Rubber composition and tire

A kind of rubber mixture and rubber technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as hazards and respiratory system injuries, and achieve the effect of improving odor problems, improving tire odor, and reducing dust hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

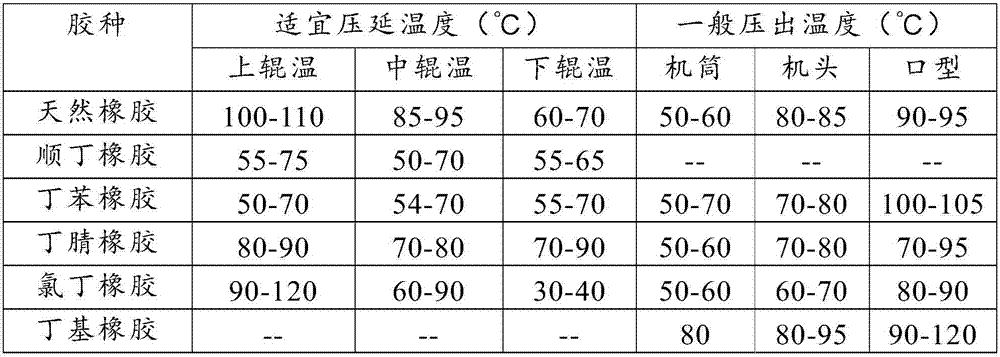

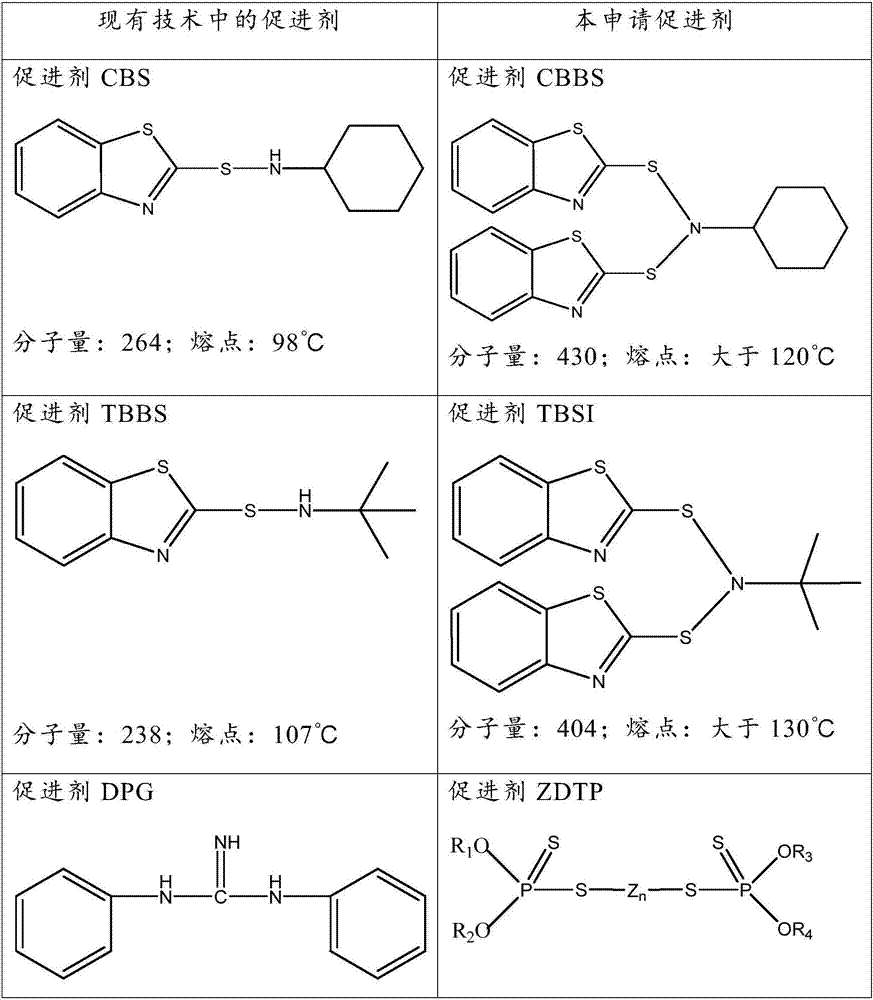

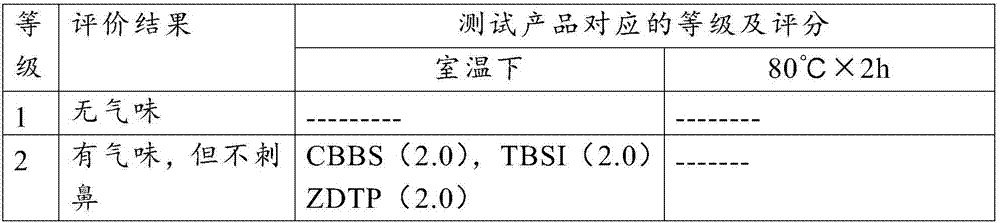

[0066] With 20phr of natural rubber, 44phr of butadiene rubber, 36phr of solution-polymerized styrene-butadiene rubber, 50phr of glass fiber, 3phr of sulfur, 1phr of ZDTP, and 1.5phr of CBBS, first remove sulfur, The components other than ZDTP and CBBS are fully mixed in a tangential mixer, and then sulfur, ZDTP and CBBS are added and mixed evenly. Heated and melted and extruded, the above mixture was further mixed uniformly, and a tire sample was formed by a conventional method in the rubber industry.

Embodiment 2

[0078] With 20phr of natural rubber, 23phr of butadiene rubber, 36phr of styrene-butadiene rubber, 21phr of ethylene propylene rubber, 30phr of glass fiber, 10phr of sulfur and 5phr of TBSI, first of all other components except sulfur and TBSI in Mix thoroughly in a tangential mixer, then add sulfur and TBSI, and mix well. Heated and melted and extruded, the above mixture was further mixed uniformly, and a tire sample was formed by a conventional method in the rubber industry.

Embodiment 3

[0086] 20phr of natural rubber, 23phr of butadiene rubber, 36phr of styrene-butadiene rubber, 21phr of ethylene-propylene rubber, 80phr of glass fiber, 10phr of sulfur, 4.5phr of TBSI and 2phr of CBBS, first remove sulfur, TBSI, and CBBS Mix the other components well in a tangential mixer, then add sulfur, TBSI and CBBS, and mix well. Heated and melted and extruded, the above mixture was further mixed uniformly, and a tire sample was formed by a conventional method in the rubber industry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com