Method for preparing porous metal by using mixed gas

A technology of mixed gas and porous metal, which is applied in the field of porous metal preparation, can solve the problems of relying on templates, complex methods, and high requirements for production equipment, and achieve the effects of uniform distribution, simple process, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

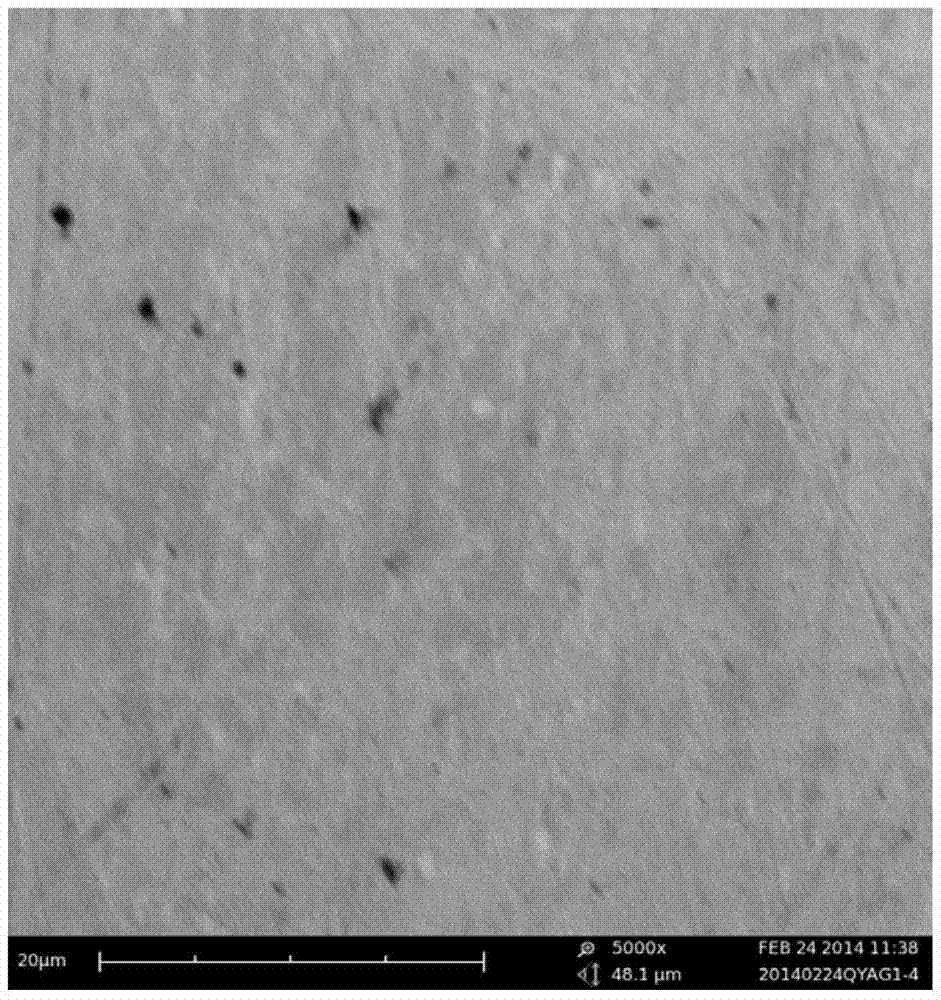

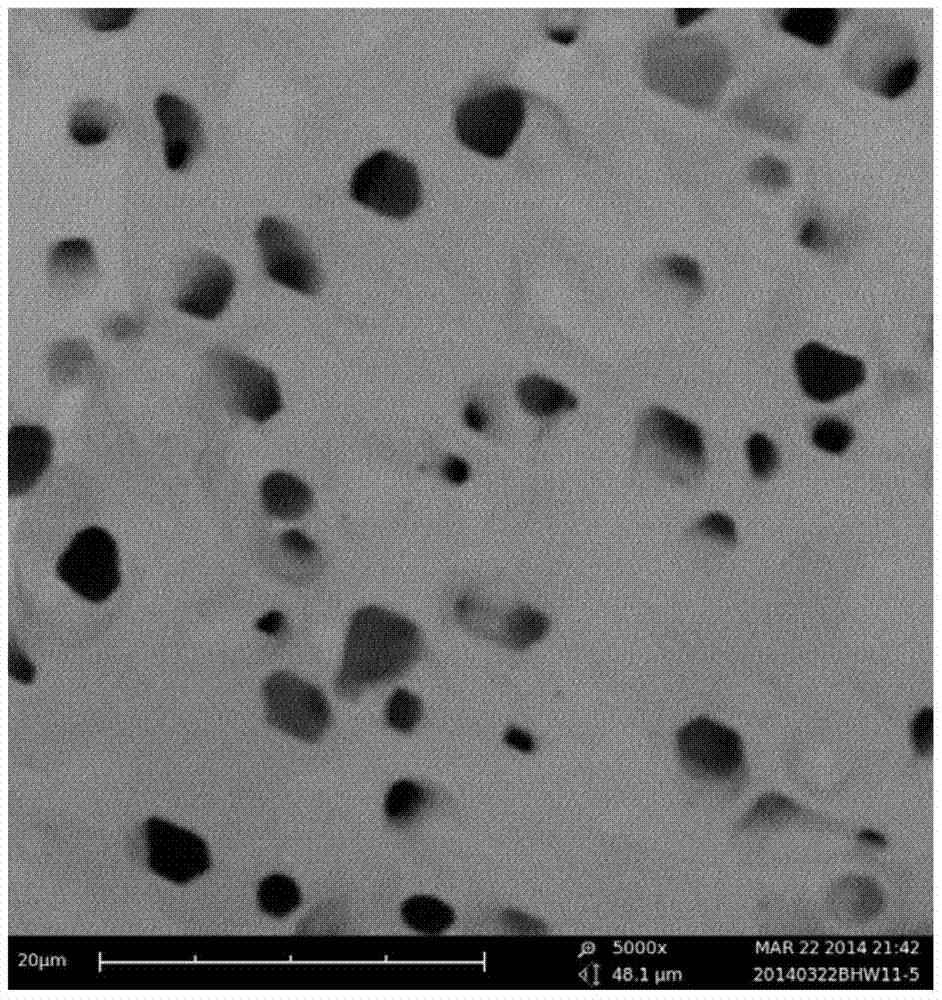

[0023] Specific Embodiment 1: In this embodiment, the method for preparing a porous metal material using a mixed gas is implemented according to the following steps:

[0024] 1. Ultrasonic cleaning the metal material or foam metal material with acetone, then using absolute ethanol and deionized water to clean it in turn, and drying to obtain the cleaned metal;

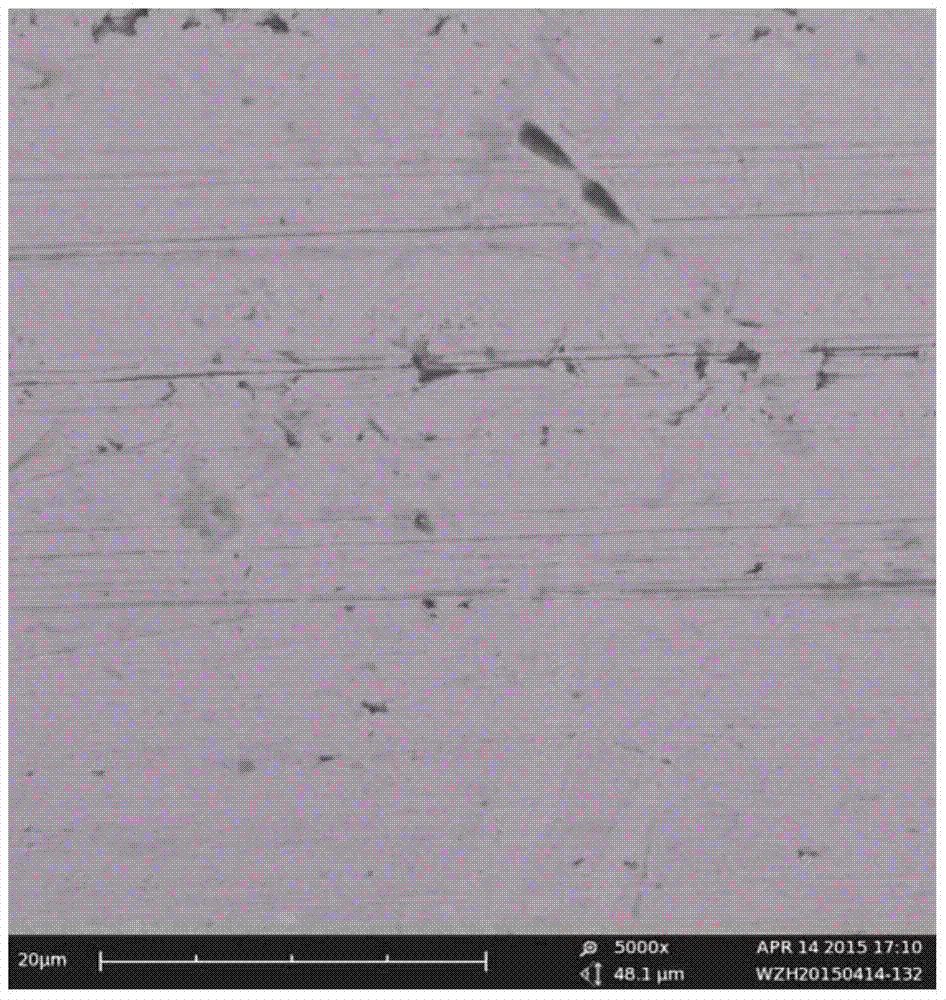

[0025] 2. Place the cleaned metal obtained in step 1 in a high-temperature-resistant carrier, raise the temperature to 550-850°C under the protection of an inert gas, and then pass the mixed gas composed of fuel gas and oxidizing gas into the carrier where the metal is placed In the body, the metal is exposed to the mixed gas for porous treatment to complete the preparation of porous metal materials;

[0026] Wherein the fuel gas described in step 2 is hydrogen, carbon monoxide, C 1 ~C 4 One or more mixed gases of hydrocarbons, biogas, natural gas, liquefied petroleum gas, coke oven gas, water gas, and petroleum gas....

specific Embodiment approach 2

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the metal materials are aluminum, gallium, indium, thallium, germanium, tin, lead, antimony, bismuth, polonium, manganese, iron, cobalt, nickel, Copper, gold, silver, ruthenium, rhodium, palladium, osmium, iridium, platinum, iron, copper or titanium alloys. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the oxidizing gas in step 2 is air or oxygen. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com