Co-crystallization molecular screen and preparation method and application thereof

A technology of co-crystallized molecular sieves and molecular sieves, which is applied in the fields of molecular sieves and base exchange compounds, chemical instruments and methods, and inorganic chemistry. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the synthesis of pure MCM-22 molecular sieve

[0029] The ZSM-35 / MCM-22 co-crystal molecular sieve provided by the present invention is prepared by using silica sol as a silicon source and hexamethylene ethylene and cyclohexylamine as templates.

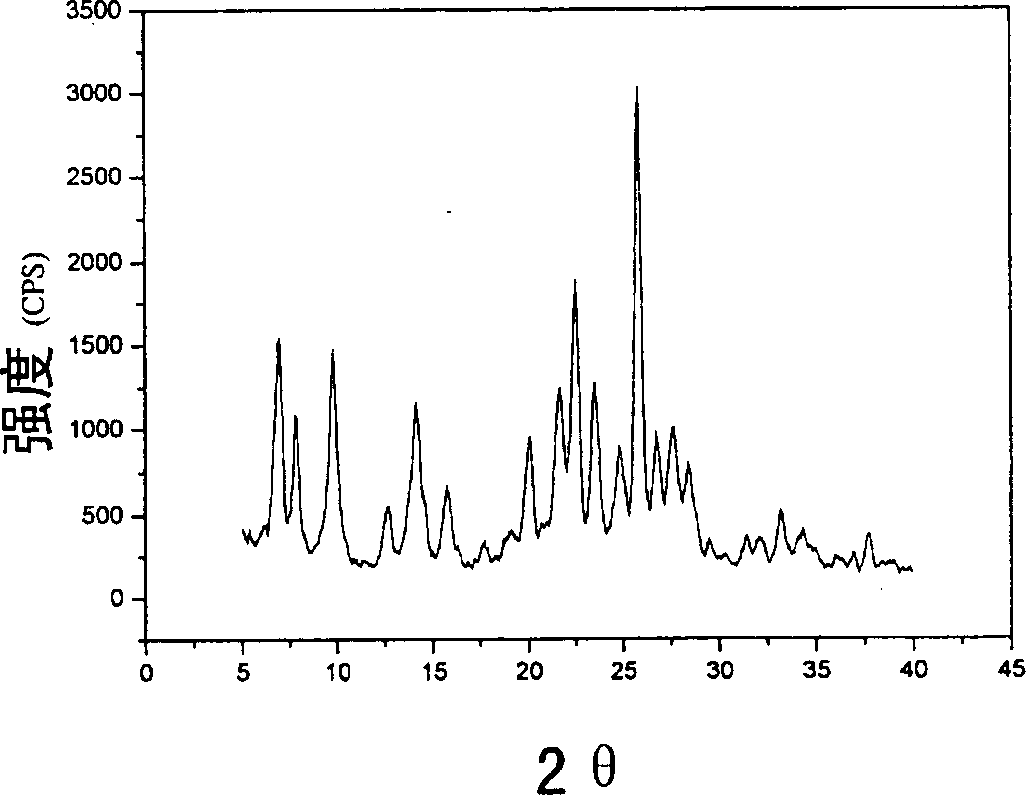

[0030] Weigh 20.3g silica sol (containing SiO 2 is 26.6wt.%) and 55.6 grams of deionized H 2 O, then weigh 2.40mL NaOH solution (0.10g / mL), weigh 0.71g NaAlO 2 (Al 2 o 3 43%, Na 2 (051.5%), after all adding in the reactor mixing, finally add 3.2 grams of mixed template agent R, wherein HMI / CHA (weight)=4:1. The final raw material ratio (molar ratio) is SiO 2 / Al 2 o 3 =30,H 2 O / SiO 2 =45, R / SiO 2 =0.35,Na 2 O / SiO2 = 0.11. The remaining steps are the same as in Comparative Example 1. The resulting product is MCM-22, and the XRD spectrum is shown in figure 2 , its crystallinity is slightly better than Comparative Example 1.

Embodiment 2

[0031] Embodiment 2: Synthesis of ZSM-35 / MCM-22 co-crystal molecular sieve

[0032] The ZSM-35 / MCM-22 co-crystal molecular sieve provided by the present invention is prepared by using silica sol as a silicon source and hexamethylene ethylene and cyclohexylamine as templates.

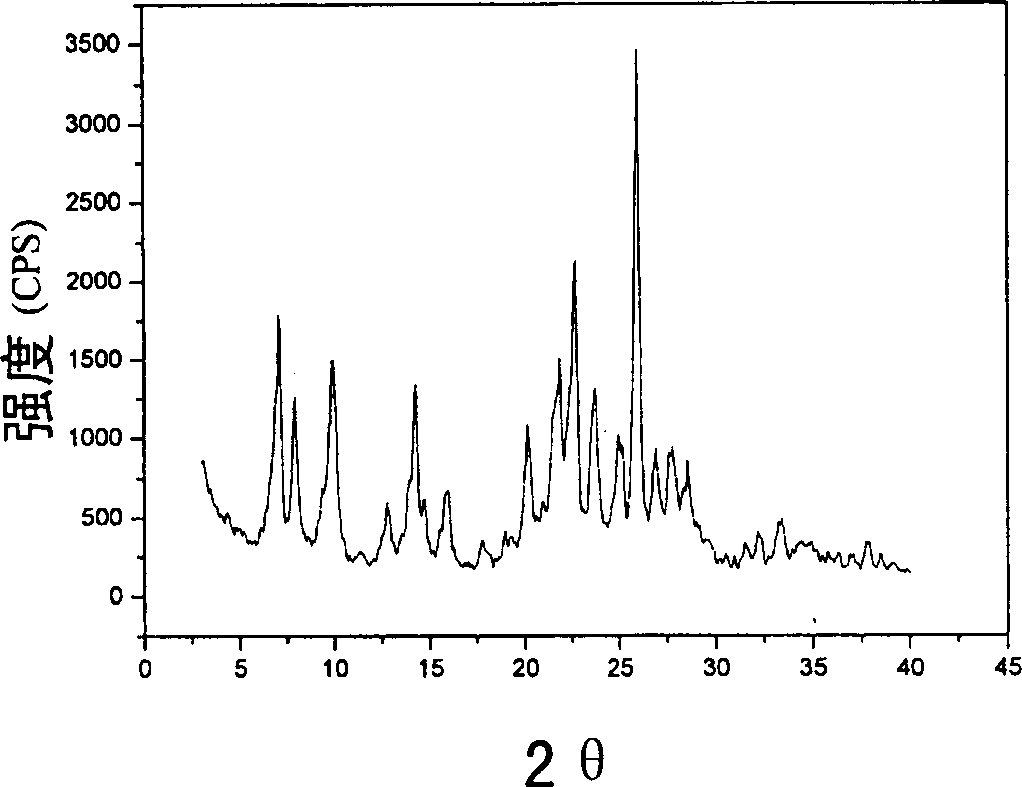

[0033] Weigh 20.3g silica sol (containing SiO 2 is 26.6wt.%) and 54.4 grams of deionized H 2 O, then weigh 3.58mL NaOH solution (0.10g / mL), weigh 0.53g NaAlO 2 (Al 2 o 3 43%, Na 2 (051.5%), after all adding in the reaction kettle and mixing, finally add 3.2 grams of mixed template agent R, wherein HMI / CHA (weight)=3:1. Its final raw material ratio (molar ratio) is SiO 2 / Al 2 o 3 =40,H 2 O / SiO 2 =45, R / SiO 2 =0.35,Na 2 O / SiO 2 = 0.11. The remaining steps are the same as in Comparative Example 1. The obtained product is ZSM-35 / MCM-22 co-crystal molecular sieve. The XRD spectrum of the molecular sieve after calcination is shown in image 3 , wherein the ZSM-35 molecular sieve accounts for ...

Embodiment 3

[0034] Embodiment 3: the synthesis of ZSM-35 / MCM-22 cocrystal molecular sieve

[0035] The ZSM-35 / MCM-22 co-crystal molecular sieve provided by the present invention is prepared by using silica sol as a silicon source and hexamethylene ethylene and cyclohexylamine as templates.

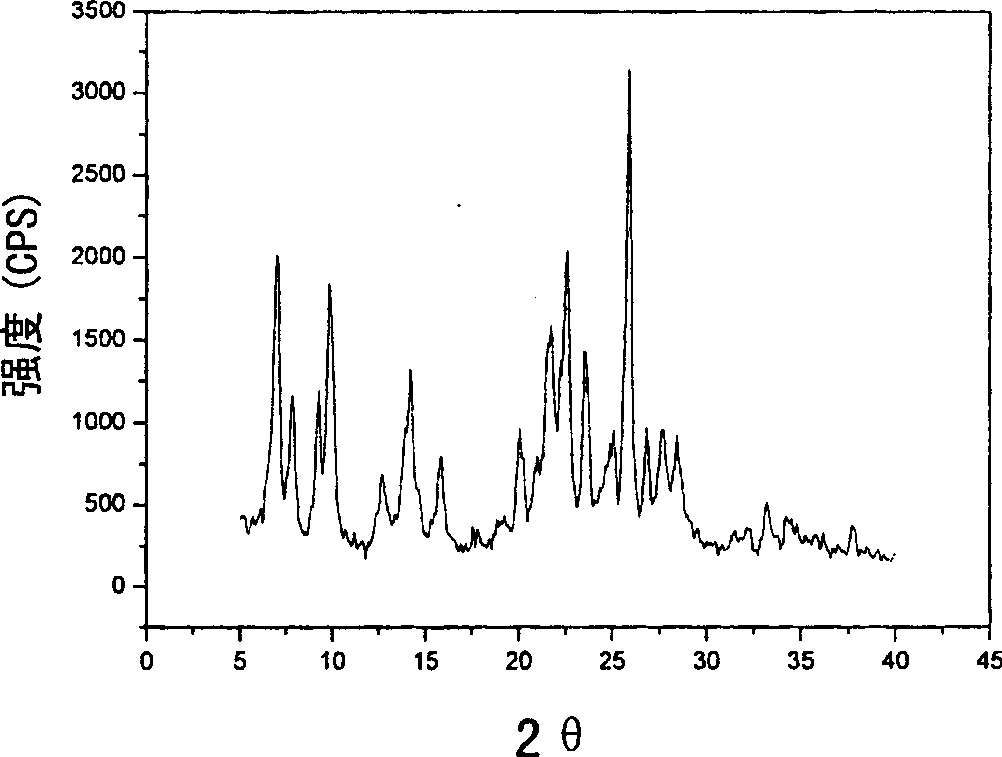

[0036] The specific steps are the same as in Example 1 except that the added template R is a mixture of 3.2 grams of hexamethylene ethylene and cyclohexylamine, wherein HMI / CHA (weight)=1:1. The obtained product is the original powder of ZSM-35 / MCM-22 co-crystal molecular sieve. The XRD spectrum of the molecular sieve after roasting is shown in Figure 4 , wherein the weight percentage of the crystalline phase containing the ZSM-35 structural part in the co-crystallized molecular sieve is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com