Pulse downdraft type high-temperature fixed bed gasification furnace

A gasifier and fixed bed technology, applied in the field of pulse down suction fixed bed high temperature gasifier, can solve the problems of solid material layer bridging and the like, and achieve the effects of less tar content, wide adaptability and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

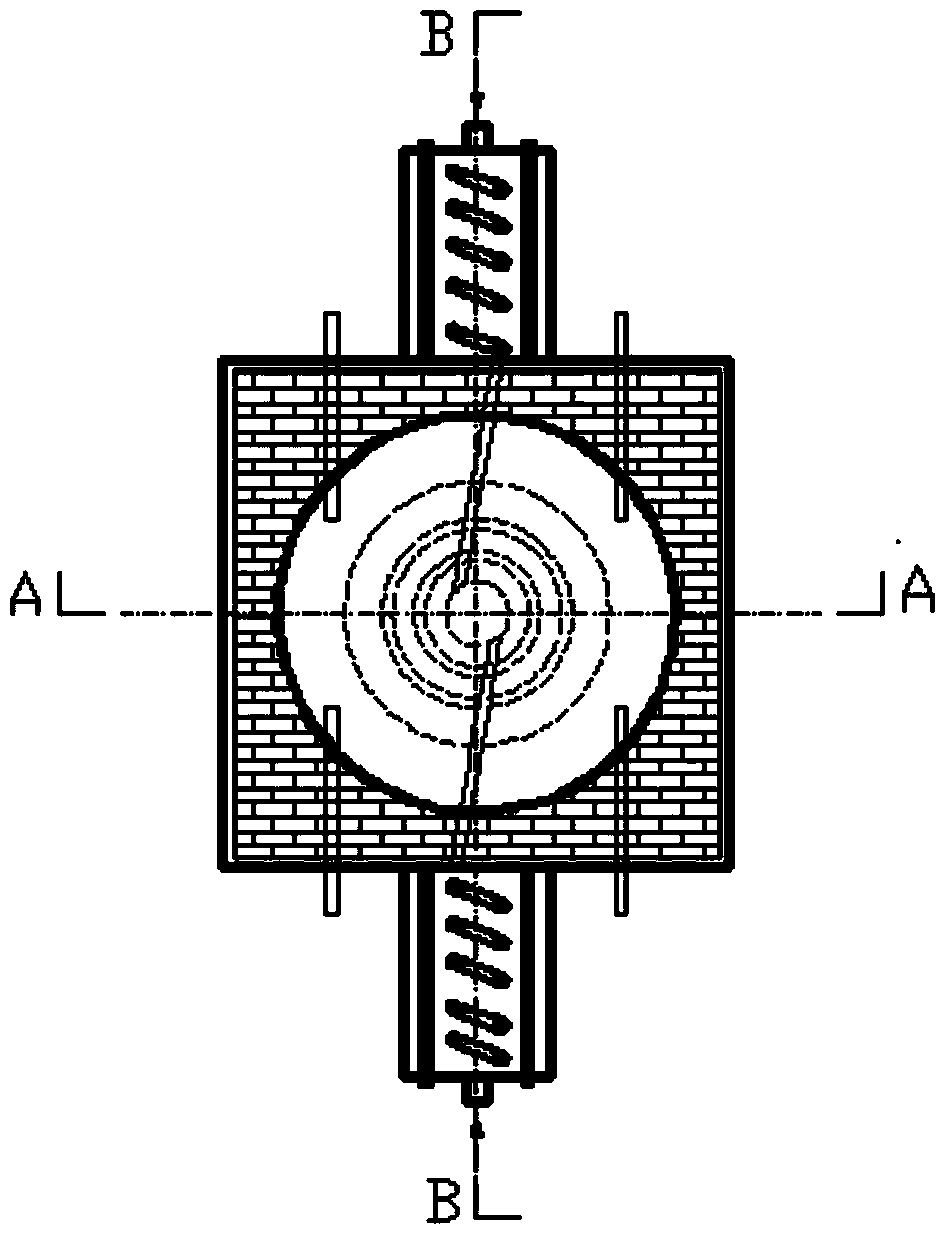

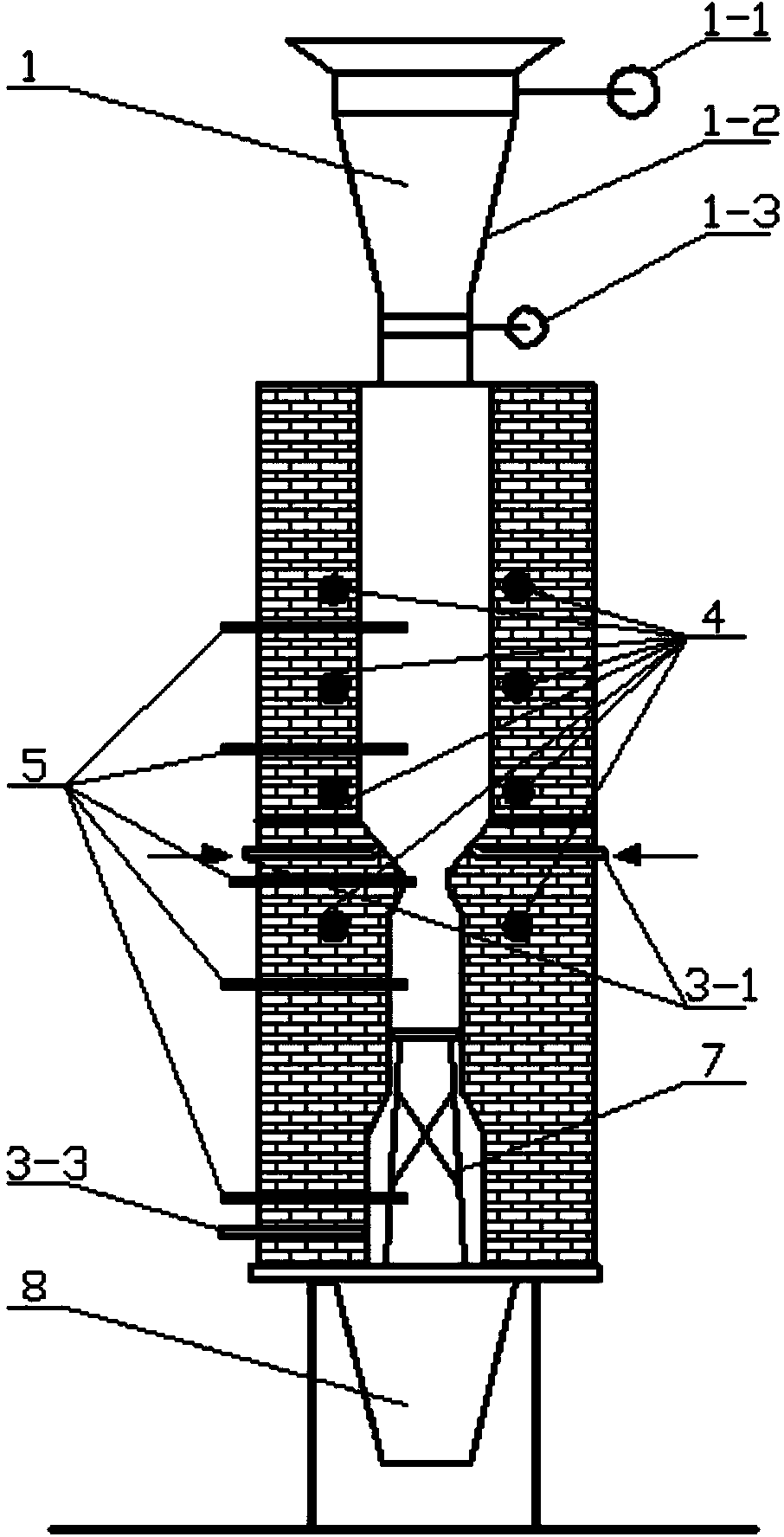

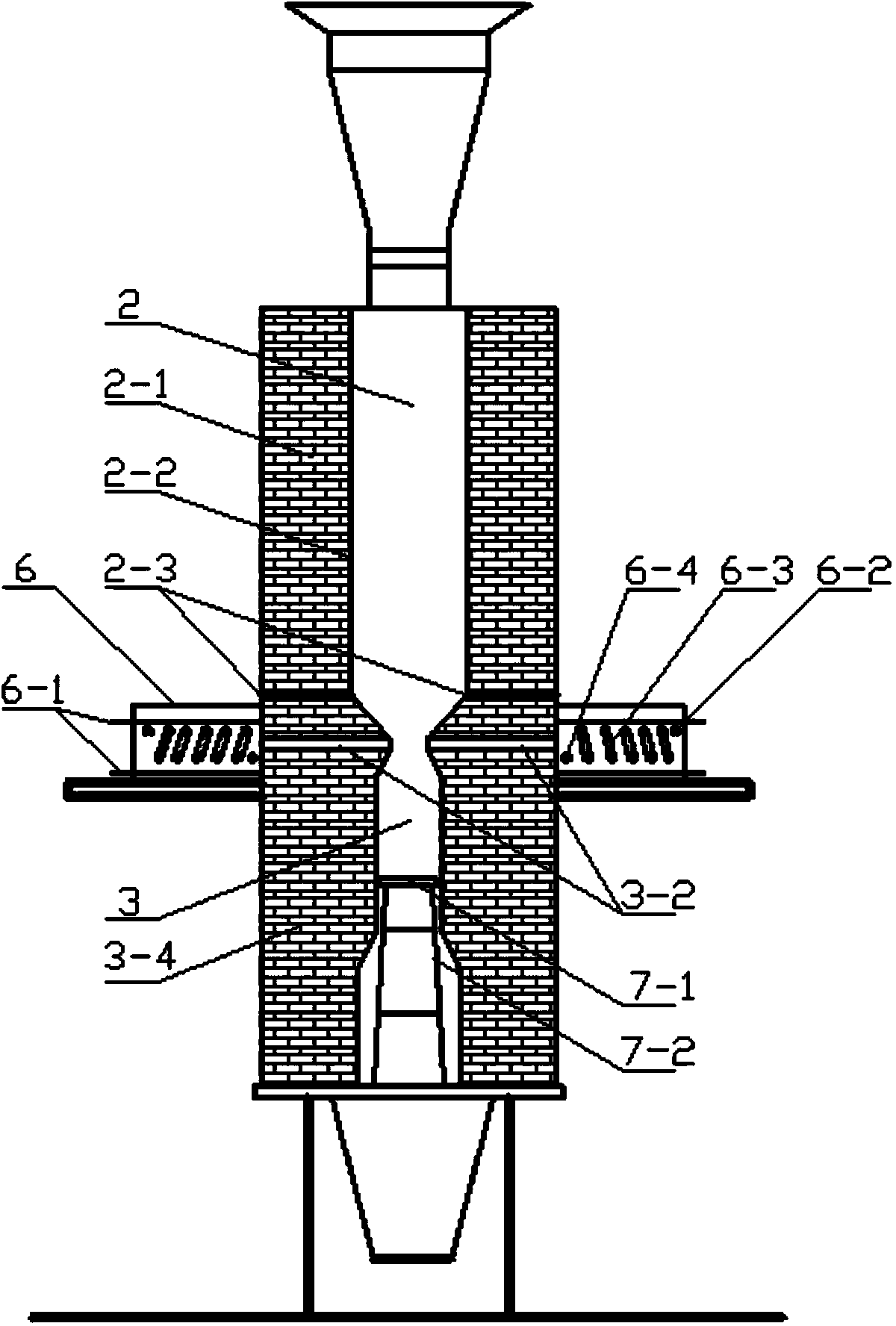

[0022] The gasification furnace and the gasification process will be further described below in conjunction with the accompanying drawings.

[0023] Pulse downdraft fixed bed high temperature gasifier, such as figure 1 , figure 2 and image 3 As shown, it includes from top to bottom: feeding device 1, butterfly valve 1-1, hopper 1-2, butterfly valve 1-3; upper gasifier body 2, refractory brick insulation layer 2-1, high-heat steel liner 2-2, the connecting flange 2-3 of the upper and lower parts of the furnace body; the lower part of the gasifier body 3, the pulse gas inlet channel 3-1, the high-temperature steam inlet channel 3-2, the product gas outlet channel 3-3, Refractory brick insulation layer 3-4; silicon carbide rod heating device 4; temperature monitoring and gas sampling point 5; high temperature steam preparation device 6, silicon carbon rod 6-1, low temperature steam inlet 6-2, spiral pipe 6-3, high temperature Steam outlet 6-4; liftable grate 7, grate 7-1, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com