Patents

Literature

40results about How to "Realize secondary processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

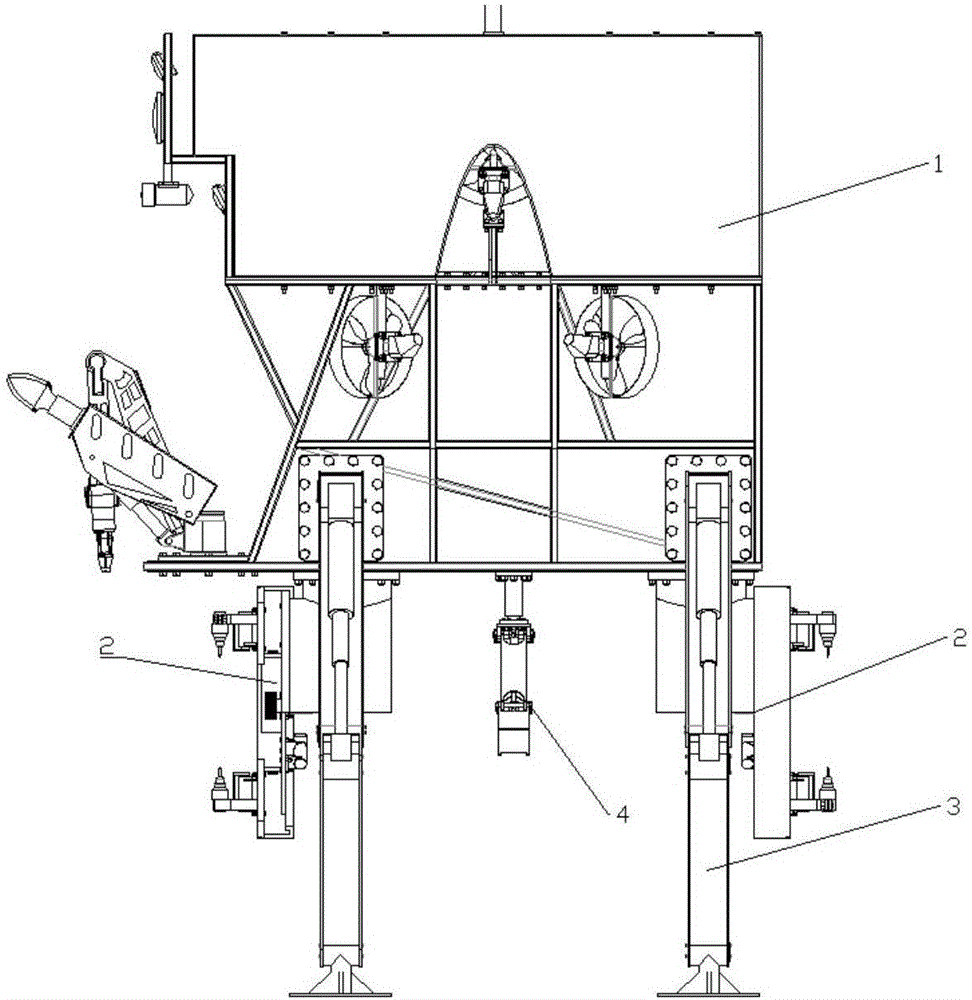

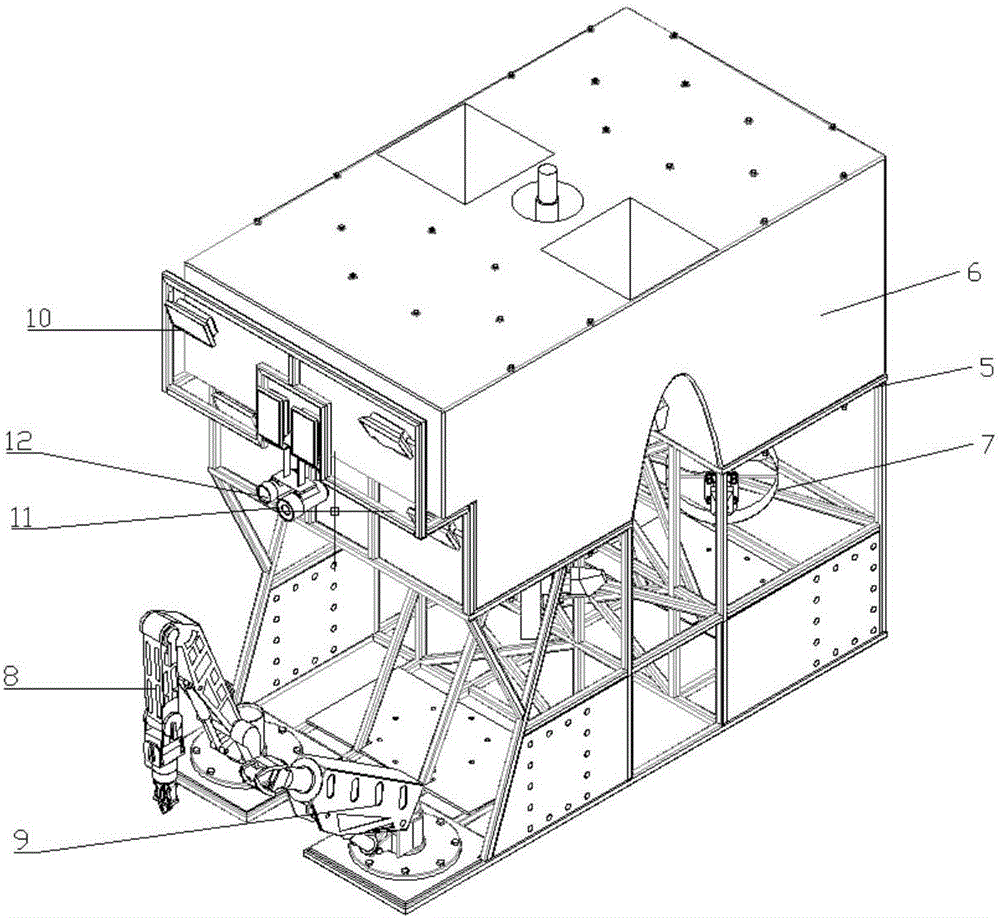

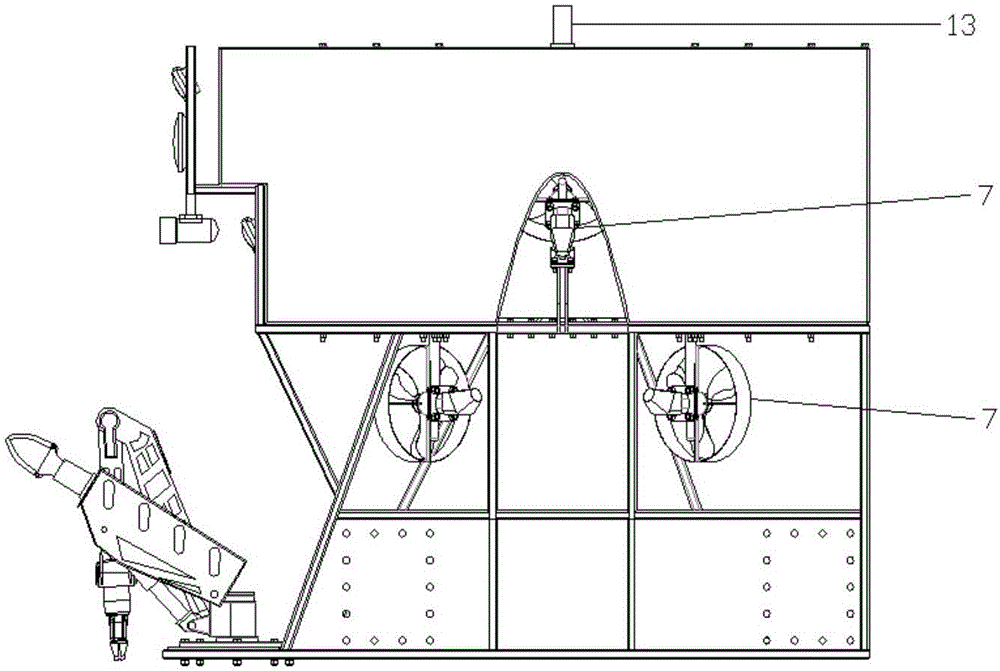

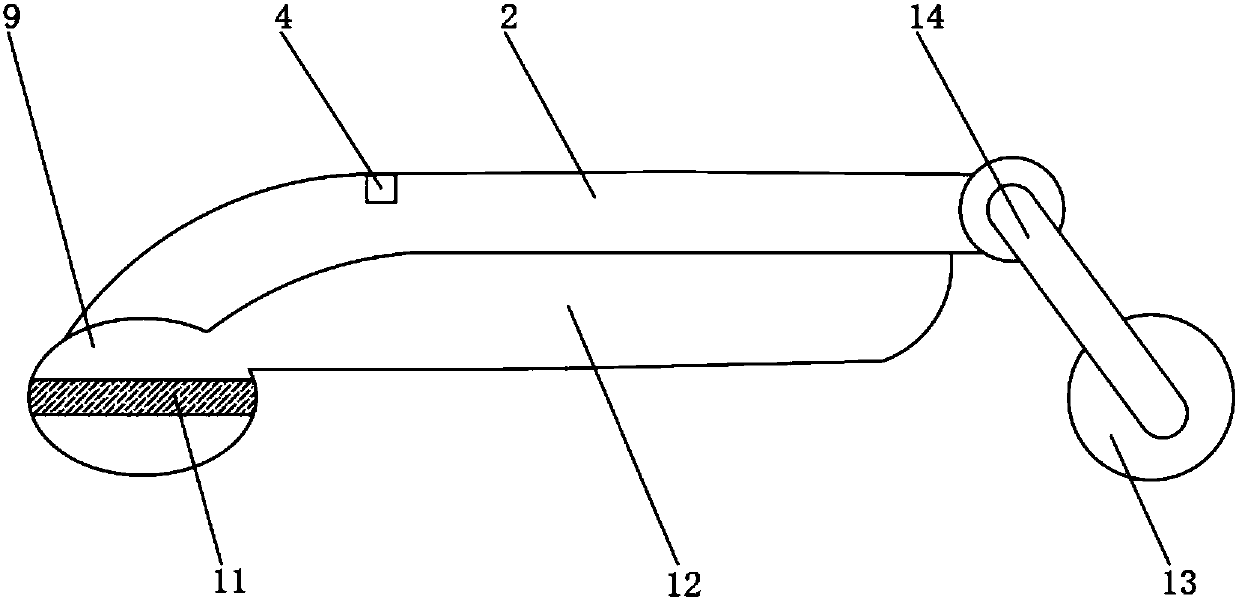

Underwater robot for submarine pipeline cutting

The invention discloses an underwater robot for submarine pipeline cutting. The underwater robot is mainly used for cutting submarine badly broken petroleum pipelines and comprises an ROV (remotely-operated vehicle) body, two cutting mechanisms, supporting legs and a small auxiliary manipulator, the ROV body comprises a frame, a buoyancy block, a propeller, a seven-degree-of-freedom manipulator, a five-degree-of-freedom manipulator, an underwater illumination device, a camera shooting device and a hydraulic electric control device, the supporting legs are uniformly distributed on two sides of the submarine pipeline cutting robot, a center line of the supporting legs is coincided with that of the cutting mechanisms, so that the ROV body is supported, the small auxiliary manipulator is connected below the submarine pipeline cutting robot through bolts and positioned in middle of the cutting mechanisms, the cutting mechanisms are fixed in the rearward front of the bottom of the submarine pipeline cutting robot through bolts, the cutting mechanisms and a pipeline are positioned by a positioning hydraulic cylinder, and the broken pipelines are cut by controlling rotation of a water cutter mechanism. The underwater robot can be automatically operated in deep water areas or special environments.

Owner:NORTHEAST GASOLINEEUM UNIV

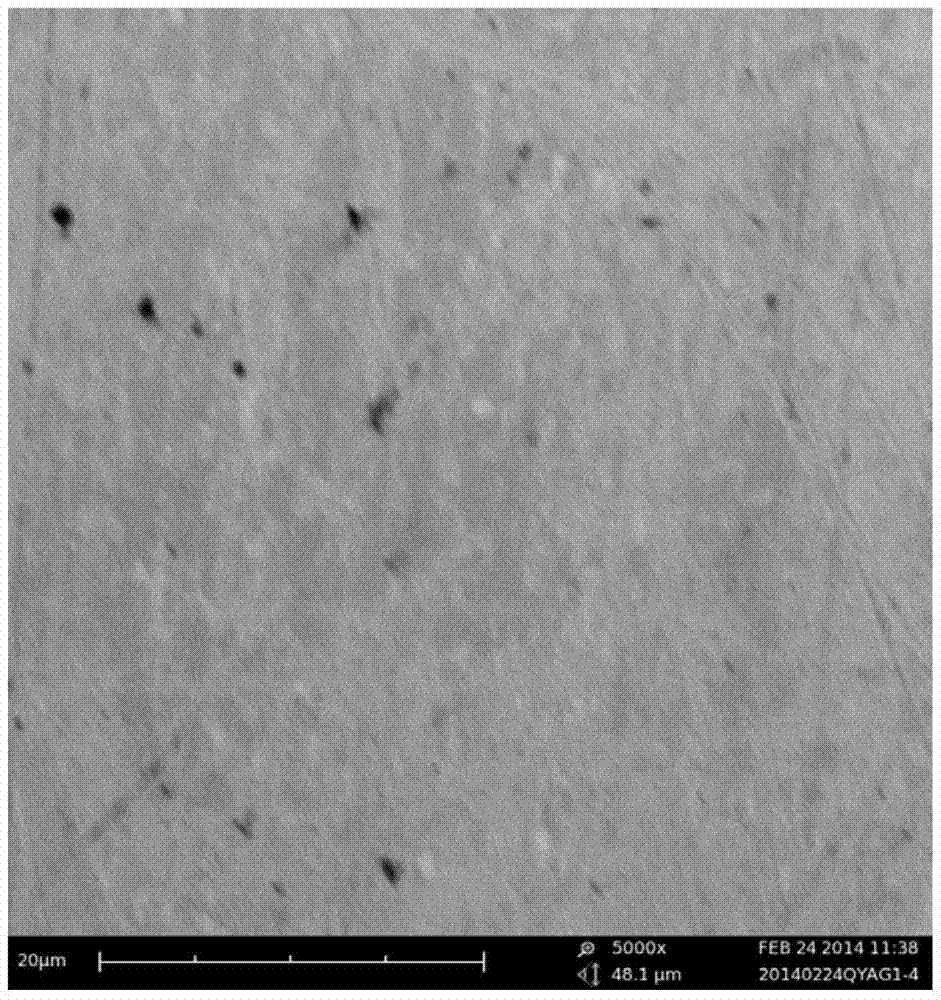

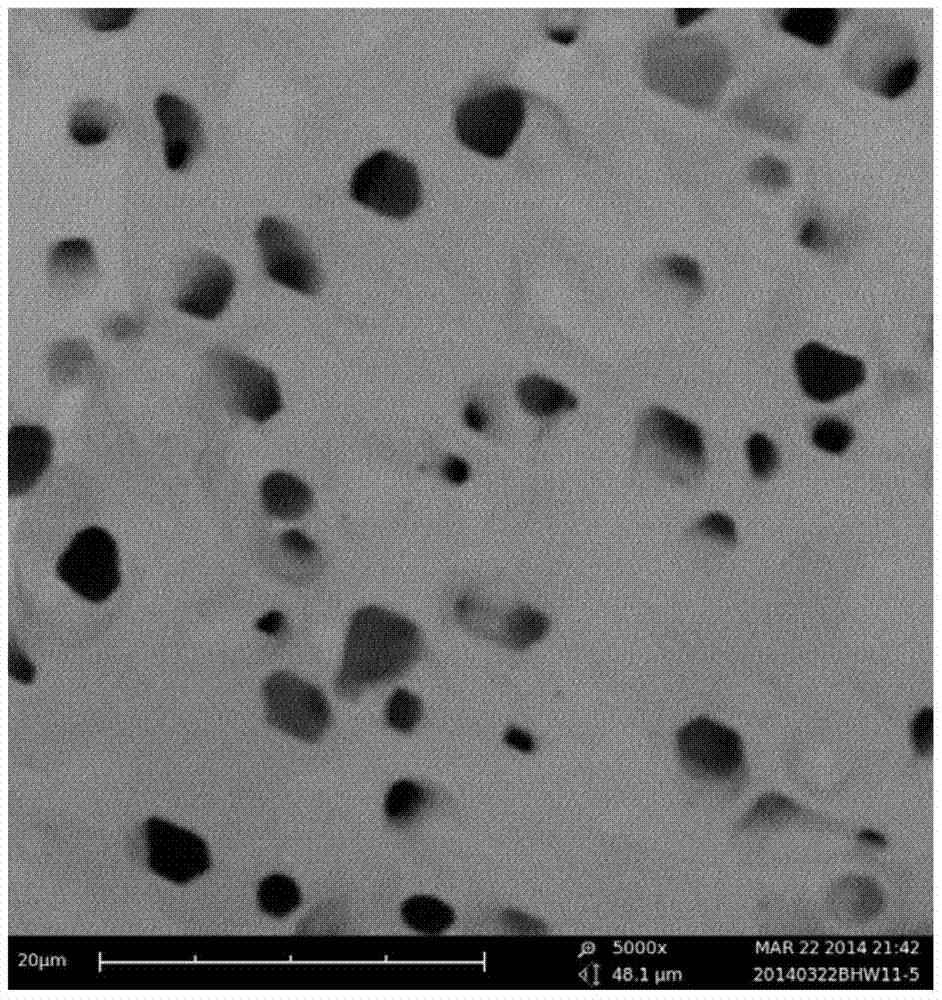

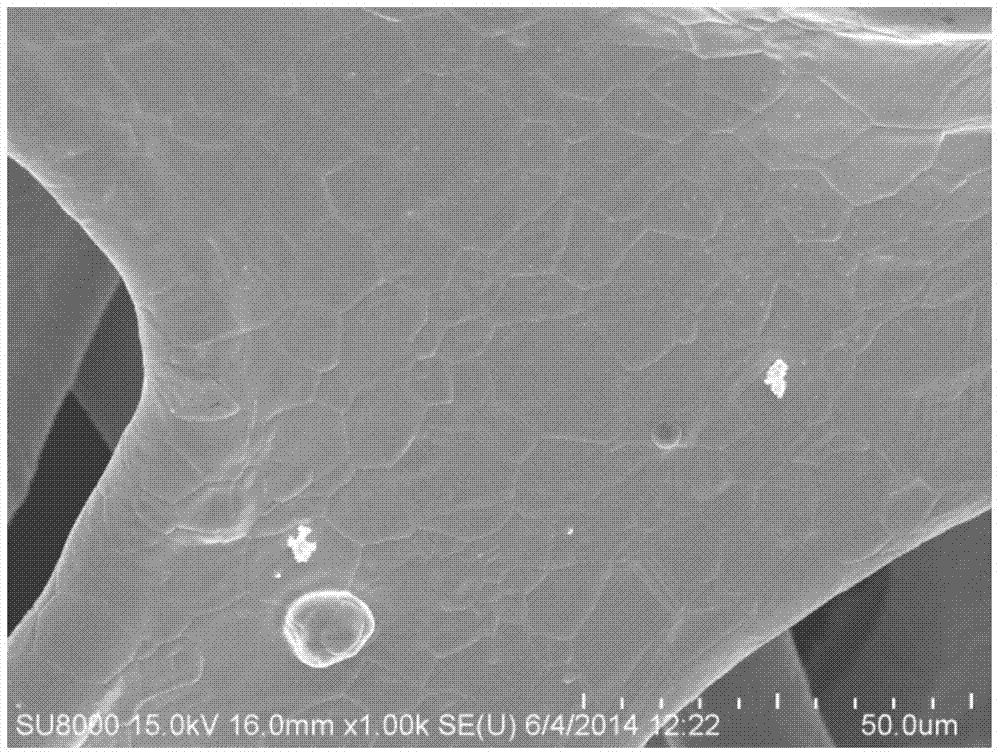

Method for preparing porous metal with mixed gas

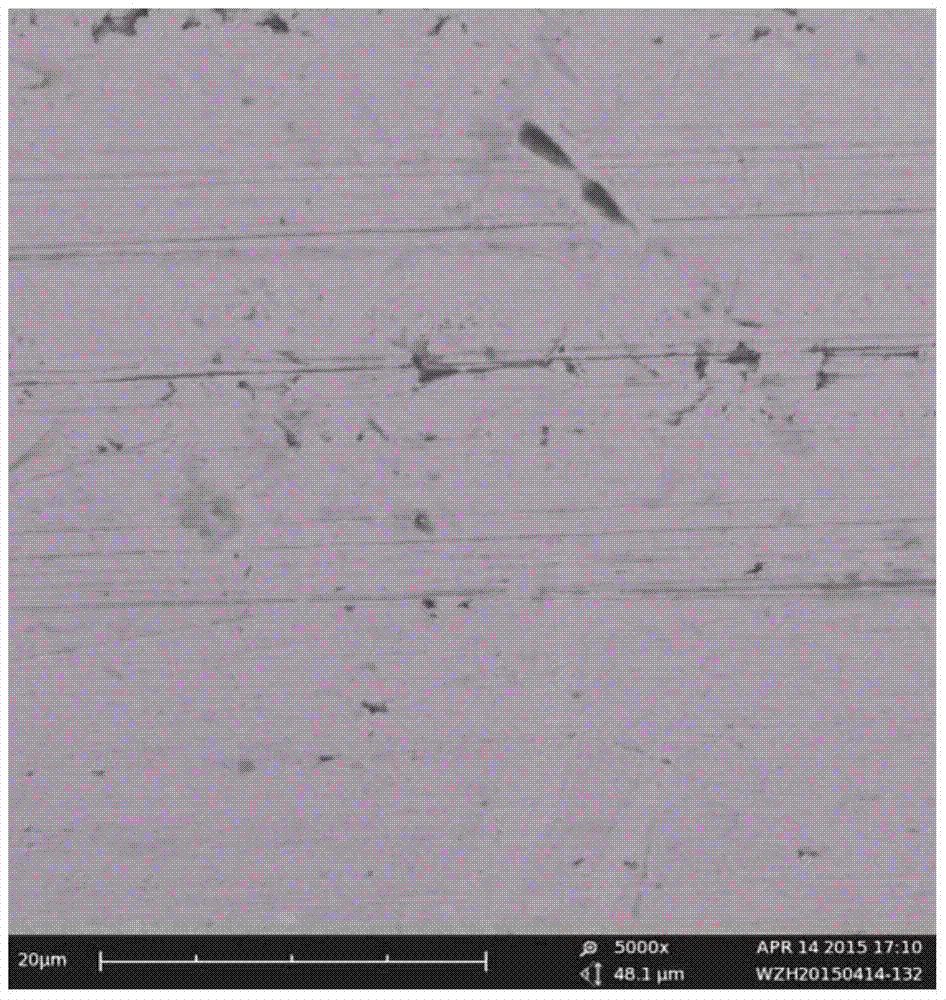

The invention provides a method for preparing porous metal with mixed gas in order to solve the problems that an existing micro-nano-porous metal preparation technology mainly concentrates on the initial formation process of metal materials, the method is complex and seriously relies on a die template, and the requirements for production equipment are high. The method for preparing the porous metal includes the steps that firstly, the metal materials are cleaned with acetone firstly and then cleaned with absolute ethyl alcohol and deionized water sequentially; and secondly, the temperature of the cleaned metal is raised to 550-850 DEG C under the protection of inert gas, then the mixed gas composed of fuel gas and oxidation gas is introduced into a carrier to carry out porous processing. A porous structure is formed on the surface of and inside the metal by directly using the expansion and overflowing of H2O gas and CO2 gas formed by the fuel gas and the oxidation gas inside the metal. The method has the advantages that the technology is simple, preparation is convenient, and pollution is avoided. Secondary processing can be achieved on a prepared complex metal device, and the requirements for the equipment are low.

Owner:HARBIN INST OF TECH

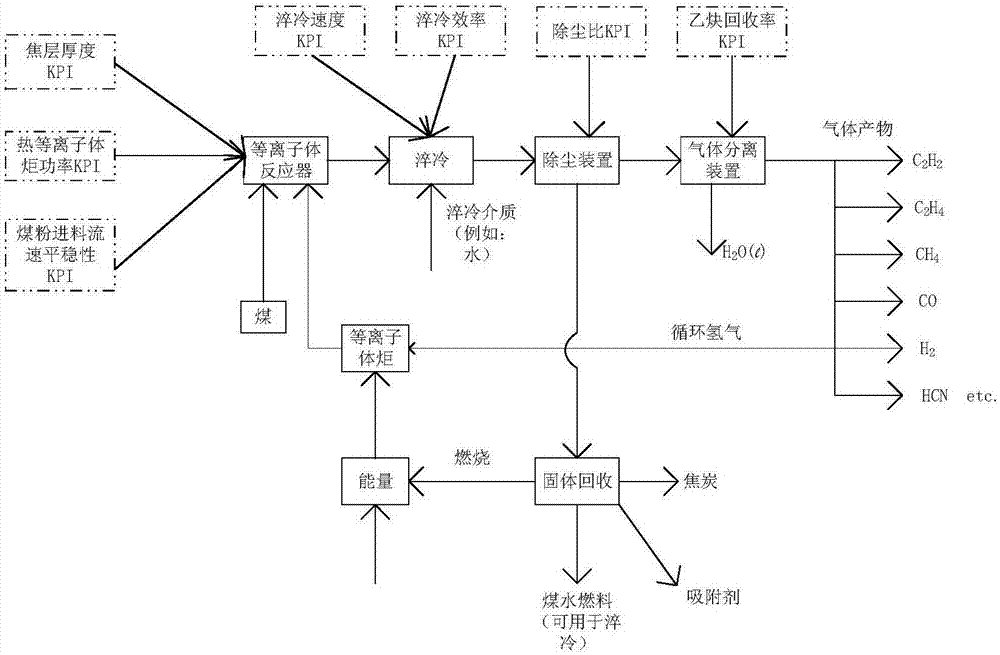

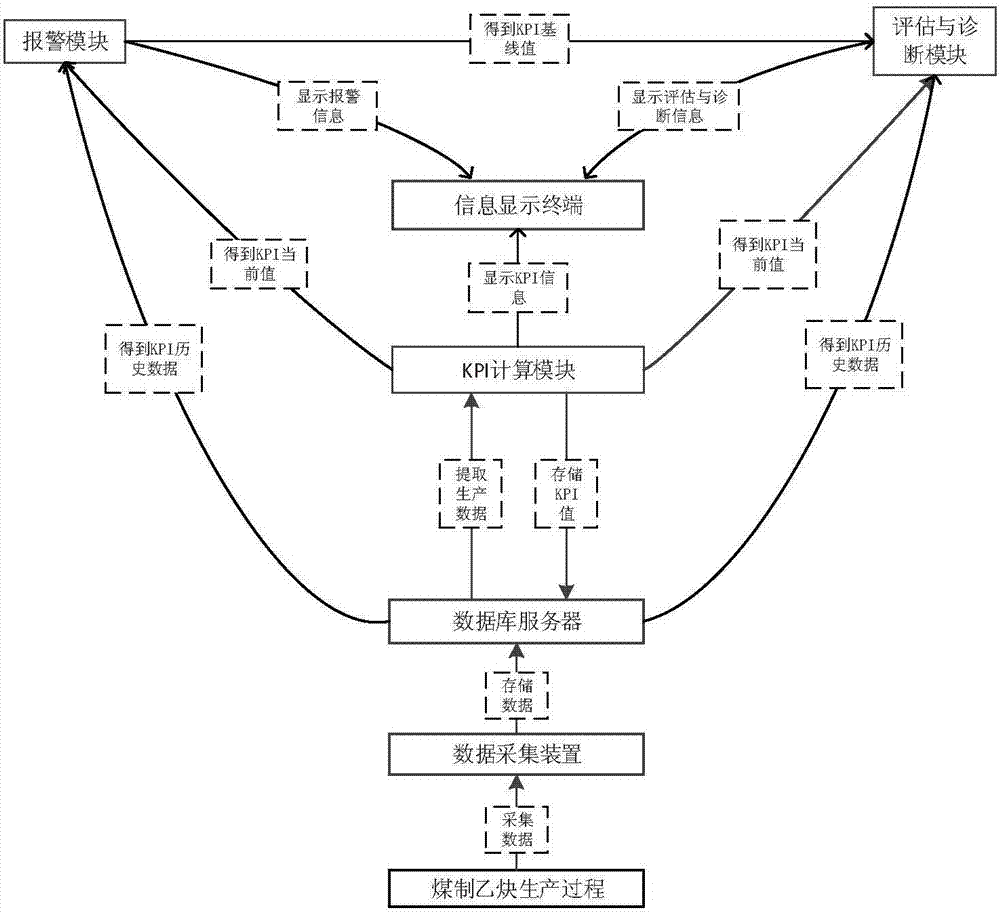

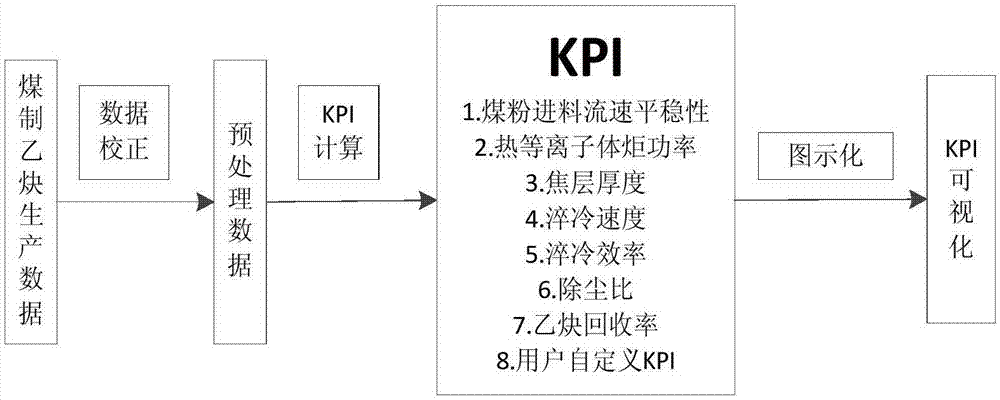

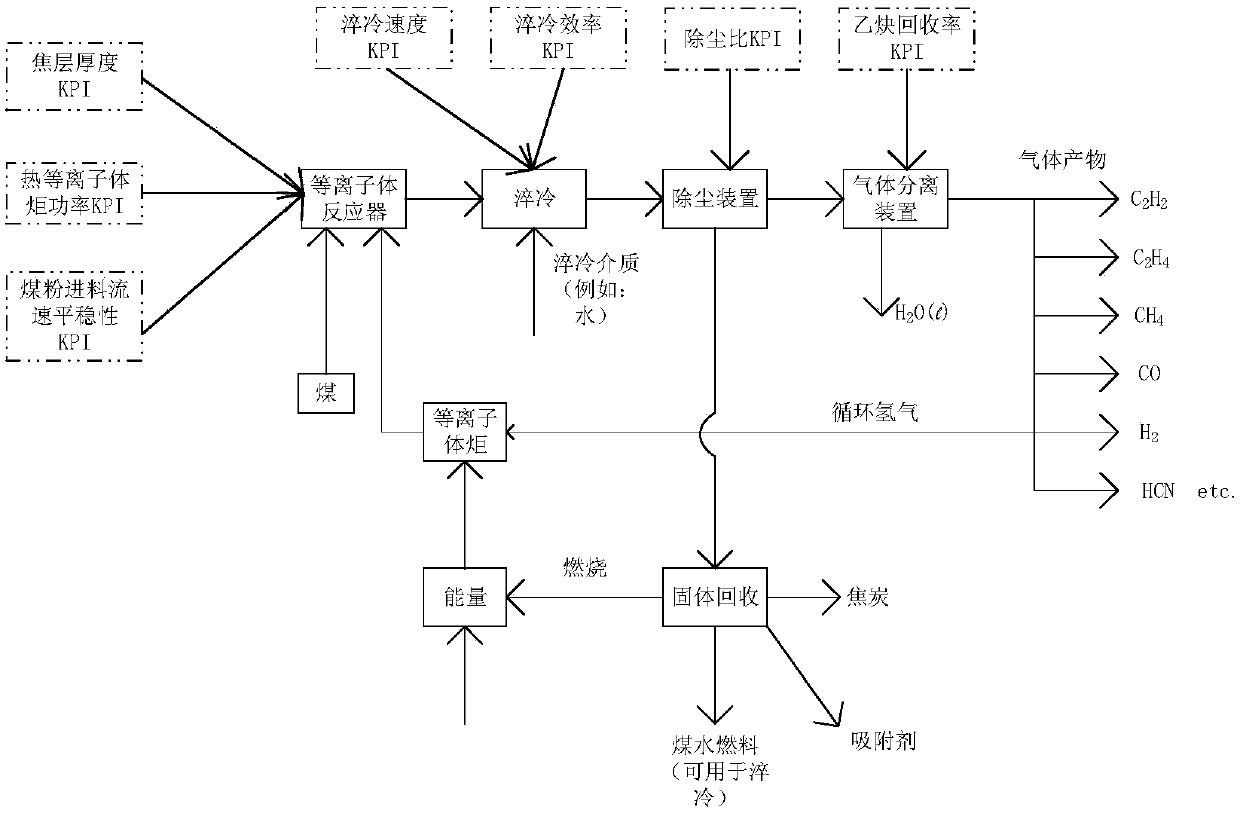

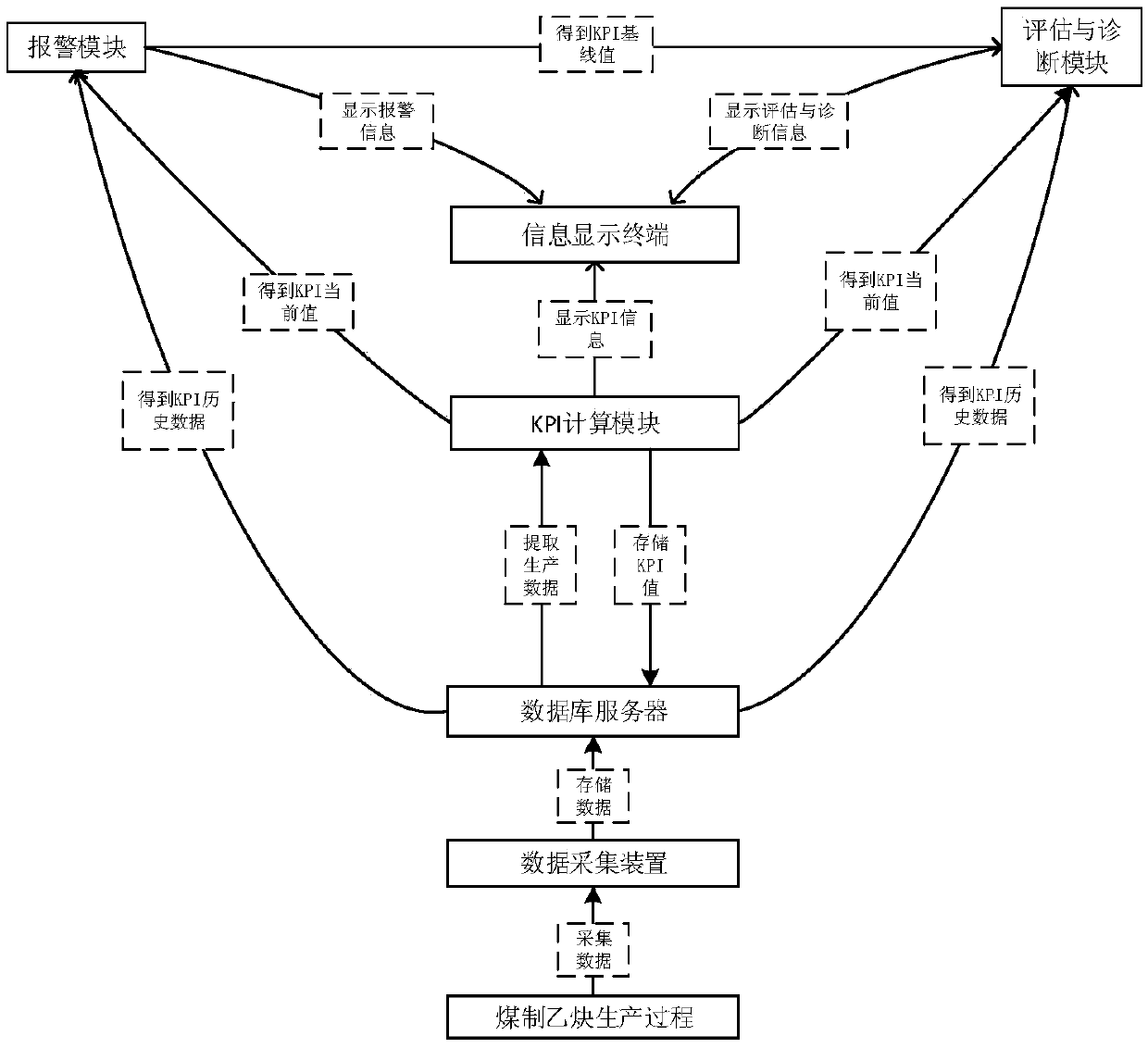

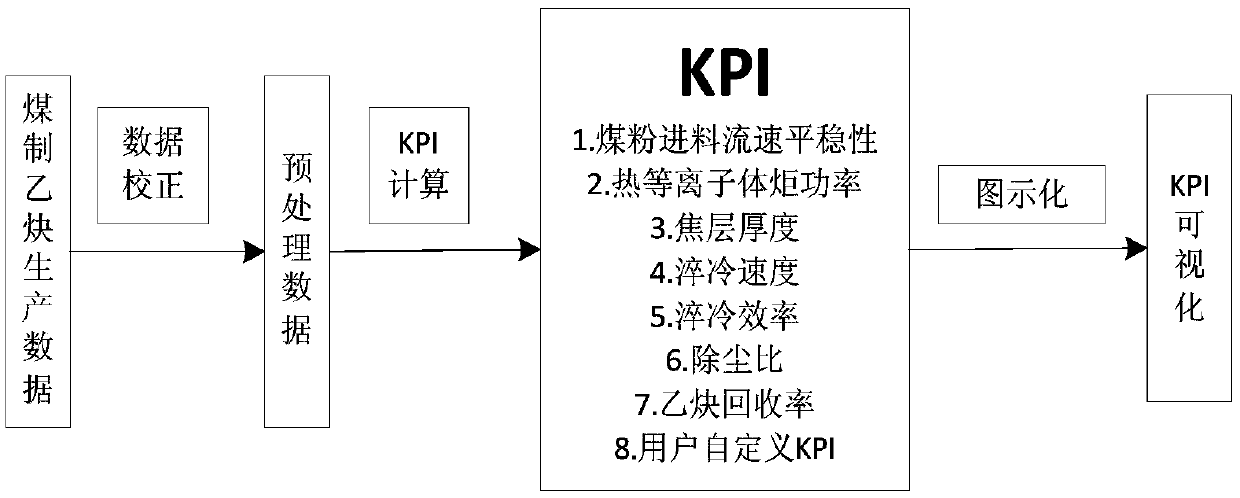

Coal acetylene production information intelligent Kanban with data analysis function

ActiveCN107515595ARealize secondary processingProfessionalTotal factory controlComplex mathematical operationsWork periodDeep level

The invention discloses a coal acetylene production information intelligent Kanban with a data analysis function, which comprises a data acquisition device, a real-time database, a data analysis device and an information display terminal, wherein the data acquisition device acquires production data in each work section during a coal acetylene production process and the data are inputted to the real-time database; the real-time database realizes real-time storage and management on the production data; the data analysis device calculates, monitors, evaluates and diagnoses the real-time production data; and the information display terminal visually displays the result outputted by the data analysis device. According to the coal acetylene production information intelligent Kanban with the data analysis function, a deep process index KPI which can not be monitored originally by devices such as a traditional distributed control system (DCS) can be pushed explicitly to an operator, the operator can be helped monitor and evaluate the production condition during each current work period more deeply and meticulously, and according to pros and cons of an upper-reach work period KPI, selection of operation parameters of a lower-reach work period and decision making of an operation mode are decided.

Owner:ZHEJIANG UNIV

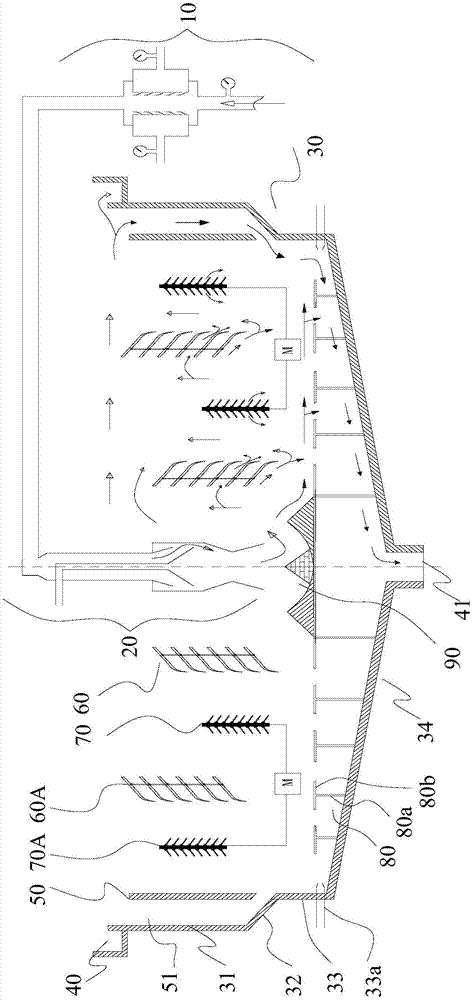

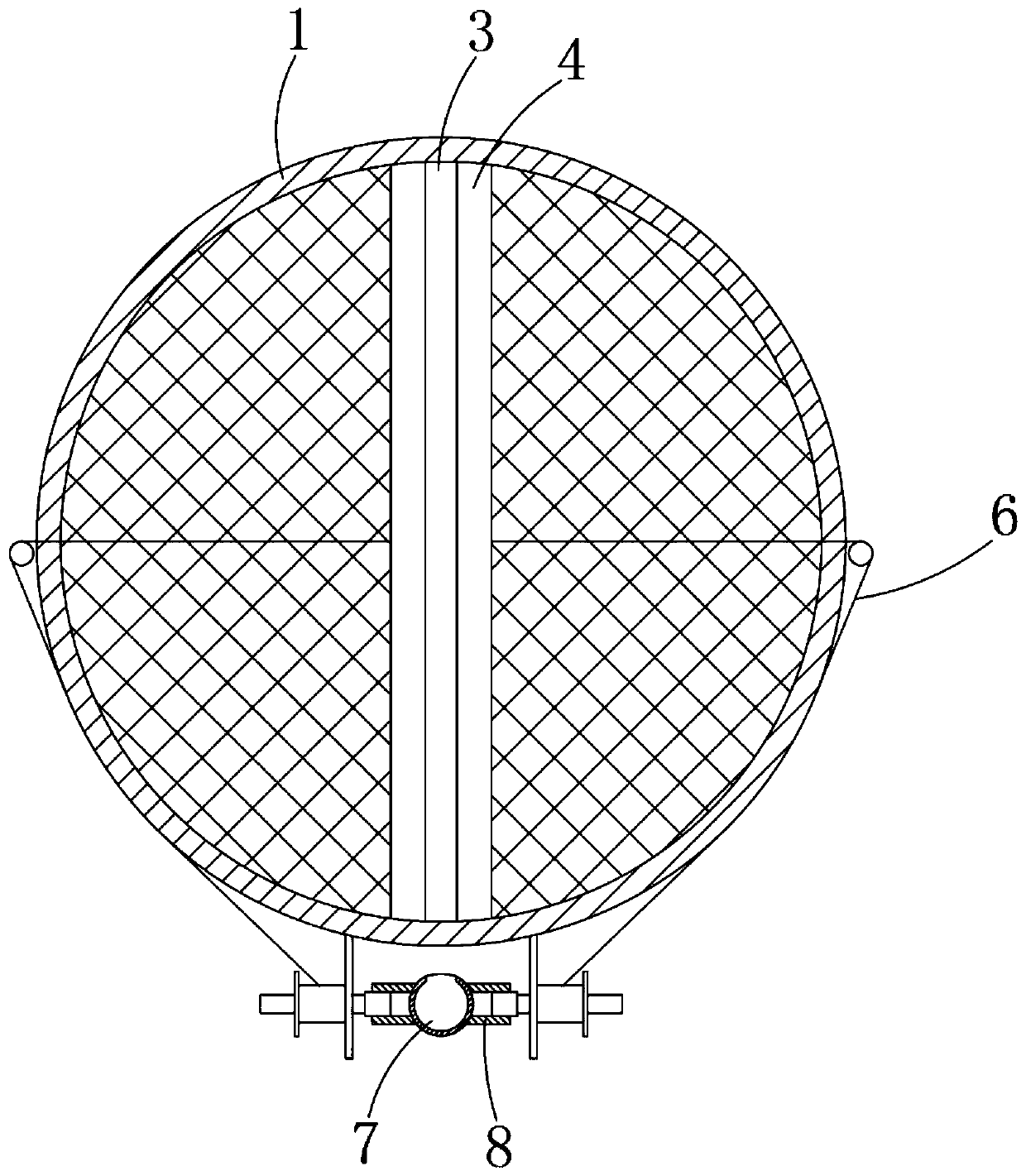

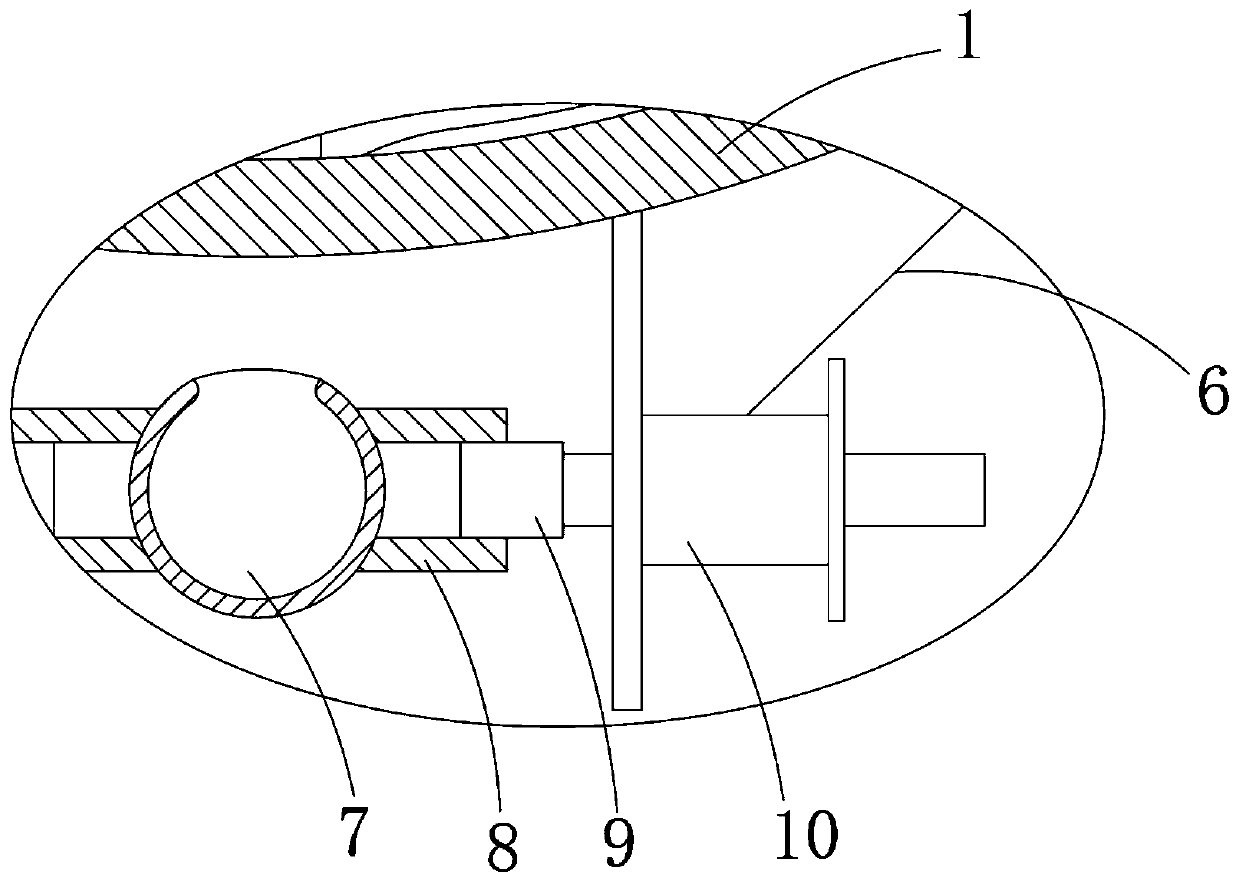

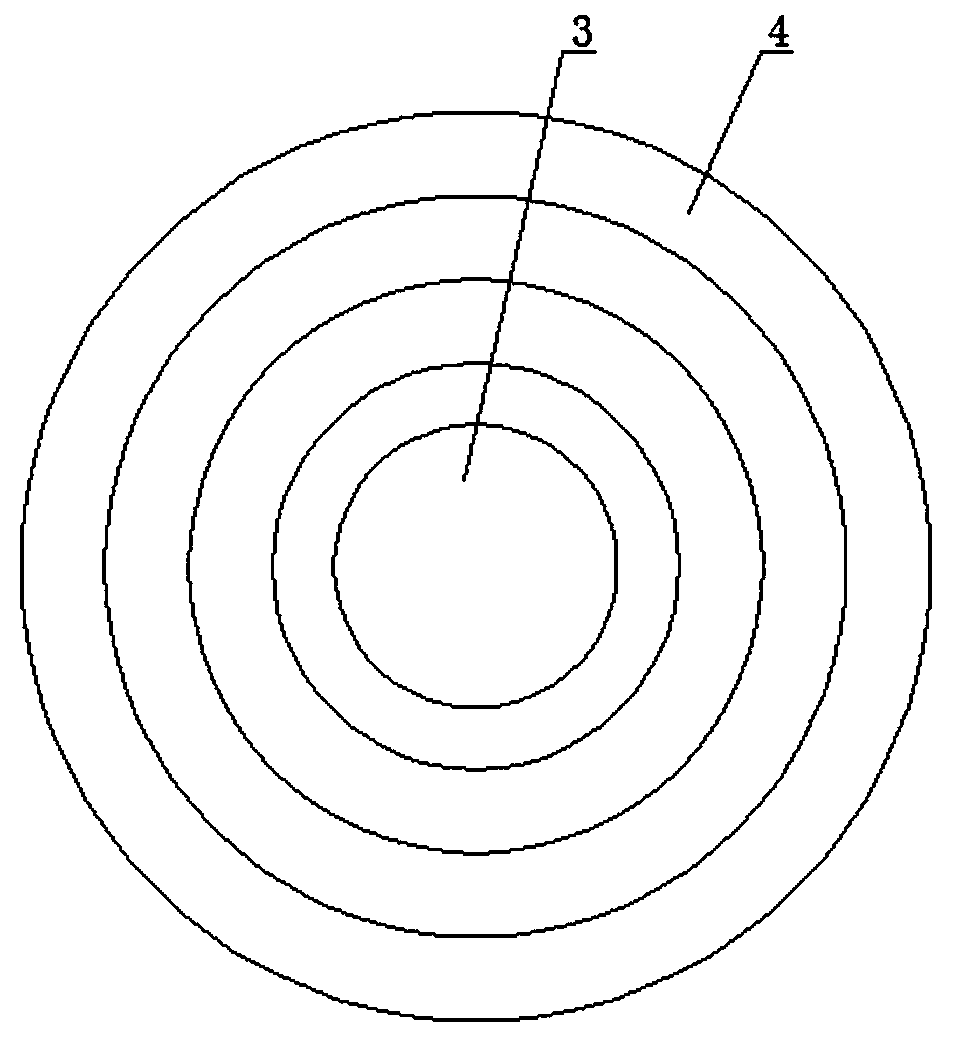

Parabolic grading concentration tank

ActiveCN106976944ATo achieve the graded effectRealize quantitative dosingWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationLiquid mediumProcess engineering

The invention belongs to the technical field of slime water treatment and specifically relates to a parabolic grading concentration tank. The invention designs the grading principle according to the difference of parabolic tracks of coal slime particles in different shape, weight and size in a liquid medium. The parabolic grading concentration tank at least comprises a drug adding system, a feeding system, a concentration tank body, a first draining mud-lagging plate unit, a second draining mud-lagging plate unit, a first adjustable vibrating plate device and a second adjustable vibrating plate device; the quantitative addition of the drug can be realized in a manner of mixing the drug with the ore pulp once while passing by an annular drug disperser; the ore pulp after being mixed once can be added again according to the practical requirement by a secondary dosing pipe in the feeding system; a big horn-shaped drug dispersing port and a surrounding zigzag structure thereof can violently disperse the ore pulp flowing out of a small horn-shaped dispersing port; the slime water is deeply cleared by a free settling area formed by encircling of an annular separating plate in the concentration tank body. The parabolic grading concentration tank has the advantages of simple structure, low construction cost, low maintenance load, obvious effect, and the like.

Owner:ANHUI UNIV OF SCI & TECH

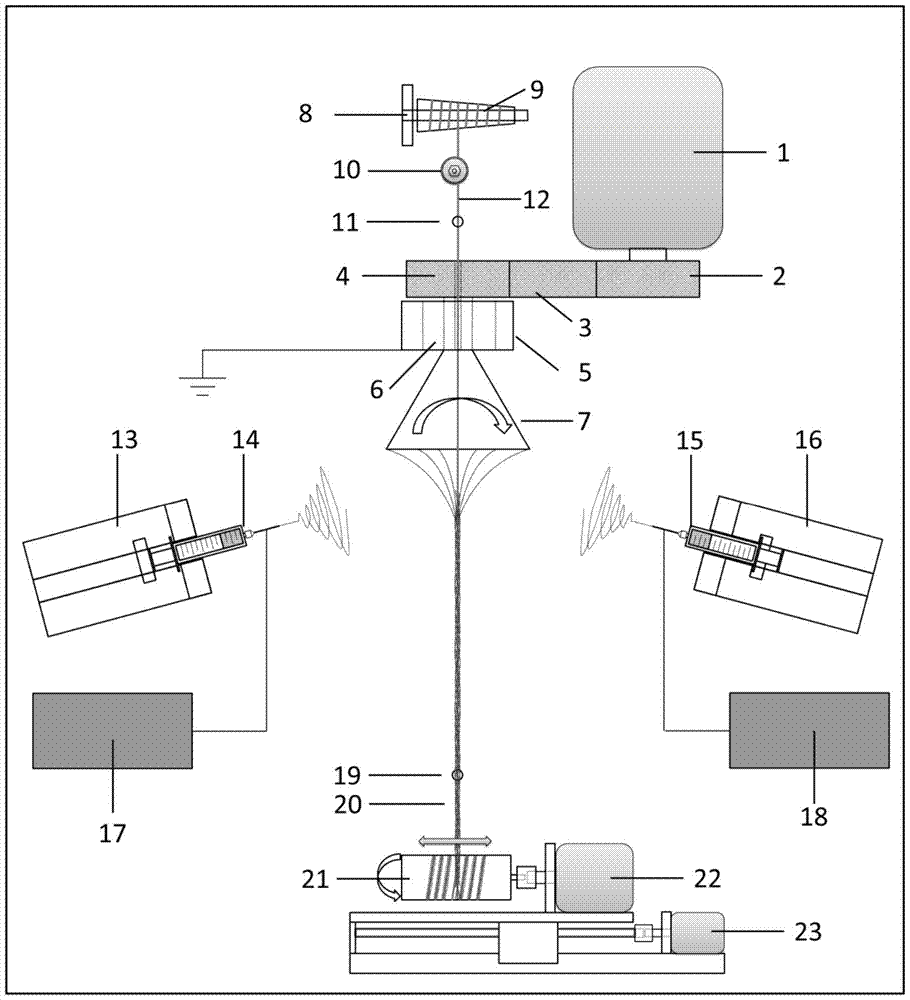

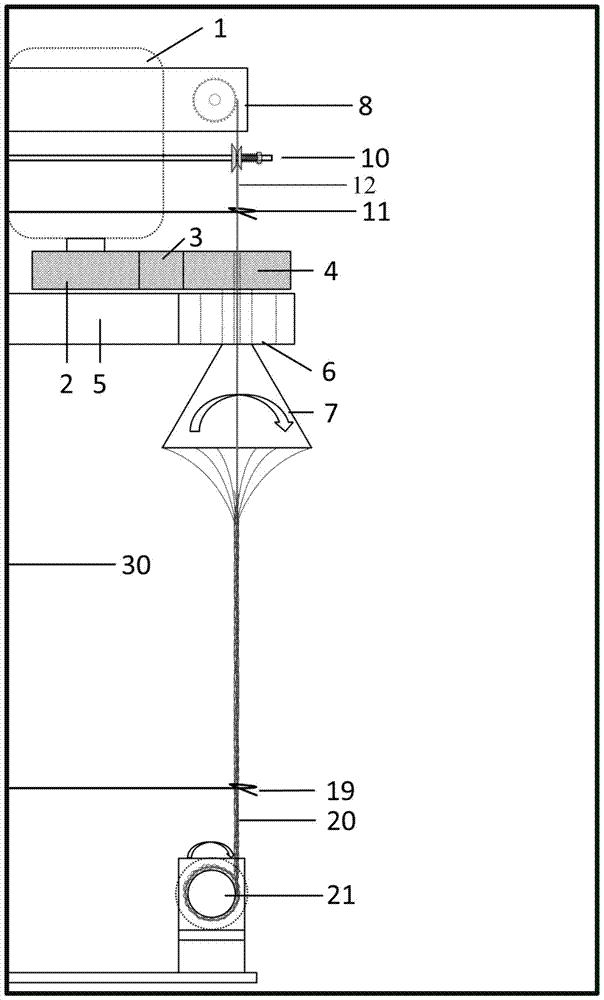

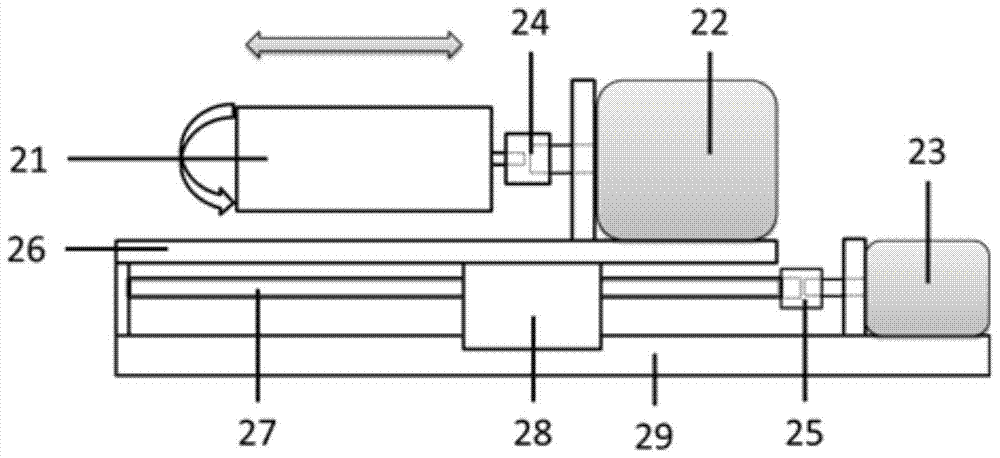

A device for electrospinning nanofiber core-spun yarn and its application

ActiveCN104032423BArrangement structure controllableControllable twistWeft knittingWarp knittingTextile technologyYarn

The invention relates to a device for preparing electrospinning nanofiber core-spun yarn and its application, comprising: a twisting device, an unwinding device, a winding device, a double-needle electrospinning device and a control system. The present invention also provides a method for preparing electrospun nanofiber core-spun yarn: the prepared spinning solution is spun through a double-needle electrospinning device, so that the nanofibers are deposited on the metal funnel and the core yarn, and the metal funnel rotates to The nanofiber is evenly wound on the core yarn moving at a constant speed, and finally forms the nanofiber core-spun yarn with the nanofiber as the cortex; the present invention also provides another preparation method of the nanofiber fabric, comprising: using water-soluble yarn as the core yarn , the nanofiber core-spun yarn is prepared by the above method; the core-spun yarn fabric is prepared by textile technology; the core yarn is dissolved to obtain the nanofiber fabric. The invention has high operability, the device has a novel structure, and the arrangement of nanofibers on the surface of the core-spun yarn has high controllability.

Owner:诺一迈尔(山东)医学科技有限公司

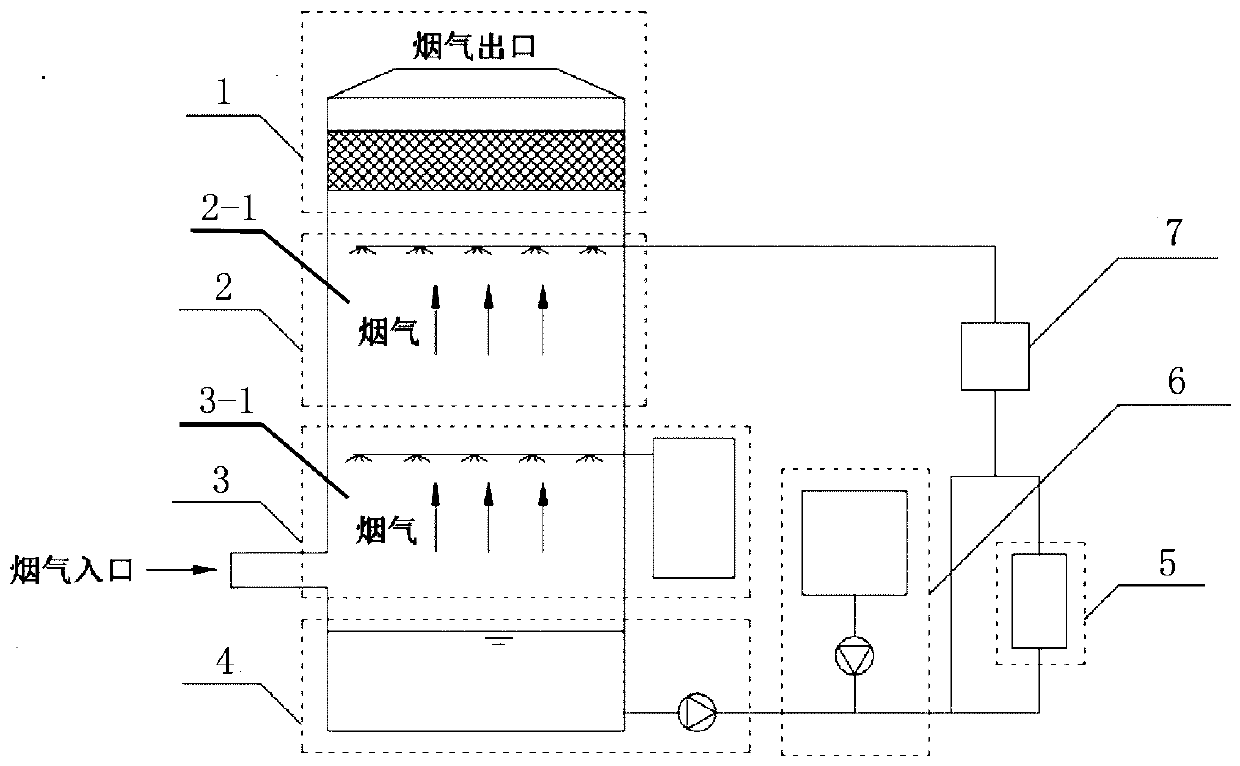

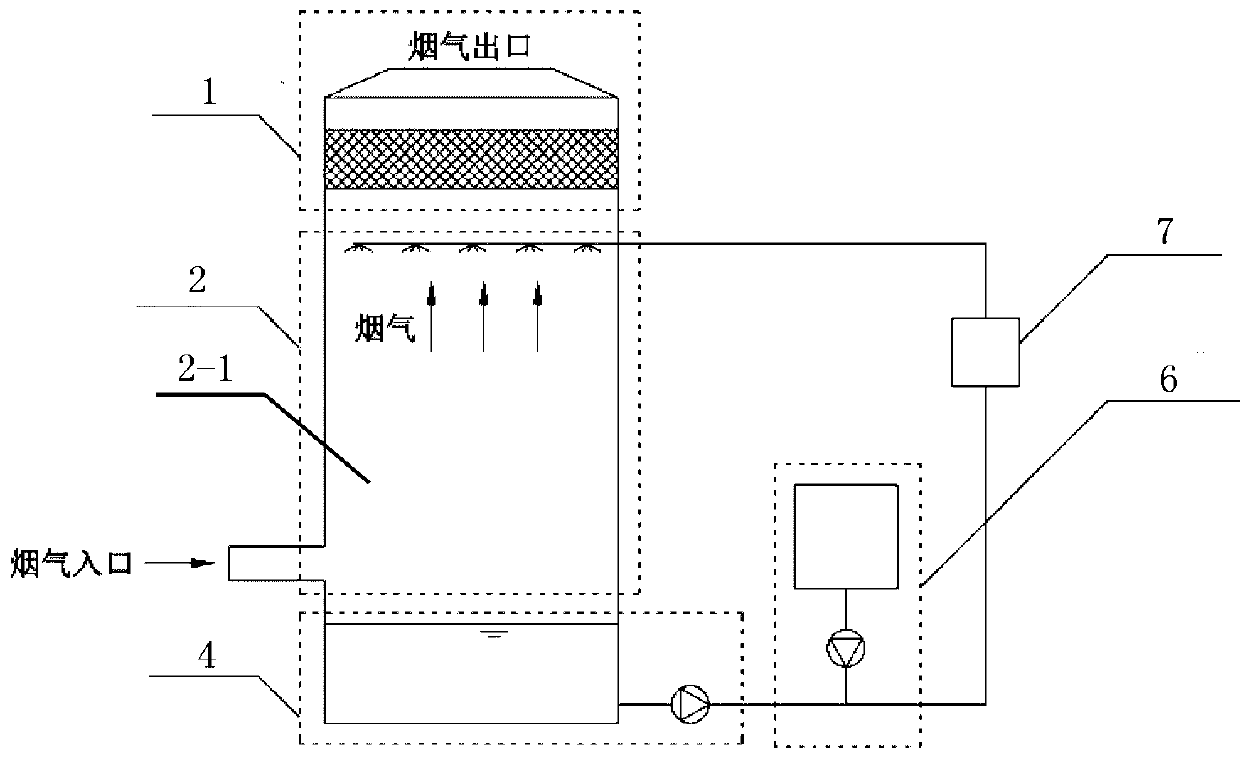

Direct-contact type flue gas waste heat deep recycling and pollution reducing device and method

InactiveCN105944527ARealize secondary processingTo achieve the purpose of comprehensive treatment and utilizationCombination devicesGas treatmentDust controlWater circulation

The invention relates to a direct-contact type flue gas waste heat deep recycling and pollution reducing device and method. The device comprises a flue gas treatment subsystem and a waste heat water treatment subsystem. The flue gas treatment subsystem comprises a flue gas oxidation module, a flue gas waste heat deep recycling module and a flue gas mist removing and dust removing module. The waste heat water treatment subsystem comprises a waste heat water circulating module, a waste heat water desulfurization and denitrification module and a waste heat water dust removing module. By means of the direct-contact type flue gas waste heat deep recycling and pollution reducing device, heat exchange between flue gas and low-temperature waste heat water is achieved, the flue gas discharging temperature is decreased to be the dew point temperature or lower, the flue gas low-temperature heat is recycled, the flue gas is subjected to desulfurization, denitrification and dust removal treatment, and emitted flue gas pollutants are reduced. According to the direct-contact type flue gas waste heat deep recycling and pollution reducing device and method, the problem of corrosion to equipment by flue gas condensate is solved, the recycled heat can be used for various low-temperature heat users, the utilization efficiency of fuel can be effectively improved, and secondary treatment on the flue gas can be achieved.

Owner:北京华源泰盟节能设备有限公司

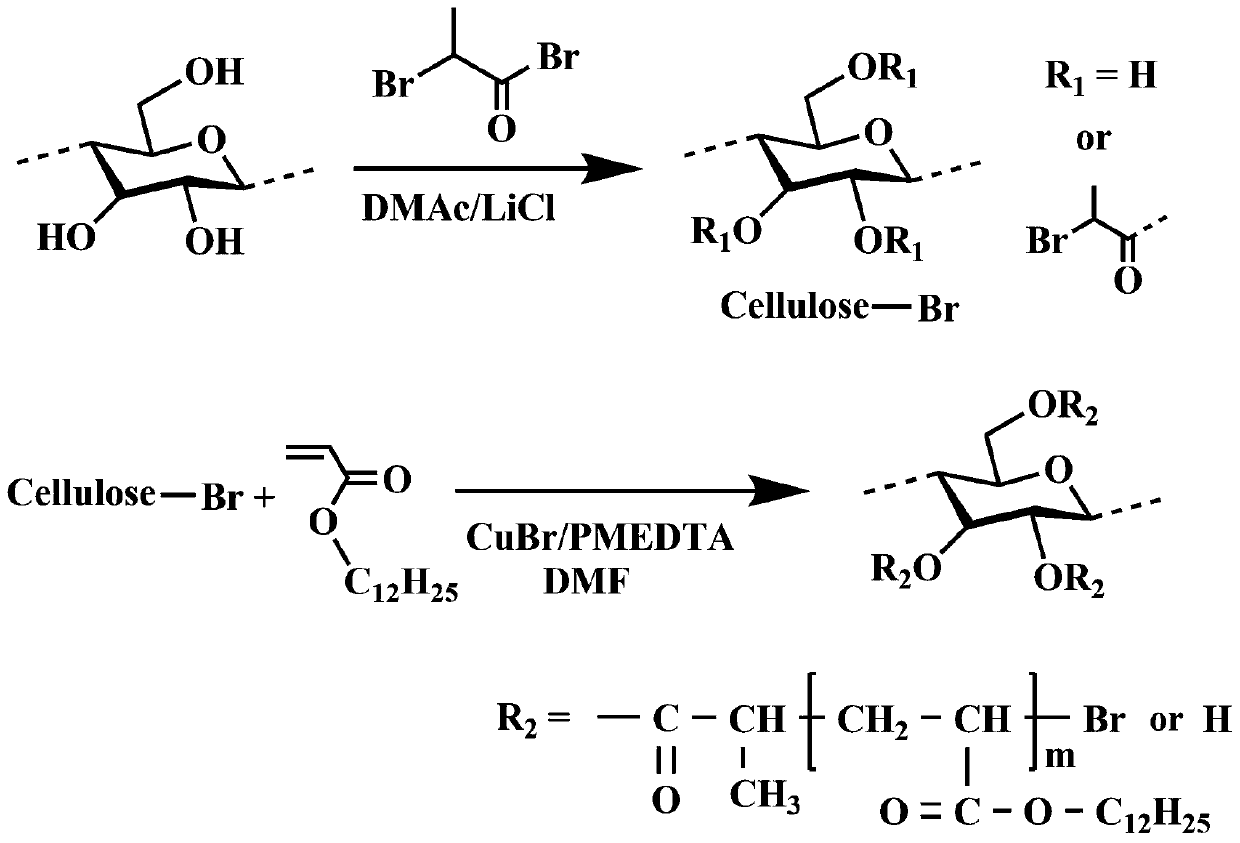

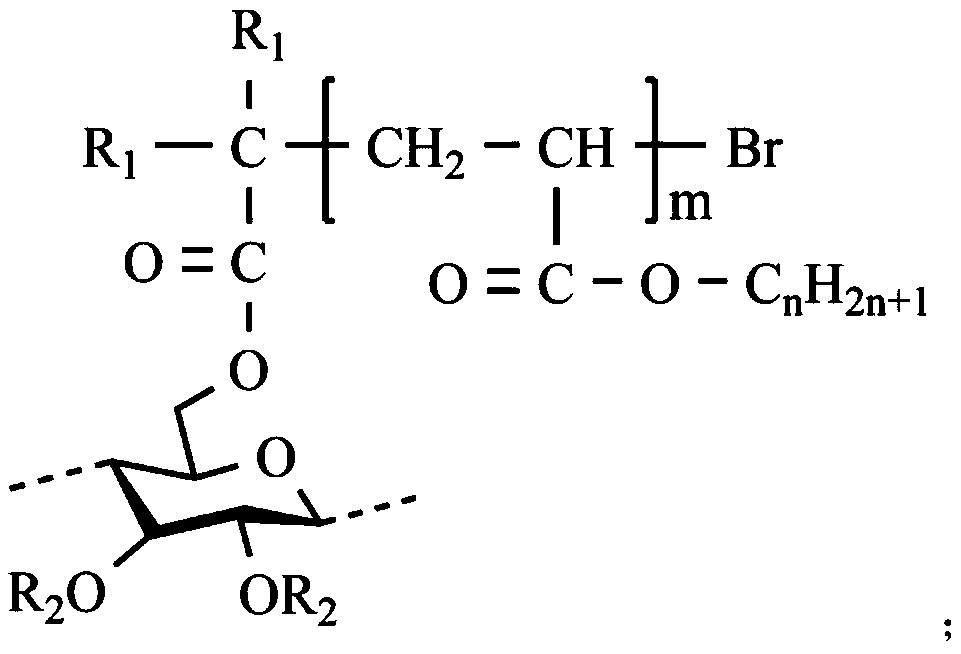

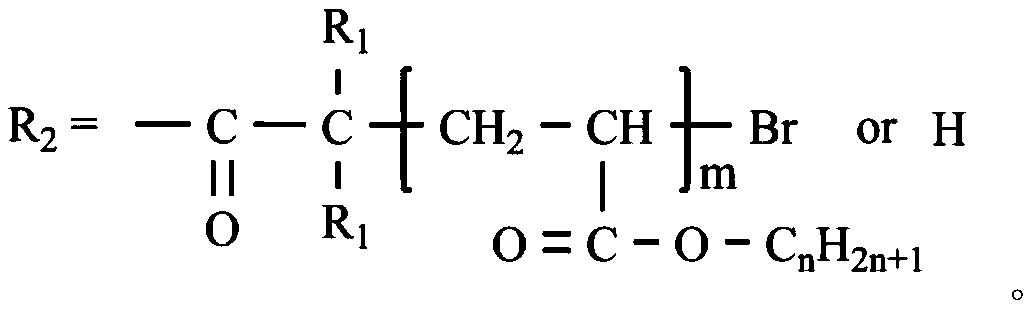

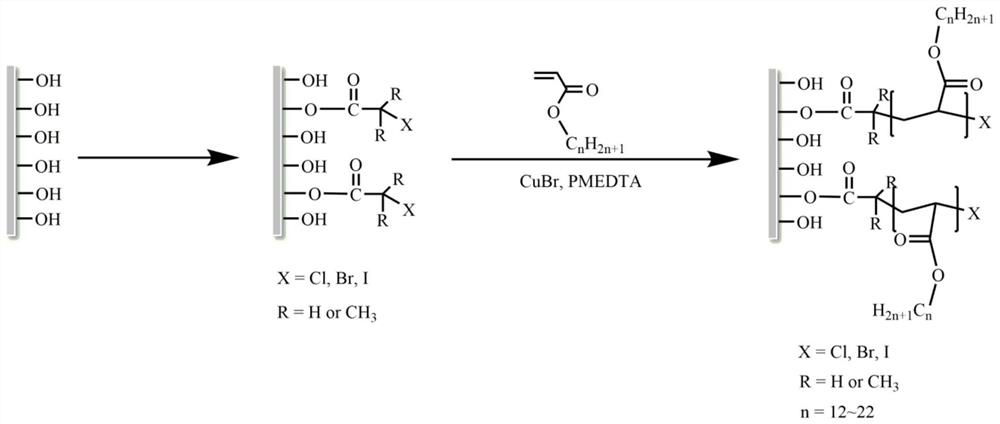

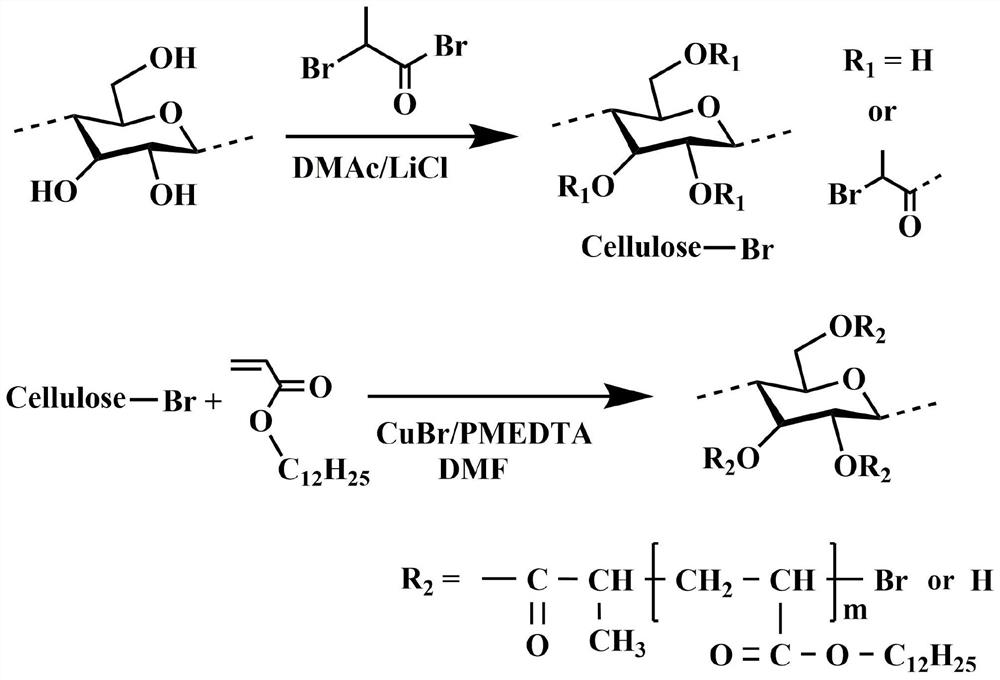

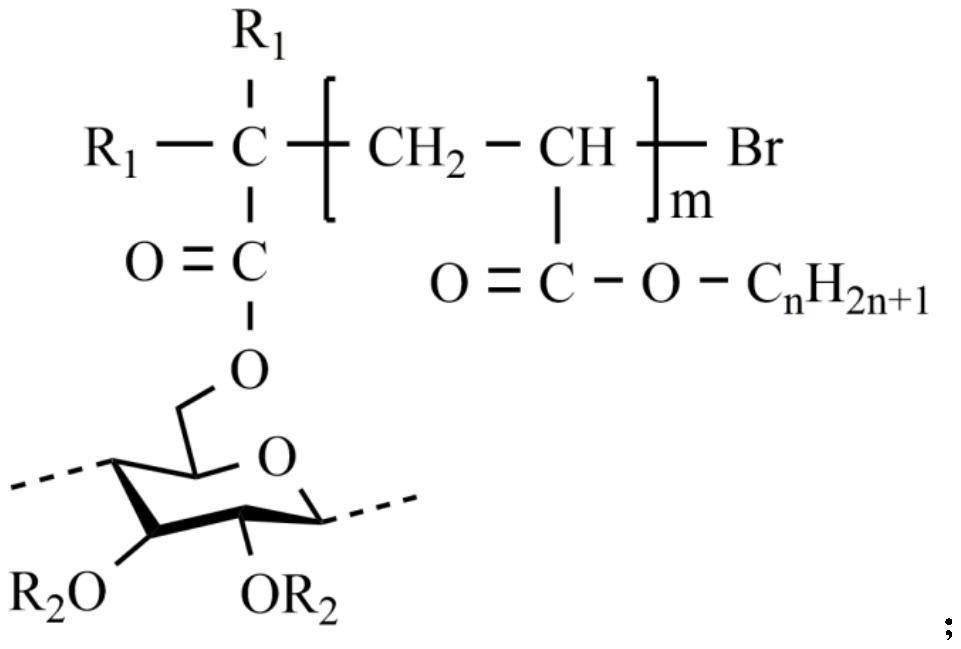

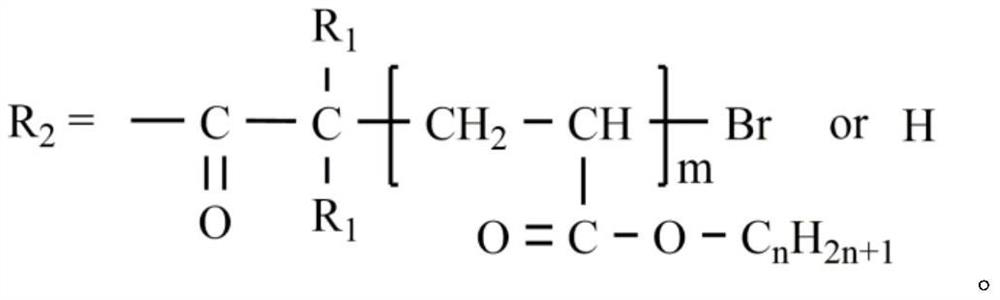

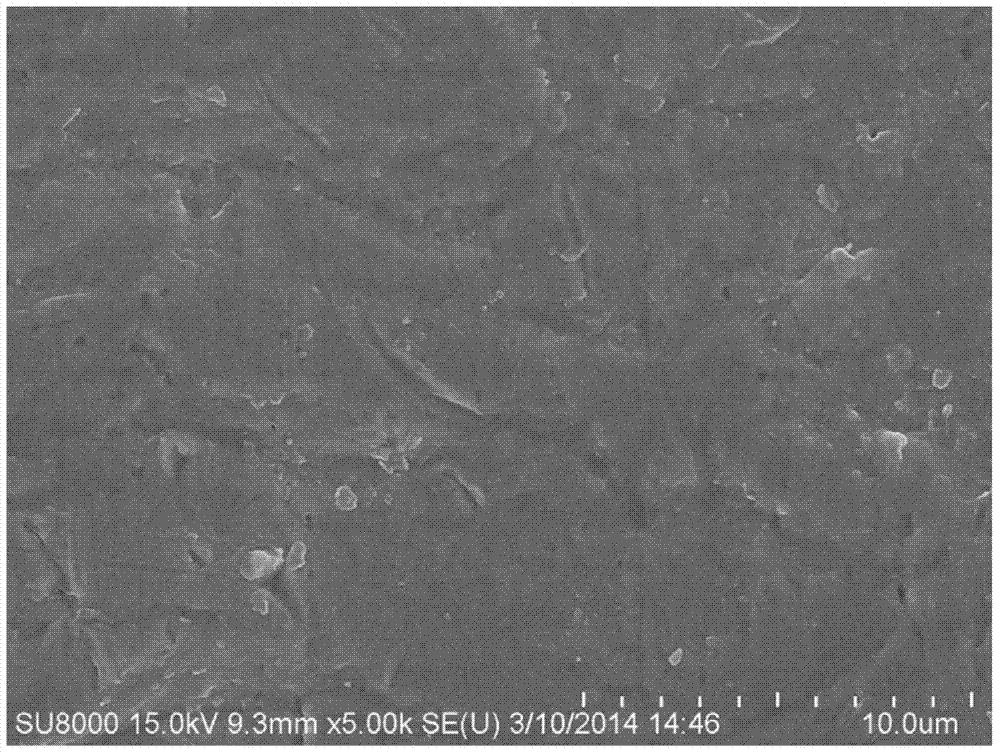

GN@cellulose based solid-solid phase change material and preparation method and application thereof

ActiveCN110698597AImprove solubilityRealize secondary processingHeat-exchange elementsMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention discloses a GN@cellulose based solid-solid phase change material and a preparation method and application thereof. The method comprises the following steps of (1) dissolving cellulose; (2) carrying out homogeneous phase grafting modification: reacting a halogenated acyl halide monomer with cellulose to obtain cellulose ester; (3) carrying out ATRP method reaction: uniformly dispersing the cellulose ester, GN and a solvent B obtained in Step (2), and then adding a ligand, a catalyst and alkyl acrylate to react to obtain a reaction mixture; and (4) carrying out purification: purifying the reaction mixture obtained in Step (3) to obtain a GN@cellulose-g-polyalkylacrylate copolymer. The copolymer is subjected to melt extrusion spinning to obtain a solid-solid phase change fiber.The copolymer is is subjected to electrostatic spinning to obtain a film. According to the method, cellulose fibers are used as a substrate, halogen functional groups are grafted through an acylationreaction, alkyl acrylate is grafted on a cellulose skeleton through ATRP, graphene is used as a reinforcing material, and later-stage processing is not needed, so that the fibers with flexibility, high thermal conductivity and high enthalpy value are prepared, and secondary processing is facilitated.

Owner:TIANJIN POLYTECHNIC UNIV

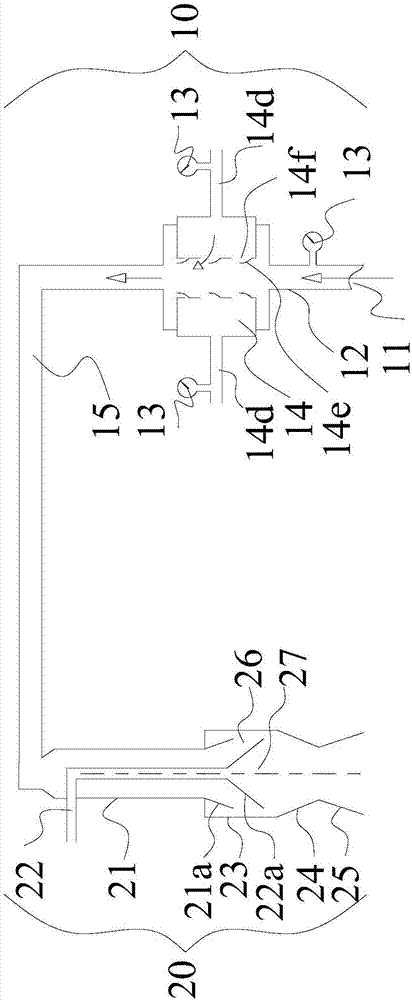

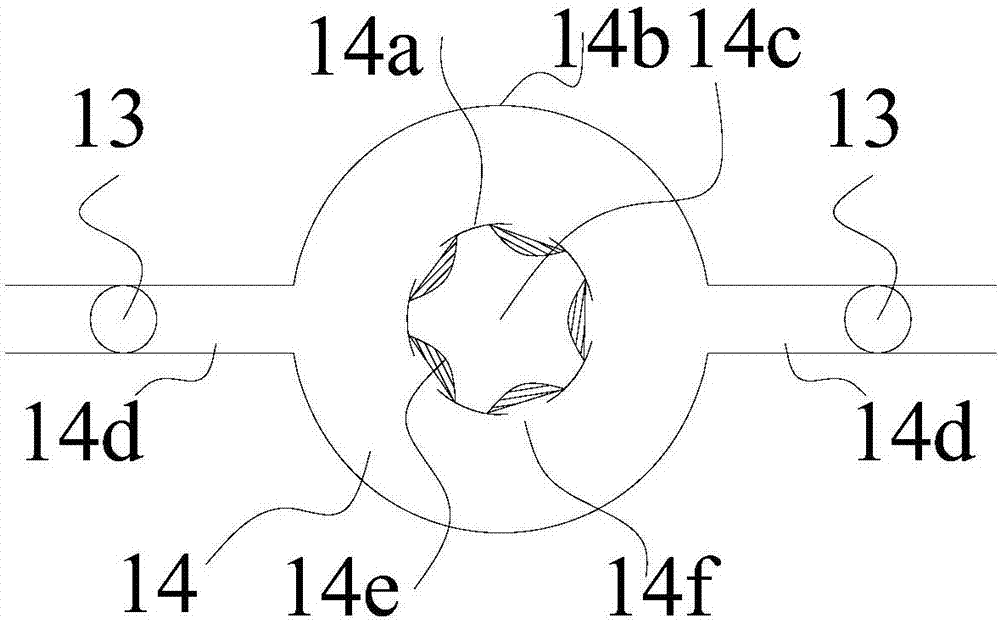

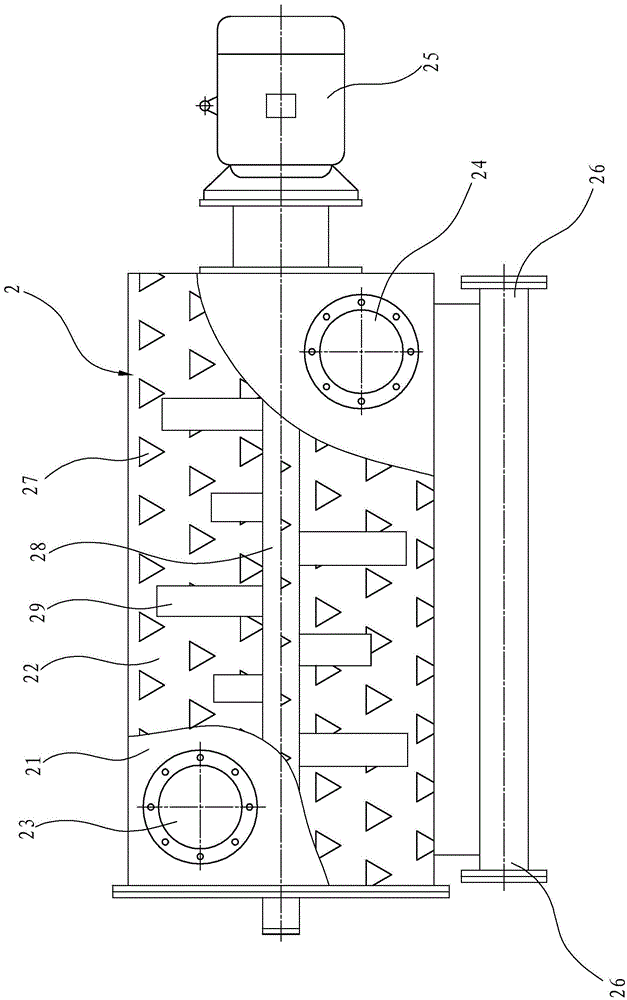

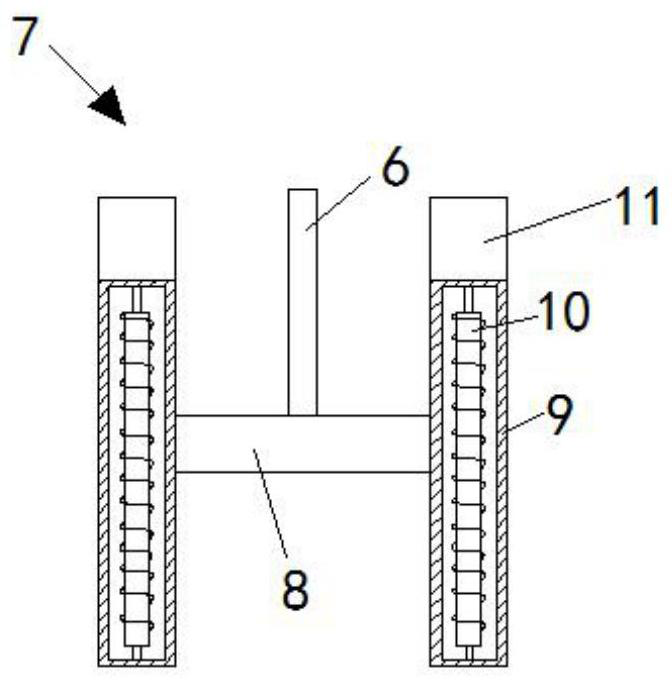

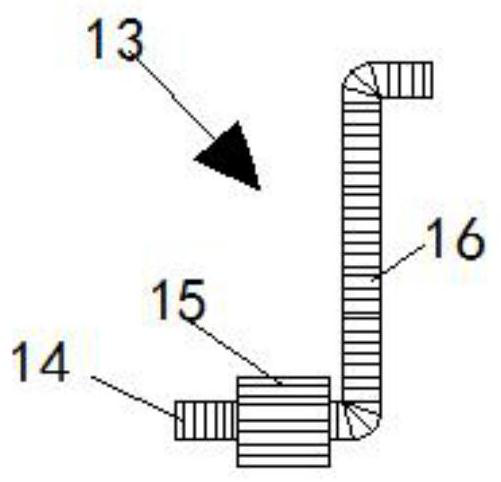

Quick lime hydrator

The invention provides a quick lime hydrator, which belongs to the technical field of slaked lime preparation equipment. In order to solve the problem of mixing nonuniformity caused by inappropriate mixing ratio of quick lime and water in an existing quick lime hydrator, the hydrator comprises a stock bin for placing the quick lime, a metering screw conveyer for conveying the quick lime and accomplishing metering work, a metering water pump connected with an external water source, a primary spiral stirrer and a secondary spiral stirrer for mixing the quick lime and the water, and a dust collection device for absorbing dust and water vapor generated during hydration reaction of the quick lime and the water, wherein the metering screw conveyer is communicated with the stock bin; the primary spiral stirrer and the secondary spiral stirrer are arranged up and down in parallel; the primary spiral stirrer is respectively communicated with the metering screw conveyer and the secondary spiral stirrer; the water spray end of the metering water pump stretches into the primary spiral stirrer and relatively gets close to the metering screw conveyer; the metering water pump starts to spray water when the quick lime enters the primary spiral stirrer; the dust collection device is communicated with the primary spiral stirrer.

Owner:肥城汇立机械有限公司

Method for preparing porous metal by using mixed gas

Owner:HARBIN INST OF TECH

Industrial waste gas treatment system

InactiveCN113828084AAchieve rotationFully integratedUsing liquid separation agentWater dischargeGear wheel

The invention belongs to the field of air purification treatment equipment, and relates to an industrial waste gas treatment system, which comprises a shell, wherein an opening is formed in the right side of the upper side wall of the shell, a motor is fixedly arranged on the left side of the upper side wall of the shell, an output shaft is arranged at the output end of the motor, a driving gear is fixedly arranged on the outer side of the output shaft, a crushing cylinder is rotationally arranged in the middle of the upper side wall of the shell, a driven gear is fixedly arranged at the upper end of the crushing cylinder, the driven gear is connected with the driving gear in a meshed mode, and a bubble making device is arranged in the crushing cylinder. According to the invention, industrial waste gas is injected into a water body through a gas channel in a gas guide cylinder, bubbles are generated, the water body generates a vortex phenomenon under the action of a smashing device to smash the bubbles so as to completely mix dust in the bubbles with the water body, water flow is discharged into a spraying head through a water discharging device, and secondary separation is conducted on the waste gas discharged into a jet flow cavity, so that a better separation effect is achieved.

Owner:谭金梅

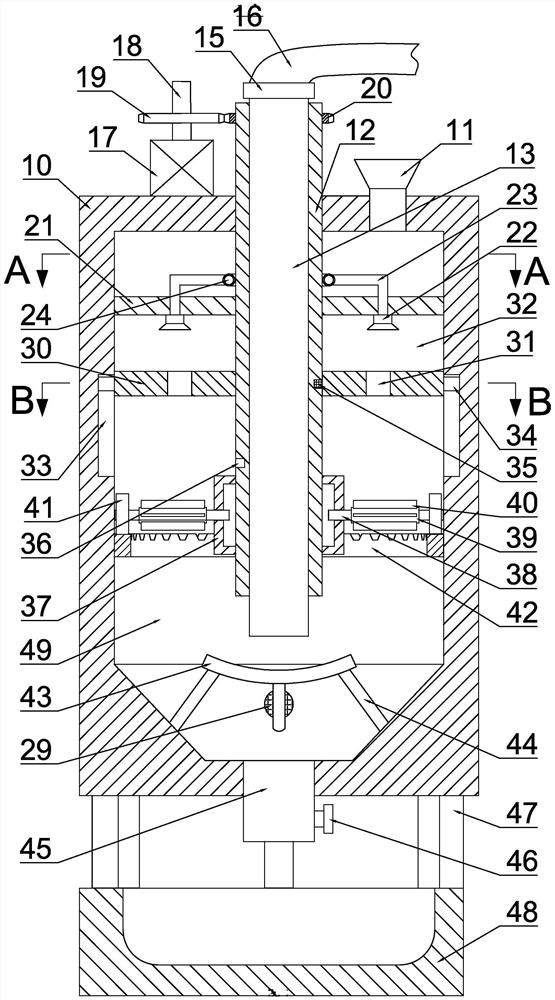

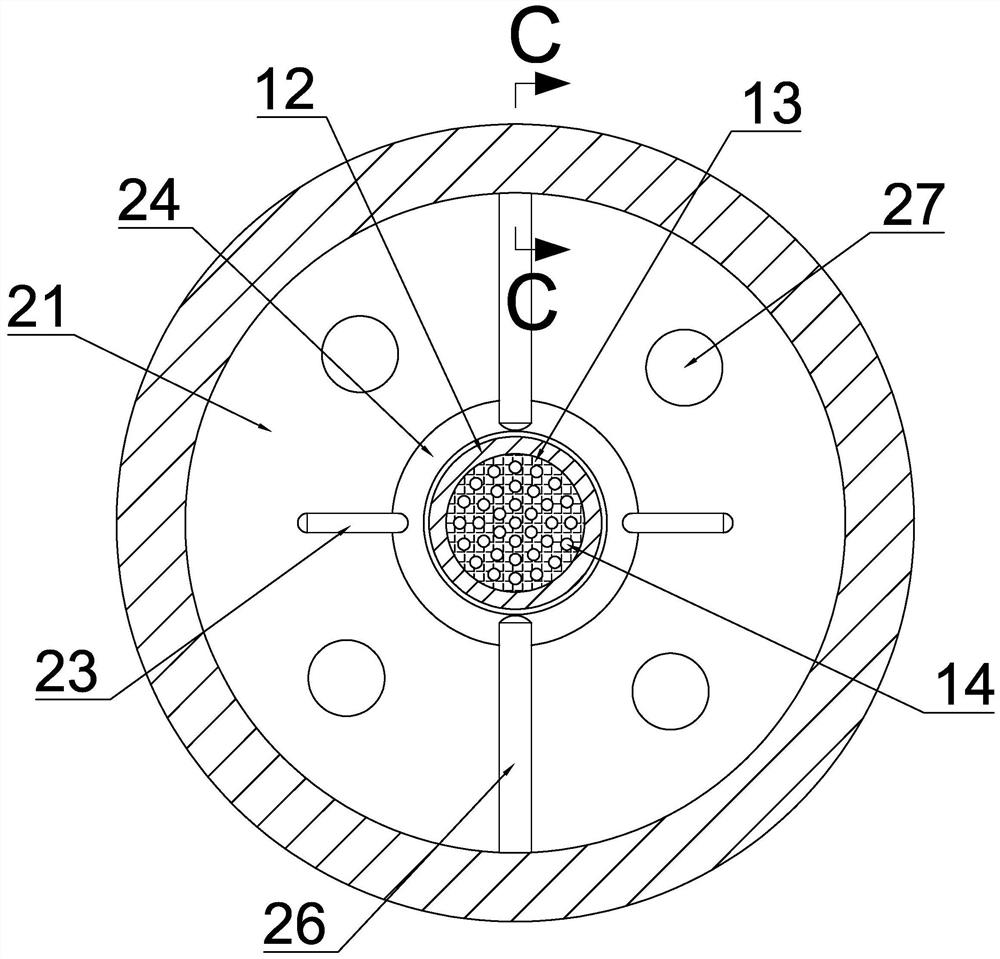

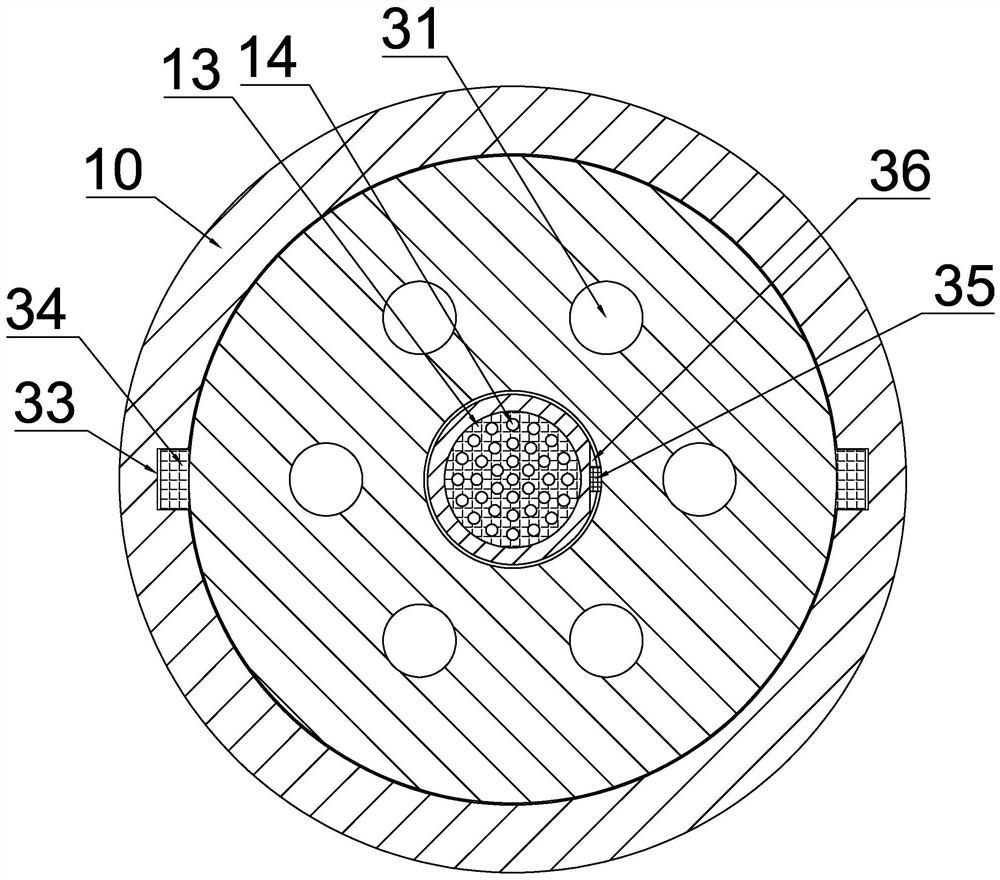

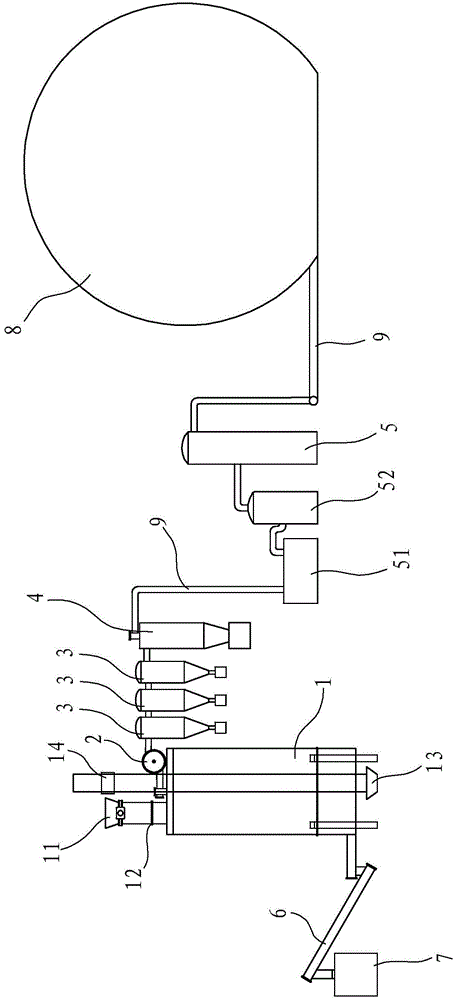

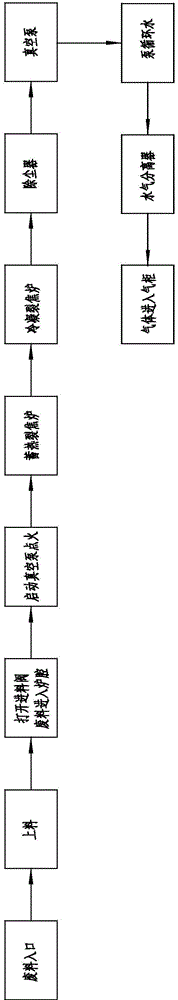

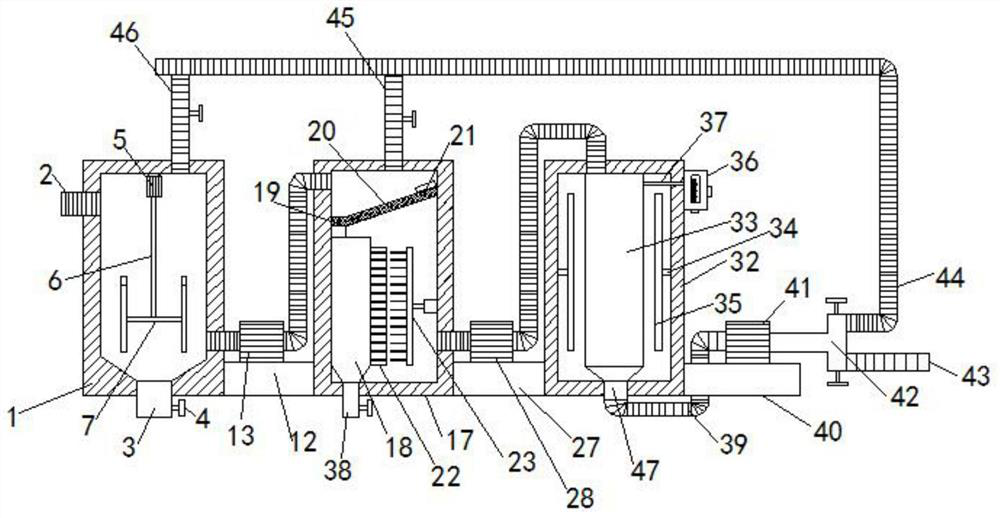

Apparatus for producing combustible gas by catalytically pyrolyzing refuse and method thereof

ActiveCN104927884AAchieve crackingRealize secondary processingSpecial form destructive distillationGas purification by non-gaseous materials condensationCombustible gasProcess engineering

The invention discloses an apparatus for producing combustible gas by catalytically pyrolyzing refuse, which comprises a pyrolysis furnace. The apparatus for producing combustible gas by catalytically pyrolyzing refuse is characterized in that the apparatus for producing combustible gas by catalytically pyrolyzing refuse also comprises a heat accumulation decoking device, condensation decoking devices, a dust collector, a water-gas separator and a gas holder, wherein the gas outlet of the pyrolysis furnace is connected with the gas inlet of the heat accumulation decoking device, the gas outlet of the heat accumulation decoking device is connected with the gas inlet of the condensation decoking devices, the gas outlet of the condensation decoking devices is connected with the gas inlet of the dust collector, the gas outlet of the dust collector is connected with the gas inlet of the water-gas separator, and the gas outlet of the water-gas separator is connected with the gas holder for storing combustible gas.

Owner:张文虎

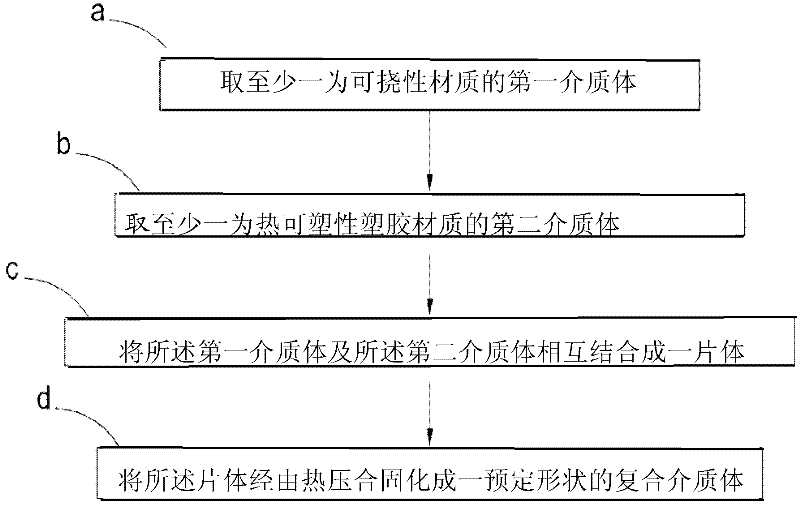

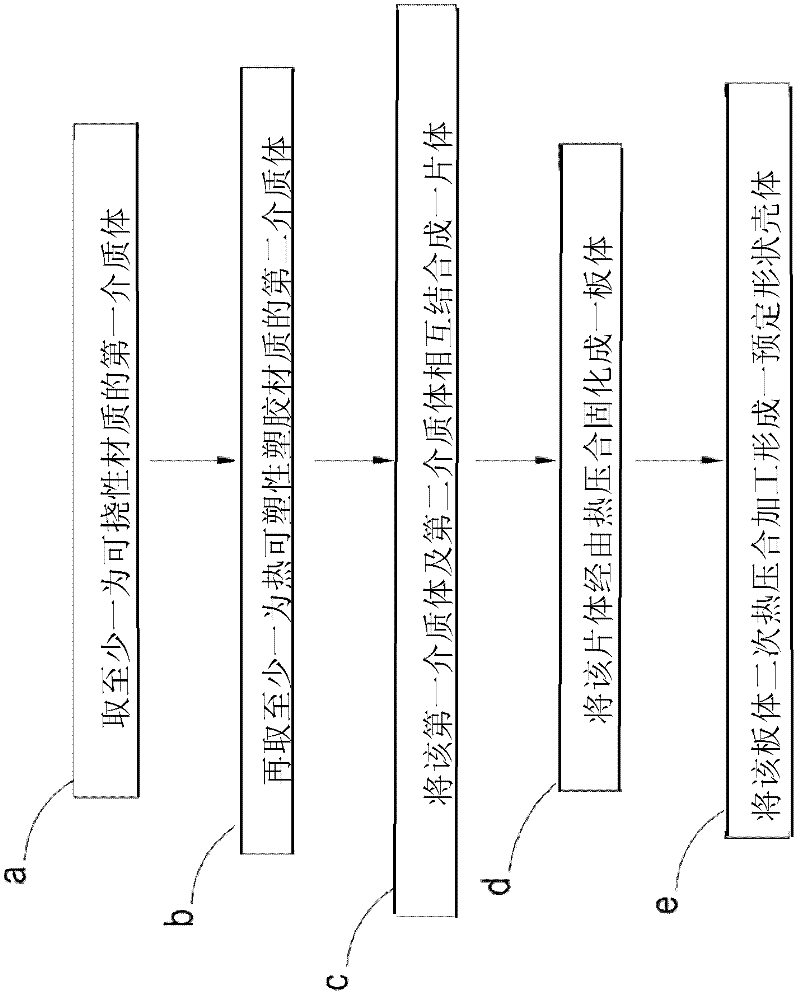

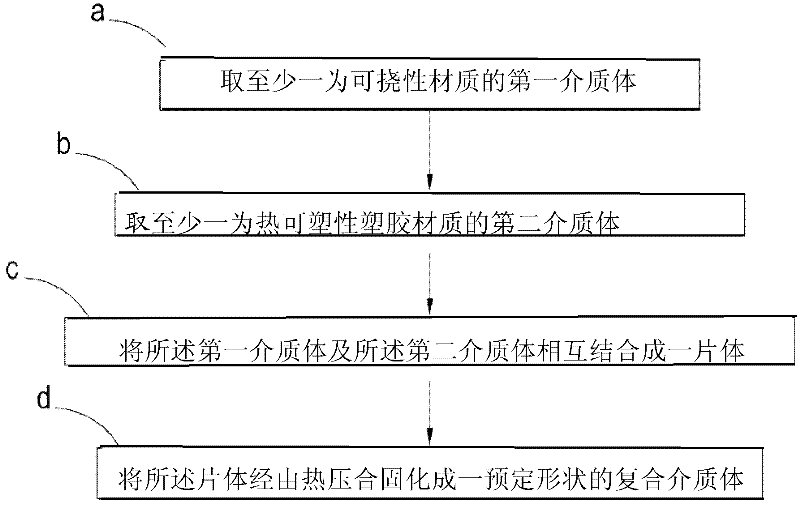

Manufacturing and processing method of flexible plate material

InactiveCN102407642AReduce processing timeRealize secondary processingSynthetic resin layered productsComposite mediaEngineering

The invention relates to a manufacturing and processing method of a flexible plate material. The method comprises the following steps: firstly acquiring at least one first medium body made of a flexible material; then acquiring at least one second medium body made of a thermoplastic material; combining the first medium body and the second medium body mutually into a sheet body; and carrying out hot-press setting on the sheet body into a preset shaped plate body. In addition, the plate body also can be subjected to secondary processing to form a secondary composite medium body of another preset shape, thus the primary processing and molding is reached, and the preset shape of the plate body can be changed through secondary processing.

Owner:SHANGHAI YI HSIN IND

Household electrostatic dust remover

InactiveCN109930324AEasy to operateSimple structureMechanical cleaningPressure cleaningEngineeringStatic electricity

The invention discloses a household electrostatic dust remover, which comprises a dust remover main body, wherein a handle is fixedly arranged in the dust remover main body; a dust removing switch isfixedly arranged on the outer surface of the upper end of the handle; a threaded hole is fixedly arranged on one side of the dust removing switch; an electrostatic switch is fixedly arranged on the other side of the dust removing switch; a conduit is fixedly arranged in the threaded hole; an atomizing nozzle is fixedly arranged at one end of the conduit; a spray hole is arranged at the bottom endof the atomizing nozzle; an outer shell is fixedly arranged on the outer surface of the bottom of one end of the handle; and a protective net is fixedly arranged at the lower end of the outer shell. The household electrostatic dust remover is provided with the atomizing nozzle, a blade and a wool sticking roller, so that the household electrostatic dust remover can absorb or stick up the dust on the surface of clothes while removing dust and wool on the clothes, and finally can effectively remove static electricity and iron the clothes, and a better use prospect is brought.

Owner:绍兴意诺贸易有限公司

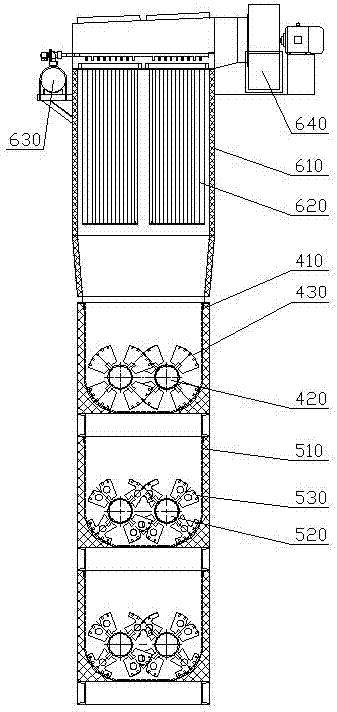

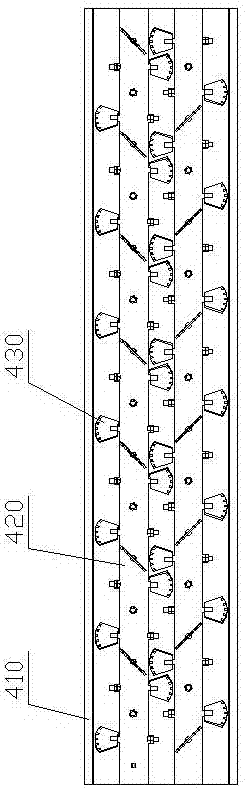

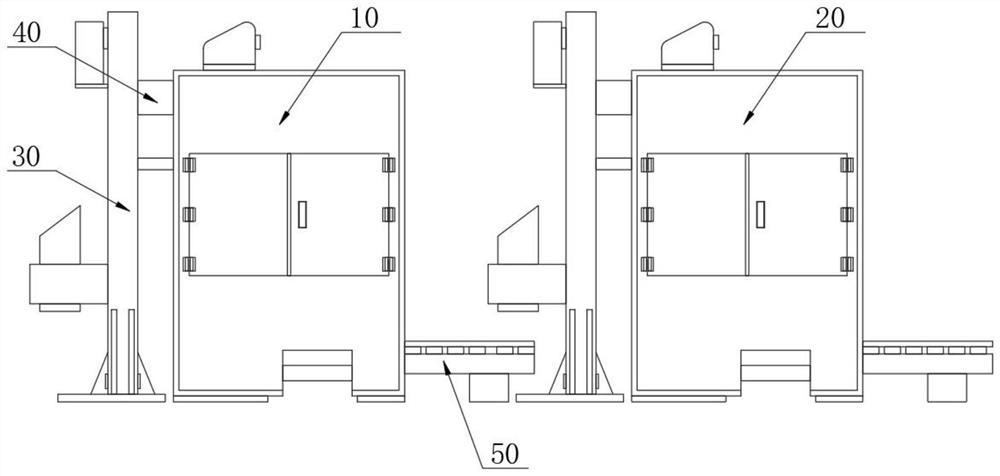

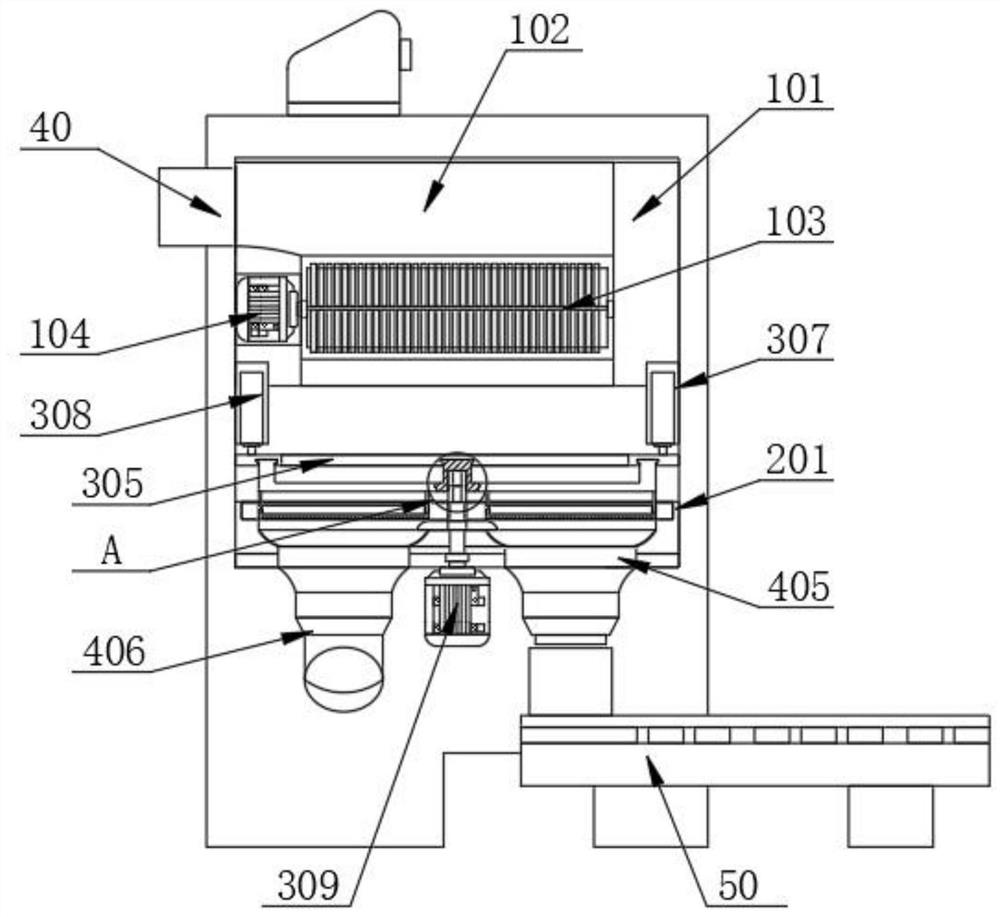

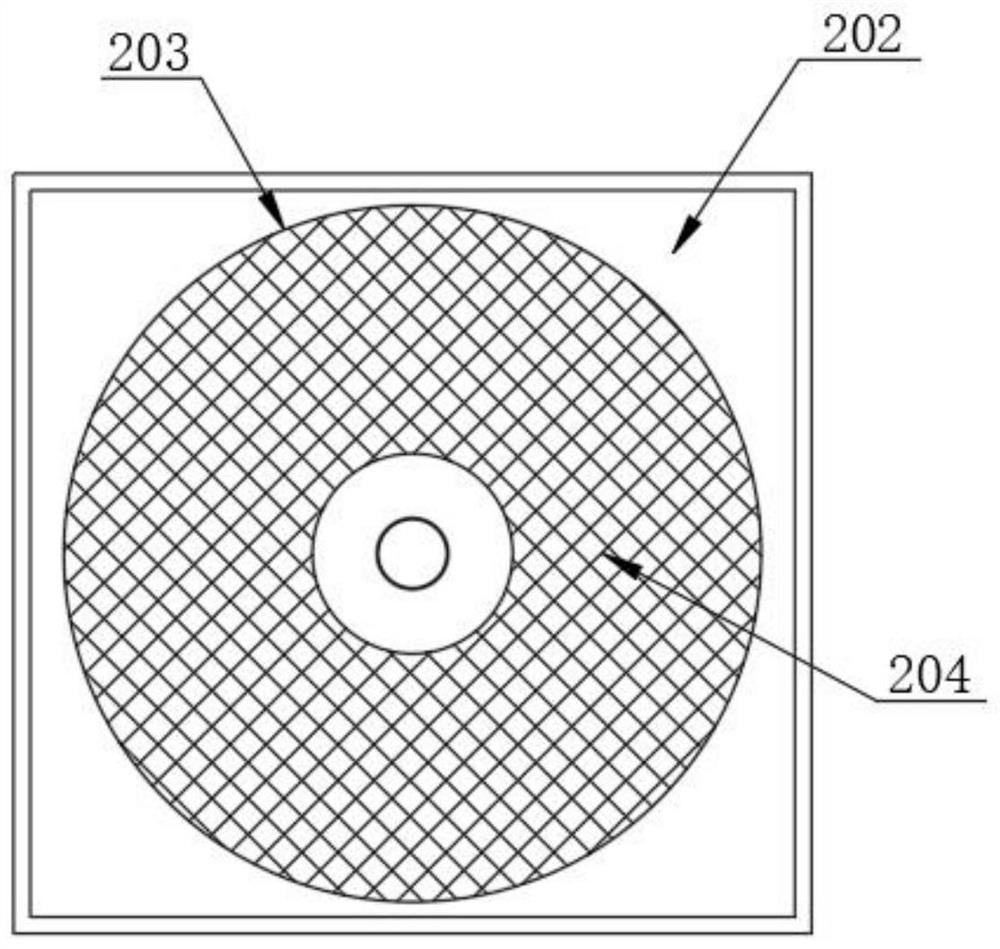

Granularity multi-stage treatment mechanism for coal samples

PendingCN113798034AAchieve unified controlImprove the efficiency of granular multi-level processingGrain treatmentsThermodynamicsStructural engineering

The invention discloses a granularity multi-stage treatment mechanism for coal samples. The mechanism comprises a first-stage treatment box and a second-stage treatment box, the first-stage treatment box and the second-stage treatment box are arranged side by side, and the left side of the first-stage treatment box and the left side of the second-stage treatment box are both provided with a material lifting pipeline. The invention relates to the technical field of coal treatment. The coal sample granularity is subjected to multi-stage treatment through the first-stage treatment box and the second-stage treatment box, pressing assemblies are arranged in the first-stage treatment box and the second-stage treatment box, the coal samples are subjected to secondary crushing through pressing rollers, and the coal samples left above a screen fall into the lower portion of the screen. Moreover, when meshes of the screen are blocked by the coal samples, the surfaces of the pressing rollers can be attached to the upper surface of the screen by adjusting the position of a pressing frame, then the coal samples in the screen are extruded out through the rotating pressing rollers, and the situation that the screen is blocked is treated. The coal sample granularity multistage treatment efficiency is effectively improved.

Owner:淮北矿业股份有限公司涡北选煤厂 +1

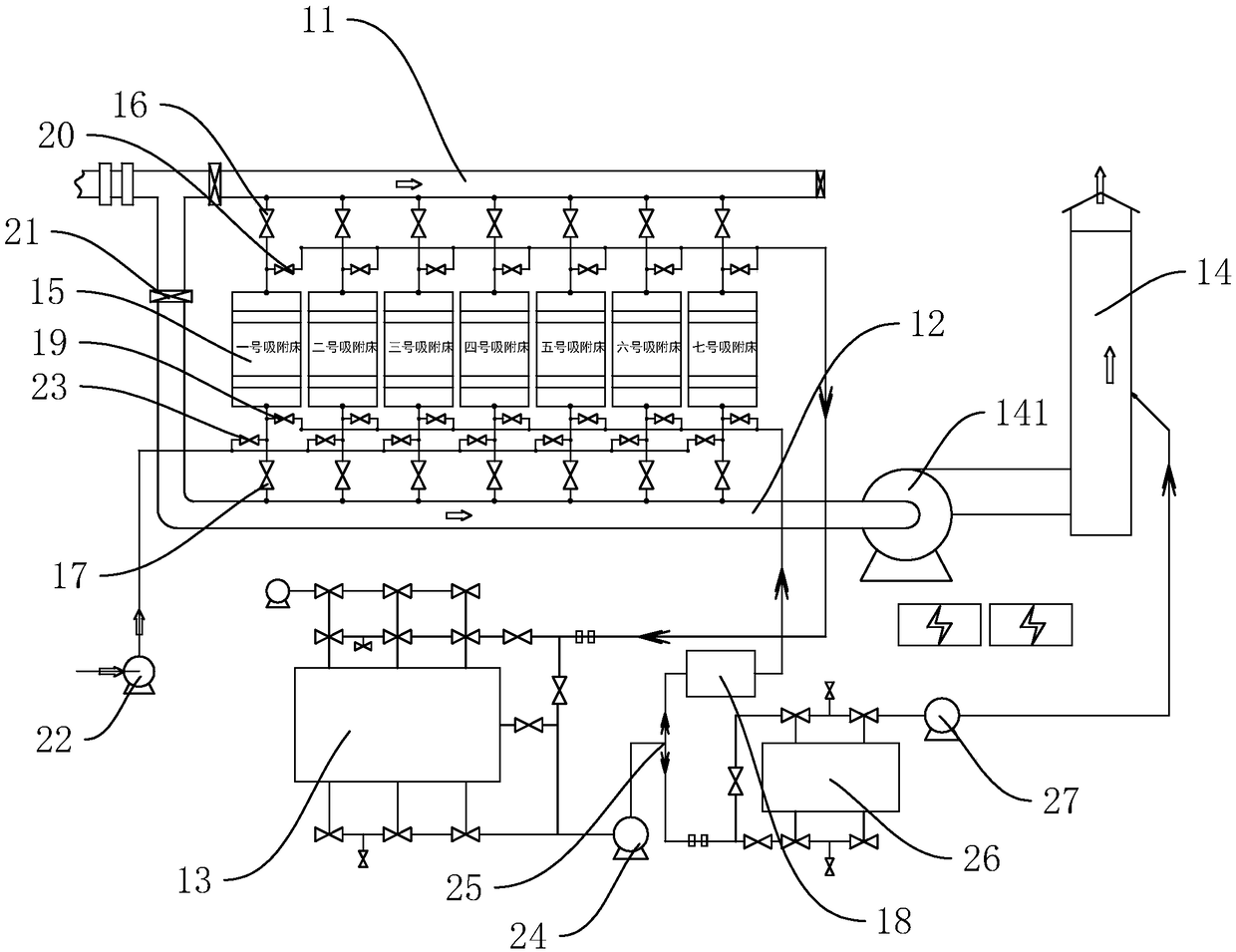

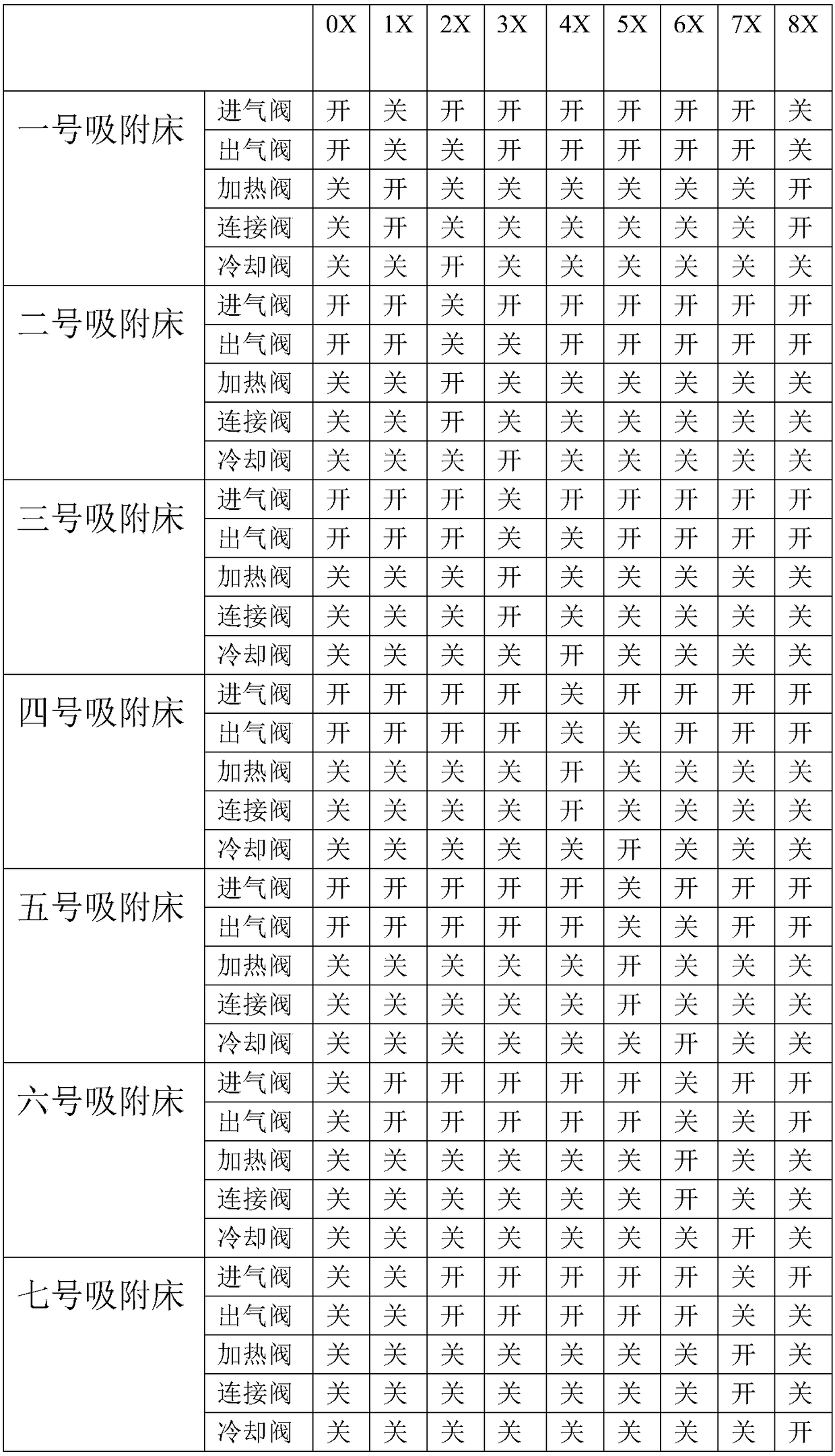

Continuous organic waste gas catalytic purification device and running method thereof

PendingCN109432943AHigh concentration of organic matterIncrease concentrationGas treatmentDispersed particle separationHigh concentrationSmoke

The invention discloses a continuous organic waste gas catalytic purification device and a running method thereof, relates to a waste gas treatment technology, and aims to solve the problem that the prior art is not suitable for low-concentration organic waste gas. The continuous organic waste gas catalytic purification device is characterized by comprising an air inlet pipe, an exhaust pipe, a primary catalytic combustion device, a smoke exhaust barrel, at least five adsorption beds and a heater, wherein the adsorption beds are communicated with the air inlet pipe, and are provided with air inlet valves; the adsorption beds are communicated with the exhaust pipe, and are provided with air outlet valves; the heater is communicated with the adsorption beds, and heating valves are arranged between the heater and each adsorption bed respectively; the primary catalytic combustion device is communicated with the adsorption beds, and connection valves are arranged between the primary catalytic combustion device and each adsorption bed respectively; and the air outlet end of the primary catalytic combustion device is communicated with the smoke exhaust barrel. The continuous organic wastegas catalytic purification device disclosed by the invention can not only be suitable for treating the low-concentration organic waste gas, but improve the purifying effect of high-concentration organic waste gas.

Owner:江嗣中

Treatment device for automobile exhaust gas abnormal emission

ActiveCN110159407AAchieve storageReduce the temperatureExhaust apparatusSilencing apparatusExhaust fumesEngineering

The invention discloses a treatment device for automobile exhaust gas abnormal emission. The treatment device comprises a pipe groove arranged on a pipe body of an exhaust pipe; the part, close to anexhaust pipe opening, of the pipe body is provided with a middle rod; the annular pipe groove is formed in the part, corresponding to the middle rod, of the pipe body; two soft rods which are symmetrical to the middle rod are arranged in the pipe groove; a square groove is formed in the end, close to the middle rod, of each soft rod; a spring is fixedly connected in each square groove; a telescopic film is fixed at one end, far away from the middle rod, of each soft rod; and the telescopic films are fixed in the pipe groove. The treatment device has the advantages that when a three-way catalyst cannot timely finish waste gas treatment due to sudden change of the automobile load, a laser emitted into a heat collecting ball is smaller, so that the temperature of a sliding sleeve is reduced,the soft rods are straightened under the action of the elastic force of a spring and is close to the middle rod; the soft telescopic films, the middle rod and the soft rods are used for blocking the pipe body jointly; the waste gas in the pipe body can be directly discharged into an air bag, so that the waste gas can be stored.

Owner:南通迈程汽车技术有限公司

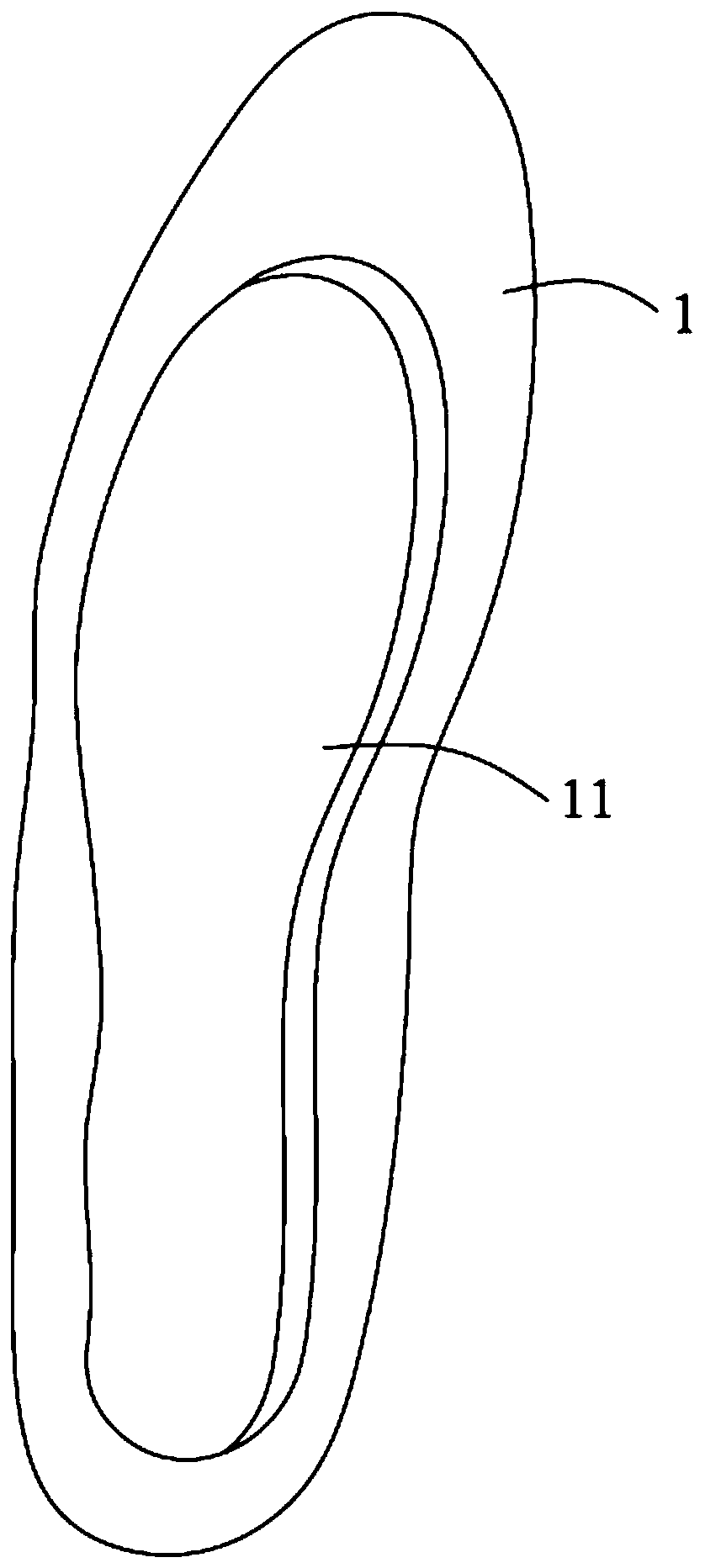

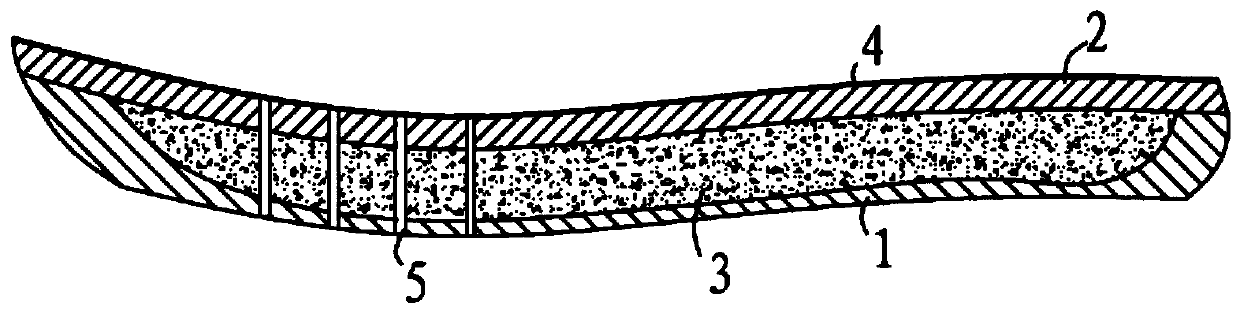

Highly matched and breathable insole and manufacturing method thereof

The invention discloses a highly matched and breathable insole and a manufacturing method thereof. The insole comprises a shoe mold layer, an upper mold layer and a filling layer, wherein the shoe mold layer is provided with a containing cavity; the filling layer is arranged at the containing cavity; the edge of the shoe mold layer is fixed to the edge of the upper mold layer; the filling layer islocated between the shoe mold layer and the upper mold layer; and the shapes of the filling layer and the upper mold layer are both consistent with the foot sole shape of a user. The manufacturing method is simple in process and wide in application range; the obtained insole is provided with the filling layer, so that the flexibility of the whole insole can be improved, the breakage phenomenon ofthe insole during use is effectively prevented, and the service life and the comfort level are prolonged and improved; meanwhile, the shapes of the filling layer and the upper mold layer are both consistent with the foot sole shape of the user, so that the insole is matched with the foot sole of the user; and through the arrangement of the filling layer, the air permeability, the sweat permeability and the bacteriostasis of the insole can be improved, the foot odor phenomenon is effectively prevented, and the use comfort is improved.

Owner:佛山市南海全益保健用品科技有限公司

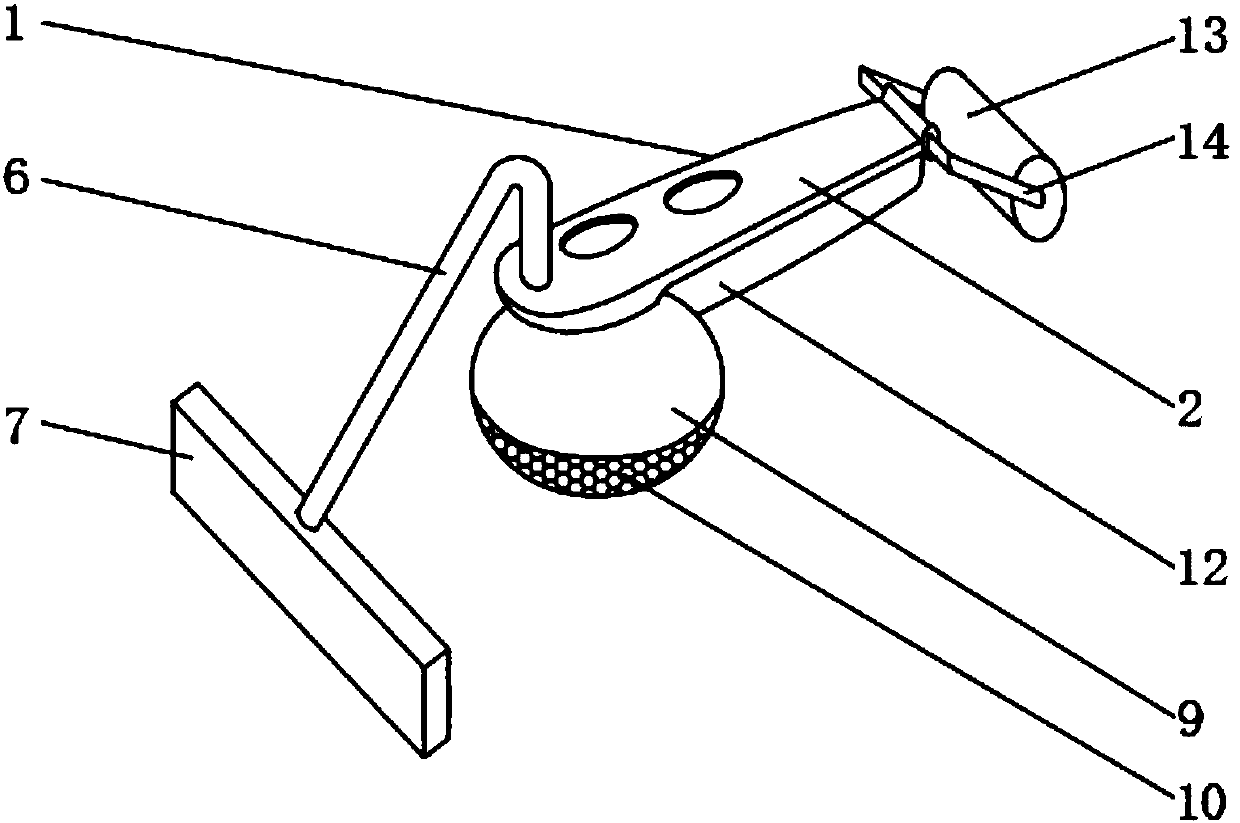

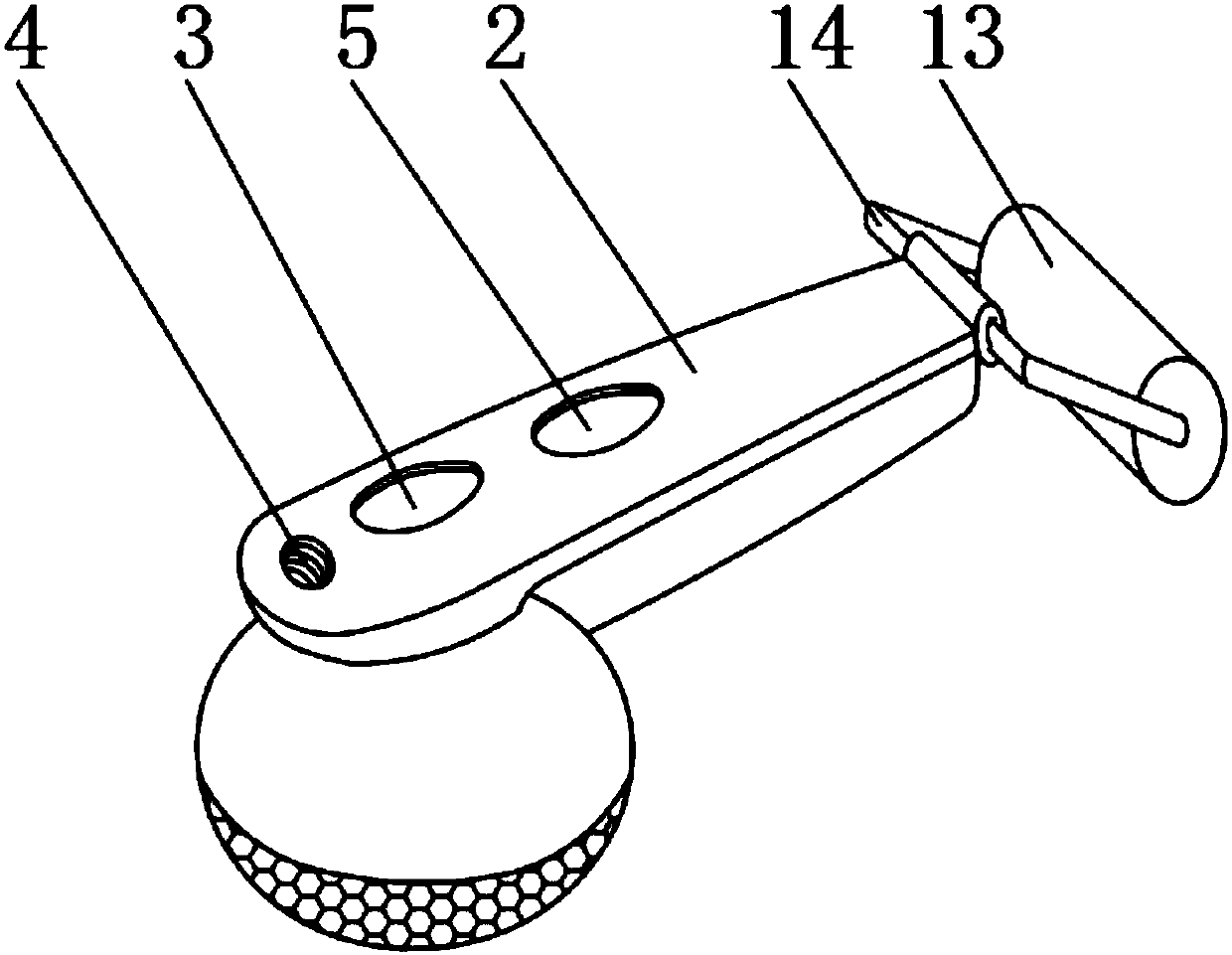

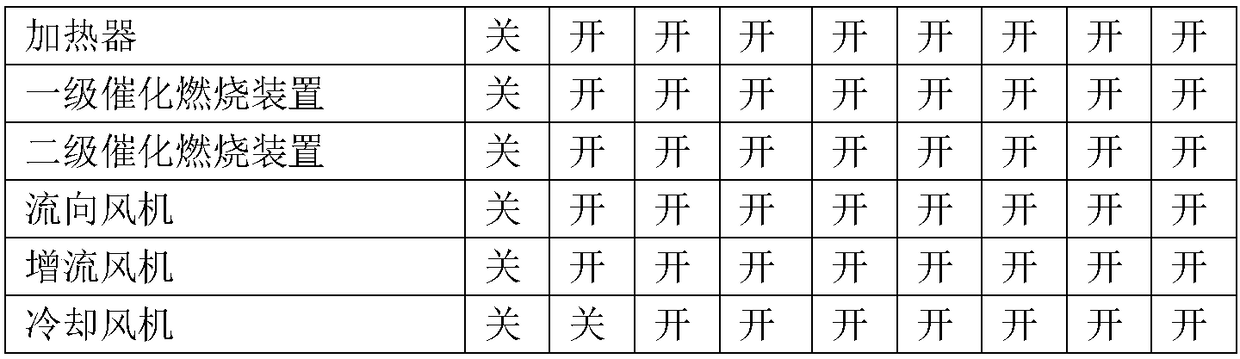

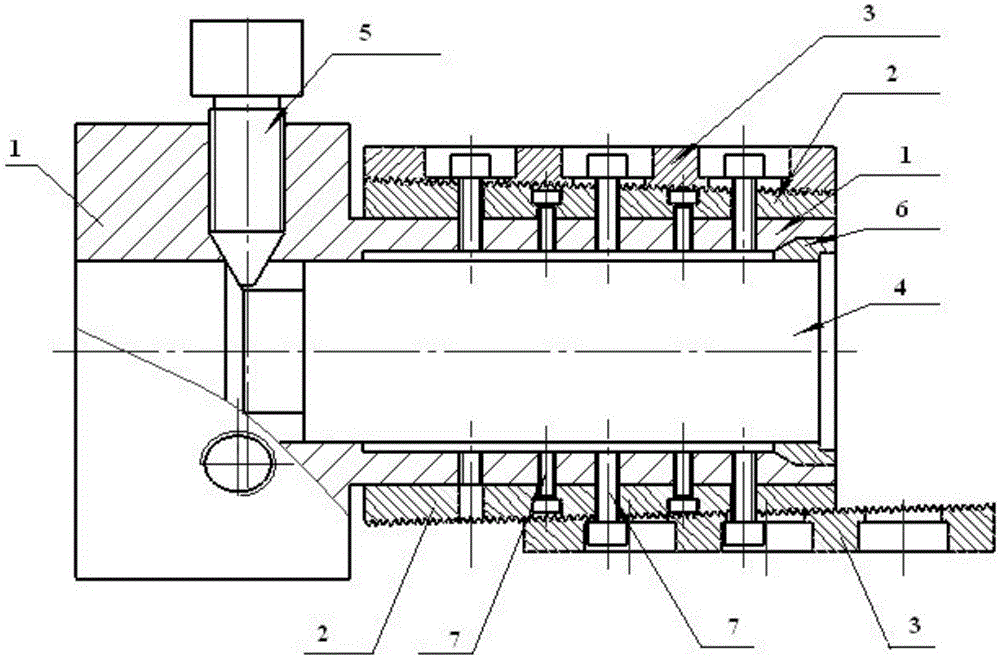

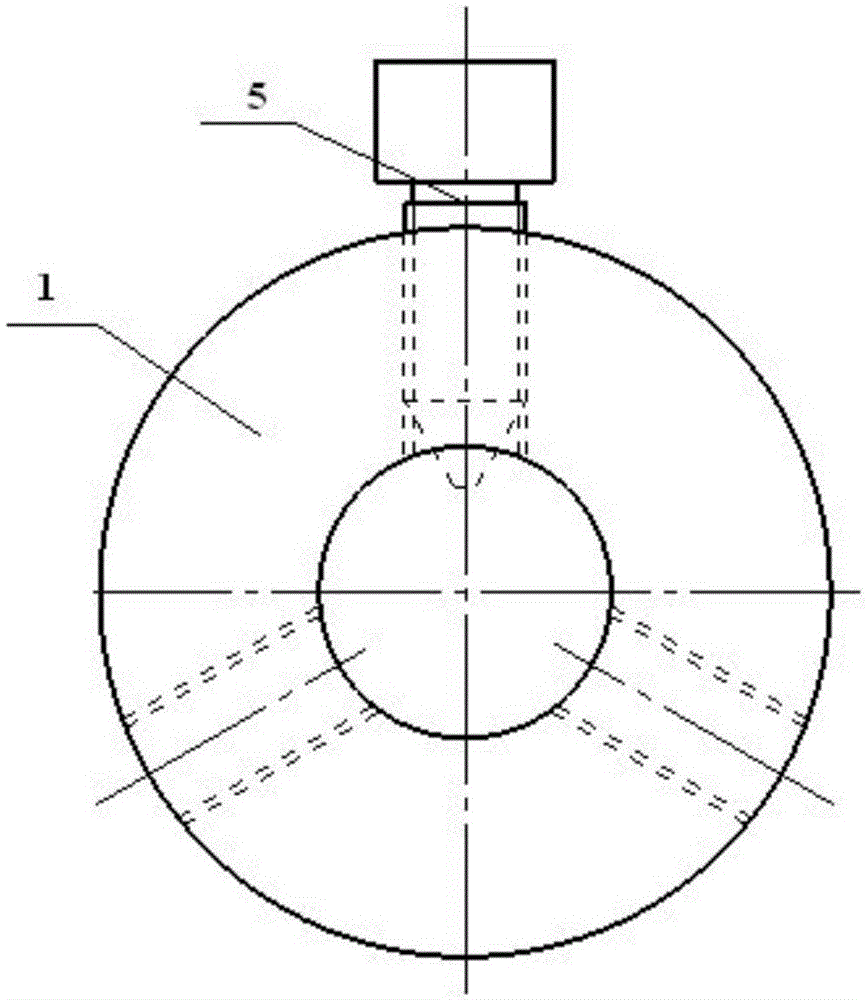

Internal bracing clamp with tightened side face and adjustable inner diameter and machining method of internal bracing clamp

ActiveCN105108510AReasonable structural designEasy to operateWork clamping meansPositioning apparatusMulti materialEngineering

The invention discloses an internal bracing clamp with a tightened side face and the adjustable inner diameter. The internal bracing clamp comprises an open sleeve (1), fixed blocks (2) fixed to the outer circle surface of the open sleeve (1), adjusting blocks (3) fixed to the fixed blocks (2) and a tensioning central spindle (4) arranged in the open sleeve (1). A tightening screw hole is formed in the side face of the large end of the open sleeve (1), a tightening screw (5) is arranged in the tightening screw hole, and one end of the tensioning central spindle (4) is clamped and locked by the tightening screw (5). The contact faces of the fixed blocks (2) and the adjusting blocks (3) are in toothed connection and have 2-degree taper. The internal bracing clamp is reasonable in structural design, secondary machining on poor-precision multi-material welding assembly blanks which are large in dimension span and high in precision requirement can be achieved, the defects that an internal bracing clamp with a fixed-diameter core rod and a tightened end face cannot meet the standard of precision can be overcome, and the internal bracing clamp can be used for locating inner holes of fixed-diameter blind hole parts.

Owner:NANJING SANLE GROUP

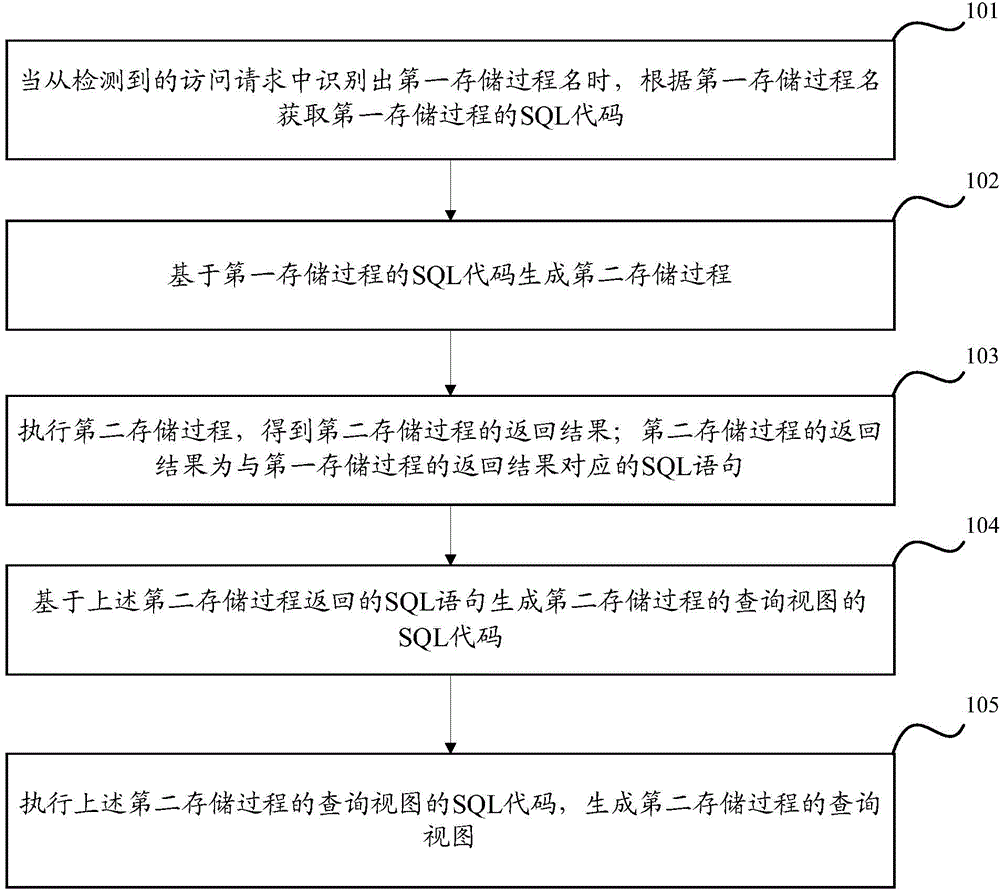

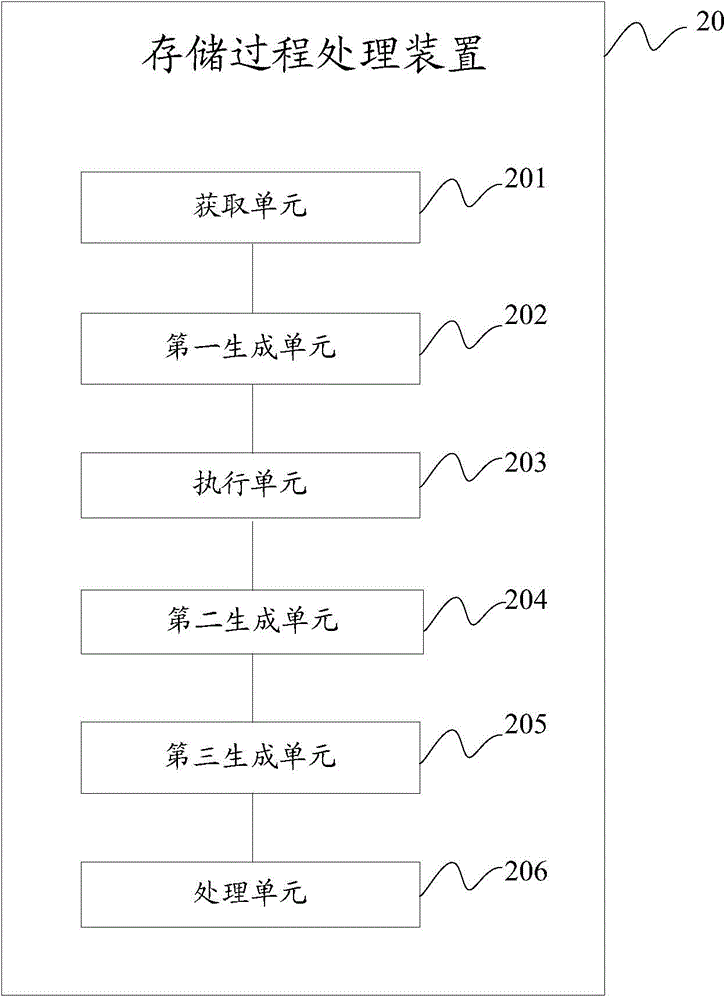

Stored procedure processing method and device

ActiveCN105740286ARealize secondary processingIncrease flexibilitySpecial data processing applicationsSQLResult set

The invention discloses a stored procedure processing method and device. A stored procedure of a return result set is compiled into a query view to achieve secondary processing of the result set. The method comprises the following steps: when a first stored procedure name is identified from a detected access request, obtaining a structured query language (SQL) code of the first stored procedure according to the first stored procedure name; generating a second stored procedure based on the SQL code of the first stored procedure; executing the second stored procedure to obtain a return result of the second stored procedure, wherein the return result of the second stored procedure is an SQL sentence corresponding to the return result of the first stored procedure; generating the SQL code of the query view of the second stored procedure based on the SQL sentence returned by the second stored procedure; and executing the SQL code of the query view of the second stored procedure to generate the query view of the second stored procedure.

Owner:HUAWEI TECH CO LTD

A Coal-to-Acetylene Production Information Intelligent Kanban with Data Analysis Function

ActiveCN107515595BRealize secondary processingProfessionalTotal factory controlComplex mathematical operationsData acquisitionOperation mode

The invention discloses a coal acetylene production information intelligent Kanban with a data analysis function, which comprises a data acquisition device, a real-time database, a data analysis device and an information display terminal, wherein the data acquisition device acquires production data in each work section during a coal acetylene production process and the data are inputted to the real-time database; the real-time database realizes real-time storage and management on the production data; the data analysis device calculates, monitors, evaluates and diagnoses the real-time production data; and the information display terminal visually displays the result outputted by the data analysis device. According to the coal acetylene production information intelligent Kanban with the data analysis function, a deep process index KPI which can not be monitored originally by devices such as a traditional distributed control system (DCS) can be pushed explicitly to an operator, the operator can be helped monitor and evaluate the production condition during each current work period more deeply and meticulously, and according to pros and cons of an upper-reach work period KPI, selection of operation parameters of a lower-reach work period and decision making of an operation mode are decided.

Owner:ZHEJIANG UNIV

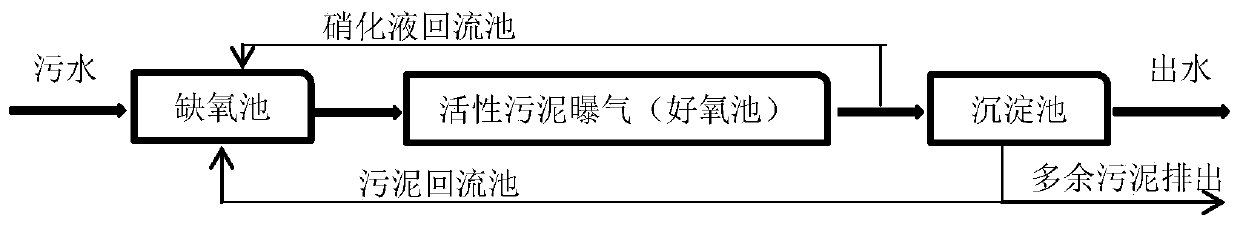

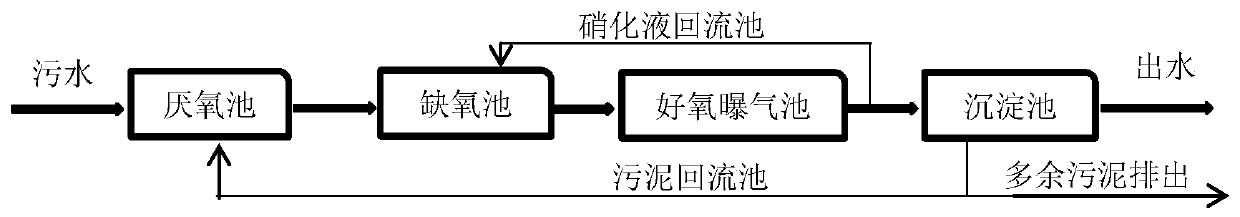

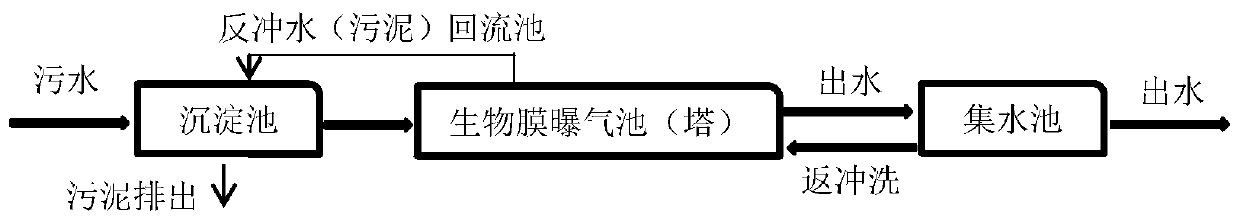

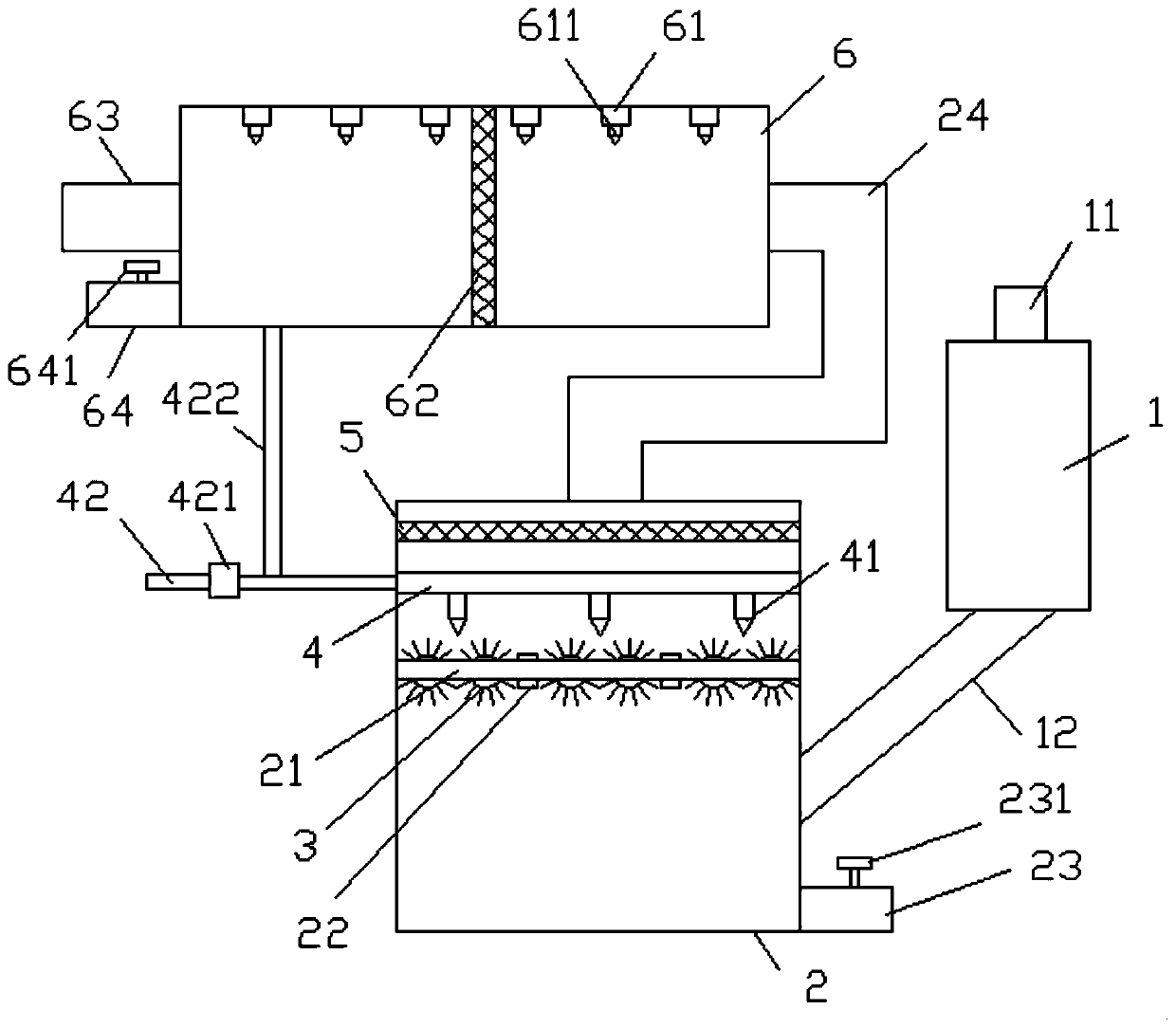

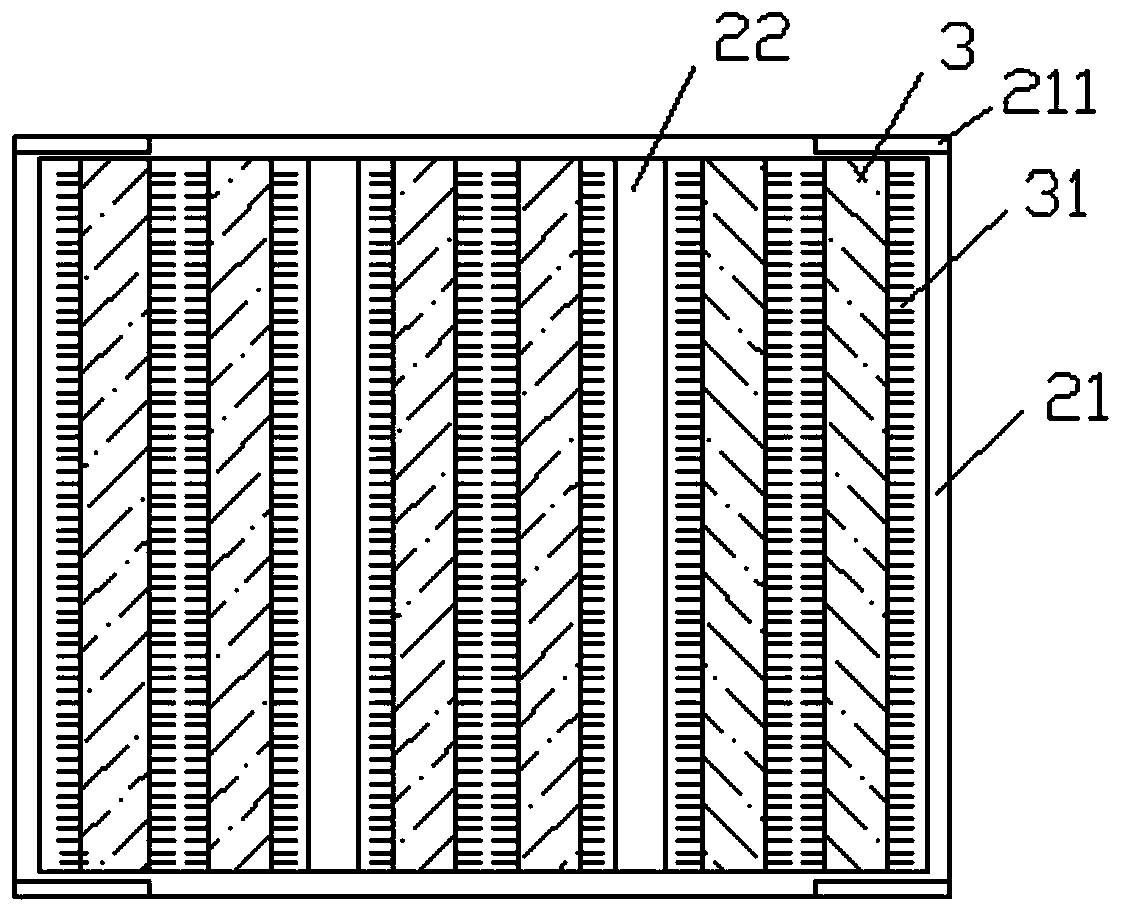

Buried-type integrated sewage treatment system

ActiveCN110117081ARealize secondary processingAvoid influenceSludge treatment by de-watering/drying/thickeningWater contaminantsEconomic benefitsSewage

The invention discloses a buried-type integrated sewage treatment system. The system comprises a sewage inlet pipe unit cooperating with an external sewage generation device, a sewage treatment bucketand a sludge treatment bucket internally provided with a drying assembly for containing sludge, wherein the sewage outlet end of the sewage inlet pipe unit is communicated with an inner bucket through a sewage inlet pipe, and the bottom of an outer bucket is communicated with the drying assembly through a sludge pump and a sludge pumping pipe; the other end of the drying assembly is communicatedwith a discharging chamber through a discharging port, and the discharging chamber is communicated with an external organic fertilizer storage pond through a perpendicular lifting assembly. Accordingto the buried-type integrated sewage treatment system, through cooperation of the buried-type sewage treatment bucket and the sludge treatment bucket, sewage can be treated, sludge generated from thesewage can also be treated, after sewage treatment, secondary processing treatment for the sludge is achieved so that the sludge can become a recyclable organic fertilizer, and meanwhile, the corresponding economic benefits are generated.

Owner:四川京宾节能环保科技有限公司 +2

CVD device tail gas treatment device

PendingCN110935301AIncrease contact areaEasy to handleCombination devicesEngineeringMechanical engineering

The invention relates to the field of semiconductor manufacturing, in particular to a CVD device tail gas treatment device. The treatment device can increase the contact area of tail gas and water andtreat the tail gas by combining a water curtain and an adsorption structure, thereby effectively solving the problem of poor treatment effect due to the fact that only the water curtain is used in the past. The device comprises a high-temperature reaction barrel, a gas inlet pipe is arranged at the top of the high-temperature reaction barrel, the bottom of the high-temperature reaction barrel iscommunicated with the right side of a first treatment barrel through a first connecting pipe, the top of the first treatment barrel is connected to the right end part of a second treatment barrel through a second connecting pipe, a first adsorption device is arranged in the first treatment barrel above a first spraying pipe, and a vertical second adsorption device is further arranged in the middleof the second treatment barrel. The device is simple to operate, convenient to use and suitable for various places.

Owner:江苏晋誉达半导体股份有限公司

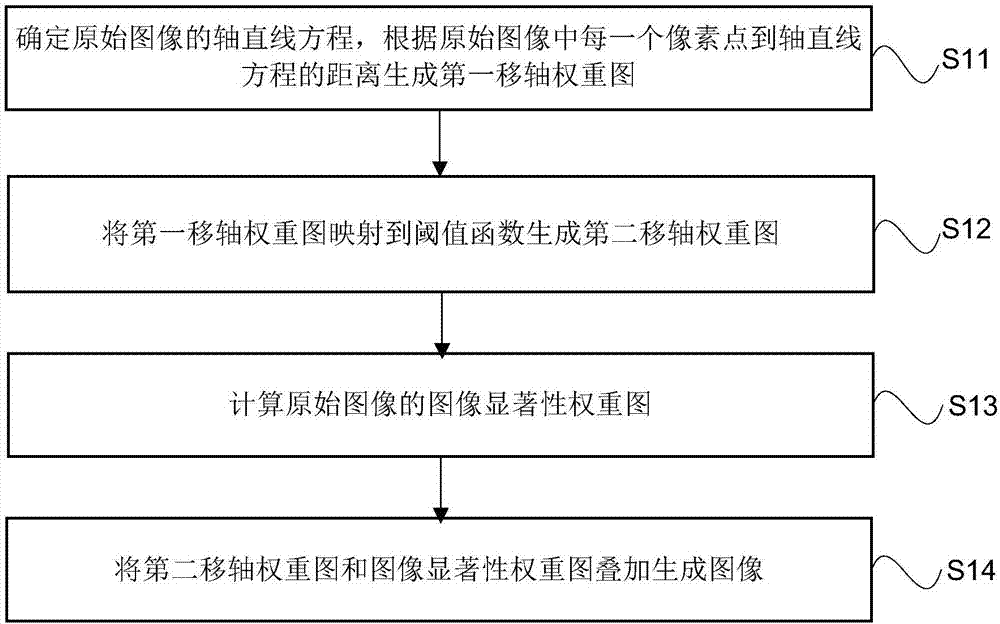

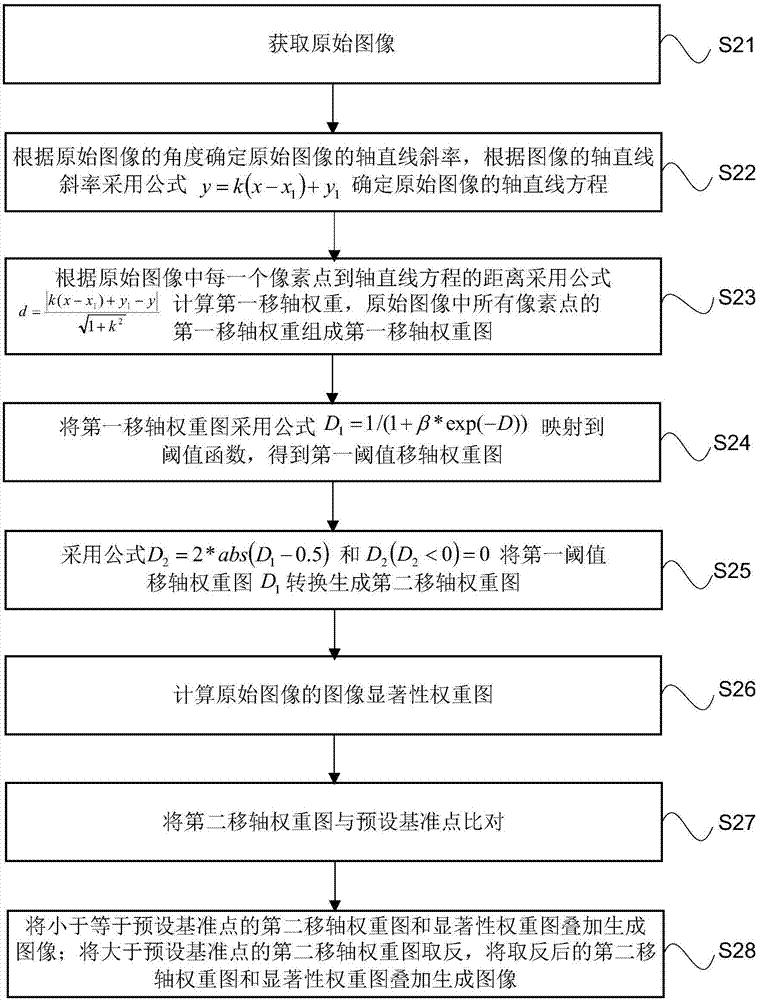

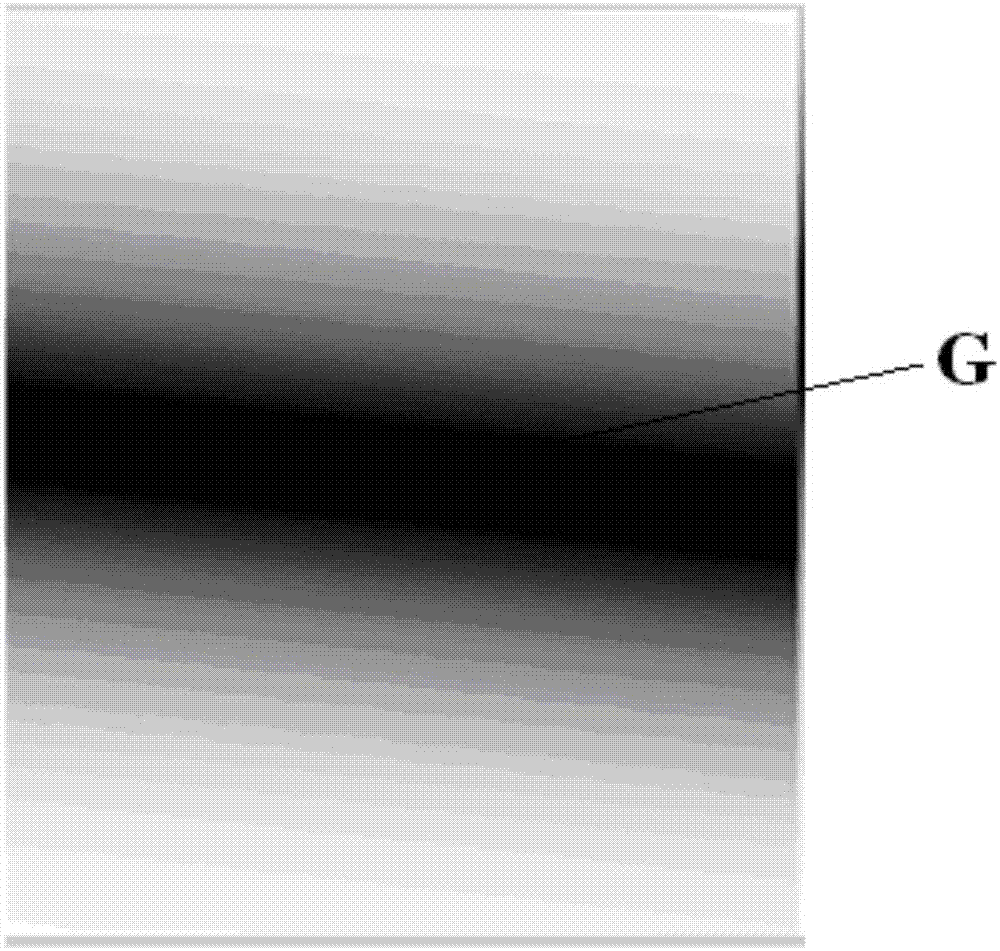

Image generation method, device and system

ActiveCN105631911BConsistent pixel valuesRealize generationTexturing/coloringThreshold functionImage generation

The invention discloses an image generation method, a device and a system. The method comprises steps of determining an axis linear equation of the original image, generating a first axis displacement weight image according to the distance between every pixel point in the original image and the axis linear equation, mapping a first axis displacement weight image to a threshold function to generate a second axis displacement image weight image, calculating the image significance weight image of the original image, and superposing the second axis displacement weight image and the image significance weight image to generate an image. The image generated by the invention can realize the image clearness of the significance area beyond the axial zone and guarantees the consistency between the pixel value of the significance area beyond the axis displacement area and the original image.

Owner:XIAOMI INC

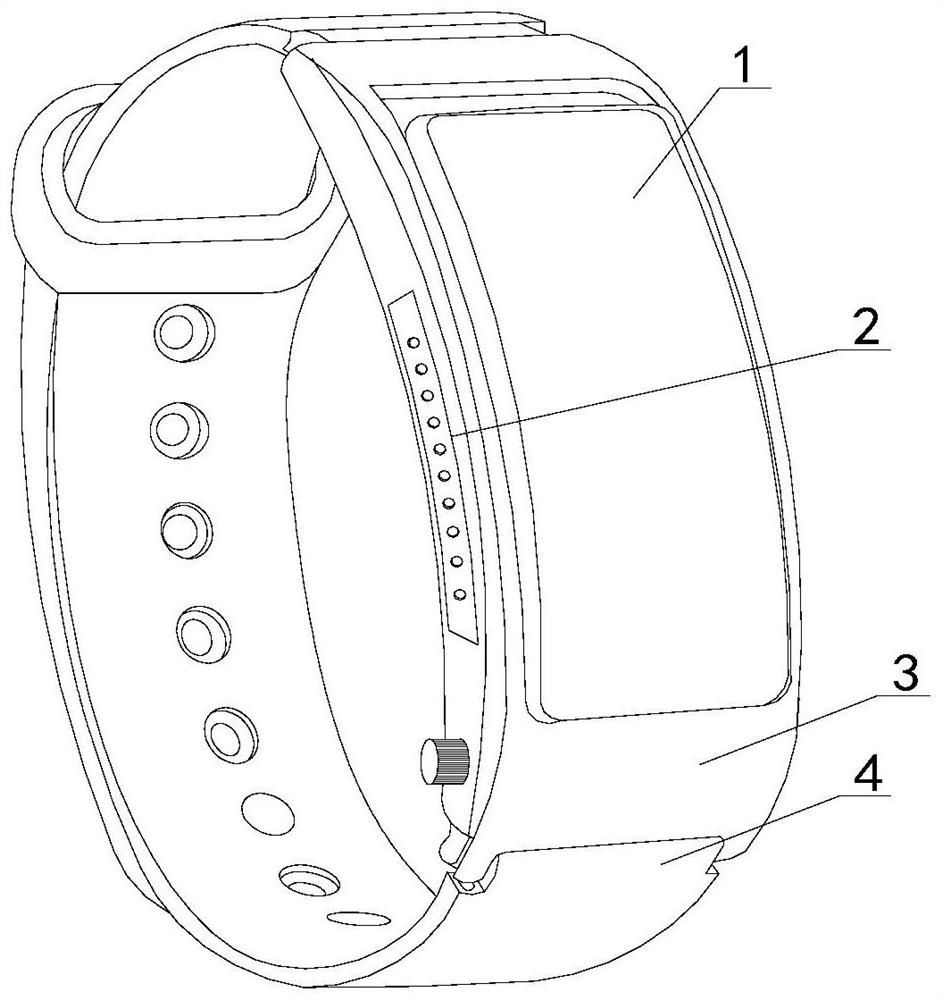

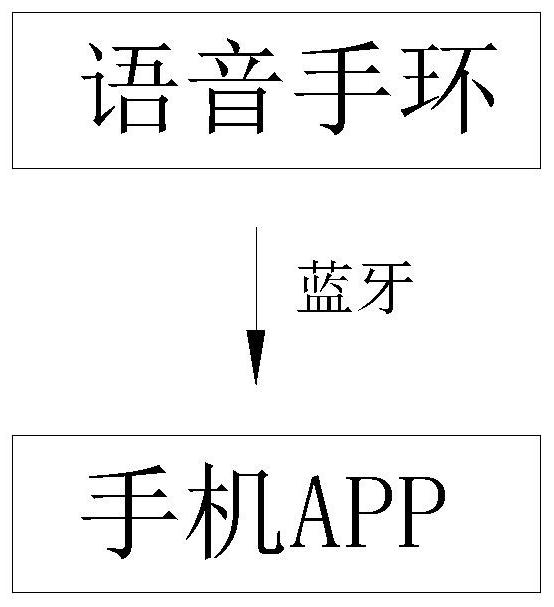

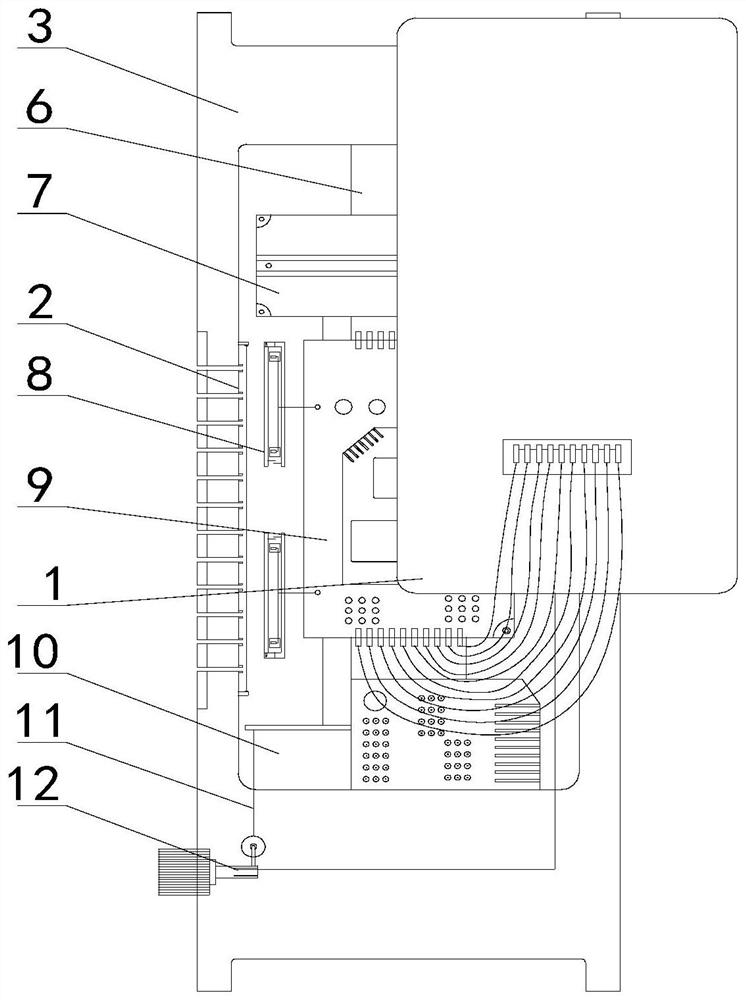

Automatic scoring device

PendingCN114681891ACompliant with Scoring MethodWon't fall offSport apparatusSports activityComputer network

The invention provides an automatic scoring device, a voice bracelet and a mobile phone APP thereof. Data in the voice bracelet is in signal connection with a mobile phone APP client through wireless transmission modes such as Bluetooth and WiFi. The voice bracelet transmits information to the mobile phone APP client, compared with a mode of shaking and displacement of a sports bracelet, voice signals are directly converted into text signals through voice, the scoring mode of sports activities such as badminton and table tennis is better met, scoring is conducted once in a field, and the scoring efficiency is greatly improved. After scoring, information can be temporarily stored through the flash memory chip and transmitted to a mobile phone APP through Bluetooth.

Owner:XIAMEN UNIV OF TECH

A method and application for preparing gn@cellulose-based solid-solid phase change fibers in different phases

ActiveCN110629551BWith heat storage and temperature adjustment functionRealize secondary processingHeat-exchange elementsVegetal fibresPolymer scienceCellulose fiber

The invention discloses a method and application for preparing GN@cellulose-based solid-solid phase change fibers in different phases. The method includes: (1) cellulose fiber dispersion; (2) surface graft modification: reacting halogenated acid halide monomers with cellulose to obtain cellulose ester; (3) SI-ATRP method reaction: step 2) After the obtained cellulose ester, GN and solvent B are uniformly dispersed, a ligand, a catalyst and an alkyl acrylate are added to react to obtain a reaction mixture; (4) purification: after purifying the reaction mixture obtained in step 3), GN@cellulose- g-Polyalkylacrylate solid-solid phase change fiber. The fiber is pressed into a film to obtain a film. In this method, cellulose fibers are used as the matrix, halogen functional groups are grafted through an acylation reaction, and alkyl acrylates are directly grafted on the surface of the modified cellulose fibers through SI-ATRP without changing the structure of the cellulose fibers. For reinforcing materials, fibers with flexibility, high thermal conductivity and high enthalpy value are prepared without post-processing, which is conducive to secondary processing.

Owner:TIANJIN POLYTECHNIC UNIV

Ecosystem applied to septic tank sewage treatment

PendingCN110304793ASimple equipmentGood effectTreatment using aerobic processesTreatment involving filtrationPipingEcosystem

The invention belongs to the field of environmental protection equipment, and relates to an environment-friendly toilet technology, in particular to an ecosystem applied to septic tank sewage treatment. The ecosystem comprises a multi-stage septic apparatus, the multi-stage septic tank is provided with a liquid discharge pipe, the liquid discharge pipe communicates with a sewage collection tank, awater outlet end of the sewage collection tank is provided with water seepage pipes, the water seepage pipes are provided with seepage holes, the water seepage pipes are pre-buried in the ground, a planting area is arranged on the ground surface, the planting area is divided into a plurality of sections from one side, close to the sewage collection tank, of the water seepage pipes to one side, away from the sewage collection tank, of the water seepage pipes, corresponding plants are sequentially planted in the corresponding areas according to the ability of absorbing nitrogen element in the soil from strong to weak, a water filtering apparatus is arranged at the underground position below the planting area along the horizontal direction, a slope is formed by excavating in the ground located below the water filtering apparatus, the low position of the slope communicates with a water inlet end of a sedimentation tank, and a water outlet end of the sedimentation tank communicates with aclarification tank.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI +2

Garbage wastewater treatment device with adjusting function

InactiveCN111807602AImprove Spin AdhesiveAvoid cloggingWater/sewage treatment by irradiationSpecific water treatment objectivesElectric machinerySewage

The invention provides a garbage wastewater treatment device with an adjusting function. The device includes a first treatment barrel, wherein a sewage inlet is fixedly formed in the upper part of theleft wall of the first treatment barrel in a penetrating connection manner; a first discharge port is fixedly formed in the bottom of the first treatment barrel in a penetrating connection manner; avalve is fixedly mounted on the right wall of the first discharge port; a motor is fixedly mounted at the top of an inner cavity of the first treatment barrel; the bottom of a rotating rod of the motor is fixedly connected with a linkage rod; a magnet is fixedly mounted at the bottom of the linkage rod; a first fixed plate is fixedly mounted below the right wall of the first treatment barrel; a sampler is fixedly mounted above the right side of the third treatment barrel; the sampler is fixedly provided with a sampling pipe which is connected with a disinfection barrel in a penetrating manner,so that the water quality can be directly sampled and detected in the last link of sewage treatment, which link of sewage purification needs to be retreated is observed, and the purity of sewage treatment is controlled; and the extraction amount can be controlled by arranging a graduated scale on the front wall of the sampler.

Owner:杭州海科杭环科技有限公司

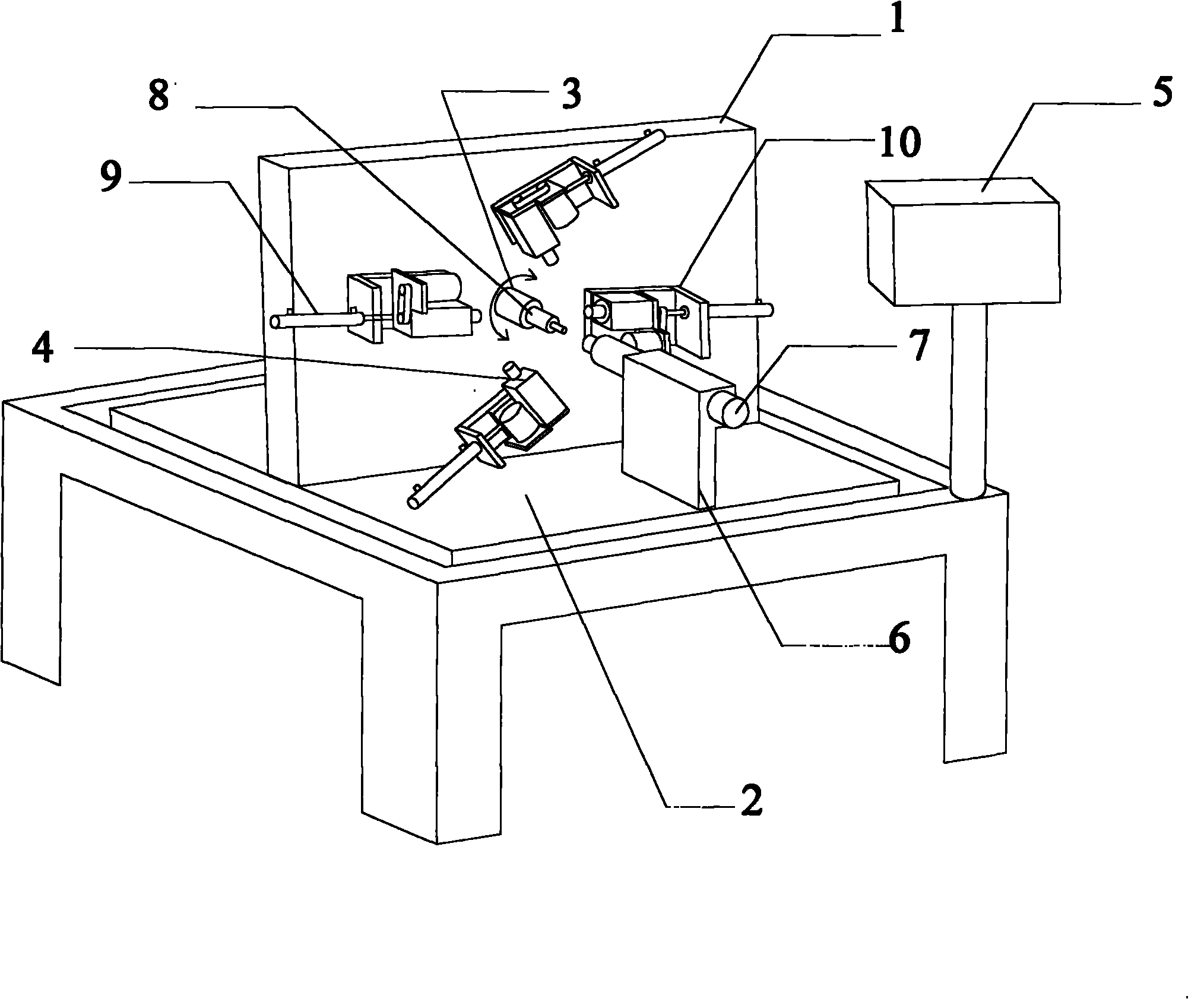

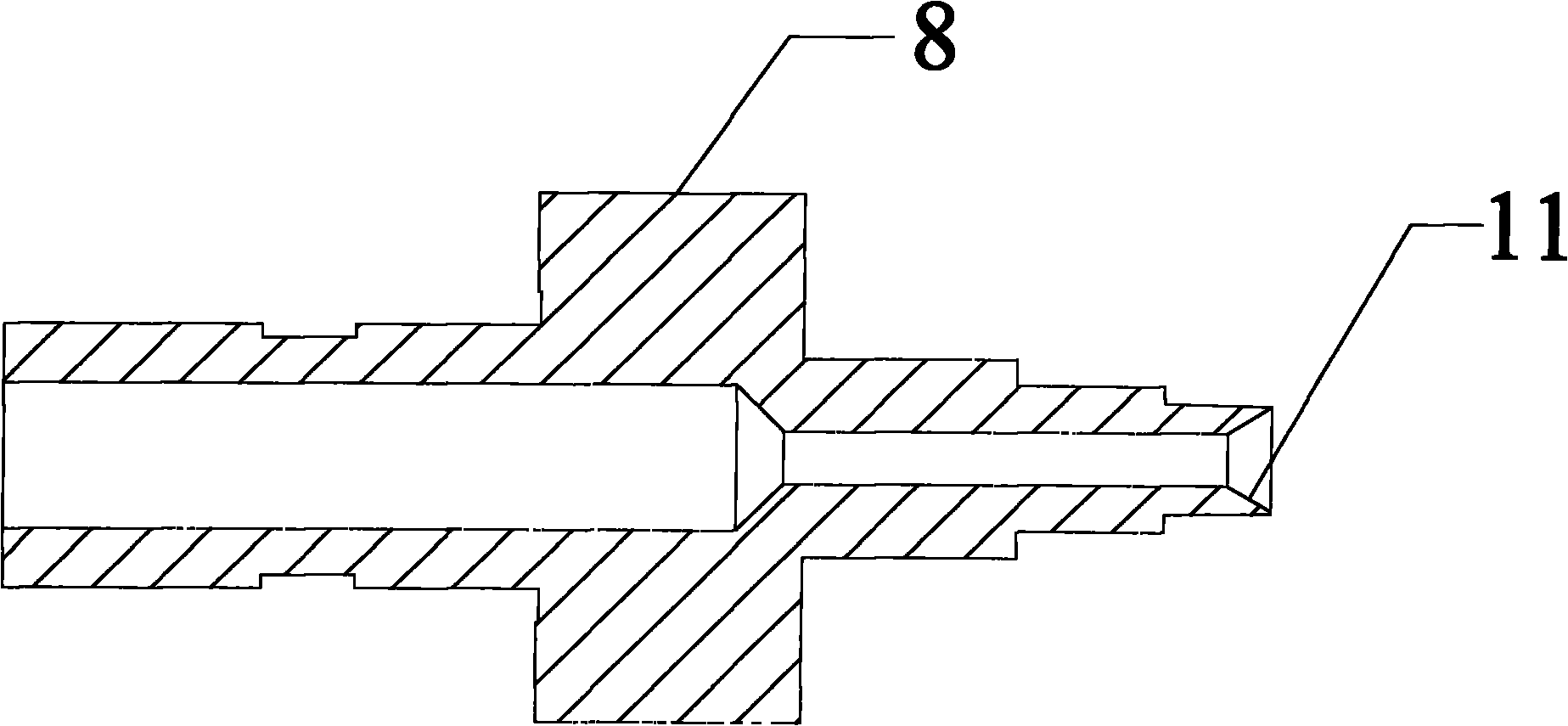

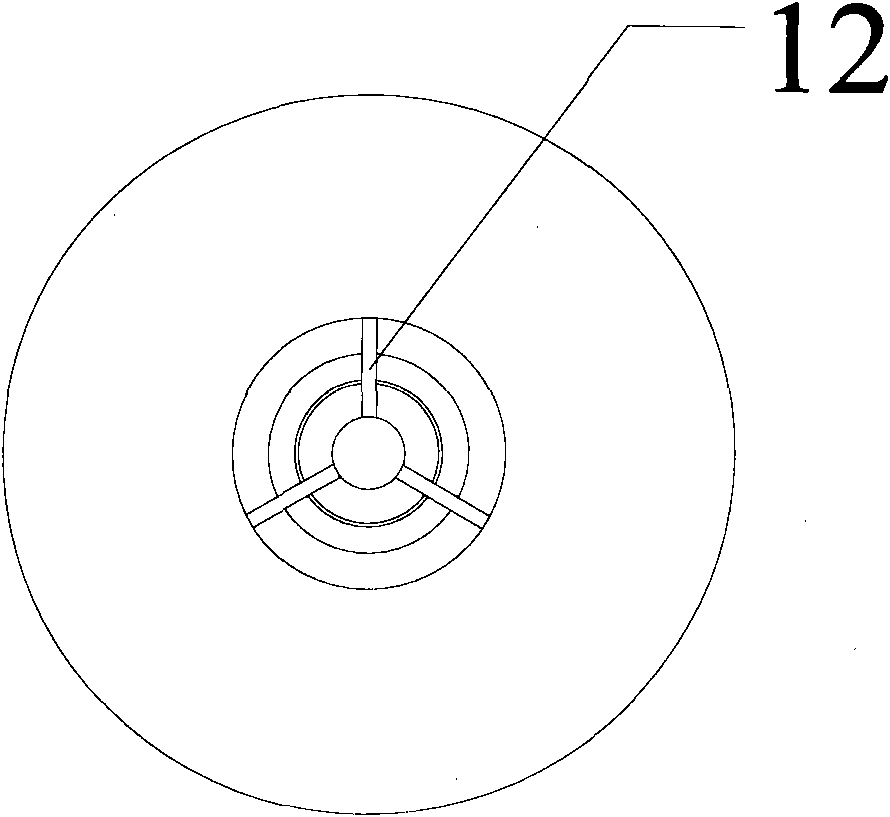

Lining chuck secondary processing machine

InactiveCN102371360ARealize secondary processingEasy to operateTurning machinesPositioning apparatusEngineeringMechanical engineering

The invention discloses a lining chuck secondary processing machine. The lining chuck secondary processing machine comprises a machine platform main body which is provided with a vertical workbench and a horizontal workbench; one side of the vertical workbench is provided with a chuck seat which can extend and retract, and multiple groups of processing tools; the horizontal workbench is provided with a distribution box and a feed mechanism seat which is provided with a feed air cylinder; the feed air cylinder is opposite to the chuck seat which is provided with a lining chuck and a tensioning connection rod; a cavity in which the tensioning connection rod is arranged is formed in the center of the lining chuck; the lining chuck is also provided with a plurality of fractures which are communicated with an outer wall and the cavity; the lining chuck forms a conical locking inner wall; the tensioning connection rod forms a conical locking surface which is matched with the conical locking inner wall; the tail end of the tensioning connection rod is connected with a tensioning mechanism; and the lining chuck secondary processing machine has the advantages that: the outer surface of a whole automobile part can be subjected to secondary processing by clamping a central inner hole of the automobile part.

Owner:延陵精密电子(昆山)有限公司

A kind of gn@cellulose-based solid-solid phase change material and its preparation method and application

ActiveCN110698597BImprove solubilityRealize secondary processingMonocomponent synthetic polymer artificial filamentHeat-exchange elementsPolymer scienceSpinning

The invention discloses a GN@cellulose-based solid-solid phase change material and a preparation method and application thereof. The method includes: (1) dissolving cellulose; (2) homogeneous graft modification: reacting halogenated acid halide monomers with cellulose to obtain cellulose ester; (3) ATRP reaction: reacting the obtained cellulose ester in step 2). After the cellulose ester, GN and solvent B are uniformly dispersed, add ligand, catalyst and alkyl acrylate to react to obtain a reaction mixture; (4) purification: after purifying the reaction mixture obtained in step 3), GN@cellulose-g- Polyalkylacrylate copolymer. The copolymer is melt extruded and spun to obtain solid-solid phase change fibers. The copolymer was electrospun to obtain a film. In this method, cellulose fiber is used as the matrix, halogen functional groups are grafted through acylation reaction, and alkyl acrylate is grafted on the cellulose skeleton through ATRP, and graphene is used as reinforcing material to prepare flexible and high thermal conductivity without post-processing. , Fiber with high enthalpy value, which is conducive to secondary processing.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing porous metal by high temperature oxidation and reduction

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com