Patents

Literature

57 results about "Diisopropyl azodicarboxylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diisopropyl azodicarboxylate (DIAD) is the diisopropyl ester of azodicarboxylic acid. It is used as a reagent in the production of many organic compounds. It is often used in the Mitsunobu reaction where it serves as an oxidizer of triphenylphosphine to triphenylphosphine oxide. It has also been used to generate aza-Baylis-Hillman adducts with acrylates. It can also serve as a selective deprotectant of N-benzyl groups in the presence of other protecting groups.

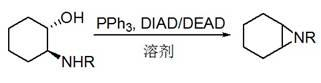

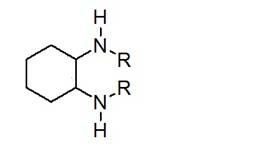

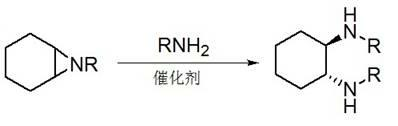

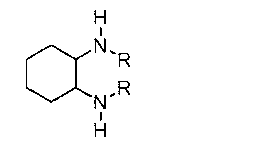

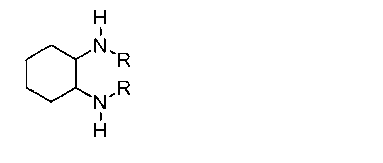

Method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine

InactiveCN102531918ASimple and fast operationMild reaction conditionsOrganic compound preparationAmino compound preparationDiisopropyl azodicarboxylateHexamethylenediamine

The invention discloses a method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine, belonging to the field of chemistry. The method comprises the following steps of: carrying out an airtight or reflux reaction on cyclohexene oxide and an aqueous solution of alkylamine for reacting at 80-120 DEG C for 1.5-5h to obtain 2-alkyl-amino cyclohexanol, dropwise adding DEAD (Diethyl Azodicarboxylate) or DIAD (Diisopropyl Azodicarboxylate) to triphenylphosphine, 2-alkyl-amino cyclohexanol and a solvent under an ice bath for reacting for 5-20h at room temperature to obtain N-alkyl-7-azabicyclo[4, 1, 0]heptane, adding a catalyst to the N-alkyl-7-azabicyclo[4, 1, 0]heptane and the aqueous solution of alkylamine at 100-120 DEG C to carry out the airtight or reflux reaction to obtain trans-N,N'-dialkyl-1,2 cyclohexanamine, dissolving the trans-N,N'-dialkyl-1,2 cyclohexanamine in an alcoholic solvent, and adding a tartaric acid type resolving agent with the equivalent weight of 0.5 to the alcoholic solvent to resolve so as to obtain the enantiomorphous pure symmetric trans-dialkyl cyclohexylamine.

Owner:ANYANG INST OF TECH

Method of preparing vinyl alcohol with low degree of polymerization

The invention relates to a method for producing low polymerization degree polyvinyl alcohol including: mixing the monomer vinyl acetate with solvent carbinol in a mass ratio of 60-80:20, adding ignition primer diisopropyl azodicarboxylate taking 0.1-0.5% of the monomer mass and chain transfer agent 2-mercaptoethanol taking 0.1-0.5% of the monomer mass, producing low polymerization degree polyvinyl acetate by solution polymerization method; dissolving the low polymerization degree polyvinyl acetate in the carbinol to get polyvinyl acetate carbinol solution, adding NaOH carbinol solution, alcoholysis to get low polymerization degree polyvinyl alcohol. The inventive method can produce low polymerization degree polyvinyl alcohol with a low polymerization degree of 50-500.

Owner:ZHONGBEI UNIV

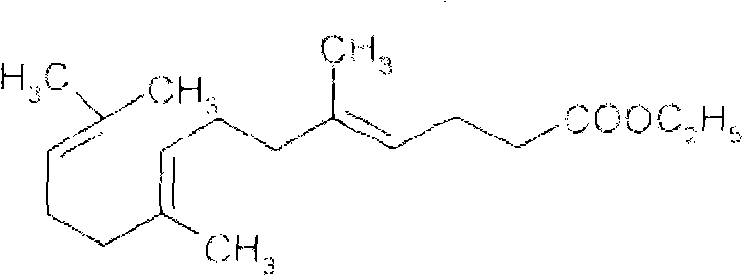

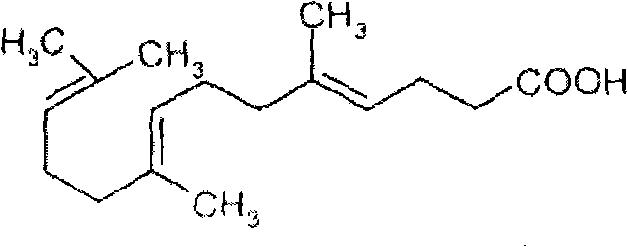

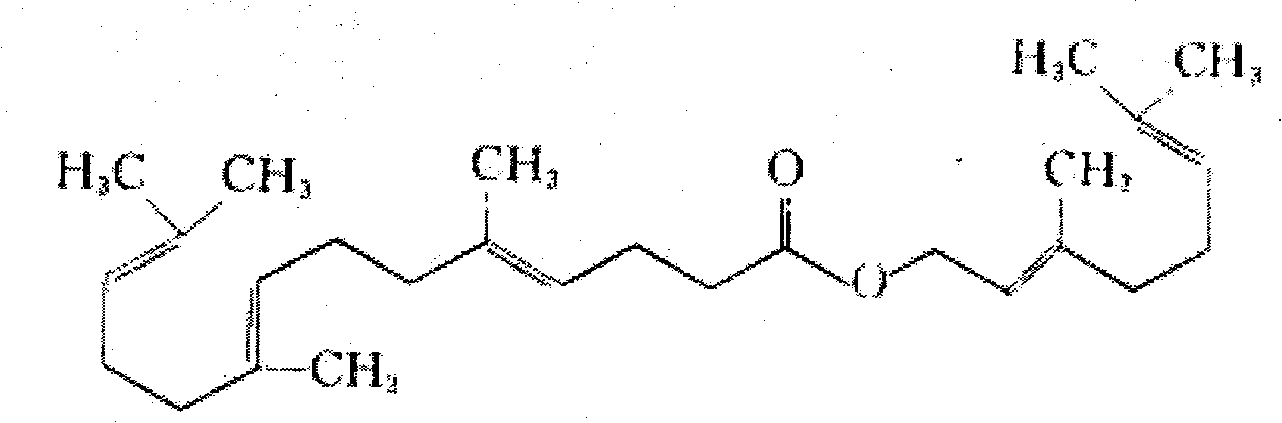

Process for synthesizing gefarnate compound

ActiveCN102146039ALow-level and harmless processHigh yieldOrganic compound preparationCarboxylic acid esters preparationTriethyl orthoacetateSodium bicarbonate

The invention relates to a process for synthesizing a gefarnate compound, which comprises the following steps of: stirring and mixing triethyl orthoacetate, nerolidol and isobutyric acid, performing heating reaction, and distilling under reduced pressure to obtain an intermediate one; adding the intermediate one into ethanol solution of potassium hydroxide, performing heating reaction, distilling to remove ethanol, extracting, taking an aqueous phase, regulating the pH value by using hydrochloric acid, extracting again, taking an organic phase, washing with water, drying, and distilling off the solvent under reduced pressure to obtain an intermediate two; adding acetaldehyde, geraniol and dichloromethane into the intermediate two, reducing the temperature to -5DEG C, slowly dripping diisopropyl azodicarboxylate, keeping the temperature to react for 2 hours, filtering, washing for three times by using 5 percent sodium bicarbonate, washing for three times by using water, drying, and distilling off the solvent under reduced pressure to obtain faint yellow oily liquid, namely the gefarnate product.

Owner:BEIJING LUNARSUN PHARMA

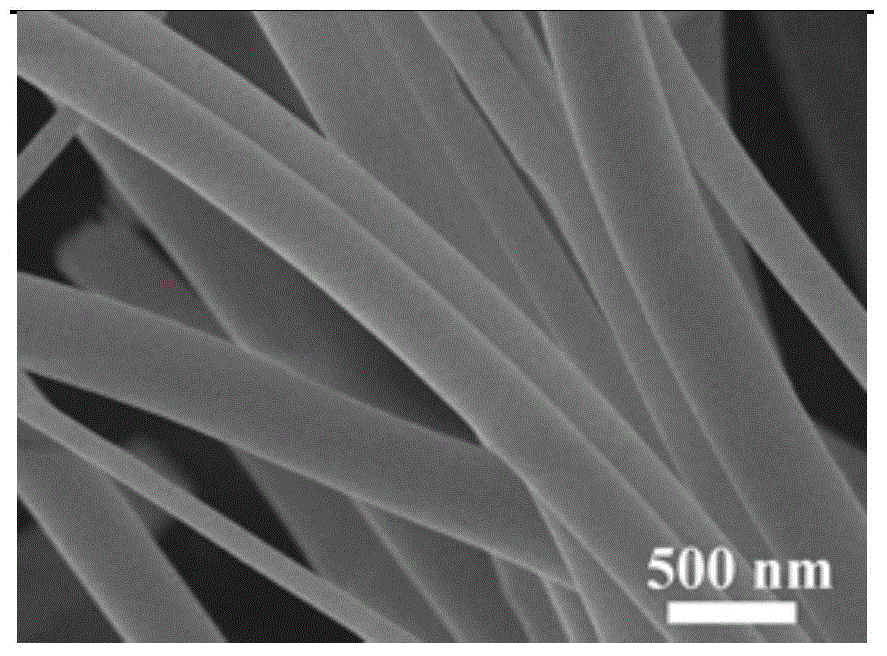

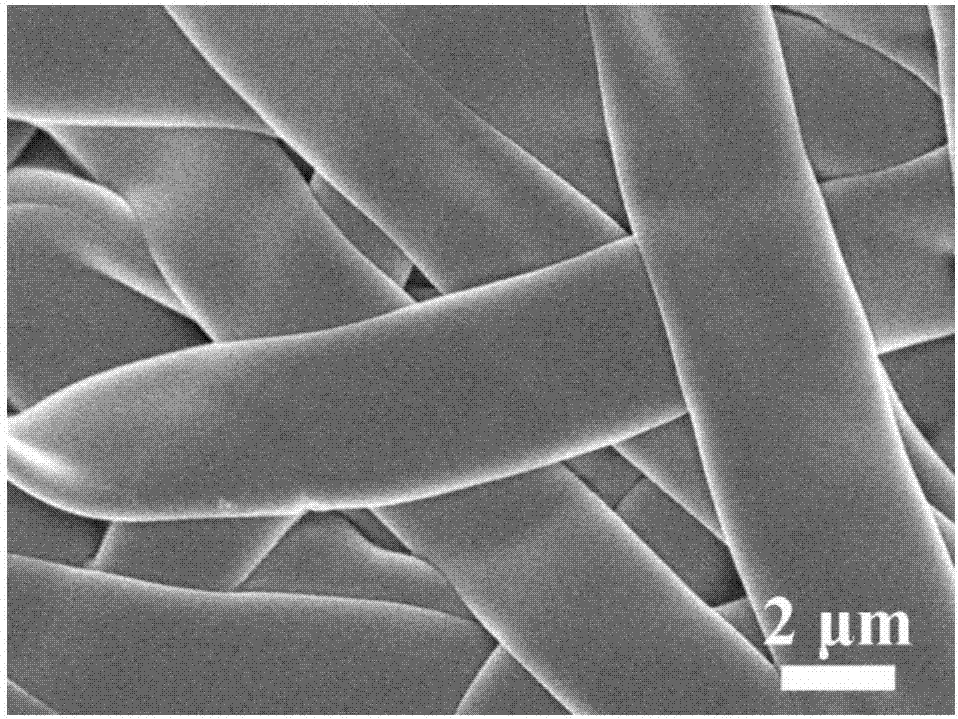

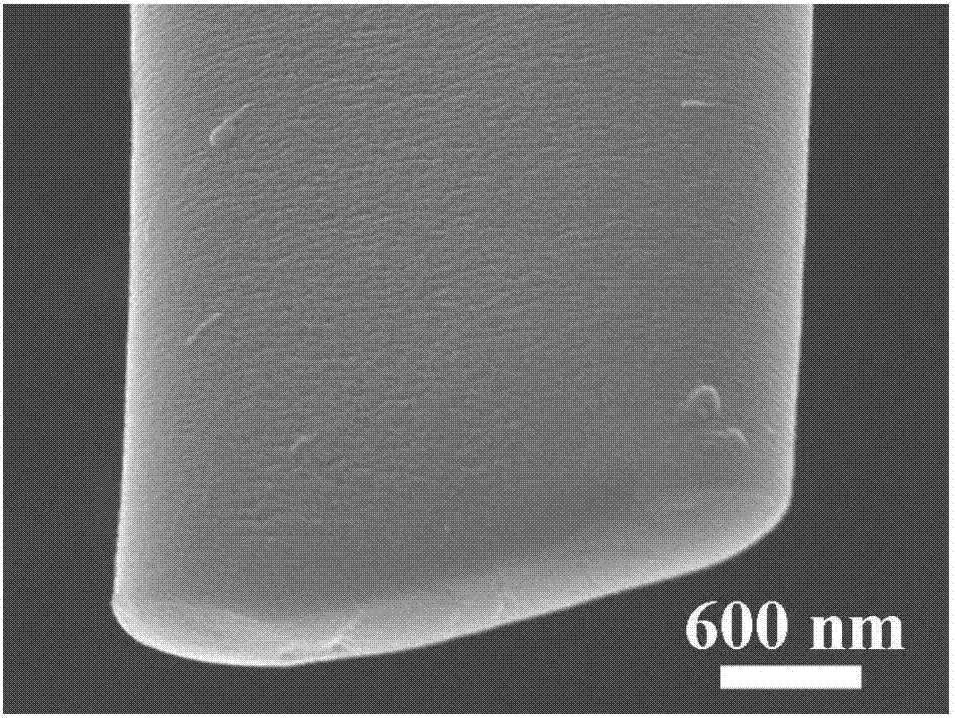

Preparation method of high-purity N-doped TiO2 mesoporous nanofiber

ActiveCN105002599AHigh sensitivityThe operation process is simple and controllableInorganic material artificial filamentsFilament/thread formingFiberNanowire

The invention discloses a preparation method of a high-purity N-doped TiO2 mesoporous nanofiber. The preparation method comprises following steps: 1) a precursor spinning solution is prepared, wherein polyvinylpyrrolidone, butyl titanate, diisopropyl azodicarboxylate, and urea are dissolved in a mixed solvent of absolute ethyl alcohol and glacial acetic acid so as to obtain the uniform precursor spinning solution; 2) precursor nanowire is prepared, wherein the precursor nanowire is obtained by subjecting the precursor spinning solution to spinning; and 3) nanowire is prepared, wherein the obtained precursor nanowire is subjected to high temperature calcinations so as to obtain the high-purity N-doped TiO2 mesoporous nanofiber. The preparation technology of the high-purity N-doped TiO2 mesoporous nanofiber is simple; production is convenient; and product quality stability is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

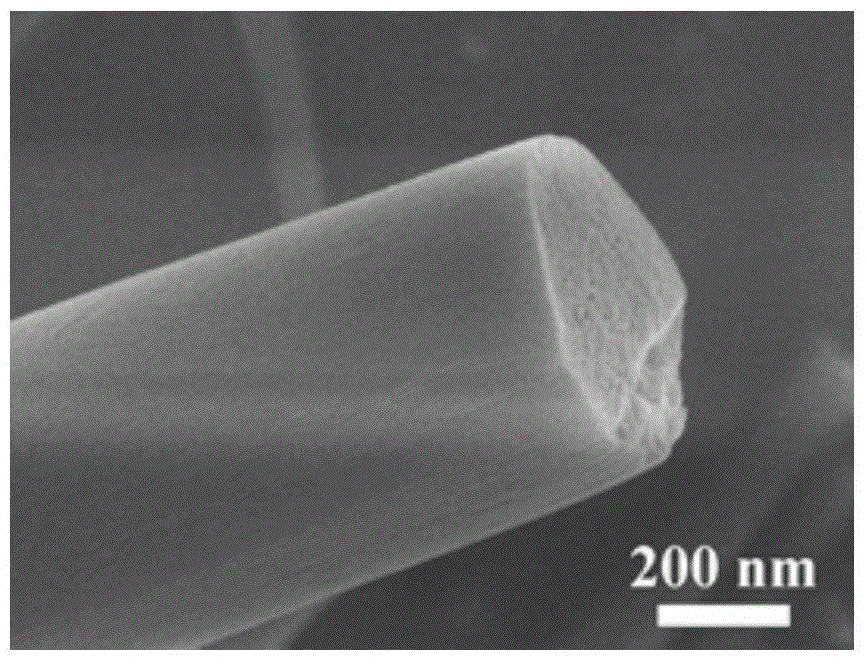

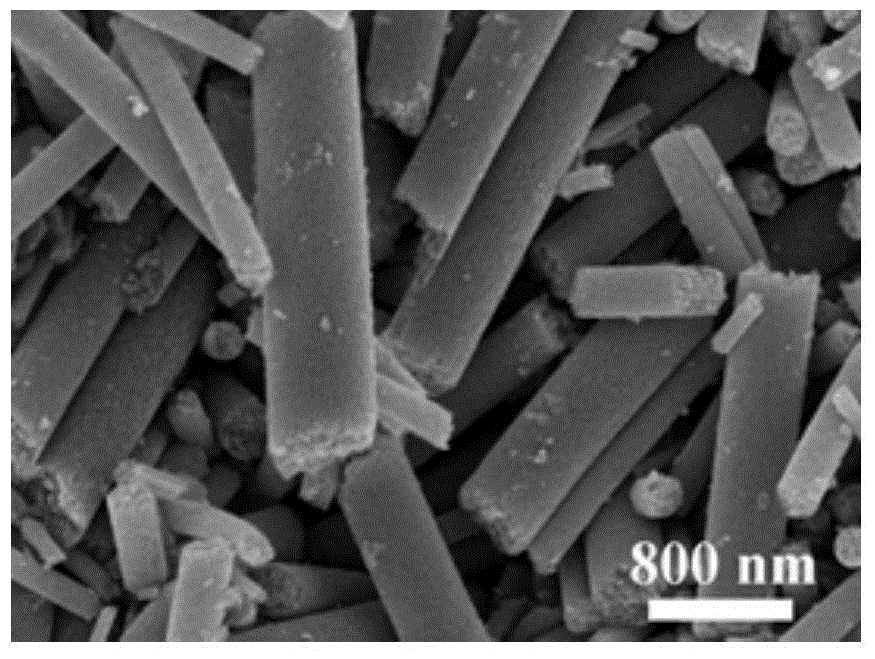

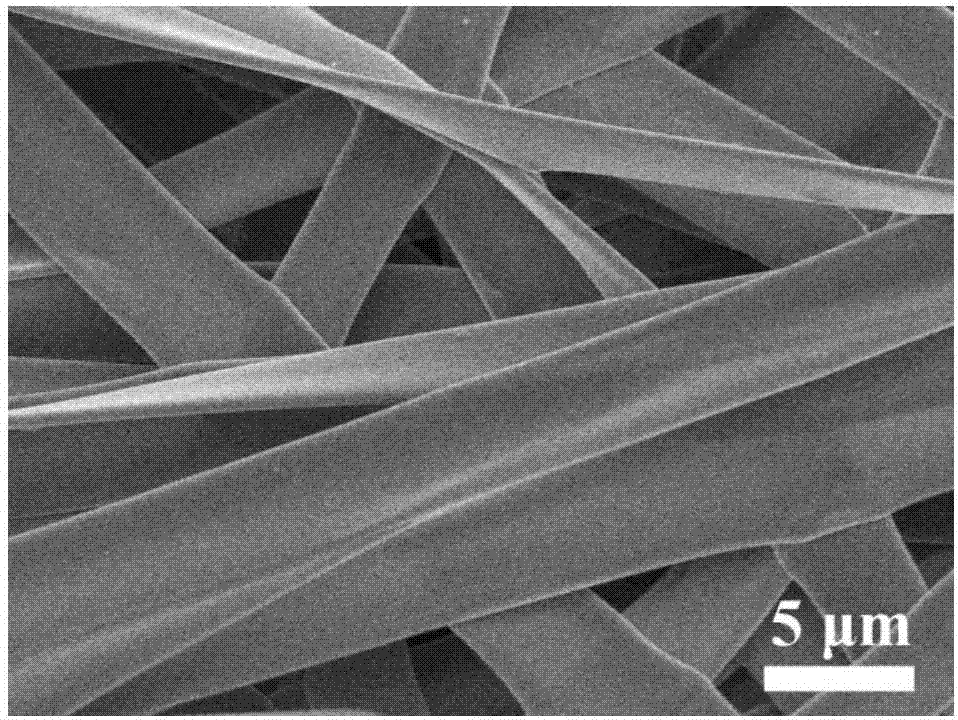

Preparation method of high-purity ZnO/BiVO4 heterogeneous micro-ribbon

ActiveCN107190362AEffective regulatory structureEffective Regulatory ComponentsInorganic material artificial filamentsHeterogenous catalyst chemical elementsDiisopropyl azodicarboxylateElectrospinning

The invention relates to a preparation method of a high-purity ZnO / BiVO4 heterogeneous micro-ribbon, and belongs to the technical field of the micro-ribbon. The preparation method includes steps of dissolving polyvinylpyrrolidone, bismuth nitrate pentahydrate, bis(acetylacetone) vanadium oxide and diisopropyl azodicarboxylate in a mixed solvent; stirring and mixing under a room temperature to form a precursor spinning fluid; performing electrostatic spinning on the precursor spinning fluid to obtain a solid precursor micro-ribbon; placing the solid precursor micro-ribbon in an atomic layer deposition system; reacting with water by diethylzinc; after circulation, depositing ZnO on the surface of the precursor micro-ribbon; performing high-temperature calcination on the precursor micro-ribbon coated with ZnO to obtain the ZnO / BiVO4 heterogeneous micro-ribbon material. Compared with the prior art, the method uses diethylzinc to strongly react with water and generate ZnO; through changing the circulation frequency in the atomic layer deposition system, the structure and component of the ZnO / BiVO4 heterogeneous micro-ribbon are effectively controlled.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

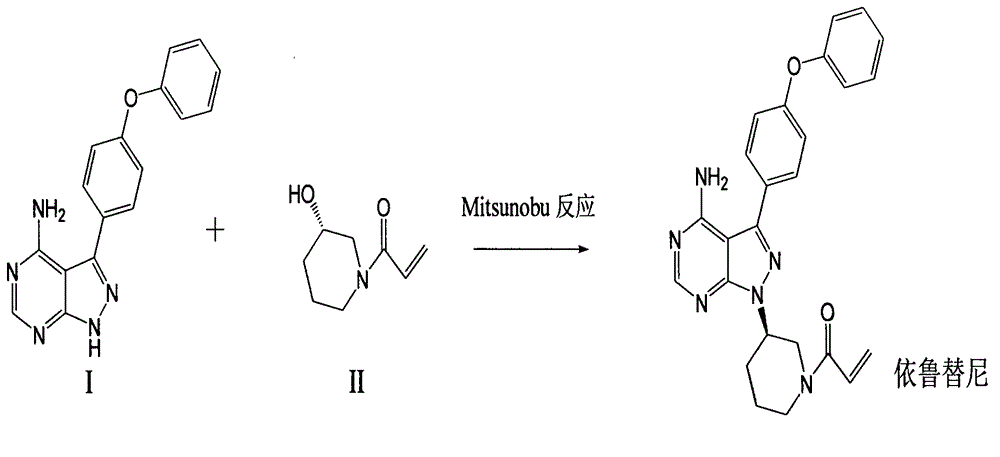

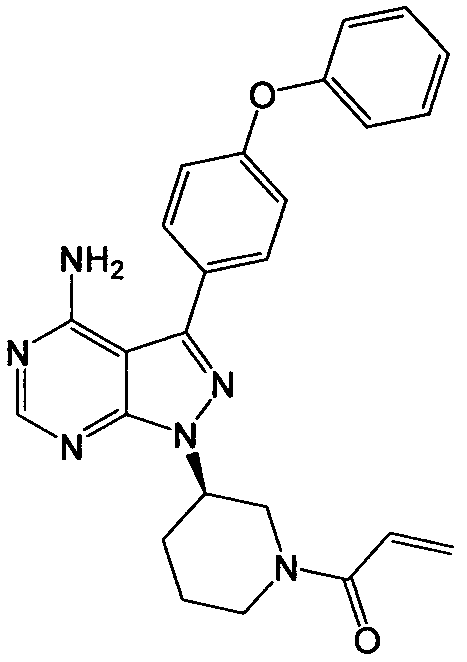

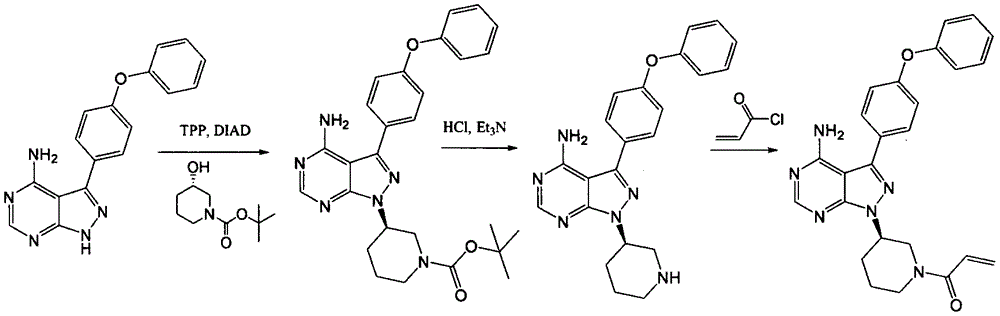

Preparation method of ibrutinib

InactiveCN104557946ARaw materials are easy to getSimple processOrganic chemistryDiisopropyl azodicarboxylateTriphenylphosphine

The invention relates to a preparation method of ibrutinib. The preparation method comprises the following steps: allowing 4-amino-3-(4-phenoxyphenyl)-1H-pyrazolo [3, 4-d] pyrimidine, 1-[3(S)-hydroxy-1-piperidinyl]-2-propen-1-one, and triphenylphosphine to be dissolved in tetrahydrofuran as a reaction solvent at a temperature of -20 to 100 DEG C, and then slowly adding diisopropyl azodicarboxylate, and stirring until the reaction is finished to obtain the ibrutinib. The preparation method provided by the invention has the advantages of easy availability of raw materials, mild conditions, simple process, economy and environmental protection, and is suitable for industrial production.

Owner:王立强 +1

Method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine

InactiveCN102531918BSimple and fast operationMild reaction conditionsOrganic compound preparationAmino compound preparationDiisopropyl azodicarboxylateHexamethylenediamine

The invention discloses a method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine, belonging to the field of chemistry. The method comprises the following steps of: carrying out an airtight or reflux reaction on cyclohexene oxide and an aqueous solution of alkylamine for reacting at 80-120 DEG C for 1.5-5h to obtain 2-alkyl-amino cyclohexanol, dropwise adding DEAD (Diethyl Azodicarboxylate) or DIAD (Diisopropyl Azodicarboxylate) to triphenylphosphine, 2-alkyl-amino cyclohexanol and a solvent under an ice bath for reacting for 5-20h at room temperature to obtain N-alkyl-7-azabicyclo[4, 1, 0]heptane, adding a catalyst to the N-alkyl-7-azabicyclo[4, 1, 0]heptane and the aqueous solution of alkylamine at 100-120 DEG C to carry out the airtight or reflux reaction to obtain trans-N,N'-dialkyl-1,2 cyclohexanamine, dissolving the trans-N,N'-dialkyl-1,2 cyclohexanamine in an alcoholic solvent, and adding a tartaric acid type resolving agent with the equivalent weight of 0.5 to the alcoholic solvent to resolve so as to obtain the enantiomorphous pure symmetric trans-dialkyl cyclohexylamine.

Owner:ANYANG INST OF TECH

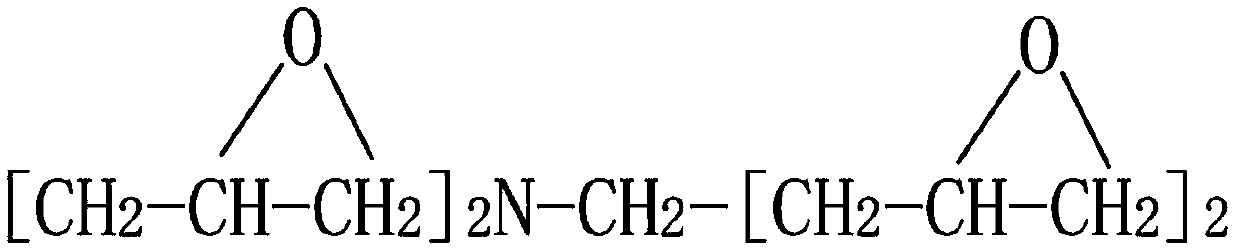

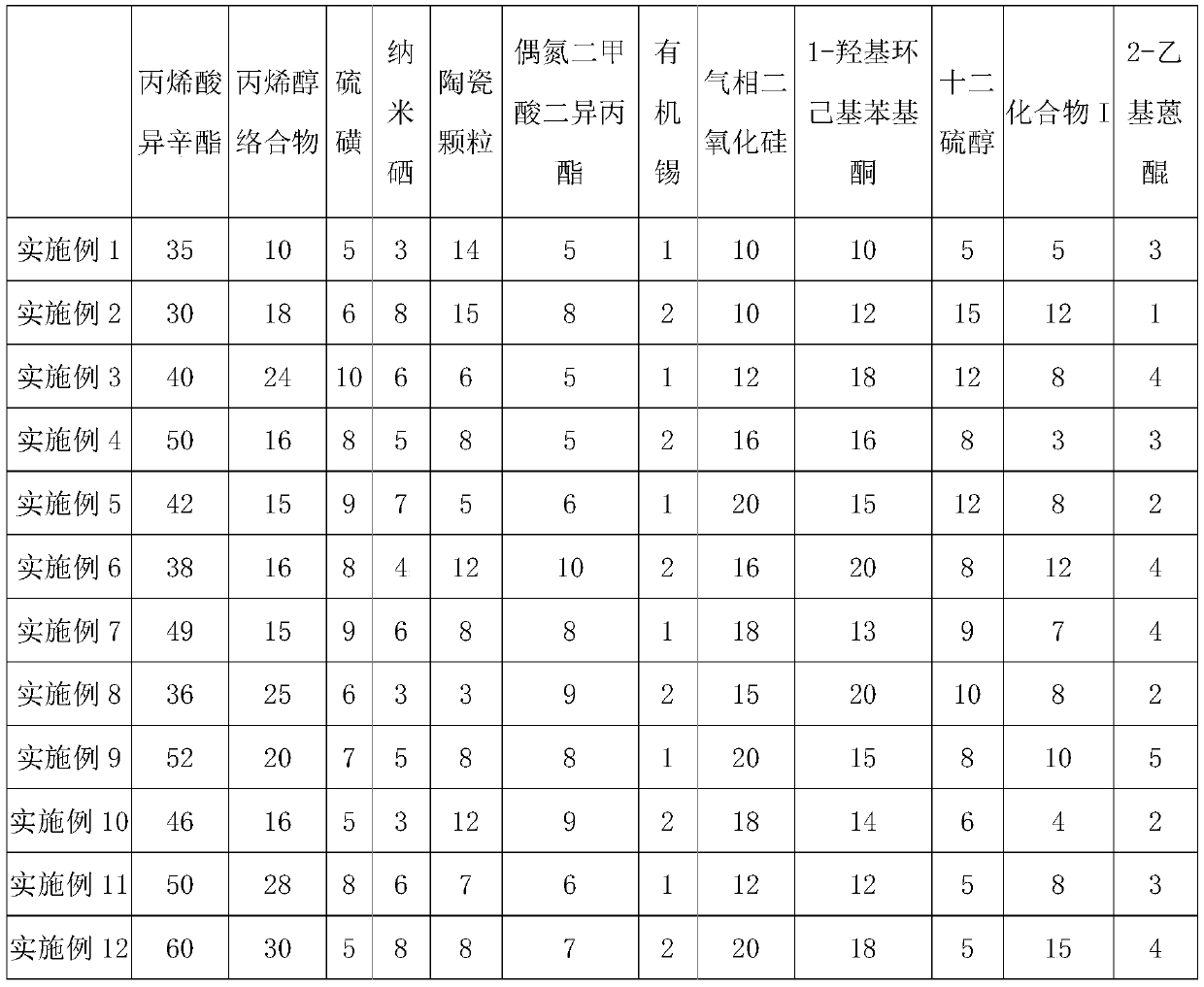

Novel formula of modified foamed ethylene-vinyl acetate (EVA) plastic

The invention discloses a novel formula of modified foamed ethylene-vinyl acetate (EVA) plastic. The modified foamed EVA plastic comprises EVA plastic and additives, wherein the additives comprise silicon nitride serving as a wear-resistant agent, chlorinated polyethylene serving as a toughening agent, maleic anhydride graft serving as a compatilizer, diisopropyl azodicarboxylate serving as a foaming agent, mercaptopropyl triethoxysilane serving as a coupling agent and triethylenetetramine serving as a cross-linking agent. By the foaming agent, the EVA plastic can become soft; by the wear-resistant agent, the wear resistance of the product can be improved, and the product is difficult to damage; by the toughening agent, the mechanical strength of the product can be improved; and by the compatilizer, the coupling agent and the cross-linking agent, the internal molecular structure of the product can be tightly combined, the reaction rate in the production process is improved, and production cost is reduced.

Owner:SUZHOU XINGWU ENG PLASTIC

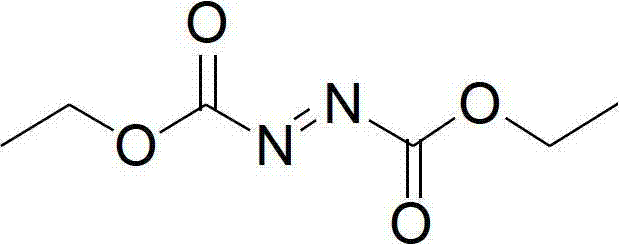

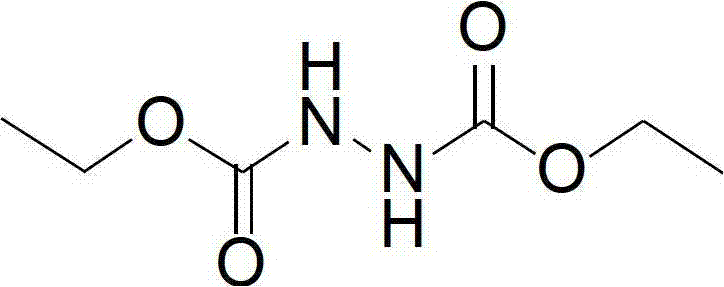

Synthesis method of diethyl azodicarboxylate and intermediate of diethyl azodicarboxylate

ActiveCN102898328ANo pollution in the processIn line with the concept of modern green chemistryHydrazide preparationDiisopropyl azodicarboxylateDistillation

The invention discloses a synthesis method of diethyl azodicarboxylate. The synthesis method comprises the following steps that (1) under the effect of sodium ethoxide, diethyl carbonate and ethyl carbazate are heated for reaction for 1 to 6 hours, the pH of solution is regulated to 3 to 8, white crystals are separated out, the recrystallization is carried out, and hydrogenated diethyl azodicarboxylate is obtained; and (2) the hydrogenated diethyl azodicarboxylate is added at minus 15 DEG C to 45 DEG C, in the acid solution, bromine or hydrobromic acid or sodium bromide and potassium bromide are used as catalysts, excessive hydrogen peroxide is dripped, the reaction is carried out for 1 to 10 hours, the extraction is carried out, organic solvents are removed through distillation, and saffron diethyl azodicarboxylate is obtained. The invention also provides a hydrogenated diethyl azodicarboxylate intermediate and a synthesis method of the hydrogenated diethyl azodicarboxylate intermediate. The synthesis method has the advantages that diethyl carbonate is used as raw materials, cleanness and environment protection are realized, no pollution exists, raw materials can be cyclically utilized, the economy is better, the operation is simple, the reaction temperature range is wide, the reaction is stable, the energy consumption is low, the yield is high, and the industrial production is favorably realized.

Owner:SHANDONG NORMAL UNIV

Synthetic wood material

The invention discloses a synthetic wood material. The synthetic wood material is prepared from the following raw materials in parts by weight: 22-30 parts of recycled polystyrene, 6-11 parts of aluminum hydroxide, 3-6 parts of N-nitroso compounds, 7-10 parts of diisopropyl azodicarboxylate, 5-7 parts of butadiene styrene rubber, 6-10 parts of high-density polyethylene, 3-5 parts of color masterbatch, 3-6 parts of a salicylate light stabilizer, 4-7 parts of an opening agent, 5-10 parts of talcum powder, 6-10 parts of modified polystyrene, 6-10 parts of zinc stearate, 4-8 parts of catechol, 3-9 parts of ethanediol and 5-10 parts of acetic anhydride. The synthetic wood material disclosed by the invention has a good wood imitating effect, that is, the synthetic wood material is visually similar to wood, and the service life of the synthetic wood material is longer than that of solid wood.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

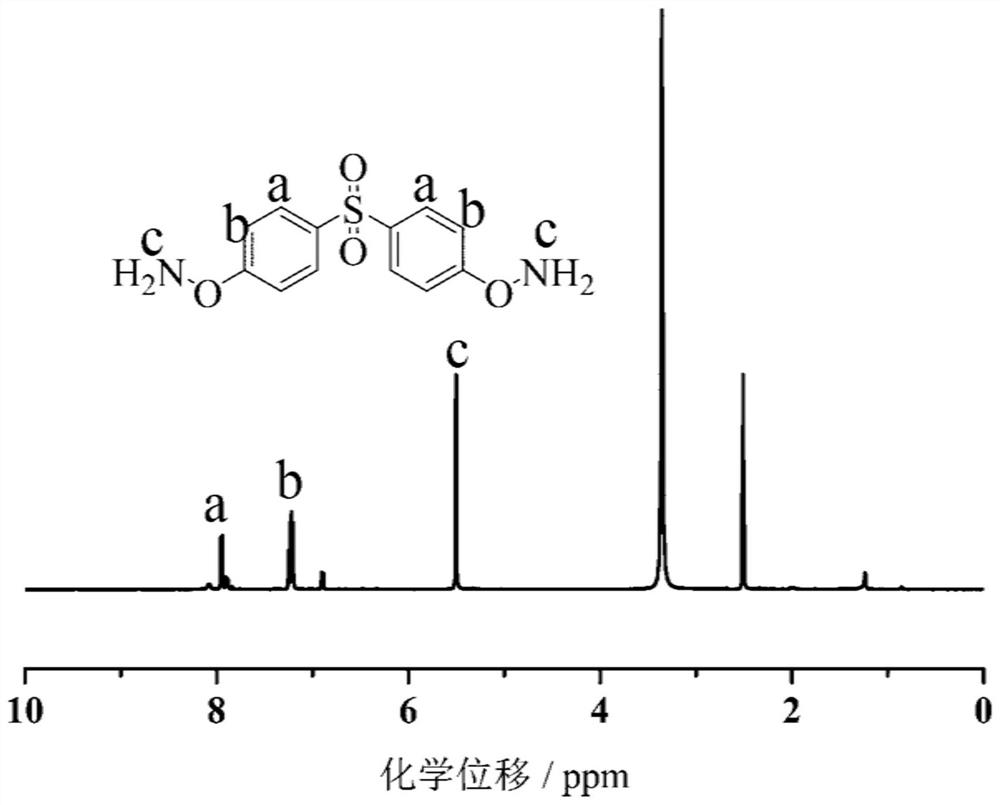

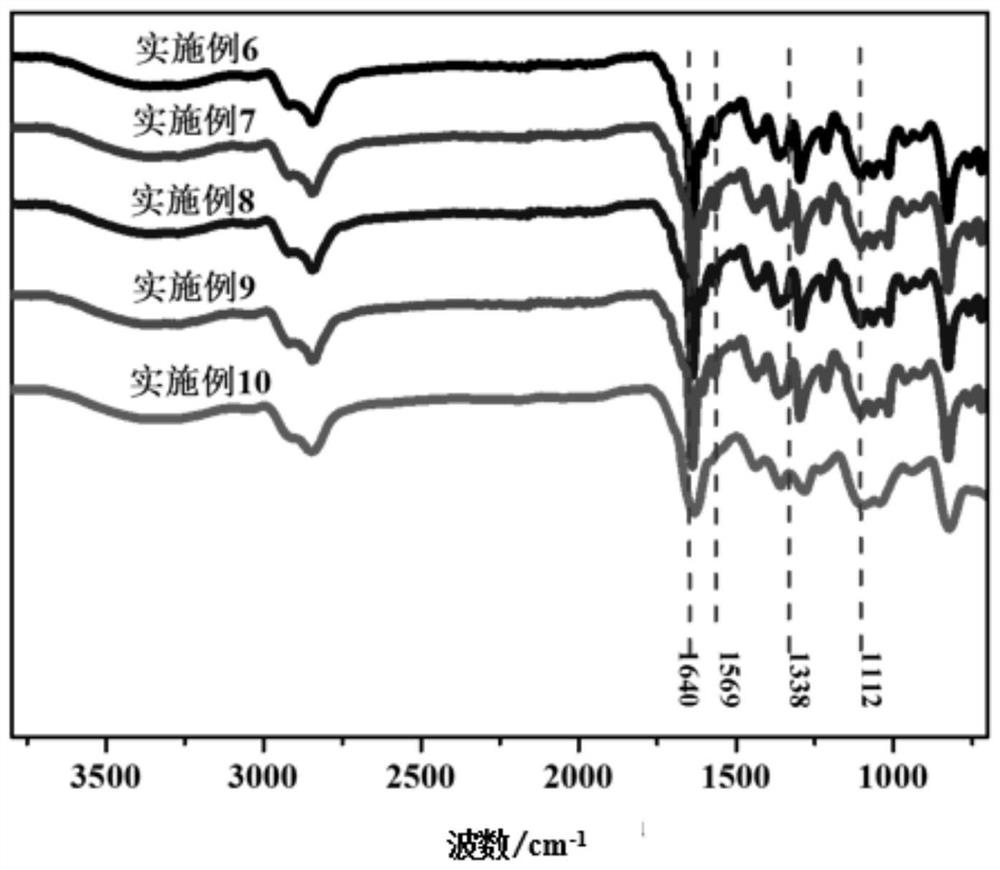

Recyclable and repairable thermosetting resin, preparation method and application thereof

ActiveCN112876631AHigh yieldEasy to separateAldehyde/ketone condensation polymer adhesivesCoatingsPolymer scienceDiisopropyl azodicarboxylate

The invention discloses a recyclable and repairable thermosetting resin, a preparation method and application thereof, and belongs to the technical field of thermosetting resin materials. The thermosetting resin is prepared from the following components in parts by weight through double dynamic covalent bond hybridization: 1-50 parts of a hydroxyamino monomer, 1-100 parts of a solvent, 1-100 parts of polyfunctional aldehyde and 1-50 parts of a cross-linking agent to carry out a Schiff base reaction on hydroxyamino, amino and aldehyde monomers, wherein the hydroxyamino monomer is prepared from the following components in parts by weight: 1 to 20 parts of hydroxyl monomer, 1 to 300 parts of solvent, 3 to 60 parts of hydrazine hydrate, 1 to 80 parts of N-hydroxyphthalimide, 2 to 80 parts of triphenylphosphine and 1 to 40 parts of diisopropyl azodicarboxylate through acylation reaction of amino and anhydride group. The preparation method of the thermosetting resin disclosed by the invention can be realized on traditional simple synthesis equipment, is low in cost and environment-friendly, and is easy to realize industrial production.

Owner:JIANGNAN UNIV

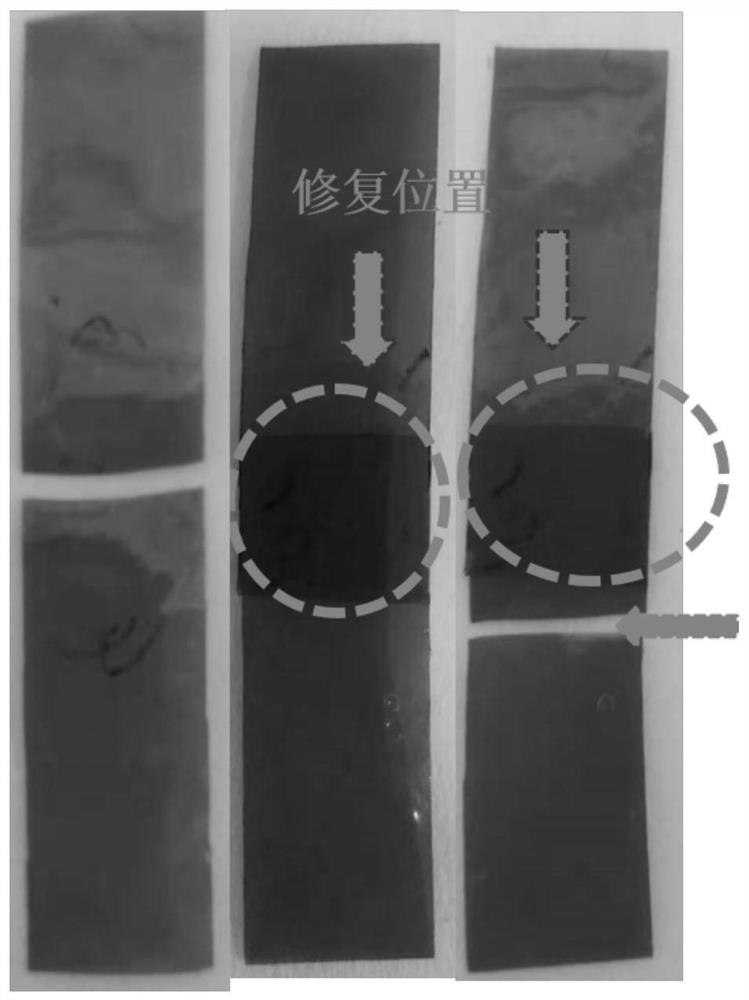

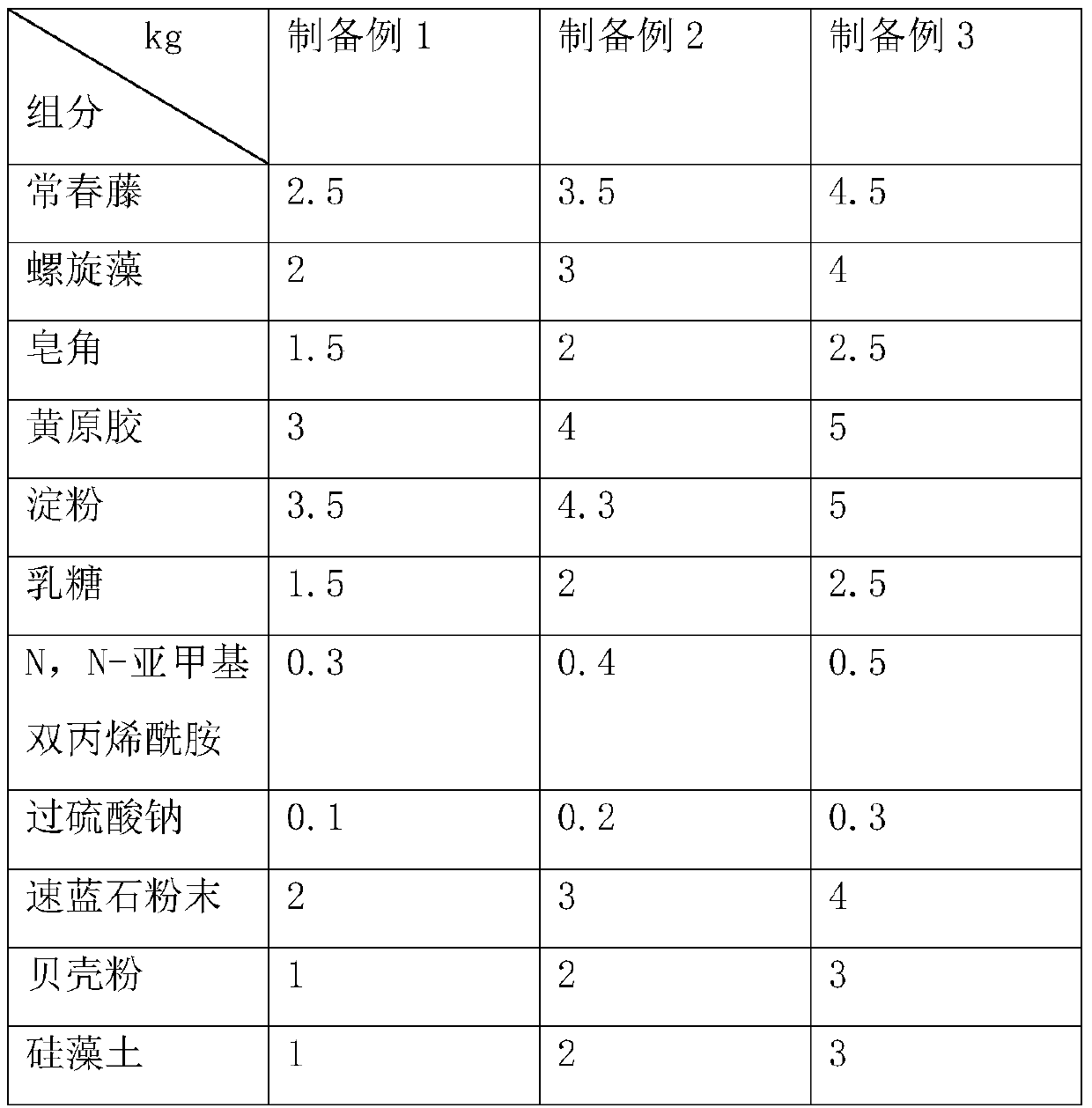

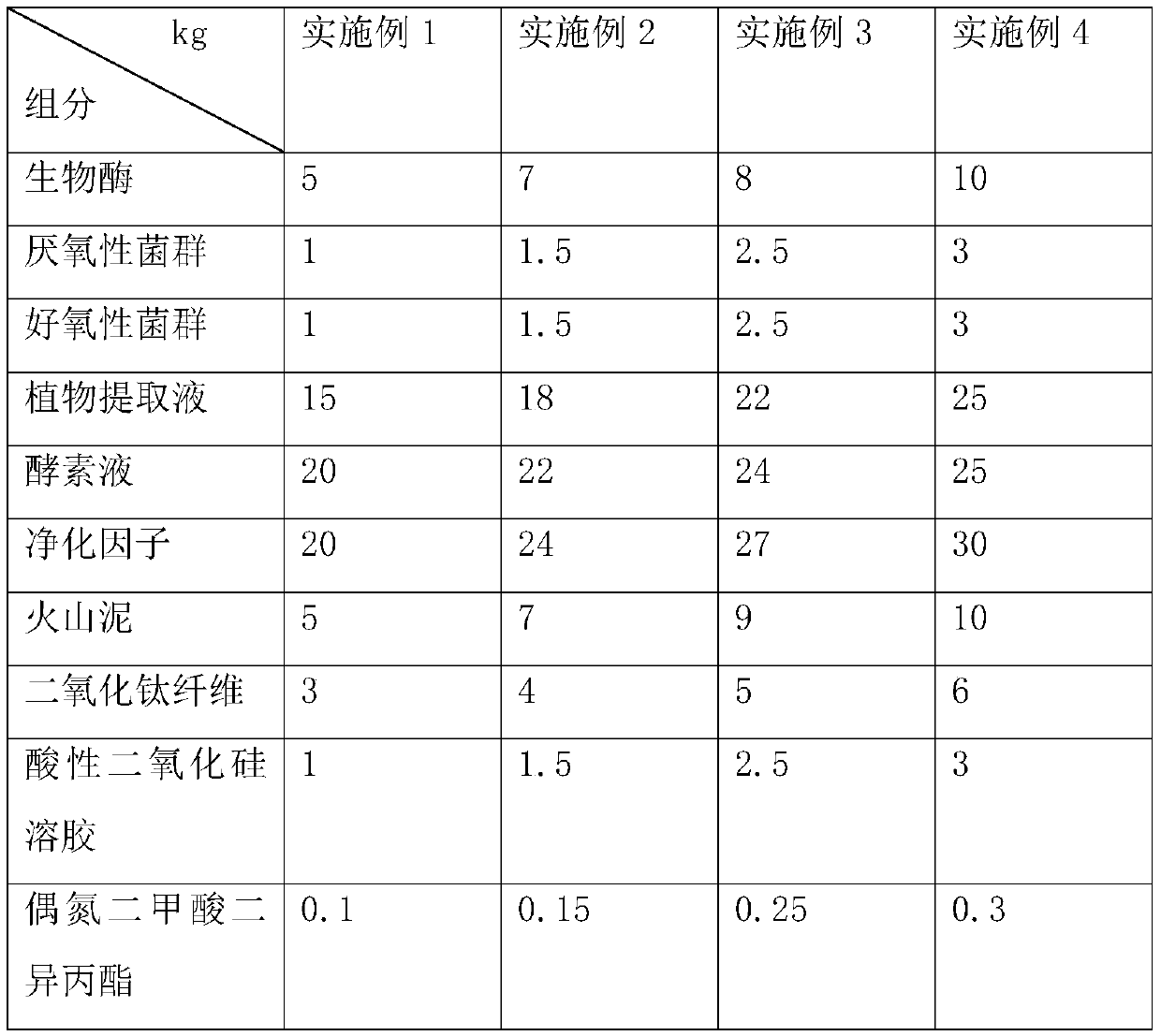

Biological deodorant and preparation method thereof

ActiveCN111514740AGood removal effectFast onset timeGas treatmentDispersed particle separationDiisopropyl azodicarboxylateOrganic synthesis

The invention discloses a biological deodorant and a preparation method thereof. The biological deodorant is prepared from the following raw materials: biological enzyme, anaerobic flora, aerobic flora, a plant extracting solution, an enzyme solution, a purification factor, volcanic mud, titanium dioxide fiber, acidic silicon dioxide sol, diisopropyl azodicarboxylate and a noble metal active component. The biological deodorant has the advantages that the deodorizing time is long for foul smells of livestock and poultry farms, sewage around the farms, municipal sewage, wasteyards, sludge and the like, the removal efficiency is high, the effect returns quickly, the removal effect is comprehensive and thorough, various odor-causing substances can be purified and absorbed, mosquitoes and fliescan be repelled to resist and inhibit bacteria; meanwhile, formaldehyde, methylbenzene and TVOC emitted by wastewater discharged from places such as organic synthesis, synthetic fibers, dyes and woodprocessing can be removed and purified to a certain extent, and harm to human bodies can be reduced.

Owner:BEIJING SHUANGLONG AMMS TECH +1

Method for synthesizing spermidine hydrochloride

ActiveCN111302953AGet efficientlySimple process conditionsAmino compound purification/separationCarbamic acid derivatives preparationMeth-Diisopropyl azodicarboxylate

The invention relates to a method for synthesizing spermidine hydrochloride. The reaction formula is shown as the following formula (I) which is described in the specification. In the formula (I), theprotective group R1 of amino in 4-amino-1-butanol of a compound 2 is one of tert-butyloxycarboryl Boc-, triphenylmethyl Trt- and p-methoxytriphenylmethyl Mmt-, and a protective group R2 of propane diamine of the compound is one of tert-butyloxycarbonyl Boc-, triphenylmethyl Trt- and p-methoxytriphenylmethyl (Mmt-). A reagent used in the Mitsunobo reaction condition is one of triphenylphosphine, di-tert-butyl azodicarboxylate, diethyl azodicarboxylate and diisopropyl azodicarboxylate. The preparation method disclosed by the invention is simple in required process condition, mild in reaction condition, capable of effectively obtaining spermidine hydrochloride, relatively short in synthesis step and relatively high in synthesis yield.

Owner:南京康立瑞生物科技有限公司

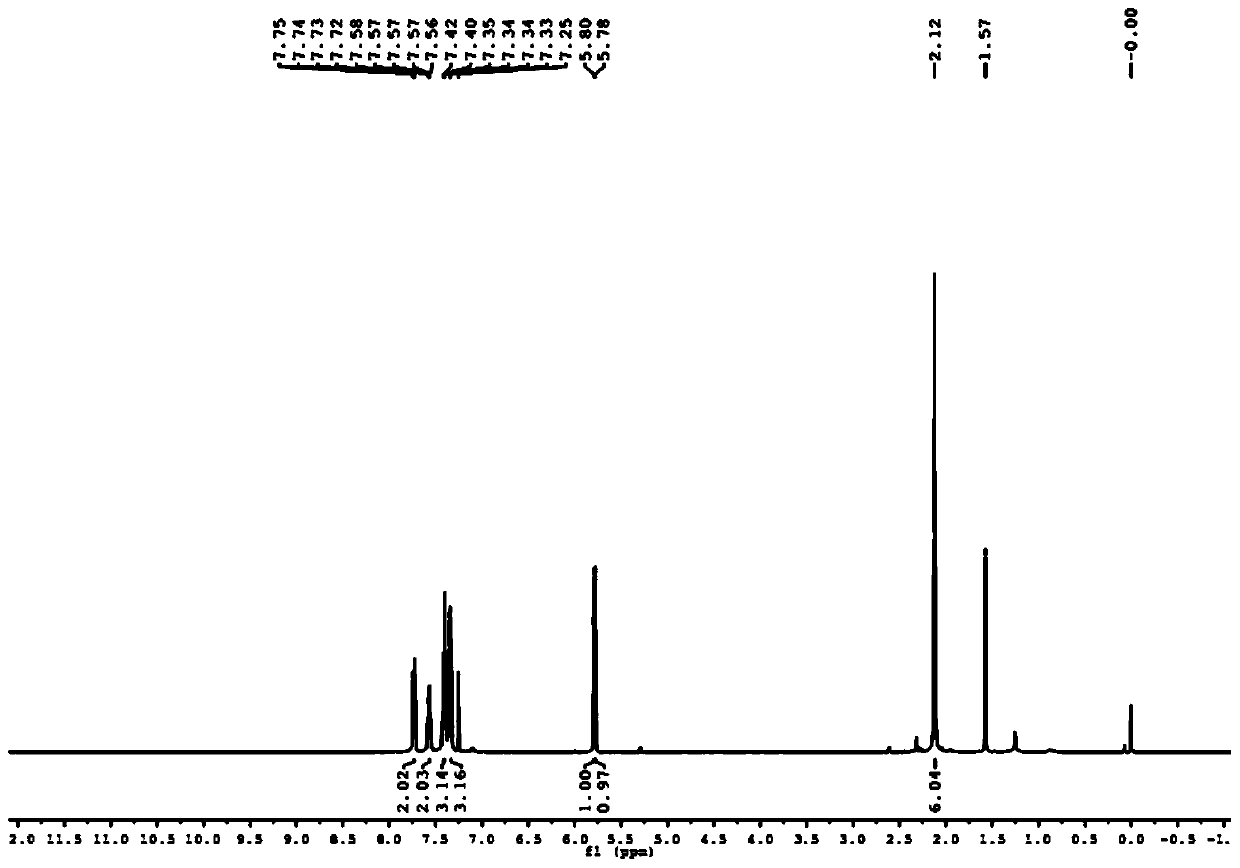

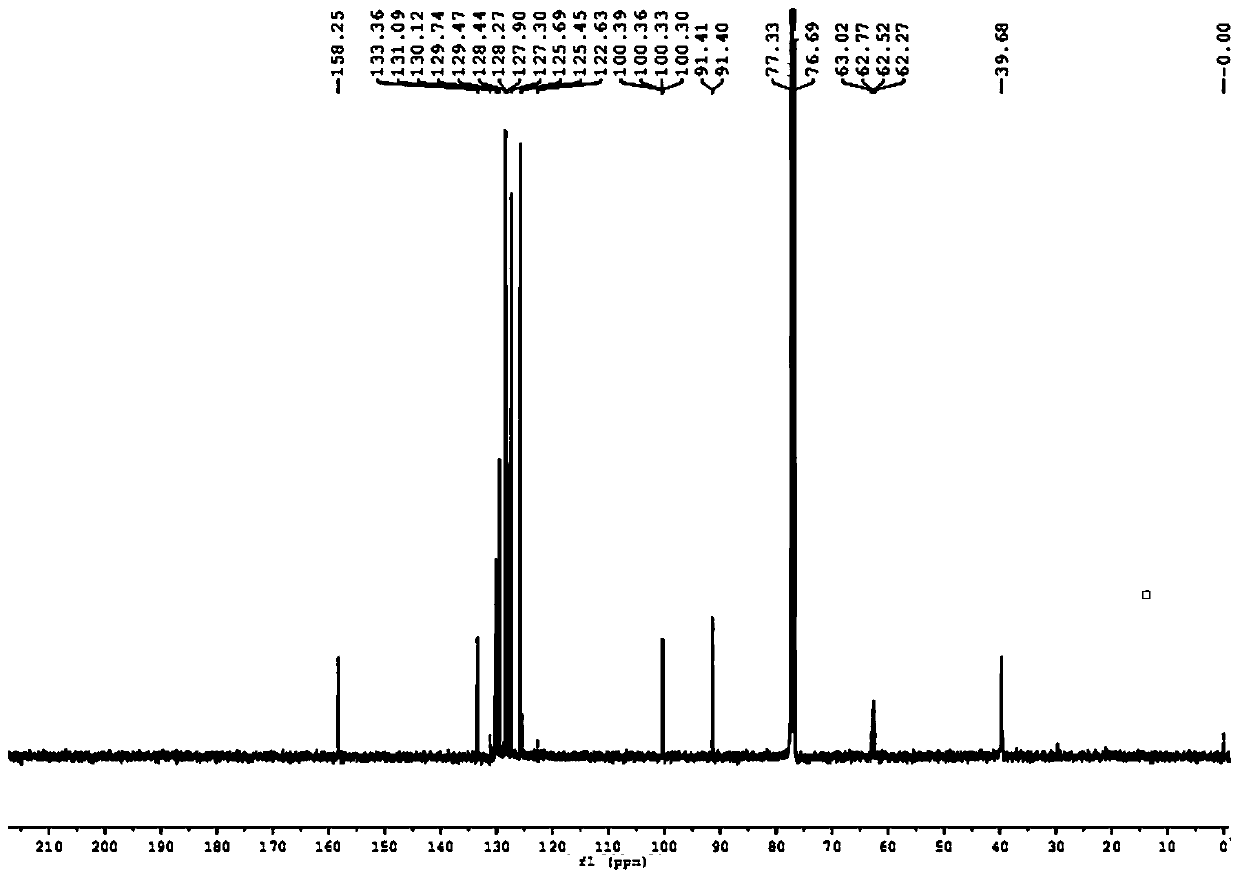

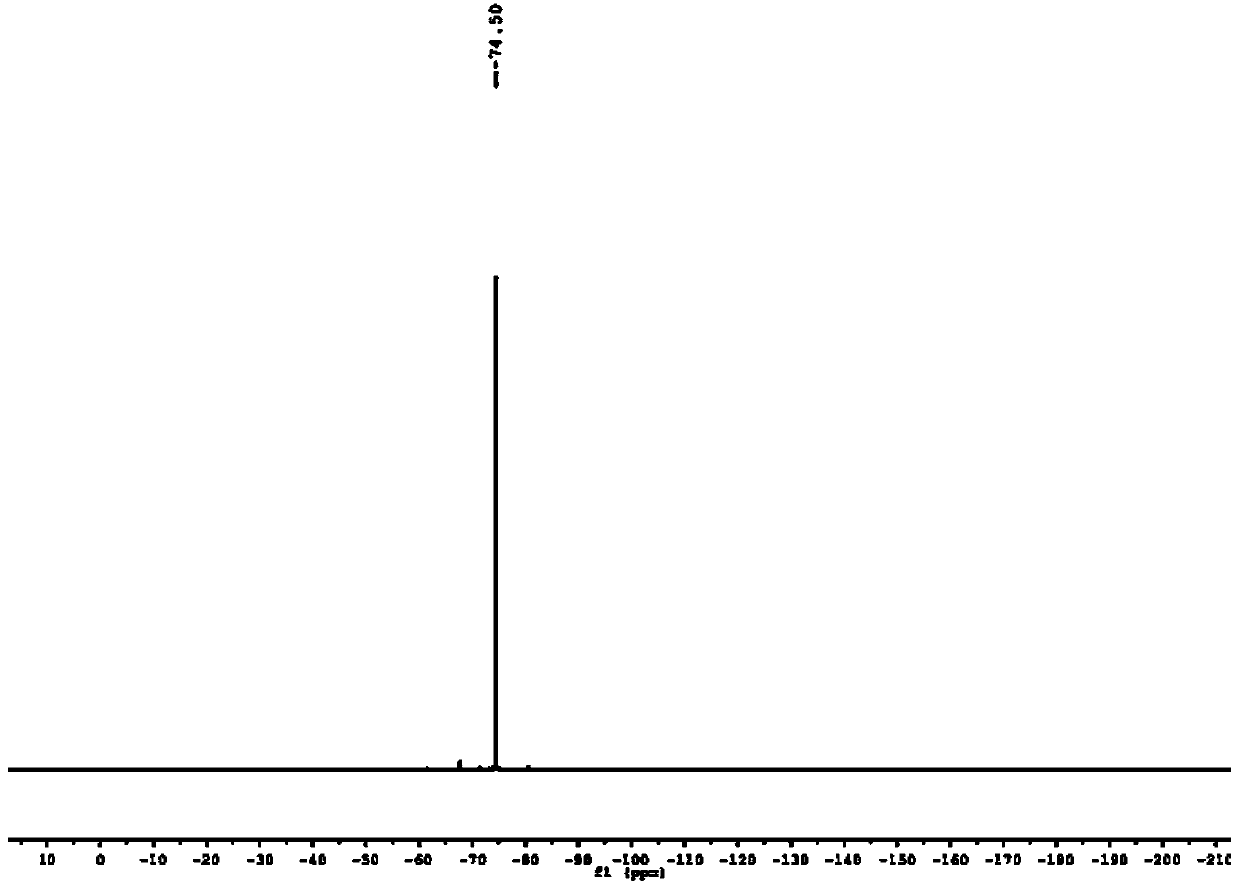

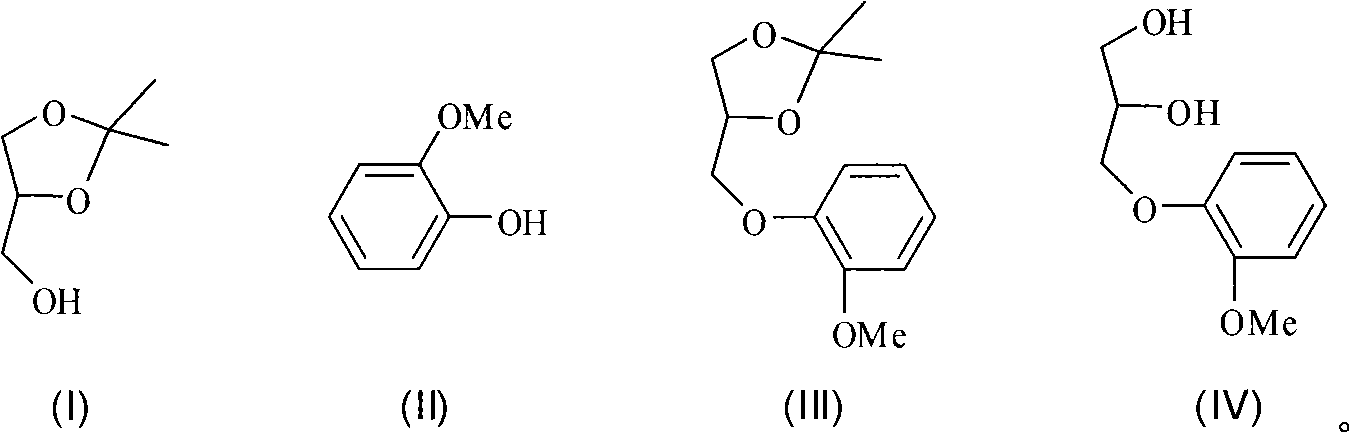

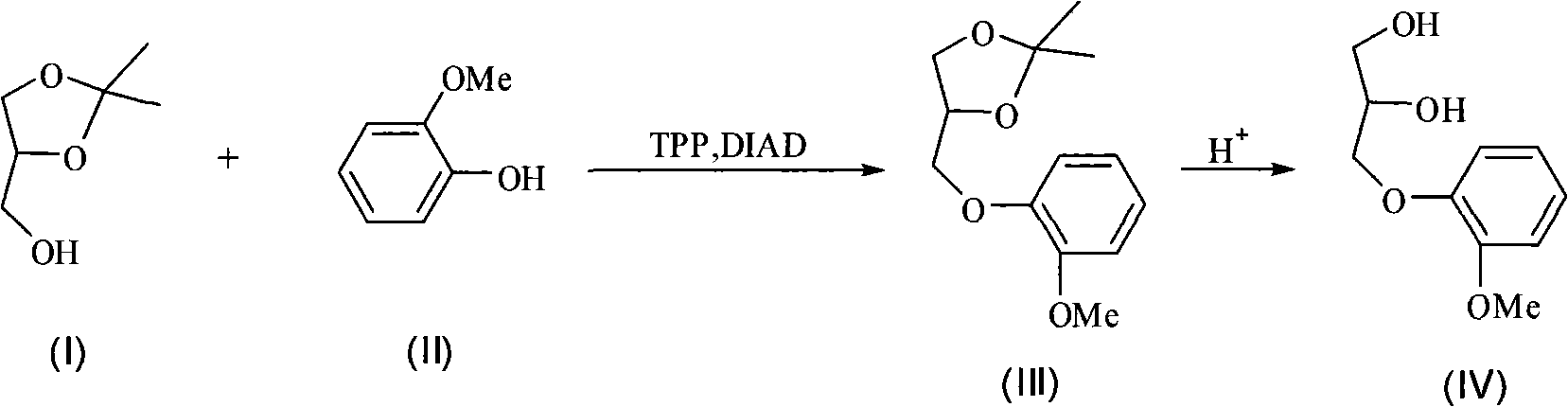

New synthetic method of guaiacol glycerin ether

InactiveCN101525278ASimple methodLow costOrganic chemistryOrganic compound preparationDiisopropyl azodicarboxylateGuaiacol

The invention discloses a new synthetic method of guaiacol glycerin ether with a structure as shown in a formula (IV), isopropylidene glycerol-4-methanol with a structure as shown in formula (I) and guaiacol with a structure as shown in a formula (II) are taken as raw materials, Mitsunobu reaction occurs in organic solvent under the effect of triphenylphosphine and diisopropyl azodicarboxylate to generate intermediate product guaiacol isopropylidene glycerol ether with the structure as shown in formual (III); after full reaction, the obtained intermediate product crude product from separation witnesses hydrolysis reaction directly under acid conditions without purification; after separation and purification of the reaction liquid, the target product guaiacol glycerin with the structure as shown in (IV) ether is obtained. The synthetic method of the invention features application of clean raw material with low cost and easy availability, moderate reaction conditions, simple post treatment processes and adaptability to industrialized production.

Owner:ZHEJIANG UNIV OF TECH

Foamed polypropylene and polymer absorbent composite material with high flame-retardant effect and preparation method thereof

InactiveCN104987591ALower decomposition temperatureStable structureLow-density polyethylenePolymer science

The invention discloses a foamed polypropylene and polymer absorbent composite material with a high flame-retardant effect. The foamed polypropylene and polymer absorbent composite material is characterized by being prepared from, by weight, 95-98 parts of high-melt-strength polypropylene, two to three parts of low-density polyethylene, two to three parts of diisopropyl azodicarboxylate, 0.6-0.8 part of polydimethylsiloxane, three to four parts of antimonous oxide, one to two parts of red phosphorus, a proper amount of deionized water, four to five parts of methylcellulose, 13-15 parts of butyl acrylate, 7.5-nine parts of dodecyl methacrylate, 0.08-0.1 part of N,N,-methylene bisacrylamide, 0.5-0.6 part of azodiisobutyronitrile, 11-12.5 parts of ethyl acetate and two to three parts of bis phosphate. The foamed polypropylene and polymer absorbent composite material is excellent in flame retardant property, spontaneous combustion, caused by oil absorption, of products is avoided, and potential safety hazards are reduced. The foamed polypropylene and polymer absorbent composite material is widely applied to petroleum leakage, water pollution control, oil-water separation, dangerous chemical protection, emergency treatment and other fields.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

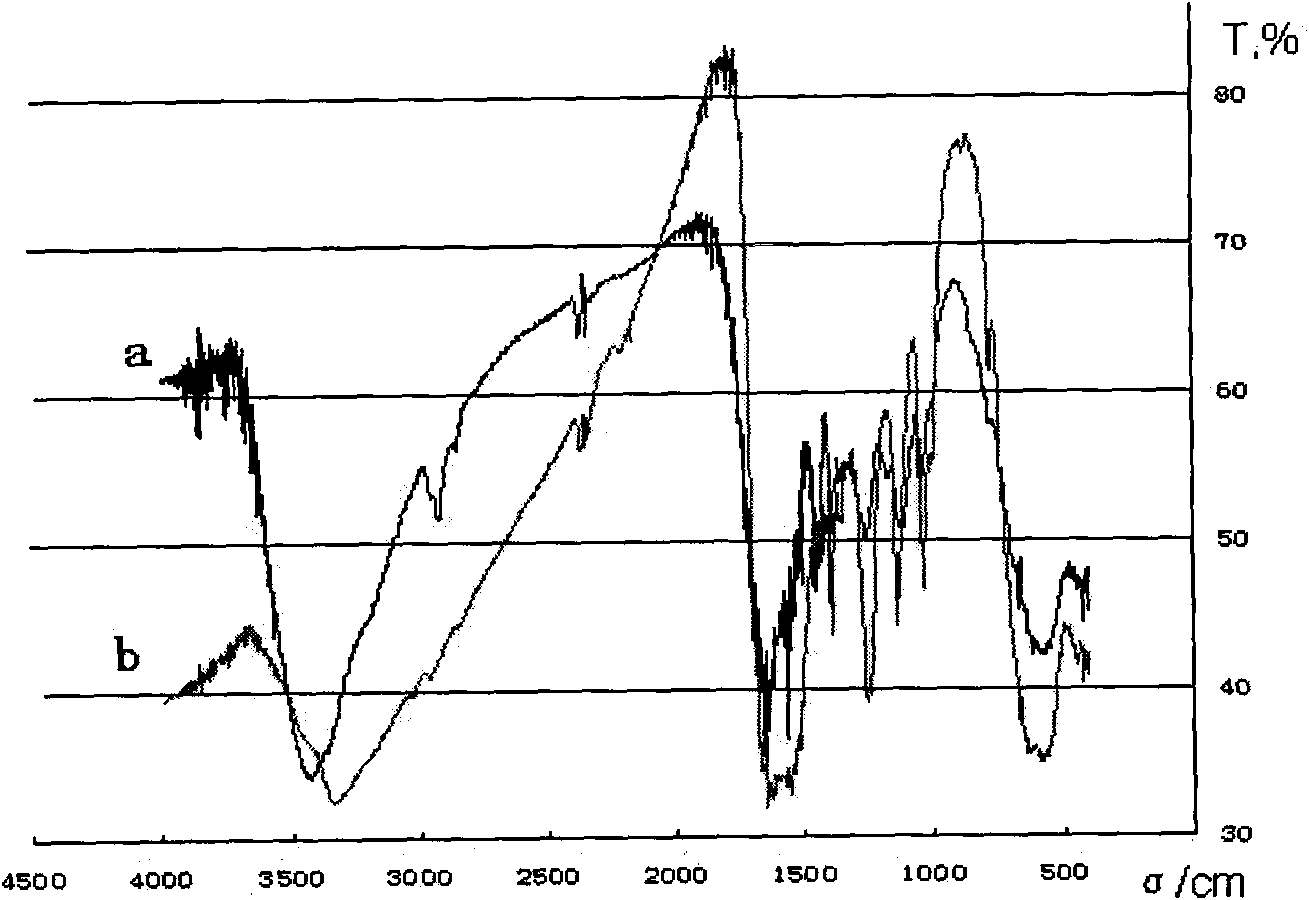

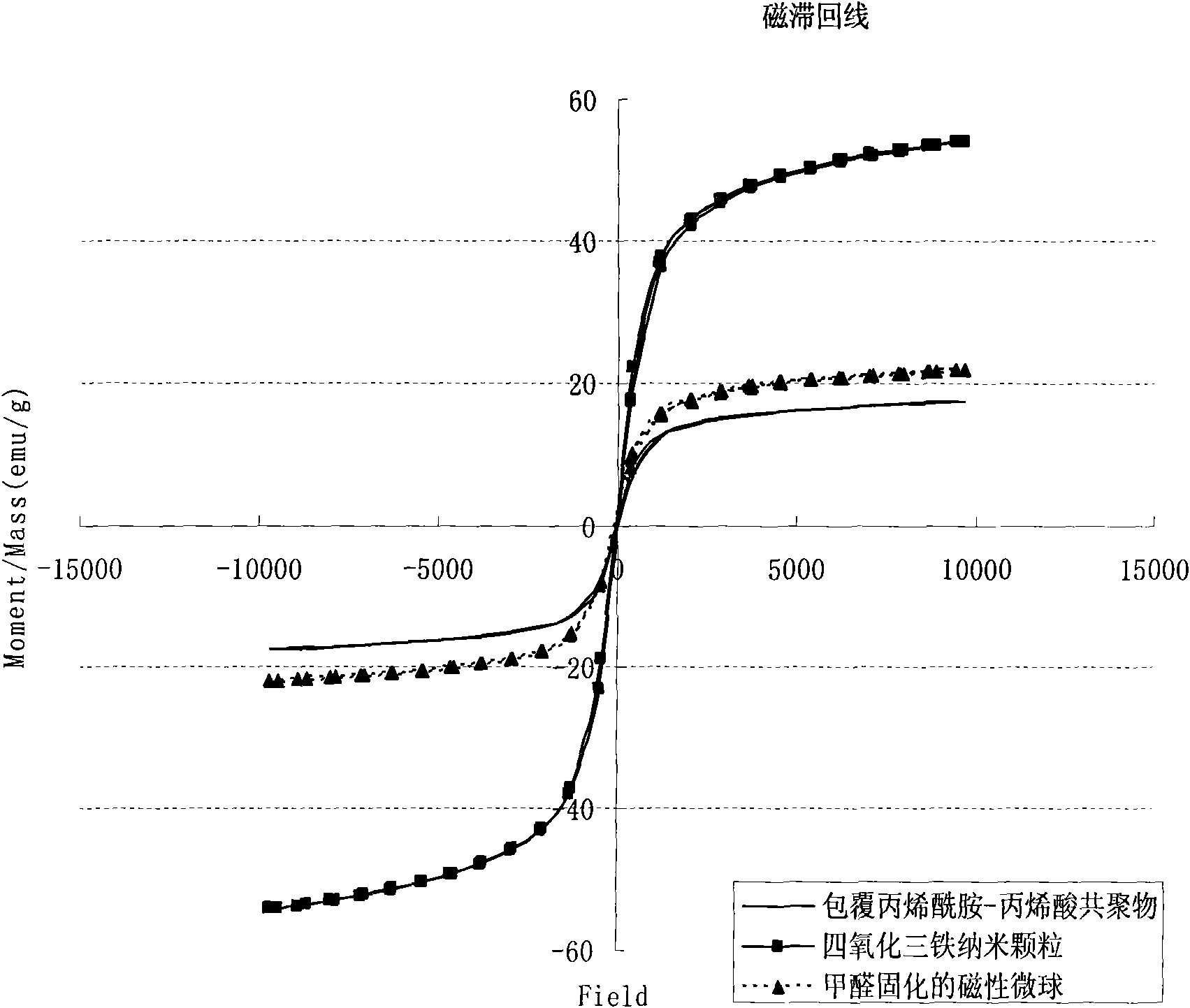

Method for preparing nuclear shell type high magnetic content super paramagnetic microsphere

The invention discloses a method for preparing nuclear shell type high magnetic content super paramagnetic microsphere. Magnetic powder is treated at certain temperature with nitric acid and urea to obtain magnetic fluid; a certain amount of formaldehyde is added to solidify the magnetic fluid under the condition of water bath after the magnetic fluid is aged for days, and thus, magnetic microspheres are obtained; a proper amount of dispersant, acrylamide and crylic acid are added to the suspension of the magnetic microsphere to prepare the mixed liquid, and then the mixed liquid stands for one day in low temperature; then a certain amount of absolute ethyl alcohol and diisopropyl azodicarboxylate are added to the mixed liquid to carry out water bath heating and deoxidation processes; the temperature is regulated to initiate reaction after PH value is regulated to neutrality; a product is washed after the reaction, and thus, the final product-magnetic microsphere with acrylamide-acrylic copolymer shell is obtained. The obtained product-nuclear shell type magnetic microsphere of the invention has the characteristics of high magnetic content, uniform grain diameter, few production process steps and low price of raw material and can be cross-linked with antibodies to prepare various types of immune diagnostic reagents.

Owner:XI AN JIAOTONG UNIV

Synthesis method of cis5-tert-butyl-3A-methyl-tetrahydro 1H-furan[3,4 c] pyrrole 3A,5(3H) dicarboxylic ester

InactiveCN107383033AReasonable reaction process designMethod route shortOrganic chemistry methodsFuranDiisopropyl azodicarboxylate

The invention relates to a synthesis method of cis5-tert-butyl-3A-methyl-tetrahydro 1H-furan[3,4 c] pyrrole 3A,5(3H) dicarboxylic ester. The method mainly solves the technical problem that no proper industrial synthesis method exists in the prior art. The method comprises five steps that: 1, a compound 1 uses sodium borohydride as a reducing agent to react in an ethanol solvent to obtain a compound 2; 2, the compound 2 uses tetrahydrofuran as a solvent to obtain a compound 3 under the effects of triphenylphosphine and diisopropyl azodicarboxylate; 3, the compound 3 and the N-methoxymethyl-N-(trimethylsilyl) benzylamine use dichloromethane as a solvent to obtain a compound 4 through room temperature reduction under the action of trifluoroacetic acid; 4, the compound 4 and thionyl chloride react under the methanol backflow condition to obtain a compound 5; 5, the compound 5 uses palladium hydroxide catalysts and Boc anhydride auxiliary agents to obtain a final compound 6 through catalytic hydrogenation reaction.

Owner:上海药明康德新药开发有限公司 +4

Environment-friendly inflaming-retarding foam material and preparing method thereof

The invention discloses an environment-friendly inflaming-retarding foam material and a preparing method thereof and relates to the technical field of foam material preparation. The material is mainly prepared from polyethylene, phenol-formaldehyde resin, melamine polyphosphoester, graphene, ammonium bicarbonate, tephra, diisopropyl azodicarboxylate, neopentyl glycol, zinc oxalate, ammonium fluoroborate, basic magnesium carbonate, bone waste porcelain powder, plant straw powder, aluminum hypophosphite, sodium antimonite, halloysite nanotube and waste foam concrete. Through cooperation of ammonium fluoroborate, basic magnesium carbonate, melamine polyphosphoester, aluminum hypophosphite and sodium antimonite, inflaming-retarding property is excellent, fuming can be prevented, droppings are not generated, toxic gas is not generated, and safety and environment friendliness are realized; tephra, halloysite nanotube and bone waste porcelain powder improve the overall performance of the foam material, and the material is made high in practicality and long in service life.

Owner:WENZHOU RENHE EDUCATION TECH CO LTD

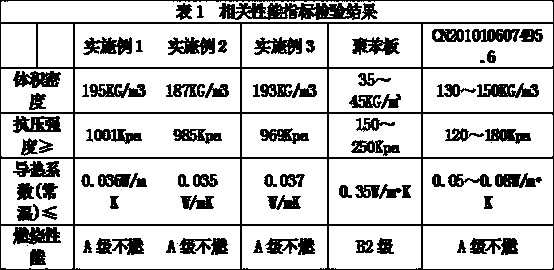

Energy-saving thermal insulation concrete block for building and preparation method thereof

The invention discloses an energy-saving thermal insulation concrete block for a building. The energy-saving thermal insulation concrete block is prepared from the following raw materials in parts by weight: 60-80 parts of ordinary Portland cement, 30-40 parts of waste paper, 9-12 parts of polyimide fiber, 6-8 parts of lithium phosphate, 65-85 parts of water, 9-12 parts of palygorskite, 4-5 parts of pyrophyllite, 7-9 parts of barite, 3-4 parts of a polycarboxylate high-performance water-reducing agent, 2-3 parts of sodium bicarbonate, 4-5 parts of docusate sodium and 1-2 parts of diisopropyl azodicarboxylate. The absolute dry apparent density of a high-strength light-weight thermal insulation concrete block is 180-200kg / m<3>, the strength is 0.95-1.01MPa, the interior of the high-strength light-weight thermal insulation concrete block adopts a closed-hole honeycomb structure, the heat conductivity coefficient is 0.035-0.037W / m.k, and the energy-saving thermal insulation concrete block for the building has the characteristics of high yield, short maintenance time, low raw material cost, simple process, energy conservation and emission reduction.

Owner:汉江城建集团有限公司

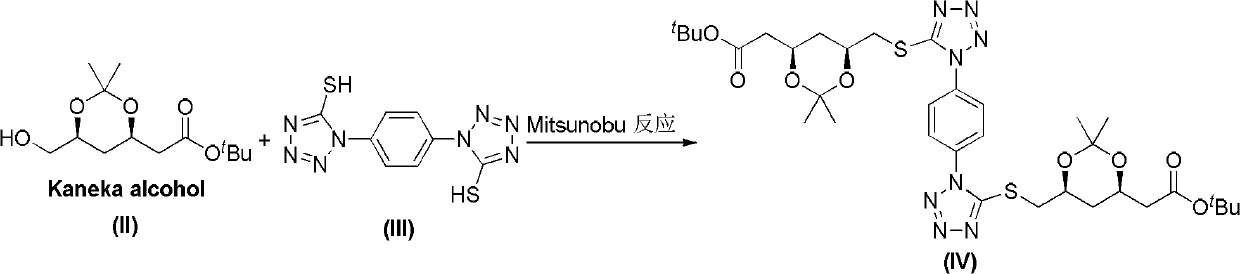

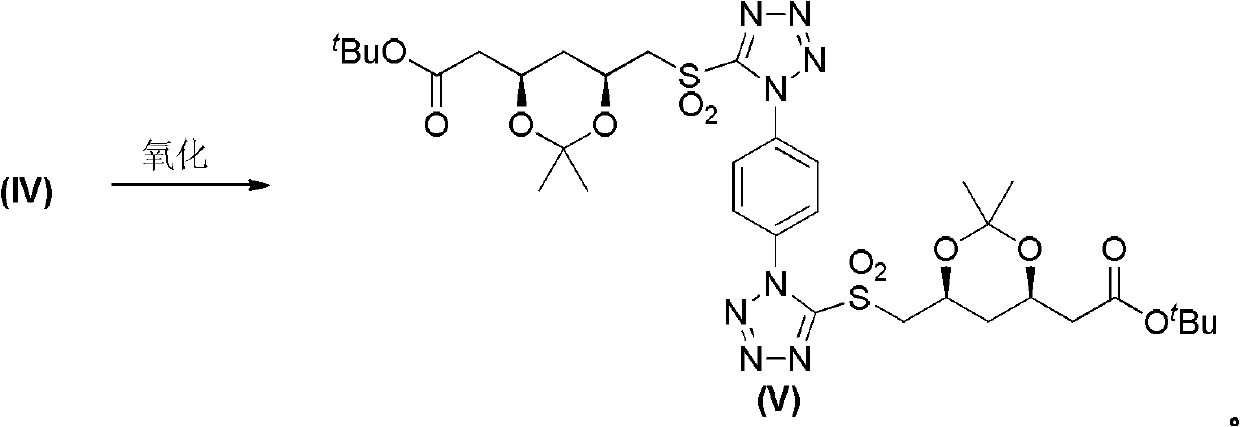

Preparation method of high-optical-purity pitavastatin calcium key intermediate

ActiveCN102174039BHigh optical purityHigh E-stereoselectivityOrganic chemistryButyl acetateDiisopropyl azodicarboxylate

The invention belongs to the technical field of blood fat reducing medicaments and relates to a preparation method of a high-optical-purity pitavastatin calcium key intermediate. The preparation method comprises the following steps of: performing a Mitsunobu reaction on (4R,6S)-6-hydroxymethyl-2,2-dimethyl-1,3-dioxane-4-butyl acetate II, a compound III, triphenylphosphine and diisopropyl azodicarboxylate (DIAD) or diethyl azodicarboxylate (DEAD) in a solvent to obtain a compound IV; performing an oxidation reaction to obtain a sulfone compound V; reacting the sulfone compound V with a compound VI under an alkaline environment to obtain the high-optical-purity pitavastatin calcium key intermediate. By the preparation method, the technical problems of low optical purity, low E type stereoselectivity, high separation and purification difficulty and low yield in the conventional pitavastatin calcium intermediate are solved.

Owner:JIANGSU WANBANG BIOPHARMLS +1

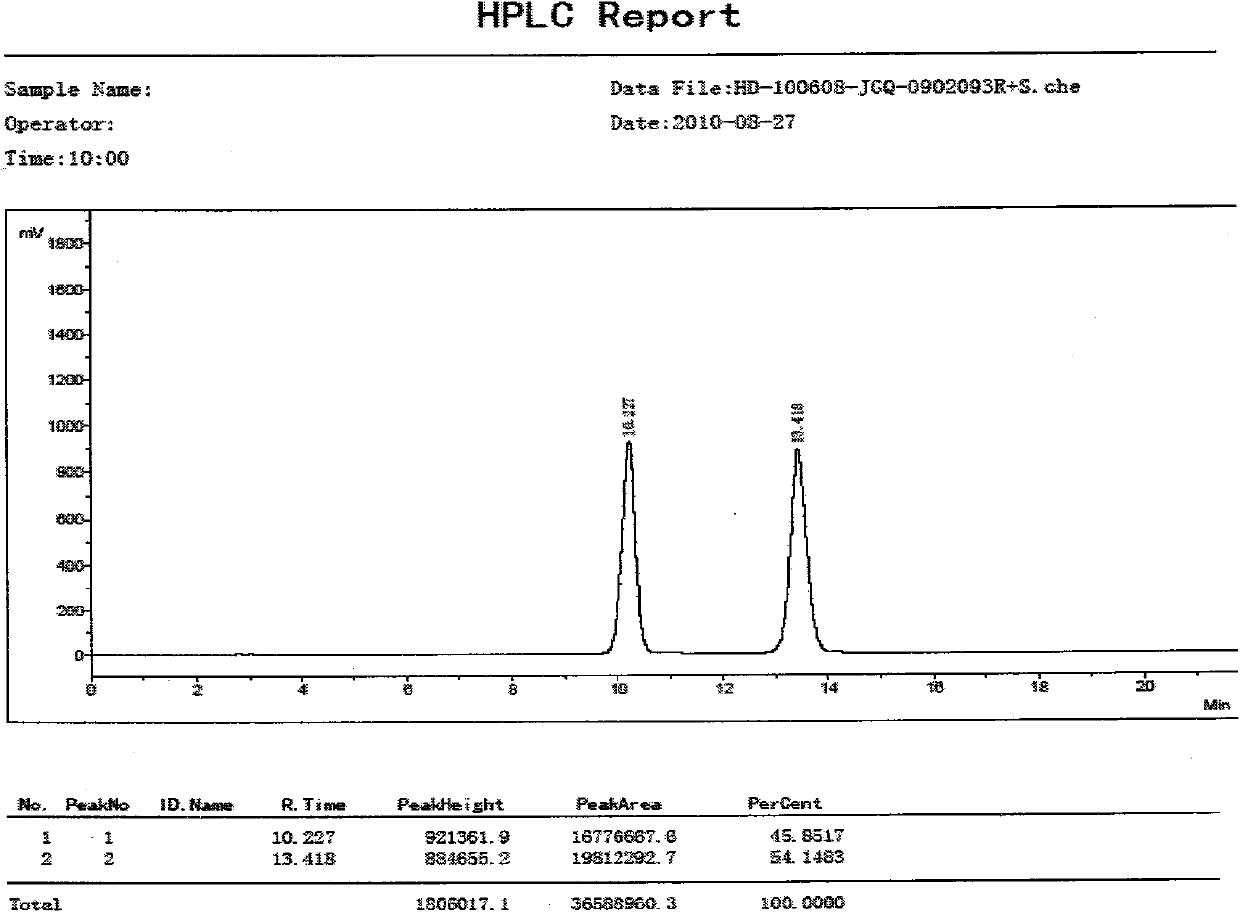

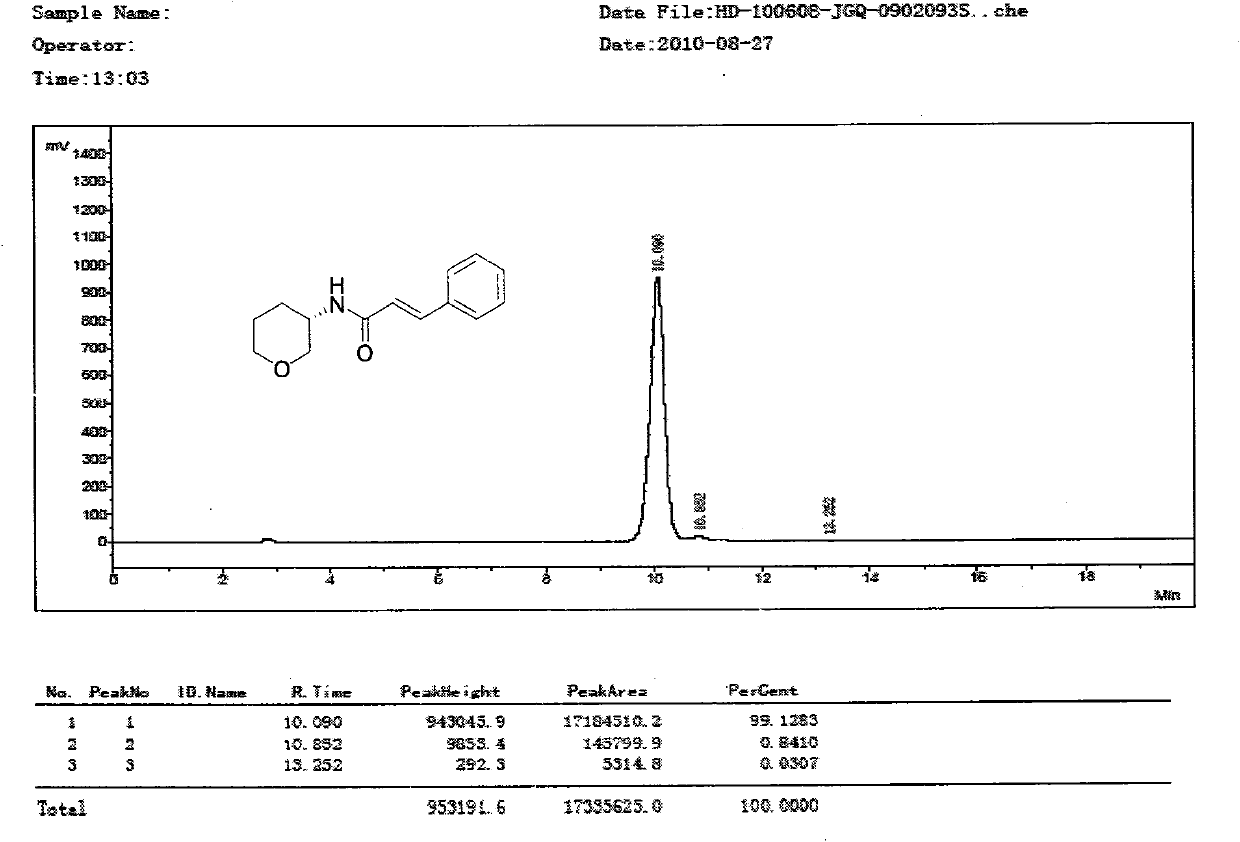

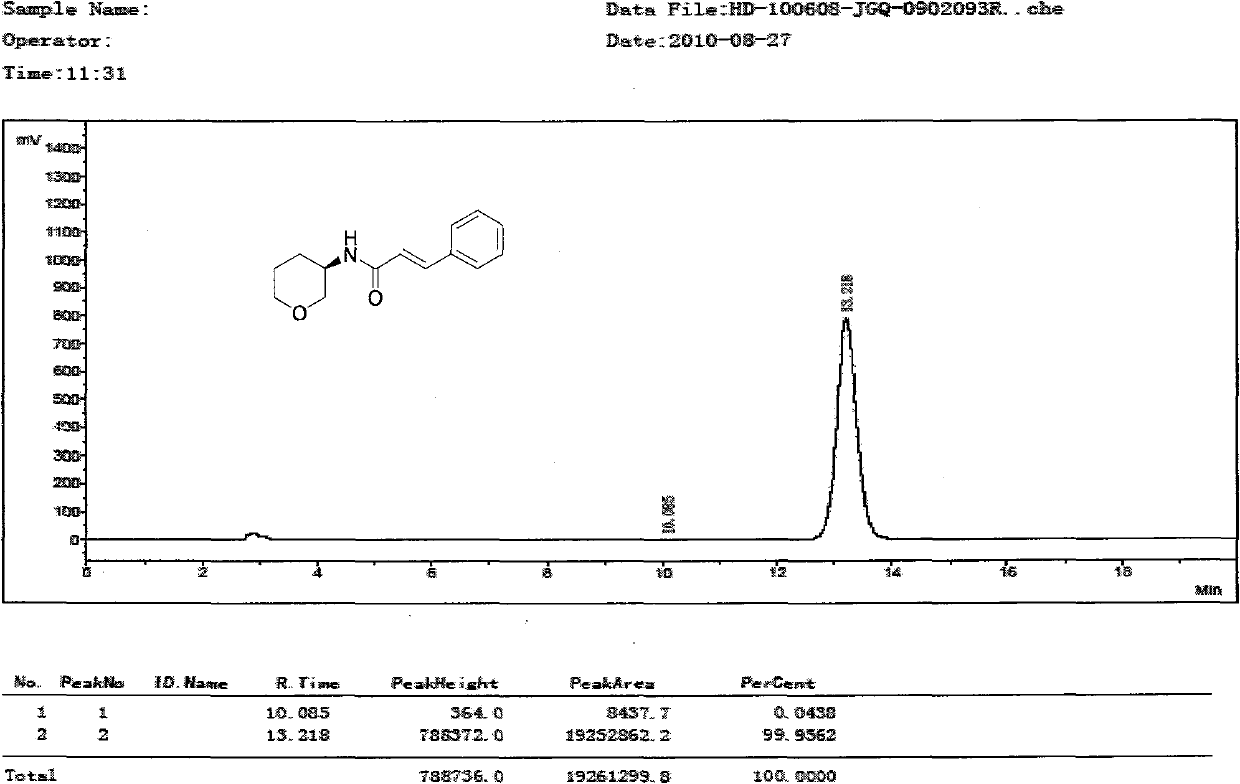

Method for synthesizing chiral pharmaceutical intermediate 3-amino tetrahydropyrane and salt thereof

InactiveCN102030734AEasy to manufactureHigh optical activityOrganic chemistryBulk chemical productionDiisopropyl azodicarboxylateReaction intermediate

The invention relates to a new method for synthesizing chiral pharmaceutical intermediate 3-amino tetrahydropyrane and salt thereof, in particular to a method for synthesizing racemic pharmaceutical intermediate 3-amino tetrahydropyrane and salt thereof. The method is characterized by comprising a step C of: cooling glycol 3 and triphenyl phosphorus to the temperature of below 0 DEG C in an ice bath under the protection of nitrogen; slowly dropwise adding diisopropyl azodicarboxylate or diethyl azodicarboxylate into a mixture of the glycol 3 and the triphenyl phosphorus; reacting at the temperature of between 10 and 30 DEG C after dripping until the reaction is performed completely; and concentrating and drying to obtain a white solid 4 rough product, wherein the molar ratio of the glycol to the triphenyl phosphorus to the diisopropyl azodicarboxylate or the diethyl azodicarboxylate is 1:(1-3):(1-3); the used raw materials are cheap and readily available; a synthesis route is short; all reaction intermediates and a final product are not required to be subjected to column chromatographic purification; and a large amount of R or S-type 3-amino tetrahydropyrane with high optical activity and racemate thereof can be conveniently prepared from natural L or D-type glutamic acid or racemate thereof serving as a raw material. The method has the advantages of low cost and higher efficiency; and an obtained product has high chemical purity and optical purity.

Owner:苏州汉德创宏生化科技有限公司

Formula of composite spiral tube material

The invention discloses a formula of a composite spiral tube material. The formula comprises polyethylene, a filled reinforcing agent, a plasticizer, an impact-resisting modifying agent, a foaming agent and a coupling agent. The filled reinforcing agent is carbon fiber, the plasticizer is dimethyl phthalate, the impact-resisting modifying agent is ethylene propylene diene monomer, the foaming agent is diisopropyl azodicarboxylate, and the coupling agent is ethylenediamine propyl triethoxy ethyl silane. Multiple types of additives are added into polyvinyl plastic to enable prepared composite spiral tube material to have the advantages of being hard in texture, good in toughness, high in tensile strength, light in weight, low in cost and the like, thereby greatly improving the performance of composite spiral tubes, decreasing weight of the composite spiral tubes and facilitating construction requirements.

Owner:KUSN QIAORUI METAL PRODS

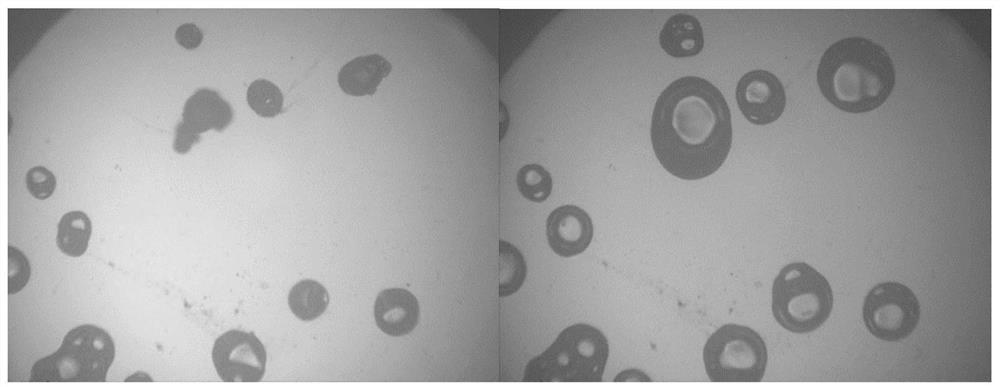

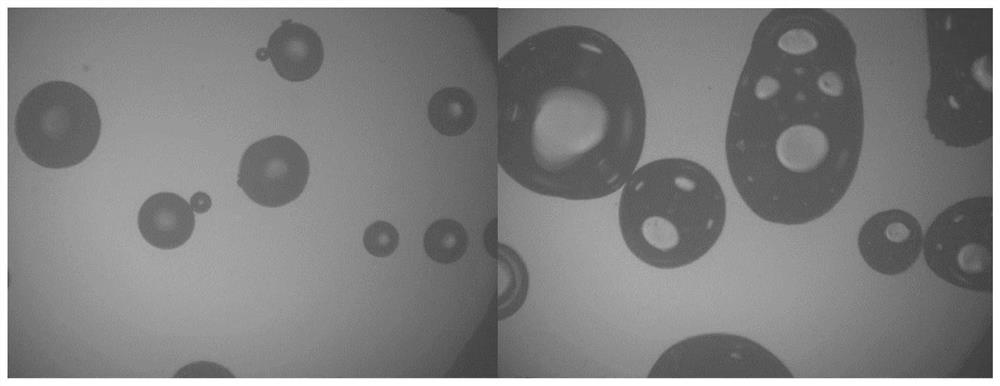

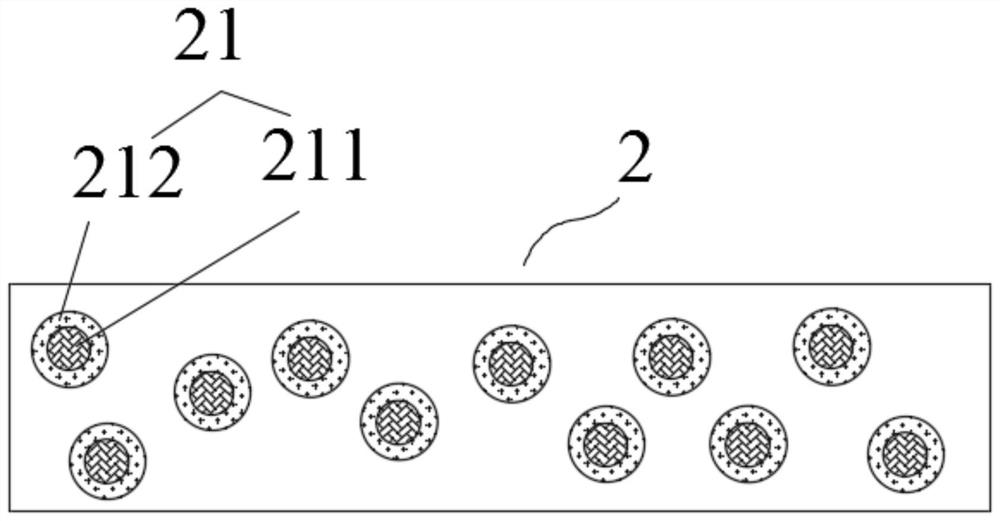

Physical expansion foaming microsphere coated with diisopropyl azodicarboxylate and preparation method thereof

ActiveCN112250900AAct as an isolation bufferImprove stabilityPolymer scienceDiisopropyl azodicarboxylate

The invention provides a physical expansion foaming microsphere coated with diisopropyl azodicarboxylate, the foaming microsphere takes polymethyl methacrylate and polyphenyl methacrylate as shell layer materials, an inner core wraps diisopropyl azodicarboxylate liquid, the foaming microsphere can be used for replacing a diisopropyl azodicarboxylate liquid foaming agent, the color is light, the compatibility with polyurethane, alkyd resin, cyanamide resin and other materials is good, and the production, transportation, use and storage safety of the microspheres is high.

Owner:ZHEJIANG UNIV OF TECH

Diaphragm for lithium ion battery and lithium ion battery

InactiveCN112768841AGuaranteed reuseAvoid breakingCell component detailsSecondary cells servicing/maintenanceDiisopropyl azodicarboxylateEngineering

The invention provides a diaphragm for a lithium ion battery. The diaphragm comprises a base membrane, a first coating, a first coating coats at least one surface of the base film; the first coating comprises an additive; the additive is of a core-shell structure, a core material is at least one of azodiisobutyronitrile, azodicarbonamide and diisopropyl azodicarboxylate azobenzene, and a shell material is an elastic material. Compared with the prior art, the additive with the core-shell structure is added into the coating of the diaphragm; according to the additive, the azodiisobutyronitrile, azodicarbonamide, diisopropyl azodicarboxylate azobenzene and other substances are adopted as the core material, and after the heat of the battery is increased, the core material substances are heated to expand, and therefore, a positive electrode and a negative electrode are separated in a volume expansion manner, the risks of fire and explosion caused by internal short circuit of the battery are reduced, and the safety performance of the battery is improved.

Owner:惠州锂威电子科技有限公司

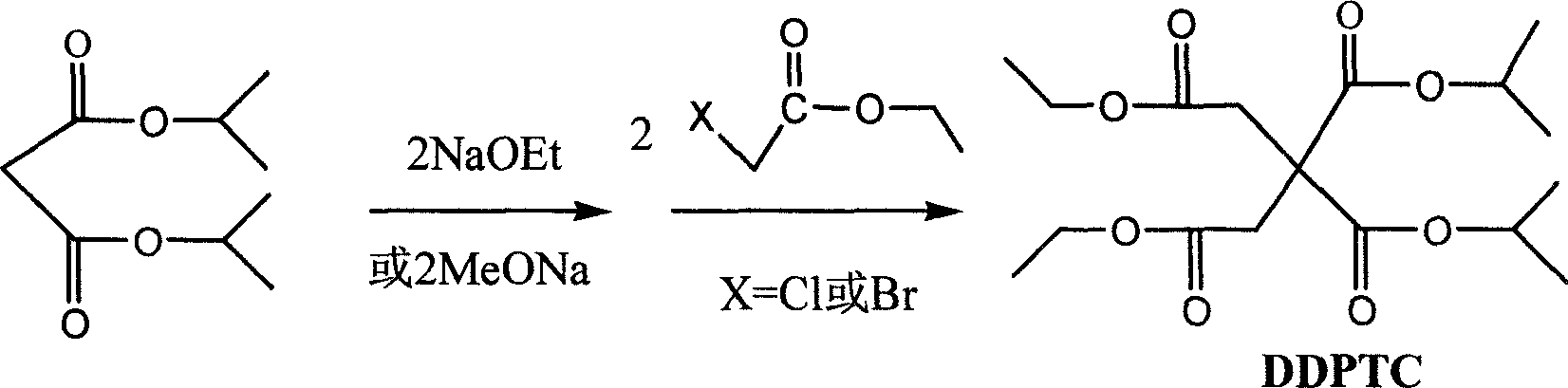

Prepn and application of diisopropyl diethyl carboxylate

InactiveCN1974532AMild reaction conditionsShort reaction timeOrganic compound preparationCarboxylic acid esters preparationDiisopropyl azodicarboxylateMalonate

The present invention is preparation process and application of diisopropyl diethyl carboxylate. Diisopropyl malonate and ethyl chloroacetate as the initial material are one-step reacted under the action of strong alkali and catalyst to synthesize diisopropyl diethyl carboxylate. After reaction, the reaction product is filtered, water washed to eliminate inorganic salt and decompression distilled to obtain the product. Diisopropyl diethyl carboxylate is colorless or yellowish transparent liquid, and has structure similar to that of triisopropyl acetyl citrate, plasticizing efficiency and cold resistance similar to that of DOP and compatibility higher than that of DOP. The present invention is used as plasticizer.

Owner:JINGGANGSHAN UNIVERSITY

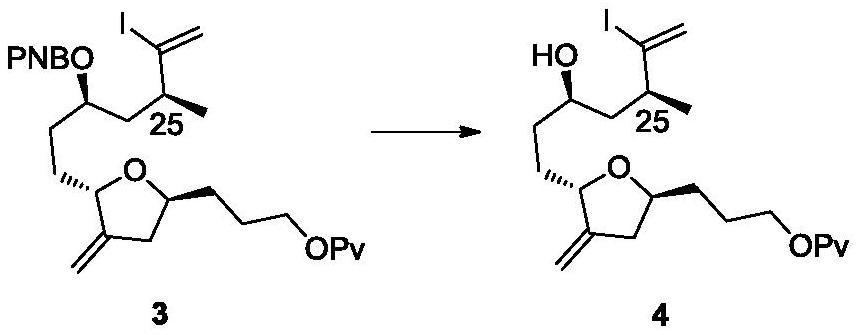

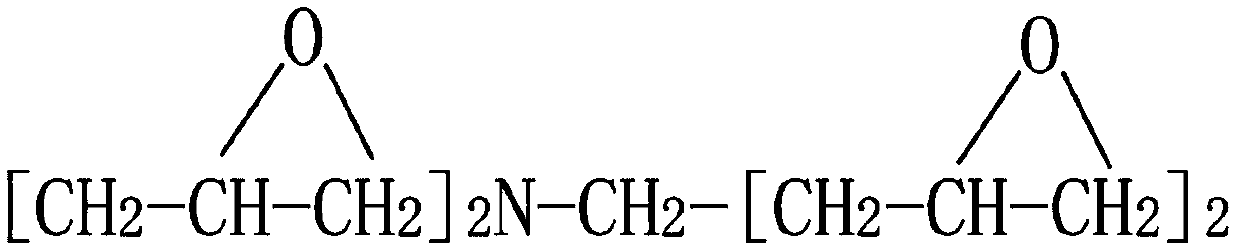

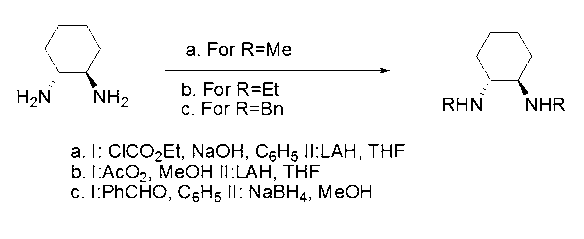

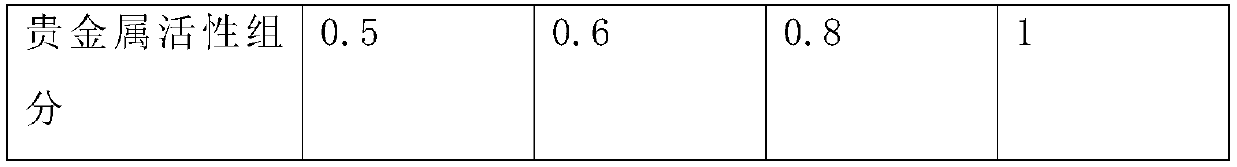

Preparation method for (R)-3-([1,1'-biphenyl]-4-radical)-2-aminopropionic-1-alcohol hydrochloride

InactiveCN106565505AIncrease profitMild reaction conditionsOrganic compound preparationAmino-hyroxy compound preparationEcological environmentDiisopropyl azodicarboxylate

The invention relates to a preparation method for (R)-3-([1,1'-biphenyl]-4-radical)-2-aminopropionic-1-alcohol hydrochloride. The preparation method for the (R)-3-([1,1'-biphenyl]-4-radical)-2-aminopropionic-1-alcohol hydrochloride comprises the steps that (S)-1-([1,1'-biphenyl]-4-radical)-3-chloropropyl-2-alcohol is dissolved by methylbenzene, triphenyl phosphine and succinimide are added under the protection of nitrogen gas, 0-5 DEG C temperature keeping is carried out, a methyl benzene solution of diisopropyl azodicarboxylate is added, and the temperature is kept for a reaction for 2-8 hours; feed liquid is subjected to decompression drying by distillation, water and hydrochloric acid are added, the mixture is heated to micro-backflow, and stirring is carried out for 16 hours or longer while the temperature is kept; and reaction liquid stands for skimming, products in a water phase and products in an organic phase in the reaction liquid are purified through organic solvents, drying is carried out for 8 hours or longer at the temperature ranging from 50 DEG C to 60 DEG C, and the product is obtained. According to the method, the process is simple, few impurities exist in the product, the yield is high, the amount of the raw materials is small, the production cost of the product can be remarkably reduced in large-scale production, generation of waste is reduced, and the ecological environment is protected. The solvents used in the purification process of the product are easy to recycle, and the treatment cost is greatly reduced.

Owner:CHONGQING BEISHENG PHARMA TECH CO LTD

Aluminum alloy surface-protecting agent

The invention relates to a metal surface coating, in particular to an aluminum alloy surface-protecting agent. The aluminum alloy surface-protecting agent is prepared from the following raw materials, by weight, of 35-40 parts of methyl-ethyloxy silicone oil, 7-15 parts of silicon resin, 4-10 parts of N-phenyl anthranilic acid, 5-15 parts of tetrabutyl titanate, 0.5-0.8 part of dimethyl phosphate, 15-25 parts of pentaerythritol esters and 5-15 parts of diisopropyl azodicarboxylate. According to the aluminum alloy surface-protecting agent, the micro-porous metal surface coating with a micropore structure is achieved, the metal surface coating has exhaust performance and adsorptivity, and meanwhile, micropores are hollow and have the function of absorbing micromolecules.

Owner:广西防城港市誉晨贸易有限公司

Polysiloxane microsphere foaming agent for expanded polypropylene plastics and preparation method

The invention aims to provide a polysiloxane microsphere foaming agent for expanded polypropylene plastics and a preparation method. The polysiloxane microsphere foaming agent is prepared from hollow polysiloxane microspheres and an azo foaming agent contained in the hollow microspheres, wherein the azo foaming agent contains at least one of azodicarbonamide and diisopropyl azodicarboxylate; the foaming agent is prepared from 67wt%-89wt% by weight of the polysiloxane microspheres, 11wt%-32wt% by weight of the azo foaming agent and the balance of water, and the particle size is 1.2-4.9 mu m. The foaming agent is applied to the expanded polypropylene plastics and has certain interactions with polypropylene macromolecules, the interactions can serve as physical cross-linking points during melting, so that slip between the polypropylene macromolecules becomes more difficult, the polypropylene melt strength is improved, and high-quality expanded polypropylene materials are obtained.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

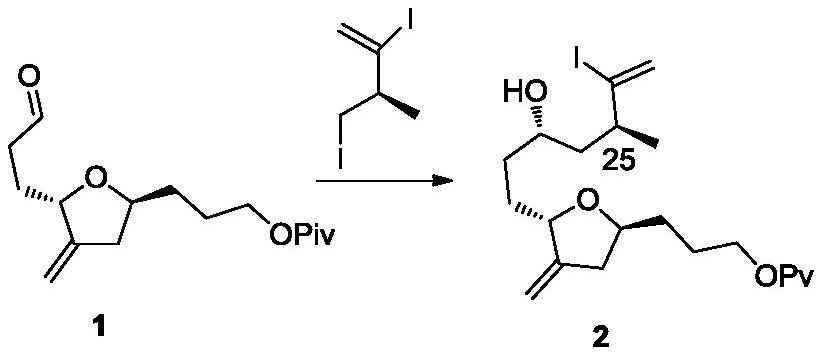

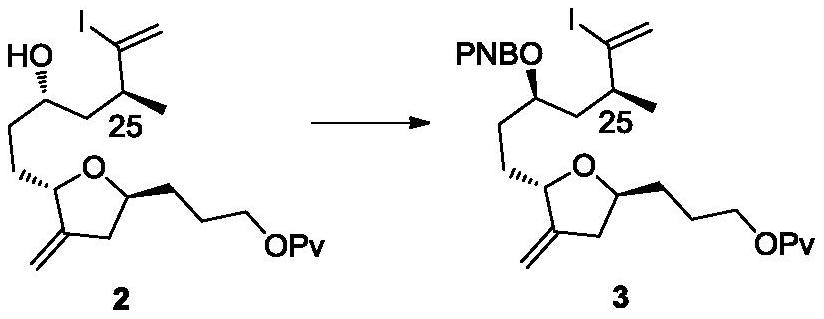

Preparation method of key intermediate isomer of eribulin mesylate

PendingCN114409617AMild reaction conditionsEasy to purifyOrganic chemistryBenzoic acidDiisopropyl azodicarboxylate

The invention provides a preparation method of an eribulin mesylate key intermediate isomer, which comprises the following steps: (1) reacting a compound 1 with (S)-2, 4-diiodo-3-methyl-1-butene to obtain a compound 2; (2) reacting the compound 2 with p-nitrobenzoic acid under the action of triphenylphosphine and diisopropyl azodicarboxylate to obtain a compound 3; and (3) removing a PNB protecting group from the compound 3 under the action of potassium carbonate to obtain a compound 4. The isomer obtained by the method has high purity, can meet the requirements of structure identification, impurity spectrum research and methodology verification, has the advantages of mild reaction conditions in each step, easy purification, simple operation and high yield, avoids the use of a liquid phase for preparation, and reduces the cost.

Owner:NANJING GEAR PHARMA & TECH CO LTD

Insulating shading adhesive tape for fixing LED backlight modules

InactiveCN111349401AImprove shadingFormula raw materials are easy to getNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateDiisopropyl azodicarboxylate

The invention provides an insulating shading adhesive tape for fixing LED backlight modules. The insulating shading adhesive tape comprises a substrate, and an adhesive which is adopted to coat the black substrate; the adhesive comprises the following components: 30 to 60 parts by weight of 2-ethylhexyl acrylate; 10 to 30 parts by weight of an allyl alcohol complex; 5 to 10 parts by weight of sulfur; 3 to 8 parts by weight of nano-selenium, 5 to 15 parts by weight of ceramic particles, 5 to 10 parts by weight of diisopropyl azodicarboxylate, 1 to 2 parts by weight of organic tin, 1 to 10 partsby weight of fumed silica, 10 to 20 parts by weight of 1-hydroxycyclohexyl phenyl ketone, 5 to 15 parts by weight of dodecanethiol and 1 to 5 parts by weight of 2-ethyl anthraquinone. According to the shading adhesive tape, the adhesive is prepared at a non-high temperature and only needs to be heated to 60-80 DEG C, the formula raw materials are easy to obtain, the processing mode is simple, operation is easy and convenient, production is more energy-saving and environmentally friendly, and the prepared adhesive tape is excellent in shading performance.

Owner:安徽富印新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of cis5-tert-butyl-3A-methyl-tetrahydro 1H-furan[3,4 c] pyrrole 3A,5(3H) dicarboxylic ester Synthesis method of cis5-tert-butyl-3A-methyl-tetrahydro 1H-furan[3,4 c] pyrrole 3A,5(3H) dicarboxylic ester](https://images-eureka.patsnap.com/patent_img/1b155c81-c2c1-47f6-ba38-9872cf0937bd/240257DEST_PATH_IMAGE002.png)

![Synthesis method of cis5-tert-butyl-3A-methyl-tetrahydro 1H-furan[3,4 c] pyrrole 3A,5(3H) dicarboxylic ester Synthesis method of cis5-tert-butyl-3A-methyl-tetrahydro 1H-furan[3,4 c] pyrrole 3A,5(3H) dicarboxylic ester](https://images-eureka.patsnap.com/patent_img/1b155c81-c2c1-47f6-ba38-9872cf0937bd/577916DEST_PATH_IMAGE002.png)

![Preparation method for (R)-3-([1,1'-biphenyl]-4-radical)-2-aminopropionic-1-alcohol hydrochloride Preparation method for (R)-3-([1,1'-biphenyl]-4-radical)-2-aminopropionic-1-alcohol hydrochloride](https://images-eureka.patsnap.com/patent_img/bb3b7d92-99fd-4197-8e44-580d3d582fc0/BDA0001147905400000011.png)

![Preparation method for (R)-3-([1,1'-biphenyl]-4-radical)-2-aminopropionic-1-alcohol hydrochloride Preparation method for (R)-3-([1,1'-biphenyl]-4-radical)-2-aminopropionic-1-alcohol hydrochloride](https://images-eureka.patsnap.com/patent_img/bb3b7d92-99fd-4197-8e44-580d3d582fc0/BDA0001147905400000021.png)