Method for synthesizing nitrogen-containing aromatic compounds by one-step photocatalytic lignin depolymerization and amination

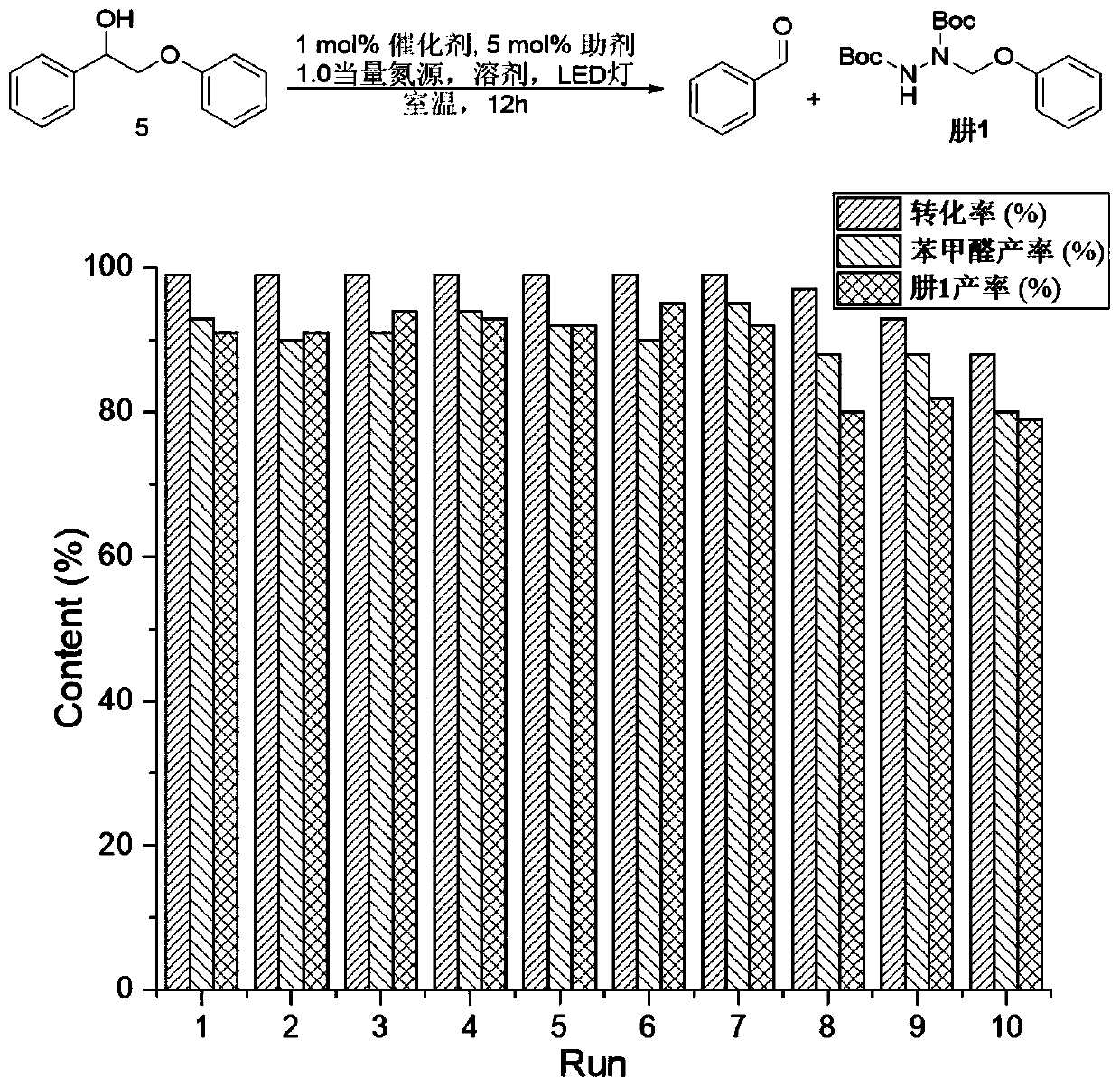

A technology for aromatic compounds and lignin, applied in the application field of lignin, can solve the problems of requiring high temperature or high pressure, harsh reaction conditions, complicated reaction steps, etc., and achieves the effects of high conversion rate, mild reaction conditions and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

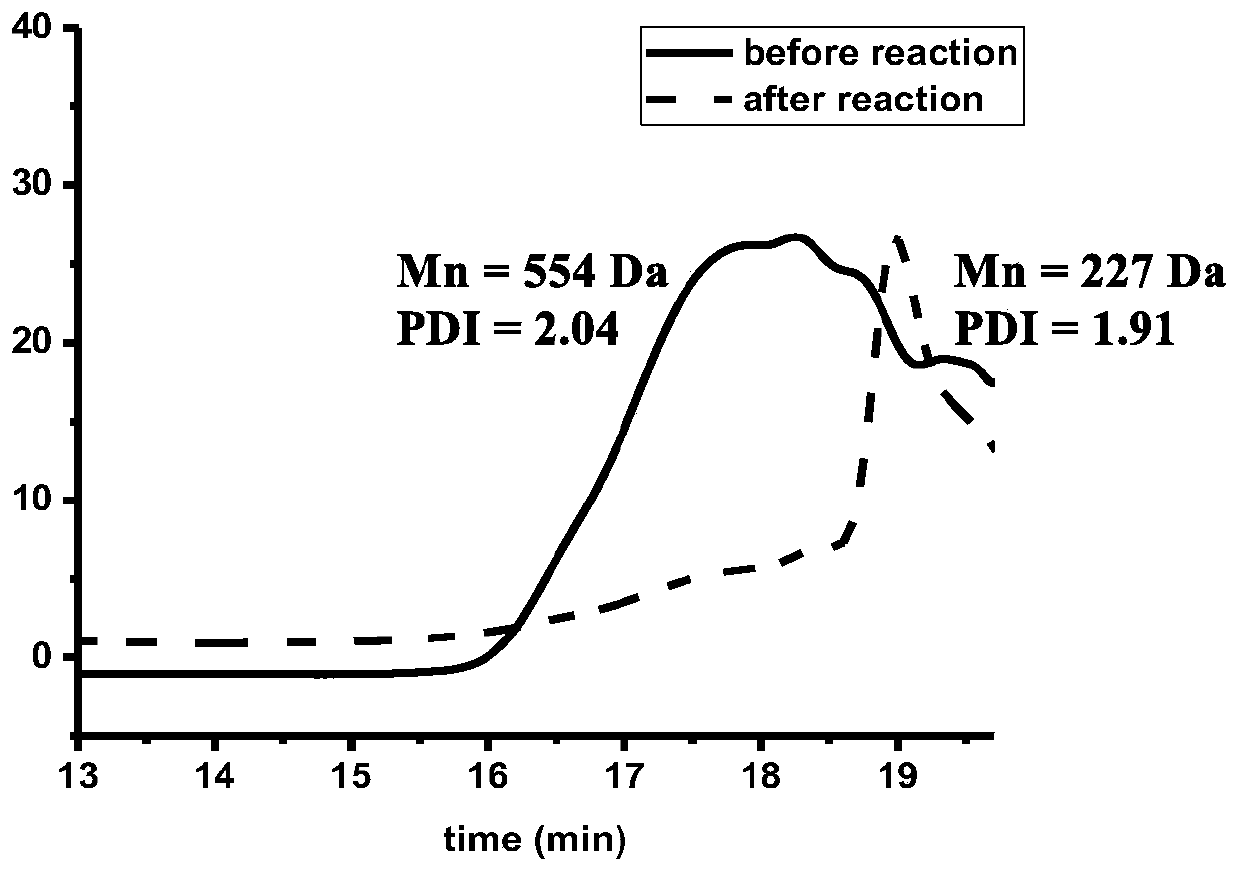

[0027] Example 1: Cleavage and Amination of Selective C-C Bonds of Lignin Dimer 1

[0028]

[0029] The reaction feed was carried out in a glove box, and lignin dimer 1 (0.1mmol, 24.4mg), photocatalyst cerium trichloride (1mol%), auxiliary agent tetrabutylammonium chloride (5mol%), azo Di-tert-butyl dicarboxylate (0.1 mmol) and 0.5 mL of acetonitrile were placed in a 10 mL reaction pressure tube. Seal the reaction pressure tube and place it under a blue light of 420nm, stir for 12 hours until the lignin dimer 1 is completely converted, and separate it by silica gel column chromatography (ethyl acetate:petroleum ether=1:5, volume ratio) to obtain The product p-methoxybenzaldehyde (12.4 mg, yield 91%) and 1-(phenoxymethyl)-1,2-dicarboxylate di-tert-butylcarboxylate-hydrazine (hydrazine 1) (30.8 mg, yield rate 91%).

[0030] NMR data:

[0031] p-Methoxybenzaldehyde: 1 H NMR (500MHz, Chloroform-d) δ9.87(s,1H),7.81–7.75(m,2H),7.01–6.95(m,2H),3.80(s,3H). 13 C NMR (126MHz, CD...

Embodiment 2

[0033] Cleavage and amination of selective C-C bond of embodiment 2 lignin dimer 2

[0034]

[0035] The reaction addition was carried out in a glove box, and lignin dimer 2 (0.1mmol, 27.4mg), photocatalyst di-n-tetrabutylcerium hexachloride [(nBu 4 N) 2 CeCl 6 ] (1mol%), auxiliary agent tetrabutylphosphorus chloride (5mol%), nitrogen source diisopropyl azodicarboxylate (0.1mmol) and 1.0mL dichloromethane in a 10ml pressure-resistant tube. Seal the reaction pressure tube and place it under ultraviolet 365nm, stir for 18 hours until the lignin dimer 2 is completely converted, and then separate it by silica gel column chromatography (ethyl acetate:petroleum ether=1:5, volume ratio) to obtain the product p-methoxybenzaldehyde (12.5 mg, yield 92%) and 1-(1-phenoxyethanolyl)-1,2-dicarboxylate diisopropyl-hydrazine (hydrazine 2) (20.4 mg, Yield 81%).

[0036] NMR data:

[0037] P-methoxybenzaldehyde: as in Example 1.

[0038] Hydrazine 2: 1H NMR (500MHz, Chloroform-d) δ7.3...

Embodiment 3

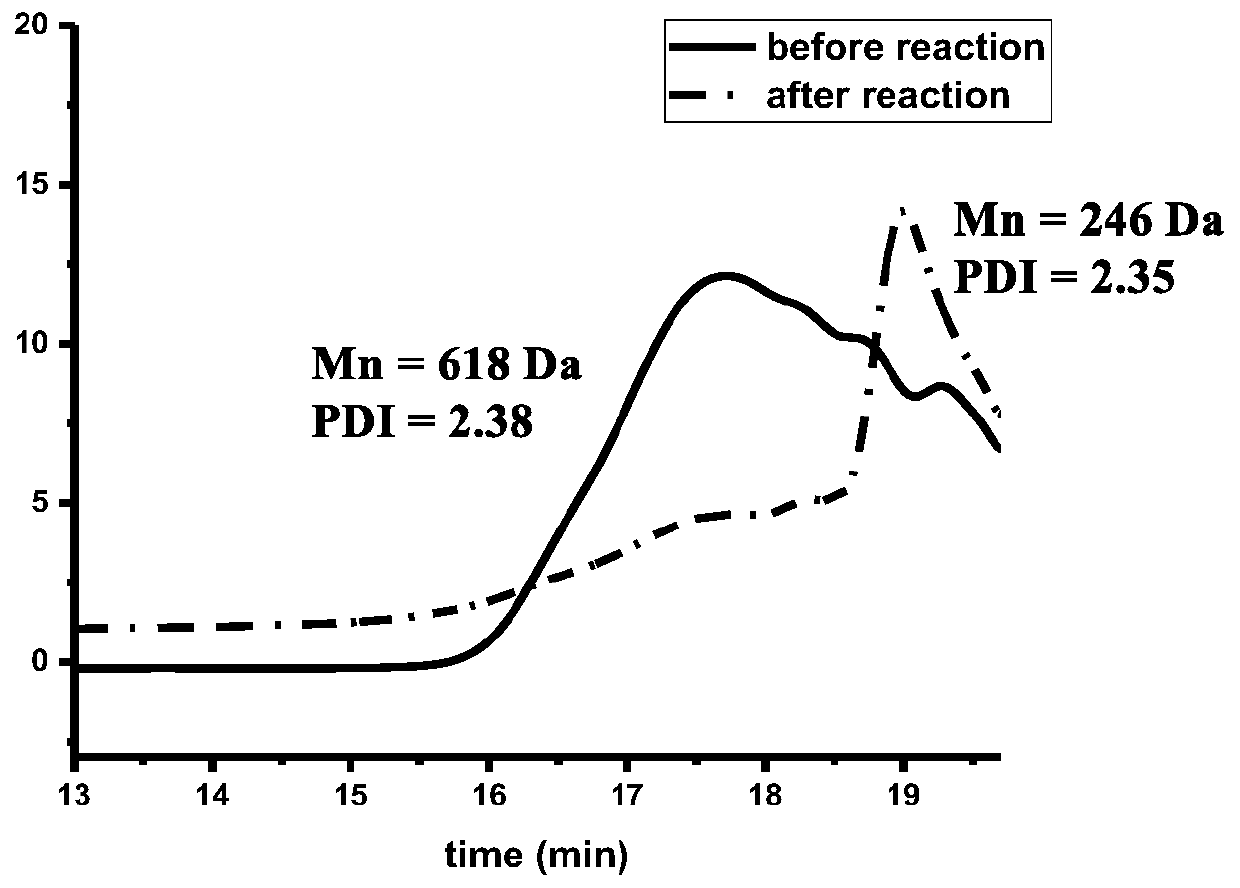

[0039] Cleavage and amination of selective C-C bond of embodiment 3 lignin dimer 3

[0040]

[0041] The reaction feed was carried out in a glove box, and lignin dimer 3 (0.1mmol, 33.4mg), photocatalyst cerium trifluoromethanesulfonate (5mol%), auxiliary agent tetrabutylammonium chloride (5mol%), Nitrogen source di-tert-butyl azodicarboxylate (1 mmol) and 2.0 mL pyridine in a 10 mL pressure-resistant tube. Seal the reaction pressure tube and place it under a purple lamp at 380nm, stir for 24 hours until the lignin dimer 3 is completely converted, and then separate it by silica gel column chromatography (ethyl acetate:petroleum ether=1:5, volume ratio) to obtain The products 3,4-dimethoxybenzaldehyde (13.4 mg, 81% yield) and 1-[1-(2-methoxy)phenoxyethanol]-1,2-dicarboxylic acid diisopropyl Esteryl-hydrazine (hydrazine 3) (28.3 mg, 71% yield).

[0042] NMR data:

[0043] 3,4-Trimethoxybenzaldehyde: 1 H NMR (500MHz, Chloroform-d) δ9.85(d, J=1.2Hz, 1H), 7.52–7.43(m, 2H), 7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com