Direct-contact type flue gas waste heat deep recycling and pollution reducing device and method

A flue gas waste heat and contact technology, which is applied in the field of flue gas treatment and waste heat recovery, can solve the problems of acid corrosion service life of flue gas, and achieve the effect of reducing emissions and improving fuel utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

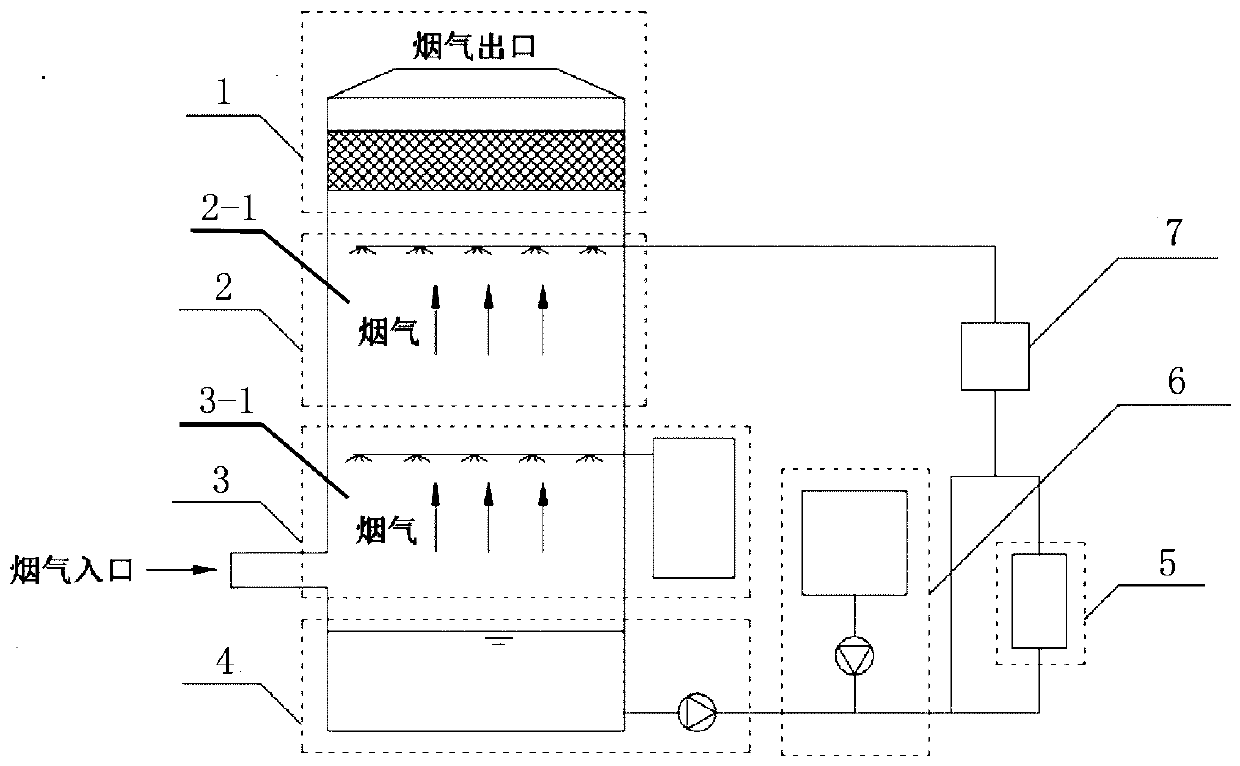

[0021] like figure 1 As shown, a direct contact flue gas waste heat deep recovery and pollution reduction device, the device includes a flue gas treatment subsystem and a waste water treatment subsystem; this equipment is suitable for treating more SO contained in coal-fired flue gas 2 , NOx and soot flue gas.

[0022] The flue gas treatment subsystem includes a flue gas oxidation module 3, a flue gas waste heat depth recovery module 2, and a flue gas demist and dust removal module 1; the flue gas oxidation module 3 includes a second flue gas channel 3-1 and a The oxidant release device in 3-1, the second flue gas channel 3-1 has a flue gas inlet connected to the source of flue gas to be treated; the flue gas waste heat deep recovery module 2 includes the first flue gas channel 2-1 And the residual hot water spraying device and the residual hot water recovery outlet arranged in the first flue gas channel 2-1, the gas outlet of the second flue gas channel 3-1 and the air inlet...

Embodiment 2

[0036] Use the direct contact flue gas waste heat deep recovery and pollution reduction device in Example 1 to carry out flue gas waste heat deep recovery and pollution reduction treatment method: This method is suitable for treating more SO contained in coal-fired flue gas 2 , NOx and soot flue gas.

[0037] Including two parallel workflows of flue gas treatment and waste water circulation,

[0038] Flue gas treatment: the flue gas first enters the flue gas oxidation module 3 for oxidation treatment; the oxidized flue gas enters the flue gas waste heat deep recovery module 2 and directly contacts the low-temperature waste water sprayed by the waste water spraying device to release heat for heating At the same time, the water-soluble pollutants and part of the smoke in the flue gas are absorbed by the residual hot water; the flue gas passes through the flue gas waste heat depth recovery module 2 and then enters the flue gas demisting and dust removal module 1 to remove the car...

Embodiment 3

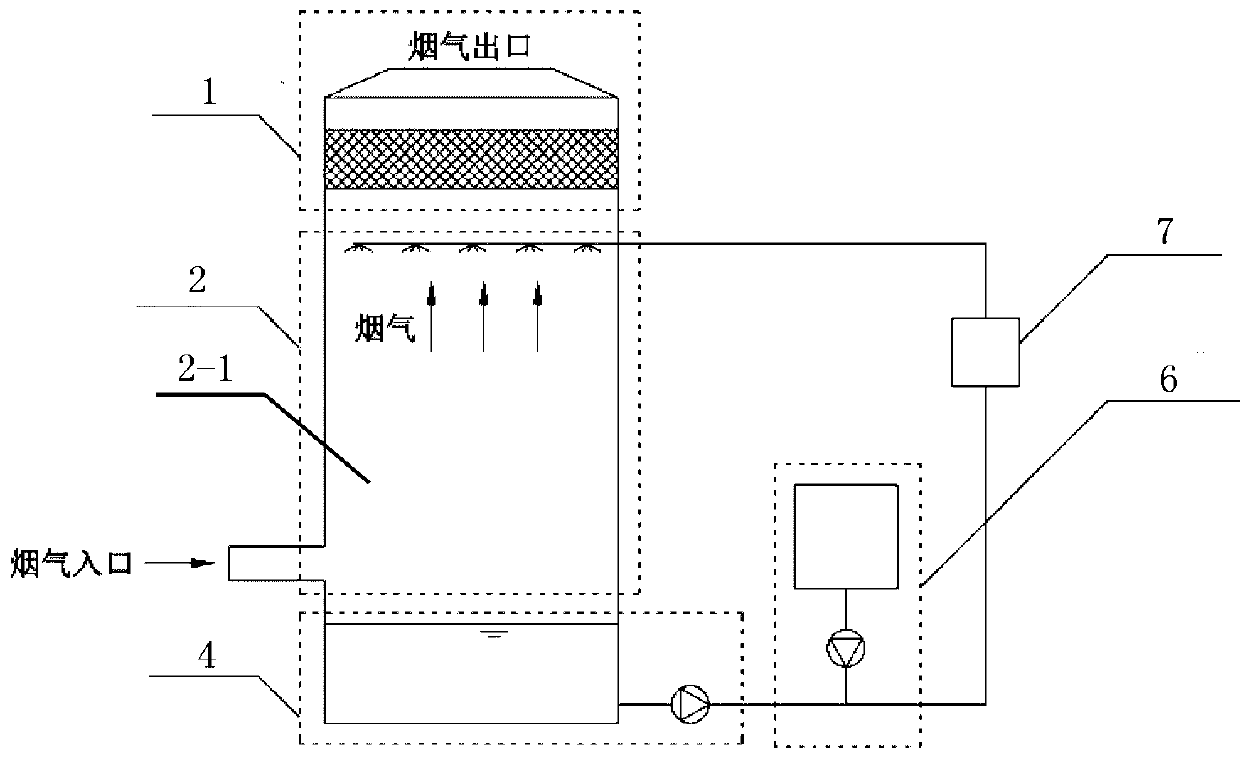

[0046] like figure 2 As shown, a direct contact flue gas waste heat depth recovery and pollution reduction device, the device includes a flue gas treatment subsystem and a waste water treatment subsystem;

[0047] The flue gas treatment subsystem includes a flue gas waste heat deep recovery module 2 and a flue gas demist and dust removal module 1; the flue gas waste heat deep recovery module 2 includes a first flue gas channel 2-1 and a The residual hot water spraying device and residual hot water recovery outlet in 2-1, the first flue gas channel 2-1 is provided with a flue gas inlet connected to the source of flue gas to be treated, and the gas outlet of the first flue gas channel 2-1 Connect the air inlet of the smoke demist and dust removal module 1, and the smoke demist and dust removal module 1 is provided with a smoke outlet connected to the atmosphere;

[0048] The waste water treatment subsystem includes waste water circulation module 4, waste water desulfurization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com