Patents

Literature

369 results about "Cyclohexylamines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A family of alicyclic hydrocarbons containing an amine group with the general formula R-C6H10NH2.

Cyclopentylamine and cyclohexylamine derivatives as NK-1/SSRI antagonists

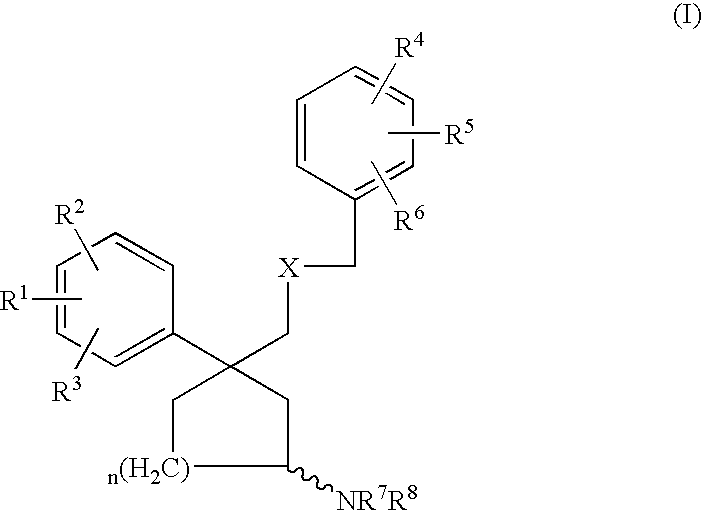

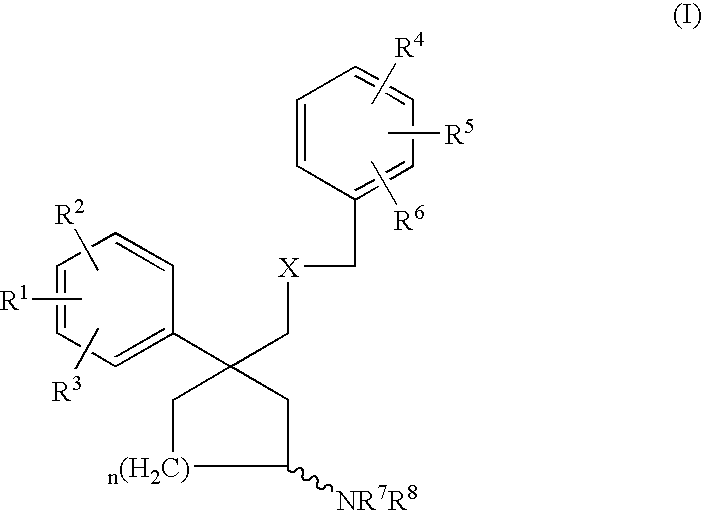

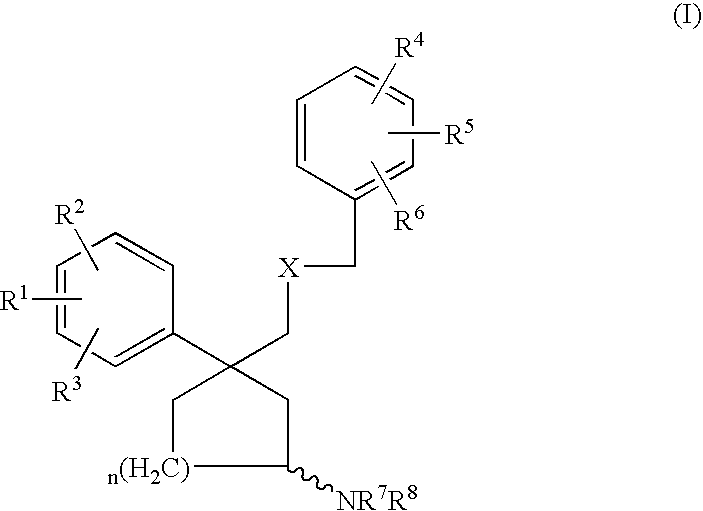

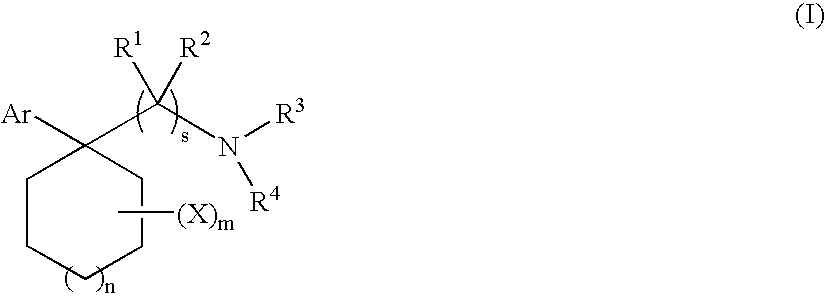

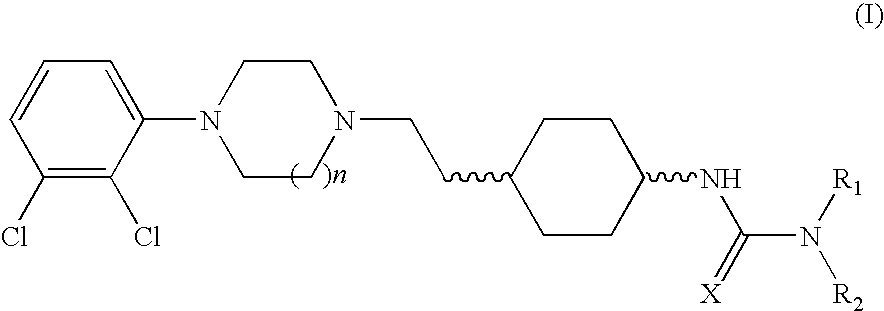

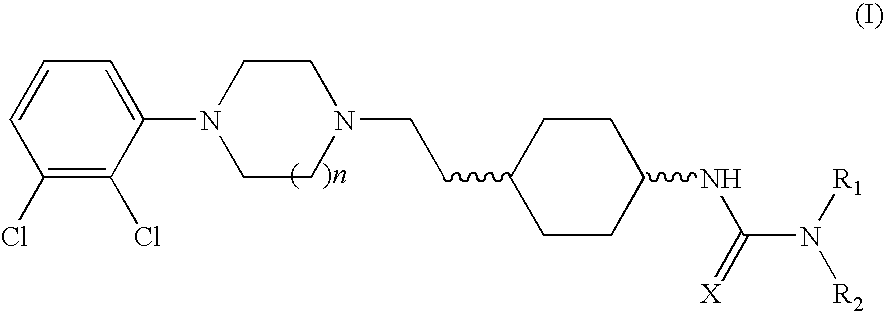

The present disclosure relates to chemical compounds and their use in human therapy. A specific embodiment of the disclosure relates to compounds of Formula (I); or an isomer, a pharmaceutically acceptable salt or solvate thereof or a pharmaceutically acceptable formulation comprising said compounds are useful for the useful for the treatment or prevention of conditions mediated by tachykinins and / or selective inhibition of serotonin reuptake transporter protein. The compounds act as dual NK-1 antagonists and selective serotonin reuptake inhibitors.

Owner:BRISTOL MYERS SQUIBB CO

Cycloalkylamines as monoamine reuptake inhibitors

InactiveUS20070203111A1Inhibit bindingInhibitory activityBiocideNervous disorderSynaptic cleftAdrenergic

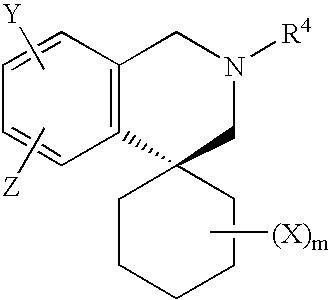

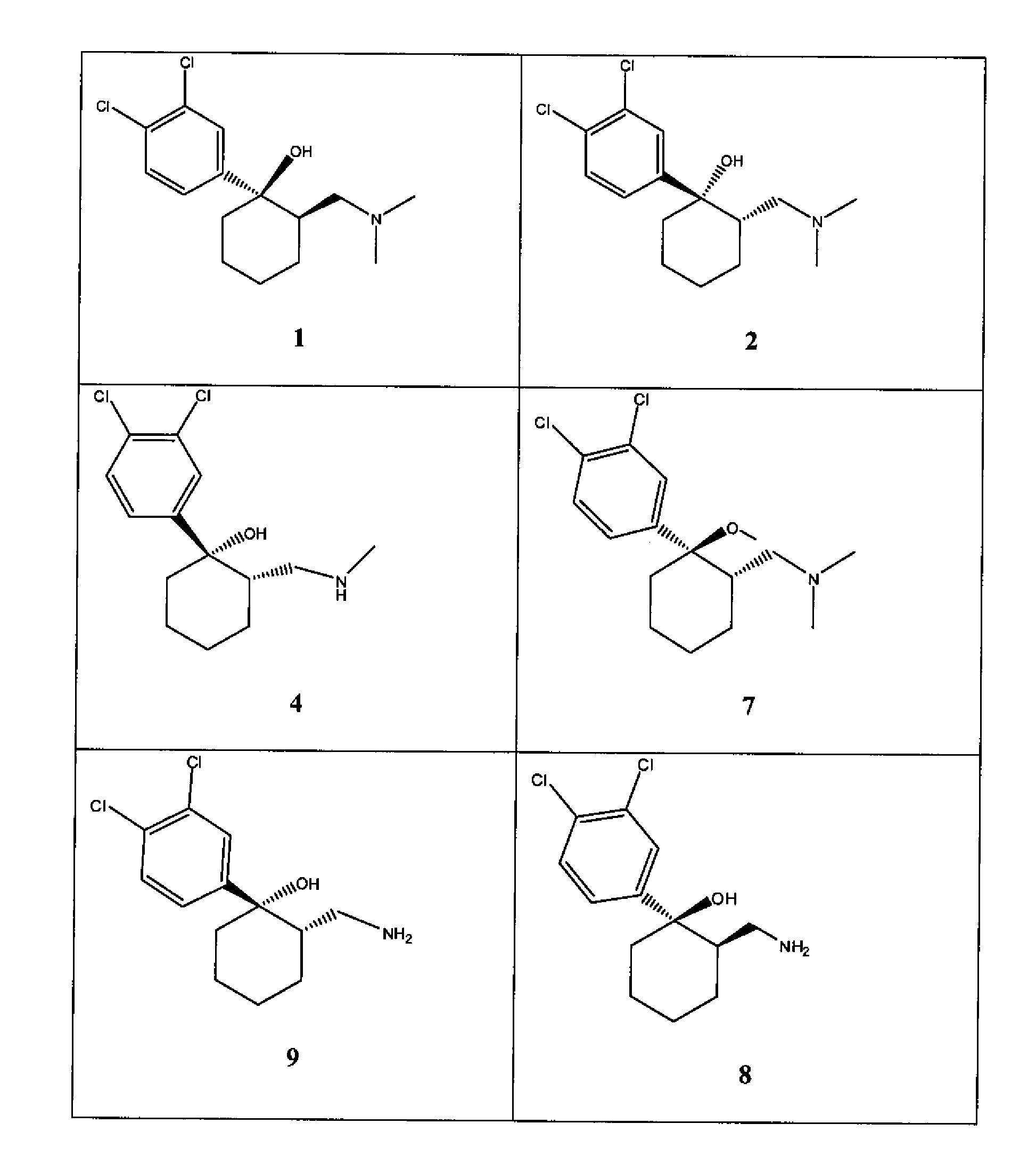

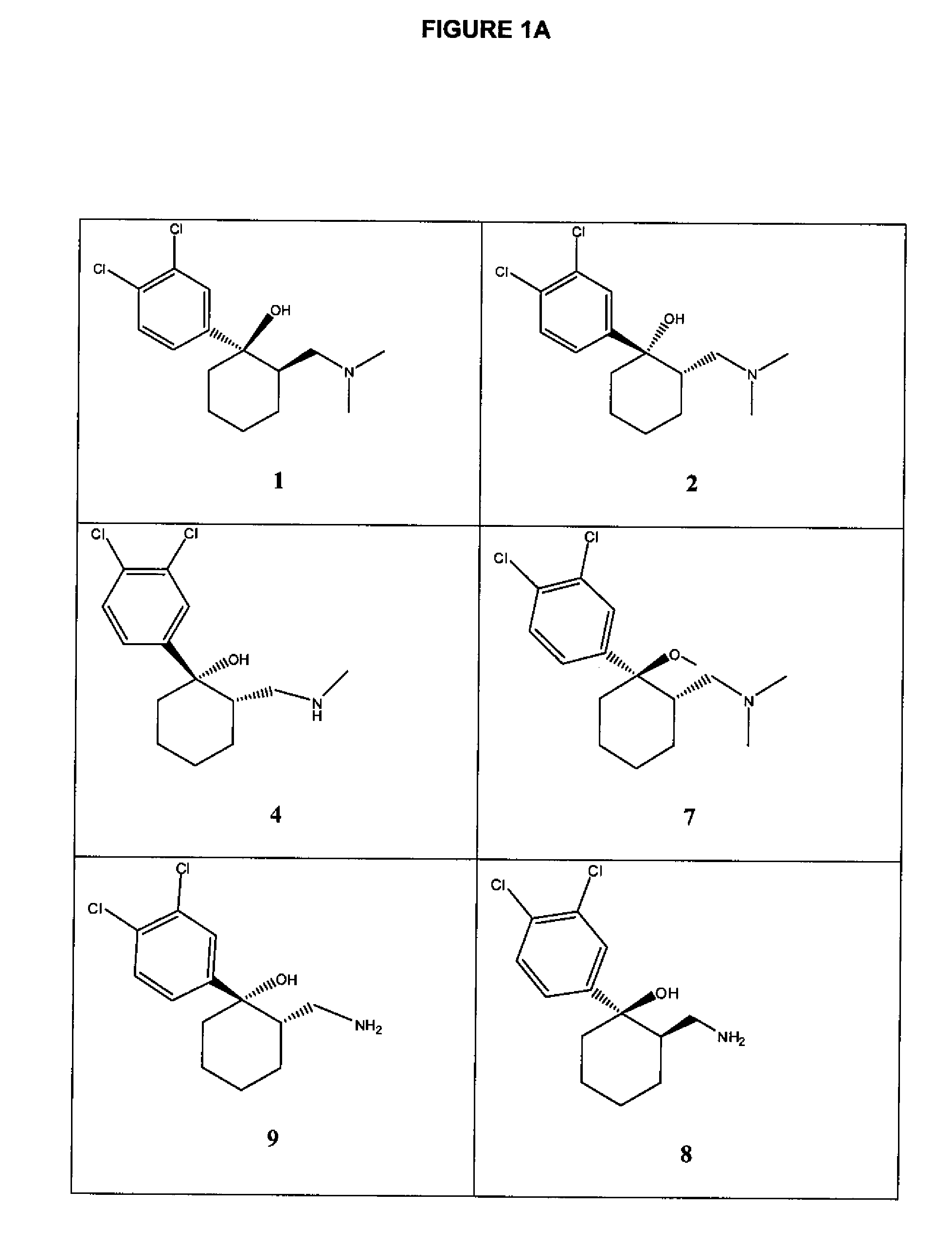

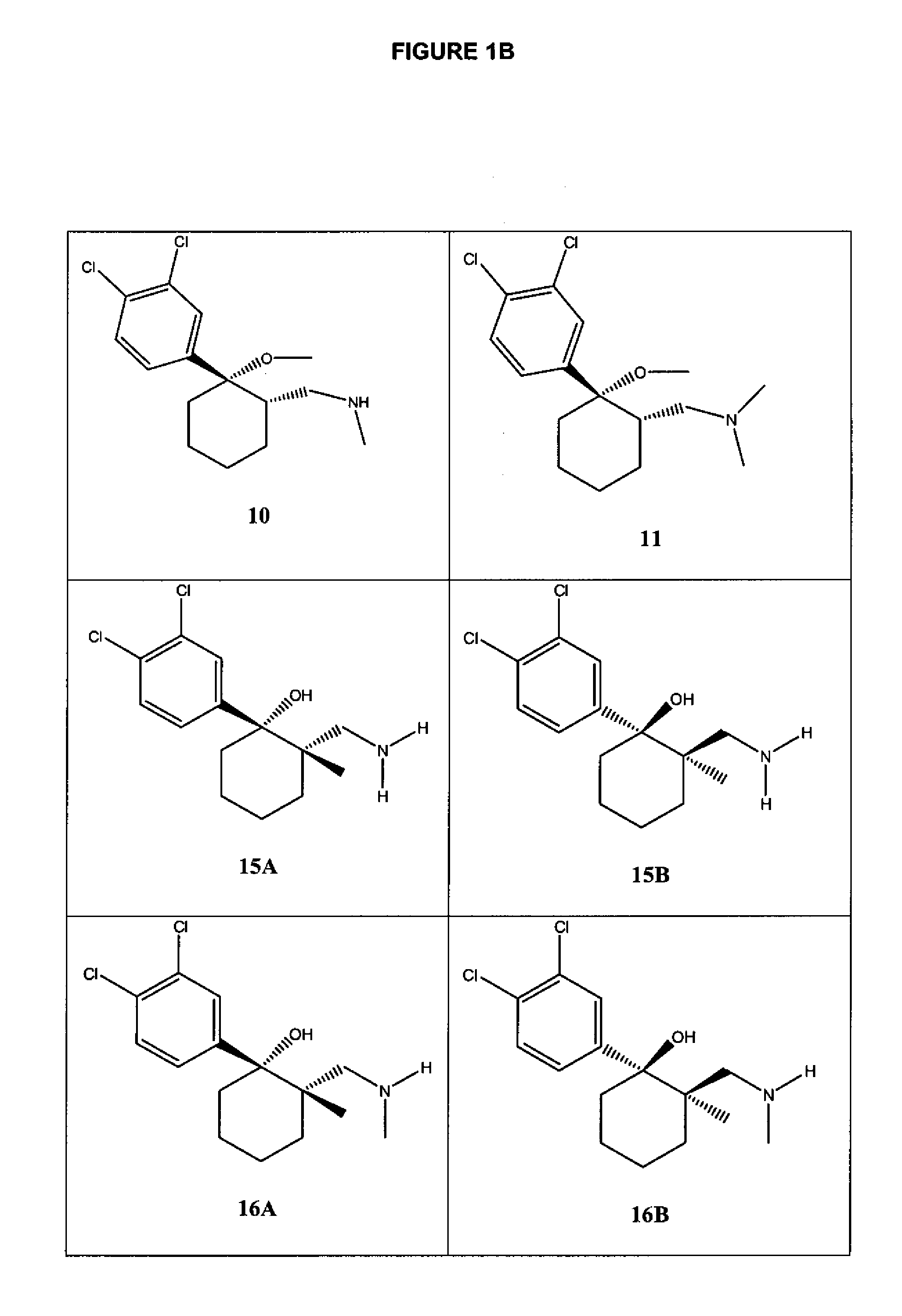

The invention relates to novel cyclohexylamine derivatives and their use in the treatment and / or prevention of central nervous system (CNS) disorders, such as depression, anxiety, schizophrenia and sleep disorder as well as methods for their synthesis. The invention also relates to pharmaceutical compositions containing the compounds of the invention, as well as methods of inhibiting reuptake of endogenous monoamines, such as dopamine, serotonin and norepinephrine from the synaptic cleft and methods of modulating one or more monoamine transporter.

Owner:SEPACOR INC

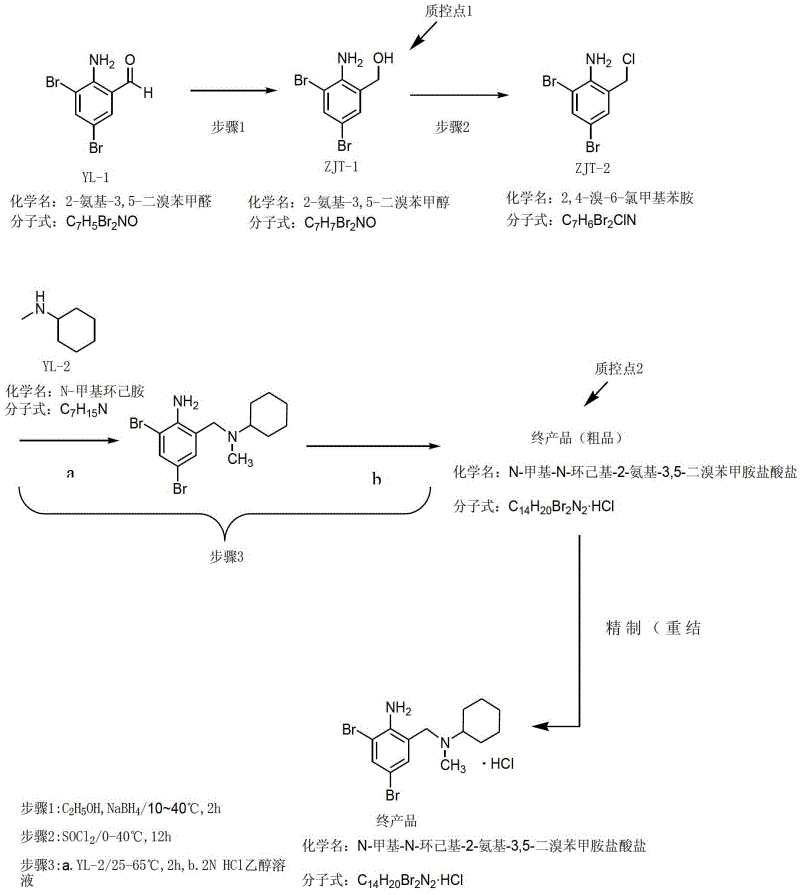

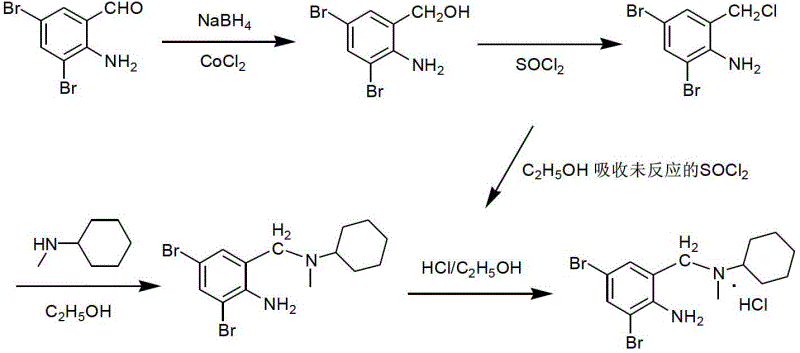

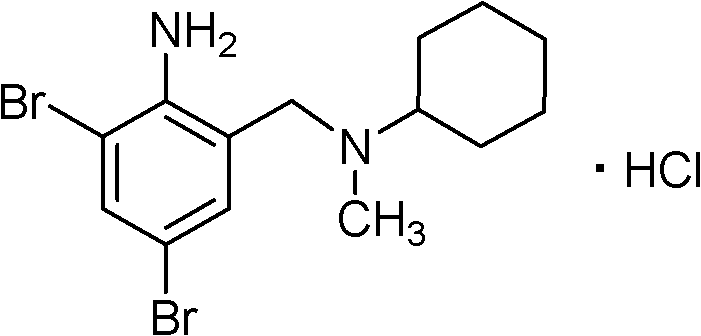

Method for preparing bromhexine hydrochloride

The invention provides a method for preparing bromhexine hydrochloride, which comprises the steps as follows: (1) 2-amino-3,5-dibromo benzaldehyde and reducing agents are in a reduction reaction to generate 2-amino-3,5-dibromo benzyl alcohol; (2) 2-amino-3, 5-dibromo benzyl alcohol that is obtained in the step (1) reacts with chlorinating agents to generate 2, 4-bromine-6-chloride methylaniline; and (3) 2,4-bromine-6-chloride methylaniline obtained in the step (2) and N-methylcyclohexylamine are in an amination reaction, and then 2, 4-bromine-6-chloride methylaniline and HCl salification agents are in a salification reaction, so that bromhexine hydrochloride is obtained. The preparation method adopts multiple advanced technologies, is easy to get starting materials, and has the advantages of stable property of intermediates, extremely low environment pollution, high yield coefficient of products and high purity.

Owner:SHIJIAZHUANG DONGFANG PHARMA

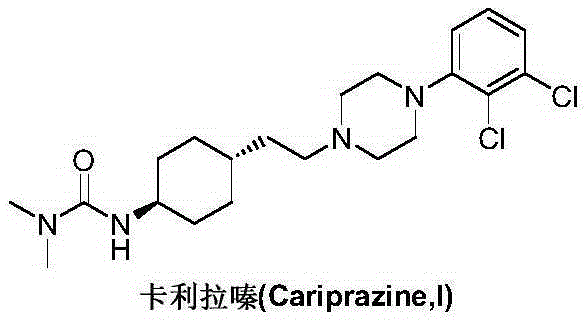

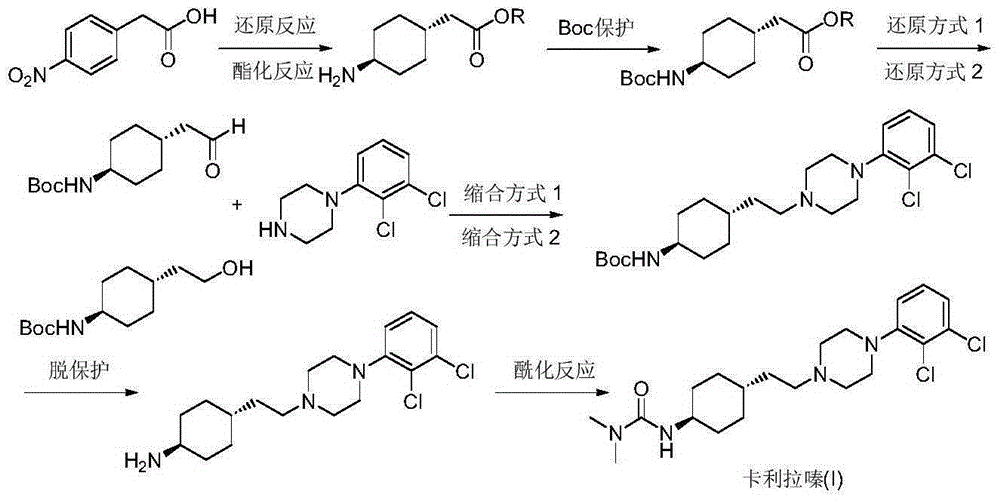

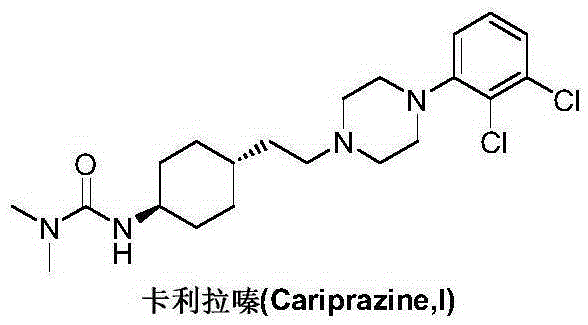

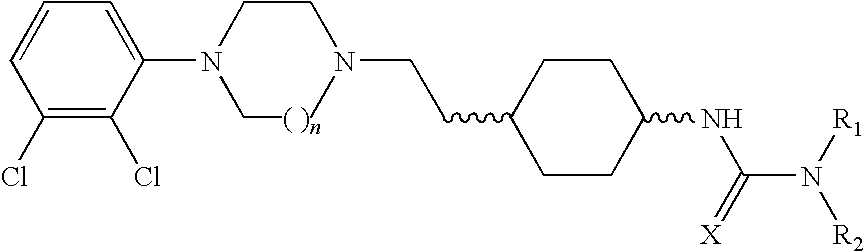

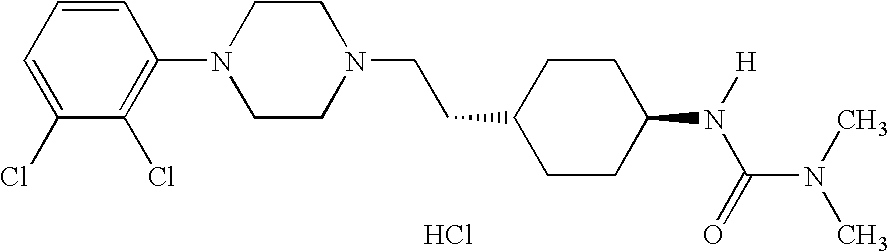

Preparation method of cariprazine

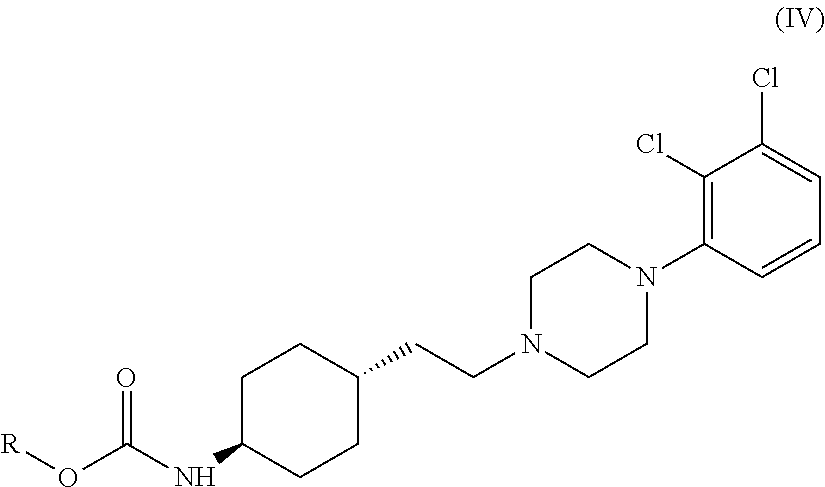

ActiveCN105330616AEase of industrial productionRaw materials are easy to getOrganic active ingredientsNervous disorderCariprazineCyclohexanone

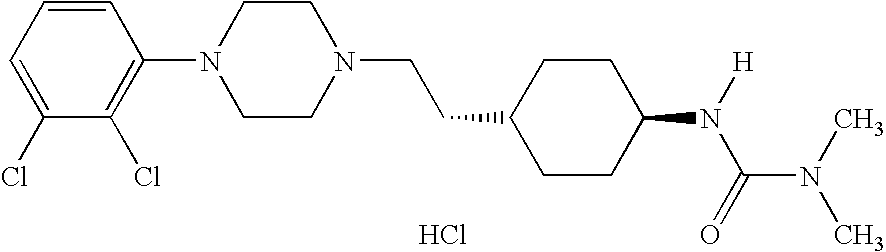

The invention discloses a preparation method of cariprazine (Cariprazine, RGH 188). The method includes the preparation steps of preparing 4-[2-[4-(2,3-dichlorophenyl)piperazine]-1-based]ethyl]cyclohexanone by making 4-(2-hydroxyethyl)cyclohexanone and 1-(2,3-dichlorophenyl)piperazine subjected to a condensation reaction, preparing trans-4-[[2-]4-(2,3-dichlorophenyl)piperazine]-1-based]ethyl]cyclohexylamine by making the obtained intermediate subjected to a reduction ammonolysis reaction, and preparing cariprazine by making the intermediate and N,N-dimethylcarbamyl chloride subjected to an acylation reaction. According to the preparation method, raw materials can be easily obtained, the process is simple, and the method is economical, environmentally friendly and suitable for industrialized production.

Owner:中科恩吉瑞特(烟台)科技发展有限公司

Phenyl substituted cycloalkylamines as monoamine reuptake inhibitors

ActiveUS20090005456A1Improve usabilityOrganic active ingredientsBiocideSynaptic cleftPharmaceutical formulation

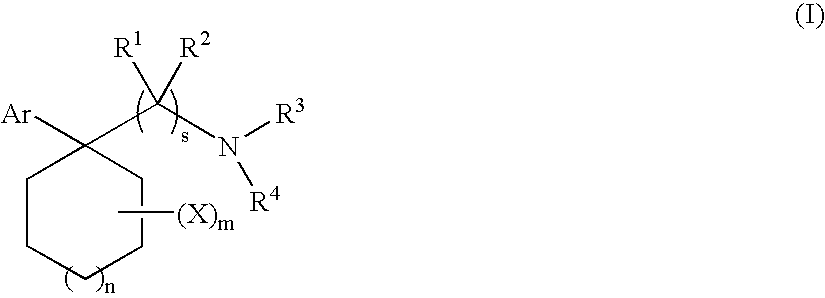

Phenyl-substituted cyclohexylamine derivatives and method for their synthesis and characterization are disclosed. Use of these compounds to treat / prevent neurological disorders as well as methods for their synthesis are set forth herein. Exemplary compounds of the invention inhibit reuptake of endogenous monoamines, such as dopamine, serotonin and norepinephrine (e.g., from the synaptic cleft) and modulate one or more monoamine transporter. Pharmaceutical formulations incorporating compounds of the invention are also provided.

Owner:SUNOVION PHARMA INC

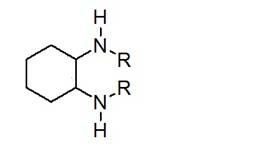

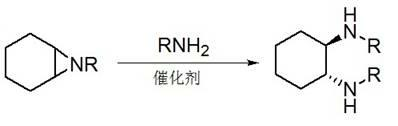

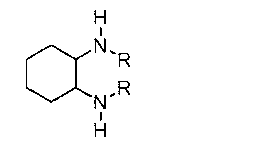

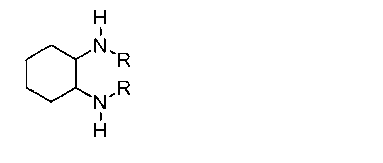

Method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine

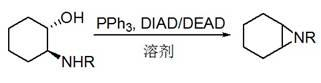

InactiveCN102531918ASimple and fast operationMild reaction conditionsOrganic compound preparationAmino compound preparationDiisopropyl azodicarboxylateHexamethylenediamine

The invention discloses a method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine, belonging to the field of chemistry. The method comprises the following steps of: carrying out an airtight or reflux reaction on cyclohexene oxide and an aqueous solution of alkylamine for reacting at 80-120 DEG C for 1.5-5h to obtain 2-alkyl-amino cyclohexanol, dropwise adding DEAD (Diethyl Azodicarboxylate) or DIAD (Diisopropyl Azodicarboxylate) to triphenylphosphine, 2-alkyl-amino cyclohexanol and a solvent under an ice bath for reacting for 5-20h at room temperature to obtain N-alkyl-7-azabicyclo[4, 1, 0]heptane, adding a catalyst to the N-alkyl-7-azabicyclo[4, 1, 0]heptane and the aqueous solution of alkylamine at 100-120 DEG C to carry out the airtight or reflux reaction to obtain trans-N,N'-dialkyl-1,2 cyclohexanamine, dissolving the trans-N,N'-dialkyl-1,2 cyclohexanamine in an alcoholic solvent, and adding a tartaric acid type resolving agent with the equivalent weight of 0.5 to the alcoholic solvent to resolve so as to obtain the enantiomorphous pure symmetric trans-dialkyl cyclohexylamine.

Owner:ANYANG INST OF TECH

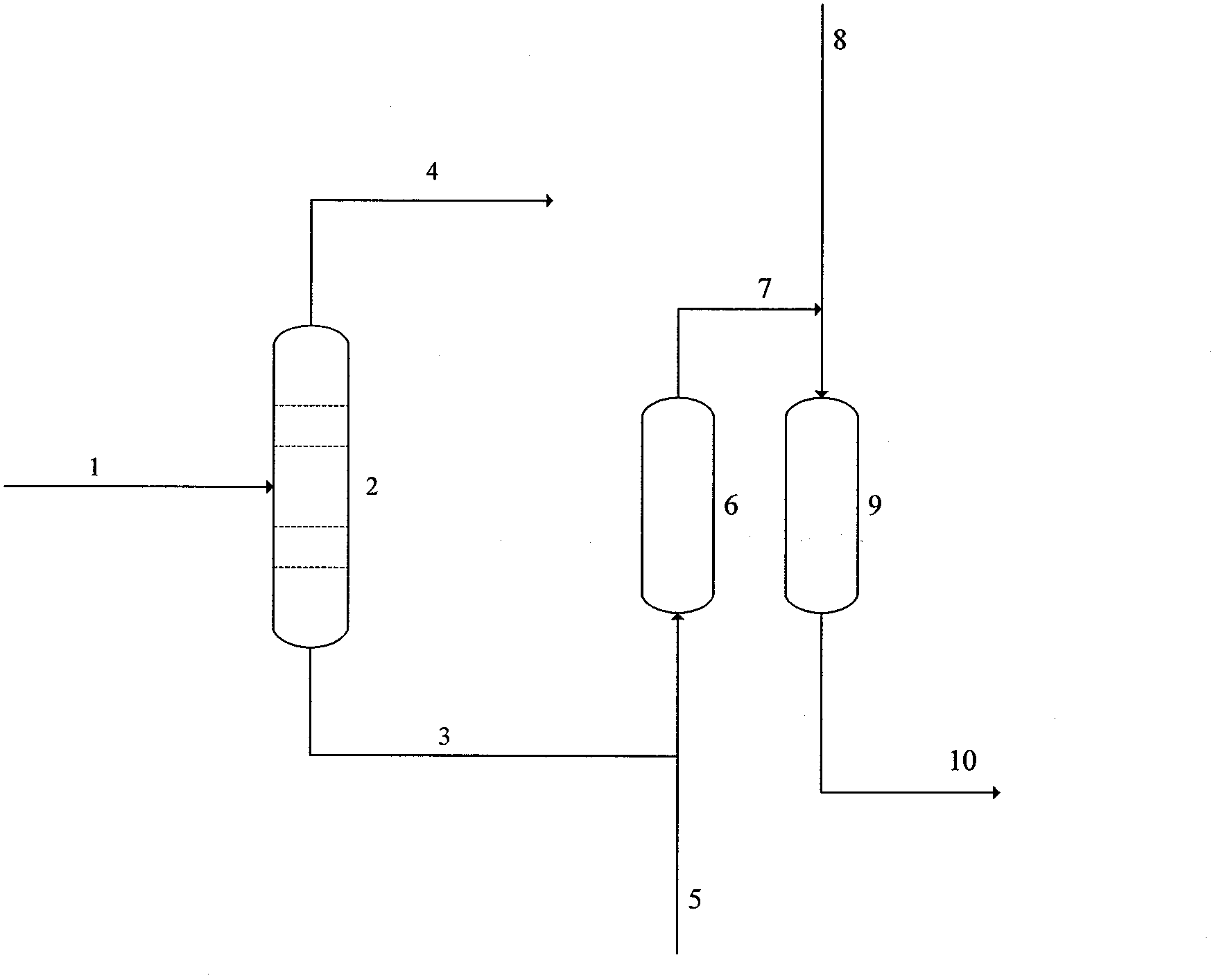

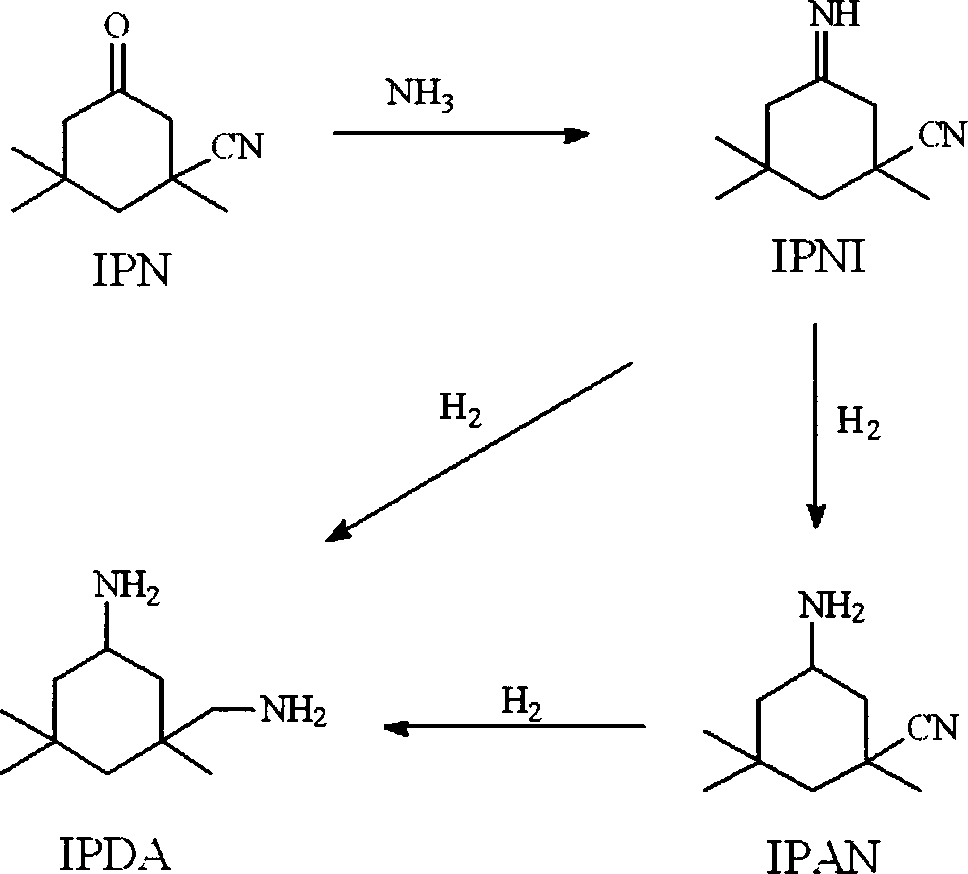

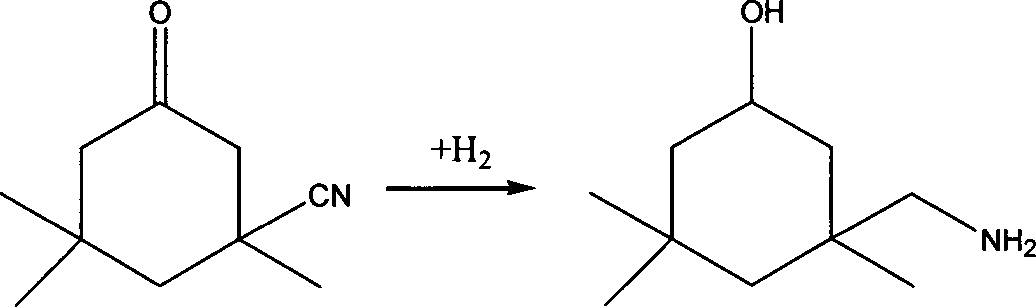

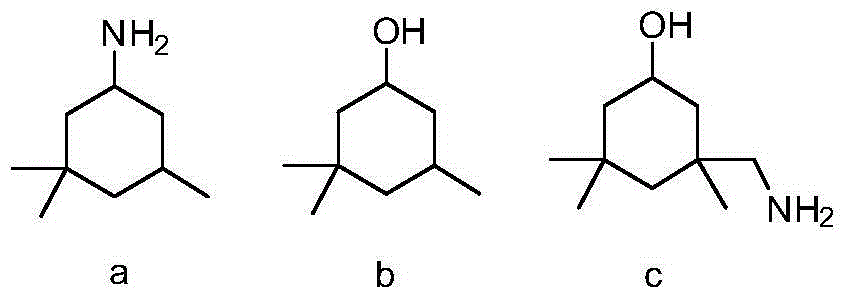

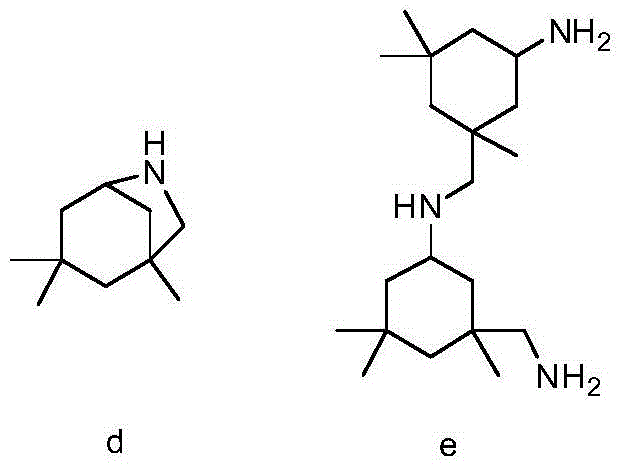

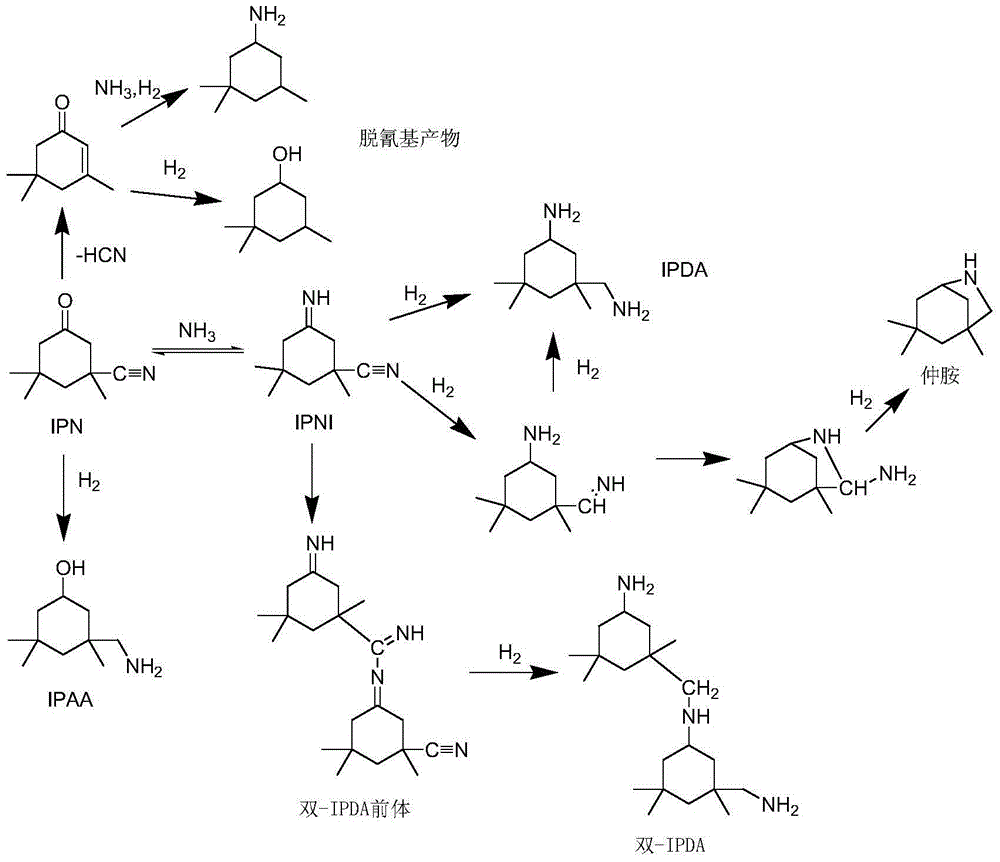

Method for preparing 3-aminomethyl-3,5,5-trimethyl cyclohexylamine

ActiveCN102976956AAvoid the hassle of separationEasy to separateOrganic compound preparationAmino compound preparationCyclohexanoneHydrogenation reaction

The invention provides a method for preparing 3-aminomethyl-3,5,5-trimethyl cyclohexylamine. The method includes: a) reacting 3-cyano-3,5,5-trimethyl cyclohexanone with excess primary amine, while removing water of the reaction, so that IPN is substantially completely converted to an imine compound; b) in the presence of an aminolysis catalyst, mixing the resulting product from step a) with liquid ammonia so as to carry out the aminolysis reaction on the imine compound to form 3-cyano-3,5,5-trimethyl cyclohexylimine and the primary amine; and c) performing the hydrogenation reaction to 3-cyano-3,5,5-trimethyl cyclohexylimine obtained in step b) to get 3-carbamoylyl-3,5,5-trimethyl cyclohexylamine in the presence of hydrogen and a hydrogenation catalyst. The method of the present invention prevents the generation of major byproducts of 3,5,5-trimethyl cyclohexanol, and 3-aminomethyl-3,5,5-trimethyl cyclohexanol in the prior art, thereby improving the yield of 3-aminomethyl-3,5,5-trimethyl cyclohexylamine.

Owner:WANHUA CHEM GRP CO LTD +1

Solar polyurethane thermal insulation material

Owner:SHANDONG LINUO PARADIGMA

Corrosion inhibitor for steam condensate system of industrial boiler and process for manufacturing same

InactiveCN1557746AWith corrosion inhibitor concentration indication functionWith concentration indication functionScale removal and water softeningMorpholineAlkyl amine

The corrosion inhibitor for industrial boiler steam condensating water system includes alkyl amine with 12-18 carbon atoms or epoxy alkyl amine, Tween-60, Span-60, morpholine, cyclohexylamine and / or ammonia, and water. The corrosion inhibitor is emulsified liquid, and has functions of filming and neutralizing, reasonable steam-liquid distribution ratio, lower consumption, concentration indication, corrosion inhibiting efficiency over 98 %, obvious energy saving function and simple use, and may be used widely in various industrial boiler steam condensating water systems.

Owner:张文利 +4

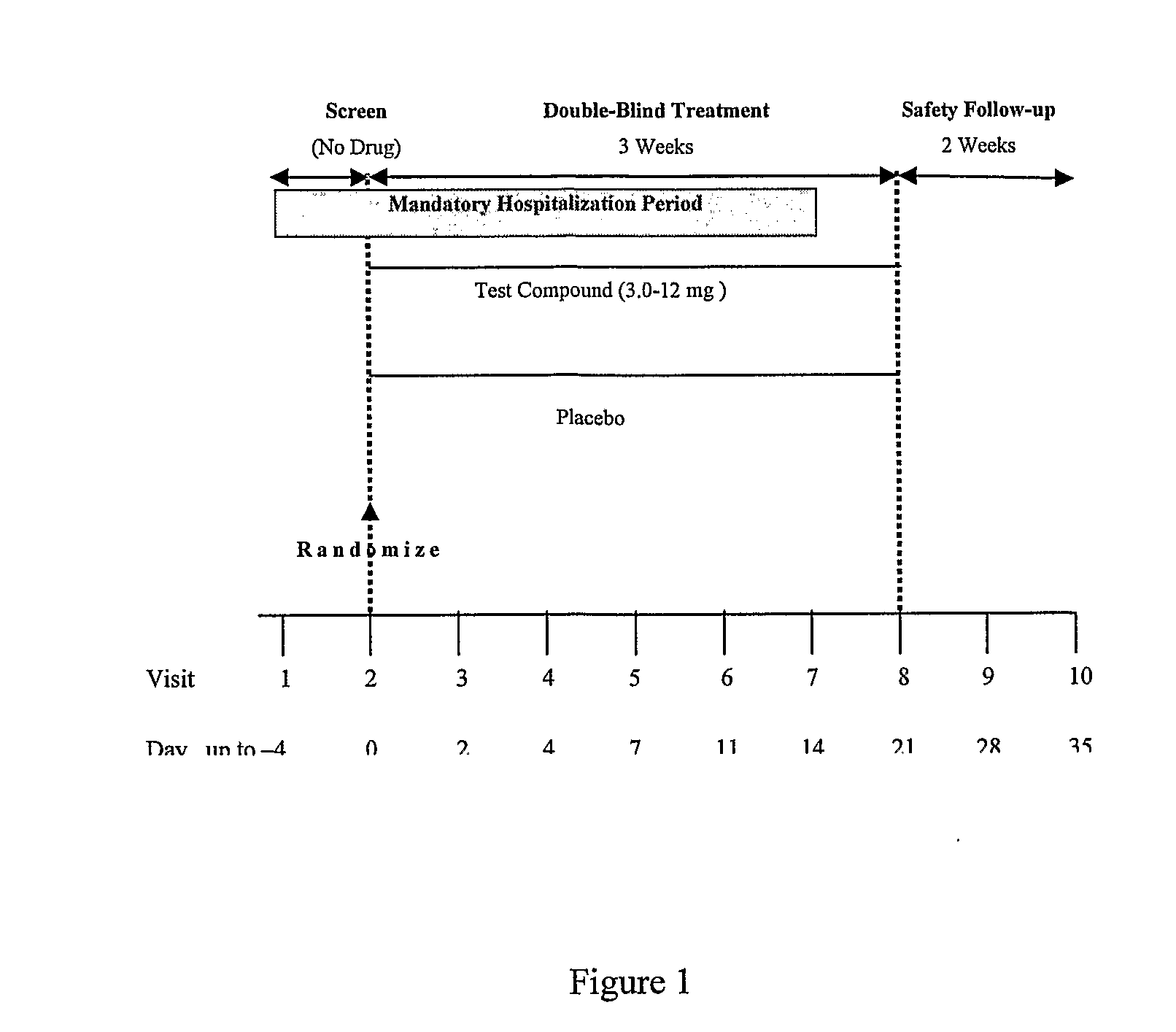

Pharmaceutical compositions and method for treating acute mania

The present invention relates to use of (thio)-carbamoyl-cyclohexane derivatives, particularly trans-4-{2-[4-(2,3-dichlorophenyl)-piperazin-1-yl]-ethyl}-N,N-dimethylcarbamoyl-cyclohexylamine and pharmaceutically acceptable salts thereof in the manufacture of a medicament for the treatment of acute mania. Furthermore, the present invention relates to the treatment of acute mania through the administration of (thio)-carbamoyl cyclohexane derivatives, particularly trans-4-{2-[4-(2,3-dichlorophenyl)-piperazin-1-yl]-ethyl}-N,N-dimethylcarbamoyl-cyclohexylamine and pharmaceutically acceptable salts thereof.

Owner:RICHTER GEDEON NYRT

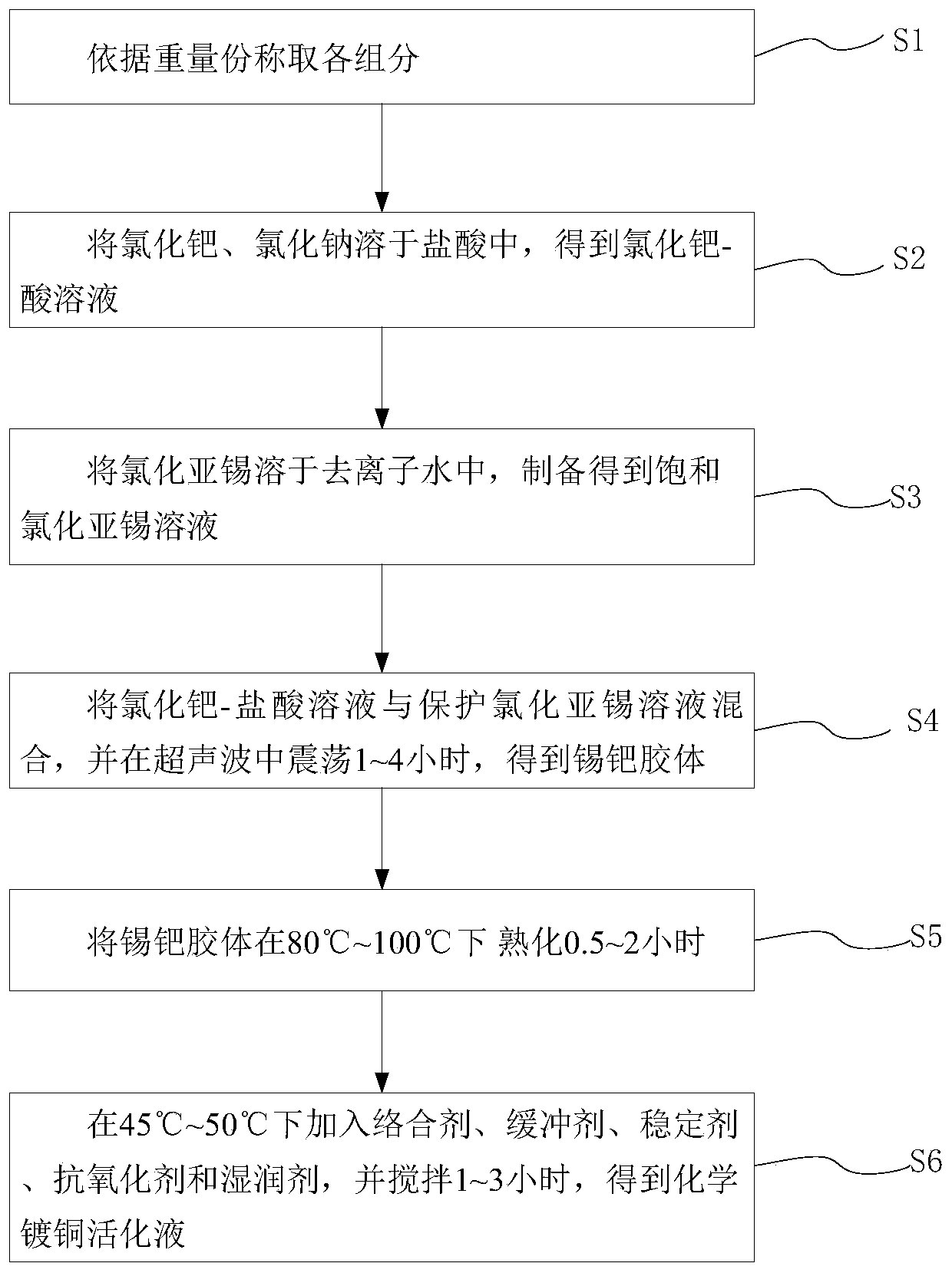

Electroless copper plating activating solution and preparation method thereof

ActiveCN110670050AImprove stabilityStrong complexationLiquid/solution decomposition chemical coatingPropanoic acidDiethylenetriamine

The invention provides an electroless copper plating activating solution and a preparation method thereof. The electroless copper plating activating solution is prepared from, by weight part, 1-10 parts of palladium chloride, 100-400 parts of stannous chloride, 50-200 parts of sodium chloride, 10-100 parts of sodium chloride, 0.1-50 parts of a complexing agent, 1-200 parts of a buffering agent, 0.1-10 parts of a stabilizing agent, 0.05-10 parts of an antioxidant and 0.1-10 parts of a wetting agent. The complexing agent is one or more of ethidene diamine, trimethyl amine, triethylanmine, diethylenetriamine, triethylenetetramine and tetraethylenepentamine. The buffering agent is one or more of ethylenediamine tetraacetic acid, glycine, propionic acid, malic acid and 2-(cyclohexylamino)ethanesulfonic acid. The electroless copper plating activating solution is high in stability and can adapt to intense circulating stirring in a horizontal electroless copper plating process.

Owner:SHENZHEN CYPRESS IND DEV CO LTD

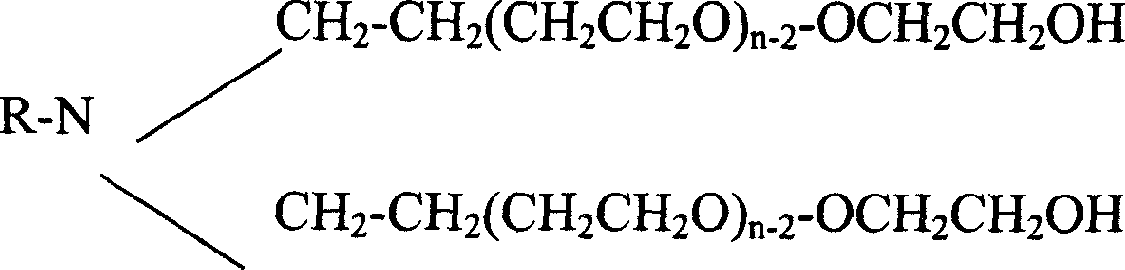

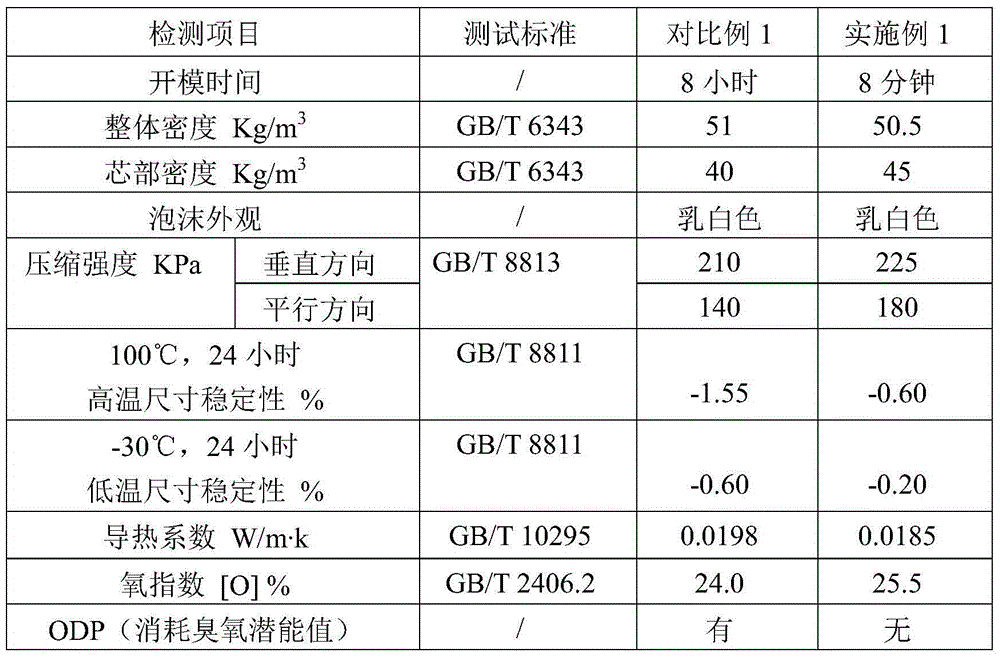

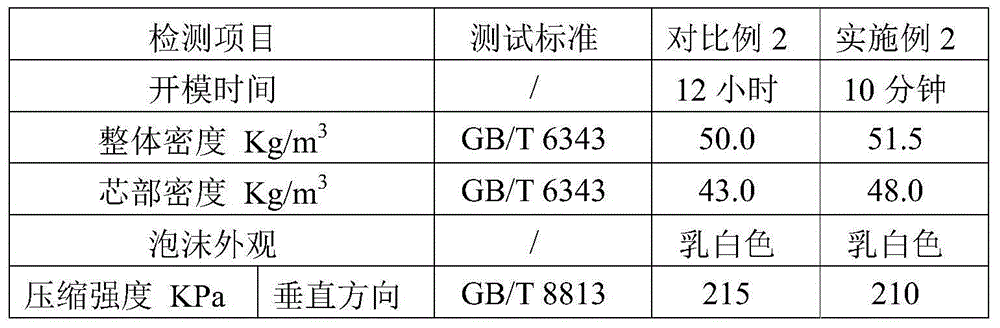

Composite polyether, composition including composite polyether and polyurethane block foam and preparing method and application of composite polyether

The invention discloses composite polyether, composition including the composite polyether and polyurethane block foam and a preparing method and application of the composite polyether. The composite polyether includes, by weight, 4 parts to 6 parts of polyether polyol A, 3 parts to 4 parts of polyether polyol B, 1 part to 2 parts of polyether polyol C, 02 part to 0.4 part of surface active agent, 0.2 part to 0.4 part of catalyst, 1 part to 2 parts of foaming agents and 0.2 part of water, wherein the surface active agent is B8545 and LK665, and the catalyst is N,N-dimethyl cyclohexylamine 1,3,5-3 (dimethylamino propyl)-hexahydro triazine and TMR-2. The density of the rigid polyurethane block foam prepared from the composite polyether is uniform, a heat conductivity coefficient is small, foam is exquisite, dimensional stability is high, compression strength is high, and mould opening production and fast demolding can be performed when the rigid polyurethane block foam is prepared.

Owner:SHANGHAI DONGDA POLYURETHANE

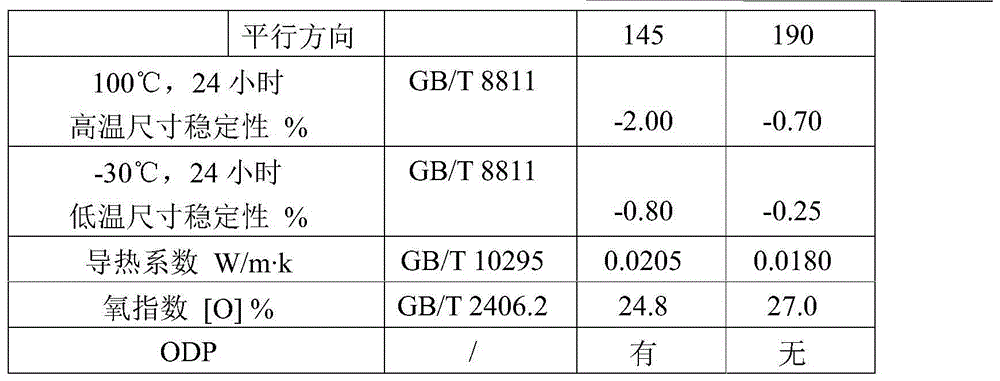

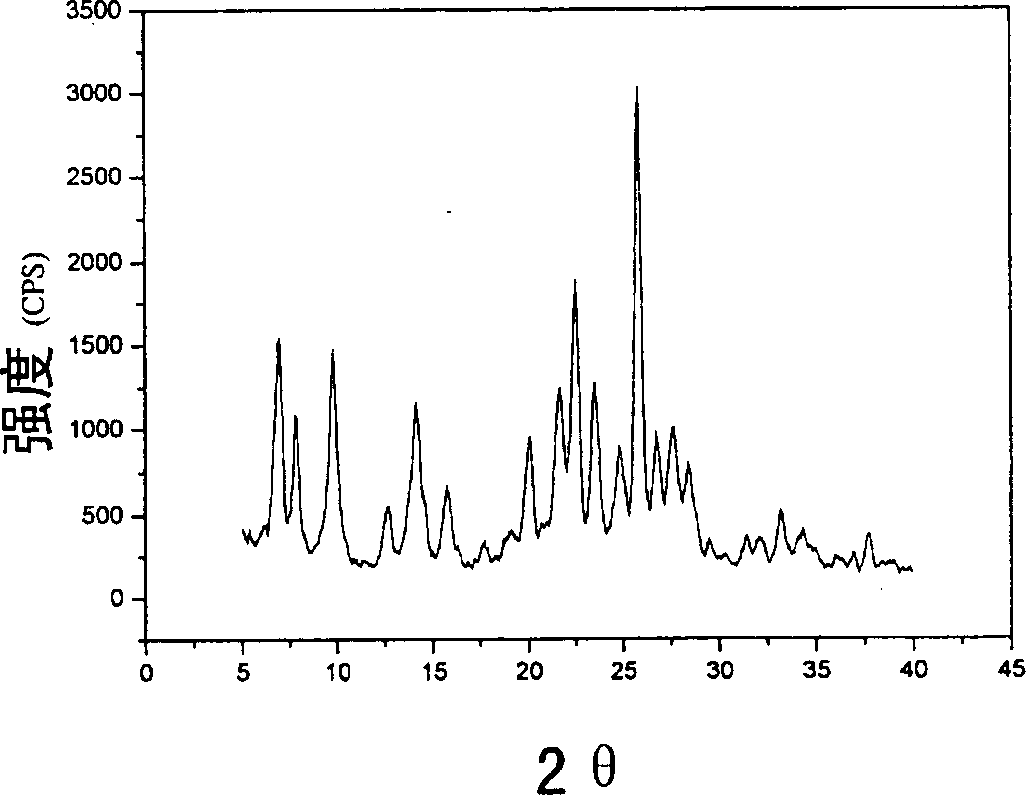

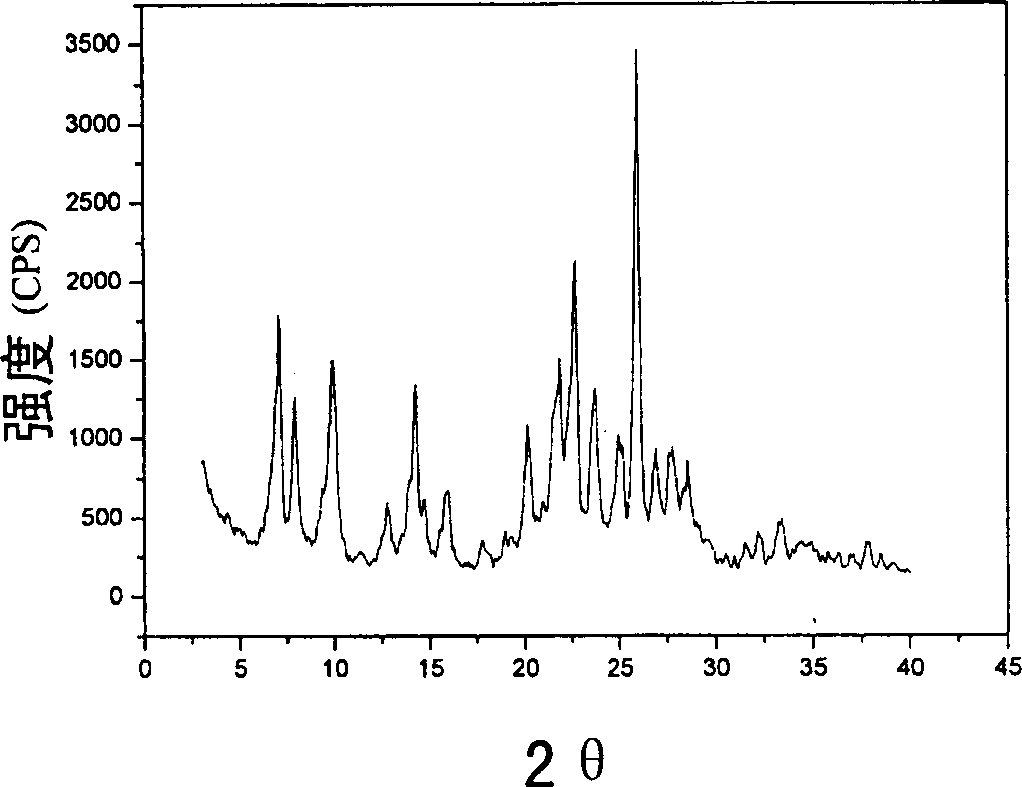

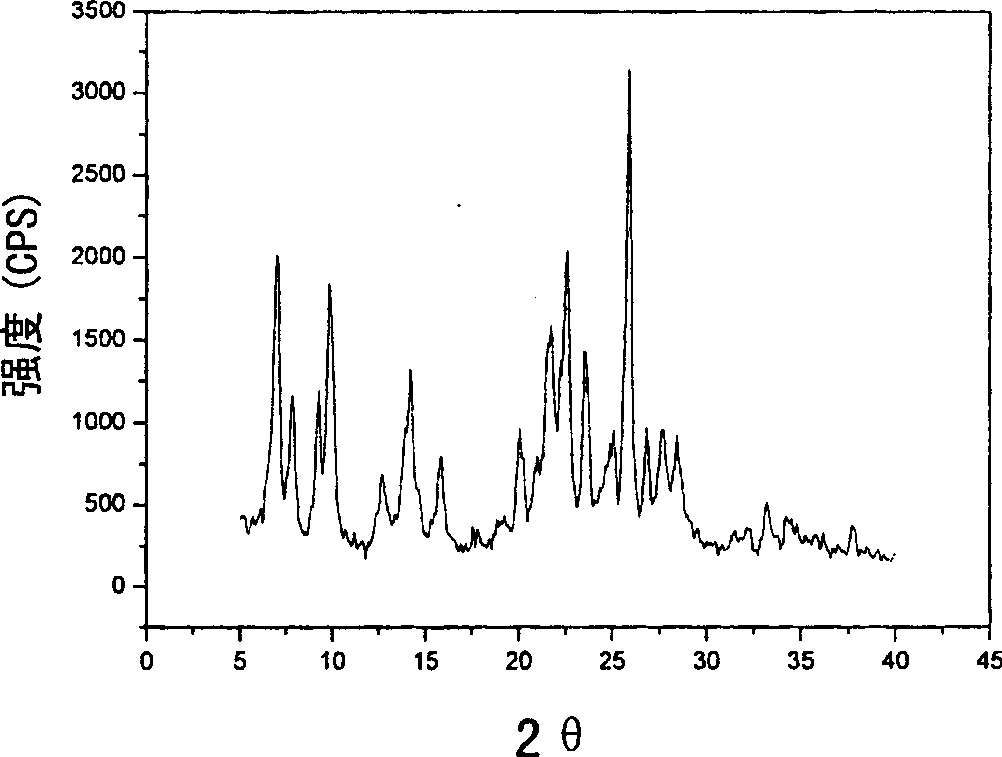

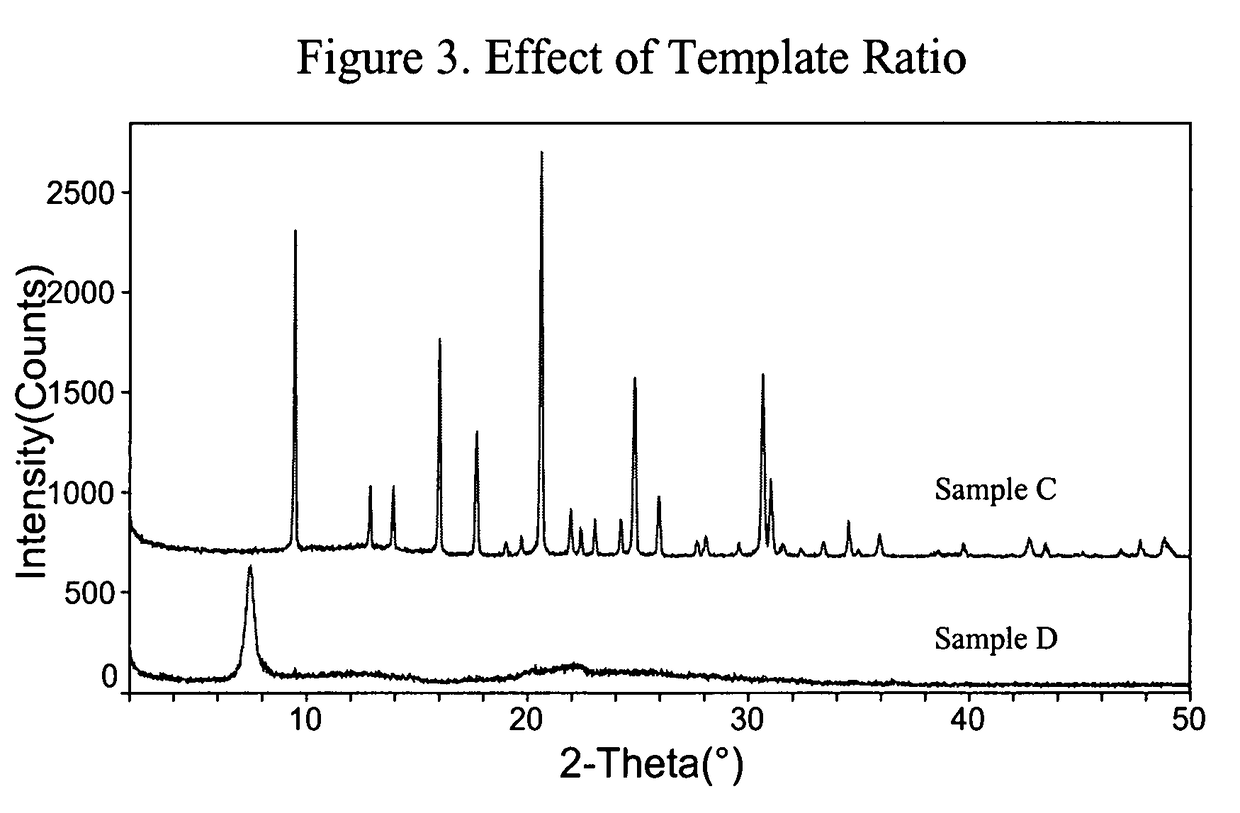

Co-crystallization molecular screen and preparation method and application thereof

InactiveCN1689972ALow priceHigh crystallinityMolecular-sieve and base-exchange compoundsIsomerizationAlkali metal

The process of preparing cocrystallized molecular sieve of ZSM-35 accounting for 0-100 wt% and MCM-22 adopts the mixture of hexamethylene imine and cyclohexylamine as template agent. Compound of silicon and aluminum, hydroxide of alkali metal, hexamethylene imine, cyclohexylamine and deionized water as materials are crystallized at 90-200 deg.c for some period and reacted completely to synthesize the molecular sieve hydrothermally. The synthesized molecular sieve is catalyst used widely in the catalytic reaction of converting hydrocarbons, such as hydrocarbon isomerization and aromatization, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

(THIO) -carbamoyl-cyclohexane derivatives and method for treating schizophrenia

The present invention relates to use of (thio)-carbamoyl-cyclohexane derivatives, particularly trans-4-{2-[4-(2,3-dichlorophenyl)-piperazin-1-yl]-ethyl}-N,N-dimethylcarbamoyl-cyclohexylamine and pharmaceutically acceptable salts thereof in the manufacture of a medicament for the treatment of schizophrenia. Furthermore, the present invention relates to the treatment of schizophrenia through the administration of (thio)-carbamoyl cyclohexane derivatives, particularly trans-4-{2-[4-(2,3-dichlorophenyl)-piperazin-1-yl]-ethyl}-N,N-dimethylcarbamoyl-cyclohexylamine and pharmaceutically acceptable salts thereof.

Owner:RICHTER GEDEON NYRT

Preparation method of 3-aminomethyl-3,5,5-trimethyl cyclohexylamine

The invention discloses a preparation method of 3-aminomethyl-3,5,5-trimethyl cyclohexylamine. The method comprises the steps: a) controlling an acid value of a raw material 3-cyano-3,5,5-trimethyl cyclohexanone at 0.02-0.50 mg KOH / g, carrying out a reaction with liquid ammonia, and thus obtaining a partial-imidization reaction liquid; b) adding an alkaline acid value regulator into the partial-imidization reaction liquid obtained in the step a) with the adding amount of 0.02-0.5% of the molar weight of the raw material 3-cyano-3,5,5-trimethyl cyclohexanone, and continuing to carry out an imidization reaction; and c) carrying out hydrogenation on the product obtained in the step b) in the presence of hydrogen, liquid ammonia and a catalyst, to produce 3-aminomethyl-3,5,5-trimethyl cyclohexylamine. The preparation method has the 3-aminomethyl-3,5,5-trimethyl cyclohexylamine yield close to 99%, the air speed is increased, the reaction efficiency is increased, and the cost of the catalyst and equipment are saved.

Owner:WANHUA CHEM GRP CO LTD +1

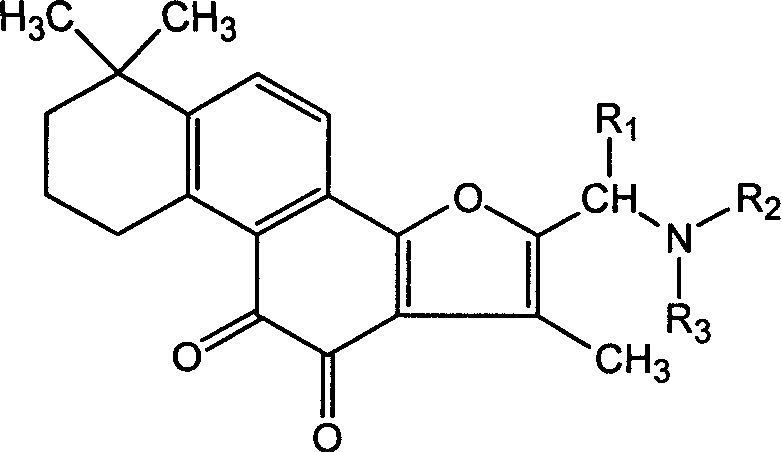

Tanshinone IIA derivatives and pharmaceutical application thereof

ActiveCN1837198ASoluble in waterReduce contentPowder deliveryOrganic active ingredientsDiethylenediamineCyclohexylamines

The invention discloses a tanshinone IIA derivant and application in pharmacy, which is characterized by the following: the derivant constitutional formula is showed in the right chart; when R1 represents -Ar, R2,R3 represents hydrogen or alkyl with one to eight carbon atoms; or R2-N-R3 represents saturated heterocycle with nitrogen, imidazoline and its derivant, glyoxaline and its derivant, diethylenediamine and its derivant, piperidine and its derivant, morpholine and its derivant; when R1 represents -H, R2,R3 represents alkyl with three to eight carbon atoms, cycloalkyl and aromatic nucleus; or R2-N-R3 represents cyclohexylamine, imidazoline and its derivant, glyoxaline and its derivant, piperazine, piperazine and derivant of derivant. The derivant can improve the bioavailability of original chemical compoundm.

Owner:JIANGSU CAREFREE PHARM CO LTD

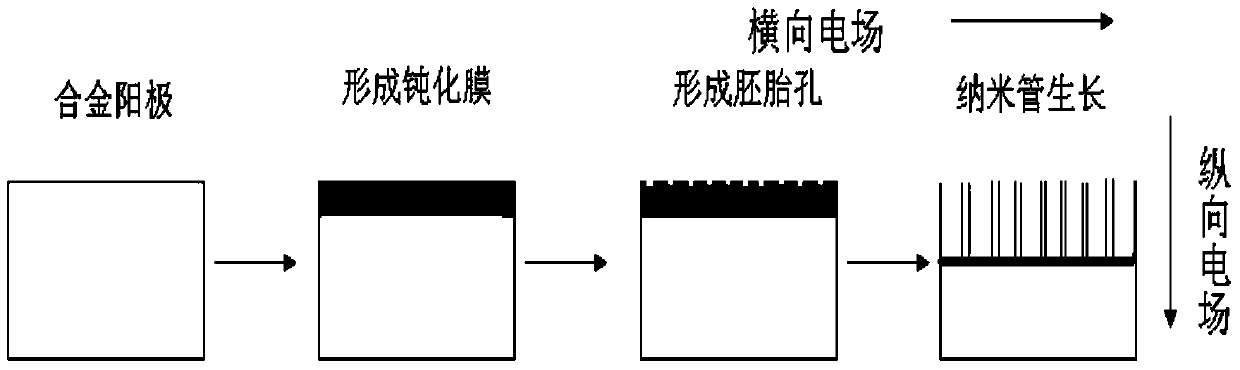

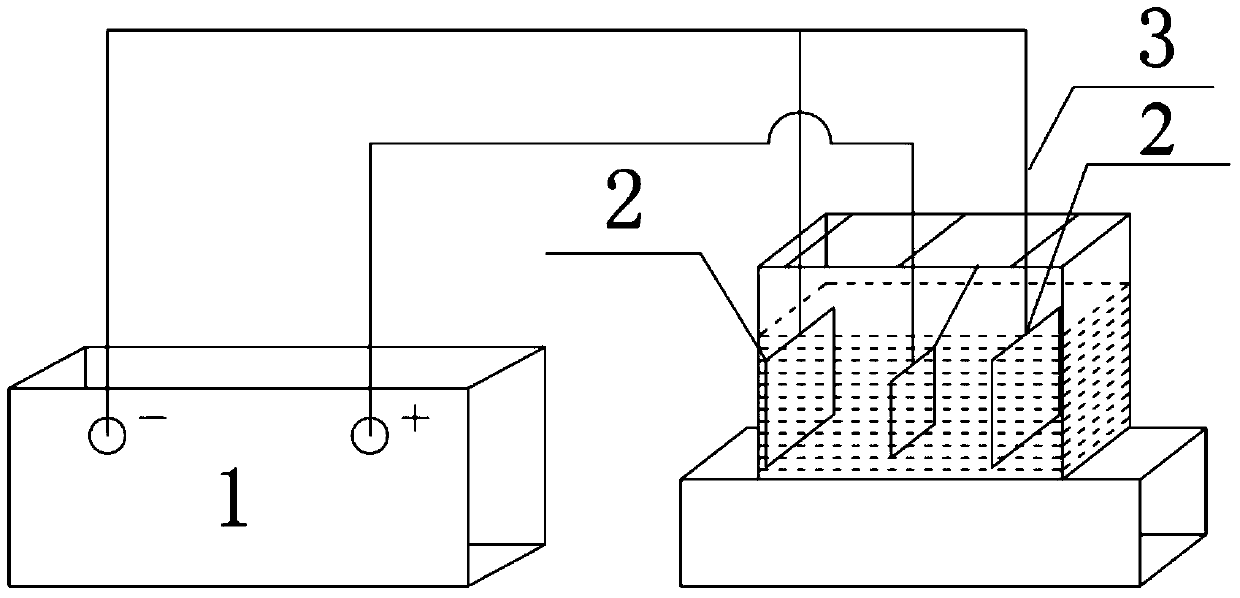

Preparation method and application of Co and Al2O3 compound nanotube array membrane catalyst

ActiveCN103464162AWon't happenFast growthAnodisationMaterial nanotechnologyCyclohexanoneCyclohexylamines

The invention discloses a preparation method and application of a Co and Al2O3 compound nanotube array membrane catalyst. The method comprises the following steps of: carrying out constant-pressure anodic oxidation in a urea-containing electrolyte by taking a Co-Al alloy sheet as an anode and high-purity graphite or an other conducting material as a cathode to prepare an alloy sheet with a Co and Al2O3 compound nanotube array membrane grown on a surface; then crushing the obtained alloy sheet into alloy granules, namely catalyst precursors; reducing the catalyst precursors by using H2 to obtain the Co and Al2O3 compound nanotube array membrane catalyst with uniform apertures, smooth tube walls, controllable pipe lengths and consistent pore path directions. The novel catalyst disclosed by the invention is used for preparing 3-aminomethyl-3,5,5-trimethyl cyclohexylamine (IPDA) by carrying out catalytic hydrogenation on 3-cyano-3,5,5-trimethyl cyclohexanone (IPN) and can achieve the maximal transformation rate of IPN by 100% and achieve the maximal selectivity of IPDA more than 98%.

Owner:WANHUA CHEM GRP CO LTD +1

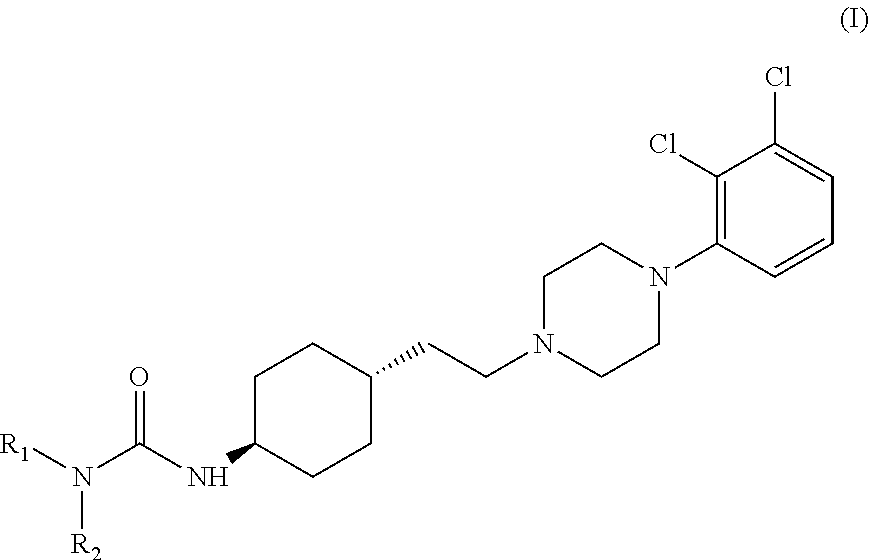

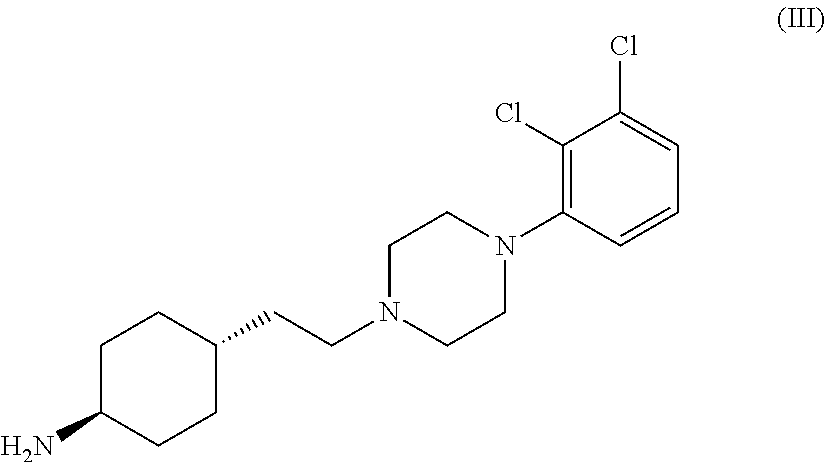

Process for the preparation of piperazine compounds and hydrochloride salts thereof

The invention relates to a new process for the preparation of compounds of general formula (I) whereinR1 and R2 represent independently hydrogen orC1-6 alkyl with straight or branched chain optionally substituted with aryl group, orC2-7 alkenyl containing 1-3 double bonds, ormonocyclic, bicyclic or tricyclic aryl optionally substituted with one or more C1-6 alkoxy, trifluoro-C1-6 alkoxy, C1-6-alkoxycarbonil, C1-6alkanoyl, aryl, C1-6 alkylthio, halogen or cyano, oroptionally substituted monocyclic, bicyclic or tricyclic C3-14 cycloalkyl group,R1 and R2 together with the adjacent nitrogen form a saturated or unsaturated optionally substituted monocyclic or bicyclic heterocyclic ring which may contain further heteroatoms selected from oxygen, nitrogen, or sulphur atomsand hydrochloric acid alts and / or hydrates and / or solvates thereof, by dissolving or suspending trans 4-{2-[4-(2,3-dichlorophenyl)-piperazine-1-il]-ethyl}-cyclohexylamine of formula (III) or a salt or a hydrate or a solvate thereof in an inert solvent in the presence a base then adding a carbonic acid derivative of general formula (VI) wherein R is alkyl with C 1-6 straight or branched chain or C1-2 fully halogenated alkyl, Z is —O—R or —X, wherein R is as described above, X is halogen, and reacting the compound of general formula (IV) obtained wherein R is as described above, in situ or, optionally in isolated state with an amine of general formula (V) wherein R1 and R2 are as described above to obtain the compound of general formula (I) and then optionally forming the hydrochloride salts and / or hydrates and / or solvates thereof.

Owner:RICHTER GEDEON NYRT

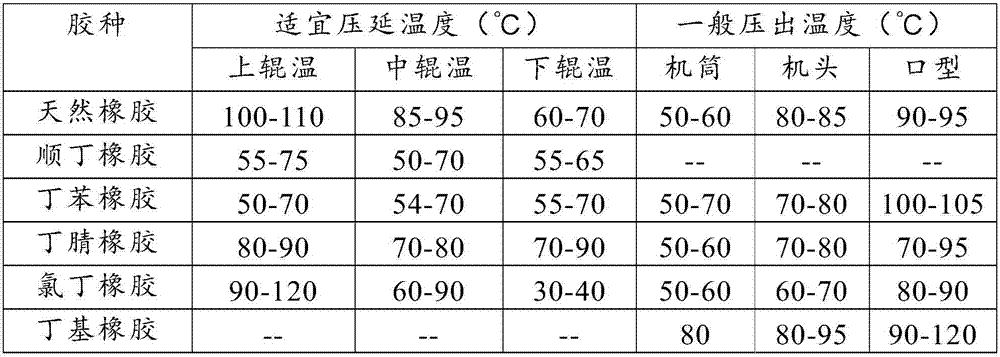

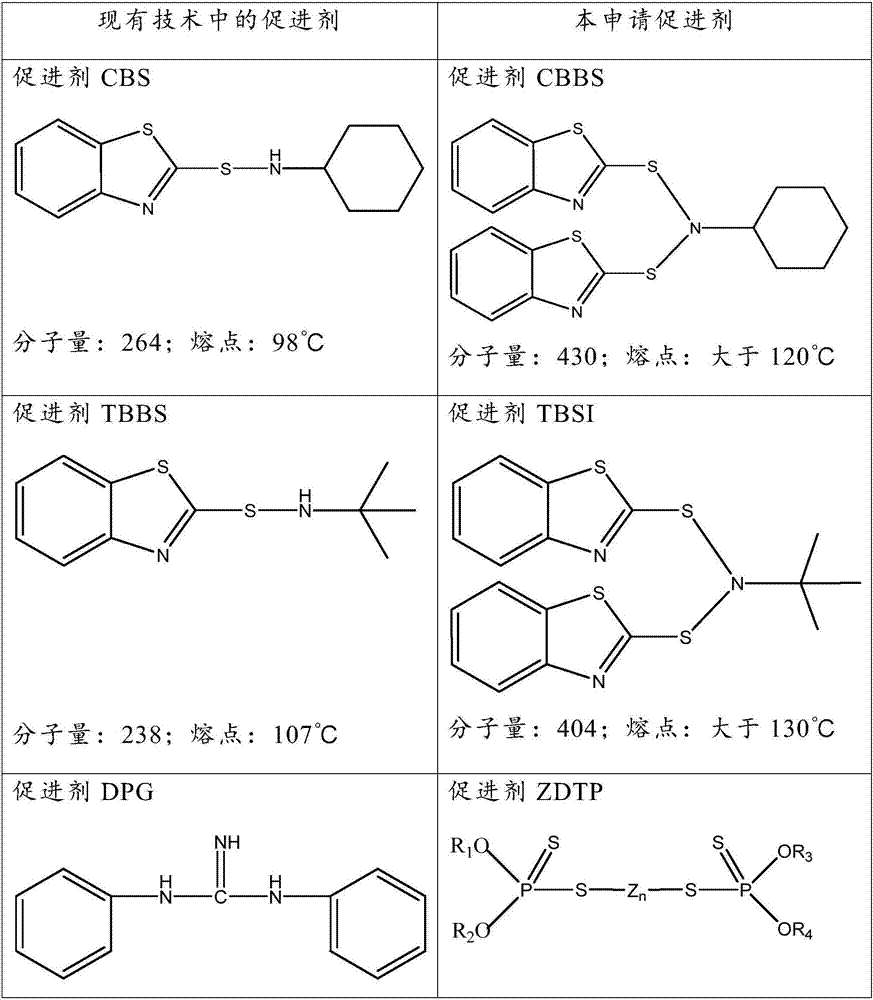

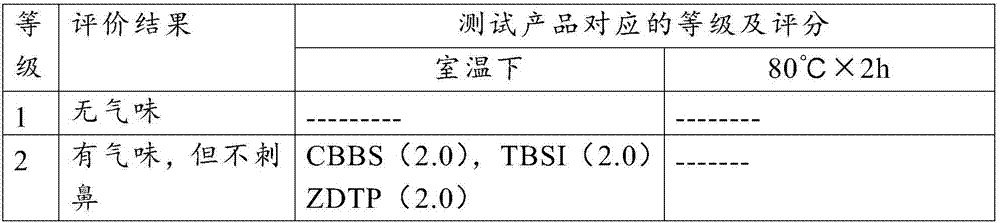

Rubber composition and tire

The invention provides a rubber composition. The rubber composition mainly comprises at least one type of polar or non-polar rubber, at least one type of fillers, at least one type vulcanizing agents, at least one type of accelerators, optional scotch retarders and optional aromatic substances. Each accelerator is a chemical compound with two or more X-Y single bonds, wherein the X selectively represents O and S elements, and the Y selectively represents N and P elements. The environment-friendly rubber composition and a tire (spare tire in particular) prepared from the rubber composition have the advantages that the rubber composition comprises the modified accelerators and the modified scotch retarders, accordingly, generation of organic volatile matters such as aniline, cyclohexylamine, tert-butylamine and imine with pungent odor can be reduced, and the problem of odor of existing tires can be solved; substances such as carbon black and zinc oxide with fine powder can be omitted, and accordingly dust hazards on operators in production procedures can be reduced; the rubber composition comprises the added aromatic substances, and accordingly fragrant smell of the tire further can be enhanced.

Owner:ZHEJIANG GEELY HLDG (GRP) CO LTD +1

Gas-phase anti-rust composite packaging film for industry and preparation method thereof

ActiveCN101319067AHigh mechanical strengthIncrease elasticityFlat articlesLow-density polyethyleneBenzoic acid

The invention relates to a rust proofing packaging film, in particular to a gas phase rust proofing industrial composite packaging film and a preparation method thereof. The gas phase rust proofing industrial composite packaging film comprises the compositions by weight proportion: 0 to 0.53 of drewamine, 0.12 to 0.42 of cyclohexane, 0.13 to 0.4 of dicyclohexylamine, 0.09 to 0.28 of phenylformic acid, 0.22 to 0.55 of tert-Butyl benzoic acid, 0 to 0.12 of cinnamylate, 29.5 to 45.1 of low density polyethylente, 29.5 to 45.1 of linear low density polyethylene, 0 to 0.02 of oleamide or erucyl amide and 0 to 0.12 of a diffusing impurity EB-FF. The gas phase rust proofing film has good barrier property and high intensity, saves cost, is nonpoisonous and harmless, prevents the pollution, and can be reused. The preparation method is simple and convenient, the process is easy to control and the production cost is low.

Owner:金荣范

Environment-friendly gasoline additive and preparation method thereof

InactiveCN108707489AReduce emission contentReduce wearLiquid carbonaceous fuelsFuel additivesOil additiveCyclohexylamines

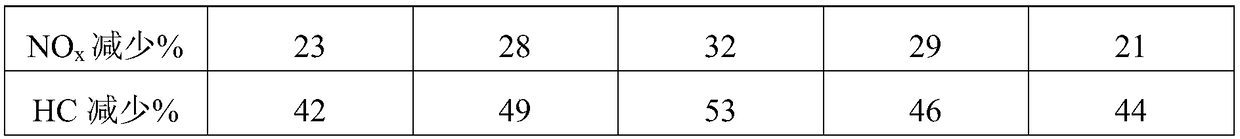

The invention discloses an environment-friendly gasoline additive. The environment-friendly gasoline additive is prepared from, by weight, 40-50 parts of dimethyl carbonate, 5-15 parts of isopropanol,5-15 parts of n-butyl alcohol, 5-15 parts of cyclohexylamine, 5-15 parts of methyl tert-butyl ether, 5-15 parts of liquid paraffin, 0.7-1.6 parts of isoamyl alcohol, 0.7-1.6 parts of petroleum ether,0.7-1.6 parts of ethanolamine, 0.01-0.05 part of benzotriazole and 0.01-0.03 part of 2,6-di-tert-butyl-p-cresol. Dimethyl carbonate has a high oxygen content and can be added to methanol gasoline toreduce the content of hydrocarbon, NOx and CO in automobile exhaust gas, in cooperation with auxiliary materials such as isopropanol, n-butyl alcohol and cyclohexylamine, the carbon deposit coking phenomenon of the methanol gasoline can be reduced, and the octane number is increased. The invention further provides a preparation method of the environment-friendly gasoline additive.

Owner:赵峰

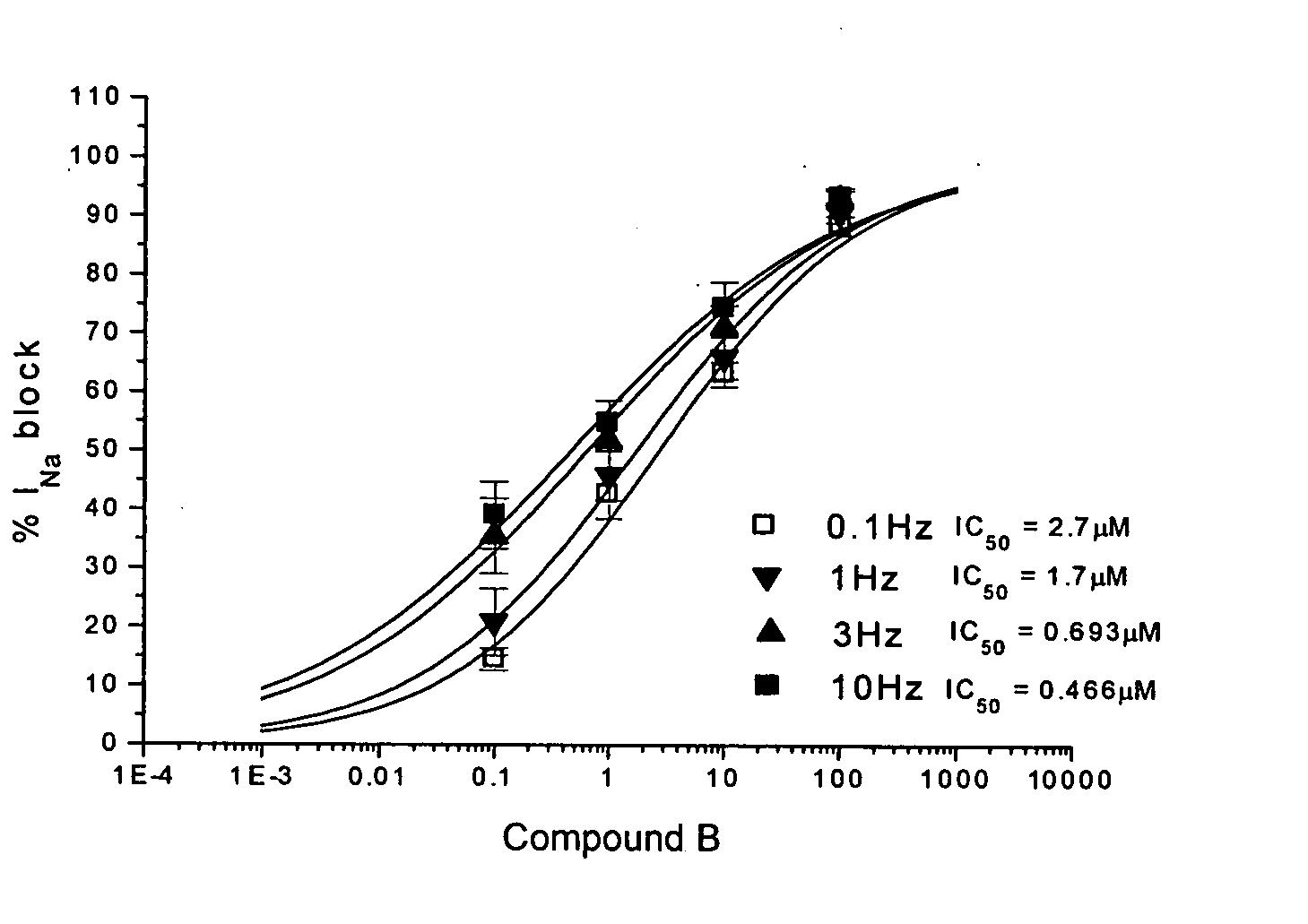

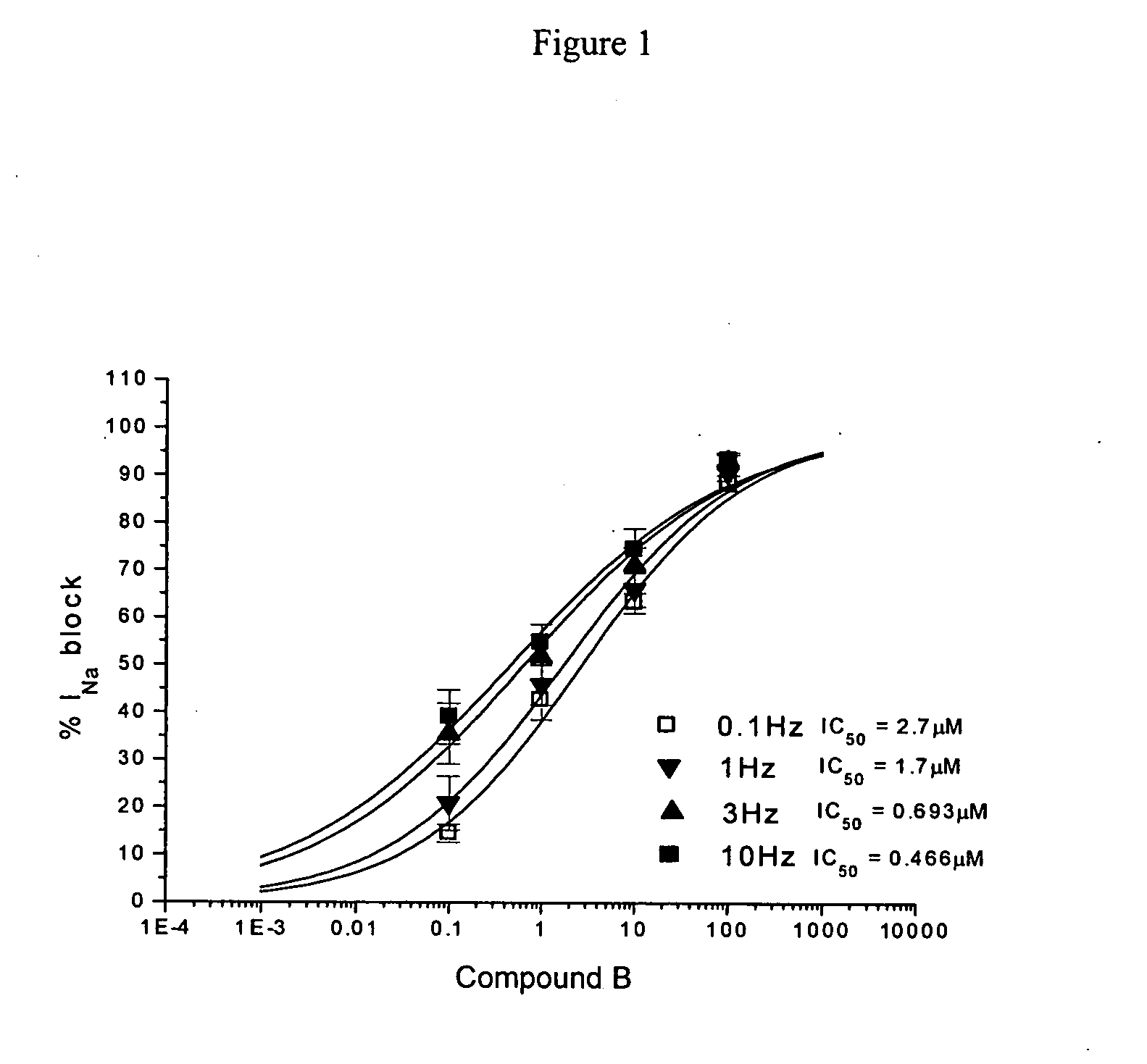

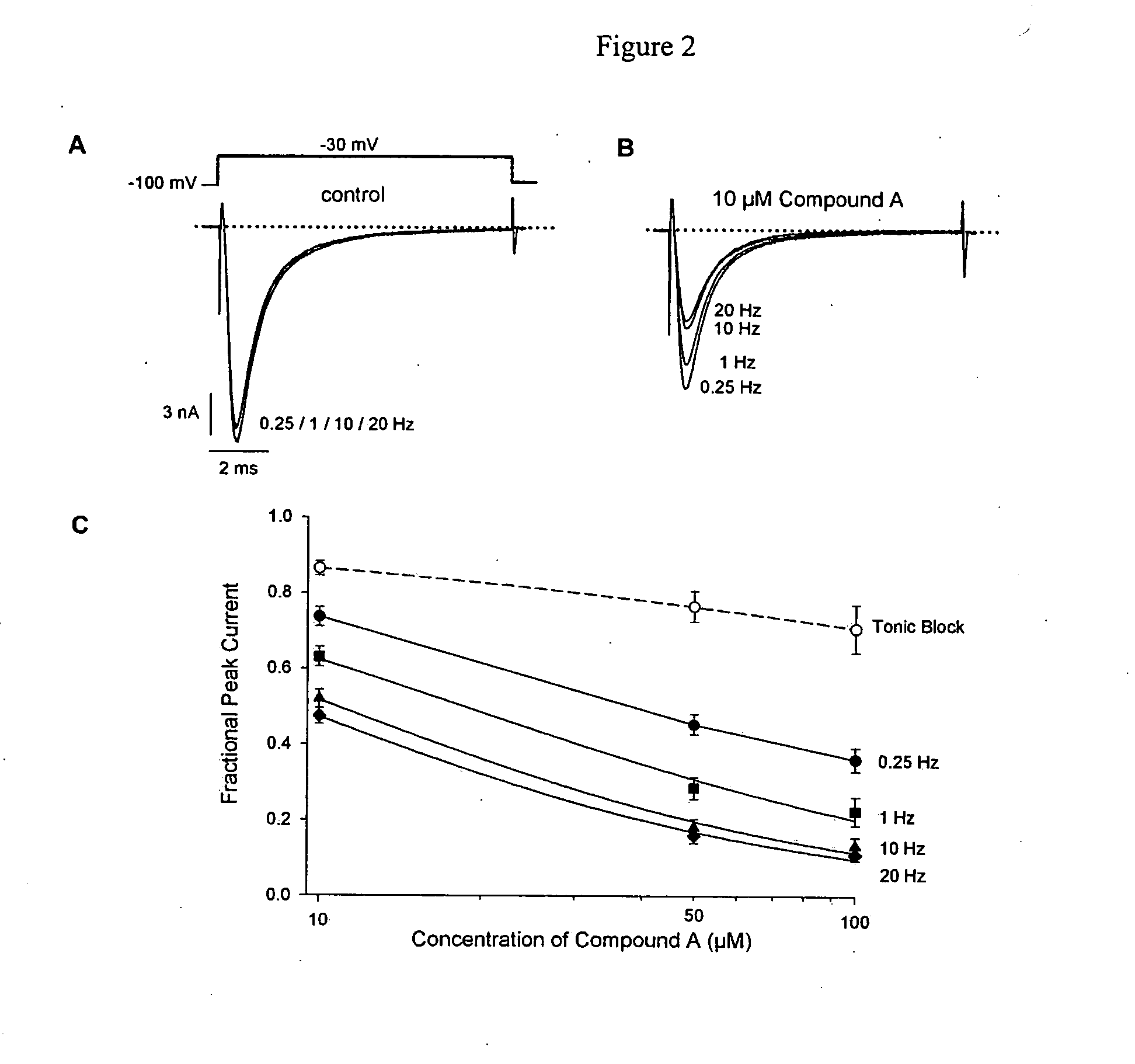

Ion channel modulating activity II

Methods, compositions, dosing regimes, and routes of administration for the treatment or prevention of arrhythmias. In these methods, arrythmias (e.g. atrial fibrillation, atrial flutter, early afterdepolarizations and prolongation of QT interval) may be reduced or eliminated by administering ion channel modulating compounds to a subject in need thereof. The ion channel modulating compounds may be cycloalkylamine ether compounds, particularly cyclohexylamine ether compounds. Also described are compositions of ion channel modulating compounds and drugs which induce early afterdepolarizations, prolongation of QT interval and / or Torsades de Pointes.

Owner:CORREVIO INT SARL

Method for preparing 3-aminomethyl-3,5,5-trimethyl cyclohexylamine

ActiveCN101417952AReduce usageOrganic compound preparationPreparation by N-O/N-N bondsMethyl groupPhotochemistry

The invention discloses a method for preparing 3-aminomethyl-3, 5, 5-trimethyl cyclohexylamine (isophorone diamine, IPDA) by 3-cyano-3, 5, 5-trimethyl cyclohexanone (IPN, isophorone nitrile), which comprises the following steps: a) 3-cyano-3, 5, 5-trimethyl cyclohexanone and oxyammonia are arranged in an organic solvent for reaction under a temperature ranging from 40 DEG C to 80 DEG C, and 3-cyano-3, 5, 5-trimethyl cyclohexanone oxime is generated; b) 3-cyano-3, 5, 5-trimethyl cyclohexanone oxime, hydrogen and liquid ammonia are arranged in an organic solvent for reaction under a temperature ranging from 50 DEG C to 120 DEG C, a total pressure ranging from 5 MPa to 15 MPa and the effect of a hydrogenation catalyst, and 3-aminomethyl-3, 5, 5-trimethyl cyclohexylamine is obtained. The method has the advantages that, the production of a by-product 3-aminomethyl-3, 5, 5-trimethyl cyclohexanol (IPAA) which is hard to be separated from IPDA is avoided; simultaneously, the amount of liquid ammonia is largely decreased.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

Method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine

InactiveCN102531918BSimple and fast operationMild reaction conditionsOrganic compound preparationAmino compound preparationDiisopropyl azodicarboxylateHexamethylenediamine

The invention discloses a method for synthesizing enantiomorphous pure symmetric trans-dialkyl cyclohexylamine, belonging to the field of chemistry. The method comprises the following steps of: carrying out an airtight or reflux reaction on cyclohexene oxide and an aqueous solution of alkylamine for reacting at 80-120 DEG C for 1.5-5h to obtain 2-alkyl-amino cyclohexanol, dropwise adding DEAD (Diethyl Azodicarboxylate) or DIAD (Diisopropyl Azodicarboxylate) to triphenylphosphine, 2-alkyl-amino cyclohexanol and a solvent under an ice bath for reacting for 5-20h at room temperature to obtain N-alkyl-7-azabicyclo[4, 1, 0]heptane, adding a catalyst to the N-alkyl-7-azabicyclo[4, 1, 0]heptane and the aqueous solution of alkylamine at 100-120 DEG C to carry out the airtight or reflux reaction to obtain trans-N,N'-dialkyl-1,2 cyclohexanamine, dissolving the trans-N,N'-dialkyl-1,2 cyclohexanamine in an alcoholic solvent, and adding a tartaric acid type resolving agent with the equivalent weight of 0.5 to the alcoholic solvent to resolve so as to obtain the enantiomorphous pure symmetric trans-dialkyl cyclohexylamine.

Owner:ANYANG INST OF TECH

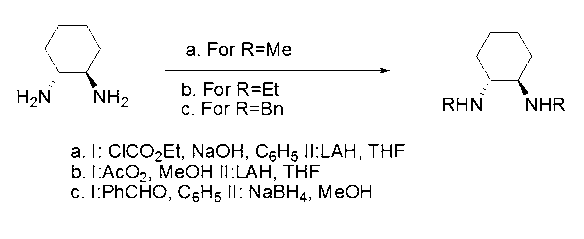

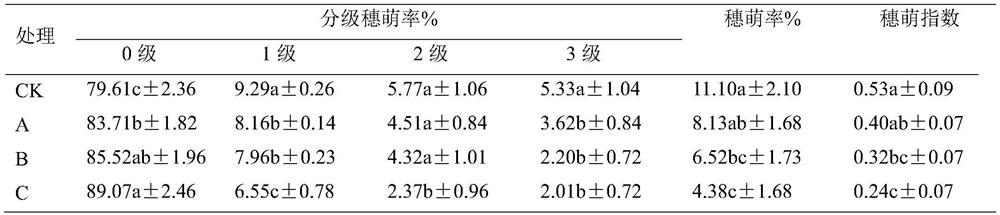

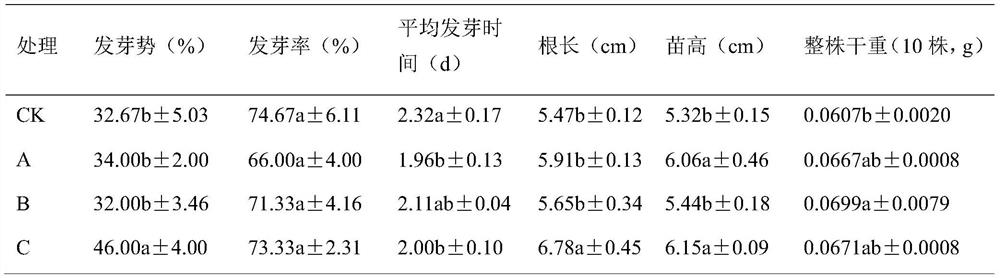

Hybrid rice pre-harvest sprouting inhibitor, preparation method thereof and method for inhibiting hybrid rice pre-harvest sprouting

ActiveCN111955459ALow toxicityEasy to degradeBiocidePlant growth regulatorsRoot growthCyclohexylamines

The invention discloses a hybrid rice pre-harvest sprouting inhibitor, a preparation method thereof and a method for inhibiting hybrid rice pre-harvest sprouting, and the hybrid rice pre-harvest sprouting inhibitor takes water as a solvent and contains abscisic acid with the concentration of 20-60mg / kg, cyclohexylamine with the concentration of 40-160mM and eugenol with the concentration of 10-60mg / kg. The abscisic acid, the cyclohexylamine and the eugenol are combined, so that the sprouting rate of the hybrid rice is effectively reduced, the growth of harvested rice seed buds and roots and the dry weight are remarkably promoted, and the comprehensive quality is improved.

Owner:ZHEJIANG UNIV

Low corresion fire retardant polyurethane composition material and its manufacturing method

The low corrosion fire retardant heat insulating polyurethane composition material includes two components, component A and component B. The component A consists of polyether polyol, cyclohexane, silicone oil, potassium acetate, dimethylethanolamine, 2, 4, 6-tri(dimethylaminomethyl) phenol, water, monofluoro trichloroethanone, trichloroethyl phosphate and silicate hydrate; and the component B is isocyanate. When the composition material is used, the component A and the component B are mixed to form the foamed heat insulating polyurethane material with low corrosion, high fire retarding performance and simple production process. The foamed heat insulating polyurethane material is used for oil and gas pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-flame retardation polyurethane composite heat insulation plate

InactiveCN105924943AImprove wear resistanceGood oil resistanceSynthetic resin layered productsMetal layered productsInsulation layerMelamine phosphate

The invention discloses a high-flame retardation polyurethane composite heat insulation plate. The high-flame retardation polyurethane composite heat insulation plate comprises two backing layers and a polyurethane heat insulation layer positioned between the two backing layers, the polyurethane heat insulation layer is made of a high-performance polyurethane foam material, and raw materials of the high-performance polyurethane foam material comprise polyether polyol, polyphenylpolymethylene polyisocyanate, hexamethylene diisocyanate, polyacrylate, liquid styrene butadiene rubber, cyclohexylamine, N,N-dimethylcyclohexylamine, dibutyltin dilaurate, methyl formate, water, hydroxy silicone oil, a fire retardant, expanded perlite, hollow glass micro-beads, pentaerythritol and sorbitol; and raw materials of the fire retardant comprise nanometer aluminum hydroxide, nanometer magnesium hydroxide, melamine phosphate, expandable graphite, hydroxy silicone oil, and a phosphamide fire retardant. The high-flame retardation polyurethane composite heat insulation plate has the advantages of high strength, excellent heat and flame retardation, and long service life.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

Environmental-friendly clean diesel oil and preparing method thereof

InactiveCN104789280AComply with the basic requirements of dispatchSimple production processLiquid carbonaceous fuelsFuel additivesSocial benefitsCyclohexylamines

The invention provides environmental-friendly clean diesel oil and a preparing method thereof, and belongs to the technical field of the energy industry. An emulsifying agent in the clean diesel oil comprises following raw materials: 15-75 parts of oleic acid, 10-45 parts of methanol, 5-52 parts of cyclohexylamine, 5-45 parts of monoethanolamine, 3-35 parts of octanol, 0.1-5 parts of a lubricant, 0.1-5 parts of ferrocene and 0.1-6 parts of an antioxidant 264. The ratio of the emulsifying agent to water in the diesel oil is 0.5-1.2:1. The diesel oil meets practical application requirements of various vehicles and engineering machines, overcomes defects of other technical schemes at present, and meets basic requirements on vehicle exhaust discharge in China. The diesel oil is simple in production process, low in investment and good in economic benefit and social benefit.

Owner:ZIBO KUNYUAN ENERGY TECH CO LTD

Concrete pumping agent with stable performances

A concrete pumping agent with stable performances is prepared from the following raw materials, by weight, 6-9 parts of triethanolamine, 5-7 parts of urea, 4-9 parts of bentonite, 1-4 parts of ultrafine fly ash, 6-9 parts of polyacrylamide, 4-9 parts of an acrylic copolymer, 5-10 parts of hydroxypropyl methylcellulose, 3-8 parts of re-dispersible latex powder, 5-7 parts of chrome oxide, 6-11 parts of phenyl salicylate, 4-10 parts of polyoxyethylene alcohol ether, 2-6 parts of sodium methyl silicate, 1-5 parts of triterpenoid saponin, 2-5 parts of monoethanolamine, 2-8 parts of sodium lauryl sulfate, 6-10 parts of p-hydroxy N-methylcyclohexylamine and 1-5 parts of a polycarboxylate water reducer. The concrete pumping agent with stable performances has the advantages of stable chemical properties, very good safety, low temperature resistance, strong applicability to cement, and wide range.

Owner:QINGDAO LAOXIANG TEA PROD

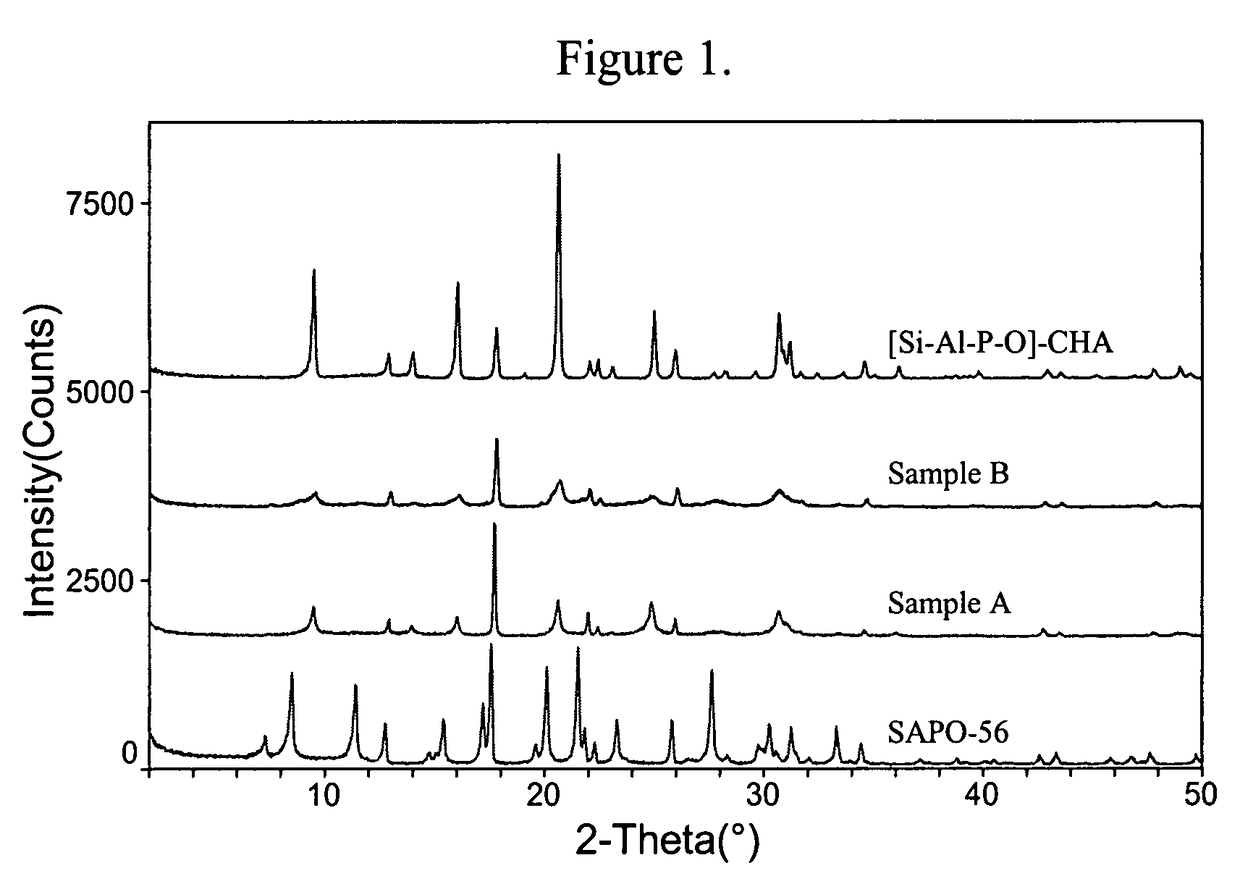

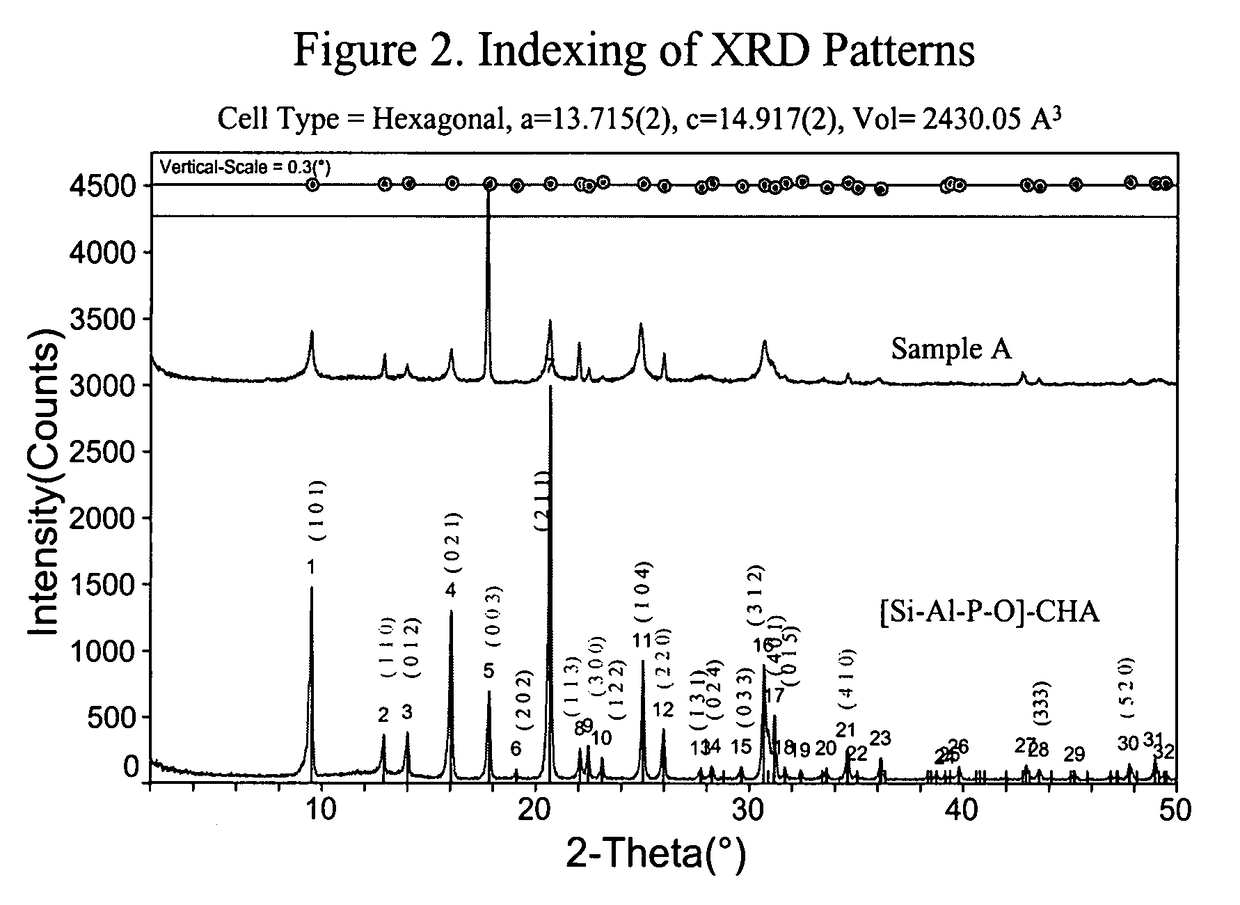

Intergrown molecular sieve, its synthesis and its use in the conversion of oxygenates to olefins

A molecular sieve comprises at least one intergrown phase of an AFX framework-type molecular sieve and a CHA framework-type molecular sieve and is conveniently synthesized using a combination of N,N,N′N′-tetramethylhexane-1,6-diamine and N,N-dimethylcyclohexylamine as organic directing agents.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com