Insulating shading adhesive tape for fixing LED backlight modules

A technology of shading tape and backlight module, applied in the direction of adhesive, film/sheet adhesive, graft polymer adhesive, etc., can solve the problem of poor shading performance of tape, achieve excellent shading performance and ensure viscosity , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

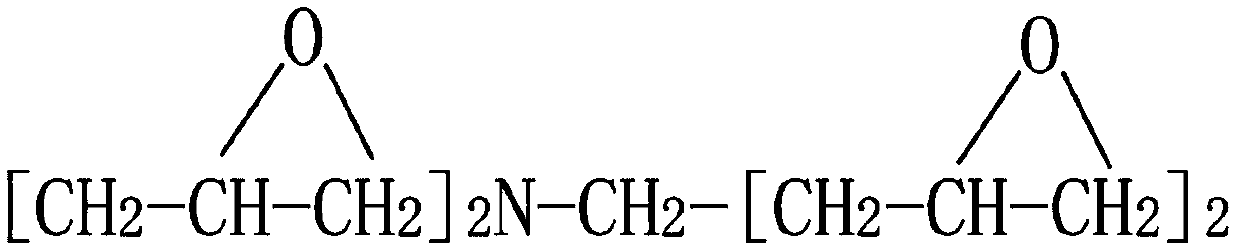

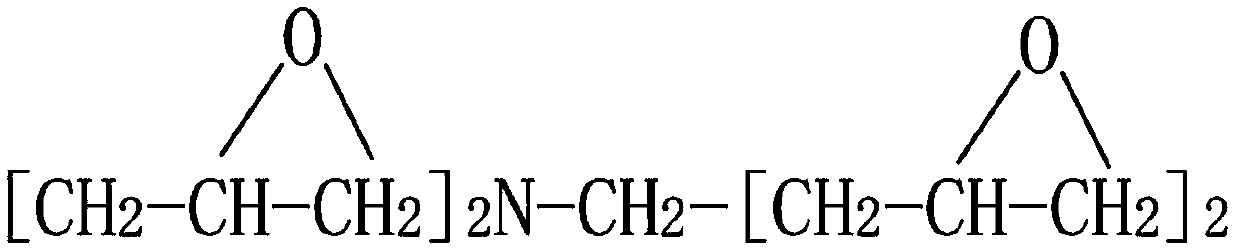

[0023] The preparation method of the allyl alcohol complex is as follows: first vacuumize the polyoxypropylene alcohol at 120° C. to remove water for 30 minutes. Then, under the atmosphere of nitrogen protection, polyoxypropylene alcohol is added dropwise to excess diisocyanate (-NCO and -OH group molar ratio is 2:1) while stirring, and a small amount of catalyst dibutyltin dilaurate is added, The reaction temperature is controlled at 90-100°C. After 1 hour of reaction, the heating is stopped and the temperature is lowered to discharge the material to obtain the allyl alcohol complex.

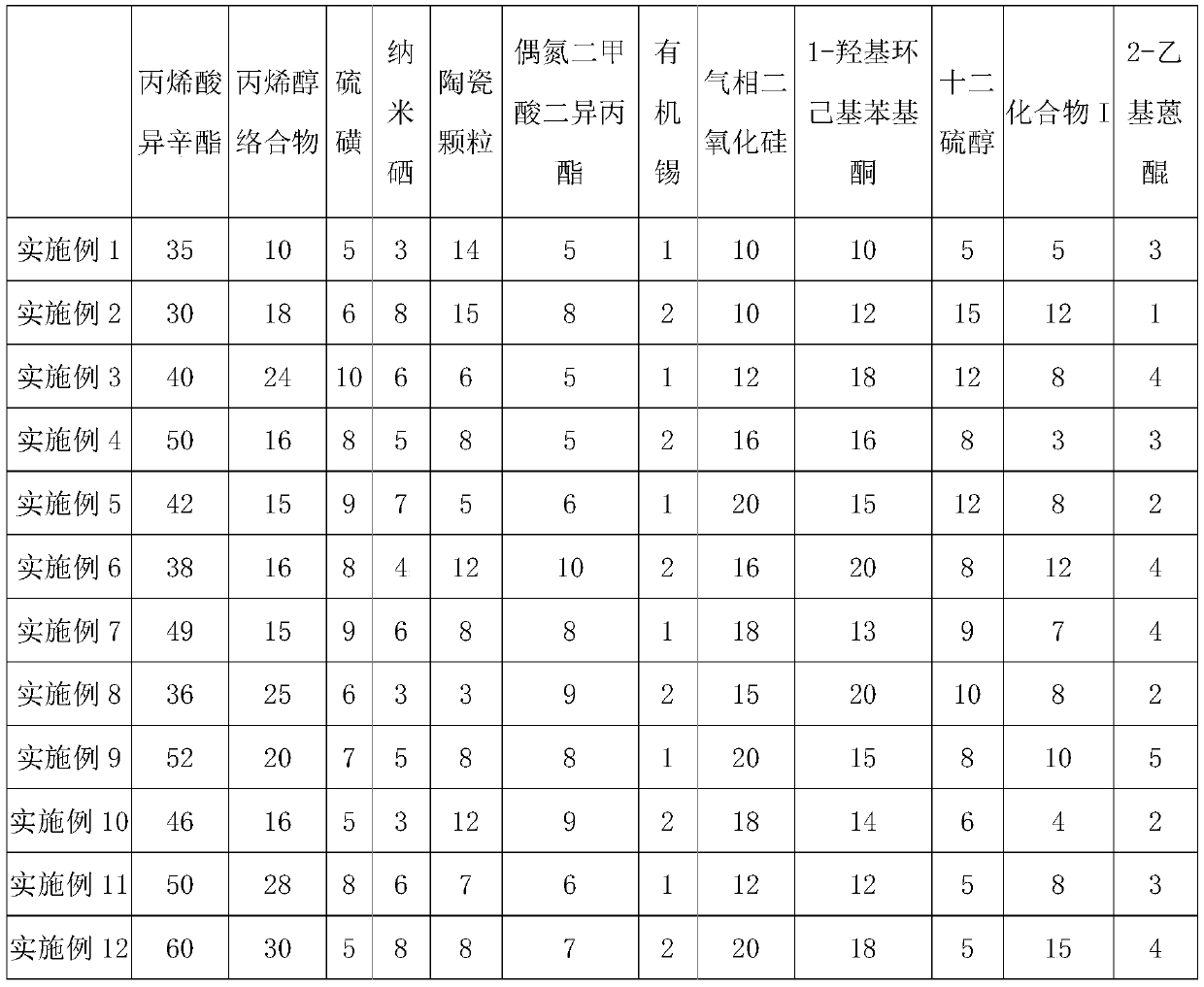

[0024] The adhesive prepared according to the formula in the following table was then coated on the substrate to prepare the insulating light-shielding tape for fixing the LED backlight module of Examples 1-12. The adhesive formula of specific embodiment is as follows:

[0025]

[0026] Isooctyl acrylate, propylene alcohol complex, sulfur, nano-selenium, ceramic particles, diisopropyl azodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com