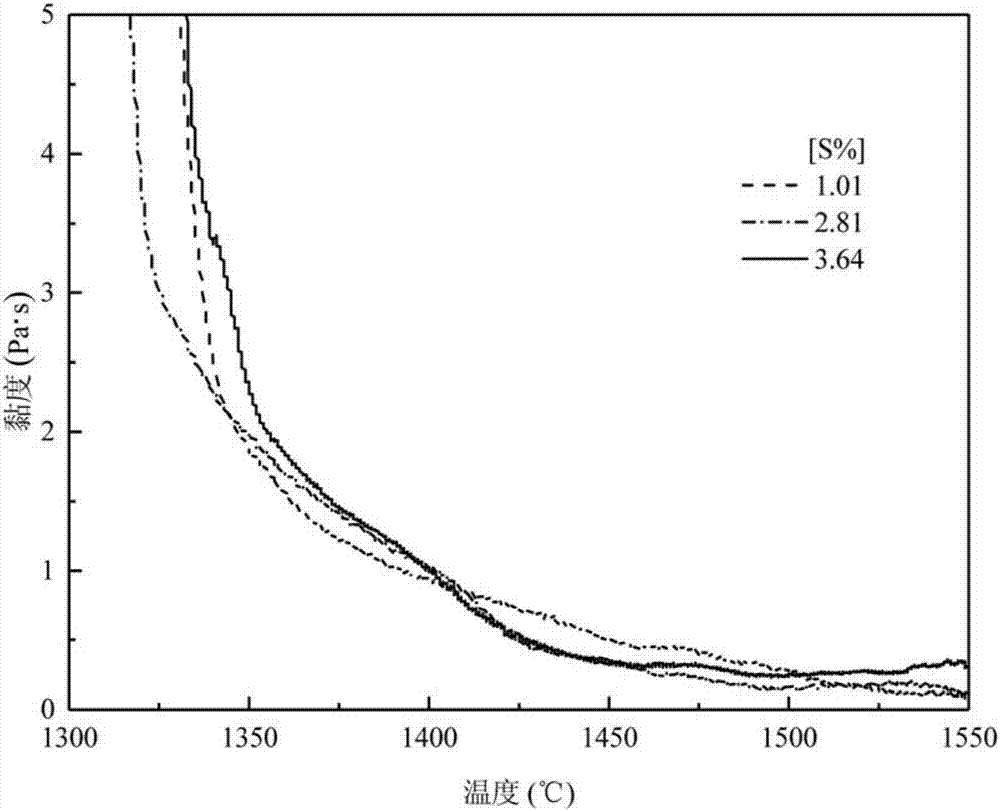

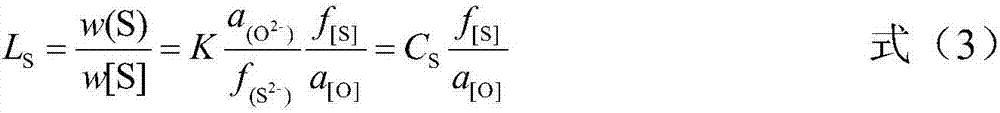

Refining slag used for producing sulfur free-cutting steel and circulated using method

ActiveCN107419063ALittle difference in physical propertiesImprove cleanlinessProcess efficiency improvementAlkalinitySlag

The invention relates to refining slag used for producing sulfur free-cutting steel and a circulated using method, and relates to a refining slag system in the ferrous metallurgy industry and a circulated using method thereof. The alkalinity of the refining slag system is high, and the molten steel cleanliness is guaranteed; 2% to 4% of sulfur is contained in the refining slag system, the desulfuration capacity of the refining slag is reduced, and the sulfur content in molten steel can be stably controlled; and the refining slag is used in a circulated manner, and the problem that the treatment cost of the refining slag is high in treatment cost is solved. Operation processes include that converter slagging is strictly controlled in the converter tapping process, and an alloy, lime and part of sulfur-containing high-alkalinity refining slag are added; in the ladle refining process, alloy compositions are adjusted, a deoxygenation agent, the lime and the sulfur-containing high-alkalinity refining slag are added for slagging; after refining is finished, a wire feeder is used for feeding sulfur-containing wires into the molten steel, and then a steel ladle is conveyed to a continuous casting machine for pouring; and finally, the ladle refining slag left after pouring is carried out is recovered, and when sulfur bearing steel is produced, the ladle refining slag is added into the steel ladle for reutilization again in the converter tapping or LF refining process.

Owner:NORTHEASTERN UNIV LIAONING

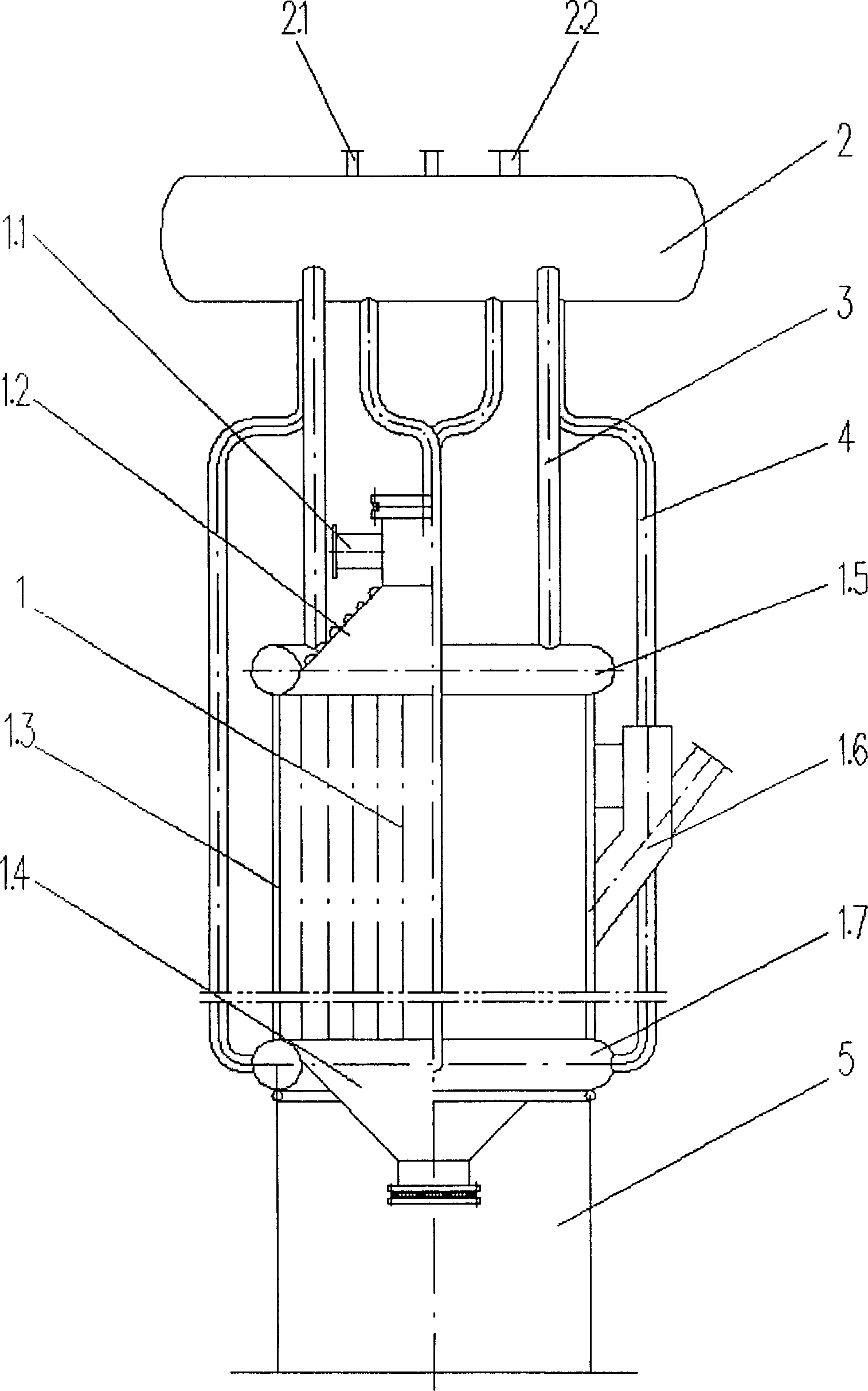

High-temperature flue gas waste heat recovery and dust extraction all-in-one device

ActiveCN103673643ALarge heat capacityModerate bulk densityDispersed particle filtrationCombustion processCombustionFiltration

The invention relates to a high-temperature flue gas waste heat recovery and dust extraction all-in-one device. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device comprises furnace connectors, material filtering beds, a left wind passing unit, a right wind passing unit and a four-way reversing valve, wherein the furnace connectors and the material filtering beds are connected with air flues on the two sides of a high-temperature kiln. Each wind passing unit comprises an upper wind opening, the corresponding low-temperature area material filtering bed, a low-temperature area frame, the corresponding high-temperature area material filtering bed, a high-temperature area frame, the corresponding furnace connector, a dust collection box and an ash outlet with movable partition plates from top to bottom. Each material filtering bed comprises accumulated ceramic balls. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device allows filtration and ash removing to be conducted in a mode that the leftward direction and the rightward direction are switched in a timed mode and filtration and ash removing are periodically and alternately conducted, and allows ash removing and heat absorption to be achieved in a mode that high-temperature flue gas from one side passes through the corresponding material filtering beds from bottom to top so that filtration and heat accumulation can be achieved, and air from the other side reversely blows the corresponding material filtering beds from top to bottom so that ash removing and heat absorption can be achieved. The ash-laden gas flue can be unceasingly filtered, waste heat in the high-temperature gas flue can be unceasingly recovered, meanwhile, function regeneration and fresh air preheating can be simultaneously conducted, cooling and dirt removing of the high-temperature flue gas are achieved, and combustion efficiency is improved.

Owner:宝武集团中南钢铁有限公司 +1

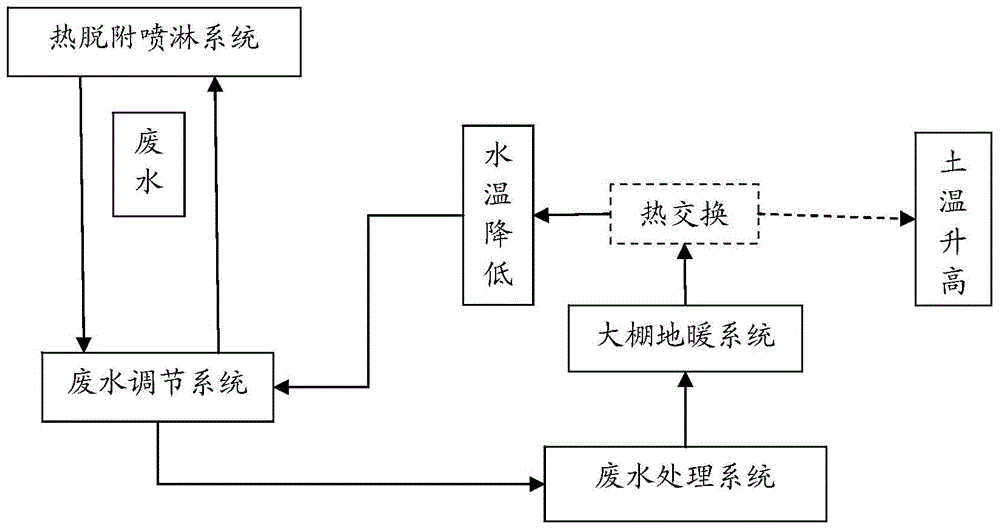

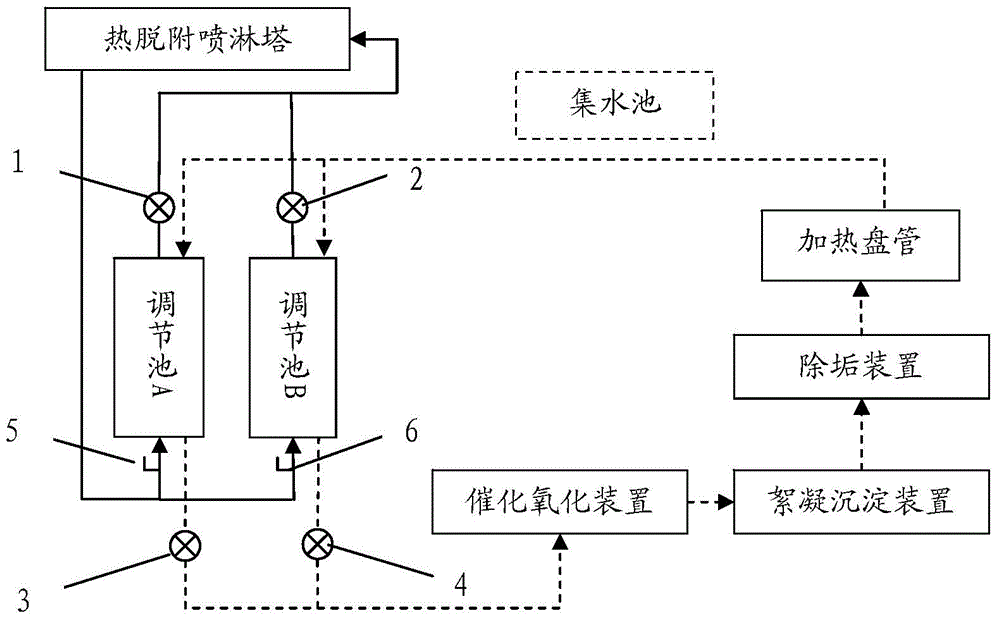

Waste heat utilization system using thermal desorption high temperature cycle spray wastewater to improve normal temperature desorption booth processing efficiency

ActiveCN104307862ARealize waste heat recoveryTake advantage ofContaminated soil reclamationMultistage water/sewage treatmentThermal desorption spectroscopyOrganic matter

The invention relates to a waste heat utilization system using thermal desorption high temperature cycle spray wastewater to improve normal temperature desorption booth processing efficiency. The system comprises a thermal desorption spraying system, a wastewater adjusting system, a wastewater processing system, and a booth ground heating system. The thermal desorption spraying system is connected to the wastewater adjusting system. The wastewater adjusting system is connected to the wastewater processing system. The wastewater processing system is connected to the booth ground heating system. The booth ground heating system is connected to the thermal desorption spraying system and / or the wastewater adjusting system. The high temperature spraying cycle wastewater generated by thermal desorption is utilized to heat the polluted soil in a normal temperature desorption booth, the energy is fully utilized, and at the same time the processing effect of the normal temperature desorption technology is improved by the waste heat utilization system. The thermal desorption technology and normal temperature desorption technology are co-used in the system, and the novel system is economic, reliable, and stable, and is especially suitable for repairing and processing soil polluted by volatile / semi-volatile organic matters.

Owner:中科华南(厦门)环保有限公司 +1

Multi-stage heat-exchange and waste heat recovery hot-air system with function of purifying fuel gas

InactiveCN101650072AEasy compatibilityEasy to optimizeUsing liquid separation agentAir heatersThermal energyWaste heat recovery unit

The invention relates to a multi-stage heat-exchange and waste heat recovery hot-air system with the function of purifying fuel gas, which is mainly and organically formed by three components including a hot-air furnace containing a heat exchanger inside the furnace, a heat exchanger outside the furnace and a waste heat recoverer. The three components make full use of the heat energy generated bythe hot-air furnace in the modes of heating the air at a high temperature, a medium temperature and a low temperature, and the heat efficiency is much higher than that of a single-stage heat exchangerhot-air furnace and a hot-air furnace without waste heat recovery. Furthermore, the waste heat recovery of the last stage adopts smoke-water-gas secondary heat exchange, and the functions of fuel gaspurification, desulfuration and denitrification and the almost complete purification can be achieved on the basis of the existing function of dust removal by adding a purification drug in to an intermediate and water. The integral design of the multi-stage heat-exchange and waste heat recovery hot-air system with the function of purifying fuel gas has the advantages that the system can be optimized and the effect of not influencing the realization of other functions while various devices realize the functions thereof can be achieved.

Owner:肖建选

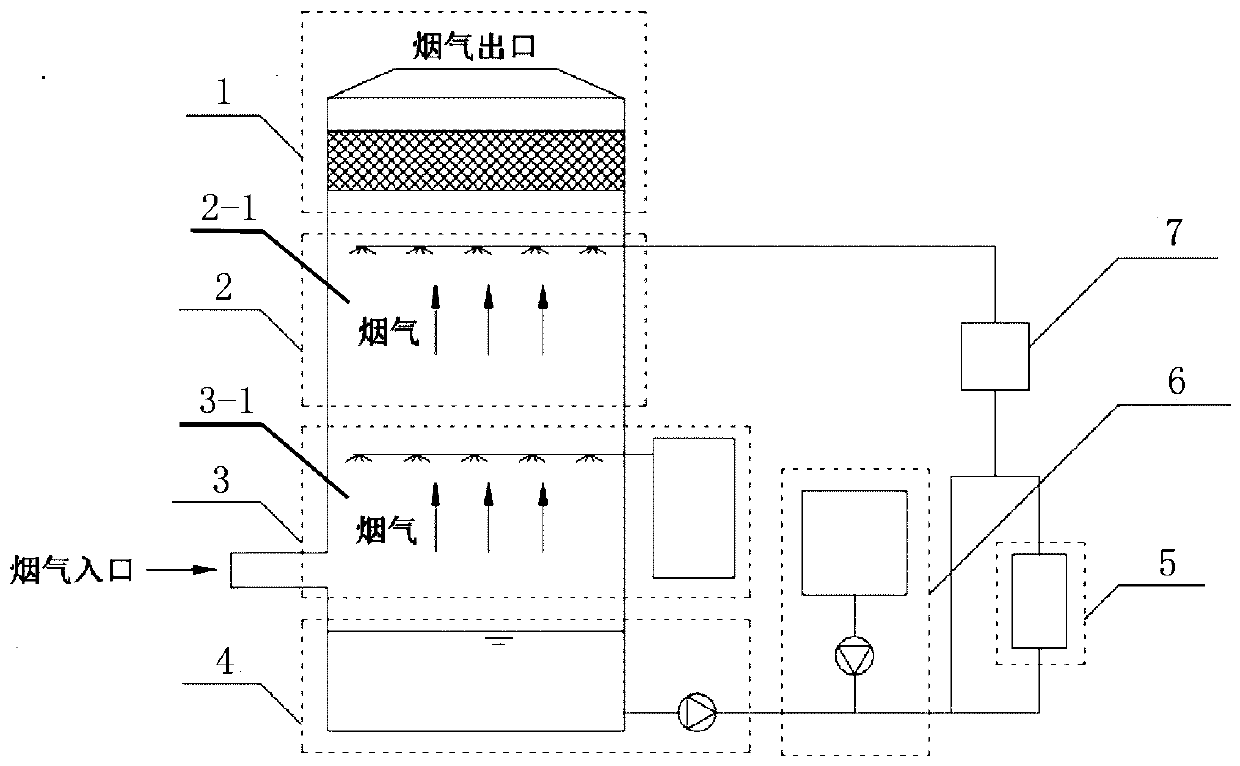

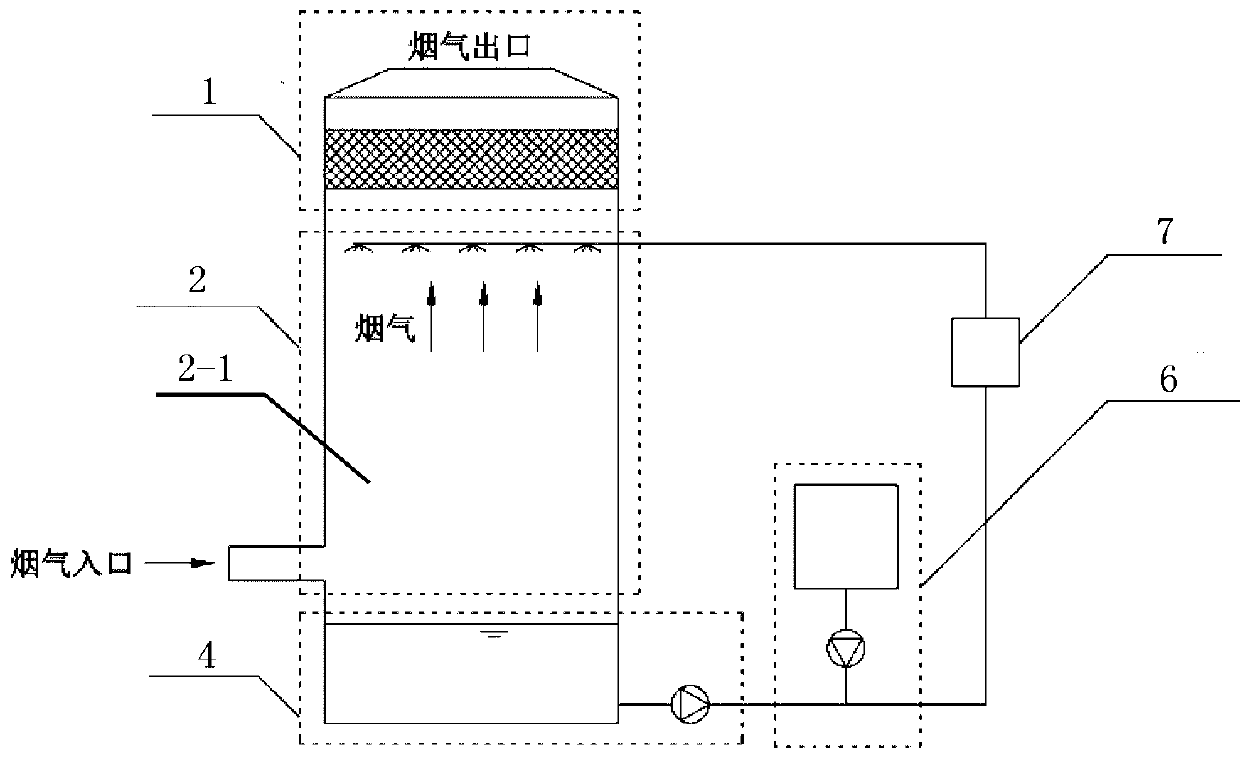

Flue gas driven waste heat recovery type absorption heat pump

InactiveCN108050731ARealize waste heat recoveryRealize deep recoveryHeat pumpsHeat recovery systemsAbsorption heat pumpEngineering

The invention discloses a flue gas driven waste heat recovery type absorption heat pump. The absorption heat pump is mainly composed of a generator, a condenser, a solution heat exchanger, an absorberand an evaporator, wherein flue gas enters the generator firstly, heat is released when the flue gas is in contact with an inner falling film heat transfer tube in the generator in the flue gas flowing process, and then the flue gas enters the evaporator, is in contact with an inner falling film heat transfer tube in the evaporator, and leaves the absorption heat pump after the heat is released again. According to the absorption heat pump, the flue gas is adopted for driving the absorption heat pump, the flue gas waste heat recovery is realized at the same time, the evaporation temperature ofthe absorption heat pump is low so that the flue gas can be reduced to a lower temperature, and further the energy utilization efficiency of various energy systems generating the flue gas is improved. In addition, the absorption heat pump can reduce the temperature of the flue gas to be below the dew point temperature, so that the water vapor in the flue gas is condensed, the condensation heat ofthe water vapor is recycled, and the generated condensed water can be used for washing and purifying the flue gas, so that the dual effects of saving energy and reducing emission of pollutants are achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

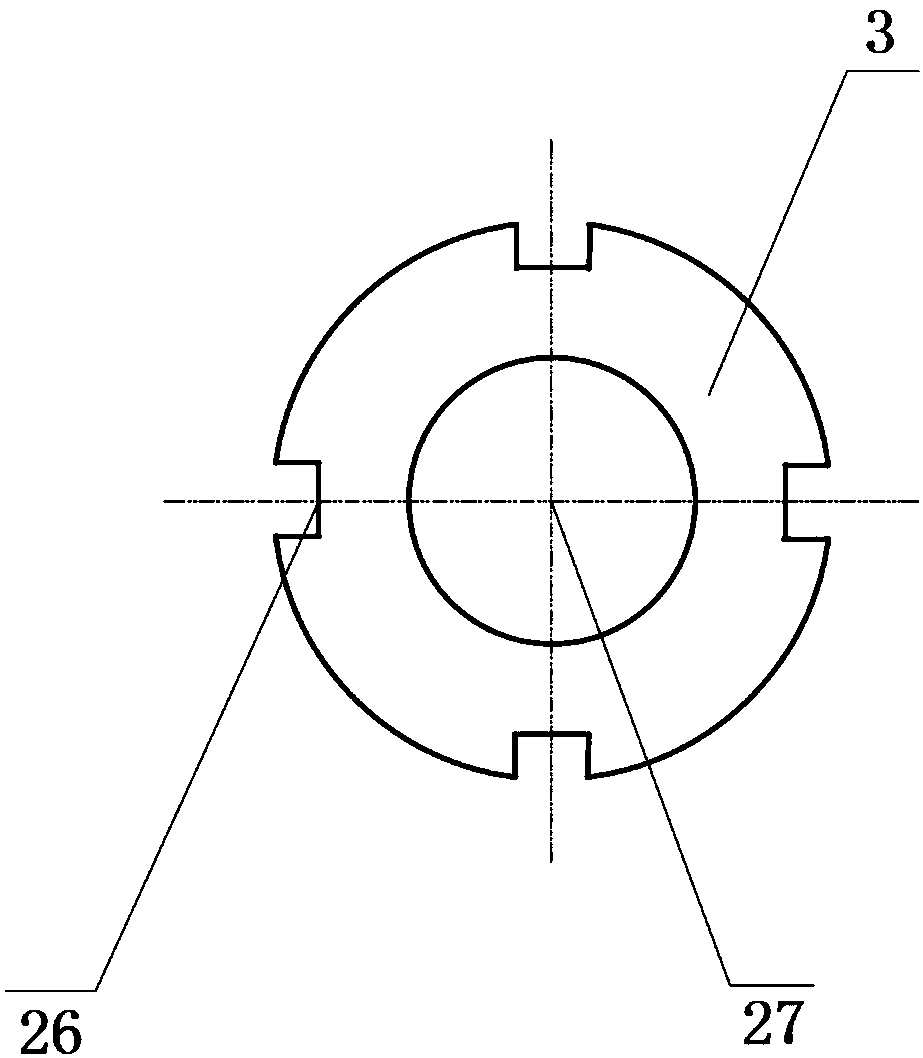

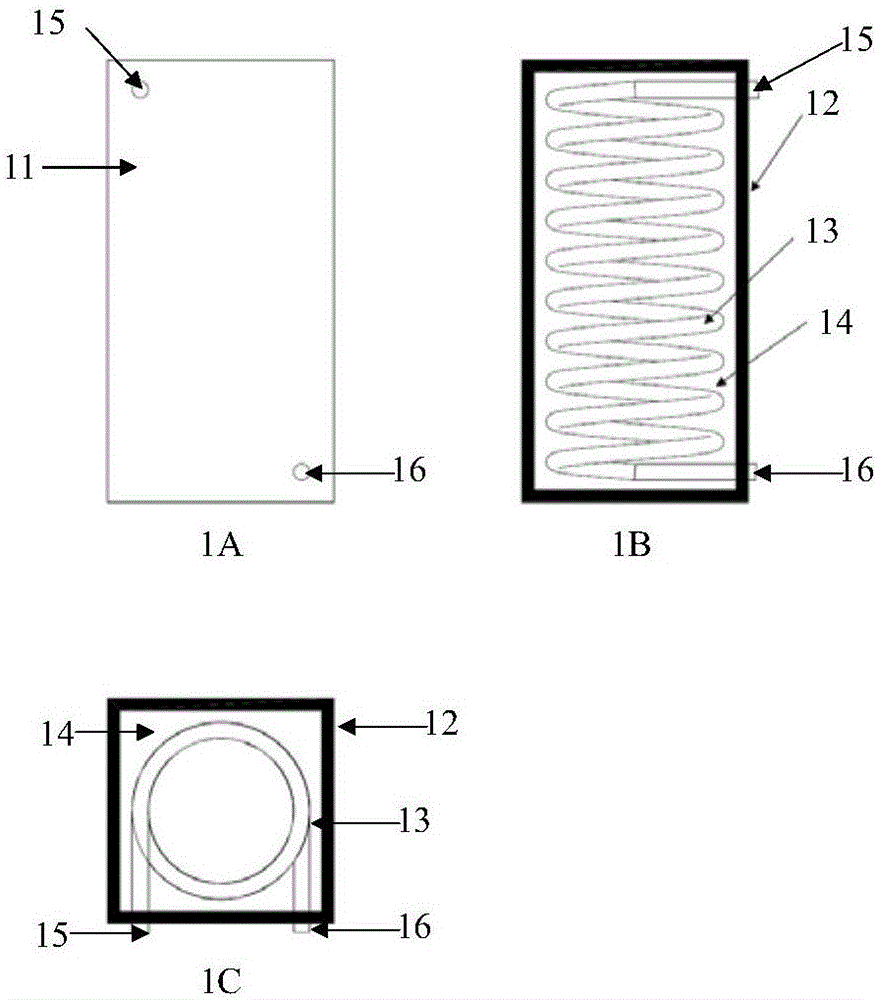

Heat reservoir based on phase-change material and movable heat storage device provided with heat reservoir

PendingCN106839849ASimple structureEasy to manufactureHeat storage plantsControl systemHeat conducting

The invention relates to a heat reservoir based on a phase-change material and a movable heat storage device provided with the heat reservoir. The heat reservoir comprises a shell, a heat-conducting phase-change material charged into the shell and a heat exchanger. The heat exchanger is located in the shell and comprises a heating fluid pipeline. The invention further relates to the movable storage device comprising the heat reservoir and a transporting unit. A large amount of the high-performance phase-change material is charged in the heat reservoir and serves as a heat storage medium, heat transmission, instead of medium transmission, between a heat source side and a client side is achieved, and the heat storage performance is remarkably superior to that of a movable heat storage device with water at the heat source side serving as the medium or a movable heat storage device filled with a small amount of the phase-change material; the heat reservoir further comprises a heated fluid pipeline independent of the heating fluid pipeline, and the heated fluid pipeline can be used for waste heat recovery of unclean high-temperature flow without pollution to such as a tap water pipeline after long-term use; and a selectable control system provided by the invention can achieve real-time monitoring and background monitoring.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

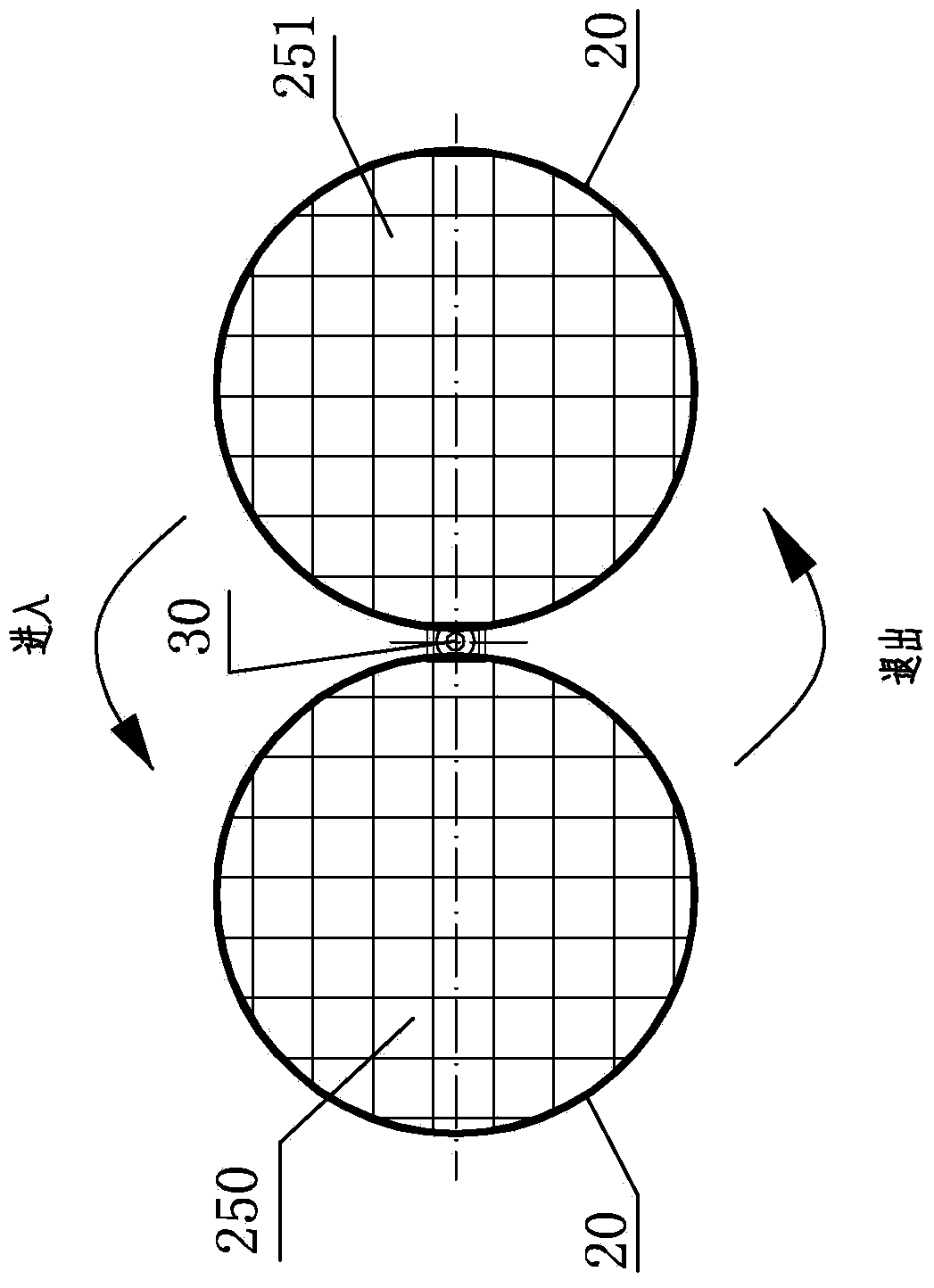

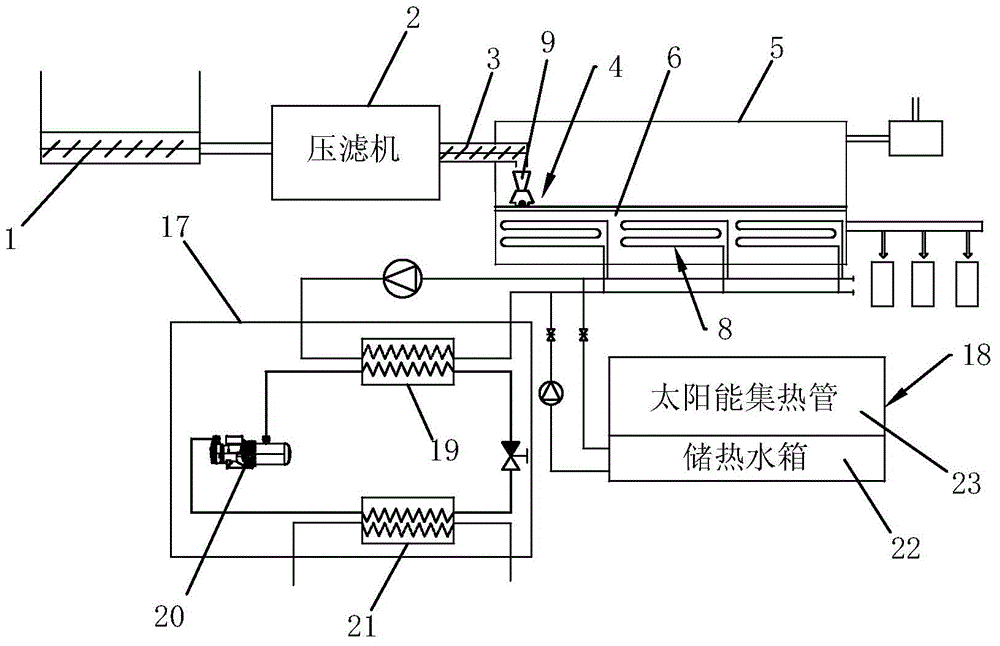

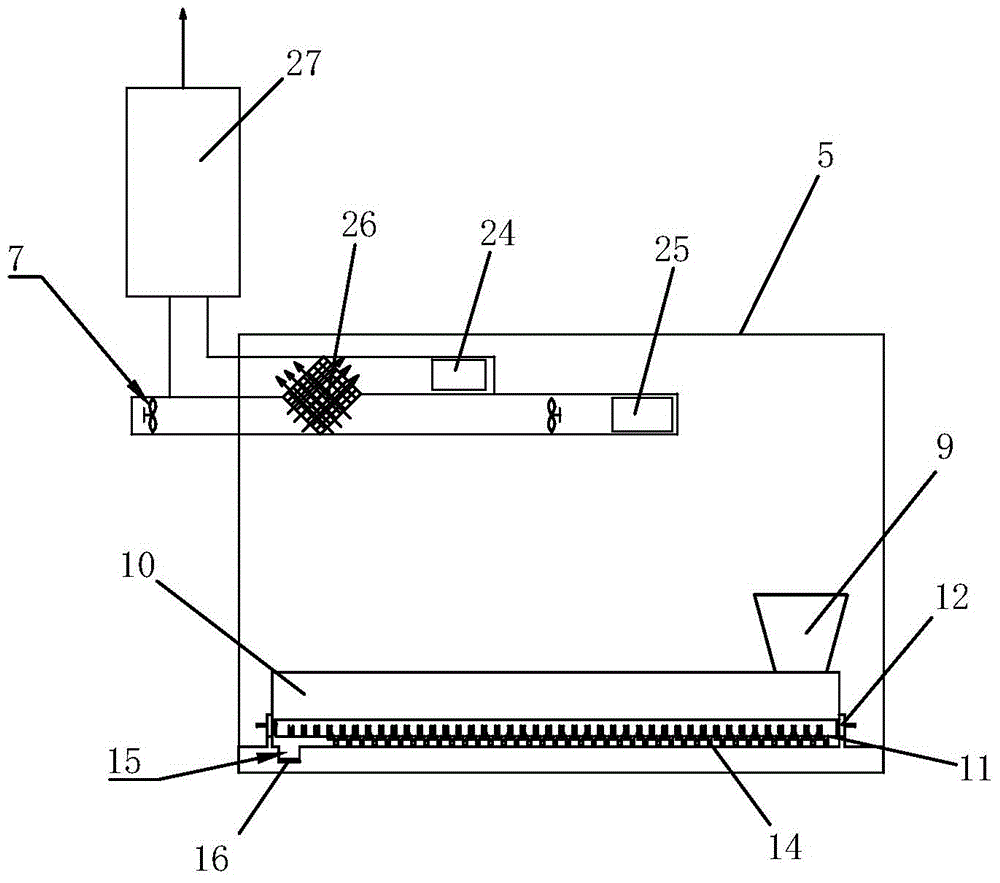

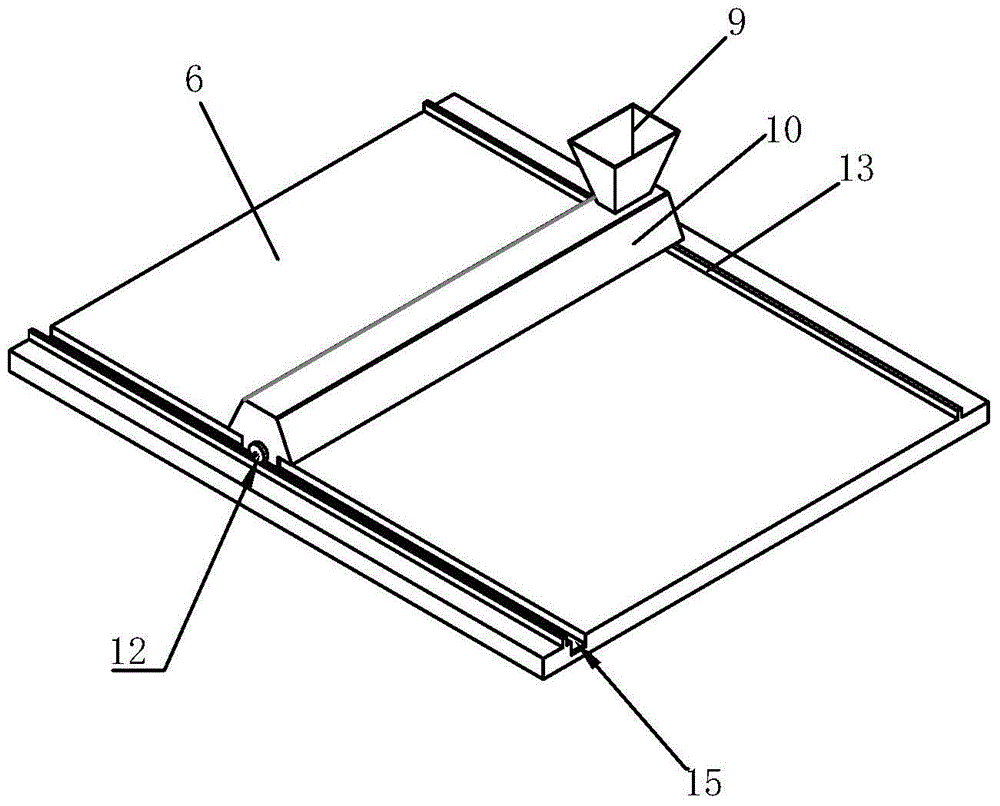

Sludge drying equipment

InactiveCN104628238ALow costSpread evenlySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentGreenhouseFilter press

The invention relates to the technical field of sludge treatment equipment and provides sludge drying equipment. The sludge drying equipment comprises a double-screw sludge pump, a filter press and a sludge conveyor, wherein the double-screw sludge pump is used for pumping crude sludge; the filter press is connected with the double-screw sludge pump and is used for mechanically dewatering the crude sludge; the sludge conveyor is connected with the filter press and is used for pushing the mechanically dewatered sludge; a sludge turning machine is correspondingly arranged at the output port of the sludge conveyor and is used for tiling and turning the sludge; the sludge turning machine is arranged in a sealed glass greenhouse; the glass greenhouse comprises a greenhouse body and a heating floor; a turbulence fan and a ventilation opening which corresponds to the turbulence fan are arranged on the greenhouse body; multiple groups of heating pipelines are arranged in the heating floor; and each group of heating pipelines is communicated with a heat supply source. The sludge is dried in a mode of supplying heat by virtue of solar energy and the heating floor, the cost is low, the sludge drying operation is performed in the sealed glass greenhouse, and the sludge drying equipment is safe and environment-friendly.

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

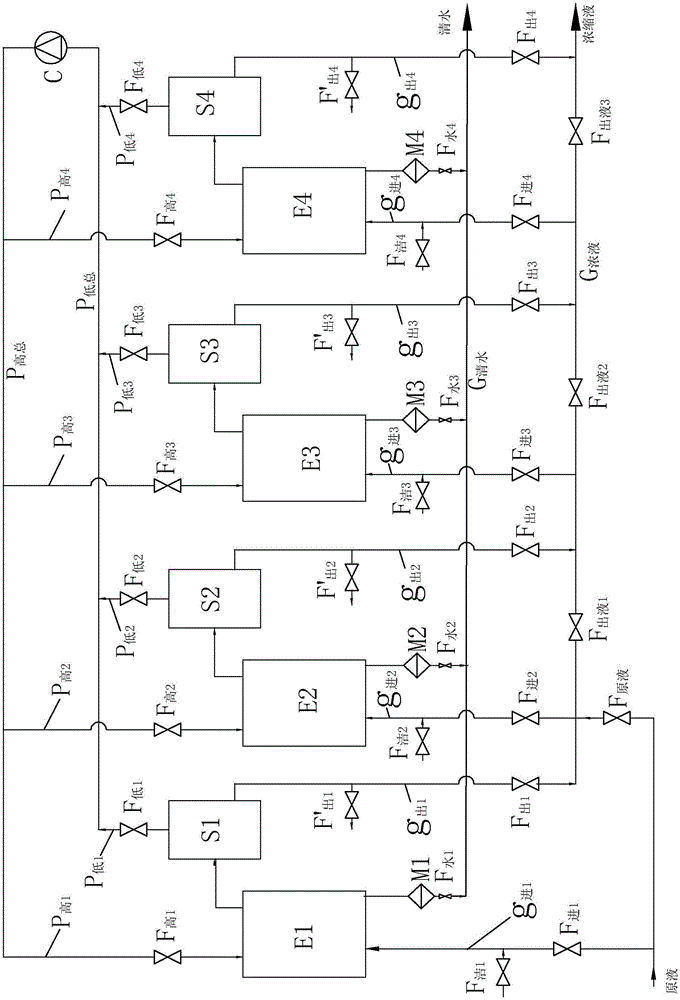

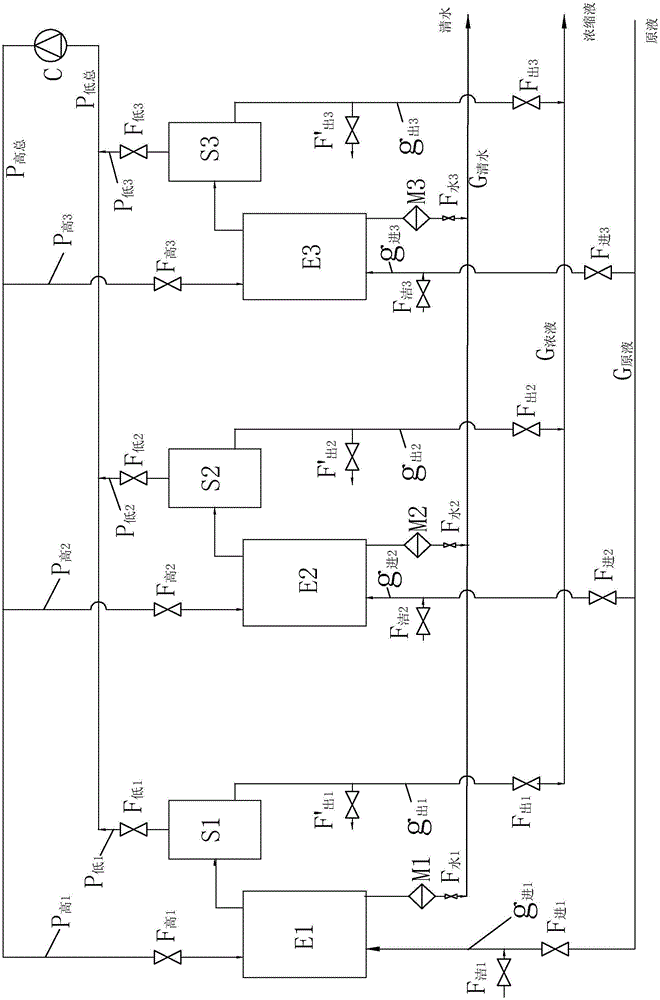

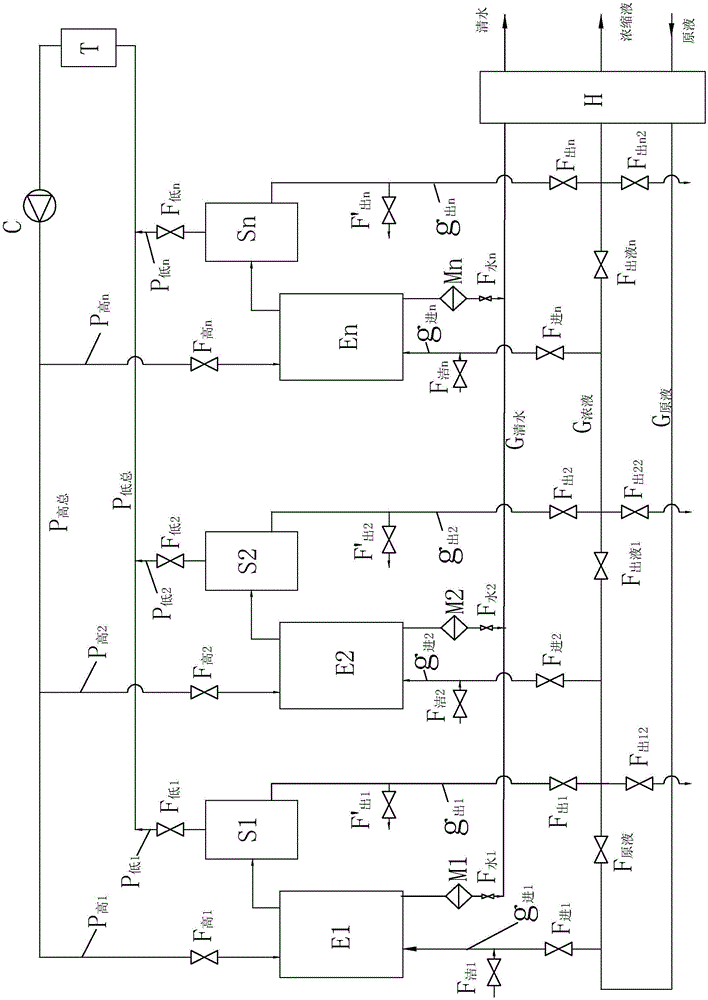

Evaporating system capable of conducting online descaling and working continuously and evaporating process

ActiveCN105999750AGuaranteed uptimeReduce the number of timesEvaporation with vapour compressionEvaporator regulation/controlEvaporationEngineering

The invention discloses an evaporating system capable of conducting online descaling and working continuously and an evaporating process. The evaporating system comprises n evaporating units, each evaporating unit is composed of an evaporator E and a steam-water separation mechanism S, the n evaporating units are connected in a feed liquor series-connection or parallel-connection evaporation mode to form the complete evaporating system, secondary steam generated by the n evaporating units shares one steam compression machine for pressurization and temperature raising, and a high-temperature steam main pipe is connected out of the steam compression machine and connected to high-temperature steam inlet pipes on the evaporating units in parallel; a liquid inlet pipe of the second-level / set evaporating unit is simultaneously connected with the first-level / set concentrate outlet pipe and a stoste inlet pipe; a concentrate main pipe is arranged, all the evaporating units except the first level / set evaporating unit are connected with the concentrate main pipe, the concentrate main pipe segment between the liquid inlet pipe and the concentrate output pipe of each evaporating unit is provided with a concentrate valve, valves on related inlet pipes and outlet pipes are controlled to isolate the evaporating units to be cleaned, and evaporating work of the system is not affected.

Owner:广州中科鑫洲科技有限公司 +1

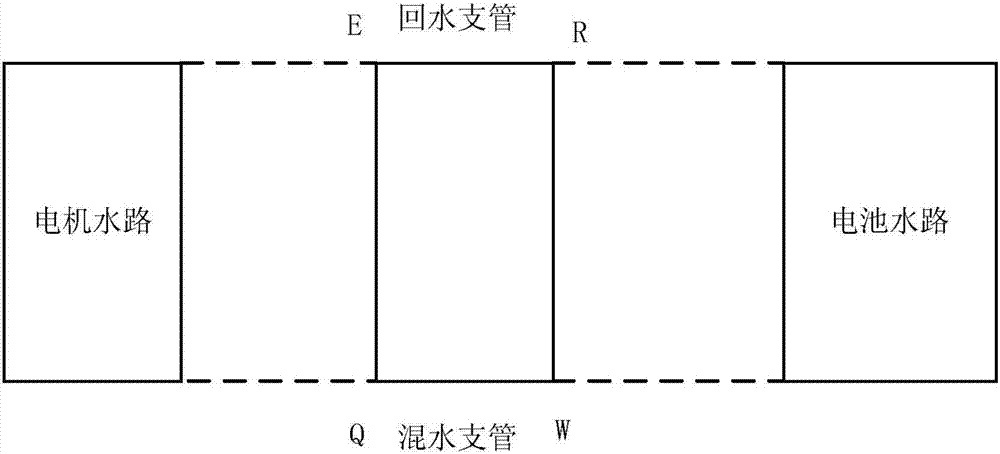

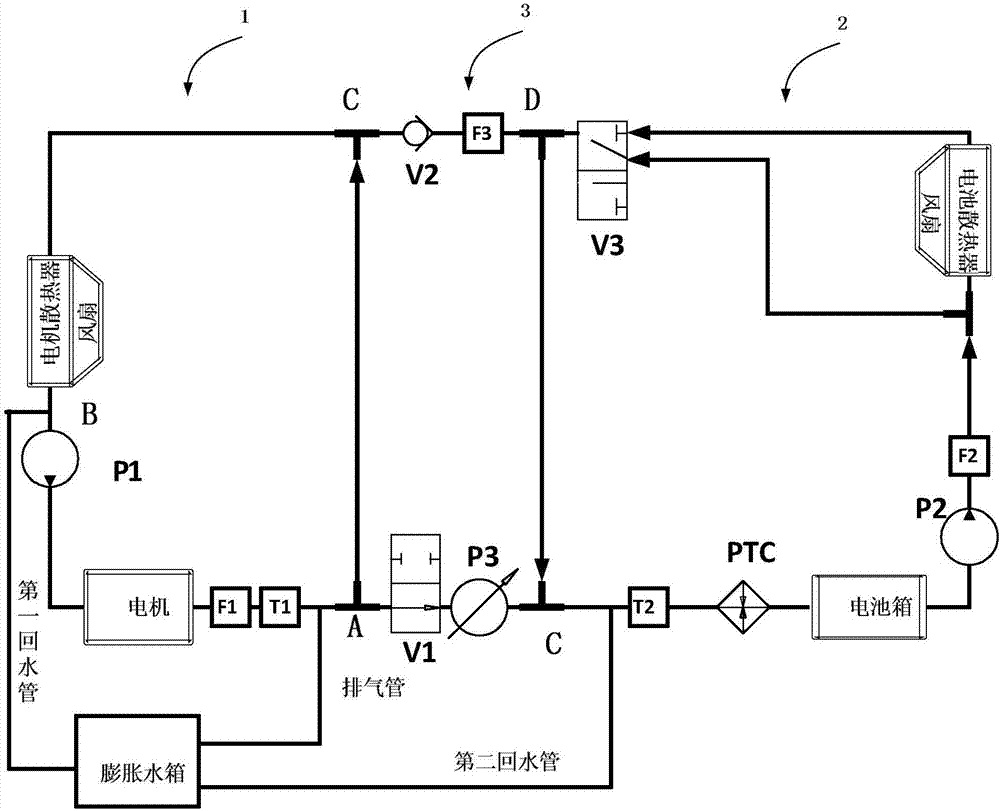

Expansion water tank sharing system for new energy vehicle and new energy vehicle

ActiveCN107199879AReduce capacityReduce weightSecondary cellsCooling/ventillation arrangementExpansion tankNew energy

The embodiment of the invention discloses an expansion water tank sharing system for a new energy vehicle and the new energy vehicle. The system comprises a motor waterway, a battery waterway, a mixed water branch pipe located between the motor waterway and the battery waterway, a water return branch pipe located between the motor waterway and the battery waterway and an expansion water tank comprising a first water return pipe, a second water return pipe and an exhaust pipe; the exhaust pipe is connected to the motor waterway, the first water return pipe is connected to the motor waterway, and the second water return pipe is connected to the battery waterway. Accordingly, the liquid storage and air-exhausting functions are provided for the motor waterway and the battery waterway simultaneously by means of a shared expansion water tank, the capacity and weight of cooling liquid are lowered, structures and mounting supports which are needed by installing the expansion water tank are saved, and the total weight and cost are lowered.

Owner:CH AUTO TECH CORP CO LTD

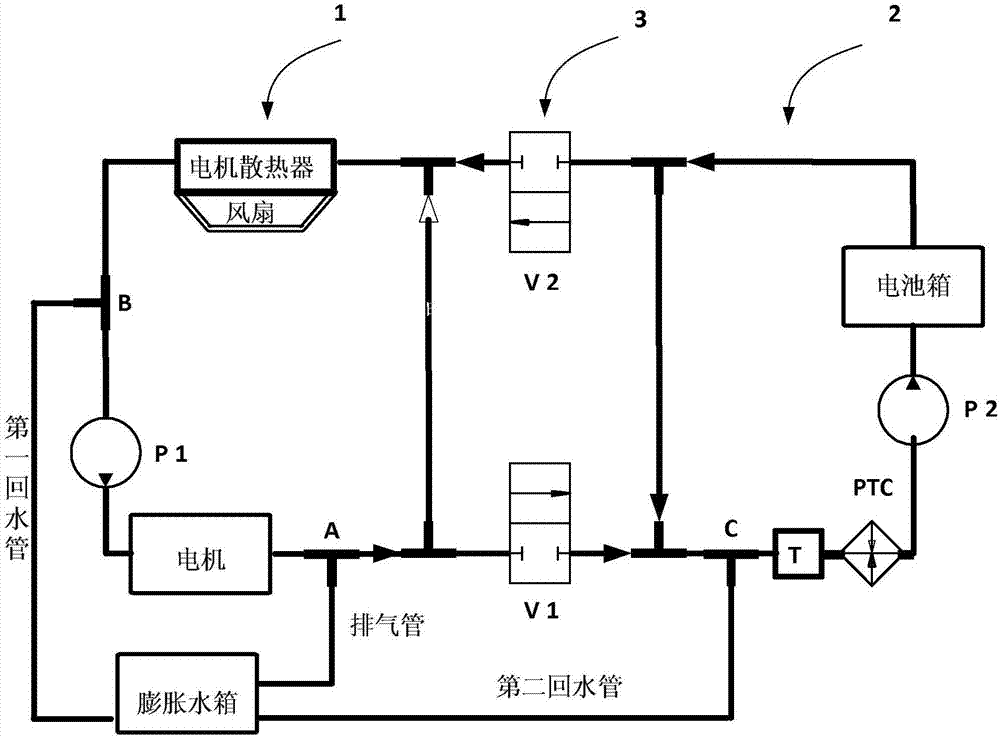

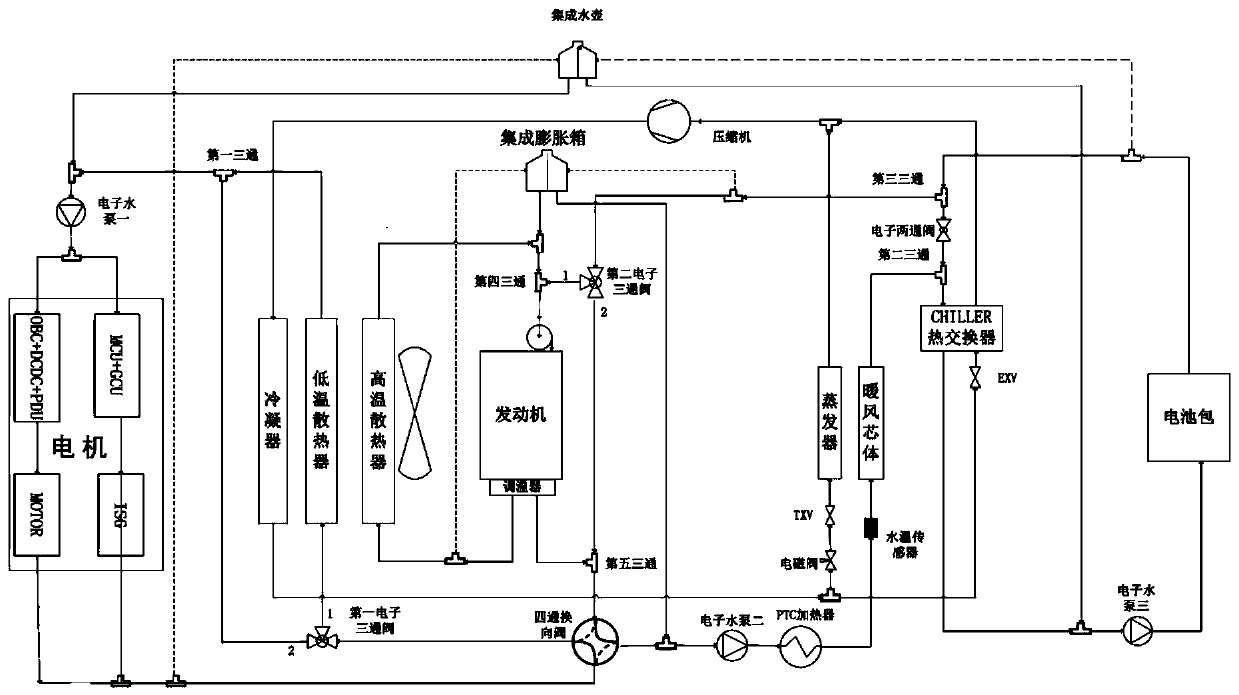

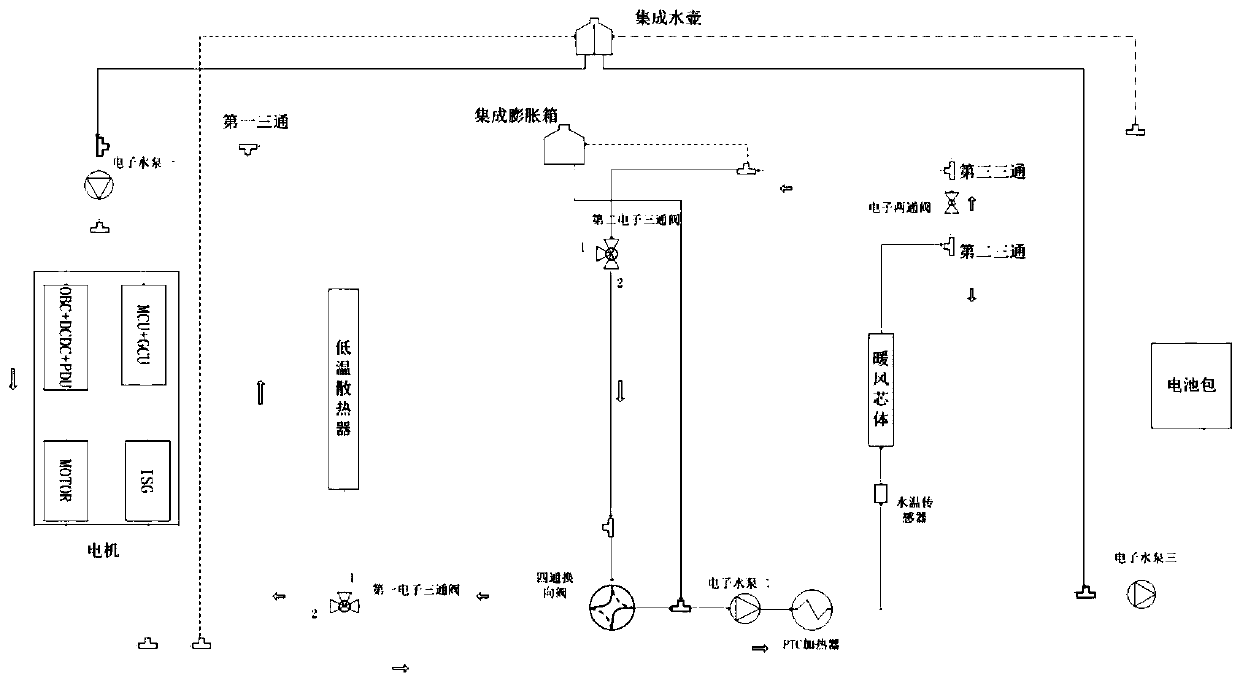

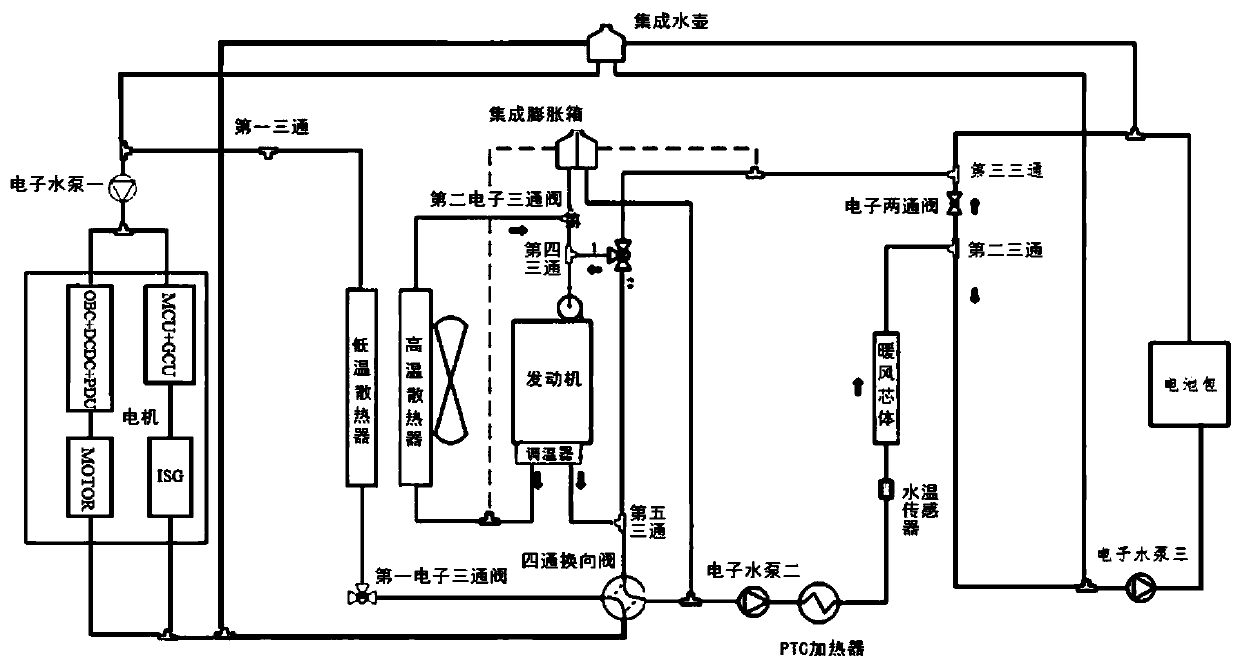

Extended-range electric vehicle heat management system and method

ActiveCN110978945ARealize waste heat recoveryReduce energy consumptionAir-treating devicesVehicle heating/cooling devicesThermodynamicsHeat management

The invention discloses an extended-range heat management system and method. On the basis of the extended-range electric vehicle heat management system, waste heat recovery of an engine and a motor isachieved, engine waste heat or motor waste heat can be distributed to a battery pack and / or a cockpit according to needs at the same time, so that the waste heat of the motor and the engine is recovered to the maximum extent to be used for heating of the battery pack and the cockpit, and the energy consumption of a PTC heater is reduced. Meanwhile, when heat is supplied to the battery pack and the cockpit, the motor waste heat or the engine waste heat can be distributed to the battery pack and an air heating core body in different proportions by controlling the rotating speed of an electronicwater pump III.

Owner:浙江威格镁汽车科技有限公司

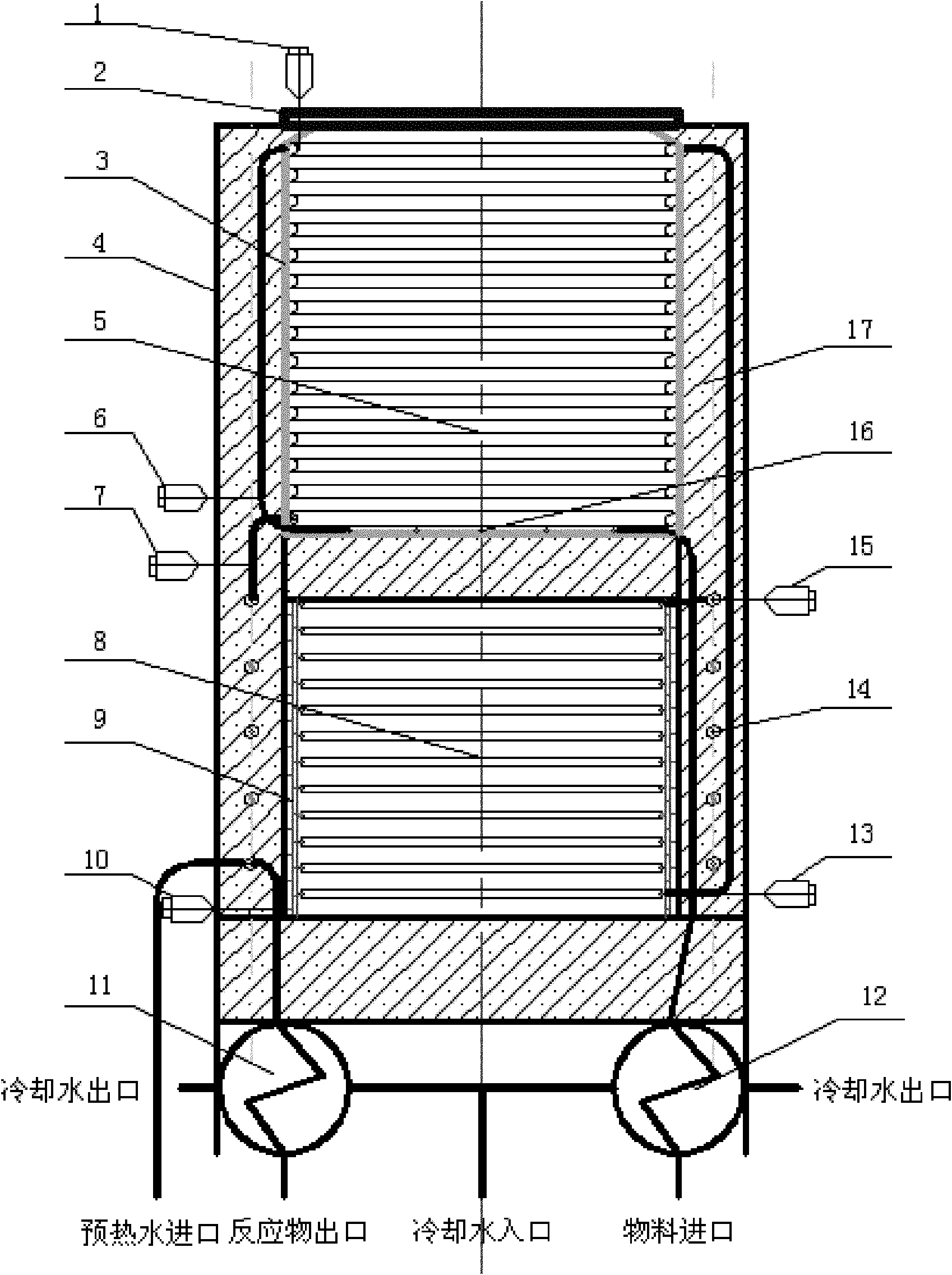

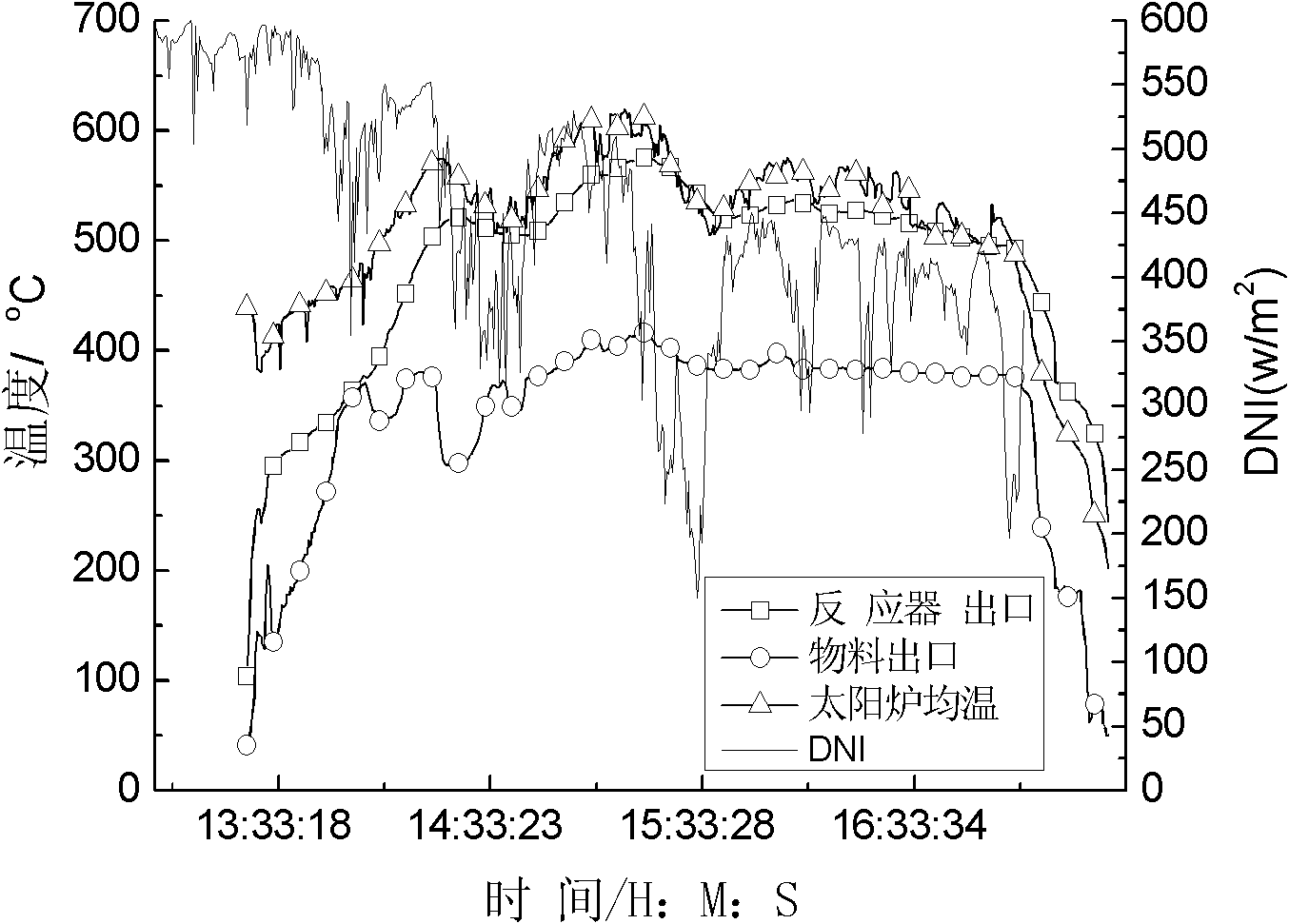

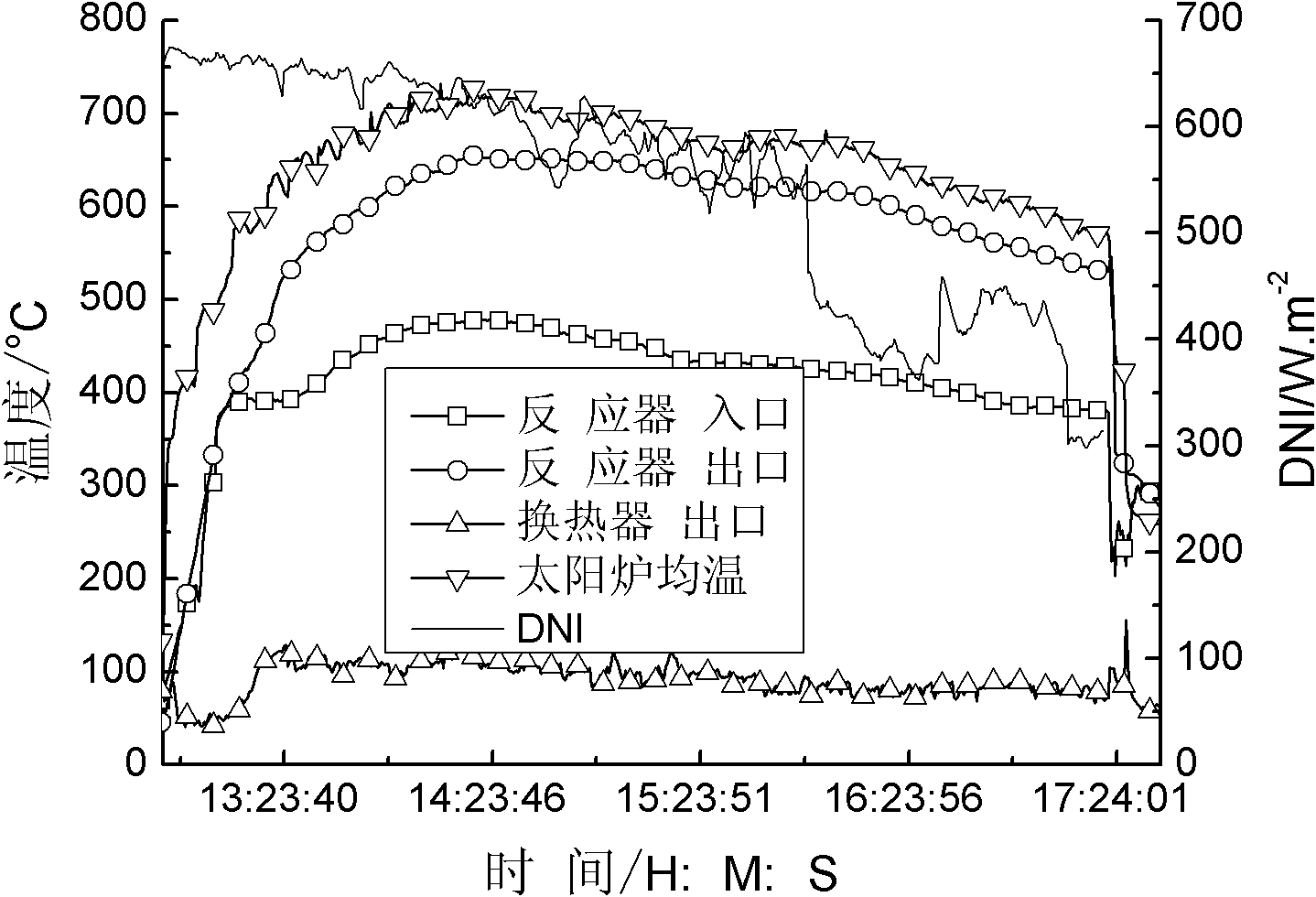

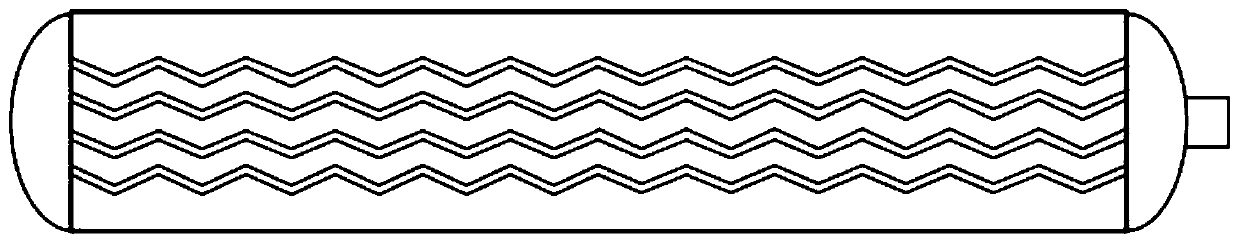

Supercritical water gasification hydrogen production and heat absorption reactor for multi-disk solar heat-collecting coupling biomass

ActiveCN102115030ASmall temperature fluctuationsReduce heat lossHydrogen productionBulk chemical productionHigh energyCoupling

The invention discloses a supercritical water gasification hydrogen production and heat absorption reactor for a multi-disk solar heat-collecting coupling biomass, which comprises a cavity type solar absorption reactor, a first cooler and a second cooler, wherein the cavity type solar absorption reactor comprises an endothermic reaction cavity and a pre-heated water heating cavity, inner cavity walls of the endothermic reaction cavity and the pre-heated water heating cavity are provided with insulating layers, an opening at the upper end of the endothermic reaction cavity is sealed by silica glass, a pipe flow reactor is arranged in the endothermic reaction cavity, and the bottom of the endothermic reaction cavity is provided with a material preheater; the pre-heated water heating cavity is internally provided with a pre-heated water heater, a crawler-type electric heater is used for heating, and a heat storage medium is filled in the pre-heated water heating cavity; and a screw shelltype high-pressure heat exchanger is wound outside the pre-heated water heating cavity. The supercritical water gasification hydrogen production and heat absorption reactor has the advantages of small temperature fluctuation in the solar absorption cavity, high biomass supercritical water gasification rate, high energy comprehensive utilization efficiency and the like, and is beneficial to the realization of efficient, low-cost and massive hydrogen production through supercritical water gasification of focused solar heat coupling biomass.

Owner:陕西中核交大超洁能源技术有限公司

Method for synergistically realizing efficient removal of PM2.5/SO3 in high-moisture flue gas and zero water consumption in wet desulphurization

InactiveCN106669345APrevent evaporationReduce the temperatureCombination devicesGas treatmentWater vaporFine particulate

The invention provides a method for synergistically realizing efficient removal of PM2.5 / SO3 in high-moisture flue gas and zero water consumption in wet desulphurization. The method comprises the following steps: making the high-moisture flue gas pass through a low-temperature heat exchanger before entering an electric precipitator, so that the smoke temperature drops below an acid dew point, gaseous SO3 in the flue gas is condensed and adsorbed onto the surface of fine particulate matters, the PM2.5 removal of the electric precipitator is enhanced, and synergistic removal of SO3 is realized; after the flue gas leaves the electric precipitator, further cooling through a low-low-temperature heat exchanger to obtain high-relative-humidity flue gas, then reaching oversaturation in a desulfurization tower within a low-temperature desulfurization fluid contact process, and nucleating and condensing the oversaturated water vapor on the acid mist surface of the PM2.5 and the SO3, so that the particle size increases, and the removal of the acid mist of the PM2.5 and the SO3 in the desulfurization process is facilitated. At the same time, an oversaturated water vapor environment is established in the tower, so that a part of moisture is condensed from the flue gas to the desulfurization fluid, and zero water consumption in the wet desulphurization is realized synergistically. The method has the characteristics of high efficiency, energy saving, low investment and treatment cost, and the like.

Owner:SOUTHEAST UNIV

Energy saving type phosphorus reaction tower for producing high pure phosphoric acid

InactiveCN1857996ASimple structureRealize waste heat recoveryPhosphorus oxyacidsMouth piecePhosphoric acid

The present invention discloses a kind of energy saving phosphorus reaction tower for producing high purity phosphoric acid. The vertical sealed tower has ring film type water cooling wall formed with stainless steel pipes and finned sheets through welding, upper header tank and upper conic end with fume outlet connected to the upper end of the ring film type water cooling wall, lower header tank and lower conic end connected to the lower end of the ring film type water cooling wall, inclined phosphorus spraying gun mouth piece in the lower part, apron type pedestal connected to the lower header tank, steam collector connected between the steam-water separator and the upper header tank, down take connected between the steam-water separator and the lower header tank, and the steam-water separator with steam outlet pipe and cold water inlet pipe. The present invention realizes the afterheat recovery of phosphoric acid producing process, and has high heat efficiency and phosphoric acid as high as 99 %.

Owner:ZHEJIANG UNIV

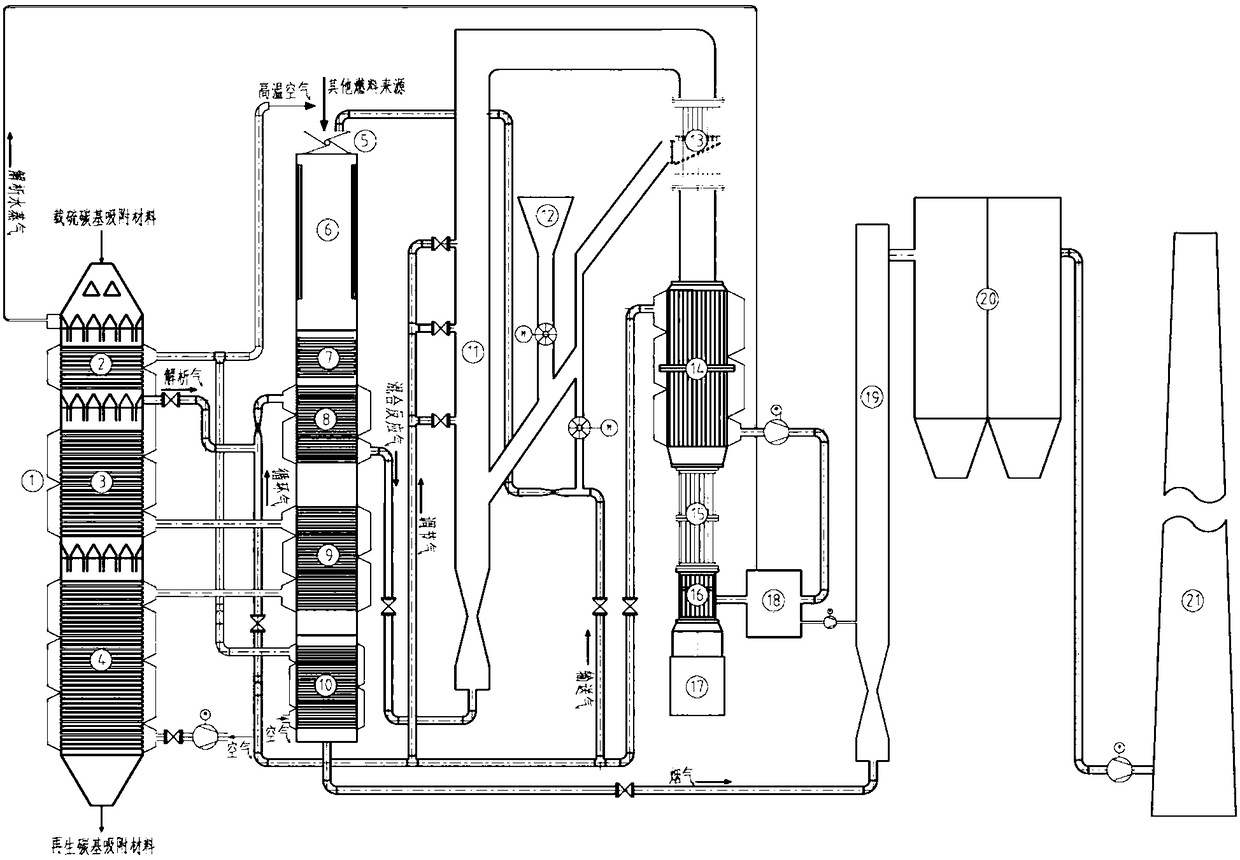

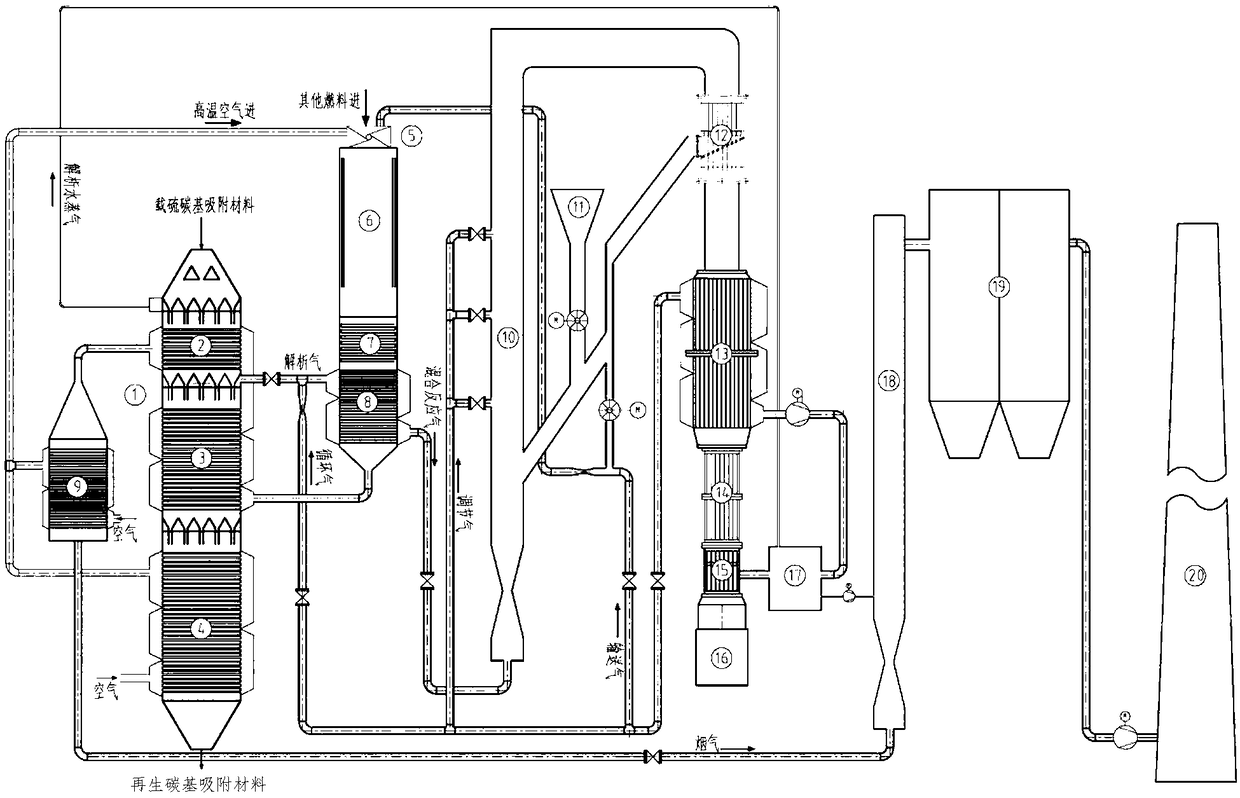

Sulfur resource recovery method and device making incineration, resolution, charcoal head reduction coordinated

InactiveCN108786370AEfficient regenerationRealize recycling of resourcesGas treatmentDispersed particle separationRecovery methodCombustor

The invention discloses a sulfur resource recovery method and device making incineration, resolution, charcoal head reduction coordinated. The sulfur resource recovery device comprises a resolution tower, an incineration furnace and a fluidized bed carbon thermal reduction tower, wherein the resolution tower is divided into a preheating section, a resolution section and a cooling section from topto bottom, the bottom of the incineration furnace is connected with a tail heated device, and the tail heated device is sequentially provided with a primary air heater, a secondary air heater, a mixedreaction gas heater from bottom to top. A tube nest outlet of the cooling section is connected with a gas inlet of the secondary air heater, a gas outlet of the secondary air heater is connected witha tube nest inlet of the resolution section, the tube nest outlet of the resolution section is connected with the tube nest inlet of the preheating section, the tube nest outlet of the preheating section and the gas outlet of the primary air heater are both connected with an air inlet of a combustor of the incineration furnace, a resulted gas outlet of the resolution tower is connected with a gasinlet of the mixed reaction gas heater, and a gas outlet of the mixed reaction gas heater is connected with a resulted gas inlet of the fluidized bed carbon thermal reduction tower.

Owner:SHANDONG UNIV

Oxygen-free cooling and residual heat recovering method for magnetizing-roasted iron ore product

InactiveCN103789536AChange the water cooling processReduce pollutionIncreasing energy efficiencyMagnetic separationIronstoneGranularity

The invention relates to the technical field of metallurgy, in particular to an oxygen-free cooling and residual heat recovering method for a magnetizing-roasted iron ore product. The method comprises the following steps: feeding a magnetizing-roasted high-temperature material being 800-850 DEG C and 8-25 millimeters in granularity from the upper part of a vertical cooler; introducing blast furnace gas of which the CO or H2 volume content is not greater than 30 percent from the lower part of the vertical cooler, and controlling the flow rate of the high blast coal gas at 0.8-1.5 m / s; performing heat exchange between the high-temperature material and the blast coal gas in the vertical cooler during inverse flow, wherein the temperature of the high-temperature material is lowered below 200 DEG C, and the temperature of the blast coal gas is raised to 700-750 DEG C. The magnetizing-roasted high-temperature material undergoes secondary oxidation in a cooling process, and can undergo secondary micro-reduction in the cooling process in the cooler, so that the quality of the magnetizing-roasted iron ore product is improved. Meanwhile, the over-reduction of the material is prevented, and cyclic utilization of residual heat is realized.

Owner:JIUQUAN IRON & STEEL GRP

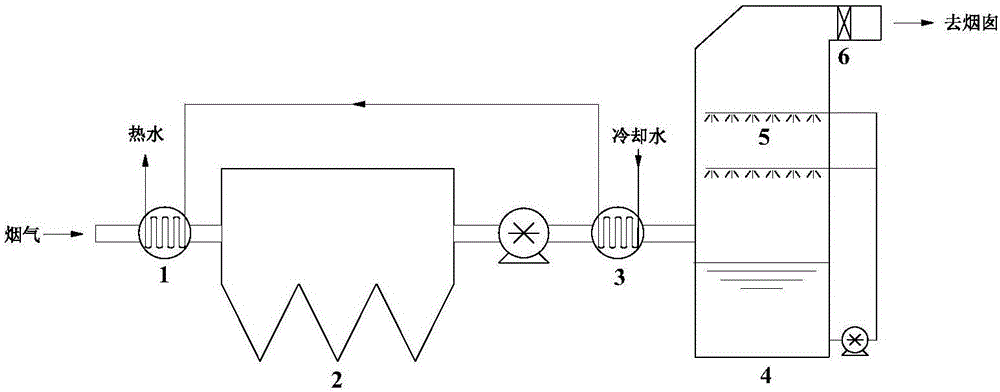

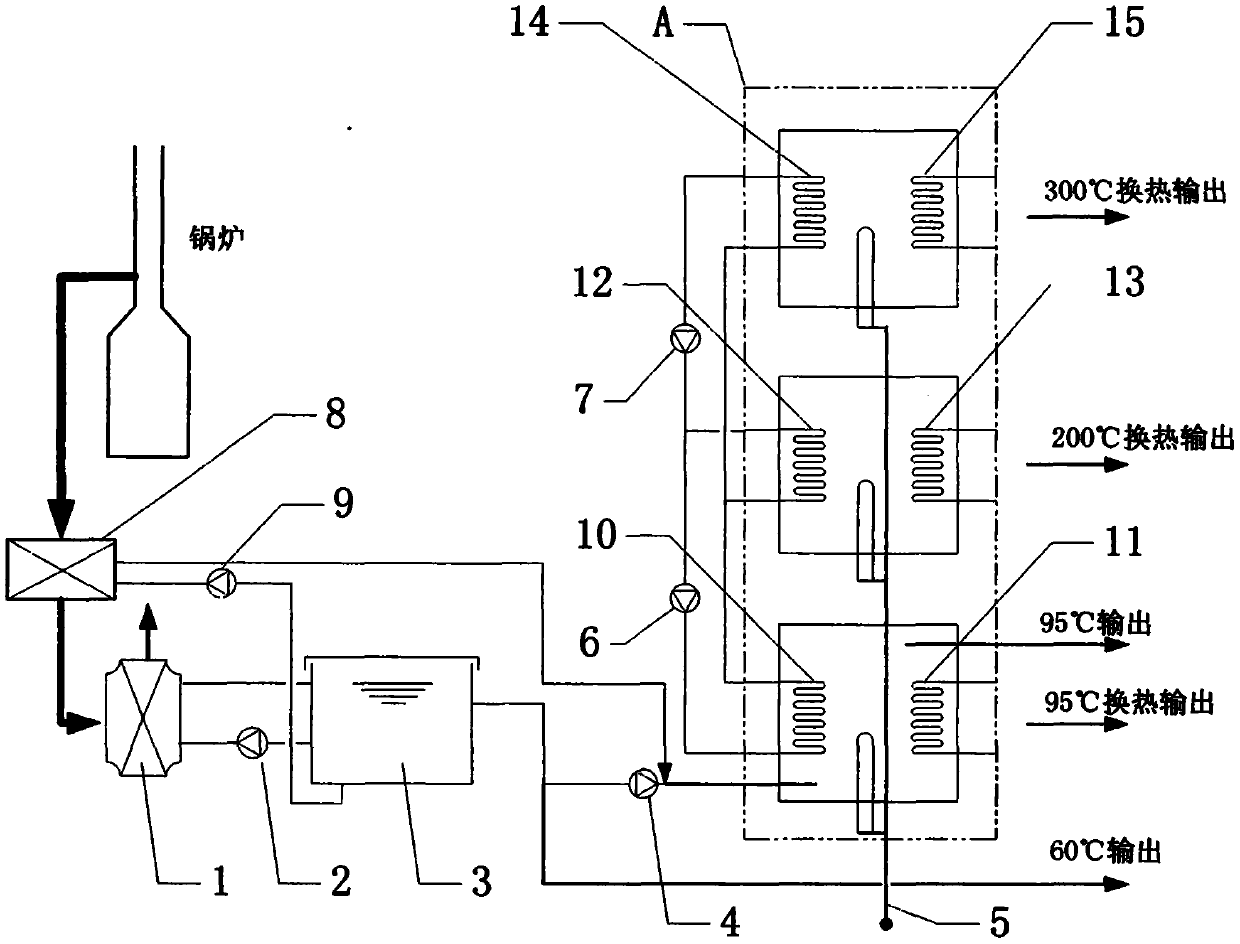

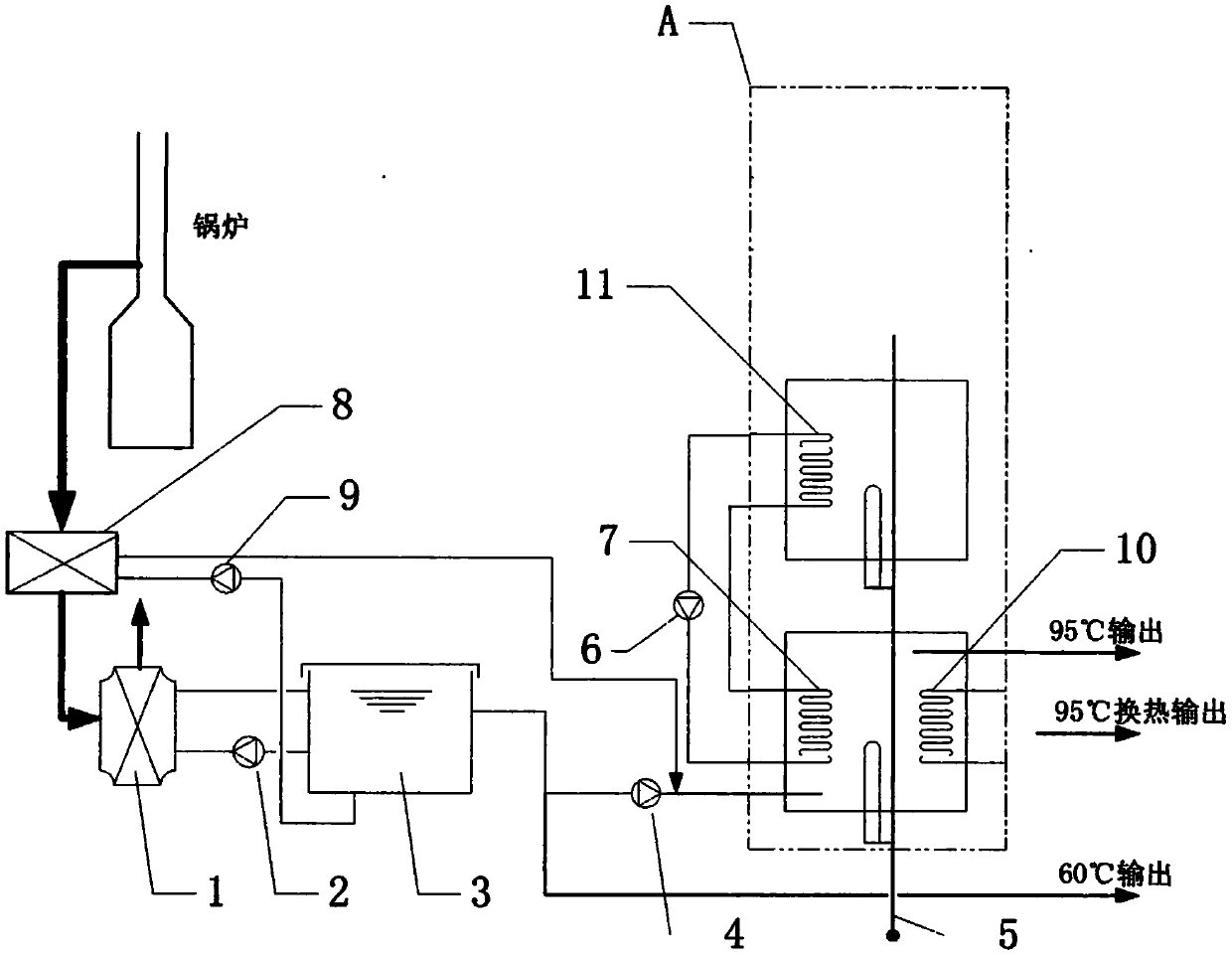

Integrated heat supply system for flue gas source heat pump waste heat recovery, flue gas white smoke removal and off-peak electricity phase change energy storage gradient temperature rise

PendingCN110529870AMeet individual heat transfer needsImprove energy efficiency ratioHeat recovery systemsHeat storage plantsThermal energyHeat pump

The invention discloses an integrated heat supply system for flue gas source heat pump waste heat recovery, flue gas white smoke removal and off-peak electricity phase change energy storage gradient temperature rise, and relates to the field of boiler flue gas white smoke removal, heat energy recycling and phase change energy storage. The objective of the invention is to solve the problem that white smoke is formed at a chimney opening in wet smoke exhausted by a boiler, visual pollution is generated, haze weather is intensified, and existing fused salt heat storage technology cannot meet theindustrial production requirement. The smoke source heat pump and the sleeve tank phase change energy storage device are creatively combined to generate a good effect. The flue gas source heat pump ofthe system can achieve complete recycling of natural gas heat energy, and the phenomenon of white smoke emission is eliminated. The sleeve tank phase change energy storage device raises 60 DEG C hotwater generated by the flue gas source heat pump into 95 DEG C hot water and 120-180 DEG C steam through the off-peak electricity energy storage warming system and supplies the hot water and the steamback to the boiler heat supply system, and environmental benefits and energy-saving benefits of eliminating chimney white smoke, reducing boiler natural gas consumption and reducing energy consumption cost are achieved.

Owner:李育勤

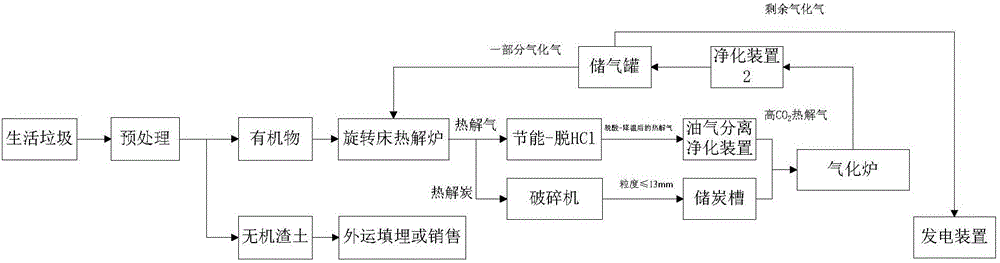

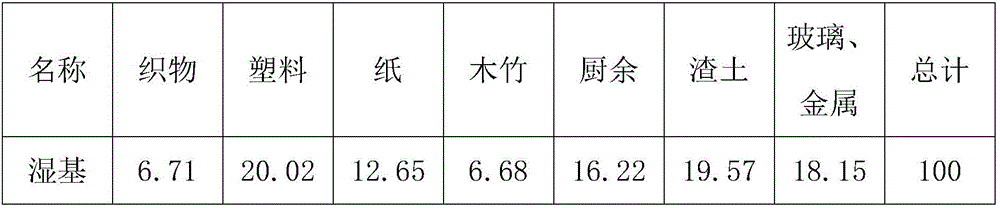

Method and system for recycling waste carbon and increasing heat value of pyrolysis gas

PendingCN106085511AIncrease profitShort processChemical industryGasification processes detailsCombustible gasEconomic benefits

The invention relates to a method and system for recycling waste carbon and increasing the heat value of pyrolysis gas. The method comprises the following steps: successively subjecting waste to pretreatment consisting of bag breaking, treatment with a roller screen, sorting, crushing, etc. so as to obtain a raw waste material; treating the raw waste material by using a revolving-bed thermal decomposition furnace so as to obtain substances comprising pyrolytic carbon and pyrolysis oil gas; and treating the pyrolysis oil gas with an energy-saving deacidification device and an oil gas separating and purifying device, and allowing obtained pyrolysis gas and the pyrolytic carbon crushed by a crusher to enter a gasifier for gasification so as to obtain gasified gas, wherein the gasified gas comprises 30 to 35% of CO and contains combustible gases like CO, H2 and CH4. The method and system provided by the invention realize recycling of the pyrolytic carbon and increase the heat value of pyrolysis gas at the same time, and are beneficial for improving the economic benefits of the whole household refuse pyrolysis process.

Owner:SHENWU TECH GRP CO LTD

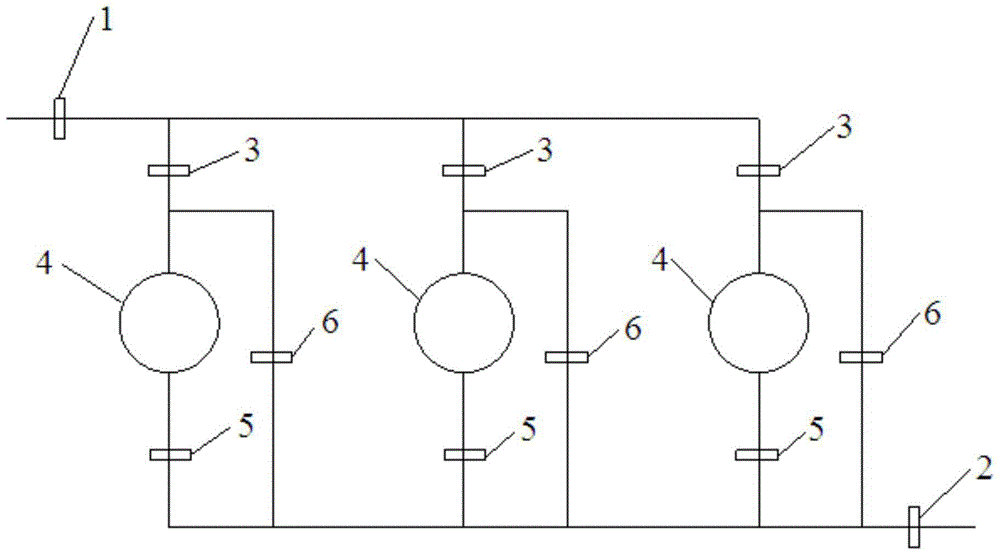

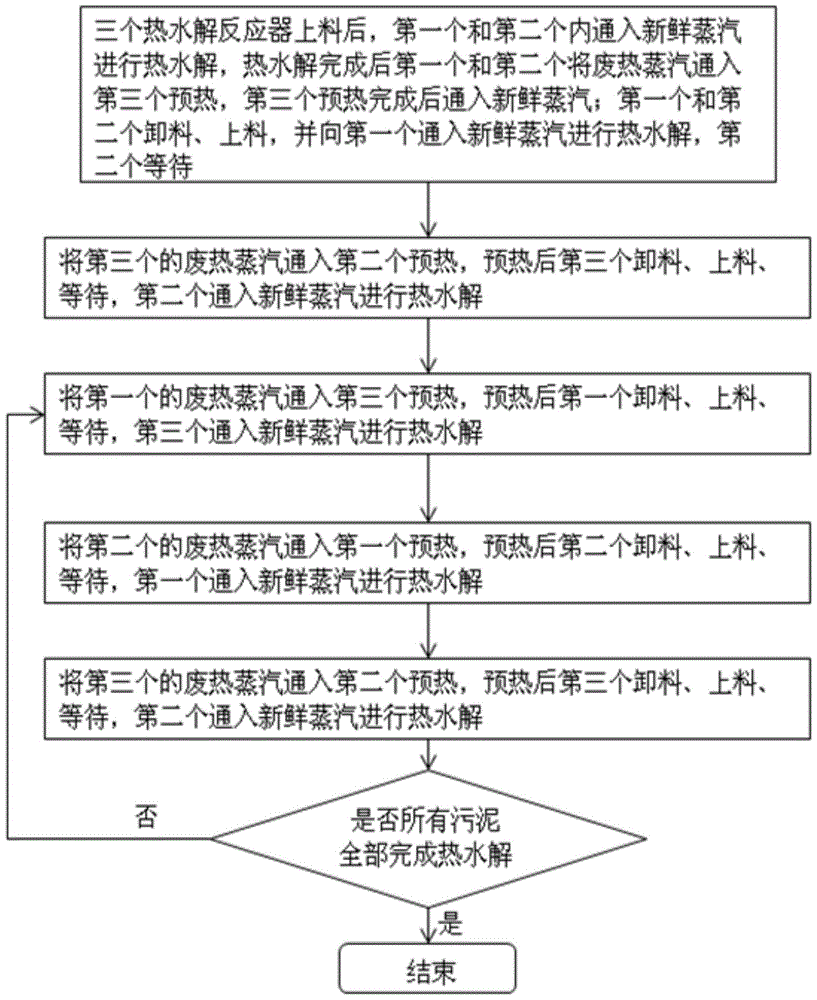

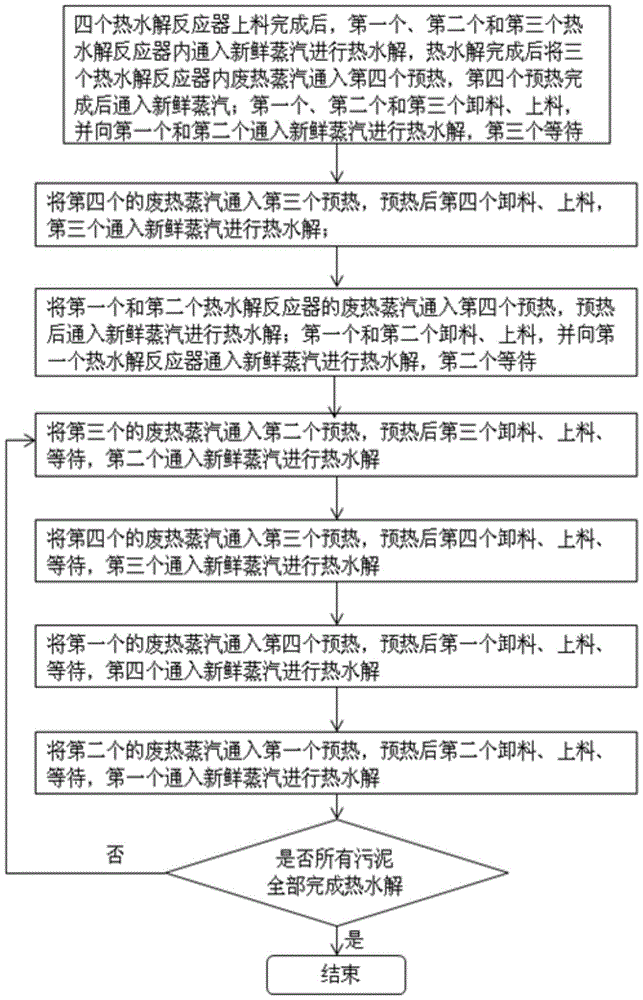

A modular sludge thermal hydrolysis treatment device and method

ActiveCN105016595BReduce consumptionEmission reductionSludge treatment by pyrolysisAutomatic controlSludge

The invention relates to a modular sludge thermal hydrolytic treatment device and method. The device comprises a steam feeding main valve, a steam releasing main valve and three-five hydrolytic modules, wherein the steam feeding main valve is arranged at the inlet of a steam main pipeline, the steam releasing main valve is arranged at the outlet of the steam main pipeline, the inlet of each of the hydrolytic modules is connected with the inlet of the steam main pipeline, and the outlet of each of the hydrolytic modules is connected with the outlet of the steam main pipeline; each hydrolytic module comprises a steam feeding valve, a thermal hydrolytic reactor, a steam releasing valve and a waste steam feeding valve; the inlet of the steam feeding valve is connected with the inlet of the steam main pipeline, the outlet of the steam feeding valve is connected with the inlet of the thermal hydrolytic reactor and the outlet of the waste steam feeding valve in parallel, the outlet of the thermal hydrolytic reactor is connected with the inlet of the steam releasing valve, and the outlet of the steam releasing valve and the inlet of the waste steam feeding valve are connected with the outlet of the steam main pipeline; each thermal hydrolytic reactor is internally provided with a temperature sensor and a pressure sensor, and each temperature sensor and each pressure sensor send collected temperature values an pressure values to an automatic control system.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

Direct-contact type flue gas waste heat deep recycling and pollution reducing device and method

InactiveCN105944527ARealize secondary processingTo achieve the purpose of comprehensive treatment and utilizationCombination devicesGas treatmentDust controlWater circulation

The invention relates to a direct-contact type flue gas waste heat deep recycling and pollution reducing device and method. The device comprises a flue gas treatment subsystem and a waste heat water treatment subsystem. The flue gas treatment subsystem comprises a flue gas oxidation module, a flue gas waste heat deep recycling module and a flue gas mist removing and dust removing module. The waste heat water treatment subsystem comprises a waste heat water circulating module, a waste heat water desulfurization and denitrification module and a waste heat water dust removing module. By means of the direct-contact type flue gas waste heat deep recycling and pollution reducing device, heat exchange between flue gas and low-temperature waste heat water is achieved, the flue gas discharging temperature is decreased to be the dew point temperature or lower, the flue gas low-temperature heat is recycled, the flue gas is subjected to desulfurization, denitrification and dust removal treatment, and emitted flue gas pollutants are reduced. According to the direct-contact type flue gas waste heat deep recycling and pollution reducing device and method, the problem of corrosion to equipment by flue gas condensate is solved, the recycled heat can be used for various low-temperature heat users, the utilization efficiency of fuel can be effectively improved, and secondary treatment on the flue gas can be achieved.

Owner:北京华源泰盟节能设备有限公司

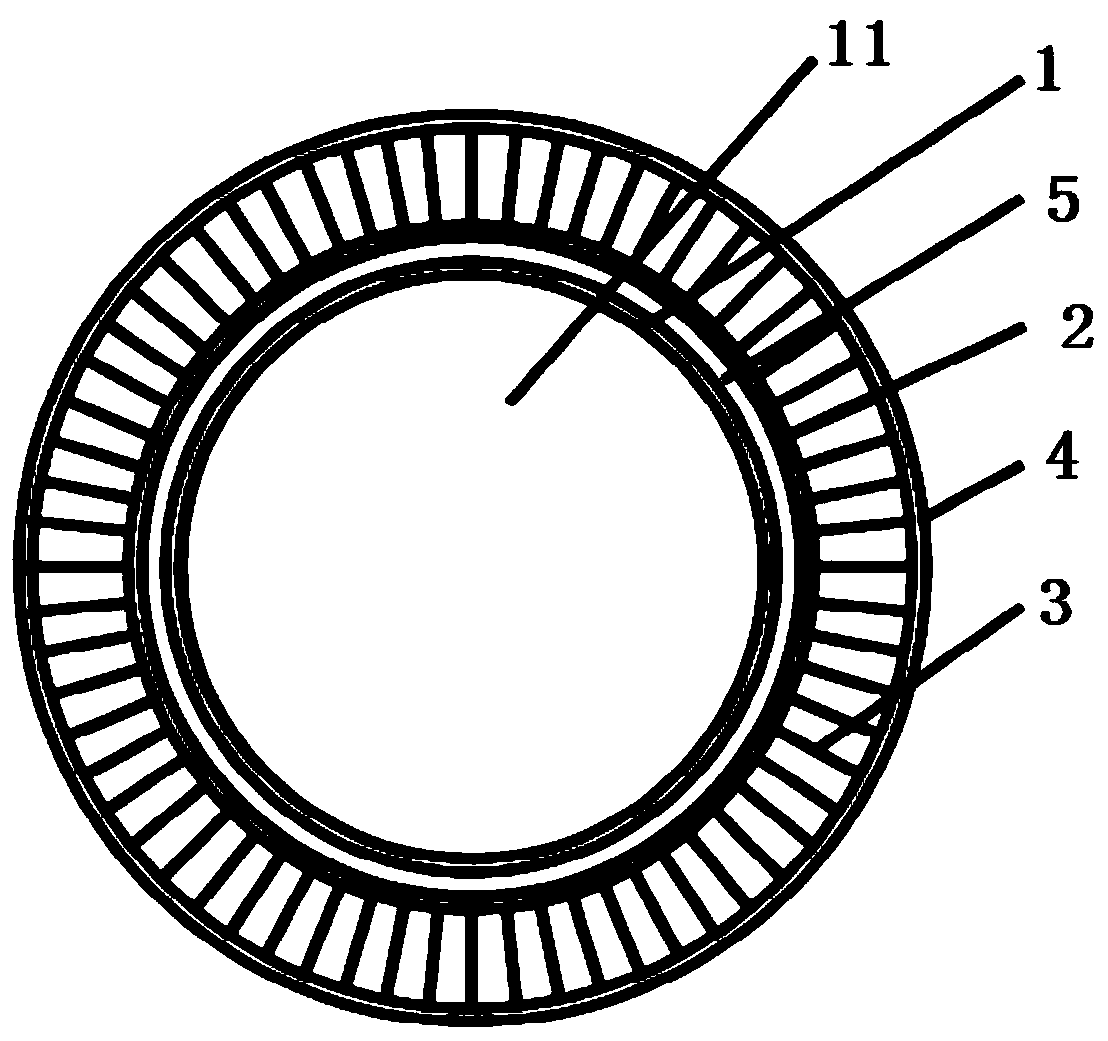

Heat transfer device and heating system

ActiveCN110783601AEasy to applyEasy to processFuel cell heat exchangeReactant parameters controlHydrogen desorptionProcess engineering

The invention discloses a heat transfer device, which is arranged outside a hydrogen storage tank and includes an inner sleeve spaced apart from the hydrogen storage tank. The outer wall of the innersleeve is provided with a plurality of fins. An outer sleeve is disposed outside the fins. The invention also discloses a heating system using the heat transfer device. The heating system includes a fuel cell, the hydrogen storage tank, a hydrogen supply pipe, an air inlet pipe, a fuel cell exhaust gas pipe or a cooling system, and the heat transfer device. The heat transfer device is disposed atthe hydrogen storage tank to transfer heat and increase turbulence intensity, thereby improving the heat transfer efficiency. The heating system, on the one hand, helps to reduce system energy consumption and improve comprehensive energy utilization efficiency, and on the other hand, achieves effective control of the hydrogen desorption working temperature of the hydrogen storage tank, and realizes the utilization of the maximum effective hydrogen storage capacity of a hydrogen storage system.

Owner:安徽伯华氢能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com