Patents

Literature

97results about How to "Achieve cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for underground in-situ extraction of hydrocarbon compound in oil shale

The invention relates to a method for the underground in-situ extraction of a hydrocarbon compound in an oil shale, which comprises the following steps: arranging at least one working well and one production well in an enclosed working region where the hydrocarbon compound in the oil shale is extracted, communicating the bottoms among the working wells by directional drilling after a drilling well enters an oil shale ore layer, injecting water and inert gas water vapor into the working well to form a near-critical water microenvironment, cracking the oil shale into organic compounds with different chain lengths to form an oil-water mixture, lifting the oil-water mixture to the ground through the production well, and obtaining the hydrocarbon compound through an oil-water separating system. The heat utilization ratio is improved through a multi-well integrated heat circulating system, the extraction ratio of hydrocarbon substances is greatly improved through repeated oil-water separating and circulating processes, and the technical process is shortened. A water micro-pool is formed after an oil shale layer is overflowed by water, the cracking of the oil shale can be realized within3 to 5 hours after a near-critical state is reached, and more energy sources and time are saved than an underground dry distillation method.

Owner:JILIN UNIV

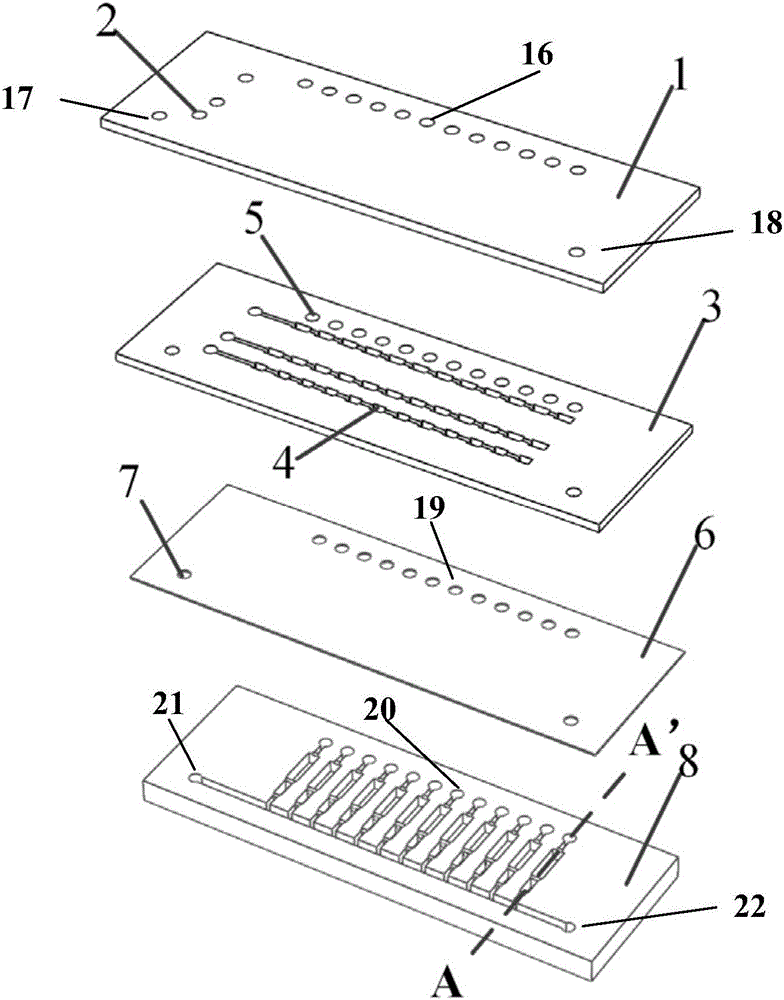

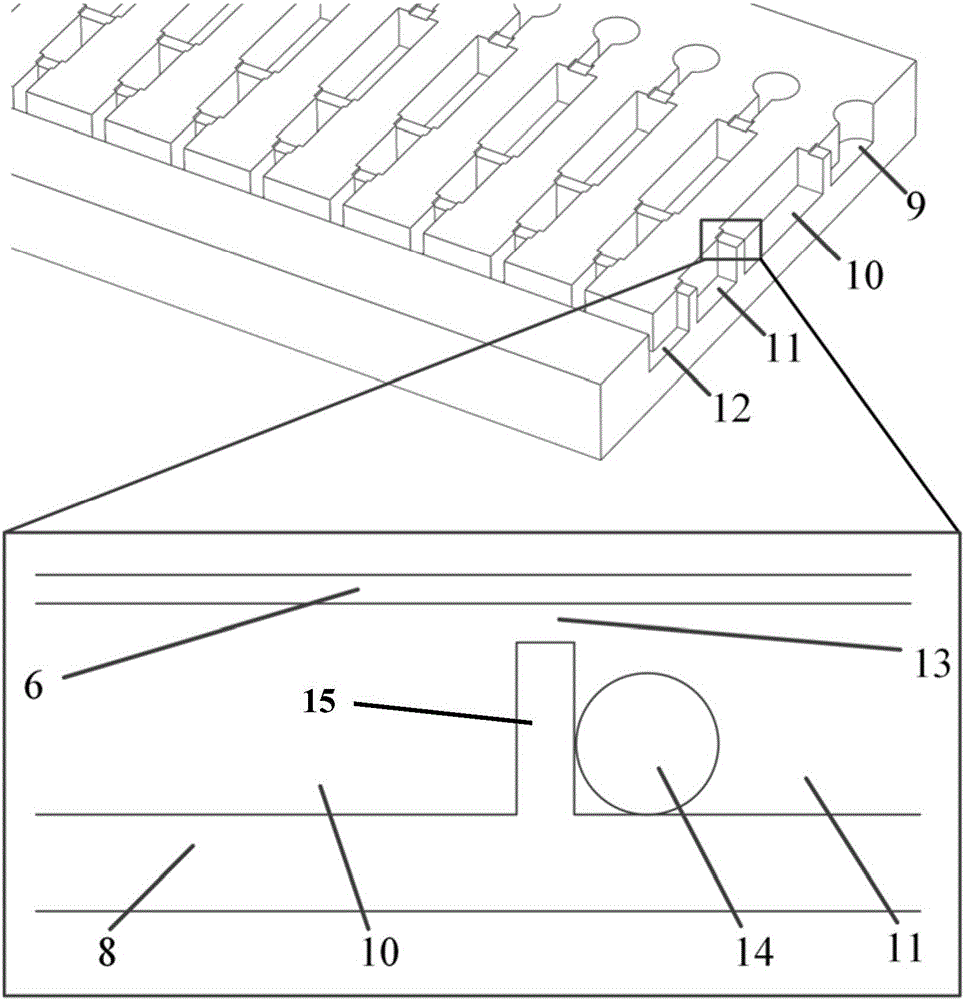

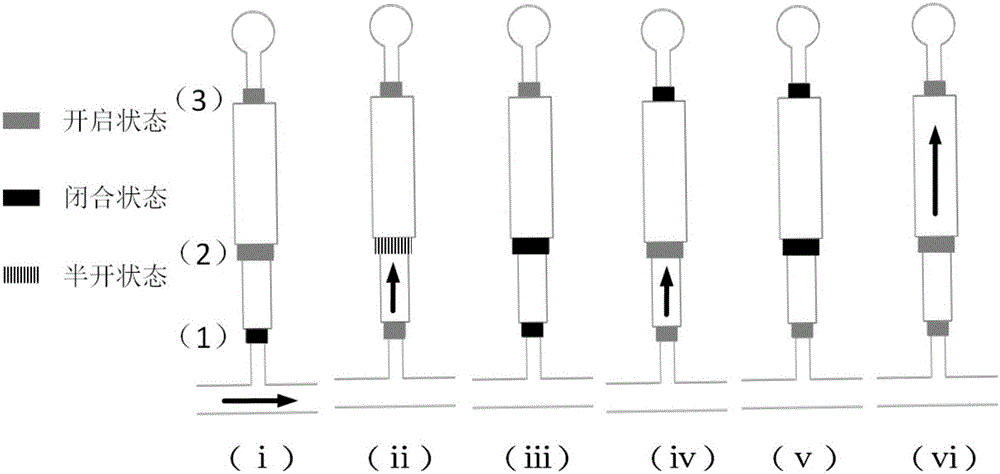

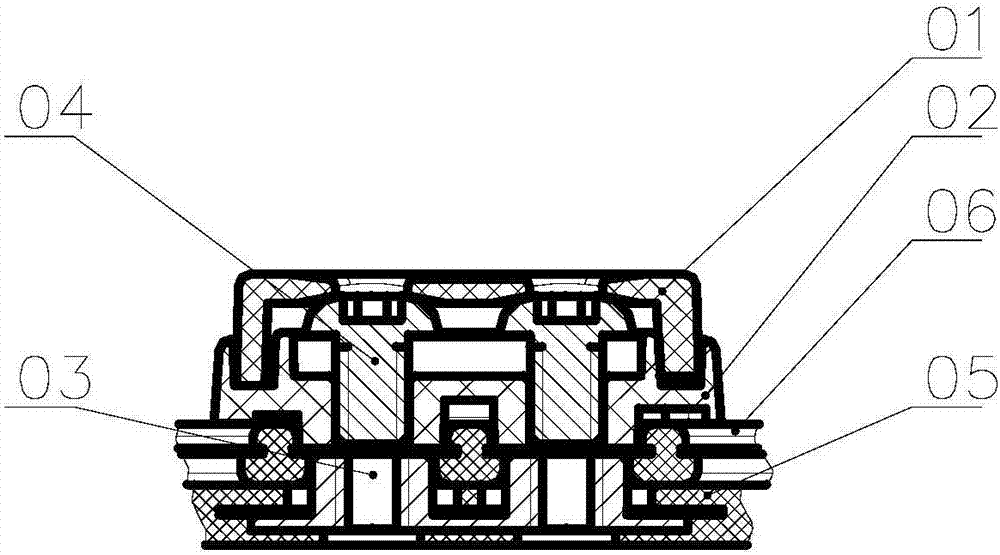

Micro fluidic chip for sorting and whole genome amplification of single cell

PendingCN106065391AEnables in situ fluorescence identificationAchieve crackingBioreactor/fermenter combinationsBiological substance pretreatmentsControl layerEngineering

The invention provides a micro fluidic chip for sorting and whole genome amplification of a single cell. The micro fluidic chip comprises a four-layer structure, wherein the four layers are stacked together in order and mutually sealed, and the structure comprises the following layers from top to bottom: a top cover, a micro valve control layer, a valve plate layer and a channel layer; and the bottom of the micro fluidic chip is externally provided with a magnet. The invention also provides a system for screening and identifying cells as well as amplification and analysis of a single cell, and the system is matched with the chip. The micro fluidic chip and the corresponding detection system can be used for sorting target cells from a large amount of cells quickly, simply and cheaply, and amplifying and analyzing whole genome DNA of a single cell therein.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

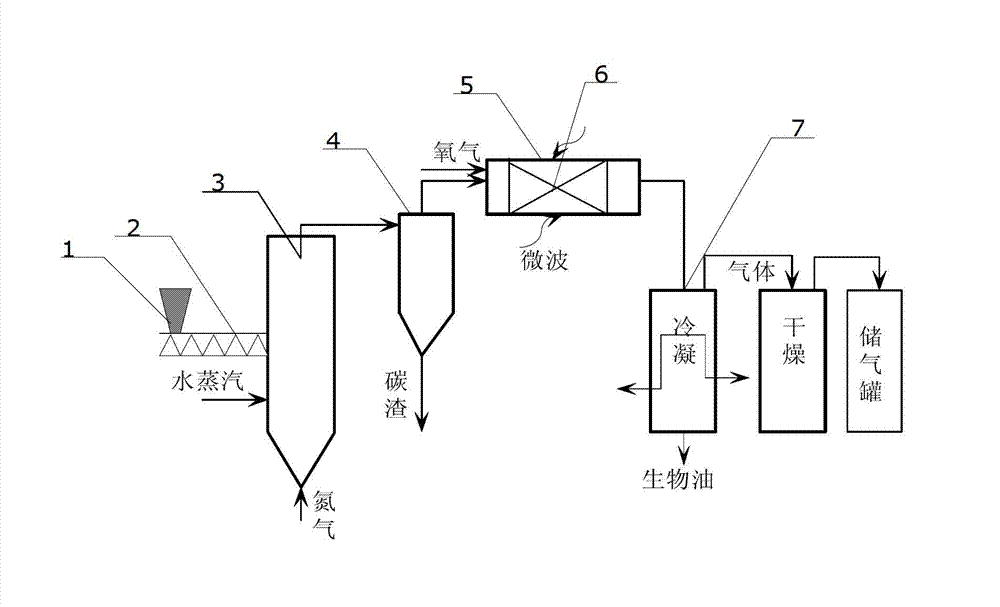

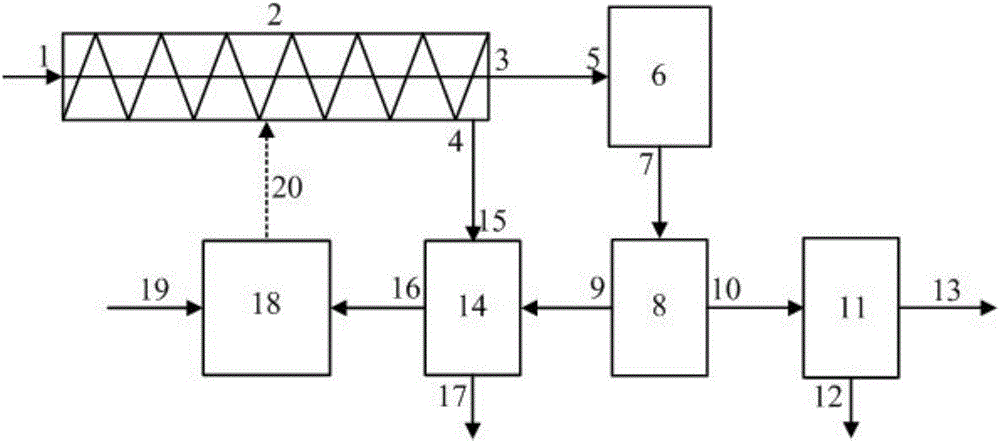

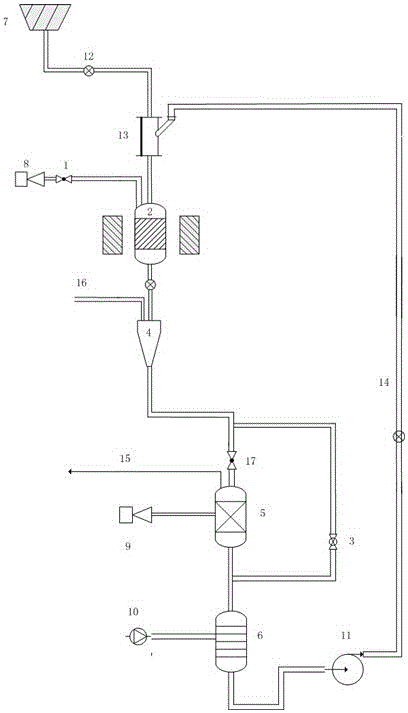

Method for preparing hydrogen-rich synthesis gas via biomass pyrolysis

InactiveCN102963866AReduce gasification cokingReduce energy consumptionHydrogenBiofuelsCatalytic reformingMicrowave

The invention discloses a method for preparing a hydrogen-rich synthesis gas via biomass pyrolysis, comprising the following steps of: by taking biomass particles having a particle size of not greater than 2 mm as raw materials, conveying the biomass particles in a fluidized bed reactor in which the N2 flow of a fluidized bed is 1.0-1.5m<3> / h and the pressure is 0.01-0.08 MPa via a spiral feeder at a speed of 0.005-0.01 t / h; performing pyrolysis at the temperature of 450-550 DEG C; performing catalytic reforming on the surface of a catalyst by the highly-hot vapour generated by the pyrolysis reaction through a microwave catalytic bed; and further transforming biological oil vapour to the synthesis gas, and charging a small amount of oxygen in the microwave catalytic bed to inhibit coking on the surface of the catalyst. According to the invention, energy consumption is reduced, and the transformation rates of hydrogen and biomass are increased by performing a catalytic reforming reaction on a microwave stationary bed via the biological oil vapour after the first-stage fluidized bed pyrolysis.

Owner:ANHUI UNIV OF SCI & TECH

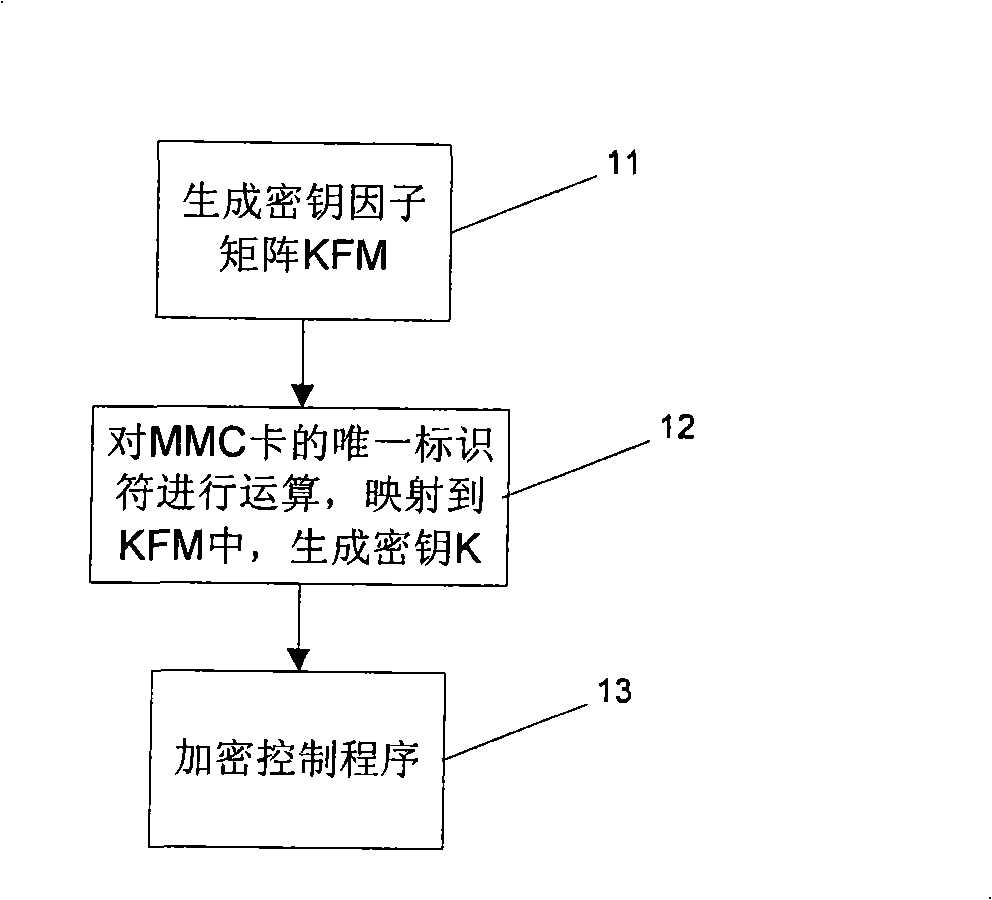

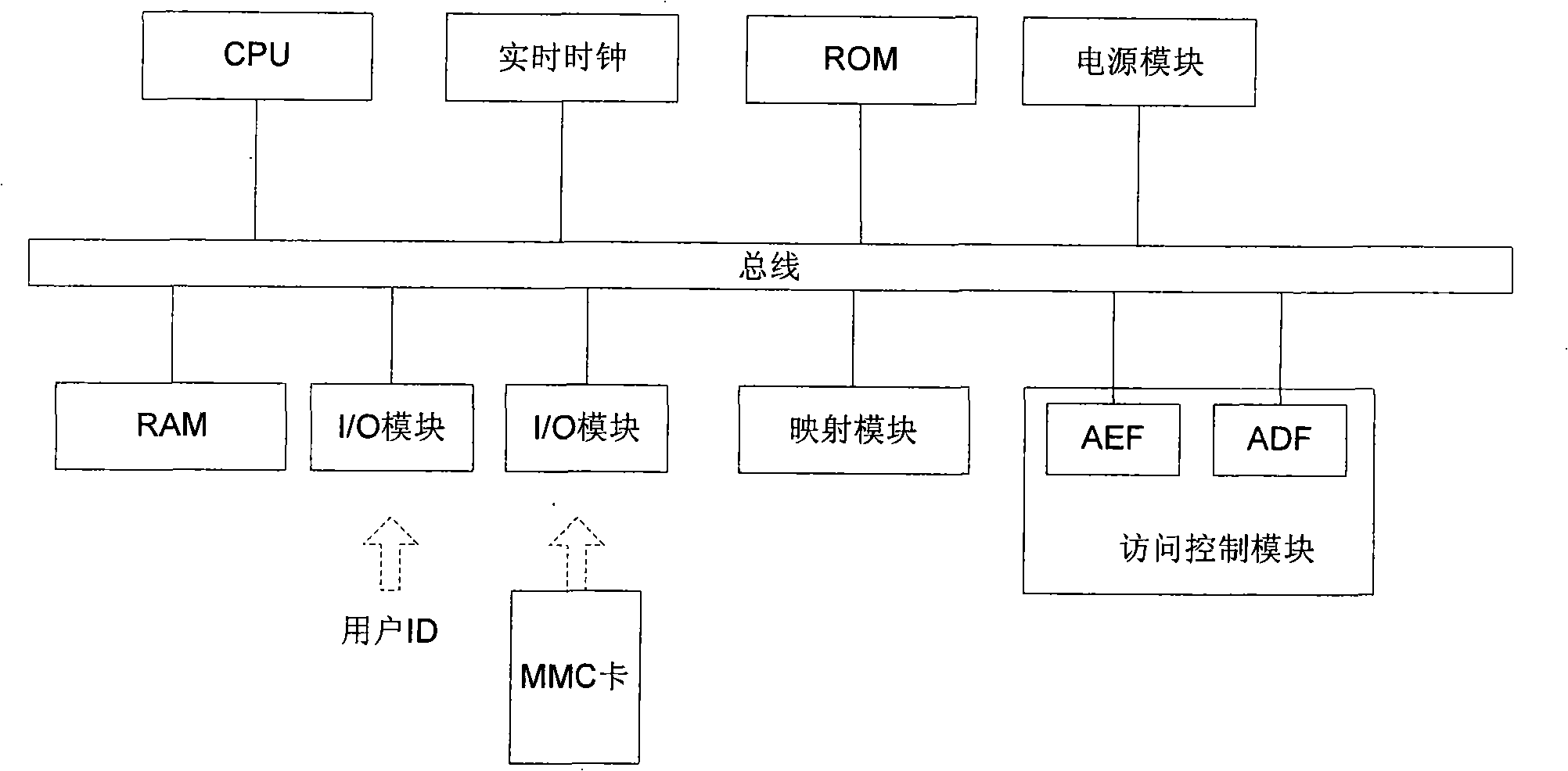

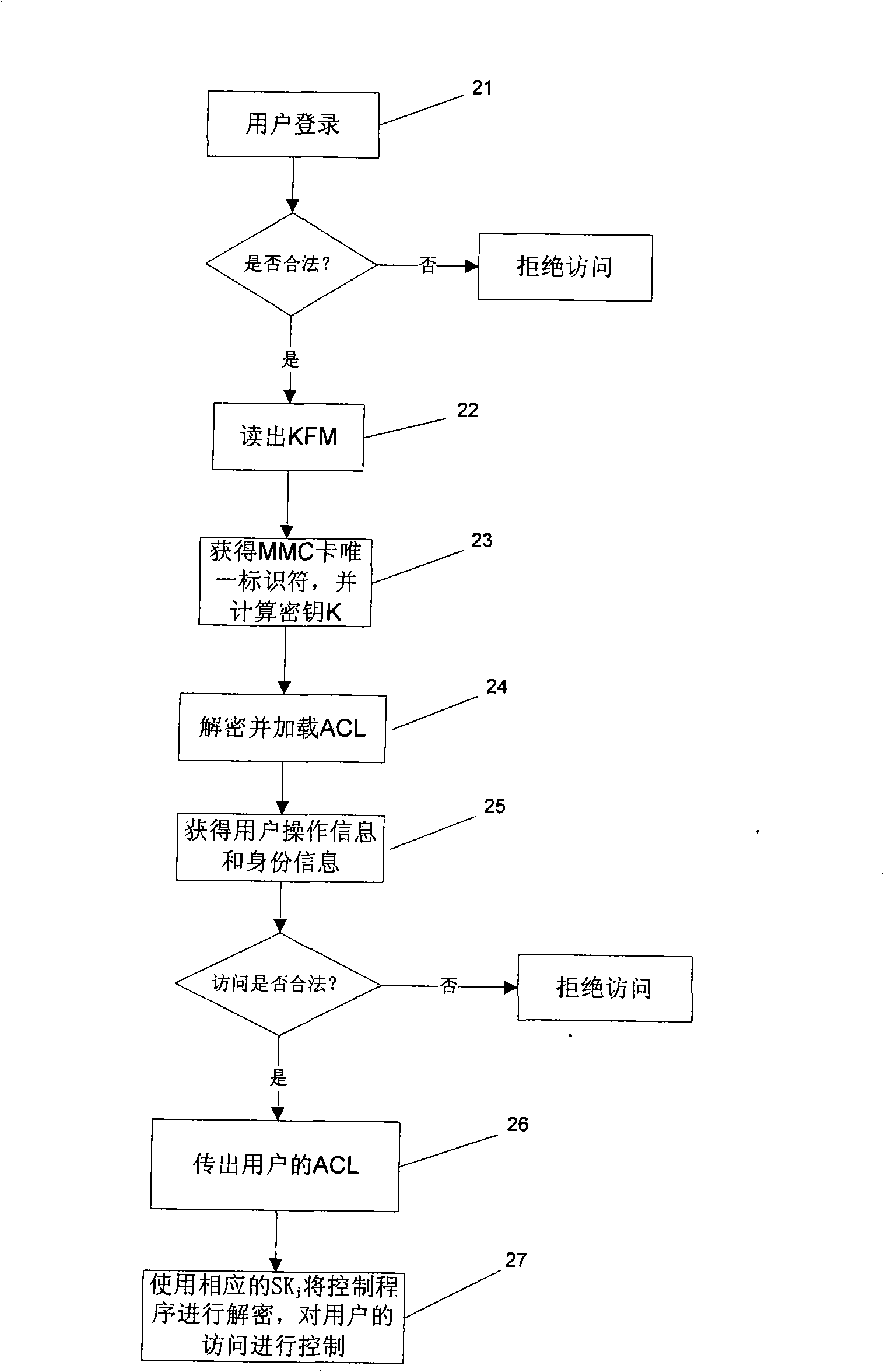

Encryption and decryption method, and PLC system using the same

ActiveCN101329658ASafety protectionImprove protectionUnauthorized memory use protectionDigital data protectionUnique identifierComputer software

The invention relates to the field of industrial computer software safety, in particular to a method for encrypting and decrypting information in a memorizer and a PLC system for applying the method. The encrypting method of the invention comprises the following steps of storing an algorithm F()in the system; mapping the unique identifier of the memorizer into a cipher key K; encrypting the information stored in the memorizer by utilizing the cipher key K based on a symmetric encryption algorithm; and predefining the access strategy based on the user identity in order to control the user's access to the information stored in the memorizer; and storing the access strategy in the memorizer by utilizing the cipher key K based on the symmetric encryption algorithm. During the decryption process, decrypting, information stored in the memorizer is decrypted by utilizing the cipher key K based on the symmetric encryption algorithm, and the access strategy is decrypted by utilizing the cipher key K based on the symmetric encryption algorithm. Then the user's access to the information stored in the memorizer is controlled based on the user identity. The method and the system of the invention have the advantage of being capable of enhancing the safety of software codes.

Owner:SIEMENS CHINA

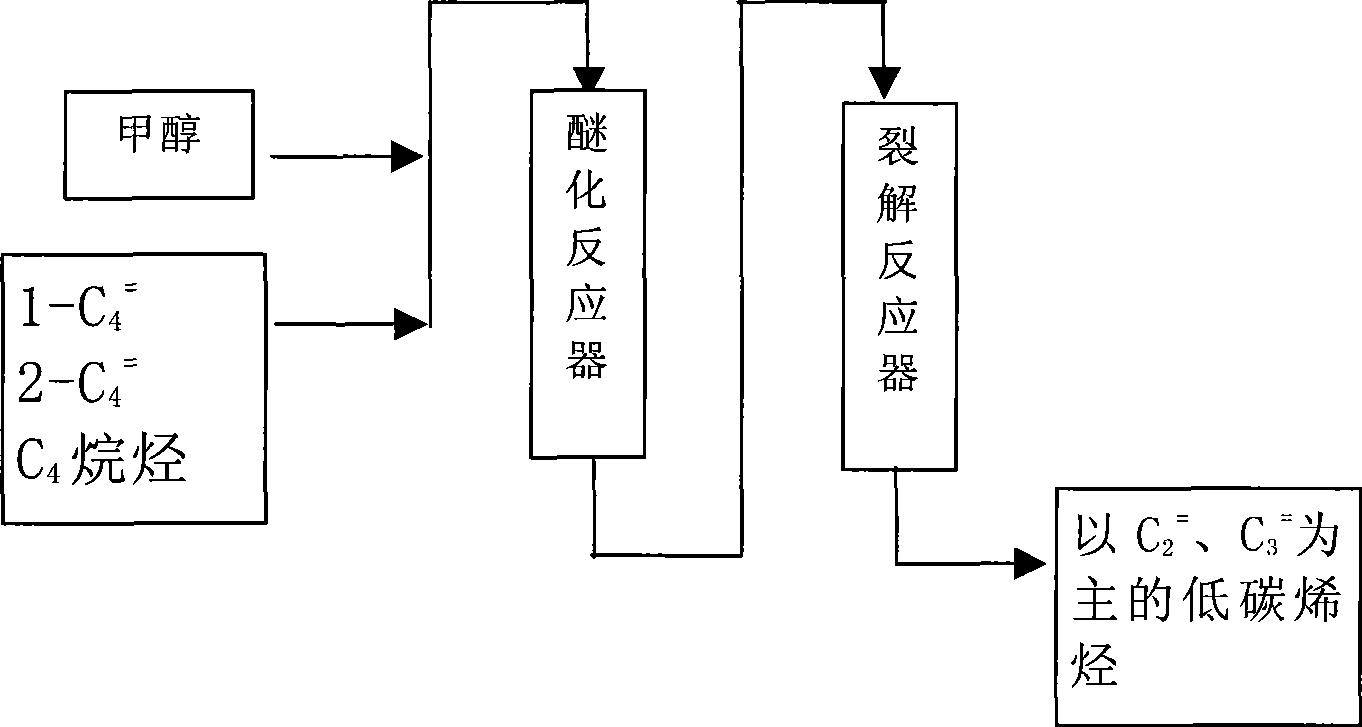

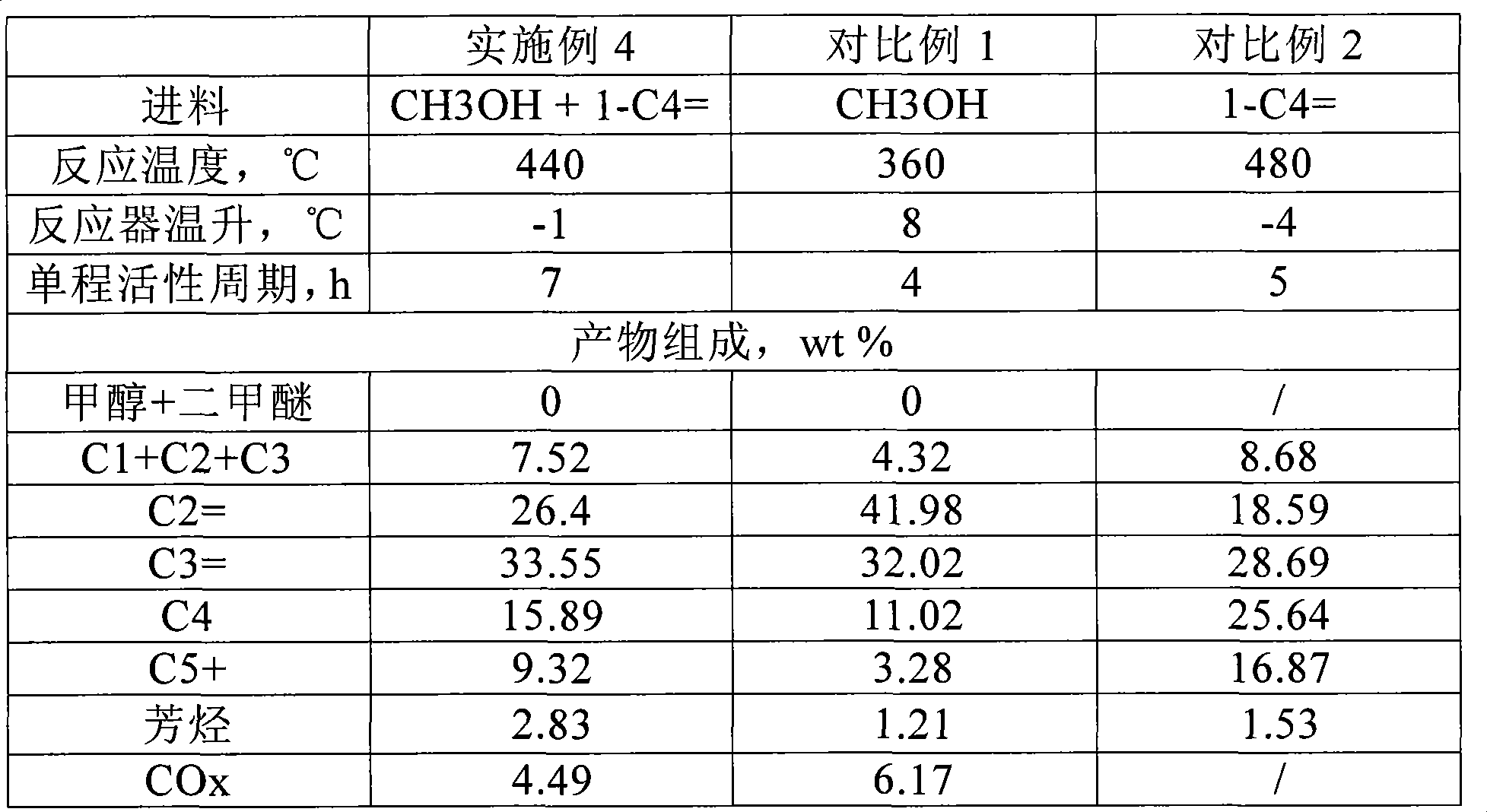

Method for preparing ethylene and propylene by two-step method

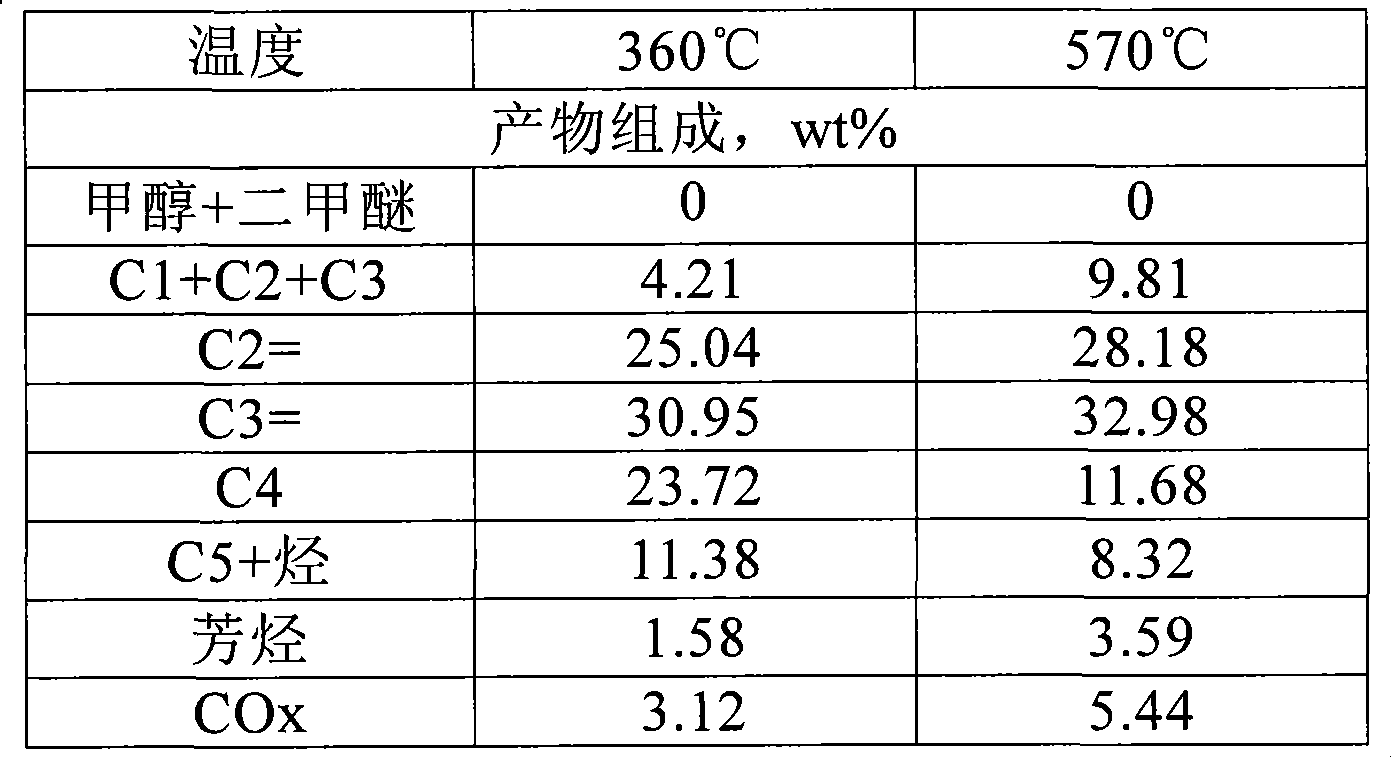

ActiveCN101381272AEasy to crackAchieve crackingHydrocarbon from oxygen organic compoundsEthylene productionAlkeneCracking reaction

The invention relates to a method for preparing ethene and propylene, in particular to a method for preparing the ethene and the propylene by using methanol and alkene with four and more than four carbon atoms as raw materials through a two-step method. The methanol and dimethyl ether used as a first raw material and the alkene with four and more than four carbon atoms used as a second raw materiel carry out etherealization reaction to generate a methyl-alkyl ether compound; and the methyl-alkyl ether compound is cracked to generate the ethene and the propylene. With the method, the cracking reaction is easier to carry out; therefore, at the relatively low temperature, the cracking of the alkene with four and more than four carbon atoms can be realized; simultaneously, the method reduces the hot load of the reaction system and saves energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

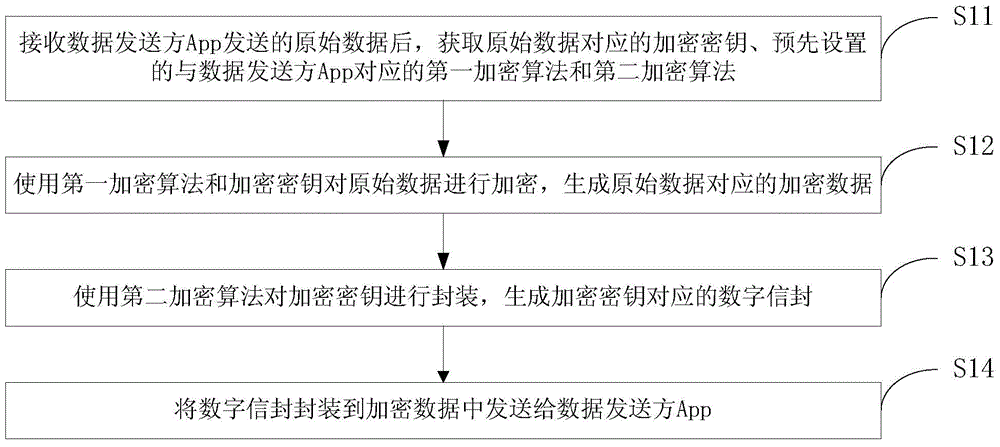

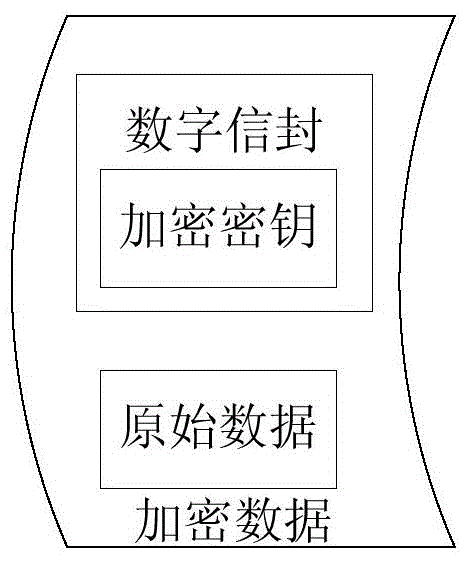

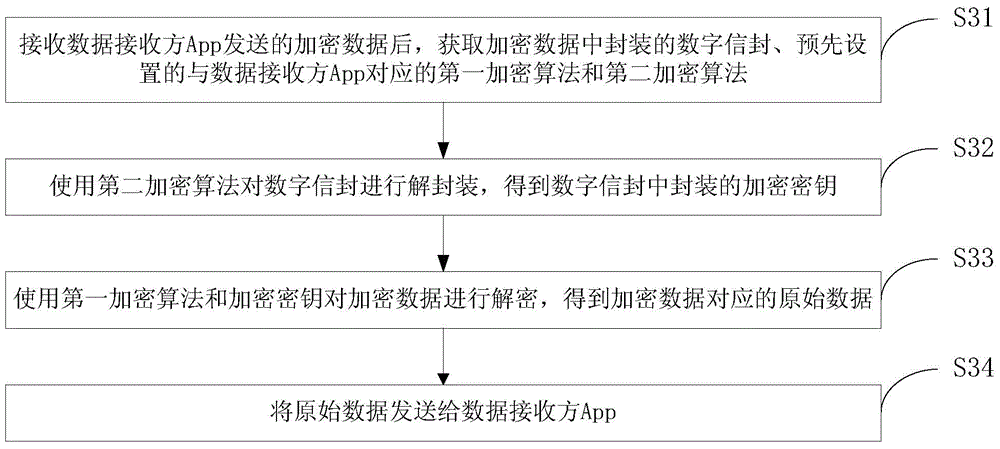

Data encryption method, data decryption method and devices

InactiveCN104580180AImprove securityImprove integrityMultiple keys/algorithms usageTamper resistanceComputer hardware

The embodiment of the invention discloses a data encryption method, a data decryption method, a data encryption device and a data decryption device. The data encryption method comprises the following steps: after receiving original data sent by a data sending party App (Application), acquiring an encryption key corresponding to the original data as well as a first encryption algorithm and a second encryption algorithm which are preset and correspond to the data sending party App; carrying out encryption on the original data by using the first encryption algorithm and the encryption key and generating encrypted data corresponding to the original data; packaging the encrypted data by using the second encryption algorithm and generating a digital envelope corresponding to the encryption key; packaging the digital envelope into the enciphered data to be sent to the data sending party App. According to the scheme, encrypted data interworking among multiple operation systems and among multiple Apps can be realized and safety, integrity and tamper resistance of the data are improved.

Owner:BEIJING BLUE POWER SOFTWARE

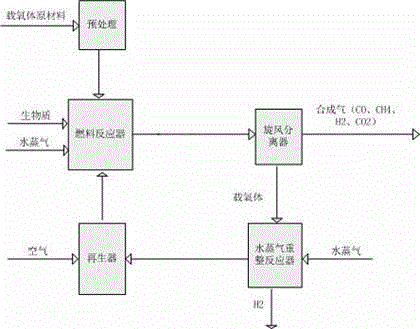

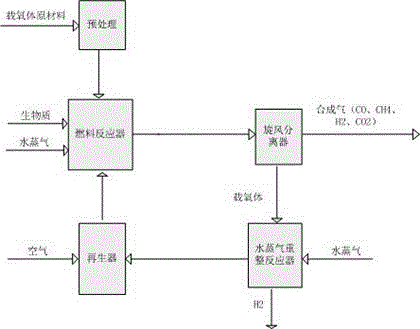

Collaborative process for reforming biomass chemical chains to produce hydrogen and inhibit production of tar

InactiveCN104591087AReduce tar contentReduced tar productionHydrogenProcess engineeringHydrogen production

The invention provides a collaborative process for reforming biomass chemical chains to produce hydrogen and inhibit production of tar. The process mainly using a catalytic cracking reactor, a hydrogen producing reactor and an oxygen carrier regeneration reactor comprises the following steps: firstly mixing biomass with an iron-based compound oxygen carrier; then, carrying out reaction on the mixed raw materials in the catalytic cracking reactor for 20-30 minutes; then, feeding resultants of reaction into a cyclone separator to be separated; discharging synthesis gas from an exhaust opening; further conveying the reduced oxygen carrier in the catalytic cracking reactor into a hydrogen producing reactor to react with steam to prepare hydrogen; and finally, feeding the oxygen carrier after reaction into the oxygen carrier regeneration reactor to continuously and circularly participate in reaction after being oxidized. Compared with the conventional biomass gasification, the collaborative process provided by the invention cooperating a hydrogen production technology by reforming chemical chains with a tar inhibiting technology has the characteristics of low energy consumption, inhibition of tar production and the like. Aiming at biomass with different contents of volatile components, the invention provides two different implementation models.

Owner:CHONGQING UNIV

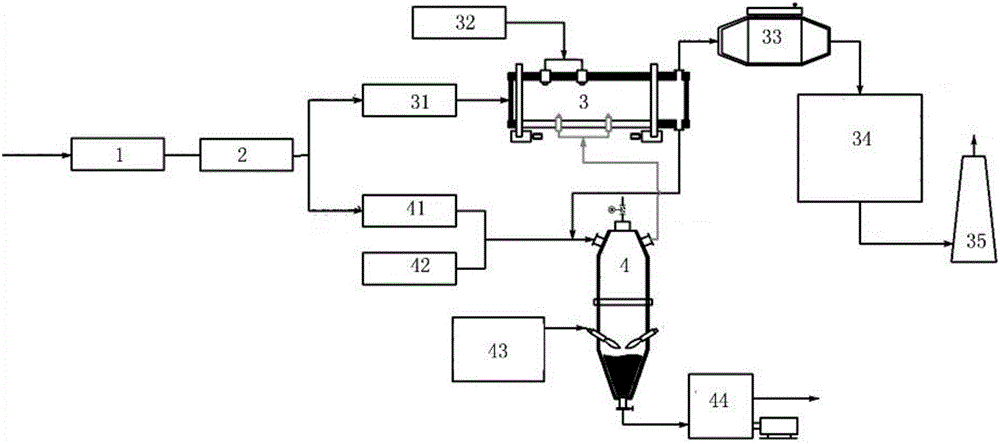

Recycling hazardous waste treatment system and treatment method by synergizing rotary kiln and plasma gasification

PendingCN106642159AImprove operational reliabilityEconomicalIncinerator apparatusHigh energyRotary kiln

The invention relates to a recycling hazardous waste treatment system and treatment method by synergizing a rotary kiln and plasma gasification. The system comprises a hazardous waste storage device, a hazardous waste sorting device, a rotary kiln incinerator, a plasma gasification furnace, a first crushing feeder and a second crushing feeder. The hazardous waste sorting device sorts hazardous wastes in the hazardous waste storage device, and easily handled hazardous wastes are fed into the first crushing feeder and hardly handled hazardous wastes are fed into the second crushing feeder; the first crushing feeder is connected to a feed inlet of the rotary kiln incinerator, and the second crushing feeder is connected to a feed inlet of the plasma gasification furnace. Through a reasonable design, hazardous waste harmless treatment is realized by virtue of technological advantages of the rotary kiln and the plasma gasification, so that the problem of dioxin and heavy metal pollution is avoided. Synthesized gas generated by gasification by the plasma gasification furnace supplements energy required by the rotary kiln, and meanwhile, a high energy utilization ratio of the system is achieved through recovered heat of a waste heat boiler.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

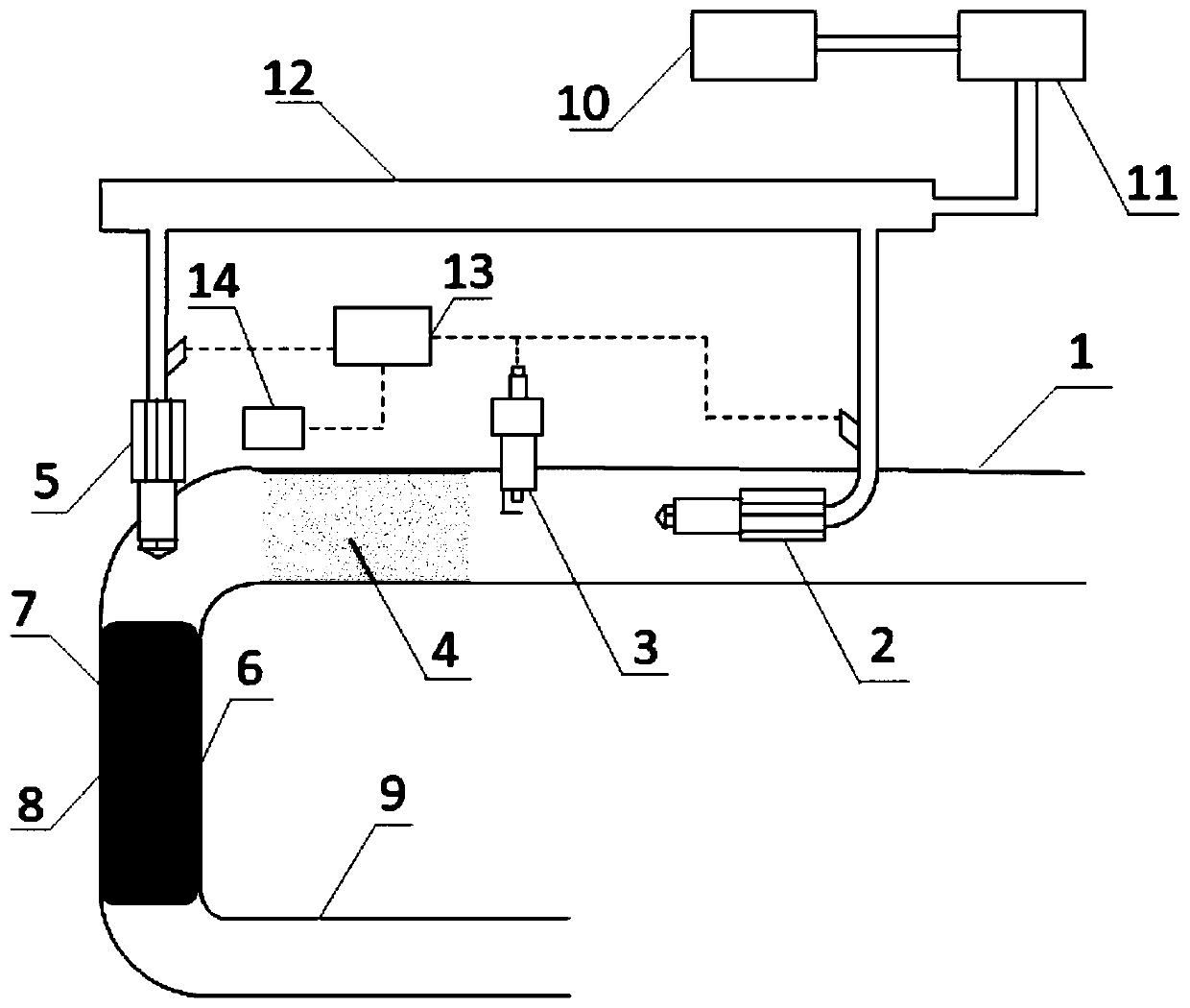

Multi-stage injection methanol engine cold start device and method

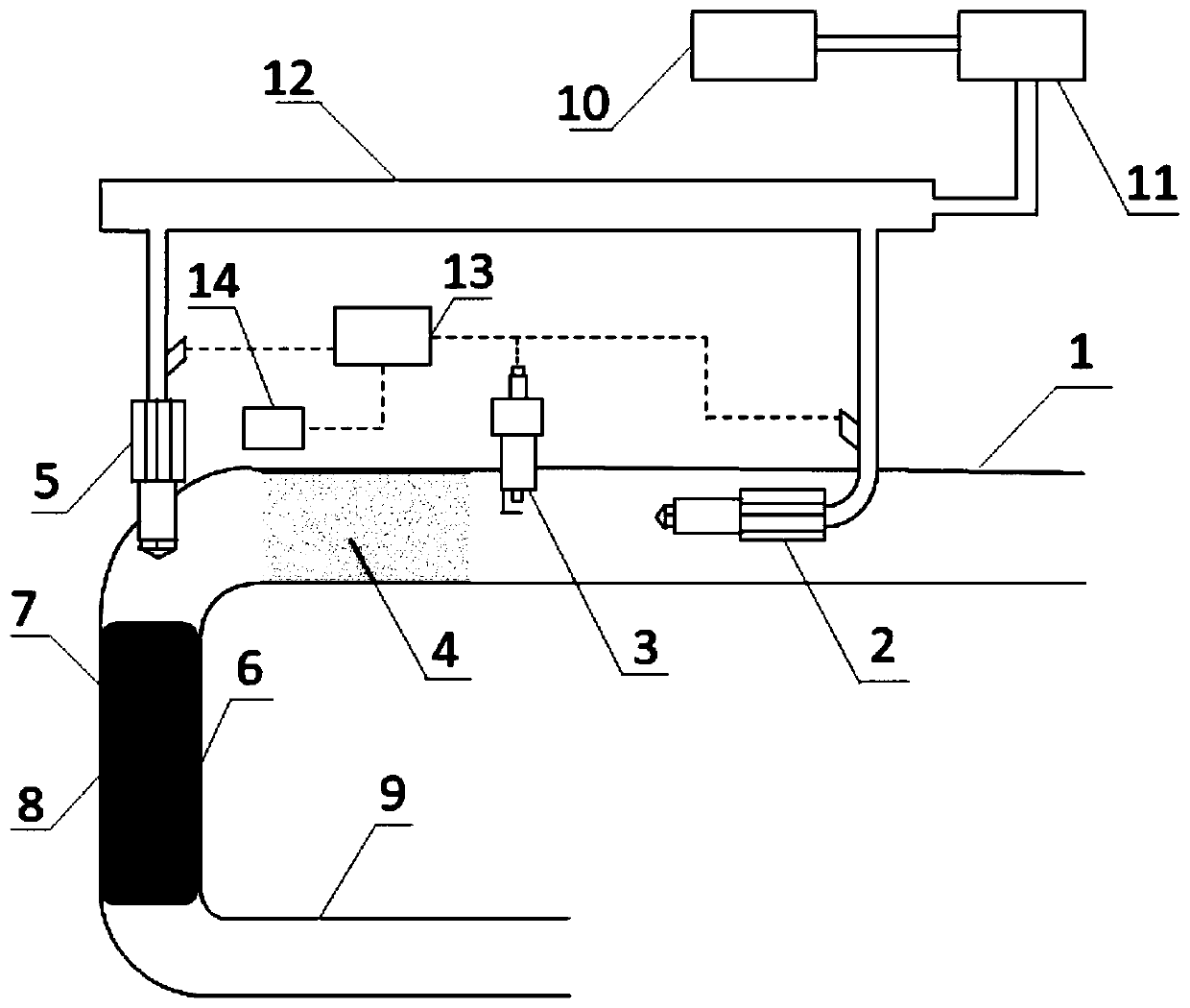

ActiveCN109973266AFast cold startLow ignition energyInternal combustion piston enginesThermal treatment of fuelElectricityCombustion chamber

The invention belongs to the field of methanol engine cold start, and discloses a multi-stage injection methanol engine cold start device and method. The device comprises a methanol evaporation and cracking module and a methanol multi-stage injection and ignition module, the methanol evaporation and cracking module comprises a first air inlet passage, a combustion chamber, an evaporation and cracking chamber and an exhaust pipe which are sequentially connected, and the methanol multi-stage injection and ignition module comprises a methanol box, a methanol high-pressure oil rail, a methanol pump, a first-stage methanol injector, a second-stage methanol injector, a sparking plug and a controller. The invention further discloses a multi-stage injection methanol engine cold start method. Methanol cracking gas can be prepared under the condition of low ambient temperature by multi-stage methanol injection and single ignition under the condition of cold start, and the methanol cracking gas and the uncracked methanol gas are introduced into an engine together to realize rapid cold start of the pure methanol engine. The device has the advantages of being high in stability, low in electricity consumption and easy to produce in an industrialized mode.

Owner:HUAZHONG UNIV OF SCI & TECH

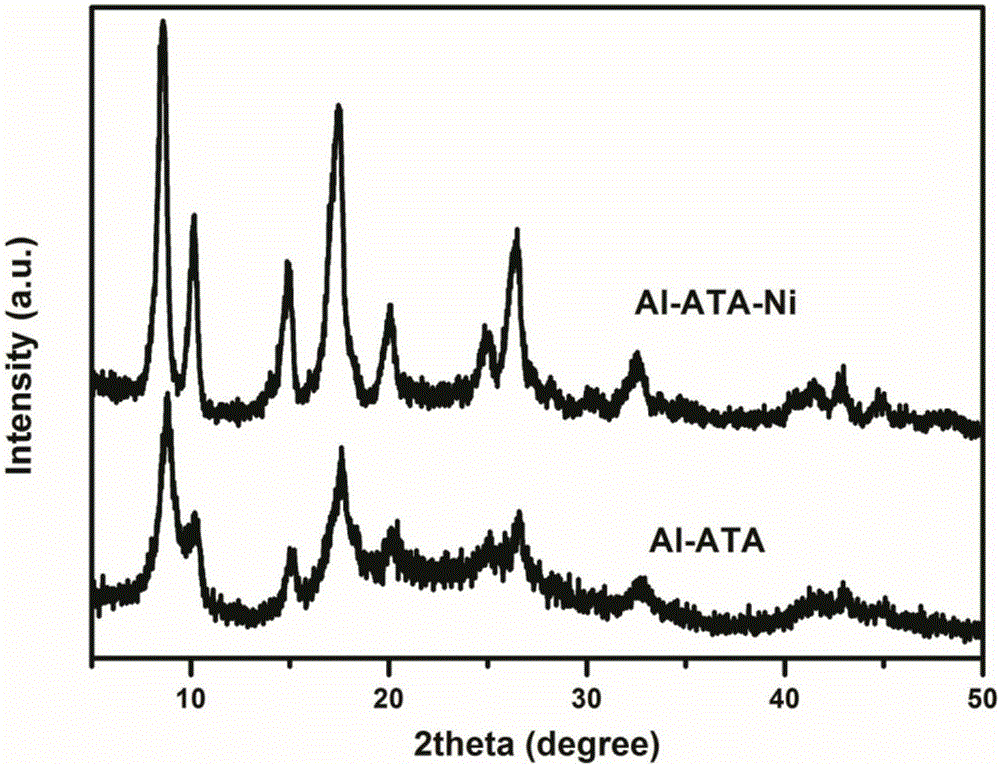

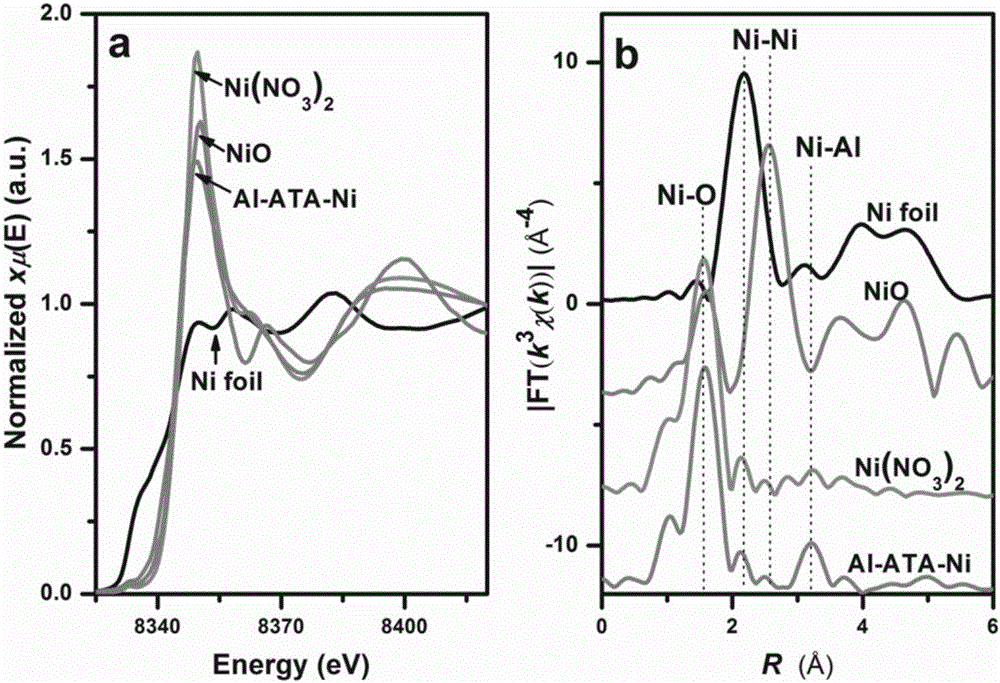

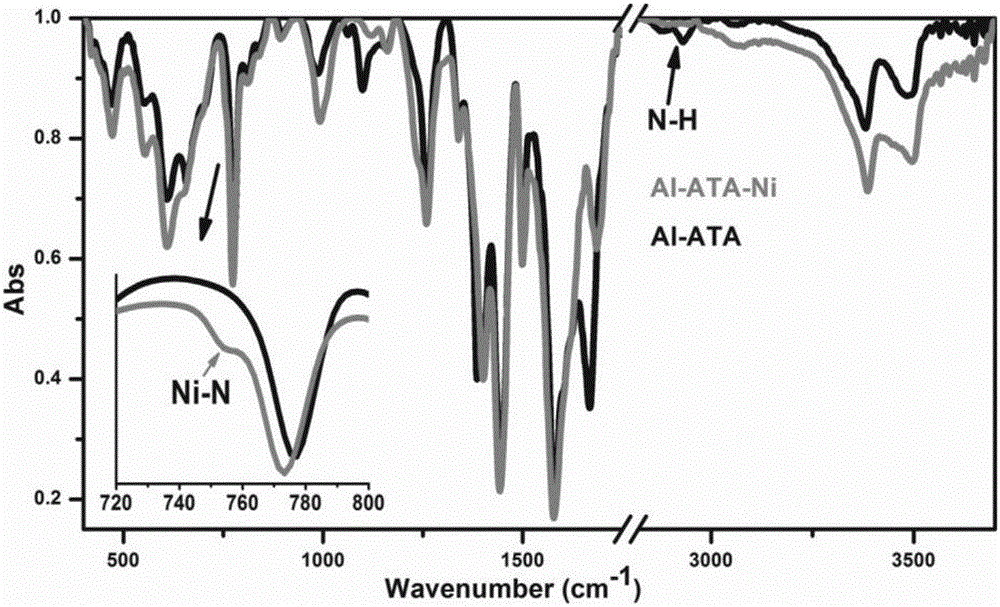

Metal organic frameworks (MOFs) material capable of photocatalyzing water cracking and preparation method thereof

InactiveCN106824279AAchieve crackingSimple methodOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionSolventChemistry

The invention discloses a preparation method of a metal organic frameworks (MOFs) material capable of photocatalyzing water cracking and an MOFs material prepared by the method. The technical scheme is as follows: the method comprises the following steps: dispersing amino-containing MOFs in an organic ligand into a solvent, adding a transition metal soluble salt, stirring uniformly, reacting for 90-100 hours, filtering, washing, and drying. Since the amino group contained in the organic ligand in the MOF material can be easily coordinated with metal ions, the transition metal ions with catalytic activity are introduced into the MOFs system in a monatomic dispersion mode, thereby implementing photocatalytic water cracking to simultaneously generate hydrogen and oxygen under the condition of no sacrifice agent. The preparation method is simple, has the advantages of wide reaction raw material sources and operable experimental steps, has universality and potential design study prospects, and can implement mass production.

Owner:SHANDONG UNIV

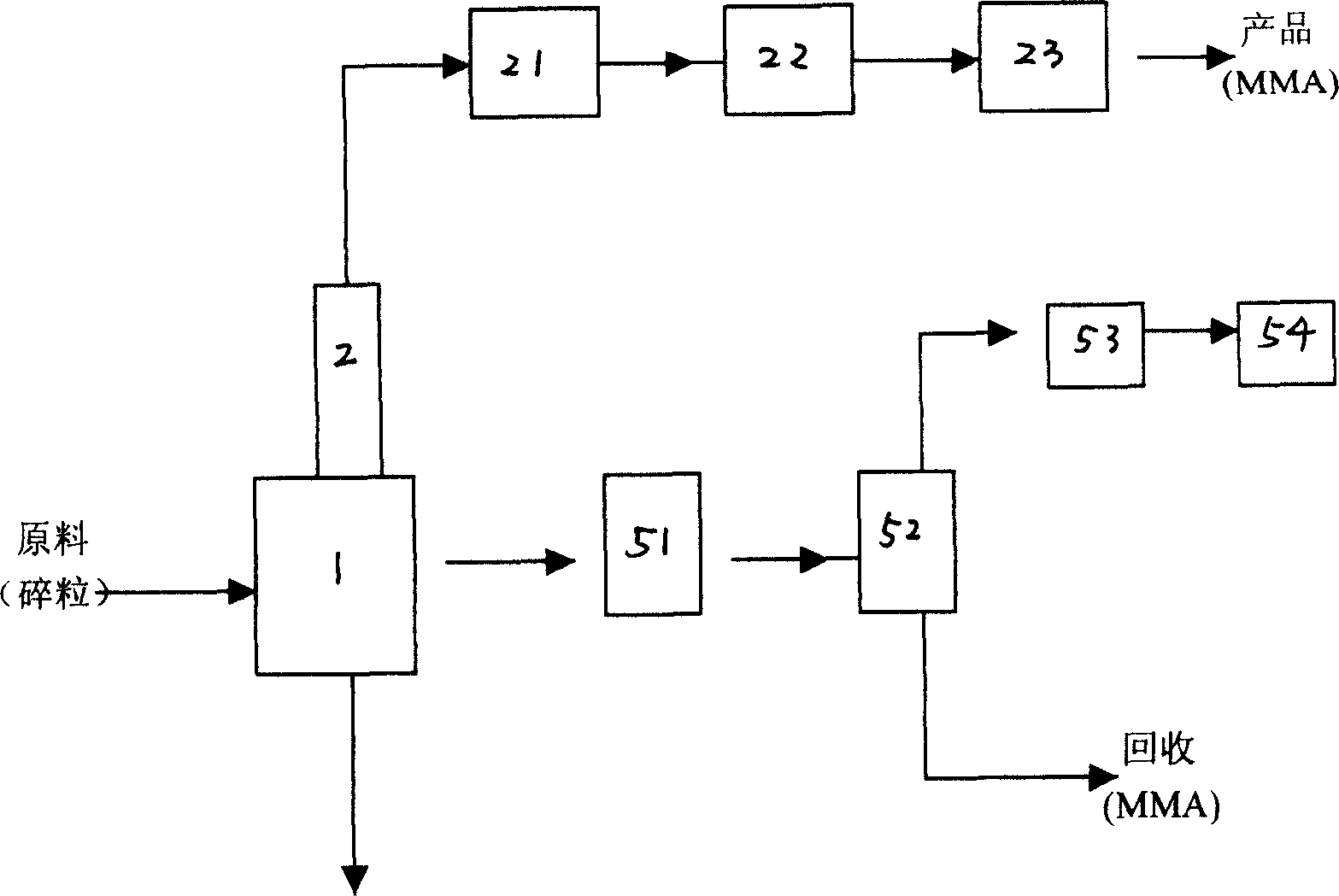

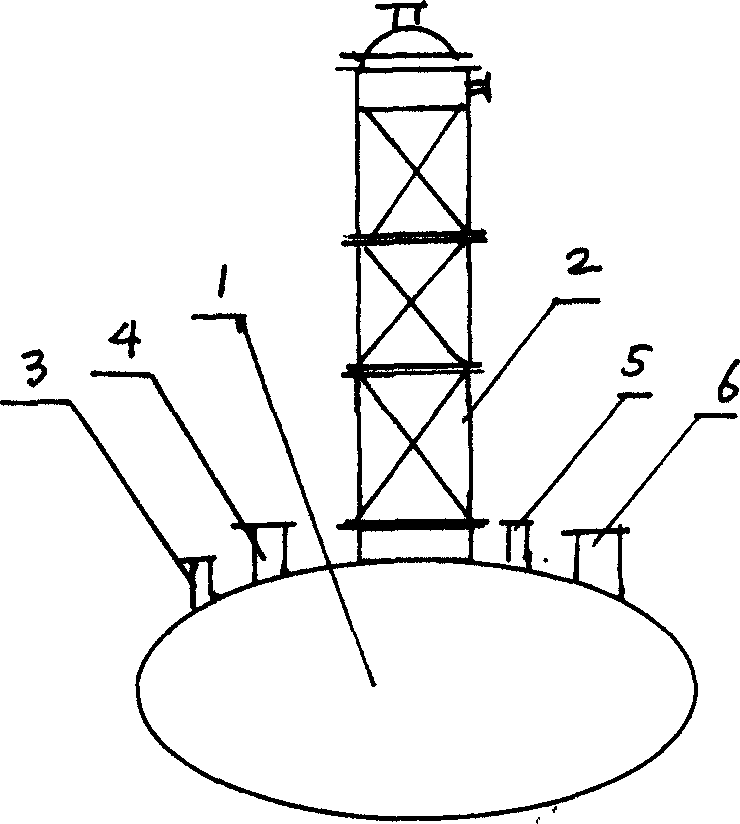

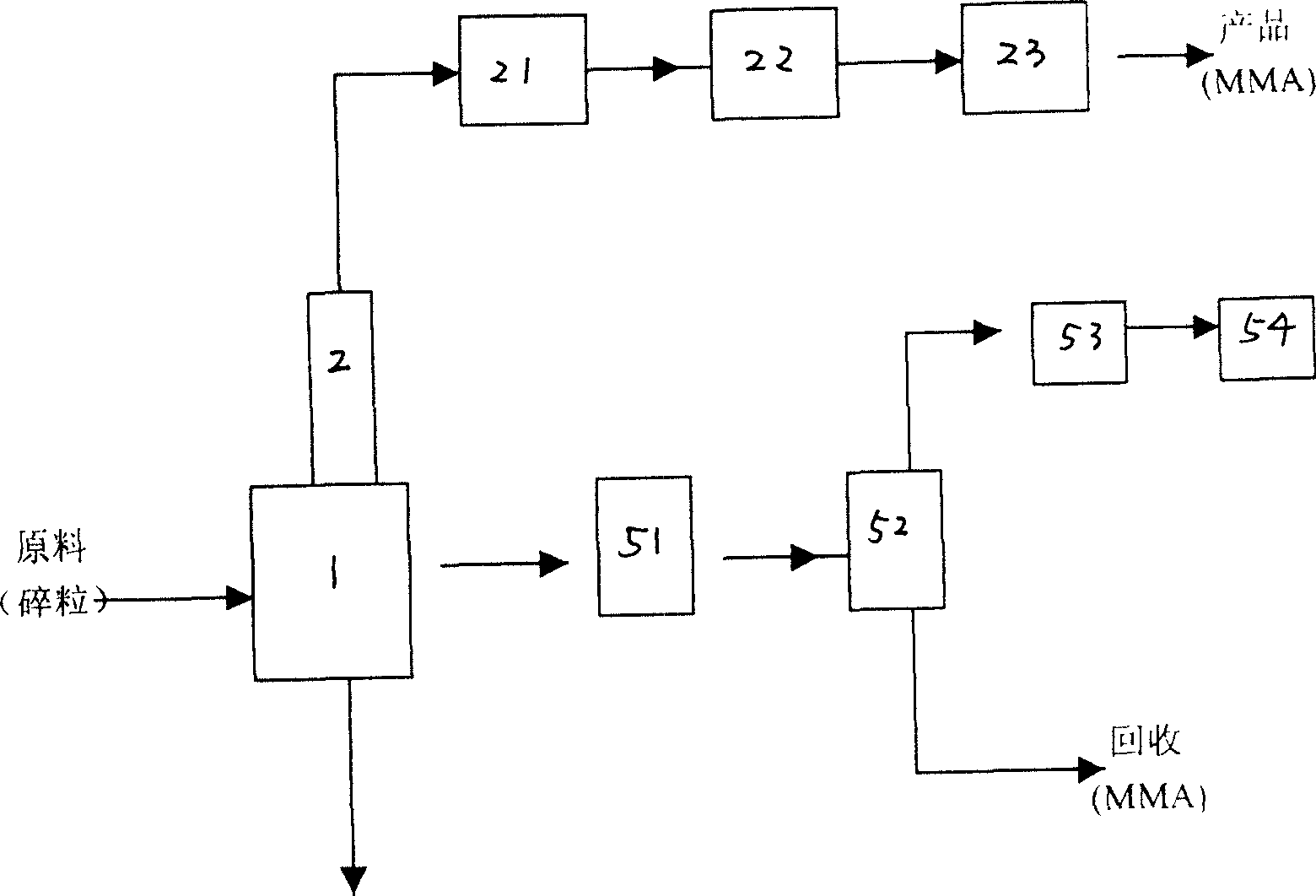

Process of preparaing methyl acrylate by waste organic glass and apparatus thereof

InactiveCN1560021AAdvanced equipment and process parametersHigh yield and purityOrganic compound preparationCarboxylic acid esters preparationMethyl methacrylateEngineering

The invention relates to a technique of preparing methyl methacrylate (MMA) by waste organic glass and its device, disclosing a semicontinuous cracking method and an integrated cracking and distilling device. It implements a technique of combining cracking and distilling and the technical courses: crushing the waste organic glass, adding the made glass particles in cracking kettles continuously, orderly and properly, temperature range 140-380 deg.C, as the glass particles reaches a certain quantity, stopping feeding and making final-period cracking and processing, where the average time of cracking and distilling in each a kettle in a cycle (by 1000 kg raw material) is 5-7 hours. On at 140 deg.C can it generate cracked MMA; the MMA product at 140-280 deg.C is dehydrated and becomes a transparent and clear liquid; the MMA purity is 97-99% and the MMA yield is 85-92%.

Owner:廖活强

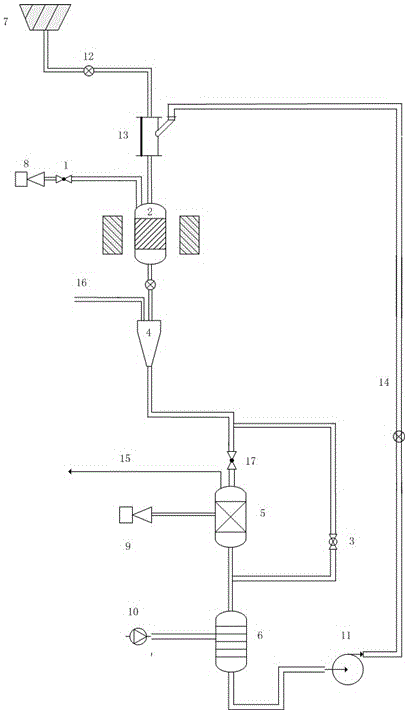

Oily sludgestepwisecontinuous pyrolysis and energy supplying integration method and device

InactiveCN106430892AAchieve emission standardsAchieve energy recoveryWater contaminantsSludge treatment by pyrolysisGas phaseSludge

The invention relates to an oily sludgestepwisecontinuous pyrolysis and energy supplying integration method and device, and belongs to the technical field of organic matter pyrolysis. The oily sludgestepwisecontinuous pyrolysis and energy supplying integration method includes the steps of 1 primary pyrolysis, wherein oily sludge enters a primary pyrolysis device to carry out pyrolysis; 2 secondary pyrolysis, wherein pyrolysis oil gas enters a secondary pyrolysis device to carry out pyrolysis; 3 spray and gas-liquid separating, wherein gas and liquid phases are separated through spraying; 4 gas drying and combusting. The gas phase enters a gas drying device, and the dried gas can serve as a clean energy source to heat the primary pyrolysis device. The oily sludgestepwisecontinuous pyrolysis and energy supplying integration device comprises the primary pyrolysis device, the secondary pyrolysis device, a spray tower, an oil-water separating device, the gas drying device and a combustion device, and the combustion device and the primary pyrolysis device are arranged oppositely. The oily sludgestepwisecontinuous pyrolysis and energy supplying integrationdevice has the advantages that multi-level pyrolysis is adopted, energy can be controlled by the pyrolysis devices themselves, and energy can be used efficiently.

Owner:中海油能源发展股份有限公司北京安全环保工程技术研究院 +2

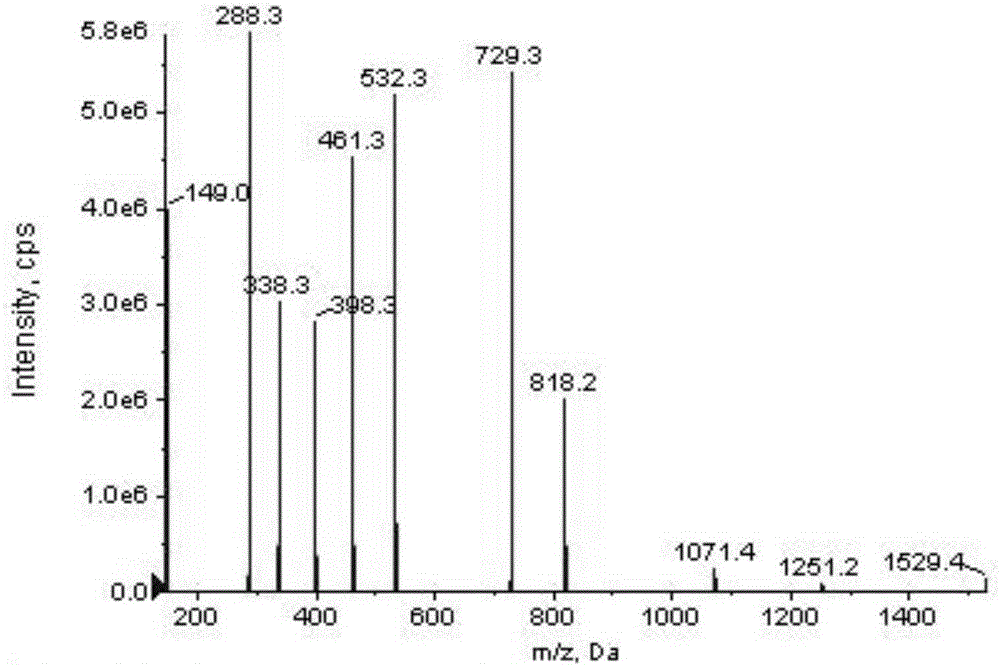

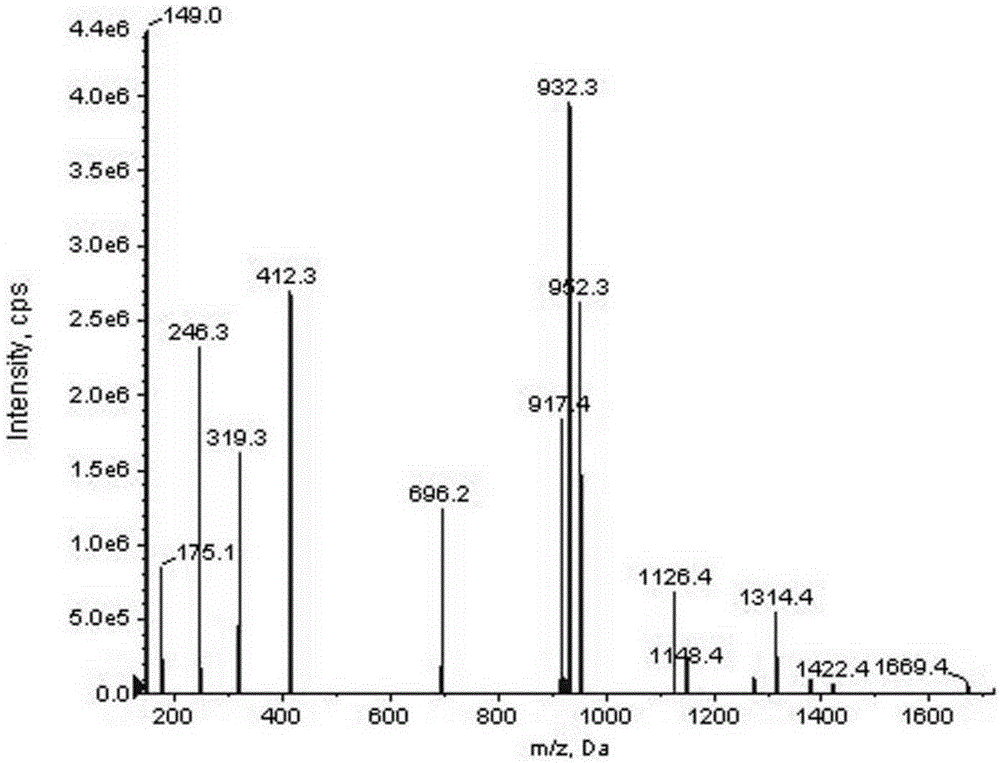

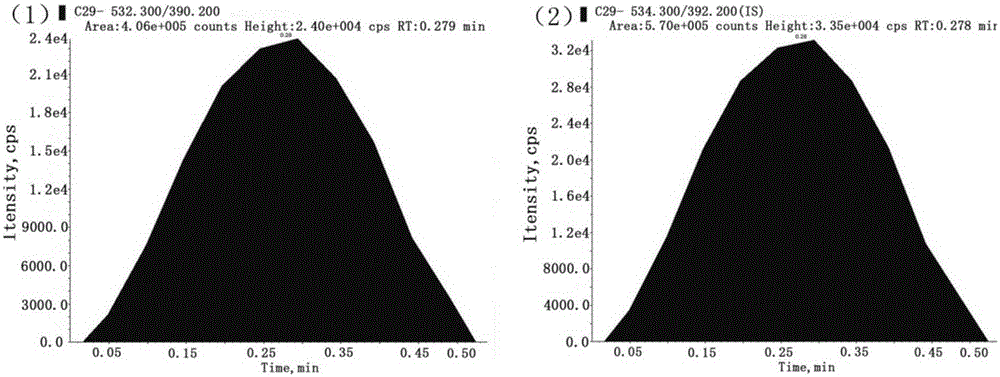

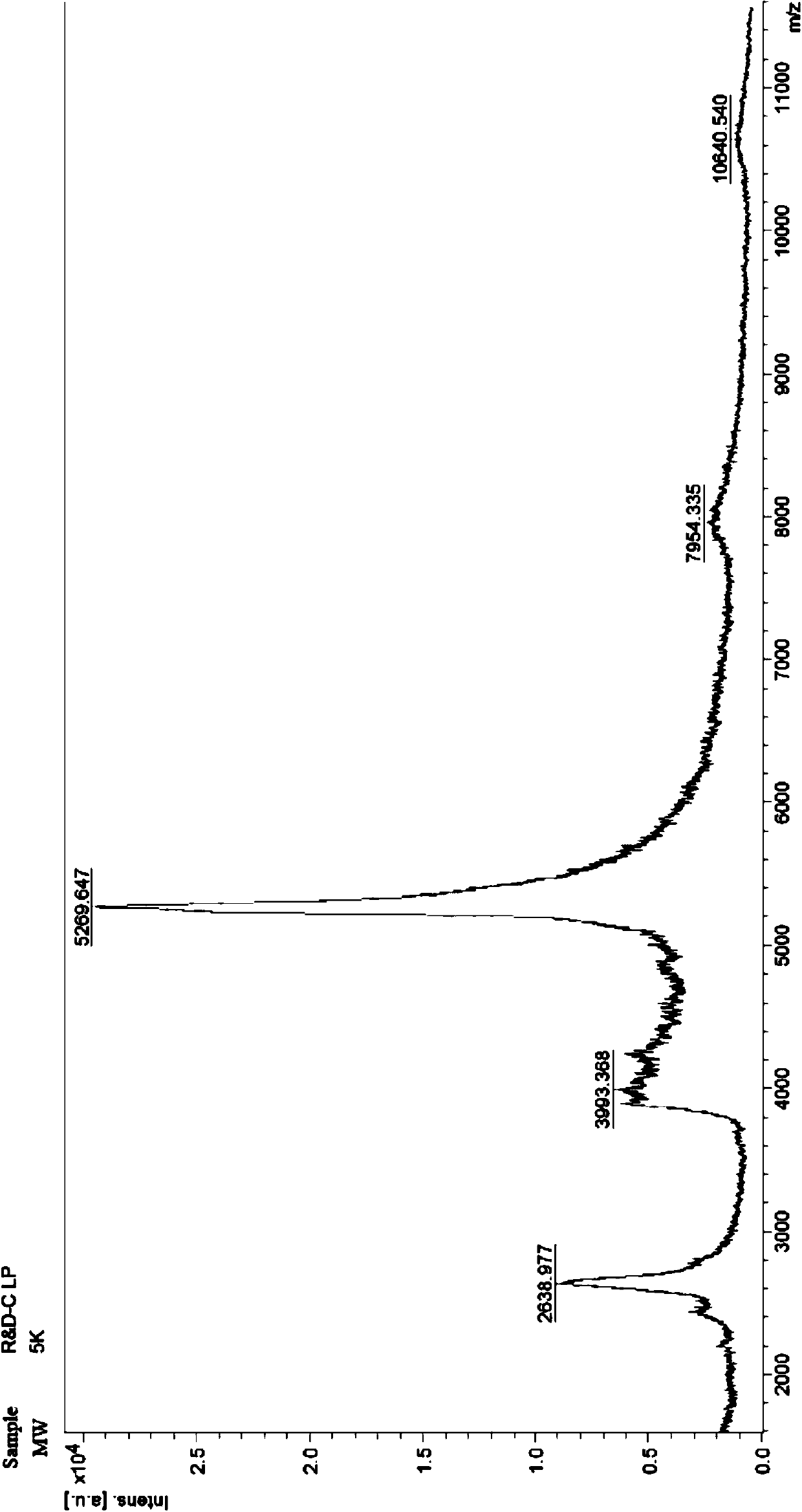

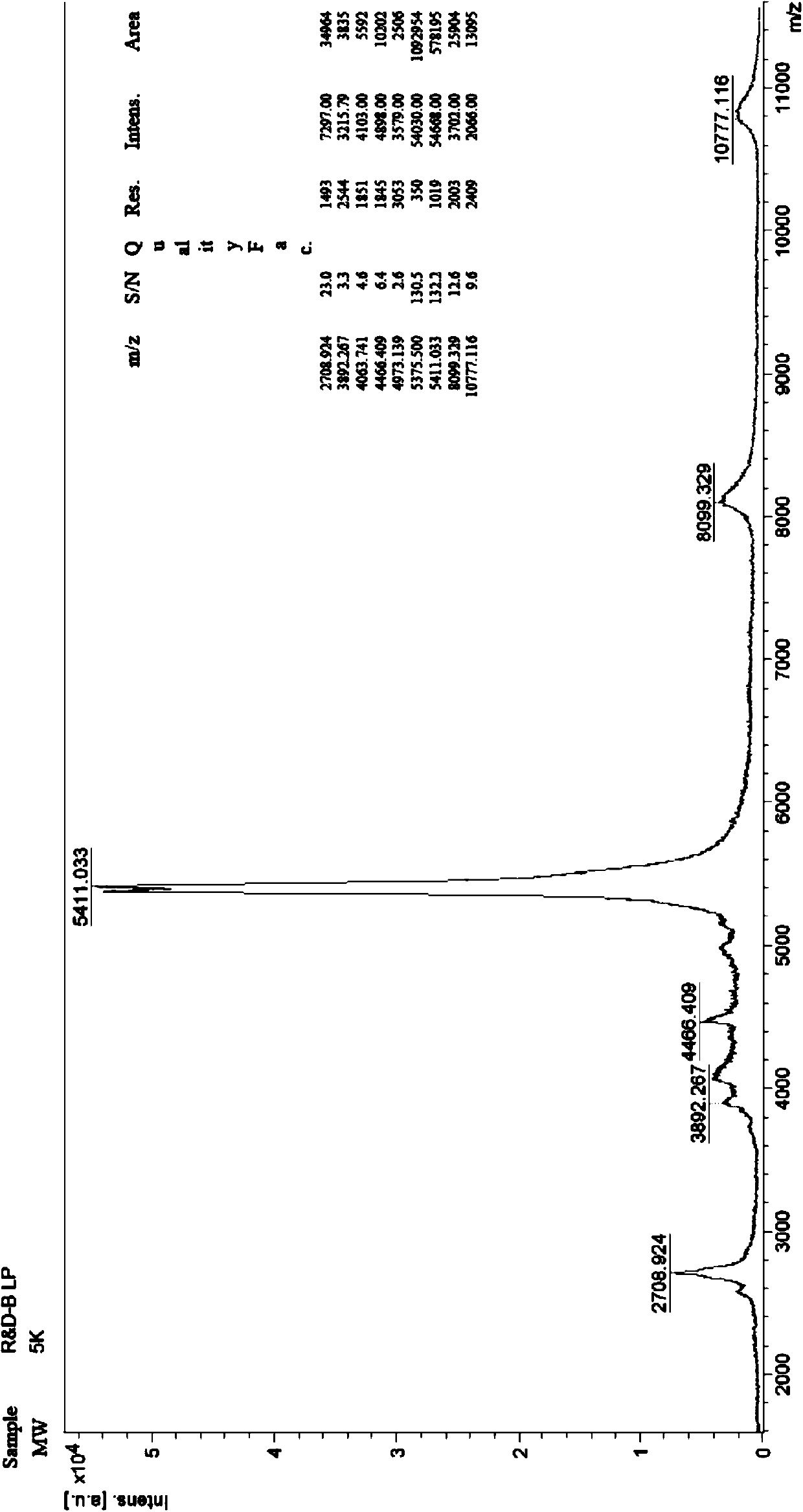

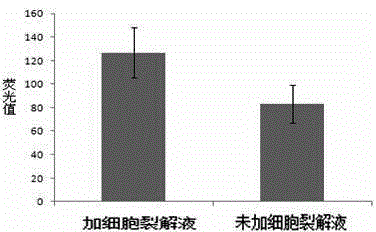

Method of determining ratio of globin chain alpha to globin chain beta in hemoglobin and application thereof

ActiveCN105223290AConvenient for long-term storage and long-distance transportationLow costComponent separationMass spectrum analysisHemoglobin F

The invention belongs to the field of biological chemical detection and particularly relates to a method of determining the ratio of a globin chain alpha to a globin chain beta in hemoglobin and application of the method in detection of beta-mediterranean anemia. The method comprises the steps that hemoglobin samples are taken and split to obtain split fragments of the globin chain alpha and split fragments of the globin chain beta; one split fragment of the globin chain alpha and one split fragment of the globin chain beta are selected and used as sign peptide fragments; a mass spectrum is used for determining the concentration of the sign peptide fragment of the globin chain alpha and the concentration of the sign peptide fragment of the globin chain beta; the ratio of the globin chain alpha to the globin chain beta is expressed just by the ratio of the concentration of the sign peptide fragment of the globin chain alpha to the concentration of the sign peptide fragment of the globin chain beta. According to the method, by means of quantitative analysis of the ratio of the globin chain alpha to the globin chain beta, different types of beta-mediterranean anemia can be identified at an early stage, and severe, medium and mild beta-mediterranean anemia can be identified.

Owner:CHILDRENS HOSPITAL OF CHONGQING MEDICAL UNIV

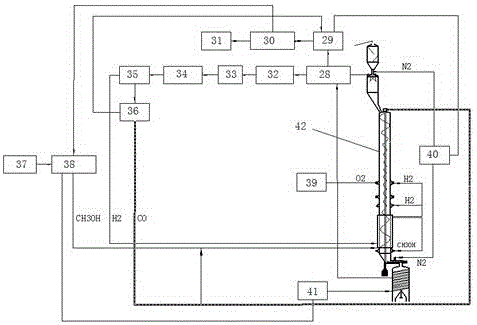

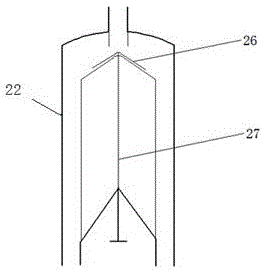

Equipment and process using methanol splitting decomposition to produce direct reduced iron

ActiveCN106521074AImprove utilization efficiencyNo pollution in the processShaft furnaceHigh carbonDecomposition

The invention discloses equipment and a process using methanol splitting decomposition to produce direct reduced iron and belongs to the technical field of production equipment and the process of reduced iron. The equipment and the process are used for using methanol splitting decomposition to produce the direct reduced iron. According to the technical scheme, a gas based reduced vertical furnace is the main body of the equipment, and the gas based reduced vertical furnace comprises a lifting machine, a material storehouse, a tail gas separating storehouse, a reduction pipe, a spiral material conveying mechanism, a methanol splitting decomposition pipe, gas combustors, a methanol heat exchanging box body, a hydrogen heat exchanging box body and a cooling tank. Methanol enters the methanol splitting decomposition pipe through a methanol vaporizer and the methanol heat exchanging box body; the reduced iron is used as a catalyst to achieve complete splitting decomposition, and then reducing agents including carbon monoxide and hydrogen are produced; the methanol and the nitrogen, slight methane and carbon monoxide constitute an adjustable carburizing atmosphere to product high-carbon reduced iron; and meanwhile, near zero emission of carbon dioxide is achieved. The methanol is used as the raw material of the gas based reduced vertical furnace to produce the high-carbon reduced iron, the combination of coal chemical industry and the direct reduced iron is achieved, so that a new path for replacing natural gas to produce the high-carbon reduced iron is developed.

Owner:石家庄水盼节能科技有限公司

Continuous unicellular inclusion analyzing method based on microflow control chip platform

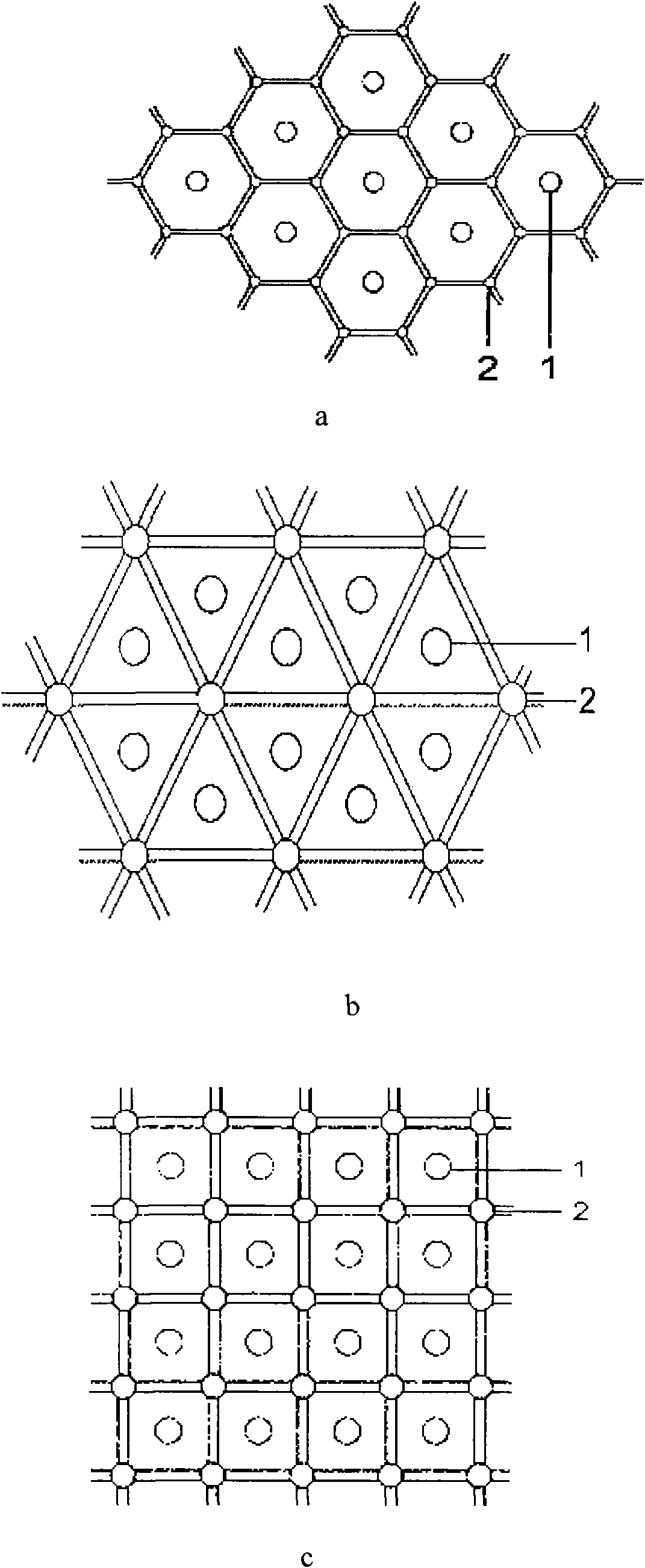

InactiveCN1548546ARealize continuous samplingAchieve crackingMicrobiological testing/measurementCapillary electrophoresisElectrophoresis

The continuous unicellular inclusion analyzing method based on microflow control chip platform features that in the cross passage microflow control chip as operation platform, after the buffering liquid with cell dividing agent and screening agent is added into buffering pool and the cell liquid is added into the cell pool, voltage is applied between the buffering pool and the waste liquid pool, so that single cell is introduced into the horizontal passage to contact with the cell dividing agent and divided and the released inclusion migrates directionally under the action of electric field to complete the electrophoresis. The method of the present invention may be used in continuous single cell sampling and cracking, and in analyzing intercellular nucleic acid, protein, amino acid, saccharide and other matters in relatively high flux and relatively simple process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

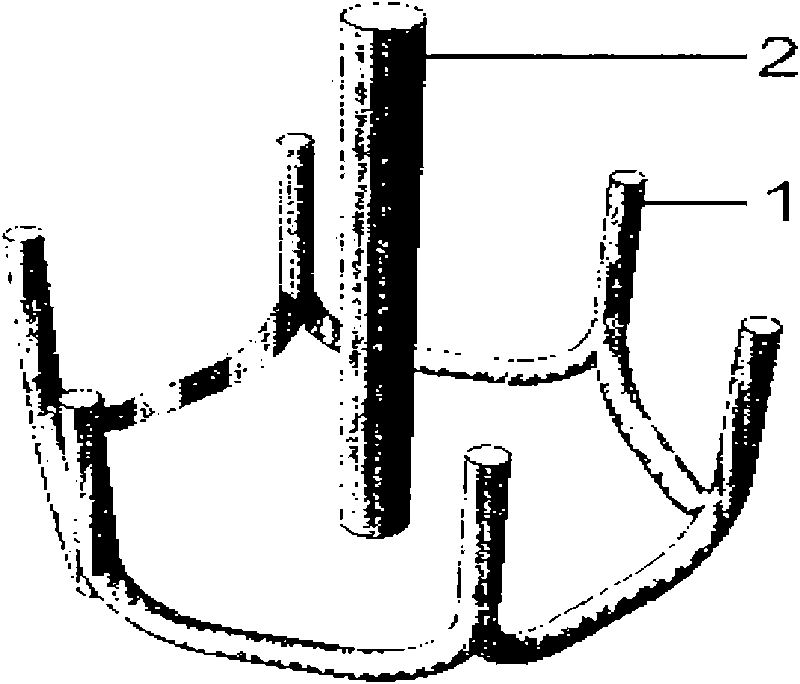

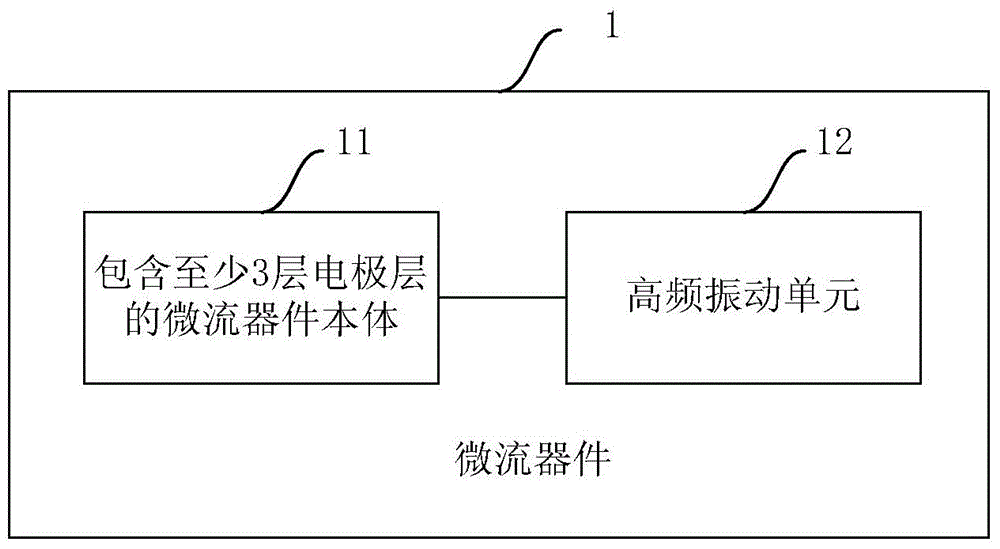

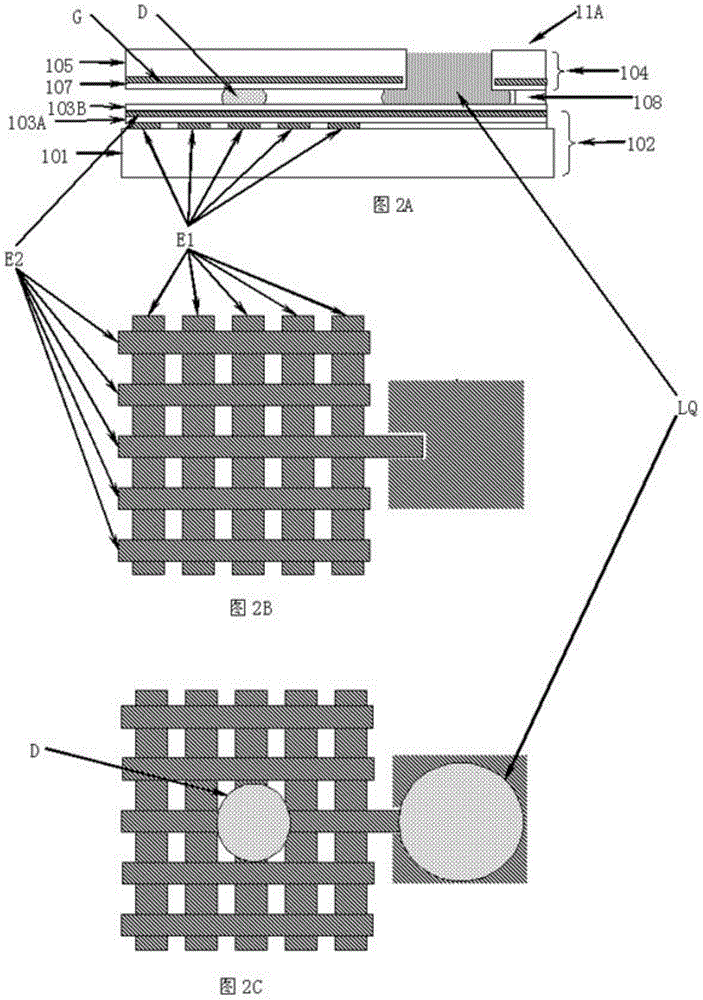

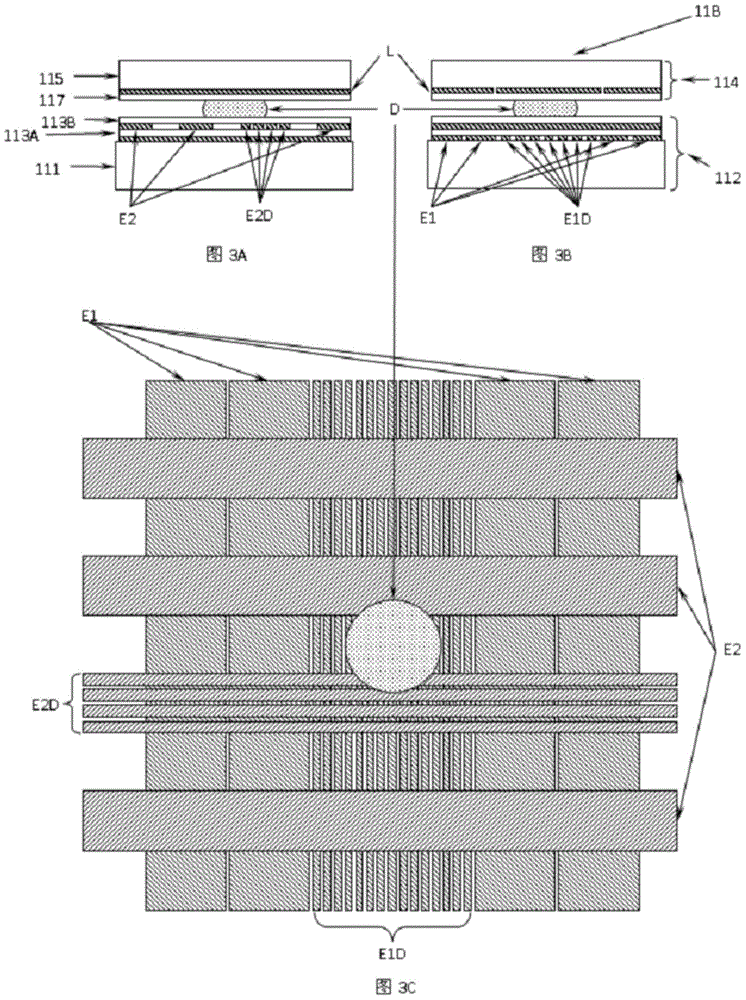

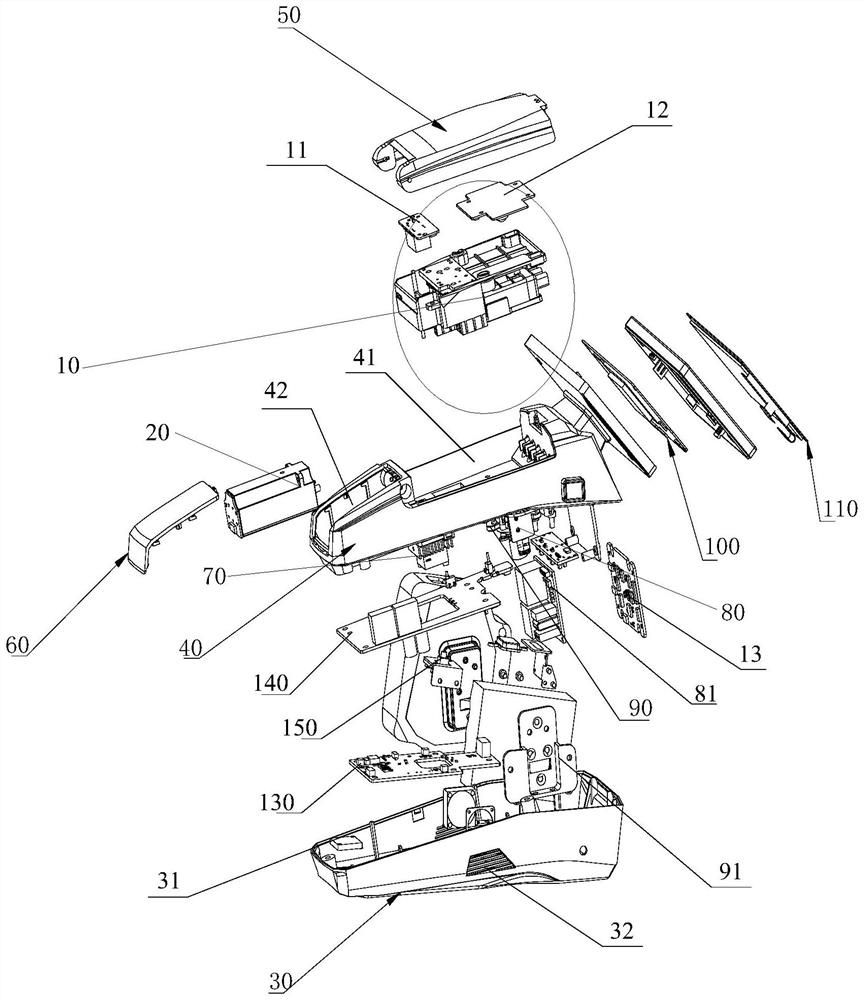

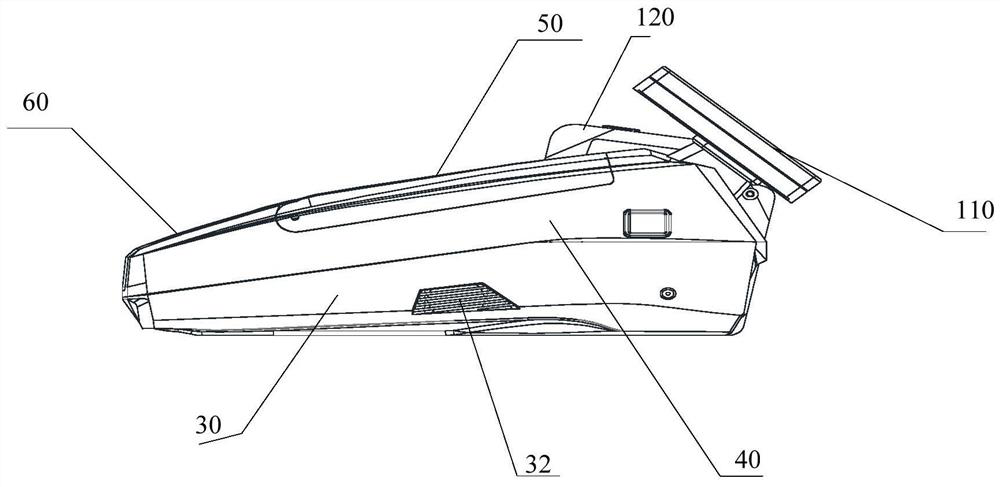

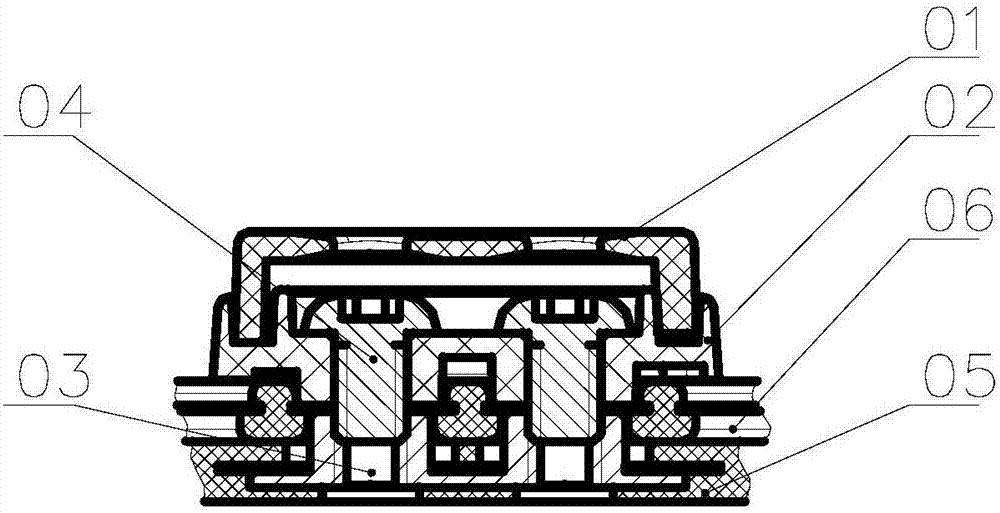

A microfluidic device with high-frequency vibration processing

ActiveCN104588136AAchieve crackingReduce surface adhesionLaboratory glasswaresSmall fragmentTransducer

A microfluidic device with high-frequency vibration processing is provided. The microfluidic device at least comprises a microfluidic device main body, and a high-frequency vibration unit disposed at a position corresponding to the microfluidic device main body, wherein the microfluidic device main body comprises at least three electrode layers, a plurality of the electrode layers are on a first substrate, and the one left of the electrode layers is on a second substrate opposite to the first substrate, the electrode layers are separated by dielectric layers, and the high-frequency vibration unit comprises a signal generator used for generating high-frequency vibration signals and a transducer used for converting the high-frequency vibration signals generated by the signal generator into mechanical energy. The microfluidic device perform treatments for samples, such as treatments of reducing surface adhesion of particles, uniformly dispersing aggregated particles, accelerating sample mixing, cutting DNA into small fragments, achieving cell lysis, and the like.

Owner:吴传勇 +1

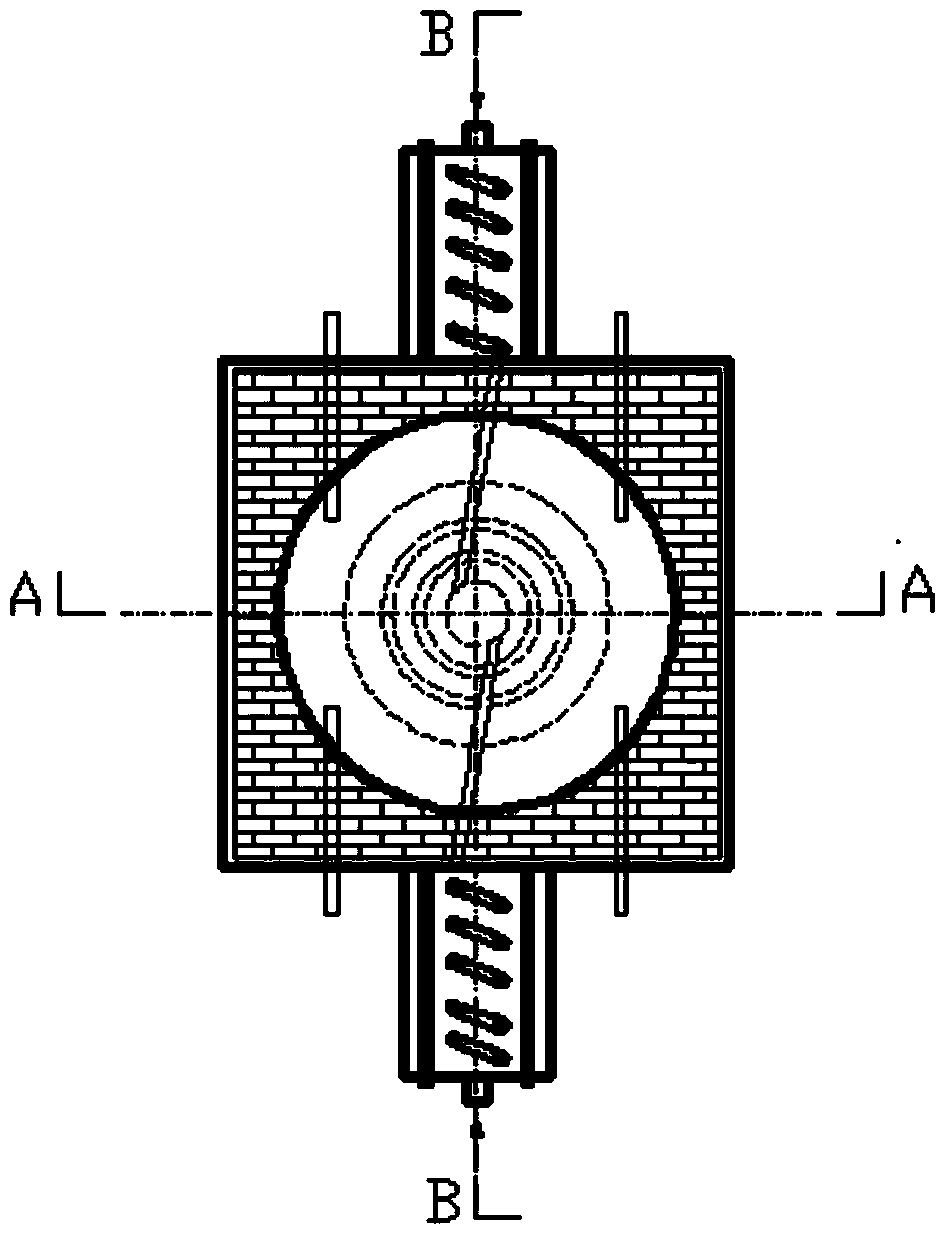

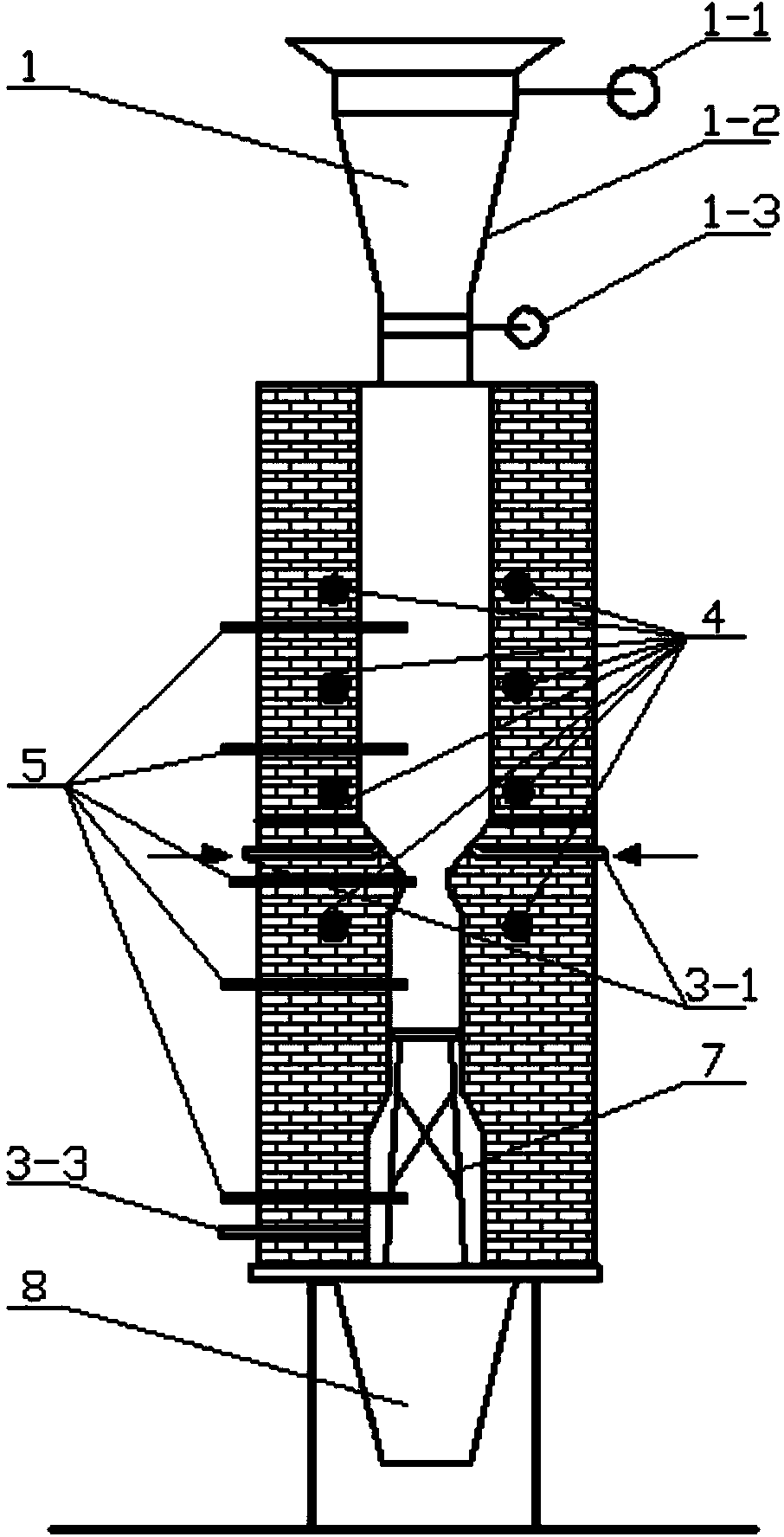

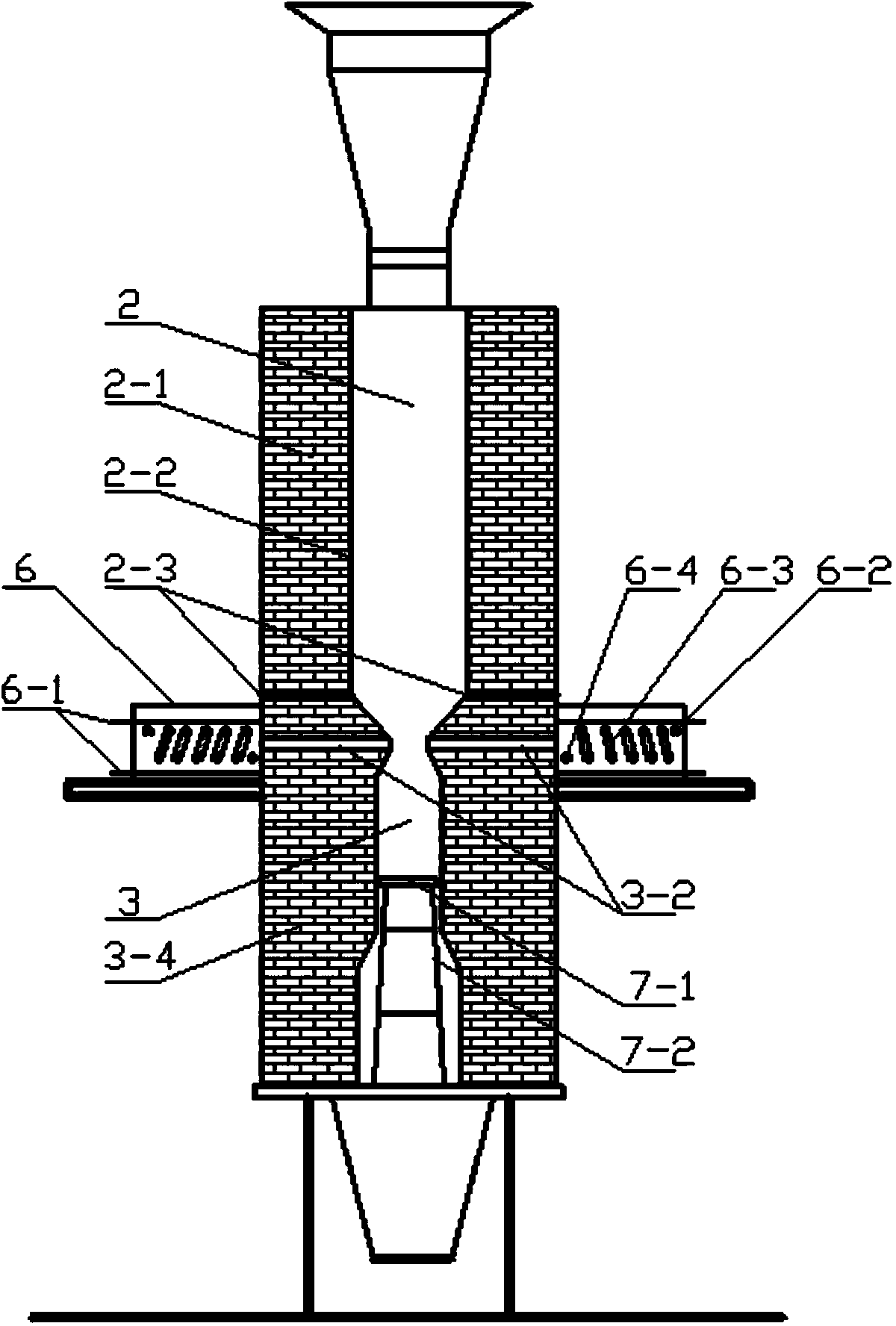

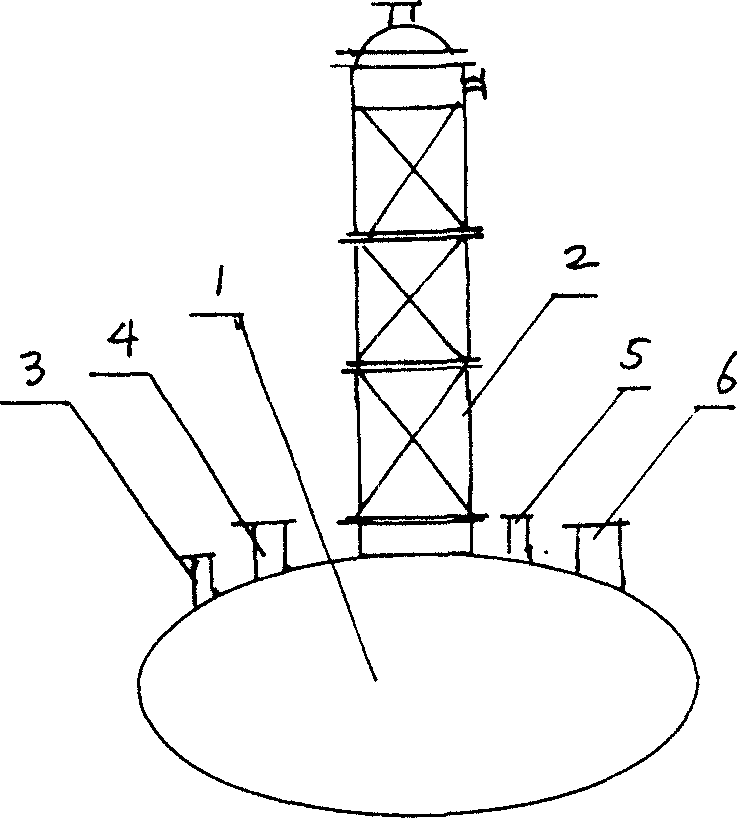

Pulse downdraft type high-temperature fixed bed gasification furnace

InactiveCN103756729ASatisfy the poking requirementsHarmlessCombustible gas productionFixed bedPower engineering

The invention relates to a pulse downdraft type high-temperature fixed bed gasification furnace, and belongs to the field of thermal power engineering. Pulse gas inlet channels, high-temperature steam inlet channels and a product gas outlet channel are formed in a gasification furnace body; the high-temperature steam inlet channels are symmetrically formed in the throat part of the gasification furnace body; the pulse gas inlet channels are formed above the high-temperature steam inlet channels; the product gas outlet channel is formed in the lower part of the gasification furnace body. According to the high-temperature fixed bed gasification furnace, high-heat-value solid fuels such as biomass, urban wastes and medical wastes can be gasified, the gasification efficiency, the gasification intensity and the fuel gas quality are high, the wastes can be harmlessly treated, reduced and recycled, the environmental protection effect is remarkable, the economic benefit is huge, and the market prospect is wide.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

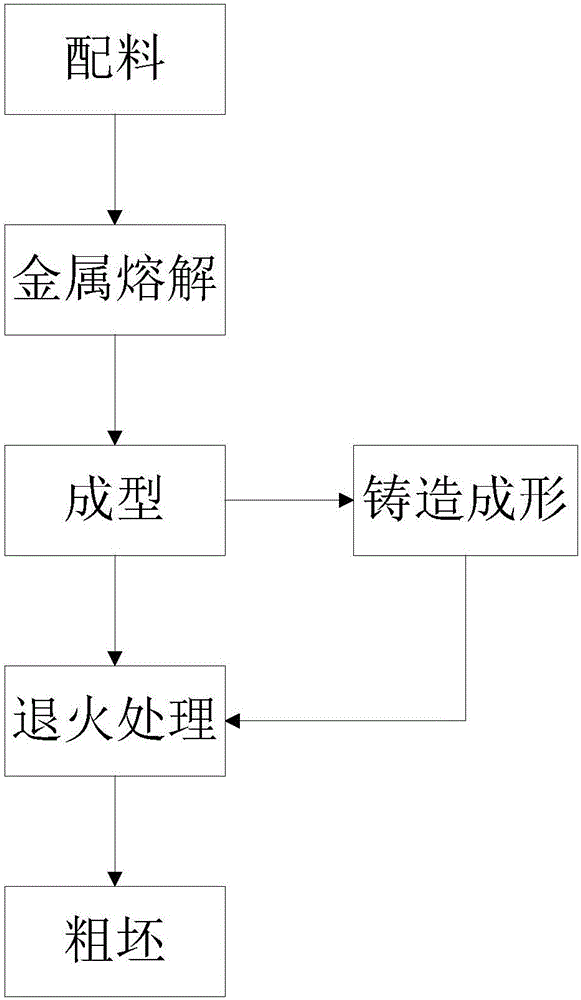

Hard platinum alloy and preparation method thereof

The invention discloses hard platinum alloy and a preparation method thereof. The hard platinum alloy is prepared from the following components in percentage by weight: 89.9-95.99wt% of platinum, 4.0-9.6wt% of cobalt and 0.01-0.5wt% of X. The preparation method comprises the following steps: burdening, metal melting, and forming, wherein metal melting is that weighed metal is put into an alumina crucible and heated to 1850-1900 DEG C to carry out melting; forming is that platinum alloy after being melted into liquid is poured into a strip groove to obtain the platinum alloy after being solidified; and the platinum alloy after being cooled is heated to 700-800 DEG C, heat preservation is carried out for 3h, slow cooling along with a furnace is carried out, and annealing treatment is realized. According to the preparation method, the phenomena that a casting breaks and deforms when a platinum alloy rough blank is casted are effectively prevented, the contractible and volatile blowholes are prevented from occurring in the platinum alloy casting, and in addition, the phenomenon that stones loosen and fall in the stone inlaying procedure is prevented.

Owner:深圳市金铸坊珠宝有限公司 +1

Process of preparaing methyl acrylate by waste organic glass and apparatus thereof

InactiveCN1235861CAchieve crackingRealize the craftOrganic compound preparationCarboxylic acid esters preparationMethacrylate methylGlass particle

Owner:廖活强

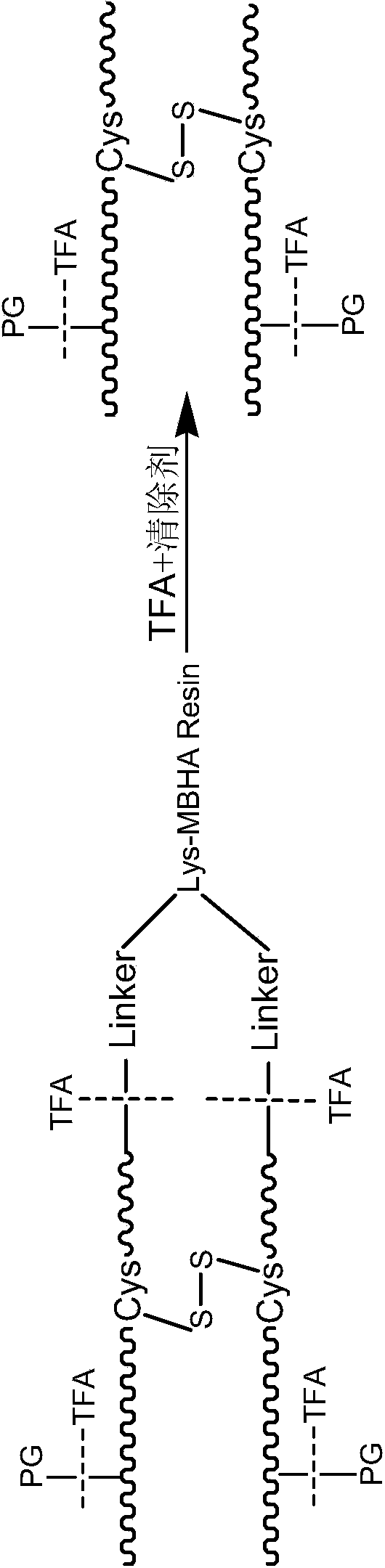

Solid-phase synthesis method for gonadotropin-releasing hormone (GnRH) castration vaccine

ActiveCN103554265AAchieve synthesisConvenient purification workLuteinising hormone-releasing hormoneCarrier-bound/immobilised peptidesSide chainCombinatorial chemistry

The invention provides a method for preparing a gonadotropin-releasing hormone (GnRH) parallel body and a vaccine in solid-phase conditions. After Lys is coupled on carrier resin, rink amide liners are respectively coupled on the two side chains of the Lys, and two same peptide chains are synthesized simultaneously. Disulfide bond bridging is realized on a solid phase, full-protective oxidation is adopted, and a large amount of impurities caused by the reaction involved by the side chains in the process are avoided.

Owner:NINGBO SANSHENG BIOLOGICAL TECH CO LTD

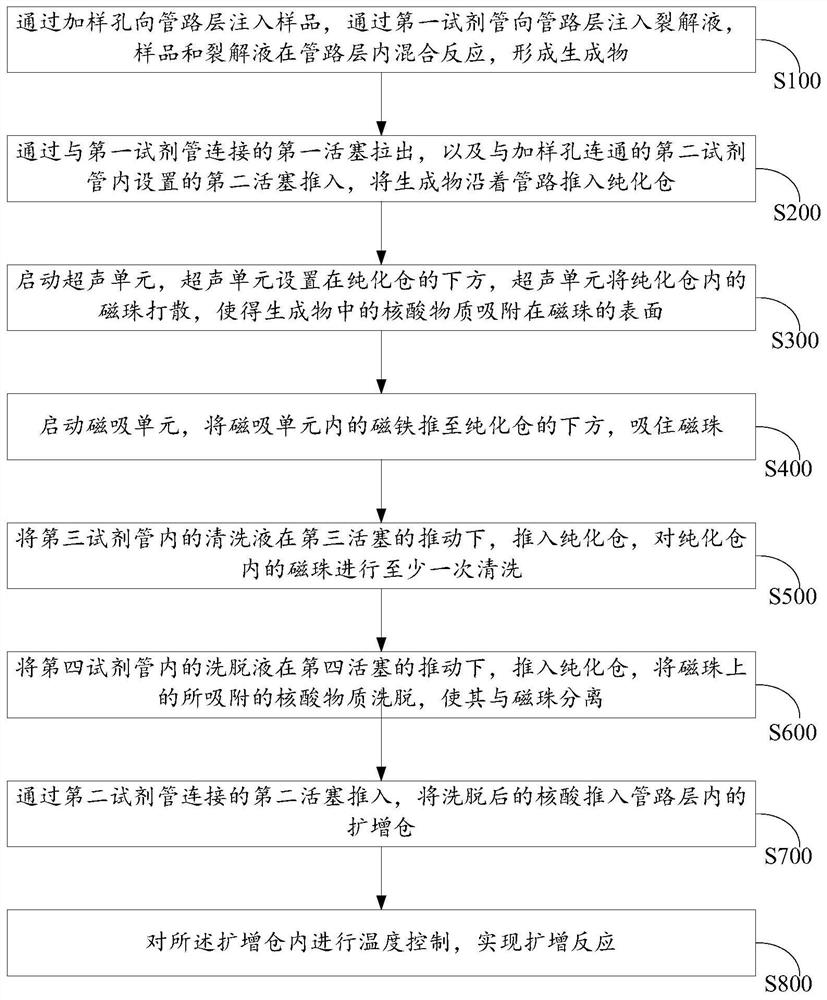

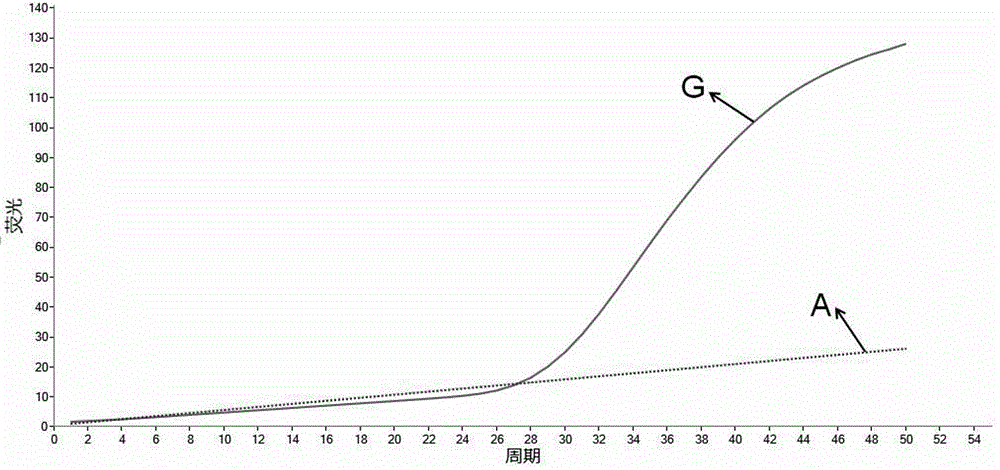

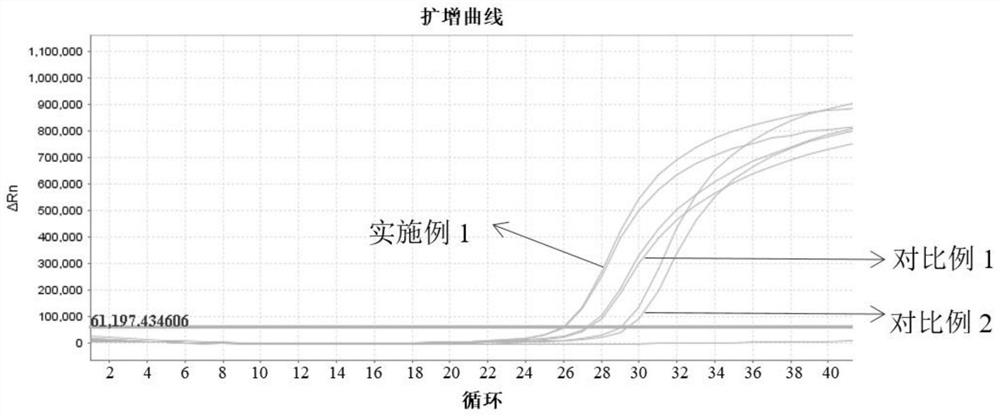

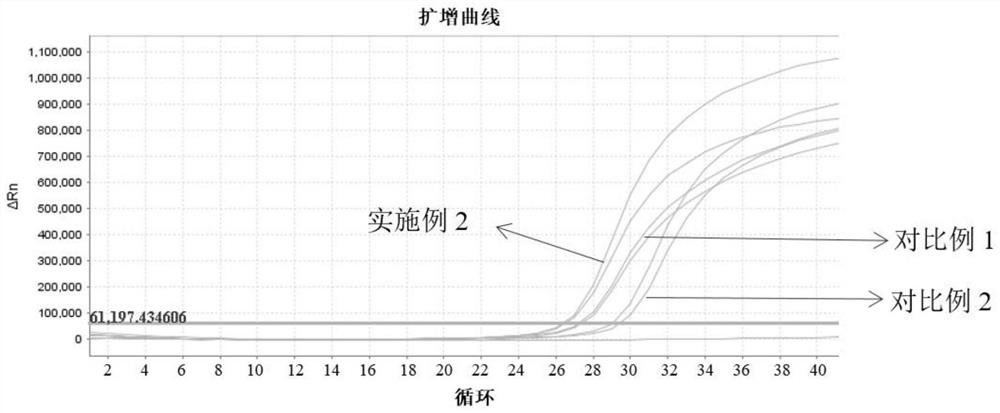

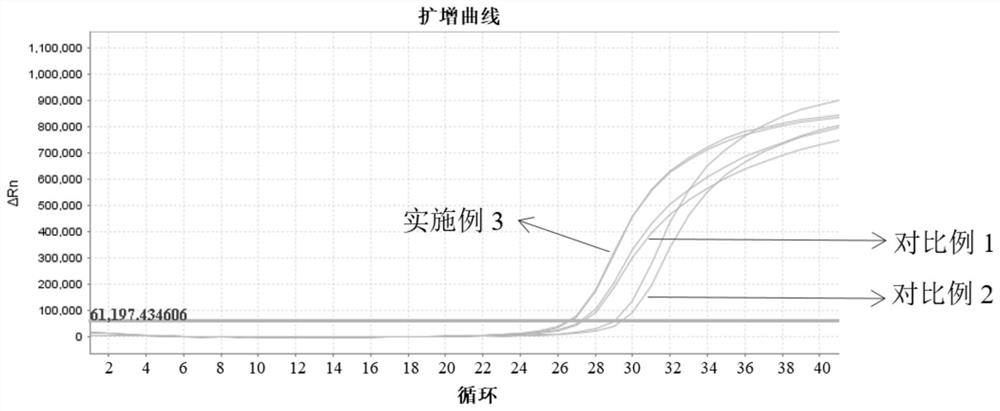

Control method of PCR continuous reaction

ActiveCN113174428AHigh degree of pipeline integrationEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsLysisNUCLEIC ACID SUBSTANCE

The invention relates to a control method of a PCR continuous reaction, which comprises: a sample is injected into a pipeline layer through a sample adding hole, and a lysis solution is injected into the pipeline layer through a first reagent tube to form a product; the product is pulled out through a first piston connected with the first reagent tube, and is pushed into a purification bin along the pipeline; an ultrasonic unit is started, the ultrasonic unit is arranged below the purification bin, and the ultrasonic unit scatters the magnetic beads in the purification bin, so that nucleic acid substances in the product are adsorbed on the surfaces of the magnetic beads; a magnetic attraction unit is started, a magnet in the magnetic attraction unit is pushed to the position below the purification bin, and the magnetic beads are attracted; the cleaning liquid in a third reagent tube is pushed into the purification bin, and cleaning is conducted at least once; the nucleic acid substance is eluted to separate the nucleic acid substance from the magnetic beads; nucleic acid is pushed into an amplification bin in the pipeline layer; and the amplification reaction is realized. According to the invention, the control on the continuous PCR reaction is realized, the pipeline integration degree in the reaction process is relatively high, the operation is simple, and the realization is easy.

Owner:INTEGRATED BIOSYSTEMS CO LTD

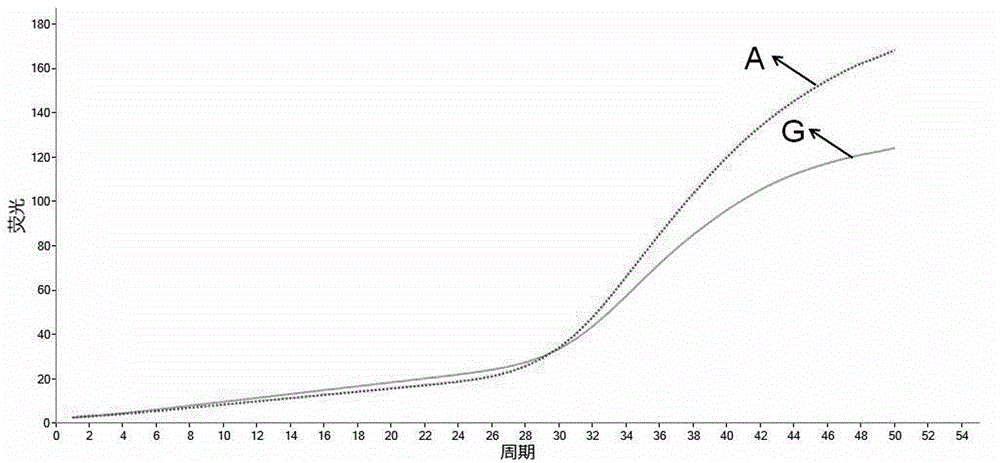

Cell lysis solution for rapid gene detection

InactiveCN104673914ARapid responseImprove efficiencyMicrobiological testing/measurementLysisWild type

The invention discloses a cell lysis solution for rapid gene detection. The cell lysis solution comprises a PCR mixed solution, wherein the PCR mixed solution is prepared from the following raw materials: DNA polymerase, dNTPs, an upstream primer, a downstream primer, a mutant-type molecular beacon, a wild-type molecular beacon, MgCl2, a PCR buffer solution and the cell lysis solution. The invention also provides the cell lysis solution which can realize gene amplification or detection by using a cell as a template in a manner of cooperating with the PCR mixed solution and an application method of the cell lysis solution.

Owner:重庆京因生物科技有限责任公司

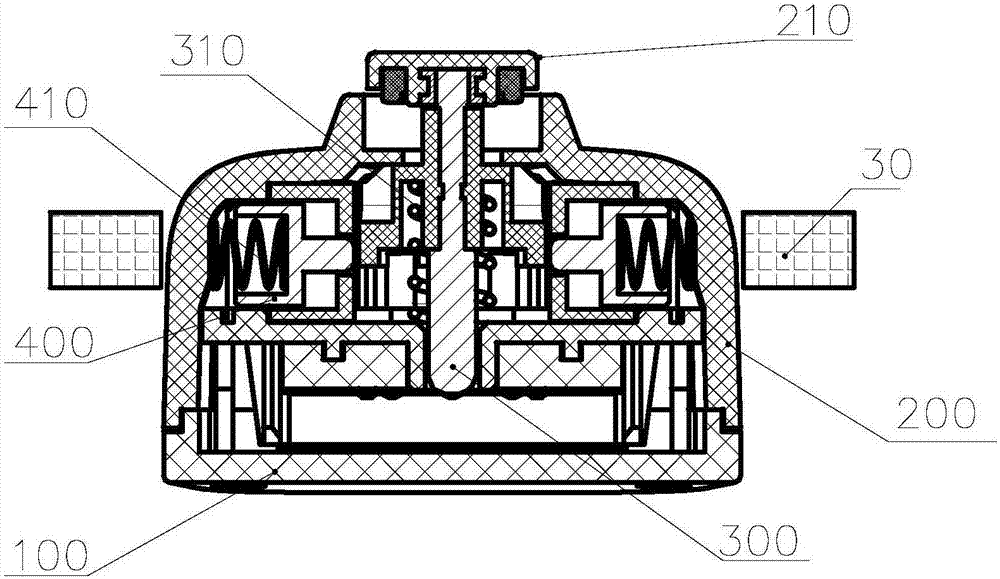

Lock catch structure and magnetic lock

ActiveCN107165511ASimple structureEasy to useLocks for portable objectsNon-mechanical controlsMagnetEngineering

The invention discloses a lock catch structure and a magnetic lock. The lock catch structure comprises a lock bottom shell, a lock upper cover fixed to the lock bottom shell, and a lock cylinder located between the lock upper cover and the lock bottom shell. One end of the lock cylinder is movably connected with the lock upper cover. The other end of the lock cylinder is suspended above the lock bottom shell through a first elastic device, the preset distance is formed between the other end of the lock cylinder and the lock bottom shell, and therefore the movable end of a to-be-locked device can be inserted in the preset distance. The lock cylinder is further provided with a clamping structure. The lock upper cover is provided with pins. One end of each pin is connected with the lock upper cover through a second elastic device, and the other end of each pin is matched with the clamping structure. The magnetic lock comprises the lock catch structure and an unlocking magnet, the structure is simple, using is convenient, the unlocking manner is simple but ingenious, and cracking is not easy.

Owner:HANGZHOU CCRFID MICROELECTRONICS

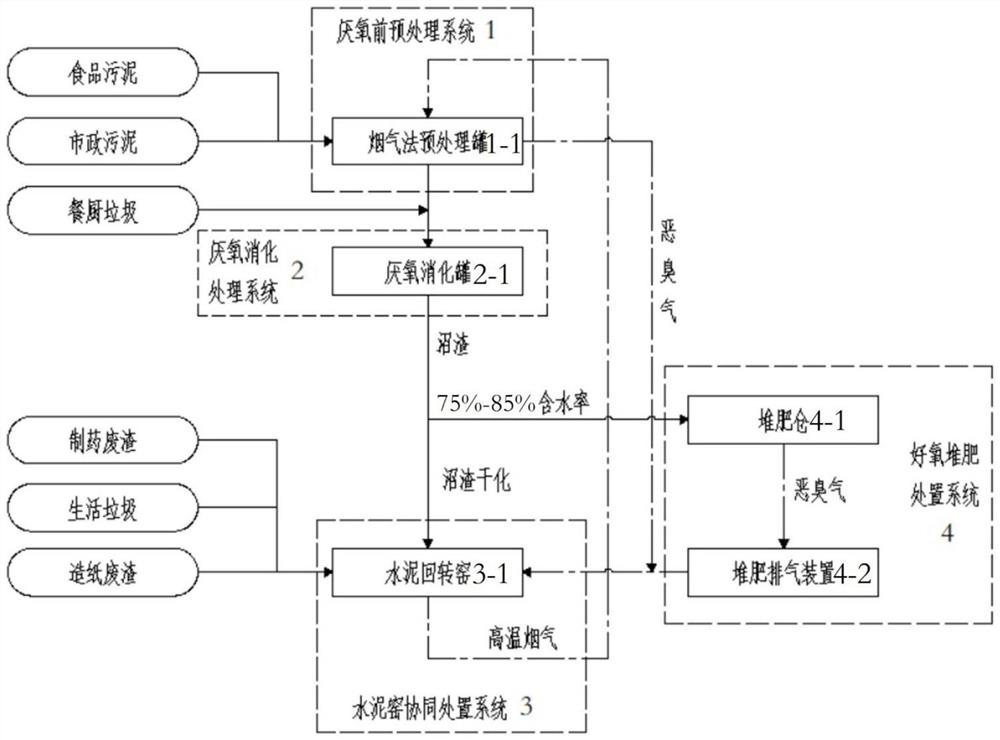

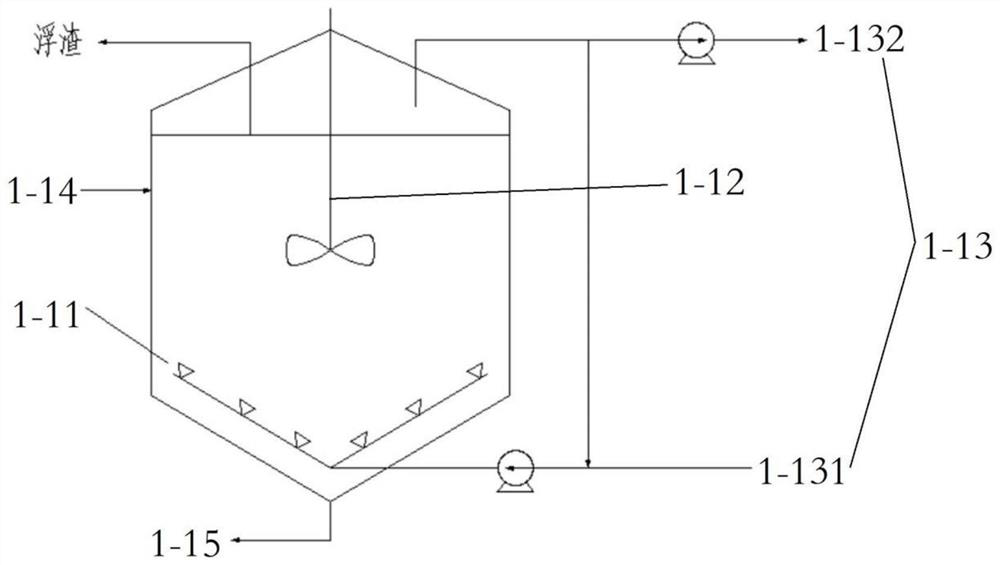

Multi-source organic solid waste treatment system and method for pollutant recycling

ActiveCN113182313AIncrease usageConducive to integration linkageSludge treatment by de-watering/drying/thickeningBio-organic fraction processingNitrogen oxidesFlue gas

The invention relates to a multi-source organic solid waste treatment system and method for pollutant recycling. The system comprises an anaerobic pretreatment system, an anaerobic digestion treatment system, a cement kiln co-treatment system and an aerobic composting treatment system, wherein high-temperature flue gas generated by the cement kiln co-treatment system is introduced into the anaerobic pretreatment system through an exhaust port; and malodorous gas of the anaerobic pretreatment system and malodorous gas of the aerobic composting treatment system are respectively introduced into an air inlet of the cement kiln co-treatment system through the exhaust port. According to the system and method provided by the invention, the conversion from the pollution attribute of the high-temperature flue gas to the resource attribute in the co-treatment process of multi-source organic solid waste in a single park is realized, and the cracking pretreatment before anaerobic digestion of sludge is performed by fully utilizing nitrogen oxides and high-temperature heat energy in the flue gas; moreover, the system provided by the invention thoroughly solves the problems caused by malodorous gas in the organic solid waste biological treatment process.

Owner:TONGJI UNIV

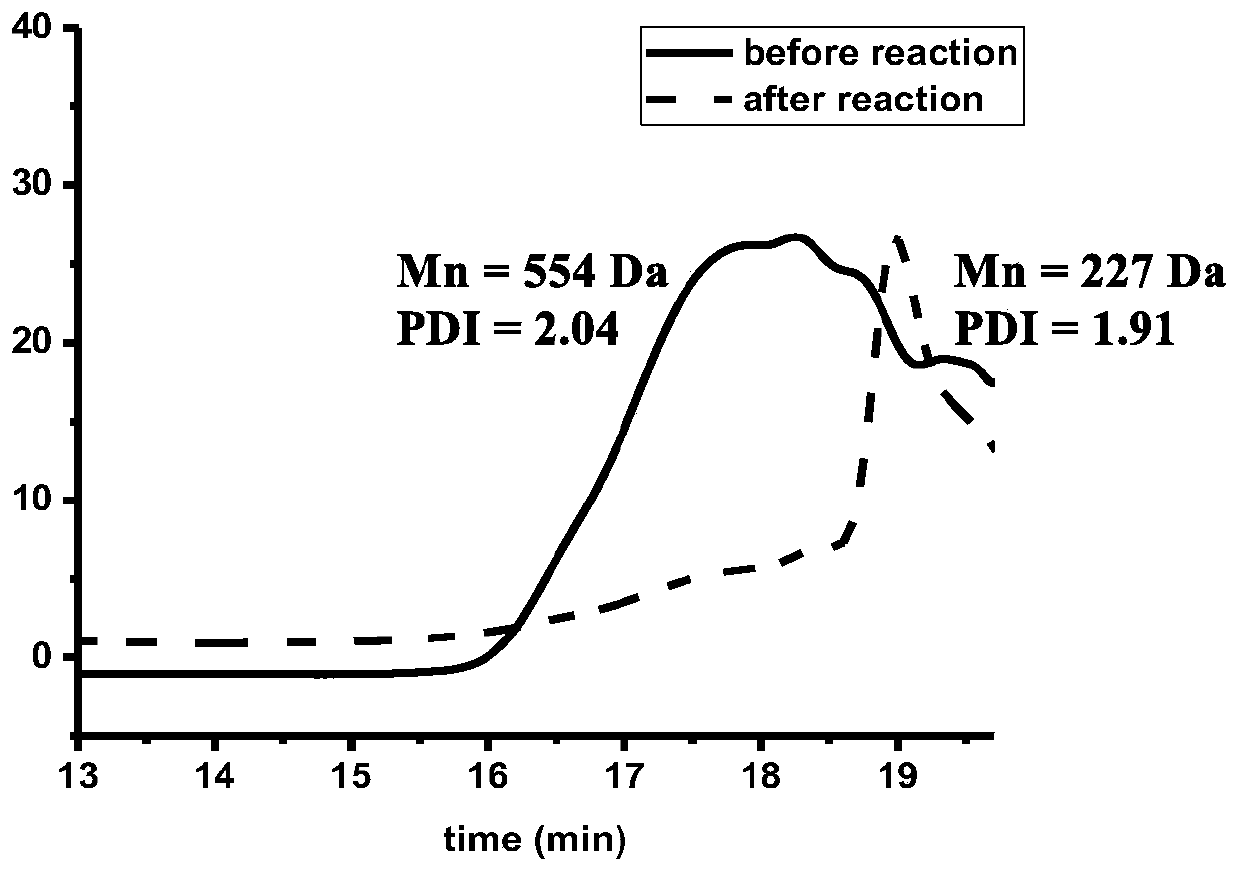

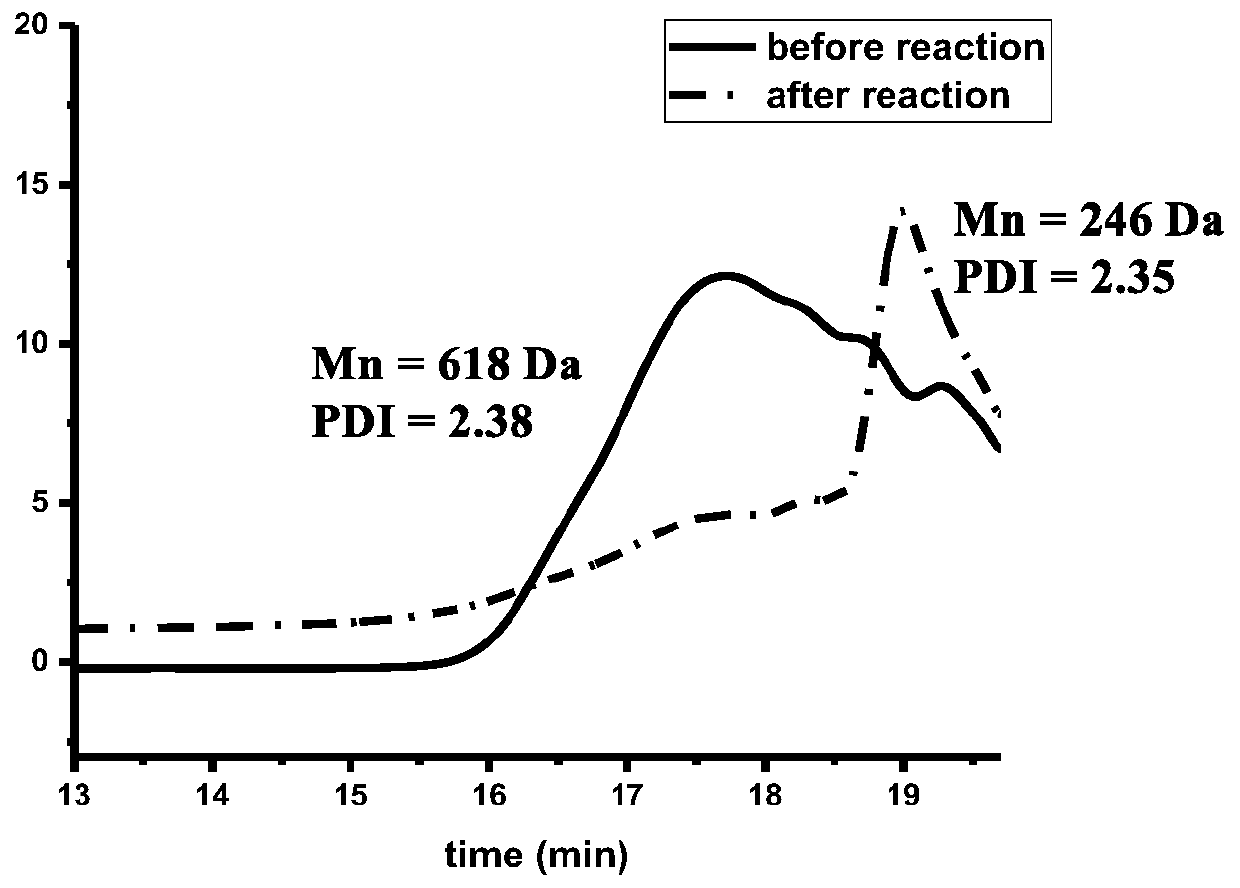

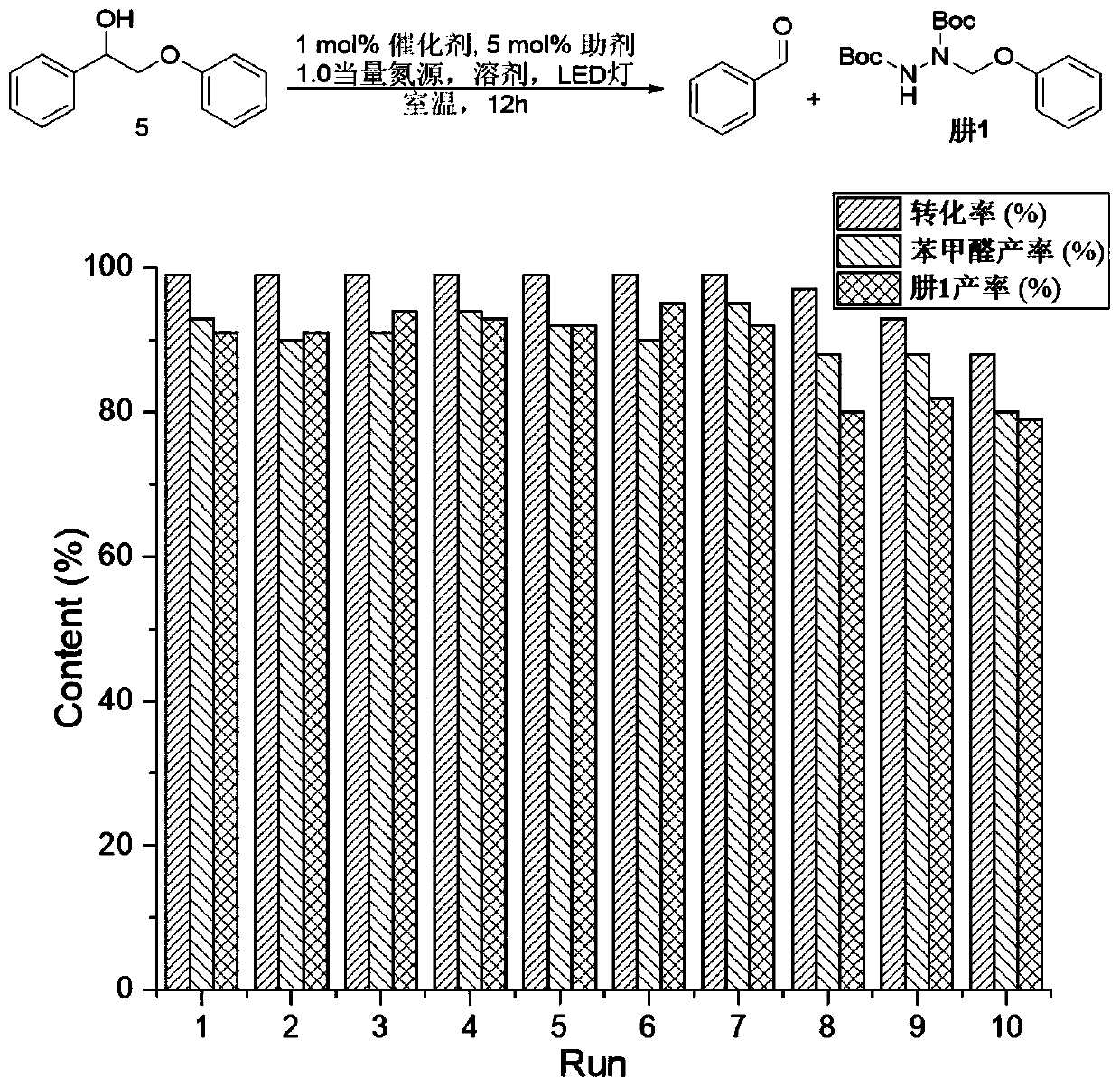

Method for synthesizing nitrogen-containing aromatic compounds by one-step photocatalytic lignin depolymerization and amination

ActiveCN110156581AEasy to operateMild reaction conditionsOrganic compound preparationCarbonyl compound preparationSolventChemistry

The invention relates to a method for synthesizing nitrogen-containing aromatic compounds by one-step photocatalytic lignin depolymerization and amination, belonging to the technical field of lignin application. The invention takes lignin or model compound thereof as a reaction substrate, dissolves the reaction substrate in a solvent, reacts at room temperature for 6-24 hours under the excitationof a light source and catalysis of a photocatalyst with the assistance of a promoter and a nitrogen source, and carries out C-C bond selective cleavage and amination to synthesize nitrogen-containingaromatic compounds; the molar ratio of lignin or model compound thereof, photocatalyst, promoter and nitrogen source is 100: (1-20): (1-100): 100. The invention has the advantages of simple reaction steps, mild reaction conditions, high bond breaking selectivity, high product selectivity, 100% atomic efficiency, environmental protection, selective cleavage and amination of C-C bond by one-step reaction, continuous feeding, good degradation of natural lignin, further reaction of hydrazine products to obtain nitrogen heterocyclic compounds and other advantages

Owner:JILIN UNIV

Kit and method for extracting DNA of FFPE tissue sample and application thereof

PendingCN113088515AReduced dewaxing timeImproved dewaxing processDNA preparationProteasesTissue Lysis

The invention discloses a kit and a method for extracting DNA of an FFPE tissue sample and application thereof. The kit comprises a dewaxing and cracking buffer solution and protease K, wherein the dewaxing and cracking buffer solution is prepared from the following components in percentage by weight: 1 to 6 percent of lauryl sodium sulfate, 50 to 300 mM of Tris-HCl, 1 to 30 mM of EDTA-2Na, 0.1 to 4 percent of Triton X-100, 0.1 to 2 M of NaCl, 0.1 to 8 percent of Tween 20 and 0.1 to 10 percent of PEG 6000; the percentage is volume percentage. According to the kit, the unique dewaxing lysis buffer solution is adopted, dewaxing and tissue lysis of the FFPE tissue sample can be achieved without independently adding a dewaxing agent, the dewaxing step is simplified, meanwhile, the manual operation process is reduced, and the nucleic acid extraction and purification efficiency is improved.

Owner:杭州康代思锐生物科技有限公司

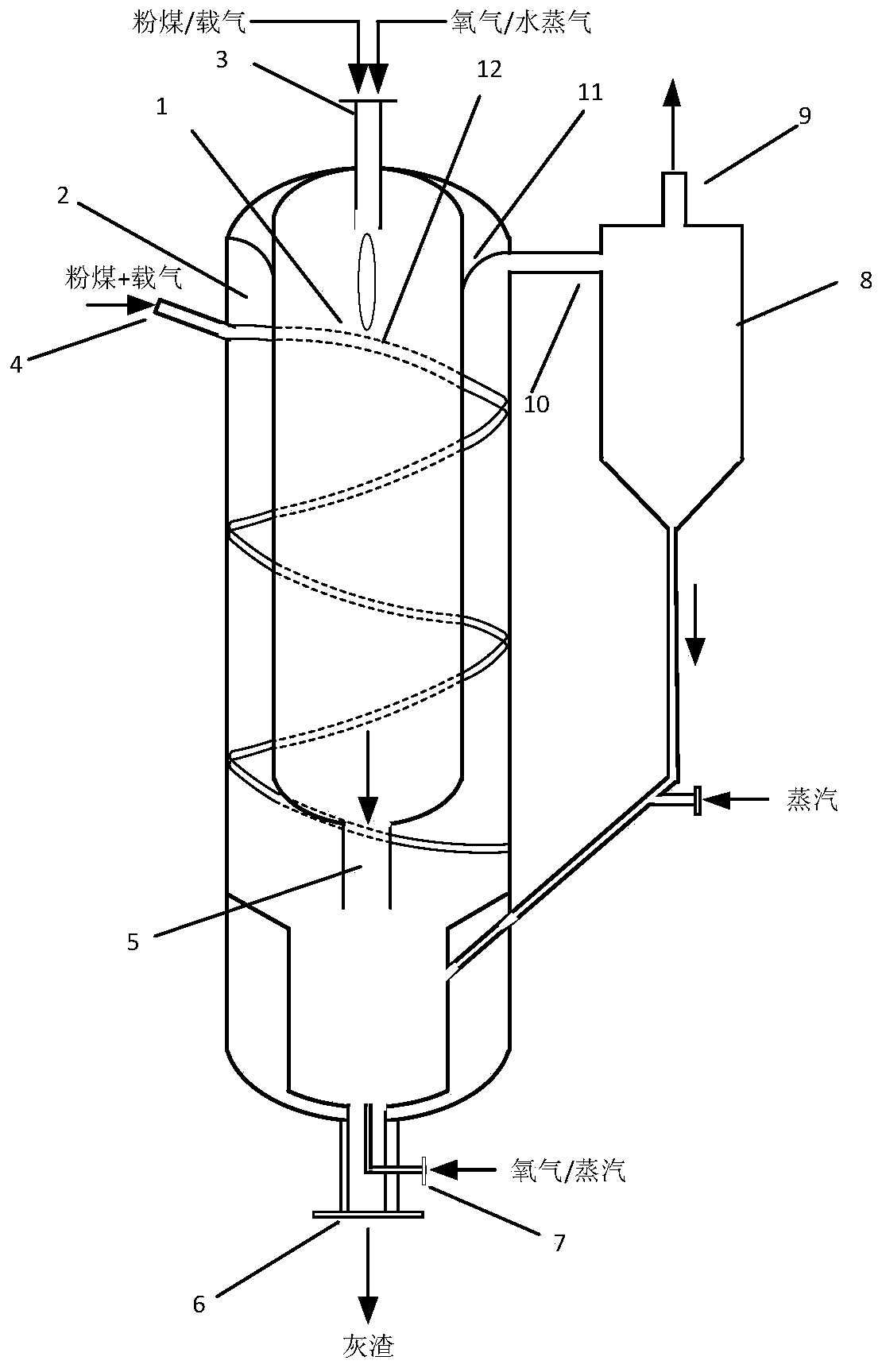

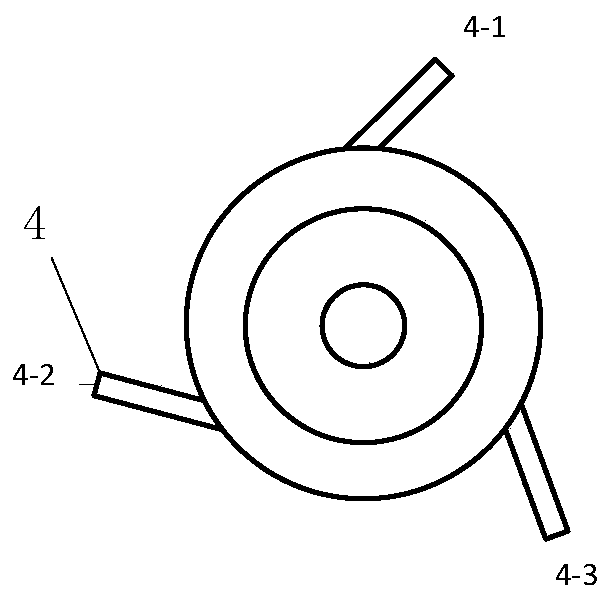

Pyrolysis-gasification integrated treatment device and method

ActiveCN110923015AAchieve crackingReduce pollutionGasification processes detailsGranular/pulverulent flues gasificationSyngasThermodynamics

The invention relates to a pyrolysis-gasification integrated treatment device and method. A two-section gasification and one-section pyrolysis device combined design is adopted, a first-section gasification area furnace body and a pyrolysis furnace body are coaxially distributed, and the first-section gasification area and the second-section gasification area are distributed up and down. Tar produced by the coal pyrolysis section is completely cracked by the high temperature of hydrogen-rich gas generated by the first-section gasification and second-section gasification, thus adjusting the hydrogen-carbon ratio in the synthesis gas at an outlet, and reducing the environmental protection problem caused by tar in subsequent wastewater; meanwhile, the two-section gasification technology is employed at the same time to further improve the residual carbon in ash residue and enhance the carbon conversion rate of the raw material. On the basis, the pyrolysis part is provided with three strands of feeding materials, a flow guide weir, a flow guide plate and the like to realize complete cracking of pyrolysis tar, the carbon conversion rate is high, the phenomenon of adhesion of pyrolysis semicoke and slag and the risk of slag blockage caused by slag accumulation at the bottom of the furnace body are avoided. The device and method are suitable for low-rank coal upgrading, inferior coal gasification and solid waste cracking resource utilization.

Owner:WANHUA CHEM GRP CO LTD +1

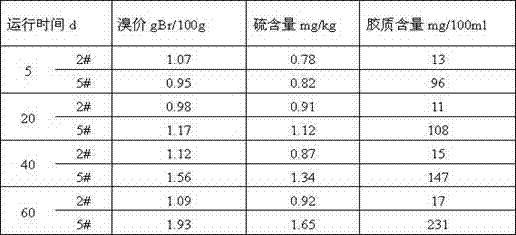

Catalyst for pyrolysis C9 two-stage hydrogenation and preparation method thereof

ActiveCN103611562AAvoid large loss of aromaticsImprove anti-glue abilityMolecular sieve catalystsHydrocarbon oils treatmentMolecular sieveComposite oxide

The invention relates to a catalyst for pyrolysis C9 two-stage hydrogenation and a preparation method thereof. The catalyst is prepared by taking a K and Ru modified composite oxide consisting of an HY molecular sieve, B2O3 and Al2O3 as a carrier and loading active components of Ni and Mo. The catalyst comprises the following active components in percentage by weight: 3.0-5.0% of NiO and 9.0-15.0% of MoO3. The catalyst provided by the invention is used for pyrolysis C9 two-stage hydrogenation, shows very high desulfurization activity and olefin saturation capacity, is strong in carbon deposition resistance and has a certain effect on macromolecular colloid pyrolysis, so that the colloid resistance of the catalyst is improved, and the service life of the catalyst is greatly prolonged.

Owner:WUHAN KELIN FINE CHEM

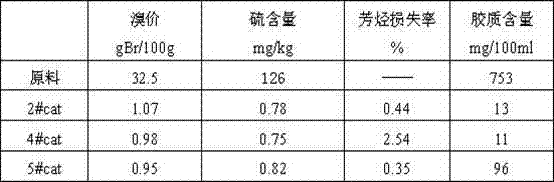

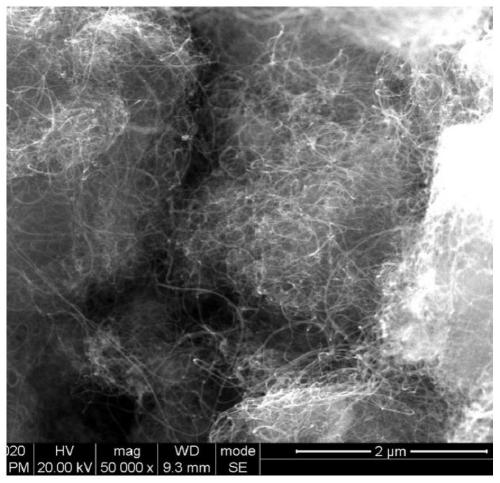

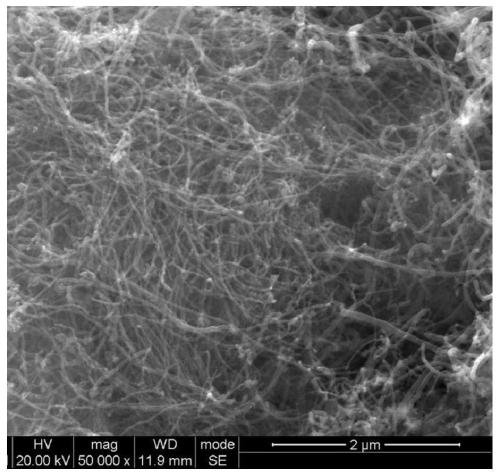

Preparation method of carbon nanotube

The invention discloses a preparation method of a carbon nanotube. The carbon nanotube is prepared by catalytically cracking a carbon source gas by using a catalyst, the carbon source gas comprises methane and polycarbon alkane, and the content of the polycarbon alkane in the carbon source gas is 5-63% of the total carbon source gas based on the number of carbon atoms. According to the preparationmethod, the addition of the polycarbon alkane in the carbon source gas can do work in the cracking reaction process so that methane cracking is promoted, the conversion rate of methane is increased,the growth rate of the carbon nanotubes can be increased, the production efficiency of the carbon nanotubes is improved and the production cost is reduced.

Owner:内蒙古骏成新能源科技有限公司

A synergistic process for producing hydrogen and inhibiting tar production by chemical chain reforming of biomass

The invention provides a collaborative process for reforming biomass chemical chains to produce hydrogen and inhibit production of tar. The process mainly using a catalytic cracking reactor, a hydrogen producing reactor and an oxygen carrier regeneration reactor comprises the following steps: firstly mixing biomass with an iron-based compound oxygen carrier; then, carrying out reaction on the mixed raw materials in the catalytic cracking reactor for 20-30 minutes; then, feeding resultants of reaction into a cyclone separator to be separated; discharging synthesis gas from an exhaust opening; further conveying the reduced oxygen carrier in the catalytic cracking reactor into a hydrogen producing reactor to react with steam to prepare hydrogen; and finally, feeding the oxygen carrier after reaction into the oxygen carrier regeneration reactor to continuously and circularly participate in reaction after being oxidized. Compared with the conventional biomass gasification, the collaborative process provided by the invention cooperating a hydrogen production technology by reforming chemical chains with a tar inhibiting technology has the characteristics of low energy consumption, inhibition of tar production and the like. Aiming at biomass with different contents of volatile components, the invention provides two different implementation models.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com