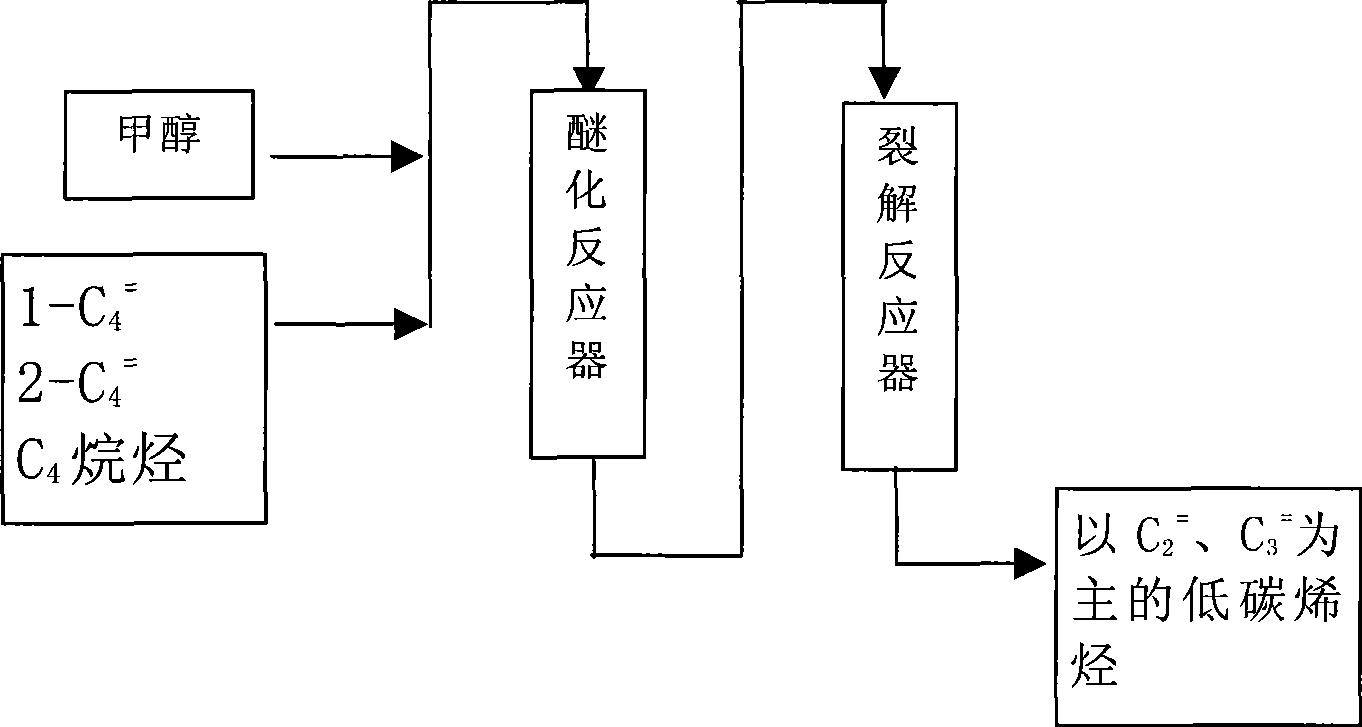

Method for preparing ethylene and propylene by two-step method

A technology of ethylene and propylene, which is applied in the field of ethylene and propylene preparation, can solve the problems of energy consumption affecting production efficiency, and achieve the effect of reducing heat load and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

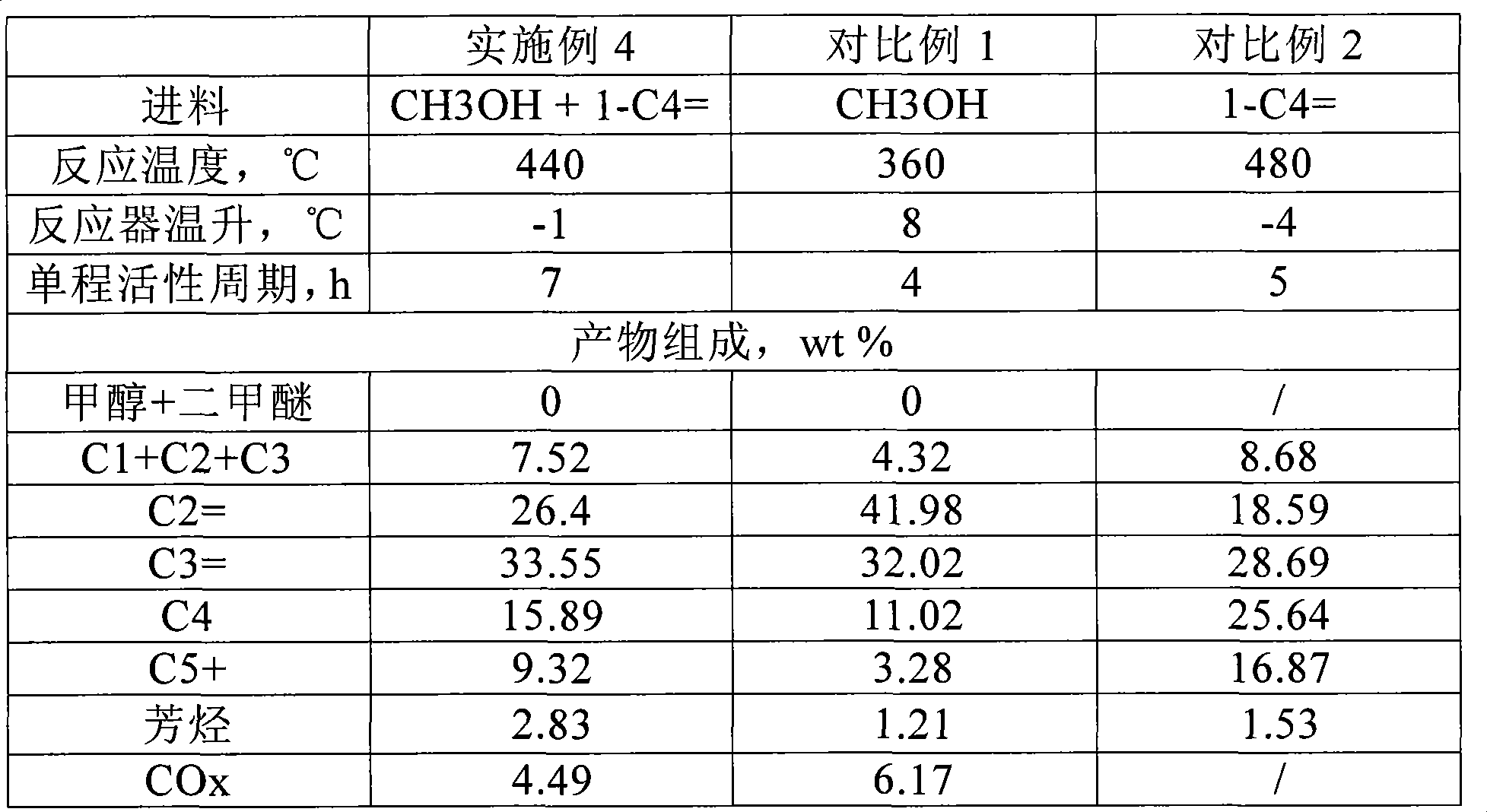

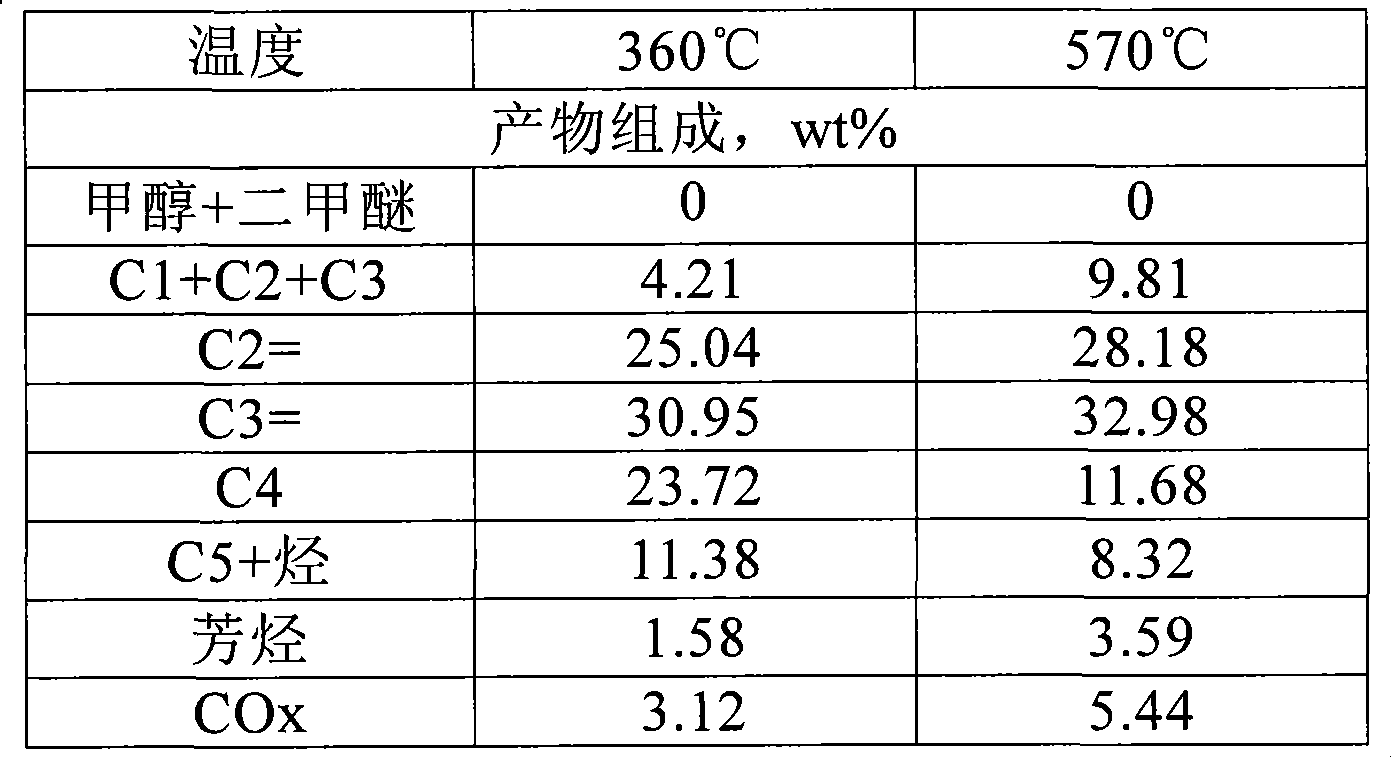

Examples

Embodiment 1

[0067] Embodiment 1, the preparation A of catalytic cracking catalyst

[0068] Mix 30.15g of aluminum isopropoxide with 54.17g of water, add 17.11g of phosphoric acid under stirring, continue to stir, add 9.32g of tetraethyl silicate, and finally add 36.19g of tetraethylammonium hydroxide template with a mass content of 30% , continue stirring to make a uniform gel. The above gel solution was transferred into a stainless steel crystallizer, sealed, and left to stand at a constant temperature of 200°C for 120 hours for crystallization. After the crystallization is completed, the product is cooled rapidly, the mother liquor is poured out, the precipitate is separated by centrifugation, and washed several times with pure water until the pH value of the solution is 8-9, and then the obtained crystal is dried at 115°C for 3 hours, 550 The templating agent was removed by calcining at ℃ for 5 hours to obtain SAPO-34 molecular sieve.

[0069] The SAPO-34 molecular sieve was directly...

Embodiment 2

[0070] Embodiment 2, the preparation B of catalytic cracking catalyst

[0071] Get the water glass 156g that modulus is 3.6 and dissolve in 50g water. Take another 1g of Al with a mass content of 99% 2 (SO 4 ) 3 18H 2O, then mix homogeneously with the concentrated sulfuric acid of 98% with 15g mass content, then mix homogeneously with 75ml water. The two solutions were mixed under vigorous stirring, and 50 g of tetrapropylammonium hydroxide template agent with a mass content of 10% was added, and the stirring was continued to form a uniform gel. Transfer the gelled object into a stainless steel crystallizer, seal it, and crystallize at 180°C for 50 hours. After the crystallization is completed, the product is cooled rapidly, the mother liquor is poured out, the precipitate is separated by centrifugation, and washed several times with pure water until the pH value of the solution is 8-9, and then the obtained crystal is dried at 120°C for 12 hours, 550 The templating agen...

Embodiment 3

[0073] Embodiment 3, the preparation C of catalytic cracking catalyst

[0074] Mix the SAPO-34 molecular sieve prepared in Example 1 with the hydrogen-type ZSM-5 molecular sieve prepared in Example 2 in a ratio of 2:3, and then mix it with Al2O3 binder in a ratio of 2:1, and put it on the extruder Extruded to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com