Preparation method of carbon nanotube

A carbon nanotube and carbon alkane technology is applied in the field of catalytic cracking to prepare carbon nanotubes, which can solve the problems of high preparation cost and low conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of carbon nanotubes in this embodiment is as follows:

[0028] 1) Preparation of iron-based catalysts by sol-gel method;

[0029] 2) Set the temperature in the reaction zone of the reactor to 770°C, and use nitrogen to replace the oxygen in the reactor during the heating process;

[0030] 3) When the oxygen content in the reactor is lower than 0.5%, and the temperature of the reaction zone reaches 770°C, add 1.00g of catalyst, and feed methane (carbon source A) and propane (carbon source B), and the flow rates of the two are V A =0.90L / min and V B =0.27L / min, in this reaction combination, per mole of carbon source gas, the Gibbs free energy of propane cracking is -49.64kJ; stop feeding carbon source gas after 60min, then feed nitrogen replacement, remove reactant.

[0031] The reactants were weighed to be 35.7g, that is, the prepared carbon nanotubes were 34.7g.

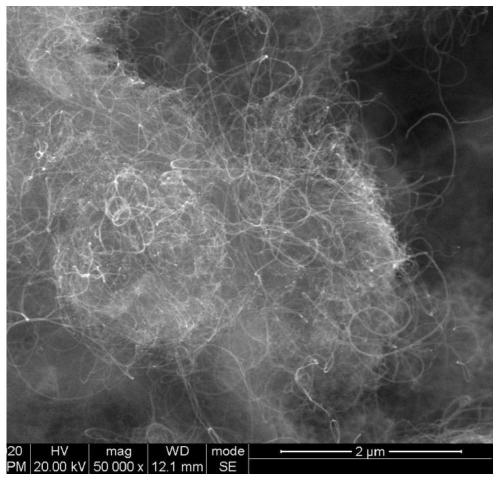

[0032] The carbon nanotubes obtained by the preparation method of this embodiment...

Embodiment 2

[0045] The preparation method of carbon nanotubes in this embodiment is as follows:

[0046]1) Set the temperature in the reaction zone of the reactor to 750°C, and use nitrogen to replace the oxygen in the reactor during the heating process;

[0047] 2) When the oxygen content in the reactor is lower than 0.5%, and the reaction zone temperature reaches 750° C., add 1.00 g of the catalyst in Example 1, feed methane (carbon source A) and butane (carbon source B), both The flow rates are V A =0.9L / min and V B =0.019L / min, in this reaction combination, per mole of carbon source gas, the Gibbs free energy of butane cracking is -6.02kJ; stop feeding carbon source gas after 60min, then feed nitrogen replacement, remove reactant.

[0048] The reactants were weighed to be 17.3g, that is, the prepared carbon nanotubes were 16.3g.

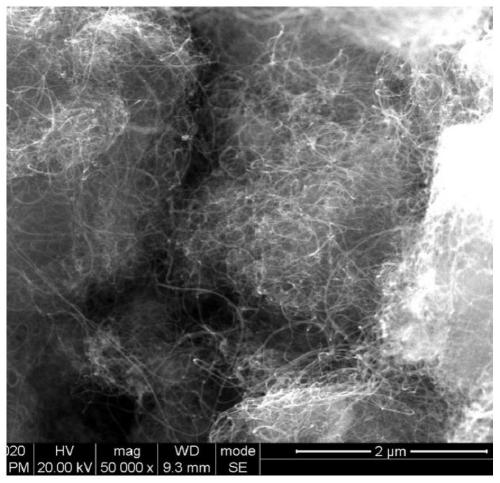

[0049] According to the method of Example 1, the carbon source conversion rate of the preparation method of this example, the ash content of the product,...

Embodiment 3

[0051] The preparation method of carbon nanotubes in this embodiment is as follows:

[0052] 1) Set the temperature in the reaction zone of the reactor to 750°C, and use nitrogen to replace the oxygen in the reactor during the heating process;

[0053] 2) When the oxygen content in the reactor is lower than 0.5%, and the reaction zone temperature reaches 760° C., add 1.00 g of the catalyst in Example 1, feed methane (carbon source A) and butane (carbon source B), both The flow rates are V A =0.9L / min and V B =0.09L / min, in this reaction combination, per mole of carbon source gas, the Gibbs free energy of butane cracking is -26.47kJ; stop feeding carbon source gas after 60min, then feed nitrogen replacement, remove reactant.

[0054] The reactants were weighed to be 25.0 g, that is, the prepared carbon nanotubes were 24.0 g.

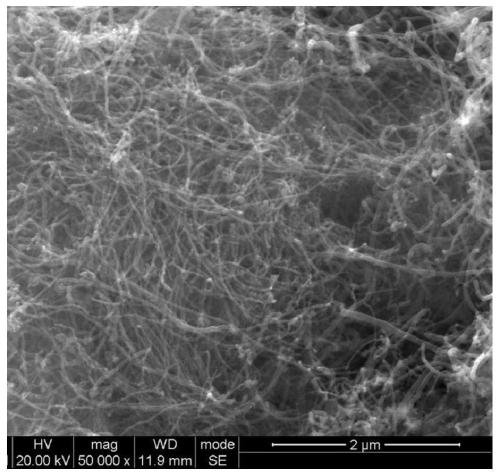

[0055] The carbon nanotubes obtained by the preparation method of this embodiment are detected by scanning electron microscopy, such as figure 2 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com