Patents

Literature

30results about How to "Reduce emission content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

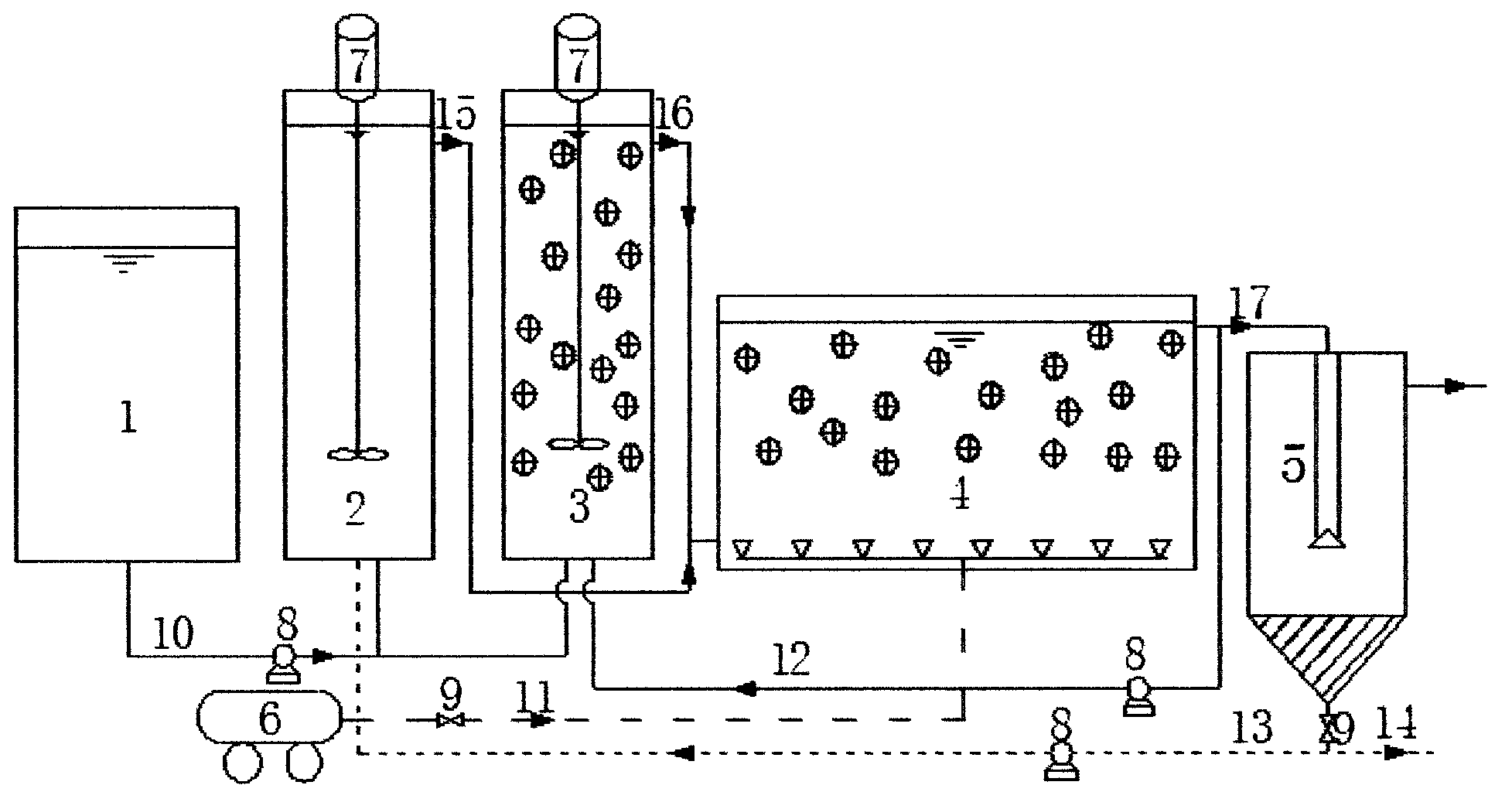

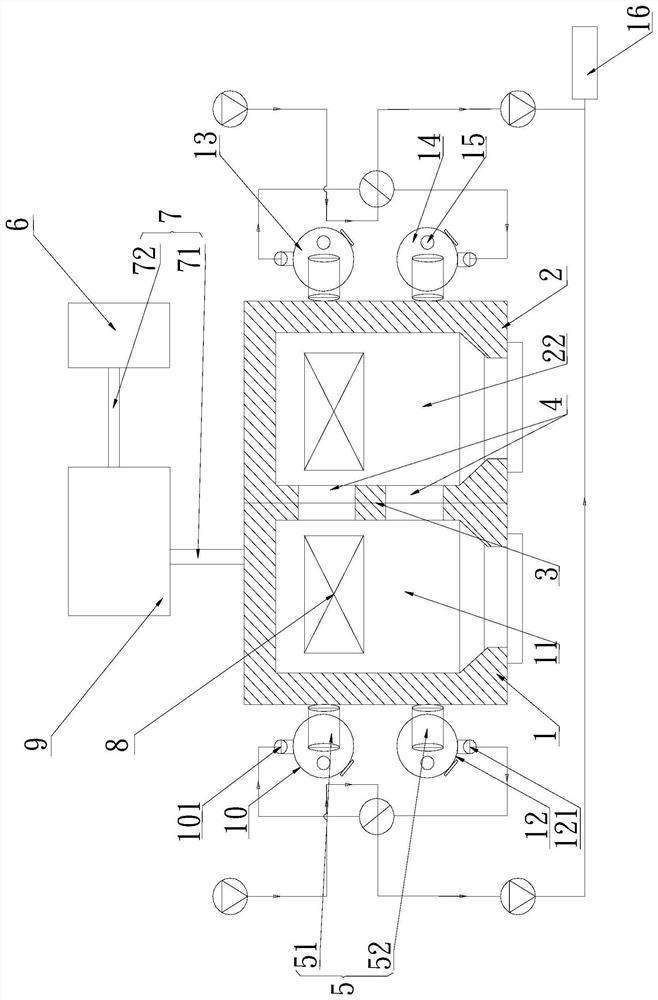

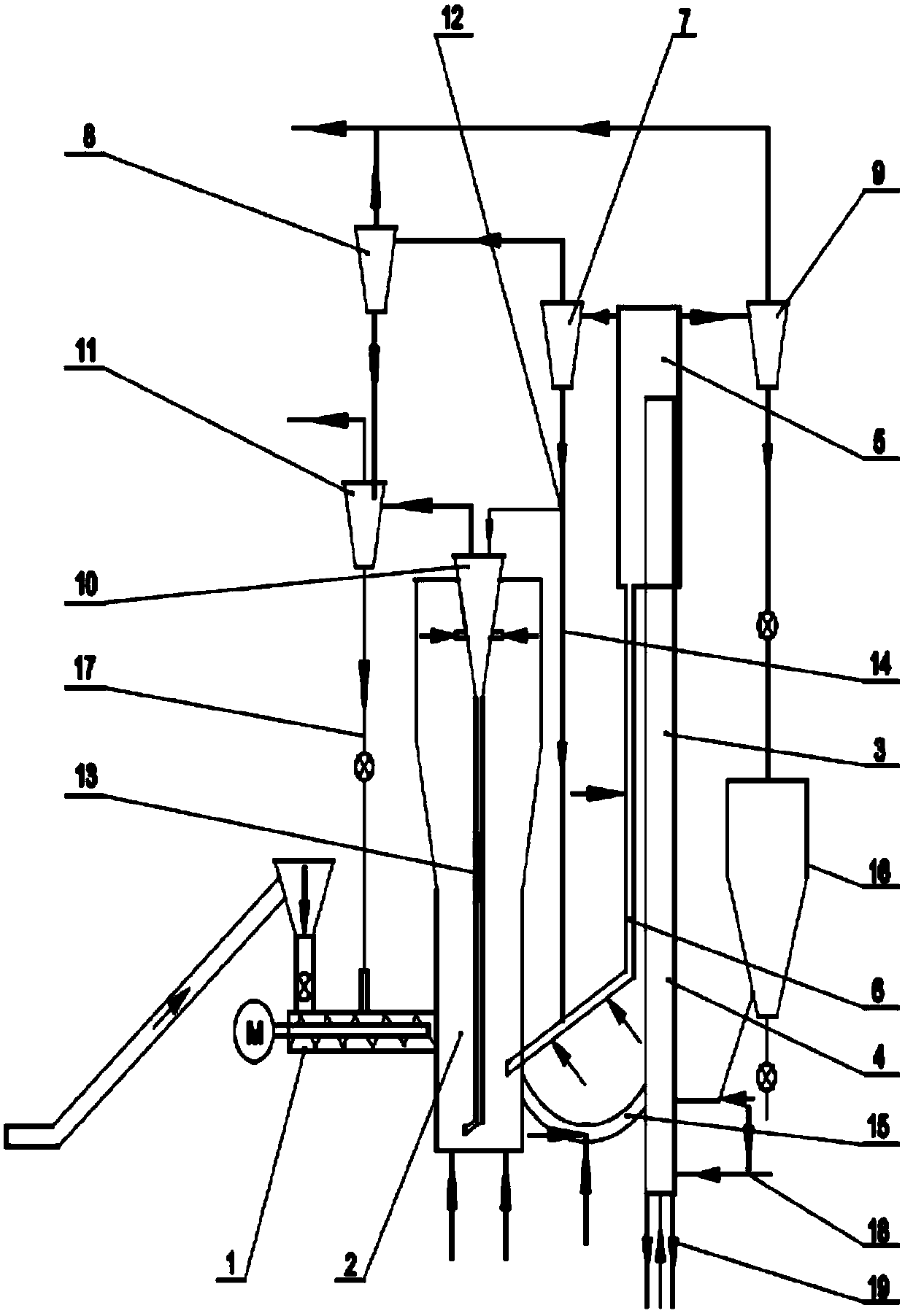

Multi-point water feeding town sewage treatment system and treatment method thereof

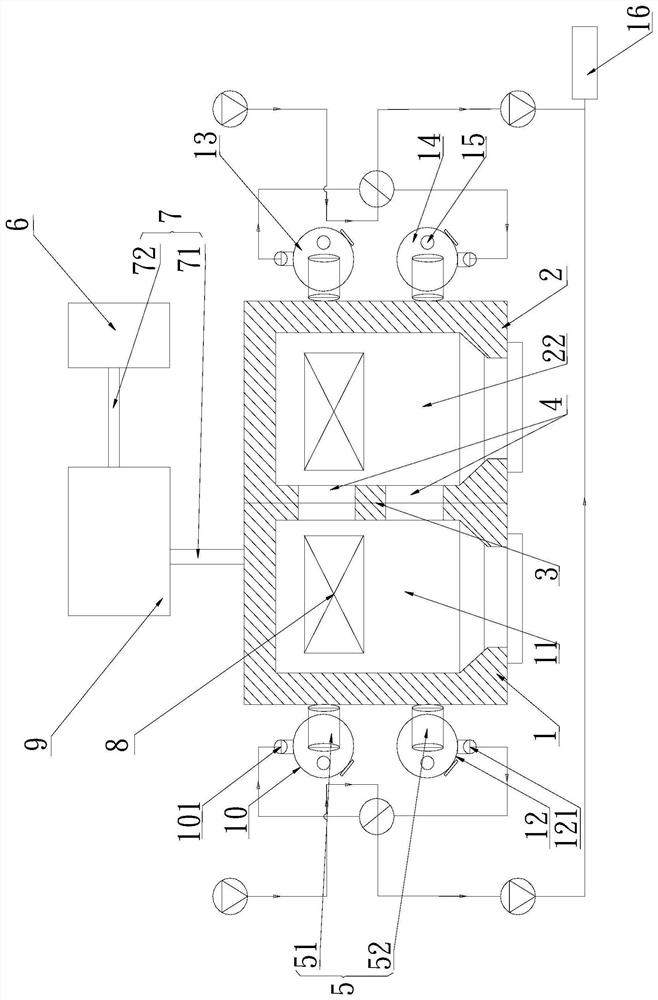

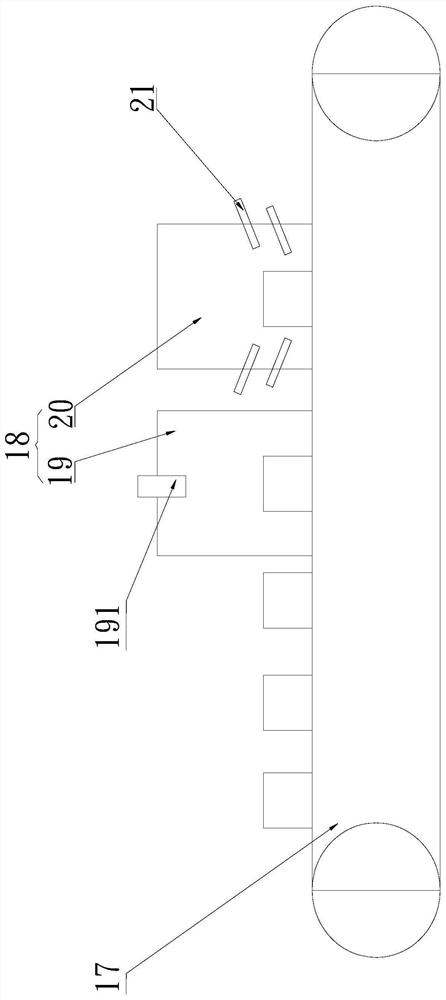

InactiveCN103253768AReduce emission contentImprove the effect of nitrogen and phosphorus removalTreatment with aerobic and anaerobic processesPeristaltic pumpSludge

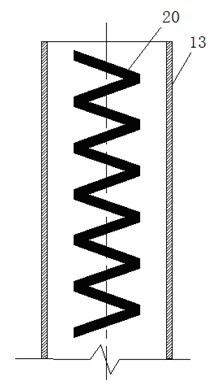

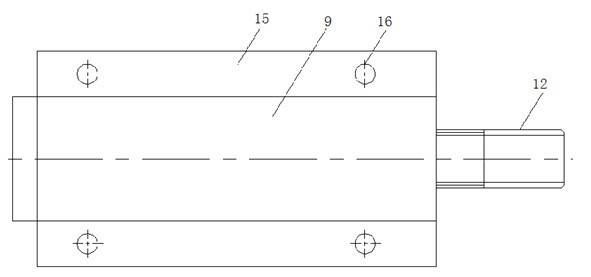

The invention provides a multi-point water feeding town sewage treatment system and a treatment method thereof so as to overcome the problems of sludge age contradiction between nitrobacteria and phosphorus-accumulating bacteria and competition for a carbon source among different populations of microbes in a traditional A2 / O process and to improve nitrogen and phosphorus removal effects of process operation. The multi-point water feeding town sewage treatment system provided by the invention comprises a raw water tank. The raw water tank is respectively connected with an anaerobic tank and an anoxic tank through peristaltic pumps; a water outlet of the anaerobic tank and a water outlet of the anoxic tank are connected with an aerobic tank, and a water outlet of the aerobic tank is connected with a sedimentation basin; a nitrification liquid outlet of the aerobic tank is connected with a nitrification liquid return pipe and the anoxic tank through peristaltic pumps; the lower part of the sedimentation basin is respectively connected with a sludge discharge pipe and a sludge return pipe through valves, and the sludge return pipe is connected with the anaerobic tank through one peristaltic pump; the lower part of the aerobic tank is connected with an air compressor through an aerator pipe; and the interiors of the anaerobic tank and the anoxic tank are respectively provided with a stirrer.

Owner:李思敏

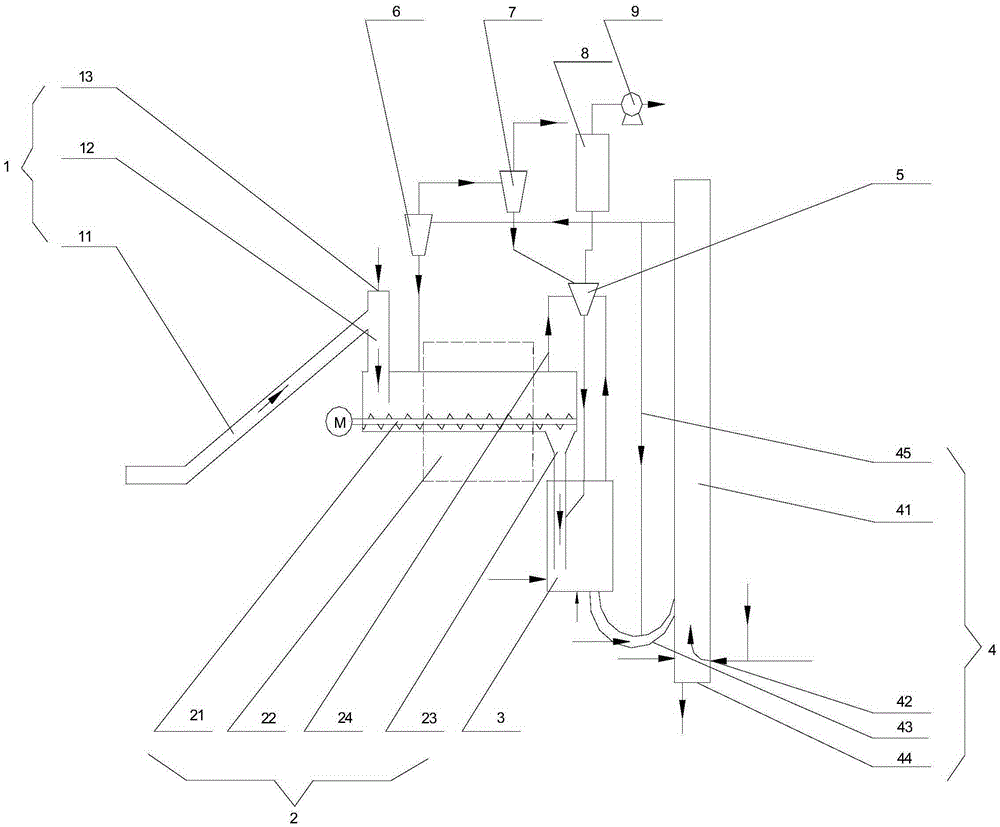

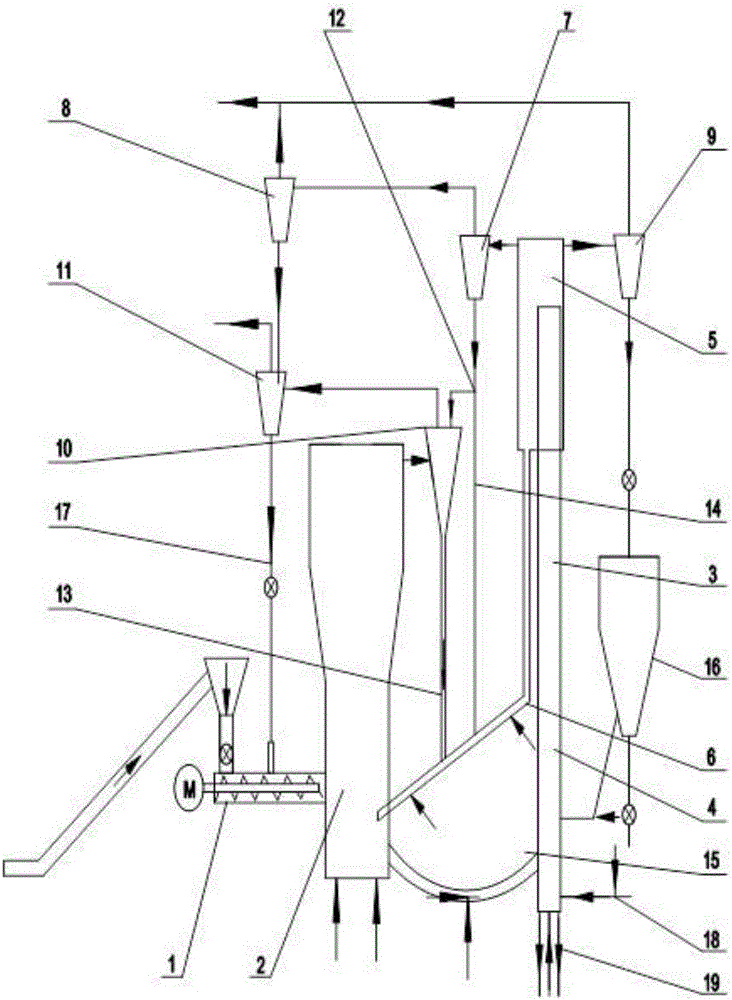

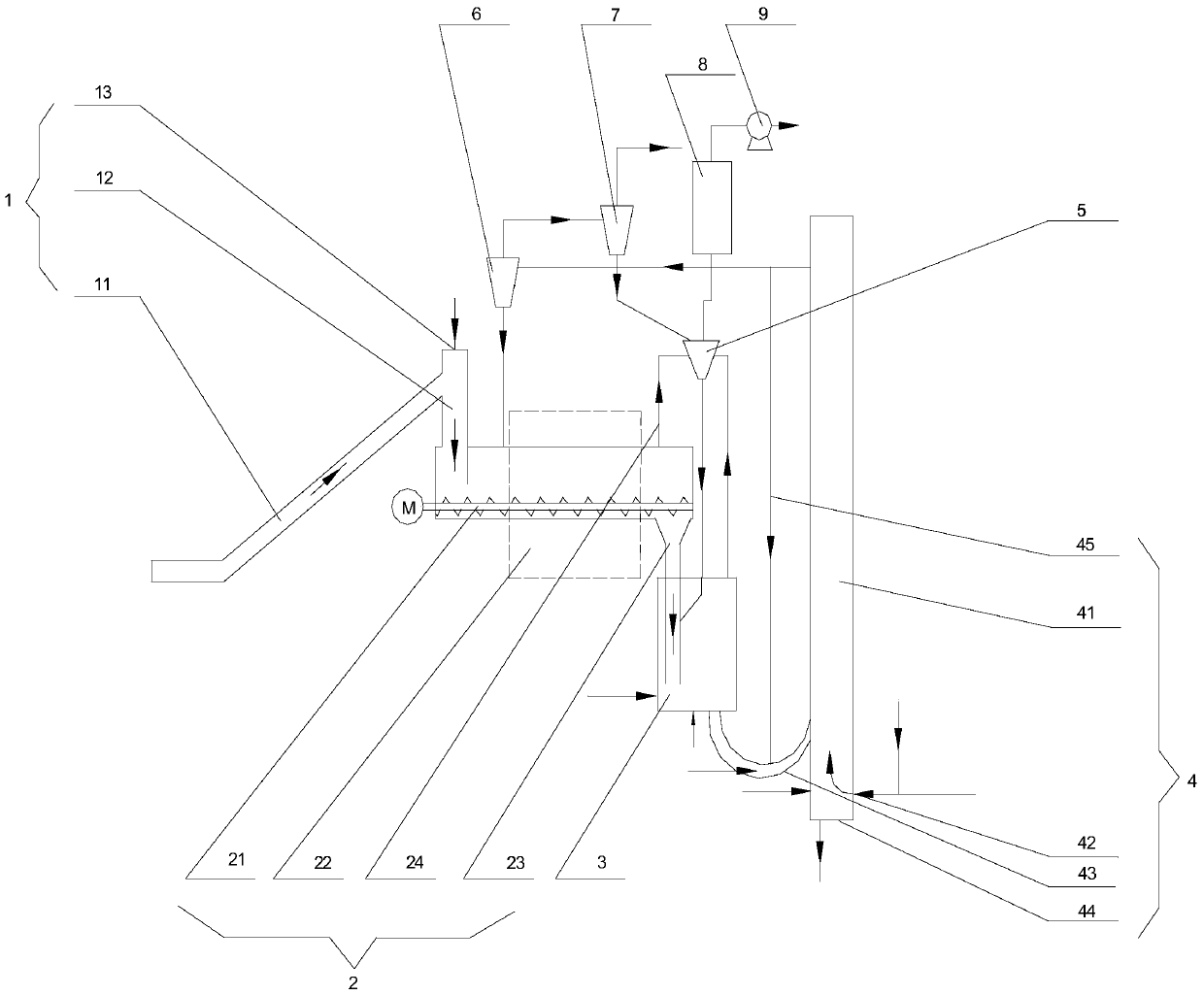

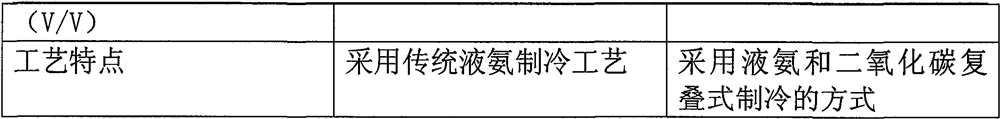

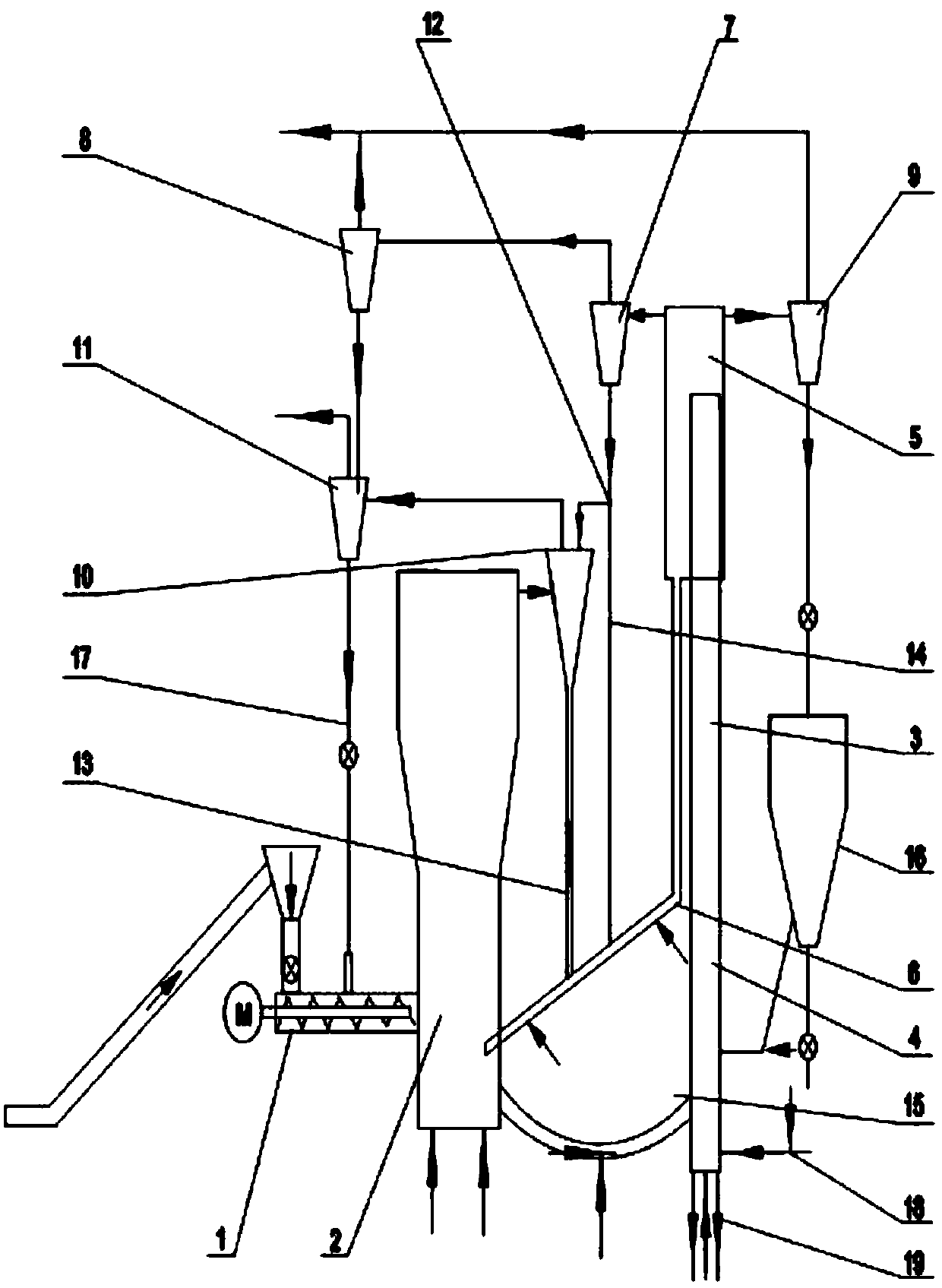

Solid waste two-stage pyrolysis gasification system based on fluidized bed and moving bed

ActiveCN105419877AImprove efficiencyReduce tar and pollutant emissionsGasification processes detailsGranular/pulverulent flues gasificationTarPollutant

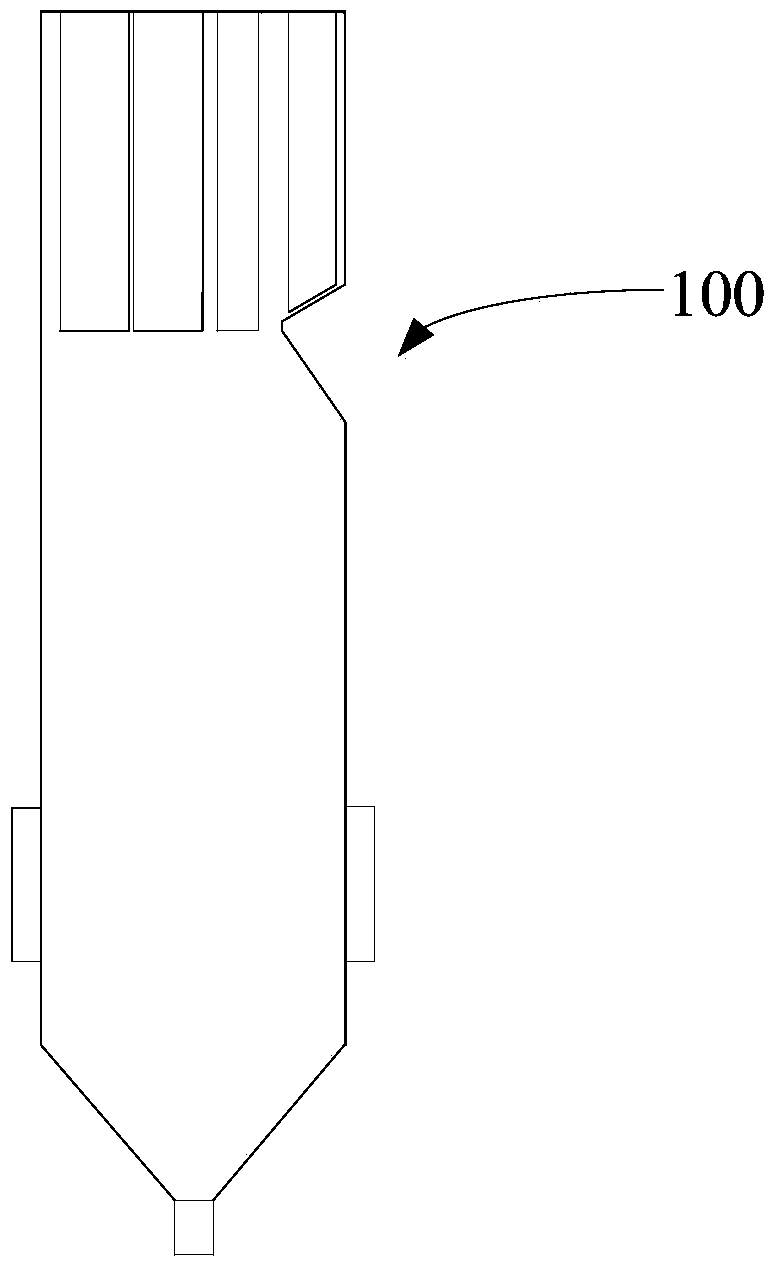

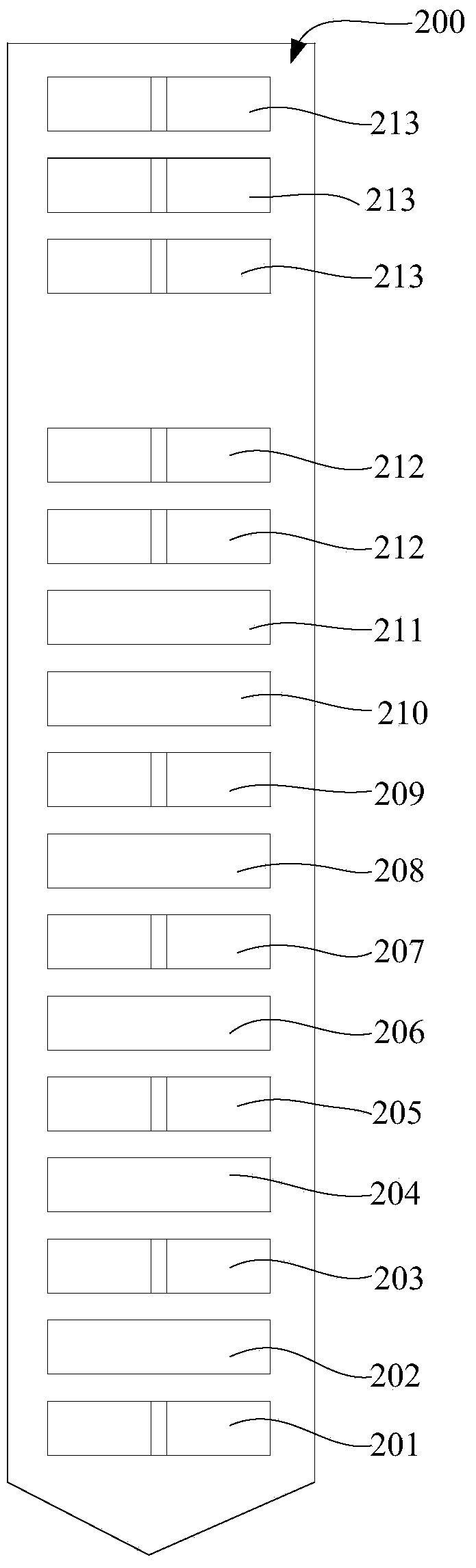

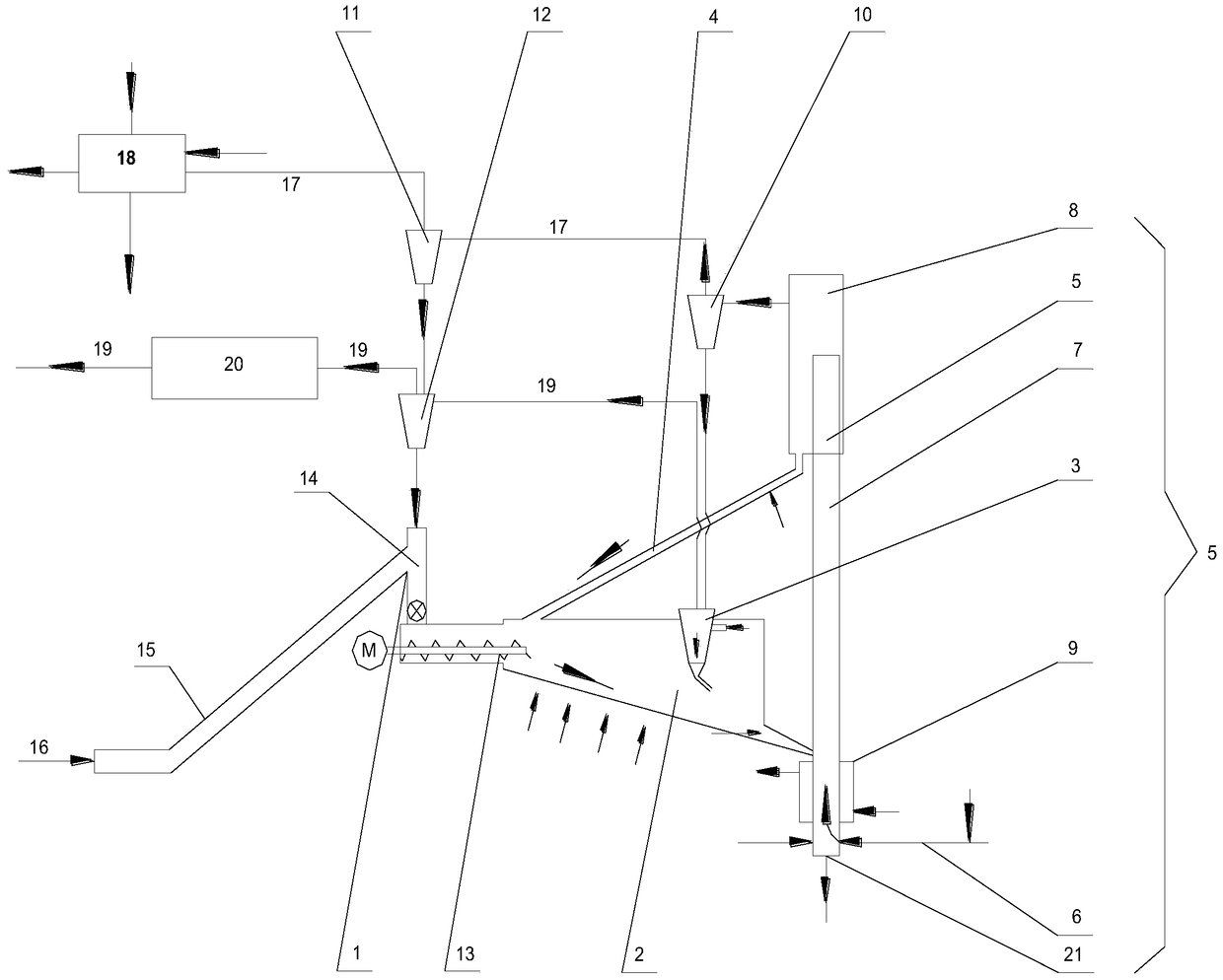

The invention relates to a solid waste two-stage pyrolysis gasification system based on a fluidized bed and a moving bed. The system comprises a circulating fluidized bed vaporizer and a secondary cyclone separator thereof, a pyrolyzer and a cyclone separation type reactor thereof, a charcoal collector, a solid waste feed system and the like. The circulating fluidized bed vaporizer and the pyrolyzer of the moving bed are used to realize two-stage pyrolysis gasification, and the cyclone separation type reactor is used to sufficiently mix hot bed materials and pyrolysis gas, thus greatly promoting tar splitting and gas purification. Through optimally designing the vaporizer and pyrolyzer structure form, mixing different bed materials for use, improving a bed material circulation flow system and gas solid mixing level, and improving the feed system, synthesis gas and the pyrolysis gas are produced simultaneously, the overall pyrolysis gasification efficiency and a pyrolysis gas heat value are greatly improved and increased, tar content in the synthesis gas and the pyrolysis gas is reduced, and the synthesis gas and the pyrolysis gas do not contain pollutants such as dioxin, thus effectively preparing the high-quality clean pyrolysis gas and synthesis gas.

Owner:代建军 +1

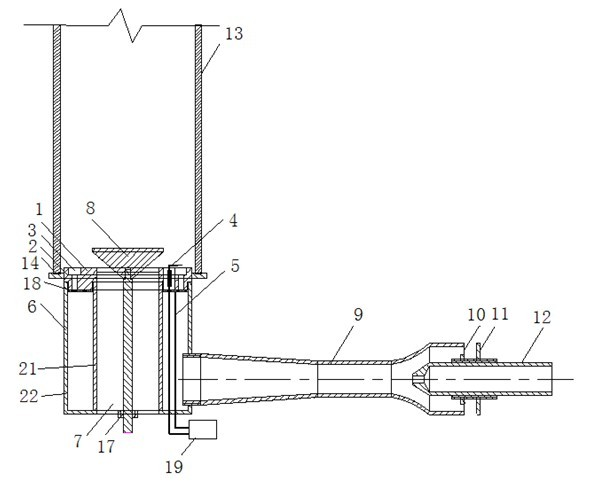

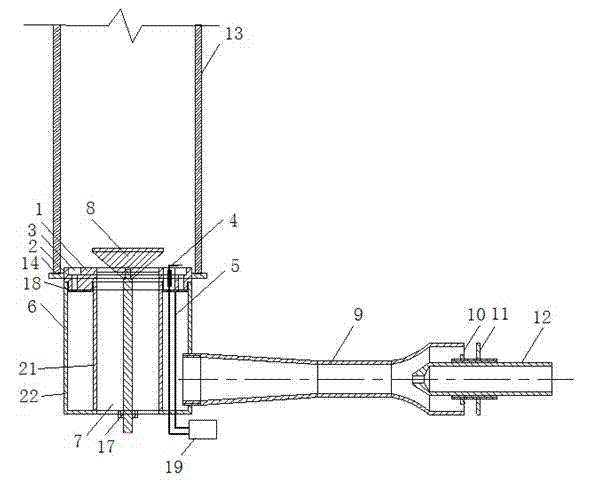

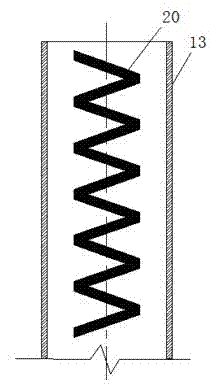

Atmospheric gas radiation heating device

ActiveCN101900324AHigh blacknessImprove Radiation AbilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEngineeringPetrochemical

The invention discloses an atmospheric gas radiation heating device which comprises a burner, a quartz glass radiant tube and an igniter, wherein the burner comprises a nozzle, an injection tube and a burner head part; the burner head part consists of an inner tube and an outer tube which are concentric, and one end of an annular belt between the inner tube and the outer tube is sealed; the injection tube is communicated with the annular belt; the end of the sealed annular belt of the inner tube is a secondary air inlet, while the other end of the inner tube is provided with an inner flame cover; a corresponding end of the outer tube is provided with an outer flame cover, and a flame hole is formed between the inner flame cover and the outer flame cover; and the inner tube is internally provided with a secondary air conditioning device. The invention has simple structure, convenient mounting, low manufacture and maintenance cost, high burning strength, long service life and large burner load regulation ratio, can meet the requirement of different heating powers to a larger extent and can be widely applied to industrial kilns of the industries of steel, petrochemical industry, machinery, building materials, boilers, waste incineration, and the like.

Owner:ENN CHINA GAS ENVESTMENT

Four-corner tangential boiler and hearth thereof

InactiveCN104033888AReduce emission contentPrevent overheatingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorPulp and paper industry

The invention relates to a hearth of a four-corner tangential boiler. Four groups of combustors are arranged in the hearth and are respectively arranged at four corners of the hearth; each group of the combustor comprises four groups of primary air nozzles, five groups of secondary air nozzles, a compact overfire air nozzle and a separation overfire nozzle along the height direction of the hearth; the four groups of primary air nozzles and the five groups of secondary air nozzles are arranged at intervals. The uppermost layer of the hearth of the four-corner tangential boiler adopts separation overfire air, and a deflection secondary air technology is adopted for part of the secondary air nozzles, so that the NOx emission content can be reduced, and the combustion efficiency can be improved; a main combustion region on the lower part can enable deflection secondary air to form a layer of air film near a water-cooling wall surface under an oxygen deficient condition, so that the phenomena of slagging and high-temperature corrosion of a water-cooling wall can be prevented; meanwhile, overtemperature pipe explosion of a water-cooling wall pipe is prevented favorably. Furthermore, the invention also relates to the four-corner tangential boiler with the hearth.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

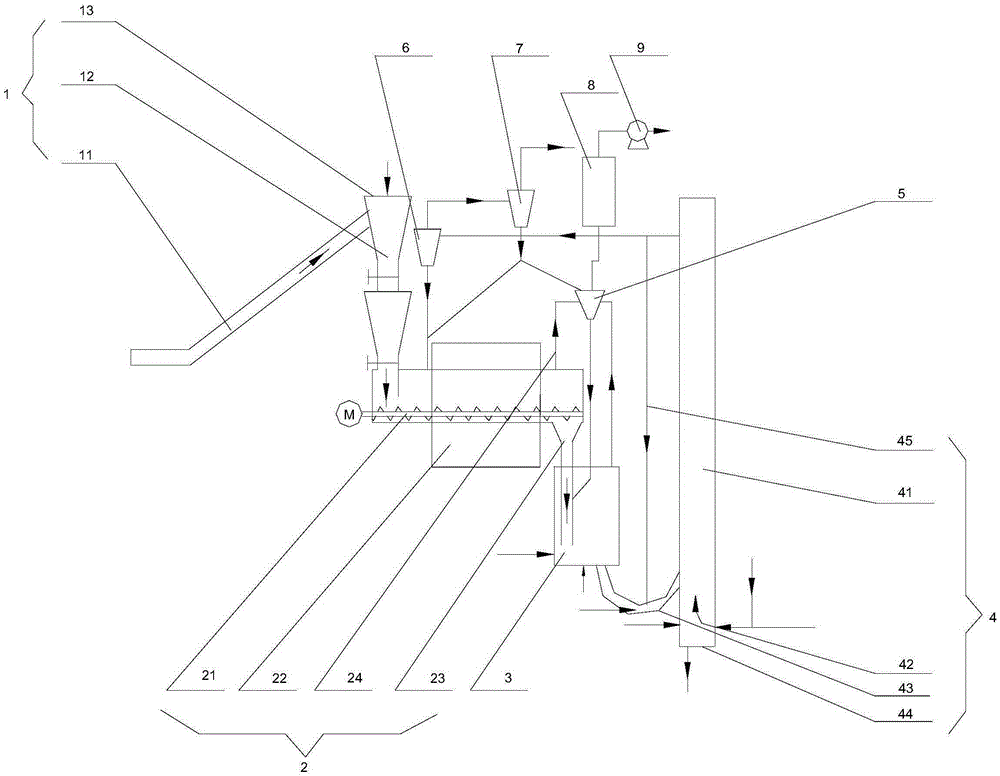

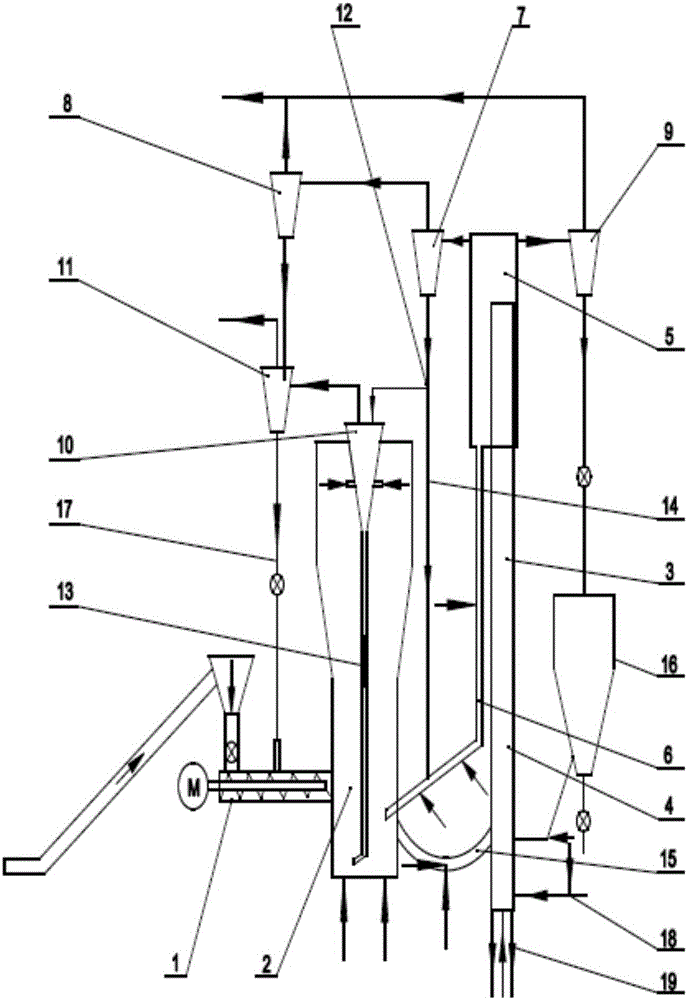

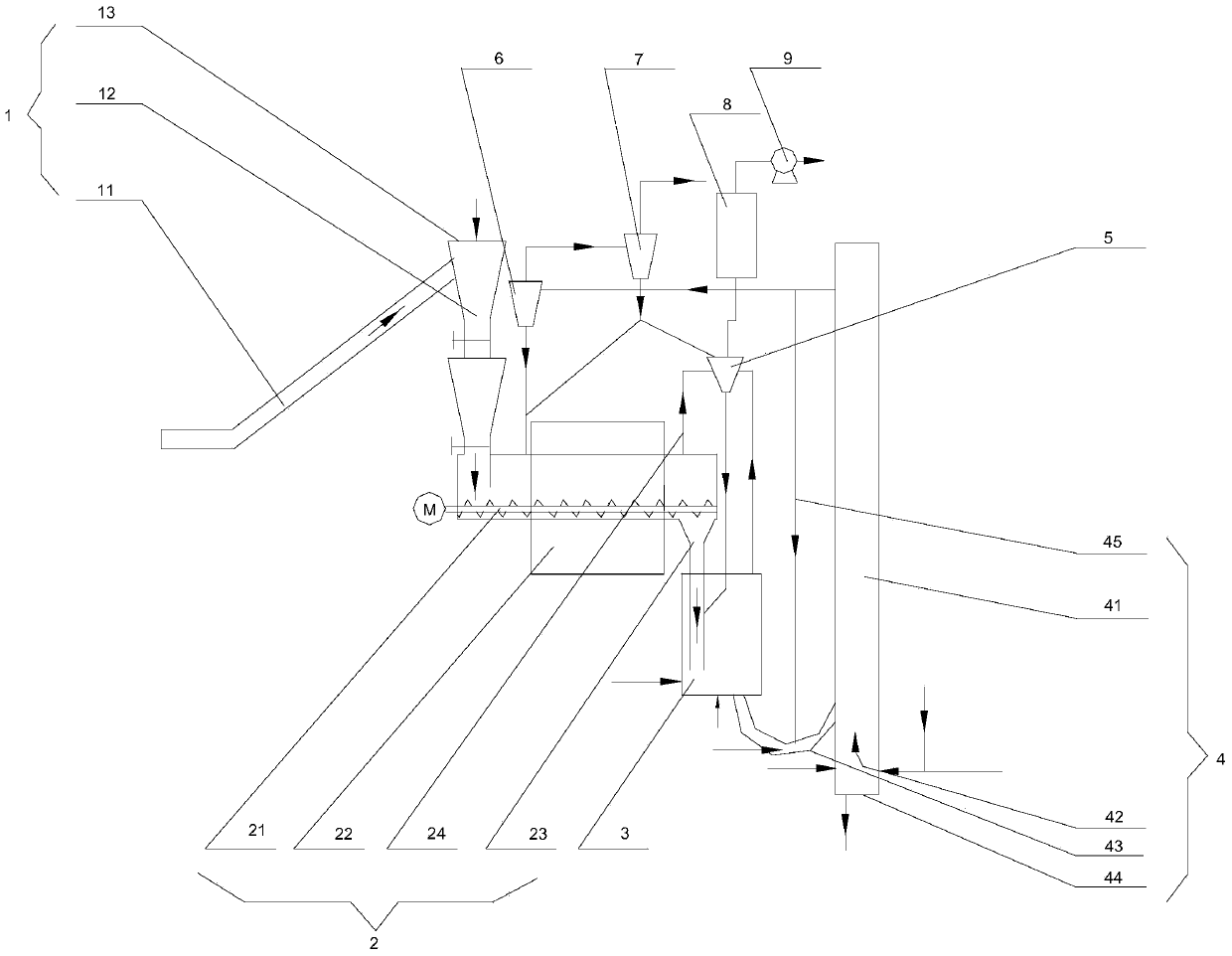

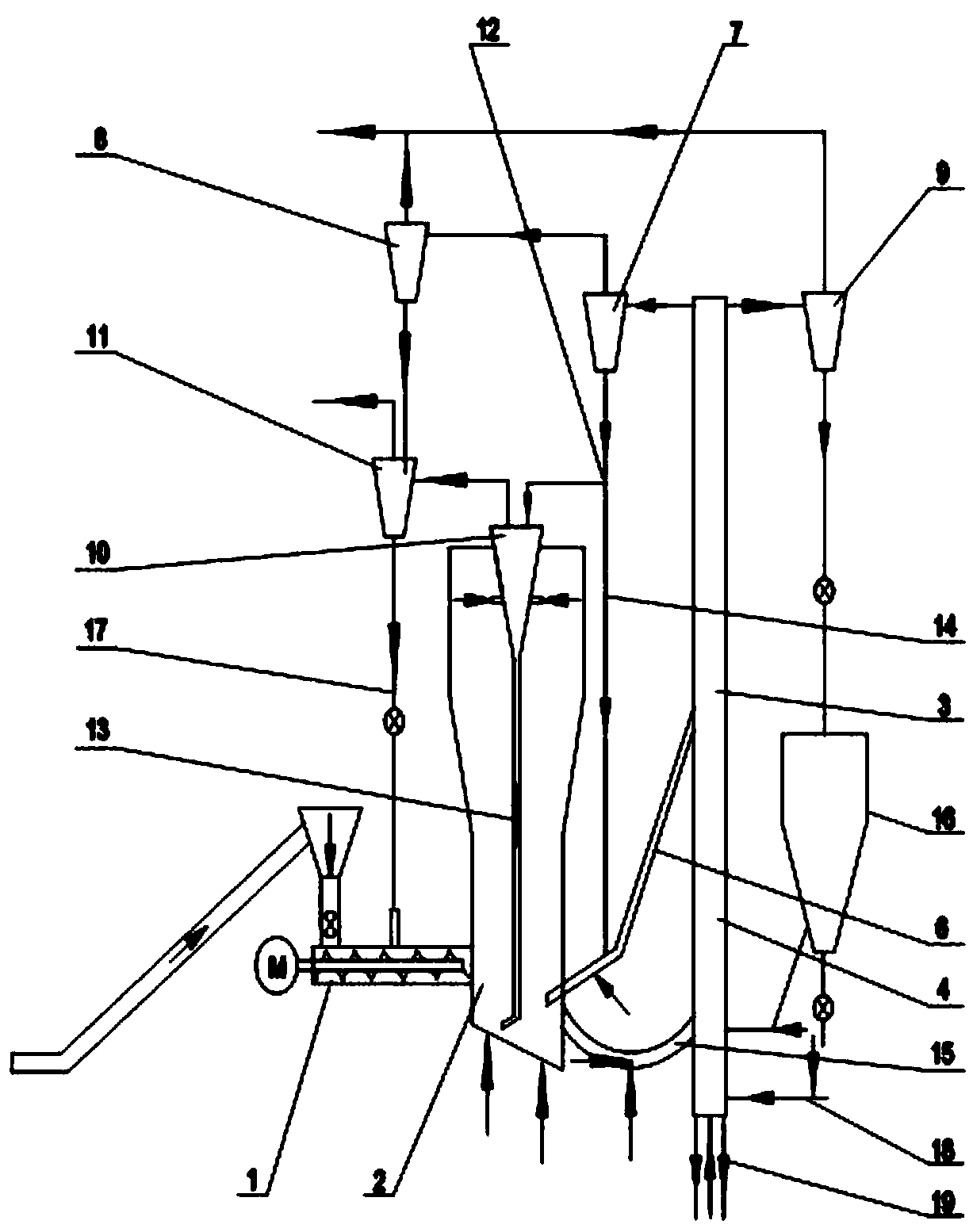

Three-bed combination pyrolysis gasification and tar cracking integrated system for solid waste

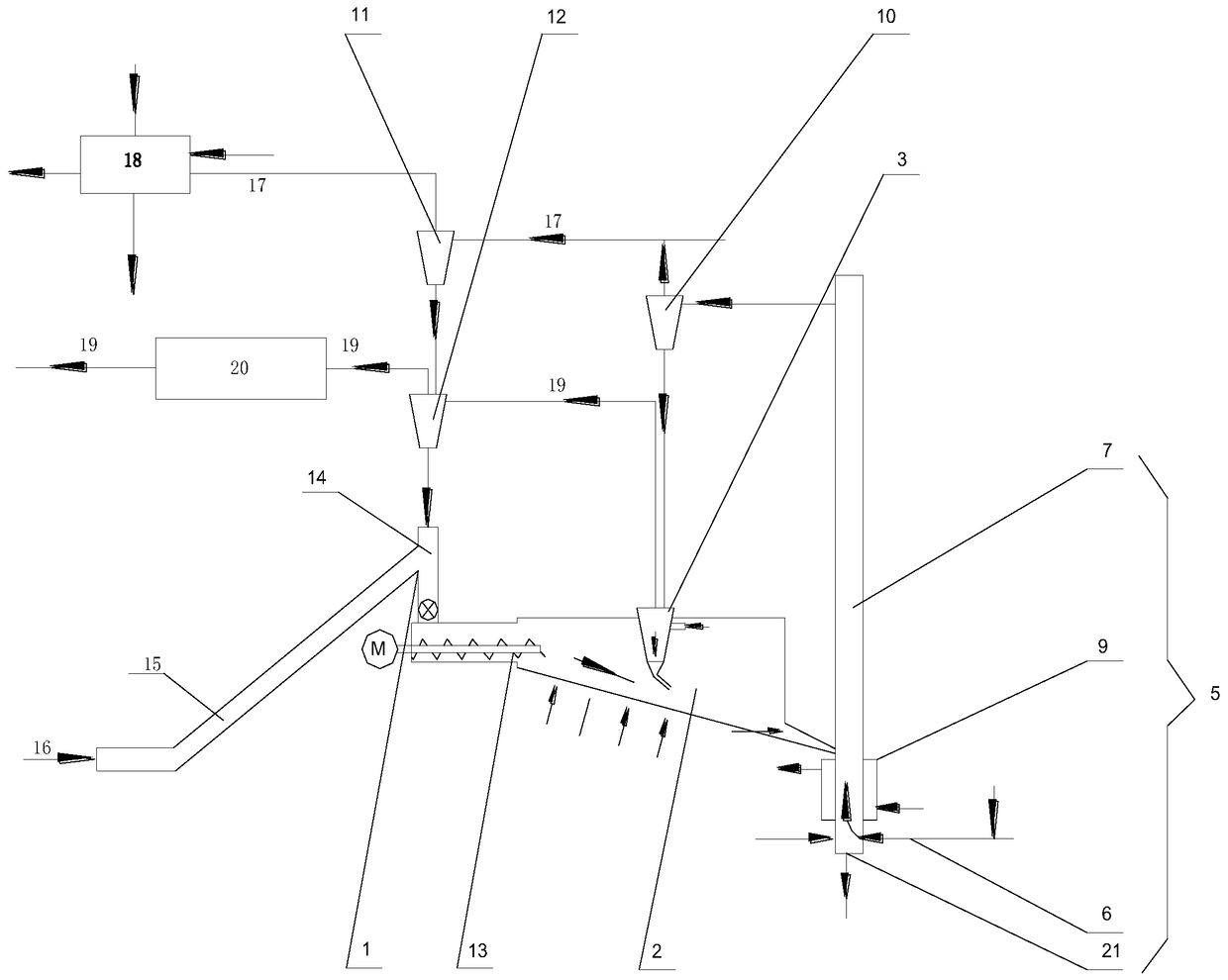

ActiveCN105885950AEasy to operateEmission reductionGasifier feeding meansBiofuelsCycloneFluidized bed

The invention discloses a three-bed combination pyrolysis gasification and tar cracking integrated system for solid waste and belongs to the technical field of solid waste treatment. The system comprises a solid waste feeding system, a pyrolyzer, an oxidizer system, an oxidizer cyclone separator and a cyclone reactor. According to the system, the circulating flow of bed materials among three bed is realized by virtue of a circulating fluidized bed oxidizer, a bubbling or turbulent fluidized bed pyrolyzer and the cyclone reactor which are combined with a gas stripping tube and a sedimentation tube, and the adequate mixing between the hot bed materials and pyrolysis gas is realized by virtue of the cyclone reactor, so that the tar cracking and the gas purification are greatly promoted; by virtue of structural optimization of an oxidizer and the pyrolyzer, the mixed use of different bed materials and the improvements of a bed material circulating flow system, the gas-liquid mixing level and a feeding system, the integral pyrolysis gasification efficiency is greatly improved, the heat value of product gas is greatly increased, the tar content of product gas is greatly reduced, and high-quality clean pyrolysis gas / synthesis gas is prepared.

Owner:BEIJING UNIV OF CHEM TECH

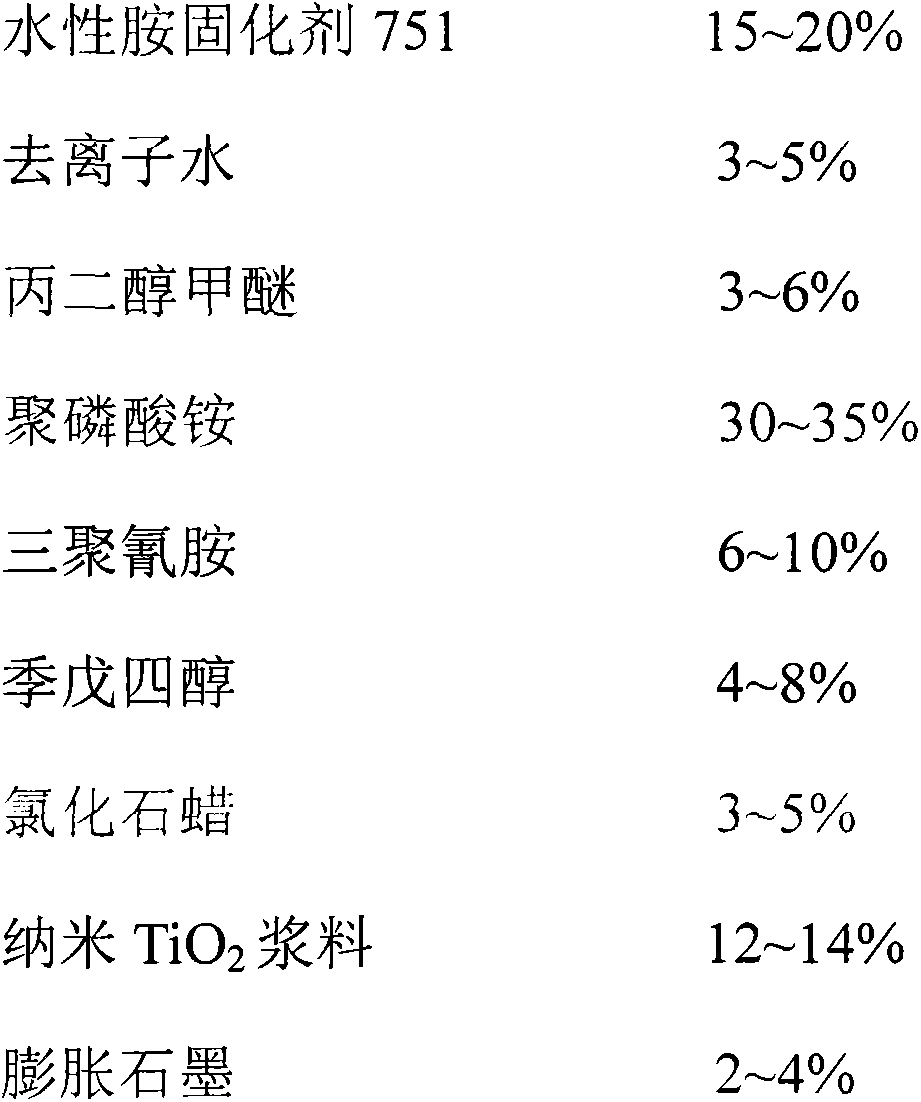

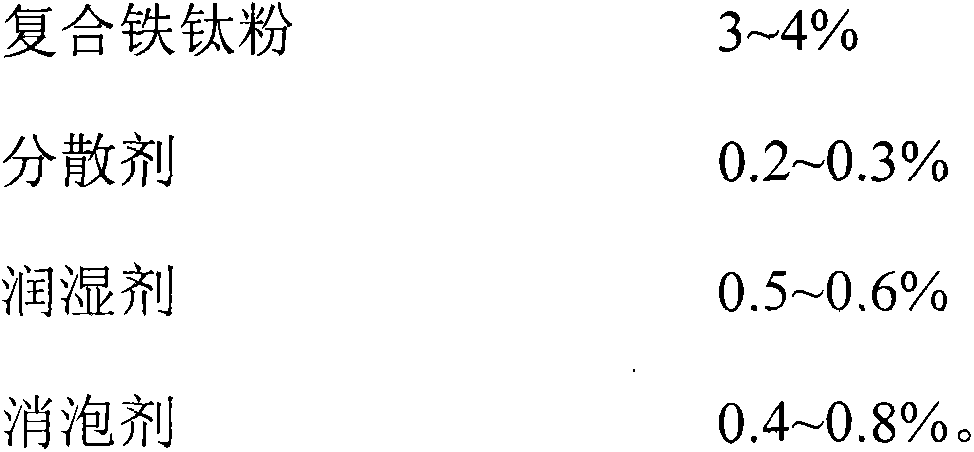

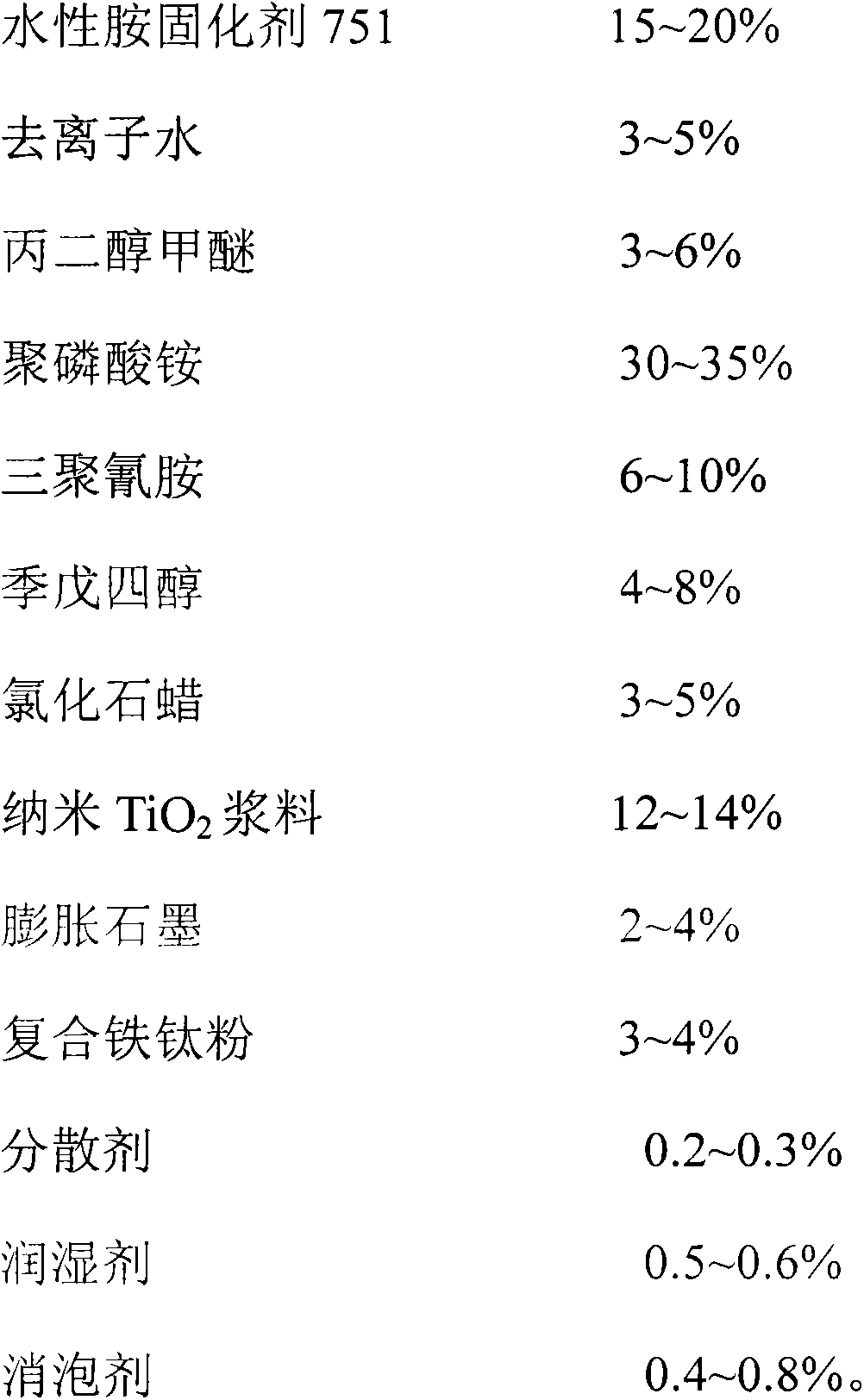

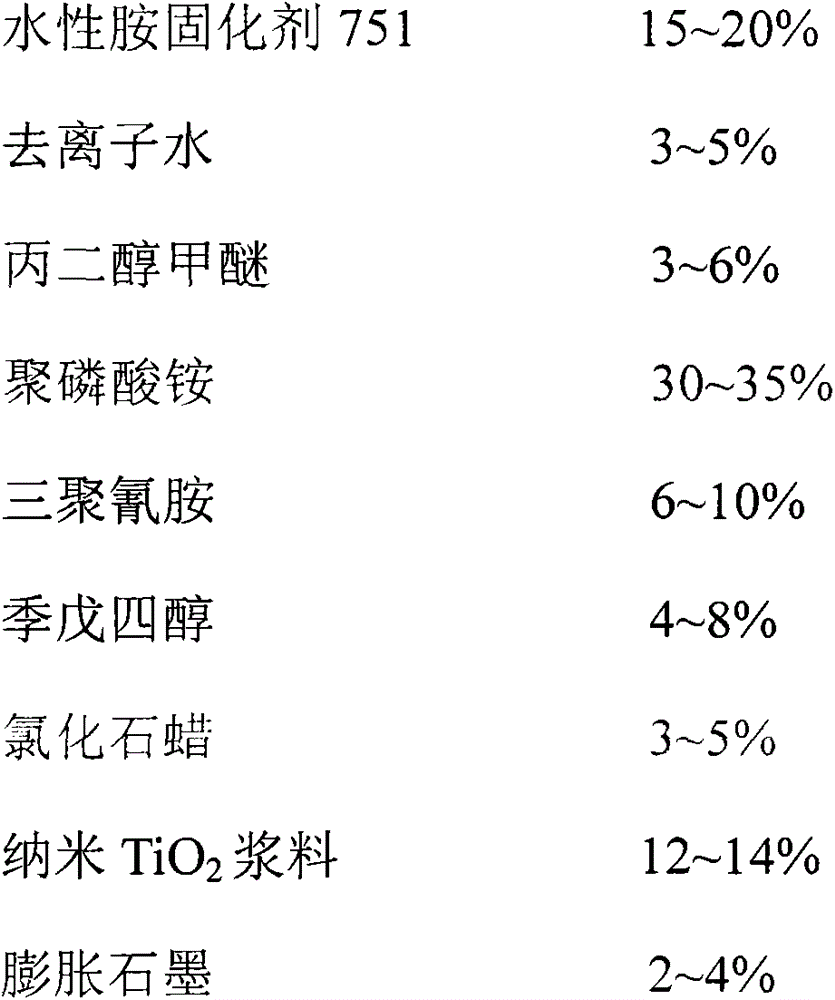

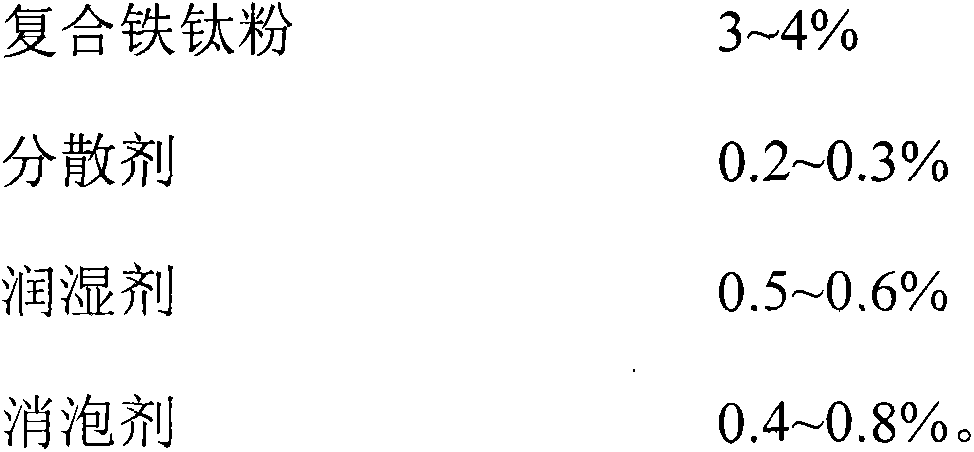

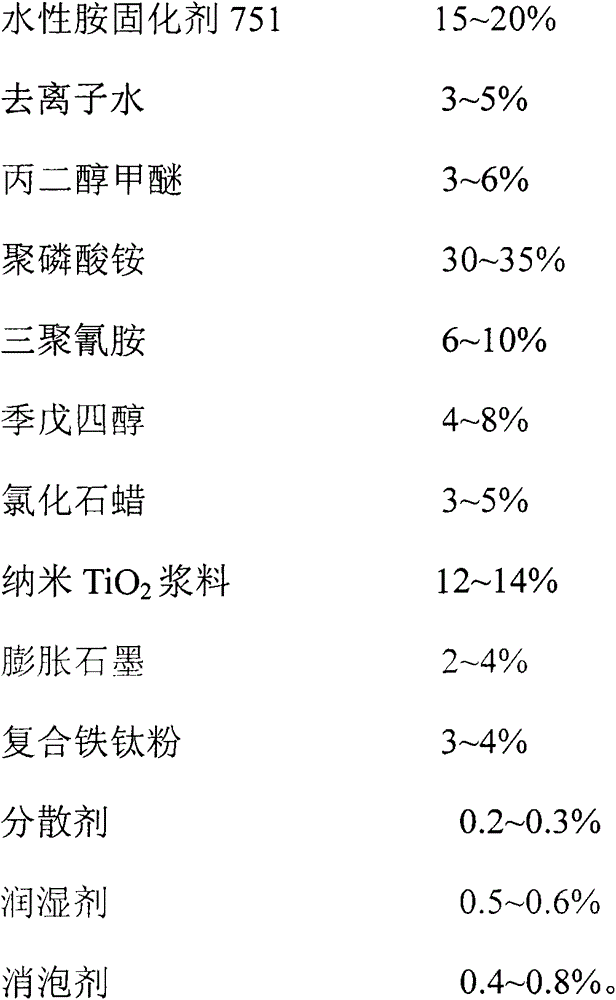

Hydrocarbon-resistant outdoor ultrathin fireproofing coating for steel structures

ActiveCN103450775AReduce emission contentGood chemical resistanceFireproof paintsEpoxy resin coatingsFireproofingSlurry

The invention provides a hydrocarbon-resistant outdoor ultrathin fireproofing coating for steel structures. The fireproofing coating consists of a component A and a component B, wherein the component A includes liquid epoxy resin OER-95 and propylene glycol monomethyl ether, and the component B includes an aquatic amine curing agent 751, de-ionized water, propylene glycol monomethyl ether, ammonium polyphosphate, melamine, pentaerythritol, chlorinated paraffin, nano TiO2 slurry, expanded graphite, compound iron-titanium powder, a dispersing agent, a wetting agent and a deforming agent, and the components A and B are mixed at 1: (5.5-6) in percentage by mass. The fireproofing coating, as an aquatic environmentally-friendly fireproofing coating, is quite low in organic compound discharge, can bear rapid temperature increasing of hydrocarbon fire, and is excellent in chemical corrosion resistance, heat resistance, acid-base resistance property, water resistance, electric insulating performance and mechanical strength; the fireproofing coating can be widely used for protecting outdoor steel structures.

Owner:石家庄雅致化工有限公司

Method for preparing environmental-friendly waterborne ceramic coating

InactiveCN108395743AImprove stabilityReduce emission contentAlkali metal silicate coatingsAnti-corrosive paintsSelf-healingCeramic coating

The invention discloses a method for preparing an environmental-friendly waterborne ceramic coating. The environmental-friendly waterborne ceramic coating is prepared from a base stock, a filler, deionized water and an additive, wherein the base stock is mainly liquid silicate, the filler is mainly aluminium powder, and the aluminium powder is pretreated to improve the stability of the coating tothe great degree; and the additive is mainly prepared from a coupling agent, a corrosion inhibitor, a thixotropic agent, a surfactant, a defoaming agent and the like, and the environmental-friendly waterborne ceramic coating is prepared through the processes of stirring and sanding. The environmental-friendly waterborne ceramic coating has the characteristics of being environmental-friendly, non-toxic, free of pungent odour, low in VOC emission, simple in construction procedure, and widely applied in multiple fields. The environmental-friendly waterborne ceramic coating has high surface adaptability to the base stock, the adhesive force of the coating is strong, and the environmental-friendly waterborne ceramic coating has good metal luster and high performances of self repairing, high temperature resistance, salt fog resistance, abrasion resistance, corrosion resistance, thermal shock resistance, static electricity resistance, mildew resistance and water resistance, and the like.

Owner:ANHUI UNIVERSITY

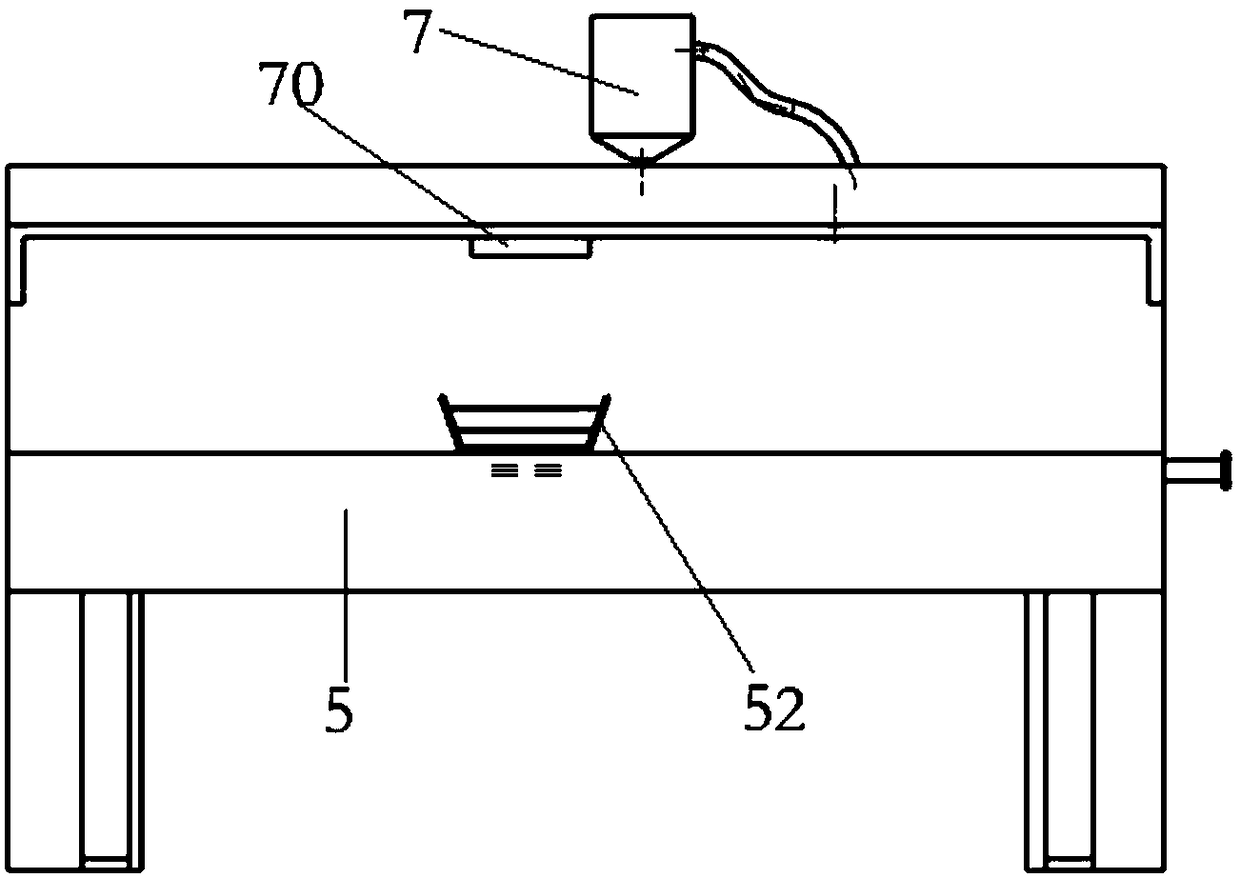

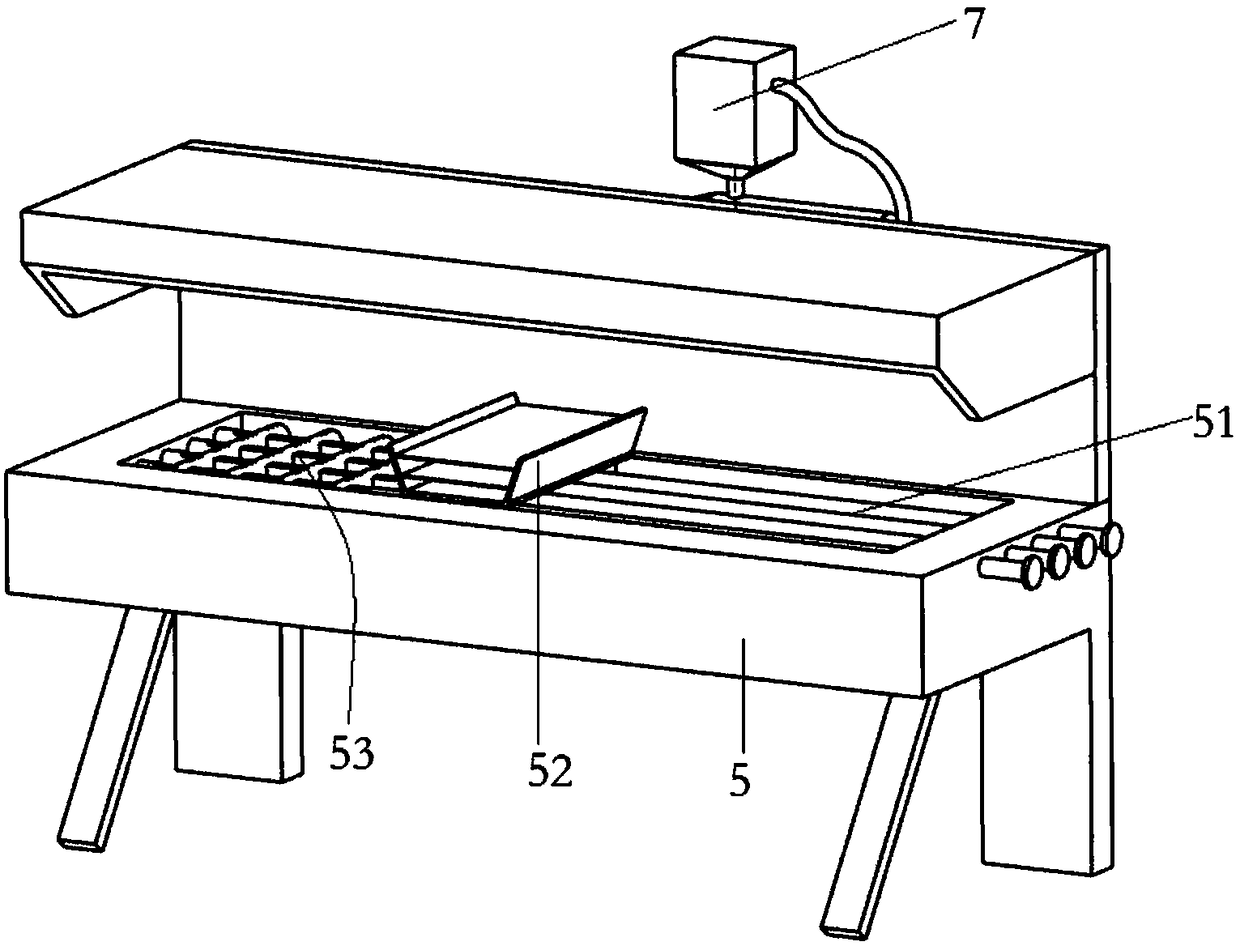

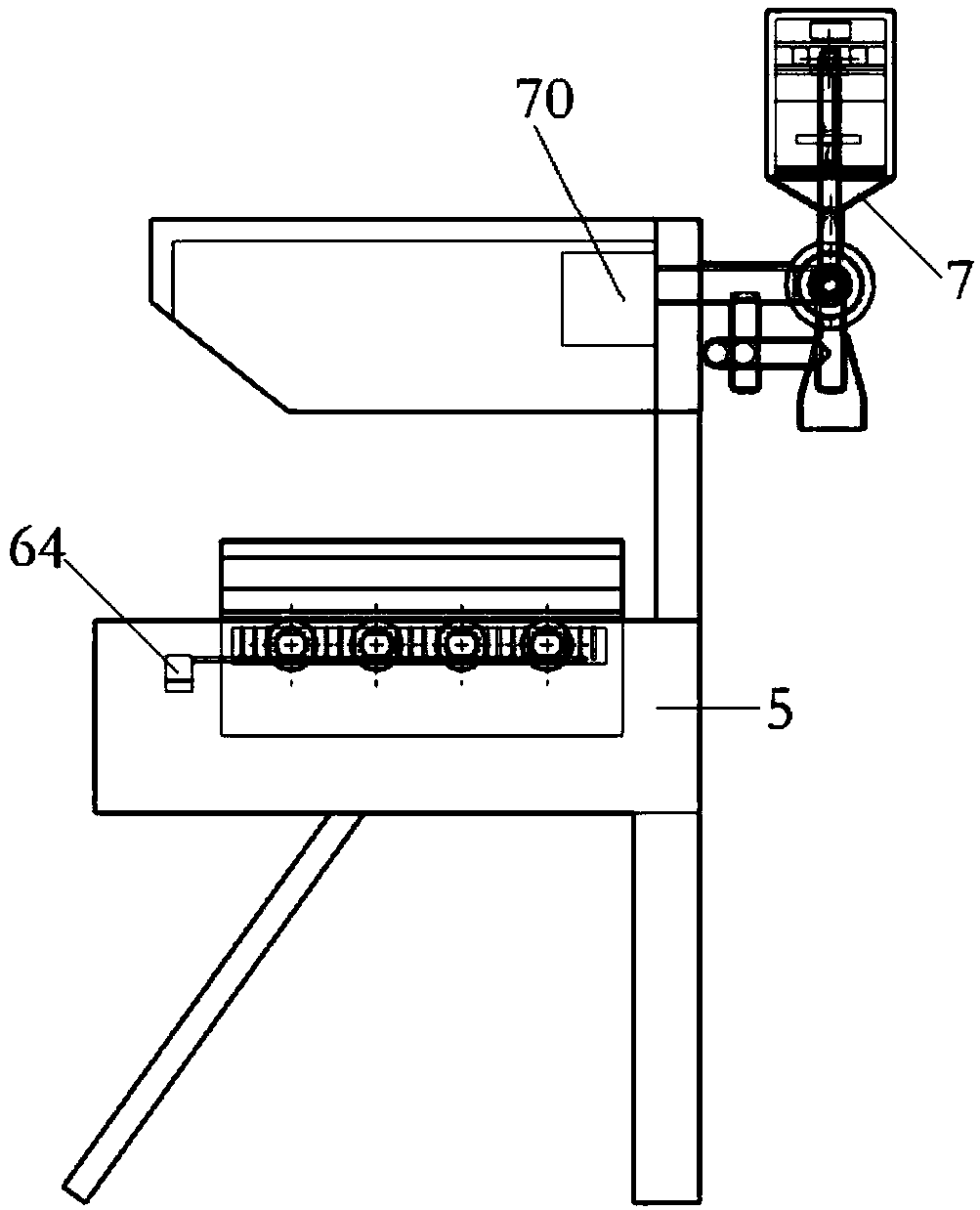

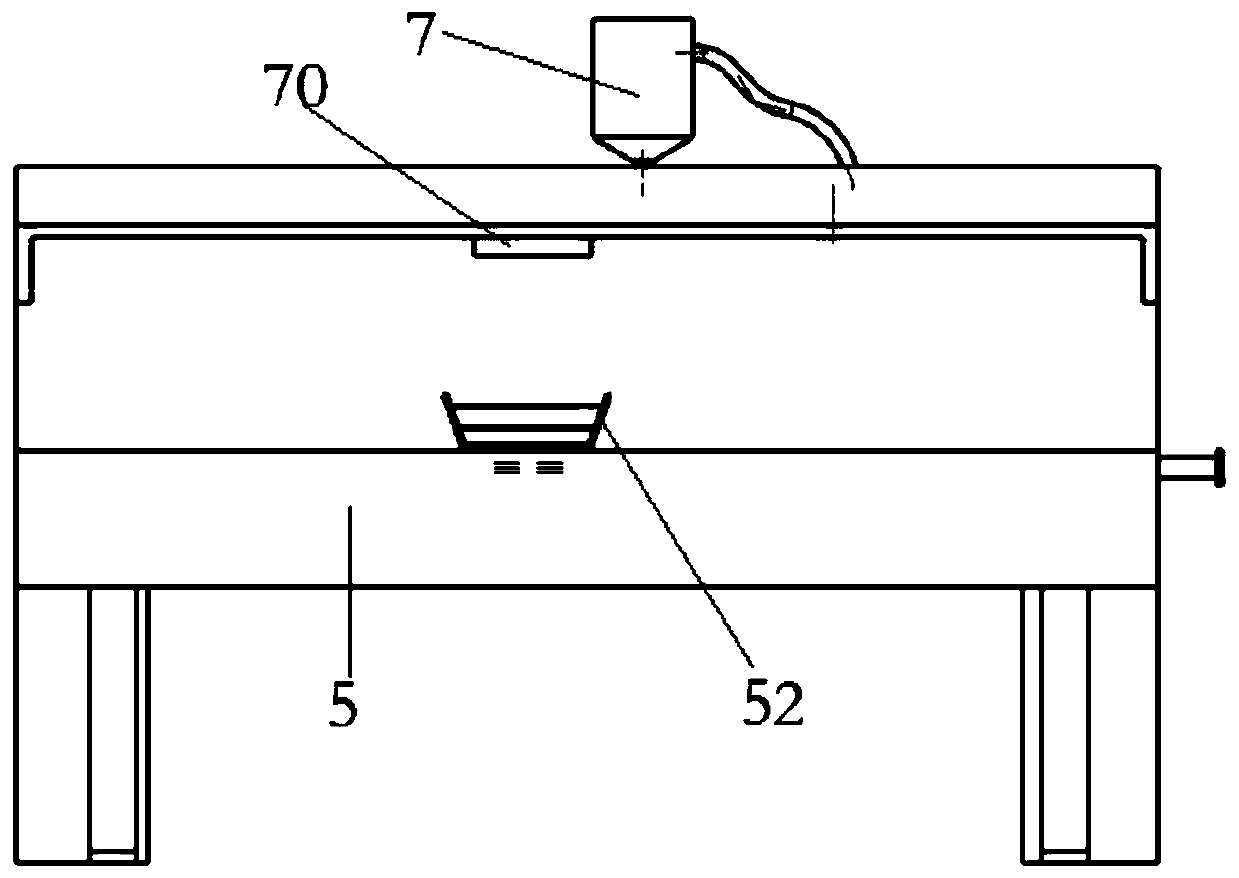

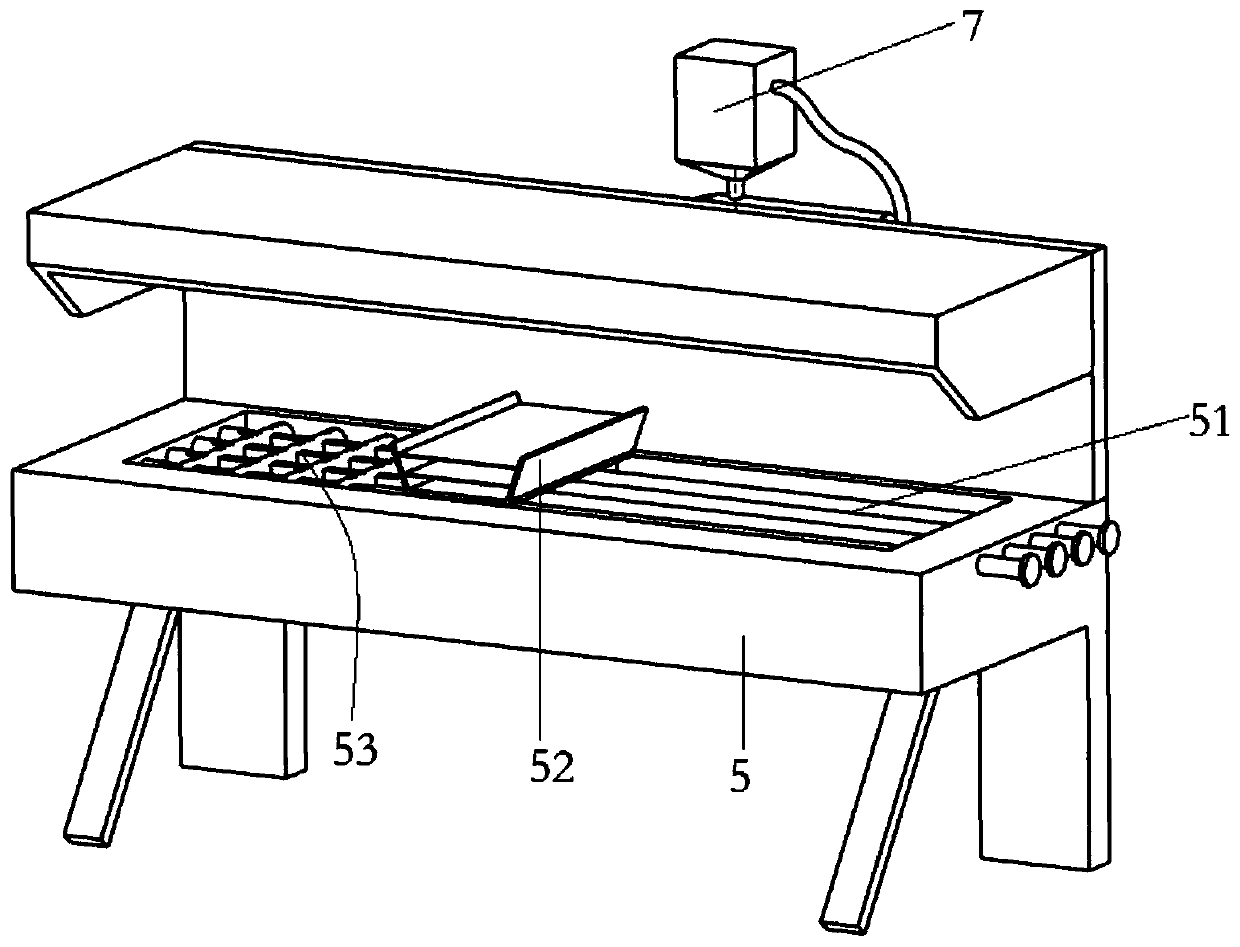

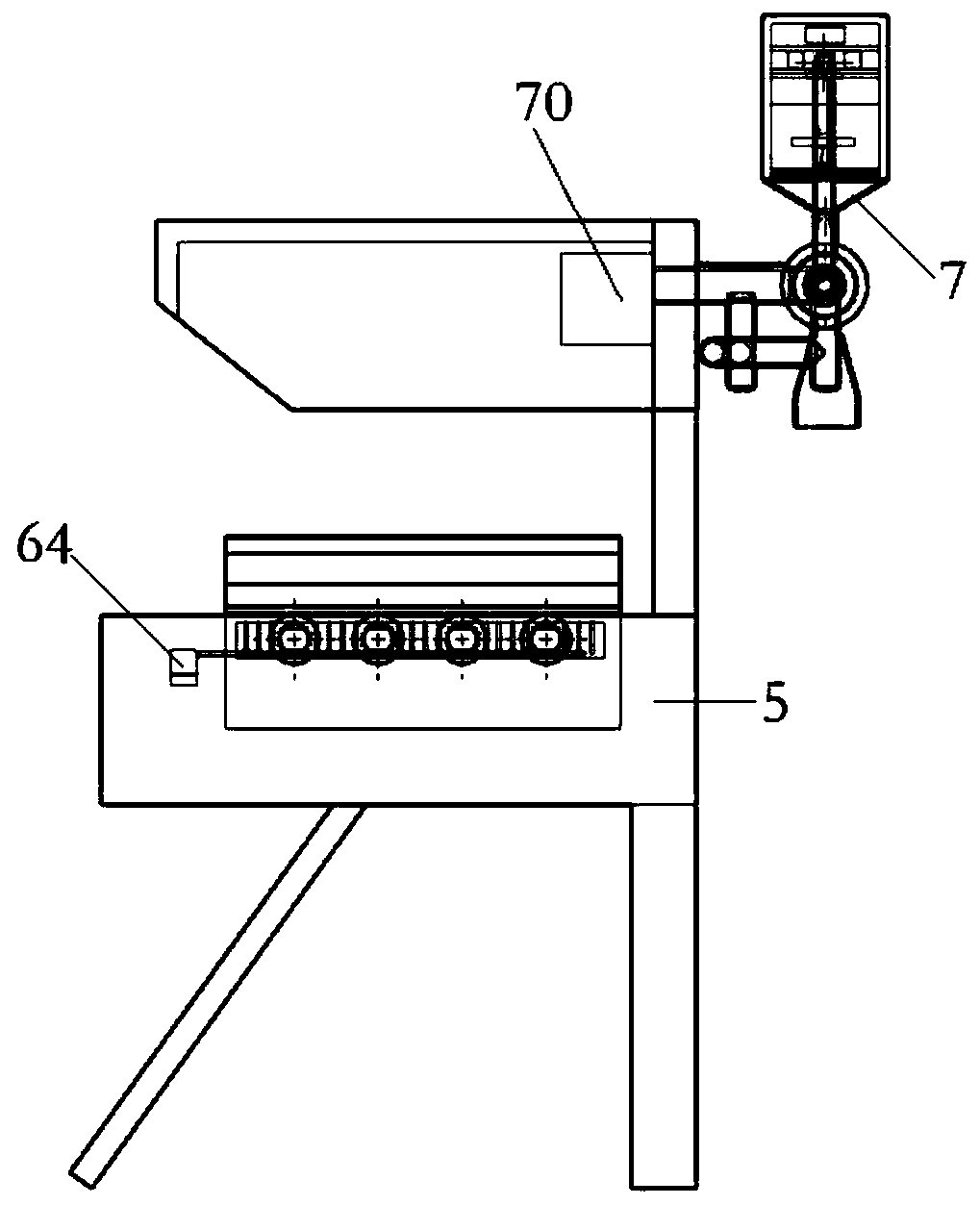

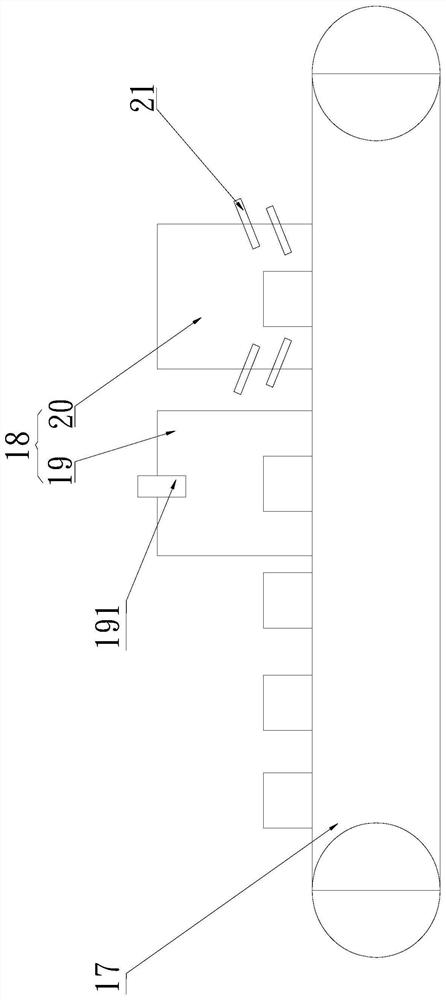

Environment-friendly grilling machine capable of absorbing smoke and method of environment-friendly grilling machine

ActiveCN108523691AEvenly heatedSlow down heat dissipationCombination devicesGas treatmentPulp and paper industrySmoke

The invention discloses an environment-friendly grilling machine capable of absorbing smoke and a method of the environment-friendly grilling machine. The environment-friendly grilling machine comprises a grilling machine body, the grilling machine body is in a rectangular groove shape, a grill of the grilling machine body comprises a first grill body and a second grill body, and the first grill body and the second grill body are adjacent in the length direction of the grilling machine body; a heat preservation assembly is arranged between the first grill body and the second grill body and arranged on the grilling machine body, the grilling machine body is further provided with a smoke absorbing assembly, and a smoke absorbing device is located above the grill and absorbs the smoke above the grill. According to the environment-friendly grilling machine capable of absorbing the smoke and the method of the environment-friendly grilling machine, the content of the smoke exhausted into airis reduced.

Owner:盐城抱璞文化传媒有限公司

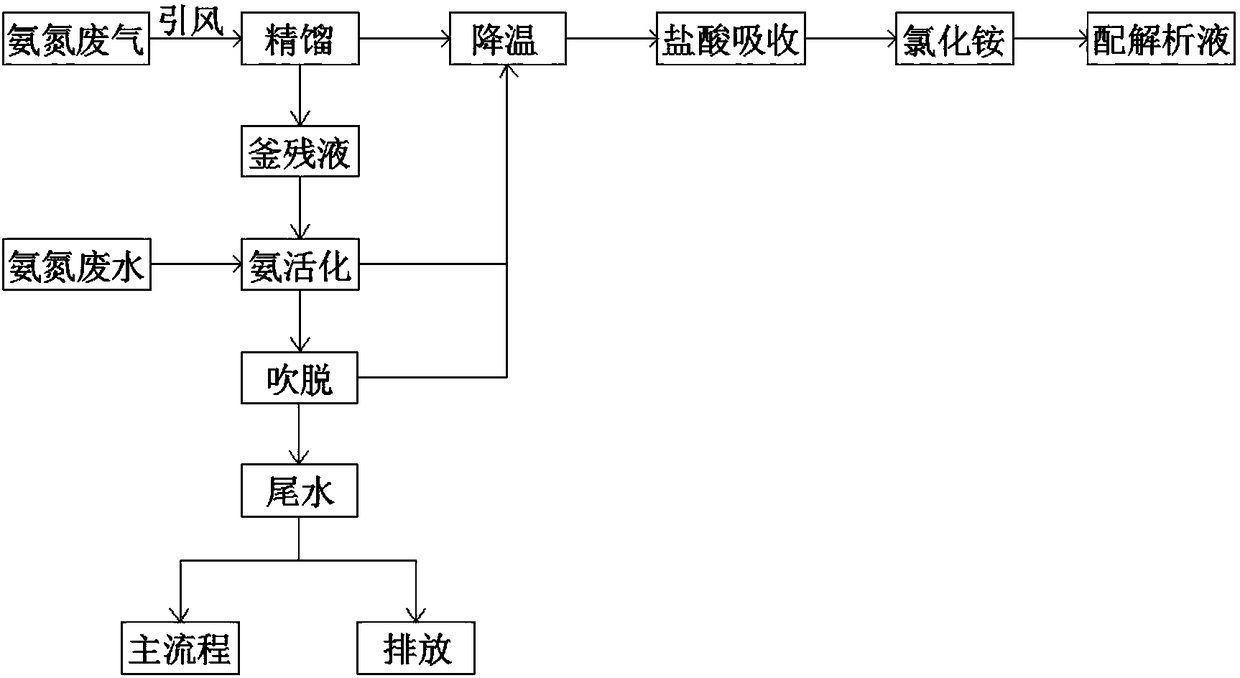

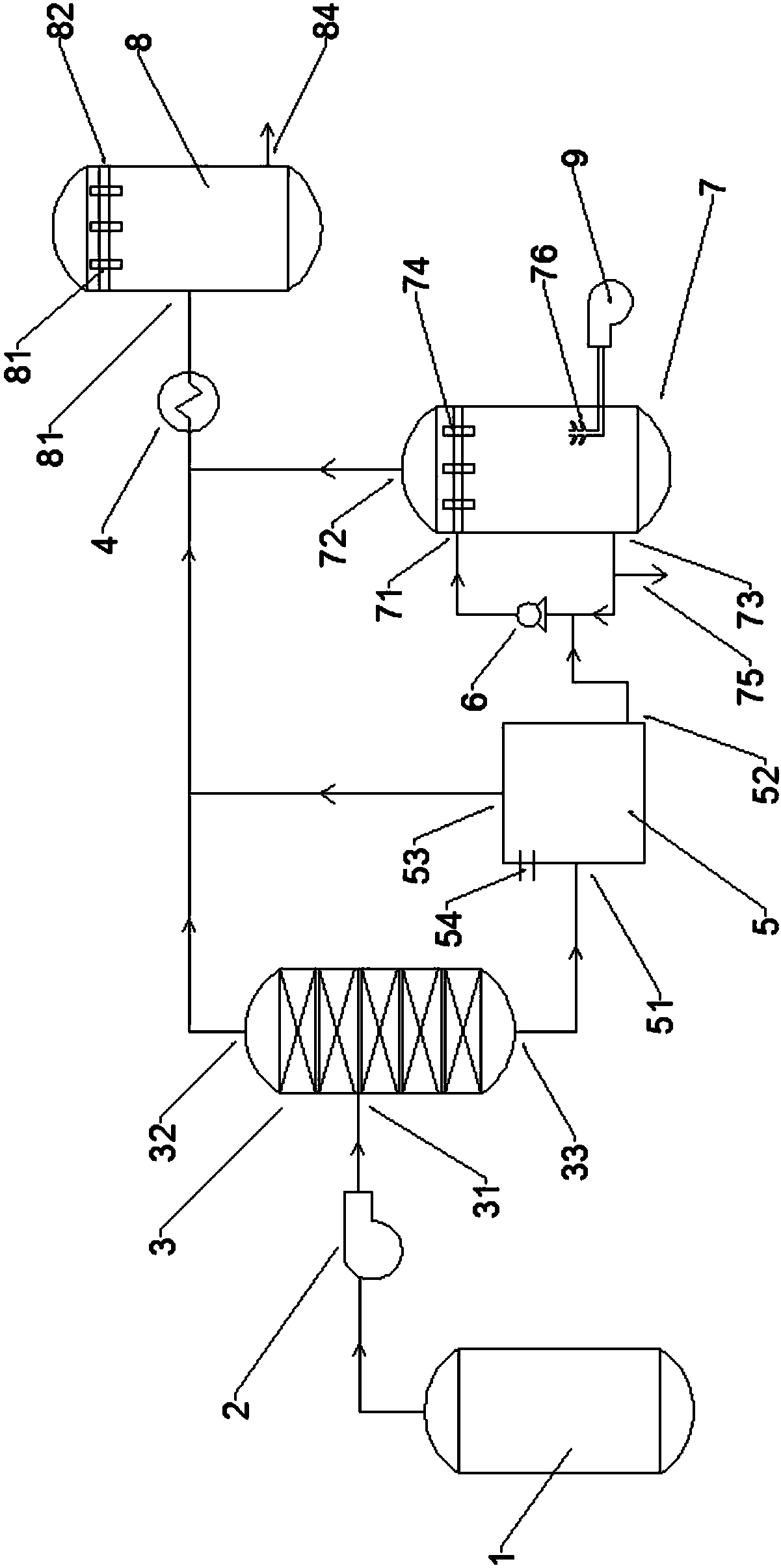

Ammonia recycling method and system in APT production process

PendingCN108371869AFully contactedImprove absorption efficiencyWater treatment parameter controlWater contaminantsDesorptionIon exchange

The invention provides an ammonia recycling method and a system in APT production process. The ammonia recycling method comprises following steps: 1, APT crystallization steam is discharged using a centrifugation blower fan, is introduced into a rectifying tower for rectification and condensation of ammonia tail gas to remove most water, and is introduced into a heat exchanger; 2, a three stage solution obtained via ion exchange is directly used for preparing a desorption agent, the rest ammonia nitrogen wastewater is pumped into a stirring tank, an alkali is added for ammonia activation, andgenerated ammonia tail gas is introduced into the heat exchanger; wastewater obtained via ammonia activation is pumped into an air stripping tower, and ammonia tail gas obtained via air stripping is introduced into the heat exchanger; when the ammonia-nitrogen value of obtained air stripping wastewater is detected to be qualified, discharging through a branch pipe is carried out, otherwise, the wastewater is pumped into the air stripping tower for air stripping; and 3, the temperature of the ammonia tail gas is reduced to be lower than 45 DEG C after treatment using the heat exchanger, the ammonia tail gas is introduced into a hydrochloric acid absorbing tower for circulating absorption, and an obtained solution is sent back to the main treatment stream directly for preparation of the desorption agent. The ammonia recycling method and the system are used for comprehensive treatment of ammonia nitrogen wastewater waste gas obtained in tungsten smelting, waste is changed into valuables,the method flow is simple, operation is convenient, the method is easy to control, and cost is low.

Owner:江西铜鼓有色冶金化工有限责任公司

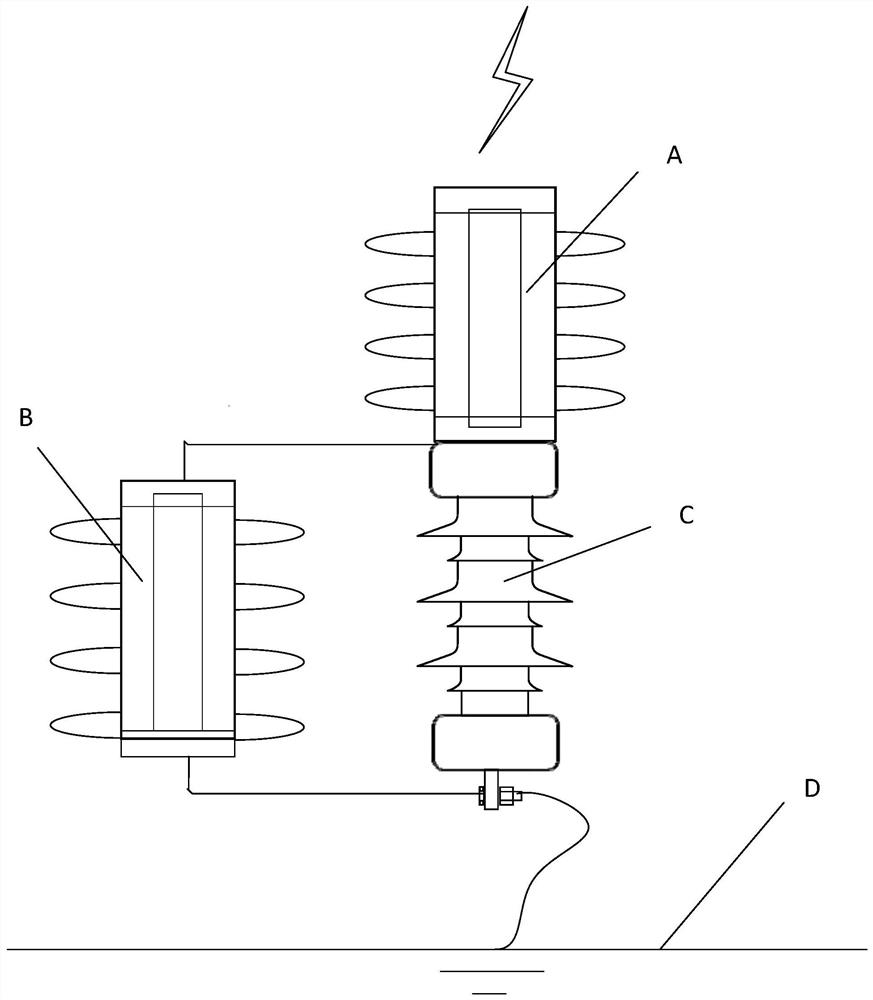

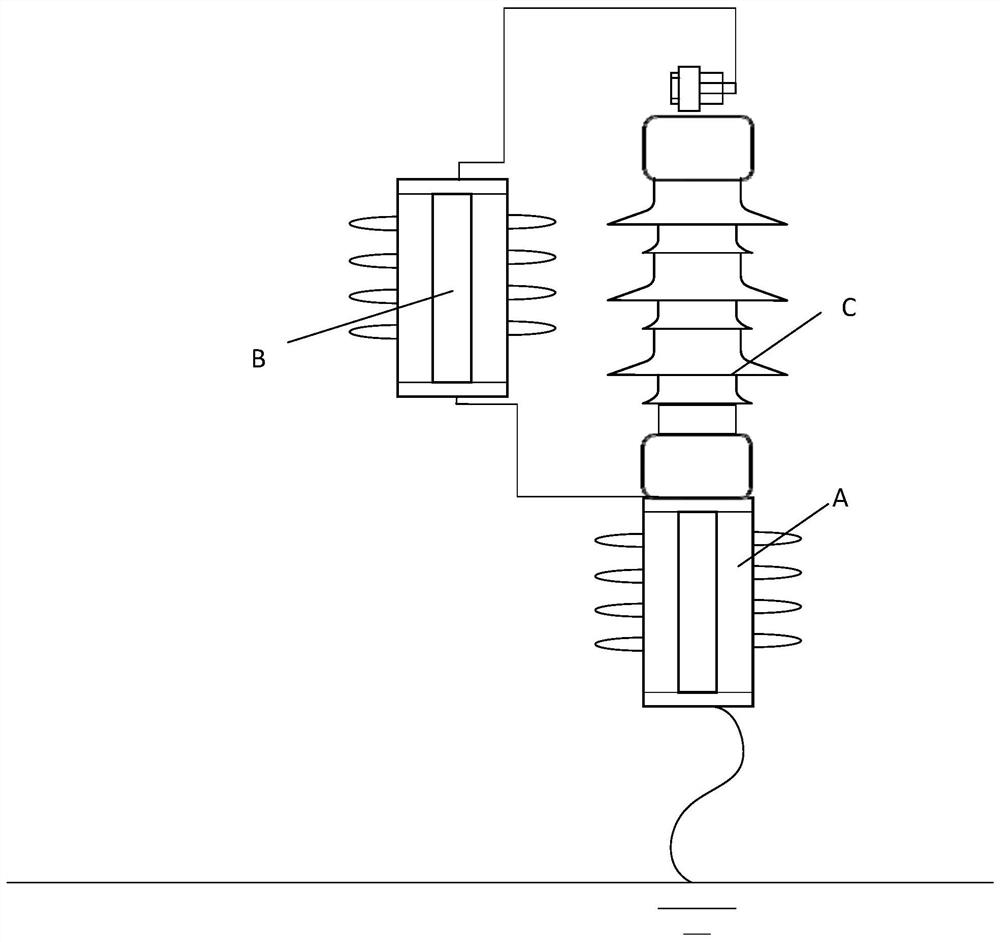

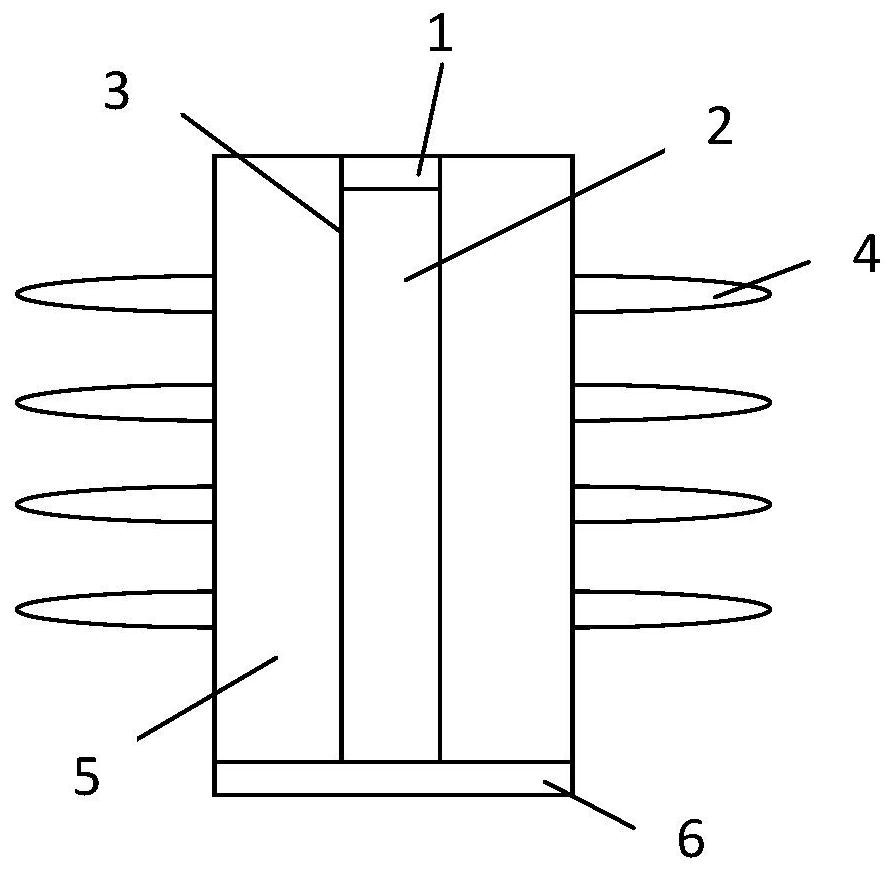

Novel combined arc extinguishing lightning protection device

PendingCN113594862AStrong integrity of arc extinguishingImprove integritySpark gap detailsMechanical engineeringArc extinction

The invention discloses a novel combined arc extinguishing lightning protection device, and belongs to the technical field of lightning protection and arc extinguishing, the novel combined arc extinguishing lightning protection device comprises an end portion arc extinguishing unit, a sealing arc extinguishing unit and an insulator chain, the sealing arc extinguishing unit is arranged on the insulator chain in parallel, and the end portion arc extinguishing unit is arranged at the upper end or the lower end of the insulator chain and is electrically connected with an insulator chain end portion metal piece. When the end portion arc extinguishing unit is arranged at the upper end of the insulator string, the bottom of the insulator string is grounded, and when the end portion arc extinguishing unit is arranged at the bottom of the insulator string, the bottom of the end portion arc extinguishing unit is grounded. The arc extinguishing integrality is high, reignition is avoided, the arc is integrally cut off at the same time instead of being cut off in sections, and the medium recovery speed tends to be infinite and reaches the limit of itself, so that the arc extinguishing speed is high, and the reignition is avoided.

Owner:南宁超伏电气科技有限公司

Moulded coal used for decoupling burning and method of producing the same

The invention discloses a combustion decoupling coal and preparing method, which comprises the following parts: fire coal made of bituminite and anthracite with weight rate at 70-80: 30-20, stable composite liquid composed of stabilizer solution and soluble glass with weight rate at 17-23: 83-77 and the weight percentage density of the stabilizer at 0. 08%-0. 12%, methyl hydroxypropylcellulose as the stabilizer; using calcium lime as sulfur fixing agent with content as 1. 4-1. 8 times as fire coal, 1%-2% potassium nitrate combustion adjuvant. The invention has stable source for raw material of molded coal, good using and storing property, low preparing cost, which realizes desulfurizing, denitrating, dedusting and environment protection, which can replace fuel to reduce combusting cost greatly and release insufficiency of the fuel.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

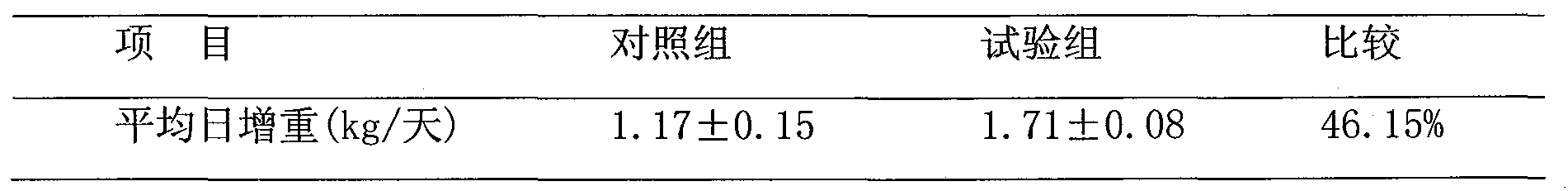

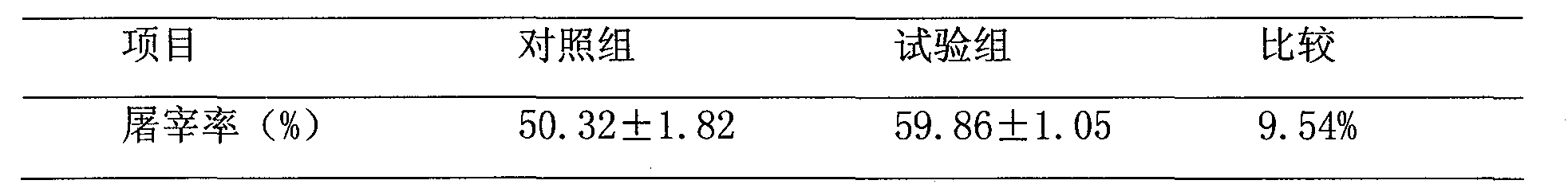

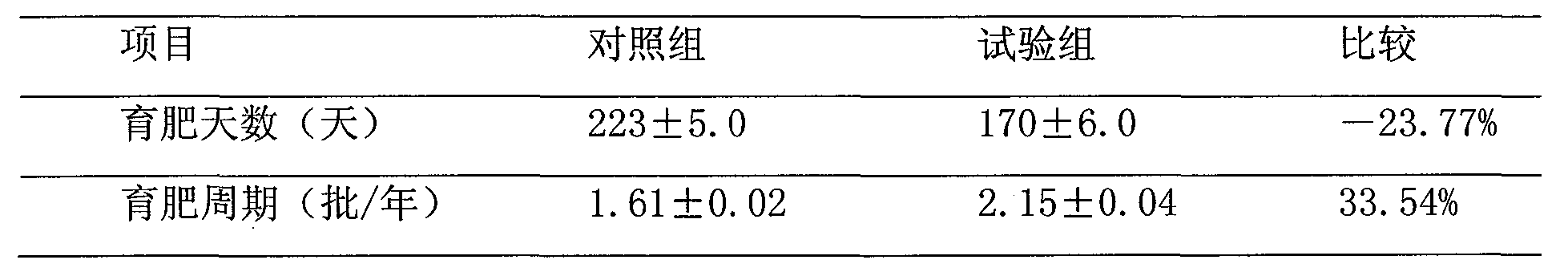

Efficient beef cattle fattening granulated feed

ActiveCN102499332BIncrease productivityStructural balanceAnimal feeding stuffAgriculture gas emission reductionNitrogenRumen

Owner:LIAONING WELLHOPE AGRI TECH

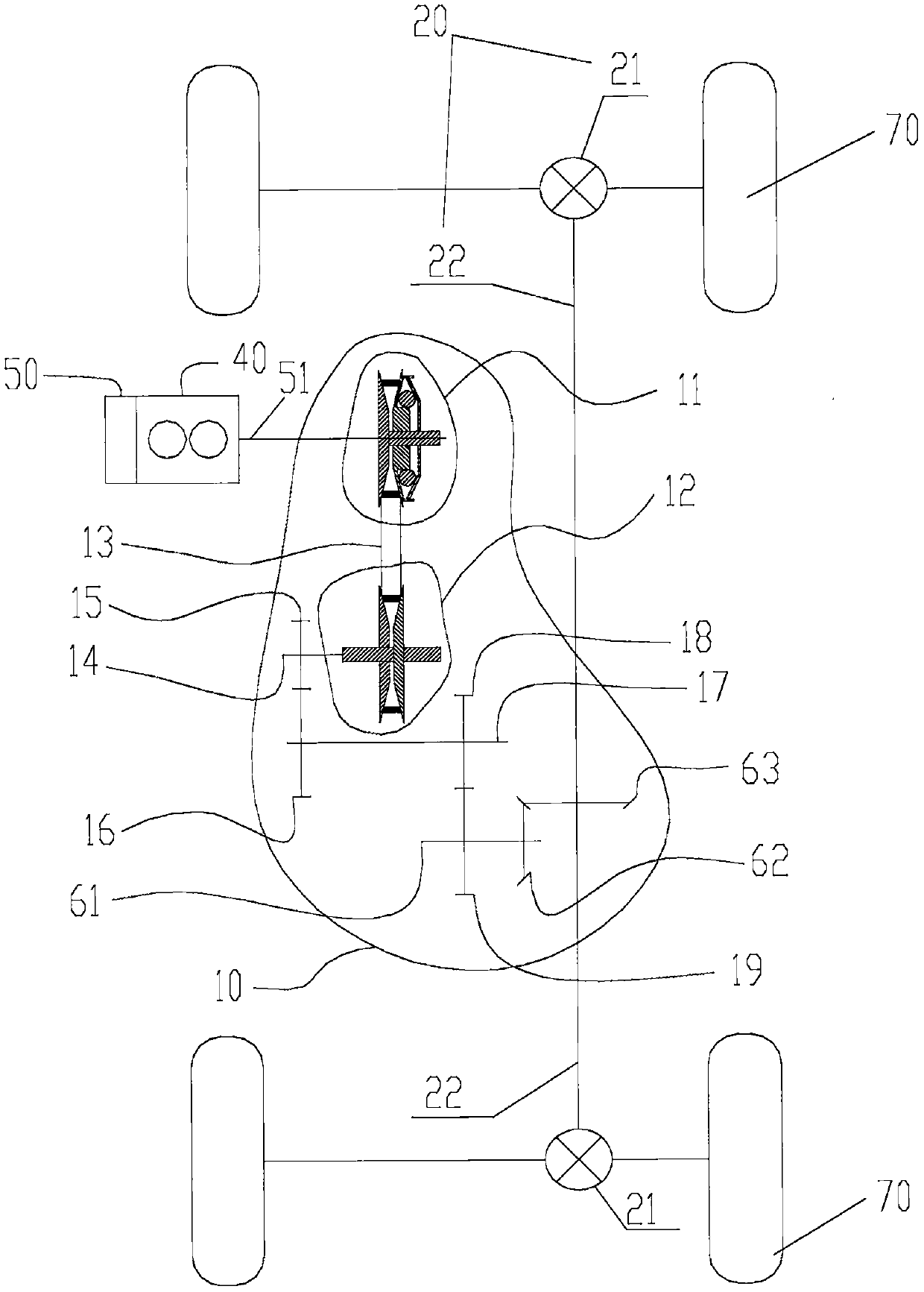

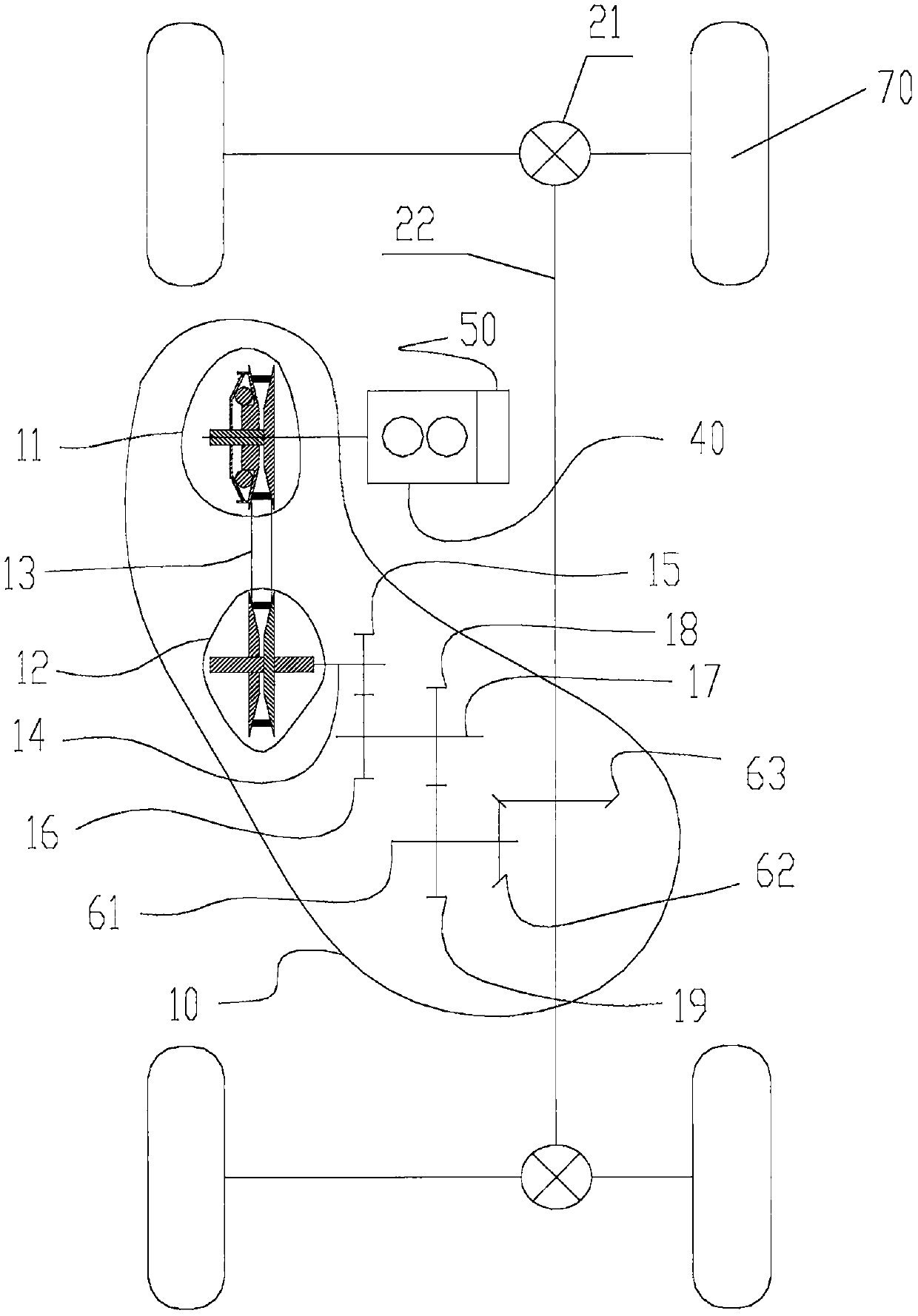

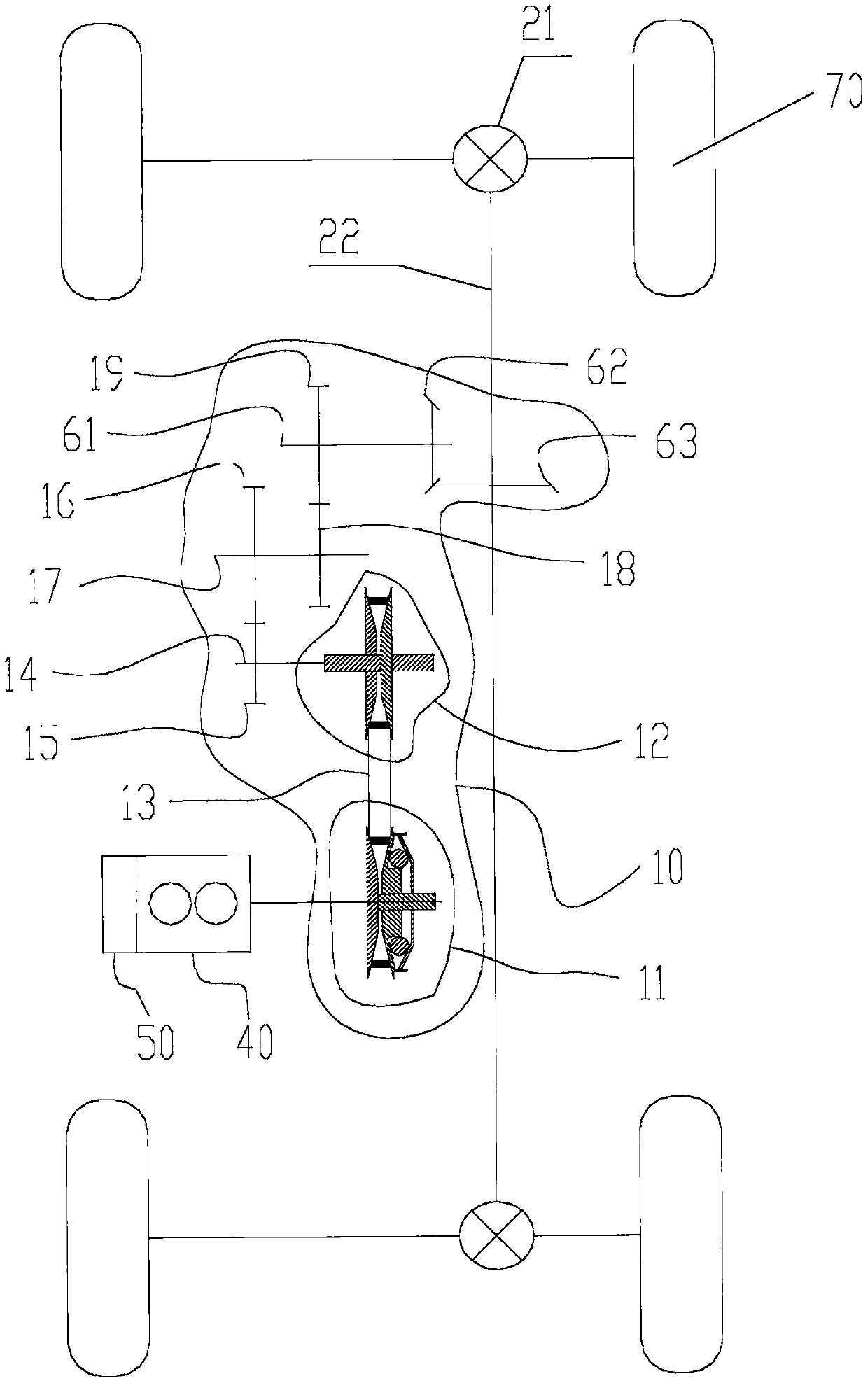

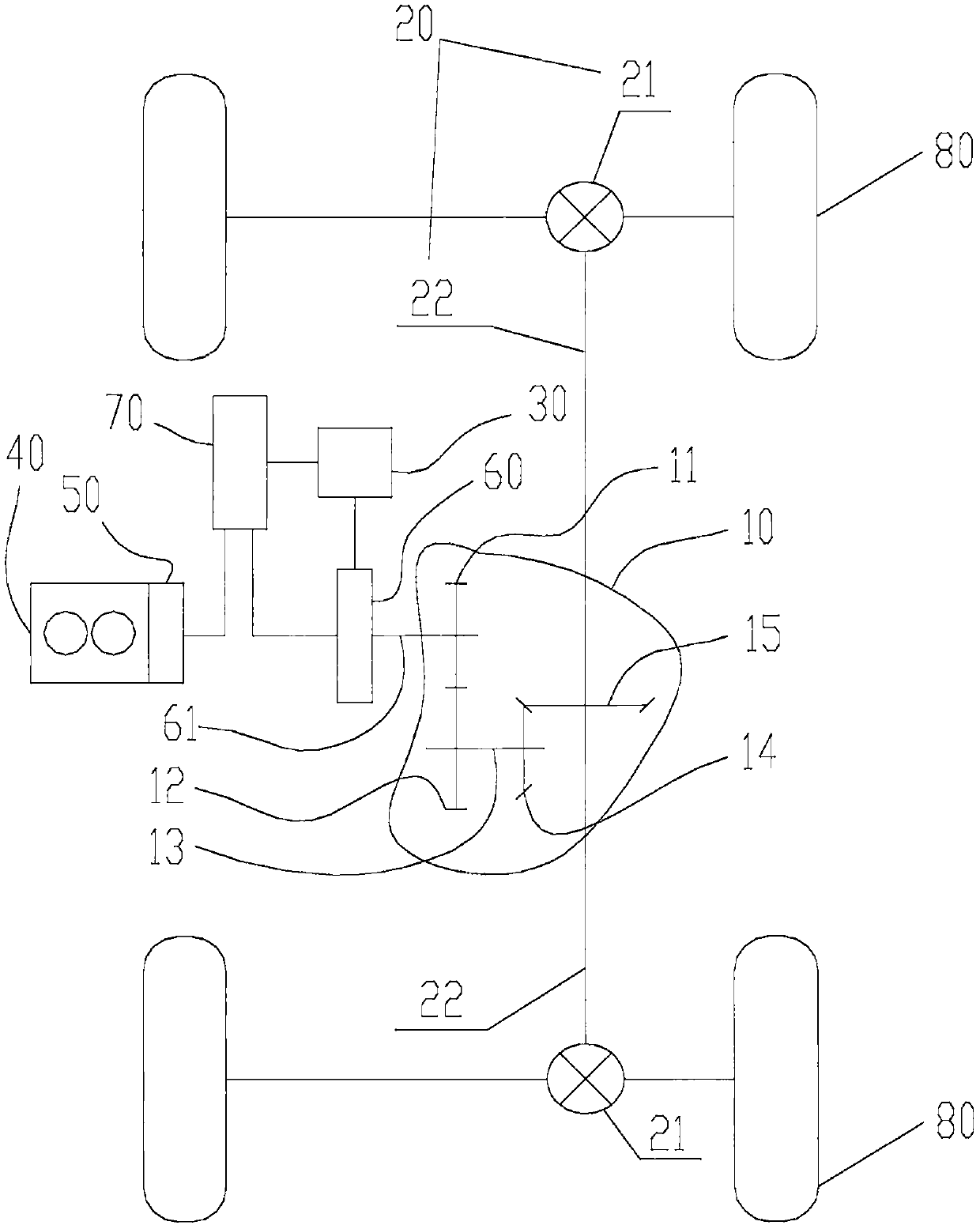

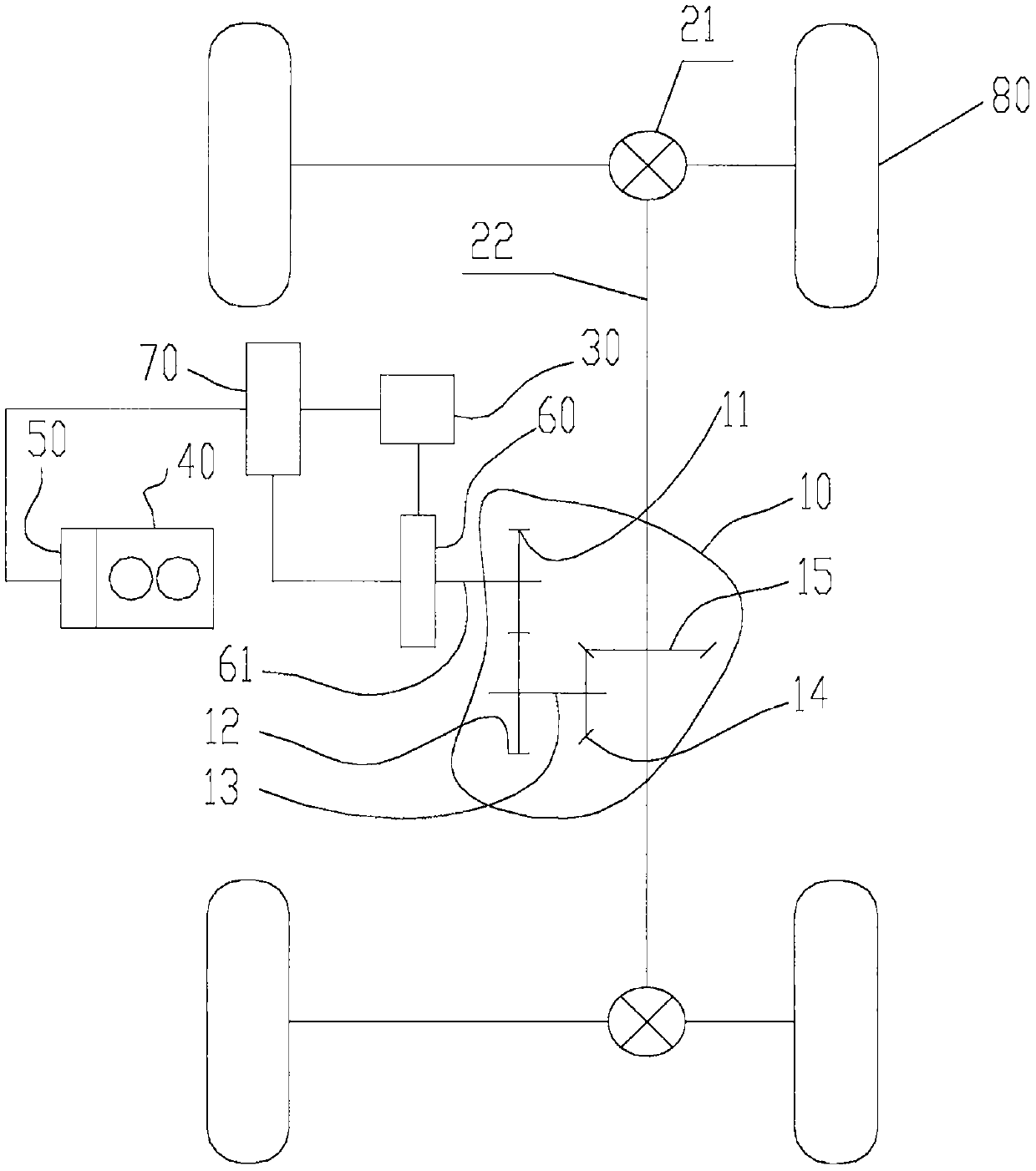

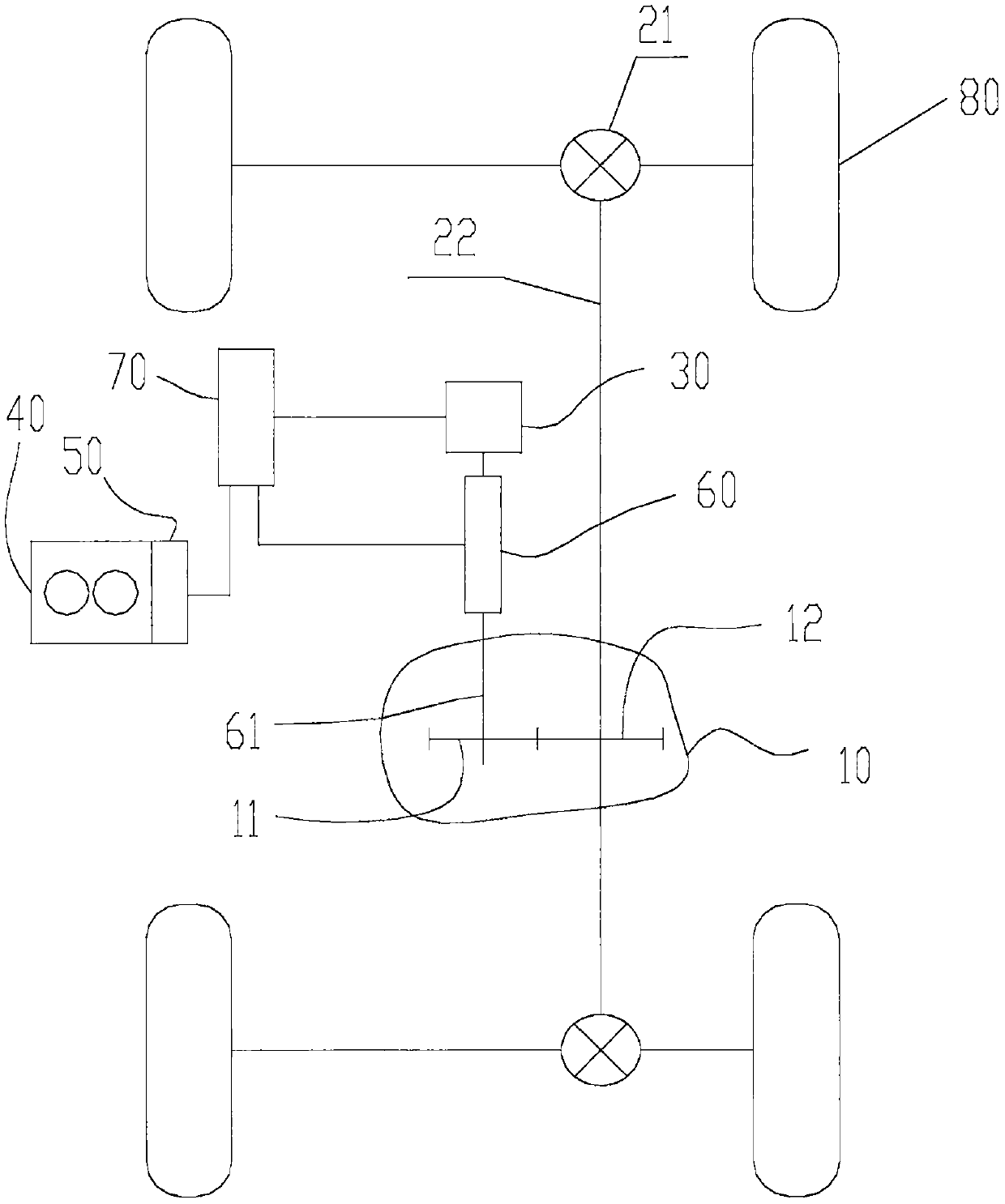

All-terrain vehicle and all-terrain vehicle control method

PendingCN111376744ASolve the problem of high emission contentReduce emission contentHybrid vehiclesGas pressure propulsion mountingControl theoryMechanical engineering

The invention provides an all-terrain vehicle and an all-terrain vehicle control method. The all-terrain vehicle comprises a hybrid power system, a transmission mechanism and an axle, wherein the hybrid power system is in driving connection with the transmission mechanism; the transmission mechanism is in driving connection with the axle so as to enable the hybrid power system to drive the axle tomove through the transmission mechanism; and the hybrid power system is a parallel hybrid power system. According to the all-terrain vehicle, the problem that the harmful gas emission content of an all-terrain vehicle in the prior art is high is solved.

Owner:NINE INTELLIGENT CHANGZHOU TECH CO LTD

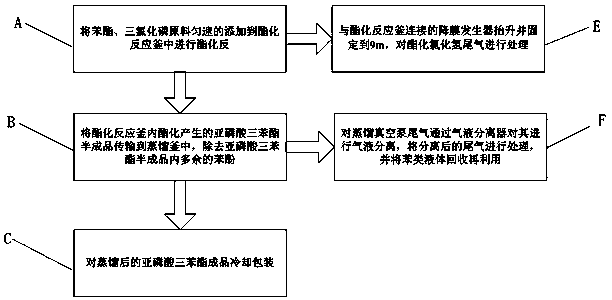

Triphenyl phosphite processing and tail gas treating technology based on graphite condenser

InactiveCN110357922AReduce the content of metal ionsHigh precisionGroup 5/15 element organic compoundsChemical industryDistillationSide reaction

The invention discloses a triphenyl phosphite processing and tail gas treating technology based on a graphite condenser. The graphite condenser is arranged to reduce the metal ion content of triphenylphosphate, greatly shorten the distillation time and reduce the side reactions of semi-finished triphenyl phosphate, so the precision of the triphenyl phosphate can reach 99.5% or more, the color ofthe triphenyl phosphate is improved, customer needs are met, and the energy consumption required for distillation is greatly reduced; a falling film generator is lifted up to greatly increase the absorption efficiency of esterified hydrogen chloride tail gas, and subsequent water washing, alkali washing and activated carbon adsorption are combined to reduce the content of toxic hydrogen chloride tail gas emission; and gas-liquid classification, alkali washing and activated carbon adsorption of distillation vacuum pump exhaust gas generated in the distillation process are also arranged, so thetechnology has the advantages of improvement of recycling of benzene liquids, reduction of the concentration of the tail gas, energy saving, environmental protection, reliable process, ensuring of thequality of triphenyl phosphite, and good application prospect.

Owner:昌和化学新材料(江苏)有限公司

An environment-friendly barbecue machine and its method for absorbing cooking fumes

ActiveCN108523691BEvenly heatedSlow down heat dissipationCombination devicesGas treatmentPulp and paper industrySoot

The invention discloses an environment-friendly barbecue machine and a method thereof for absorbing and treating oily smoke, comprising a barbecue machine body, the barbecue machine body is in the shape of a long rectangular groove, and the barbecue frame of the barbecue machine body includes a first barbecue frame and the second grill, the first grill and the second grill are arranged adjacent to each other along the length direction of the grill body, a thermal insulation component is arranged between the first grill and the second grill, and the thermal insulation The assembly is arranged on the grill body, and the grill body is also provided with an oil fume absorbing assembly, the oil fume absorbing device is located above the grill, and the oil fume absorbing device absorbs the oil fume above the grill. The invention provides an environment-friendly barbecue machine and a method thereof for absorbing and treating oil fume, which can reduce the content of oil fume discharged into the air.

Owner:盐城抱璞文化传媒有限公司

Atmospheric gas radiation heating device

ActiveCN101900324BHigh blacknessImprove Radiation AbilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelPetrochemicalEngineering

The invention discloses an atmospheric gas radiation heating device which comprises a burner, a quartz glass radiant tube and an igniter, wherein the burner comprises a nozzle, an injection tube and a burner head part; the burner head part consists of an inner tube and an outer tube which are concentric, and one end of an annular belt between the inner tube and the outer tube is sealed; the injection tube is communicated with the annular belt; the end of the sealed annular belt of the inner tube is a secondary air inlet, while the other end of the inner tube is provided with an inner flame cover; a corresponding end of the outer tube is provided with an outer flame cover, and a flame hole is formed between the inner flame cover and the outer flame cover; and the inner tube is internally provided with a secondary air conditioning device. The invention has simple structure, convenient mounting, low manufacture and maintenance cost, high burning strength, long service life and large burner load regulation ratio, can meet the requirement of different heating powers to a larger extent and can be widely applied to industrial kilns of the industries of steel, petrochemical industry, machinery, building materials, boilers, waste incineration, and the like.

Owner:ENN CHINA GAS ENVESTMENT

Hydrocarbon-resistant outdoor ultra-thin steel structure fireproof coating

ActiveCN103450775BReduce emission contentGood chemical resistanceFireproof paintsEpoxy resin coatingsFireproofingSlurry

The invention provides a hydrocarbon-resistant outdoor ultrathin fireproofing coating for steel structures. The fireproofing coating consists of a component A and a component B, wherein the component A includes liquid epoxy resin OER-95 and propylene glycol monomethyl ether, and the component B includes an aquatic amine curing agent 751, de-ionized water, propylene glycol monomethyl ether, ammonium polyphosphate, melamine, pentaerythritol, chlorinated paraffin, nano TiO2 slurry, expanded graphite, compound iron-titanium powder, a dispersing agent, a wetting agent and a deforming agent, and the components A and B are mixed at 1: (5.5-6) in percentage by mass. The fireproofing coating, as an aquatic environmentally-friendly fireproofing coating, is quite low in organic compound discharge, can bear rapid temperature increasing of hydrocarbon fire, and is excellent in chemical corrosion resistance, heat resistance, acid-base resistance property, water resistance, electric insulating performance and mechanical strength; the fireproofing coating can be widely used for protecting outdoor steel structures.

Owner:石家庄雅致化工有限公司

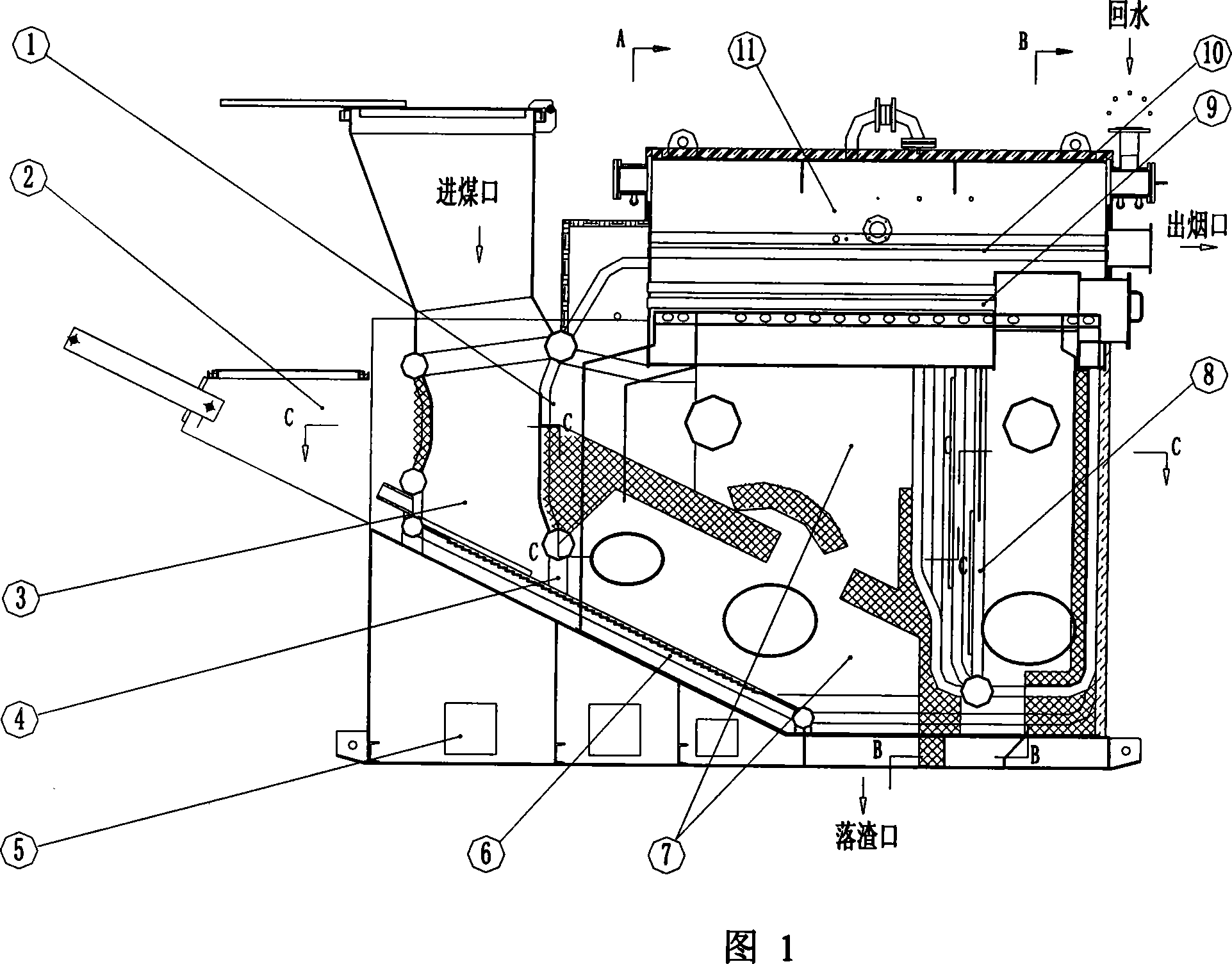

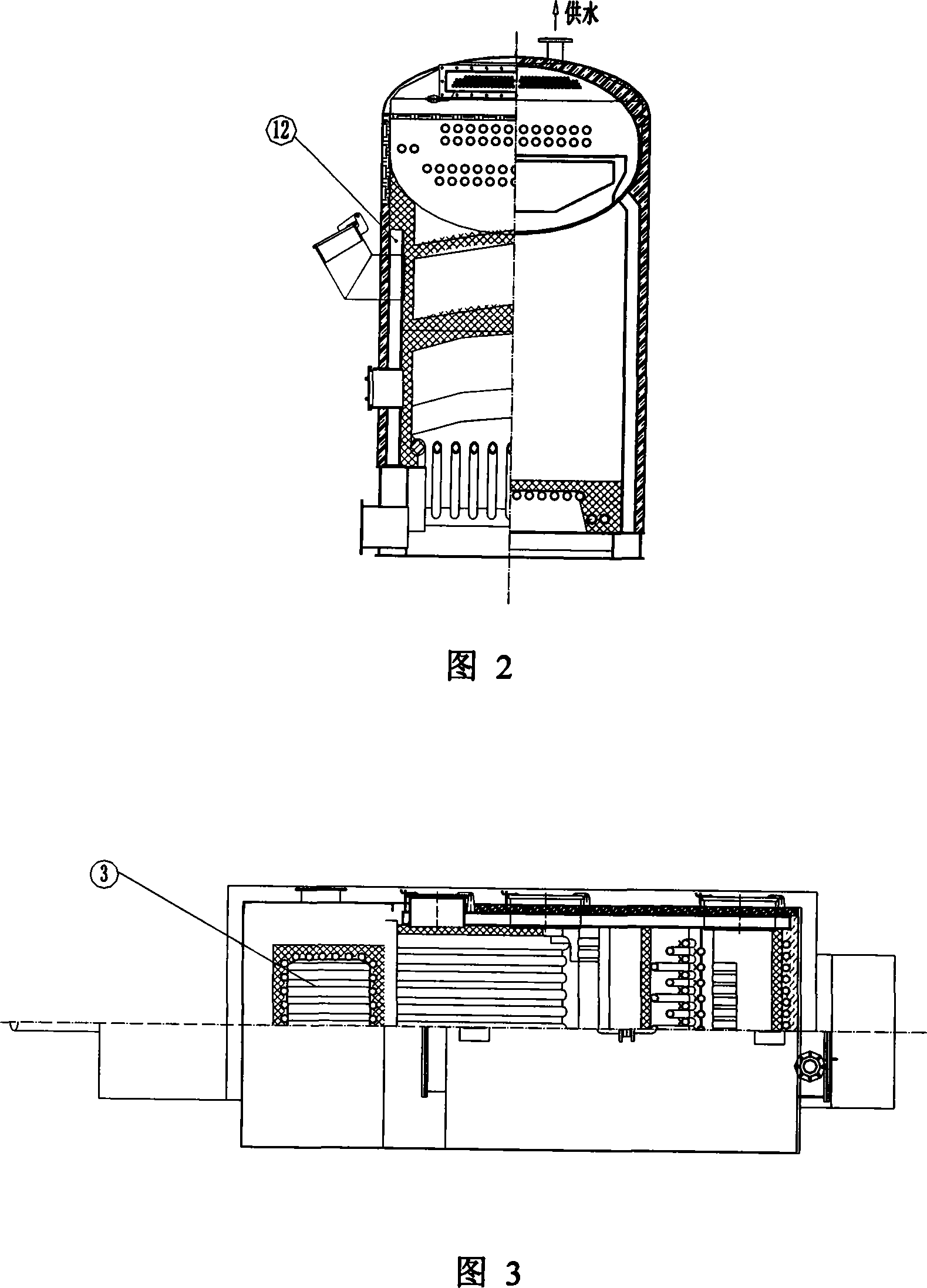

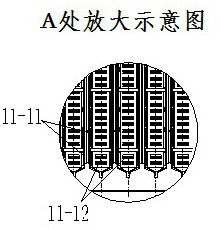

Clean-burning coal vacuum boiler

InactiveCN101178172ABurn fullyImprove combustion efficiencyWater-tube boilersCombustion chamberAtmospheric air

The invention relates to a clean coal-burning vacuum boiler, belonging to the technical filed of a vacuum boiler. The invention comprises a boiler body, a drum and a grate. The drum is arranged at the upper part of the boiler body and the grate is arranged at the lower part of the boiler. A burning chamber is arranged at the middle part of the boiler body. The invention is characterized in that the front part of the burning chamber of the boiler body is provided with a gas generation chamber; the upper part of the gas generation chamber is provided with a gas outlet; the gas outlet is communicated with the upper part of the burning chamber; the gas generation chamber is communicated with the lower part of the burning chamber and is provided with a fixed grate; an exit of the burning chamber is provided with a dedusting water-cooling pipe bank; and the two sides of the burning chamber are provided with a boiler lateral water-cooling tank. The invention has the advantages of increasing the coal burning efficiency, saving the energy resource, realizing smoke eliminating and dust removing effects, decreasing the atmosphere environmental pollution, economy and environmental protection, etc. The invention can be widely used in the coal-burning vacuum boiler industry.

Owner:天津天大胜远冷暖设备有限公司

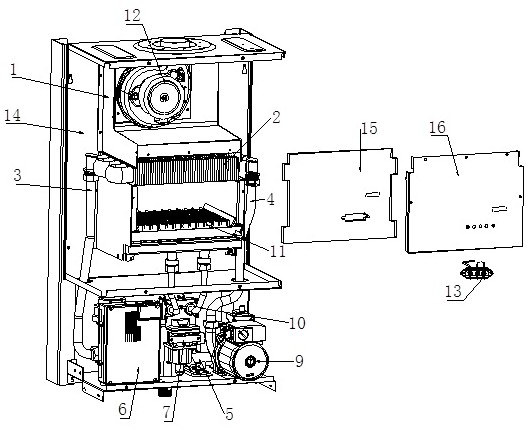

Atmospheric combustion low-nitrogen wall-hanging stove

PendingCN114353332AReduce emission contentSmall minimum loadControl of fluid heatersCombustorExhaust fumes

The invention discloses an atmospheric combustion low-nitrogen wall-hanging furnace which is characterized by comprising a furnace body, the device comprises an exhaust fume collecting hood assembly, a heat exchanger, a heating water outlet pipe assembly, a heating water inlet pipe assembly, a water inlet valve assembly, a main controller, a segmented fuel gas proportional valve, a heating water return pipe fitting, a circulating water pump, a gas inlet pipe assembly, an atmospheric combustion low-nitrogen combustor, an up-draft direct-current fan and an ignition needle assembly. The up-draft direct-current fan is fixed in the exhaust fume collecting hood assembly, and the main controller is connected with the up-draft direct-current fan; the heat exchanger is installed below the exhaust fume collecting hood assembly, and water heated by the heat exchanger flows out through the heating water outlet pipe assembly. The ignition needle assembly is of a three-needle integrated structure, is installed on the outer side of the atmospheric combustion low-nitrogen combustor and has the ignition and flame feedback functions. The device is simple in structure, better in cost performance, easy to control and relatively low in technical requirement.

Owner:MACRO THERMAL ENERGY TECH

All-terrain vehicle and all-terrain vehicle control method

PendingCN111376743ASolve the problem of high emission contentReduce emission contentHybrid vehiclesGas pressure propulsion mountingControl theoryMechanical engineering

The invention provides an all-terrain vehicle and an all-terrain vehicle control method. The all-terrain vehicle comprises a hybrid power system, a transmission mechanism and an axle, wherein the hybrid power system is in driving connection with the transmission mechanism; and the transmission mechanism is in driving connection with the axle so as to enable the hybrid power system to drive the axle to move through the transmission mechanism. According to the all-terrain vehicle, the problem that the harmful gas emission content of an all-terrain vehicle in the prior art is high is solved.

Owner:NINE INTELLIGENT CHANGZHOU TECH CO LTD

Metal re-forming assembly line

ActiveCN111748692AReduce emission contentReduce pollutionCharge treatment typeCrucible furnacesImaging processingEngineering

The invention provides a metal re-forming assembly line. The assembly line is characterized by comprising multiple smelting furnaces which communicate with one another, a casting cavity and a drainagegroove used for draining molten metal into the casting cavity, smelting cavities are formed in the smelting furnaces, one end of the drainage groove communicates with each smelting cavity, the otherend of the drainage groove communicates with the casting cavity, in the flowing direction of the molten metal, the casting cavity is located on the downstream portions of the smelting furnaces, a worktable is arranged in the casting cavity, a conveying assembly and multiple workstation modules are arranged on the worktable, each workstation module comprises an imaging workstation block, a deburring workstation block and an image processing assembly, each imaging workstation block comprises an imaging instrument, a lens of each imaging instrument faces the conveying assembly, the imaging instruments are in communication connection with the image processing assemblies, each deburring workstation block comprises a deburring gun and a driving device for driving the deburring gun to move relative to the conveying assembly, the driving devices are in communication connection with the image processing assemblies, according to the assembly line, the production efficiency is improved, labor force is reduced, and the automatic intelligent degree is high.

Owner:FOSHAN NANHAI HUITAI TECH MACHINE

Solid waste two-stage pyrolysis gasification system based on fluidized bed and moving bed

ActiveCN105419877BEmission reductionReduce emission contentGasification processes detailsGranular/pulverulent flues gasificationGas solidCyclonic separation

Owner:代建军 +1

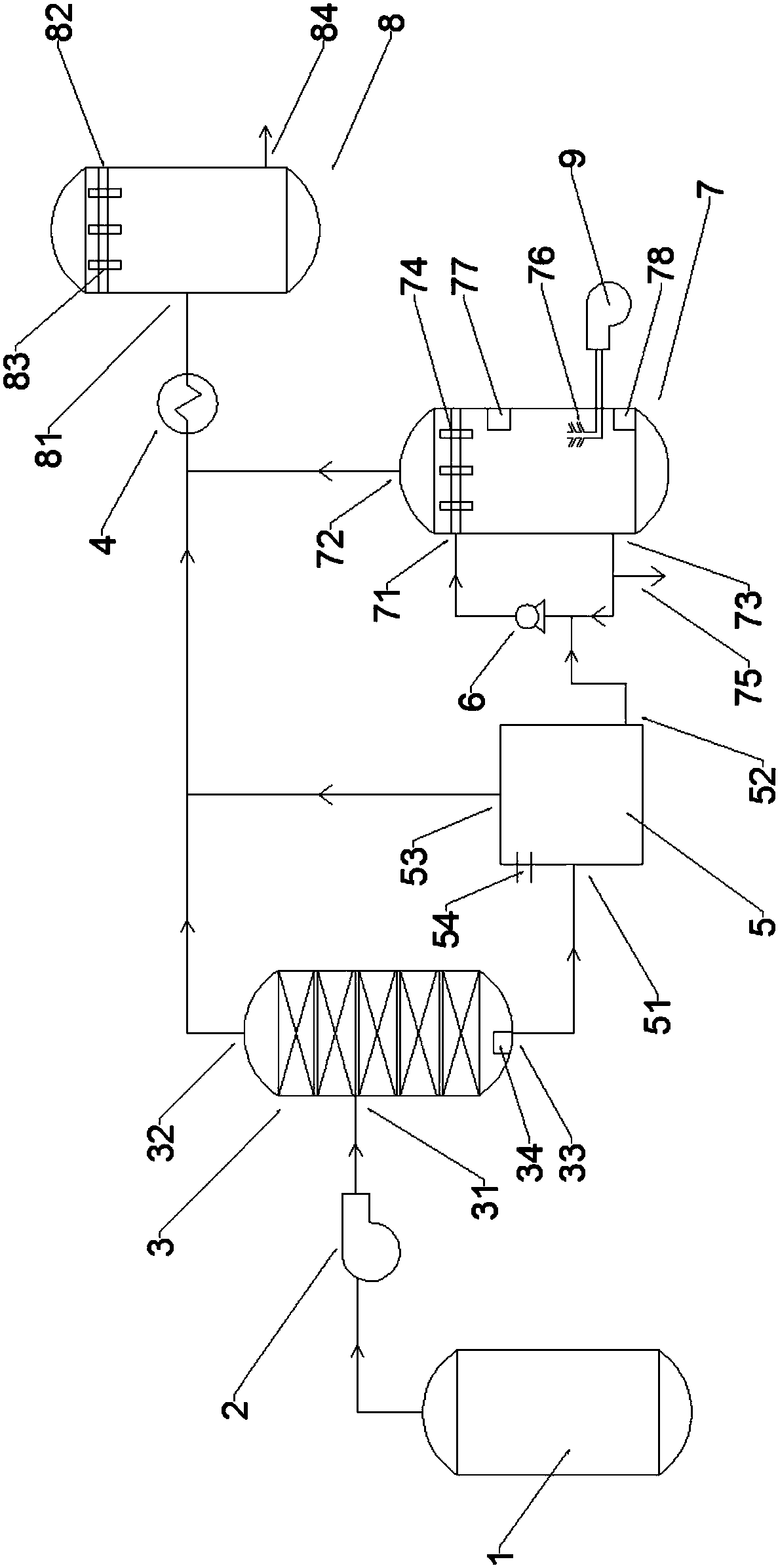

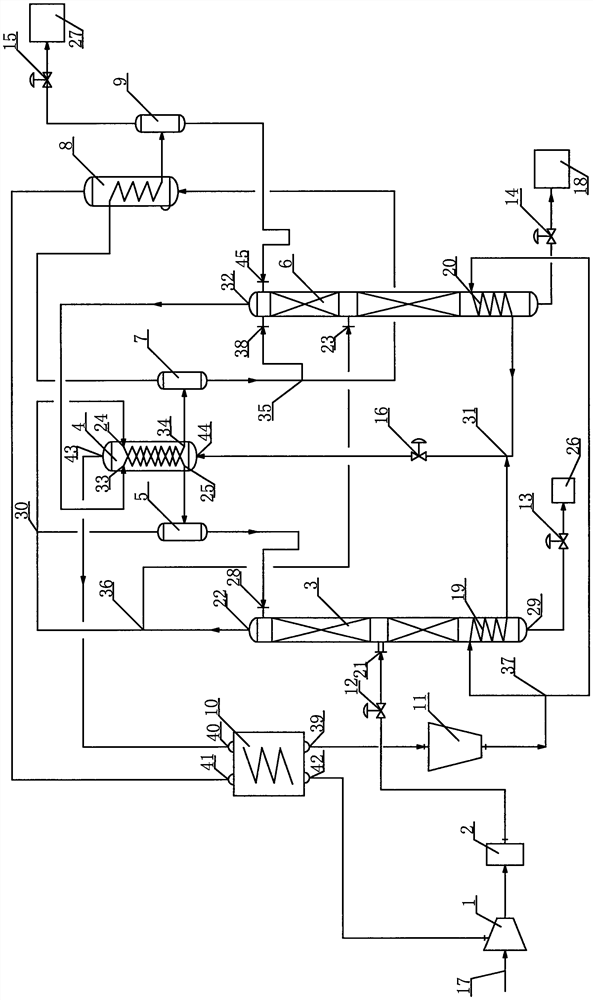

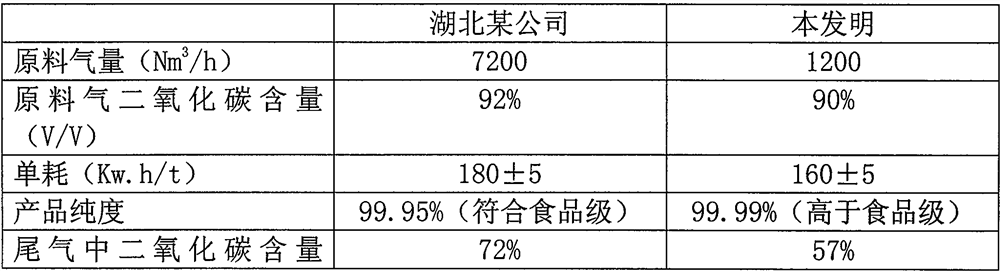

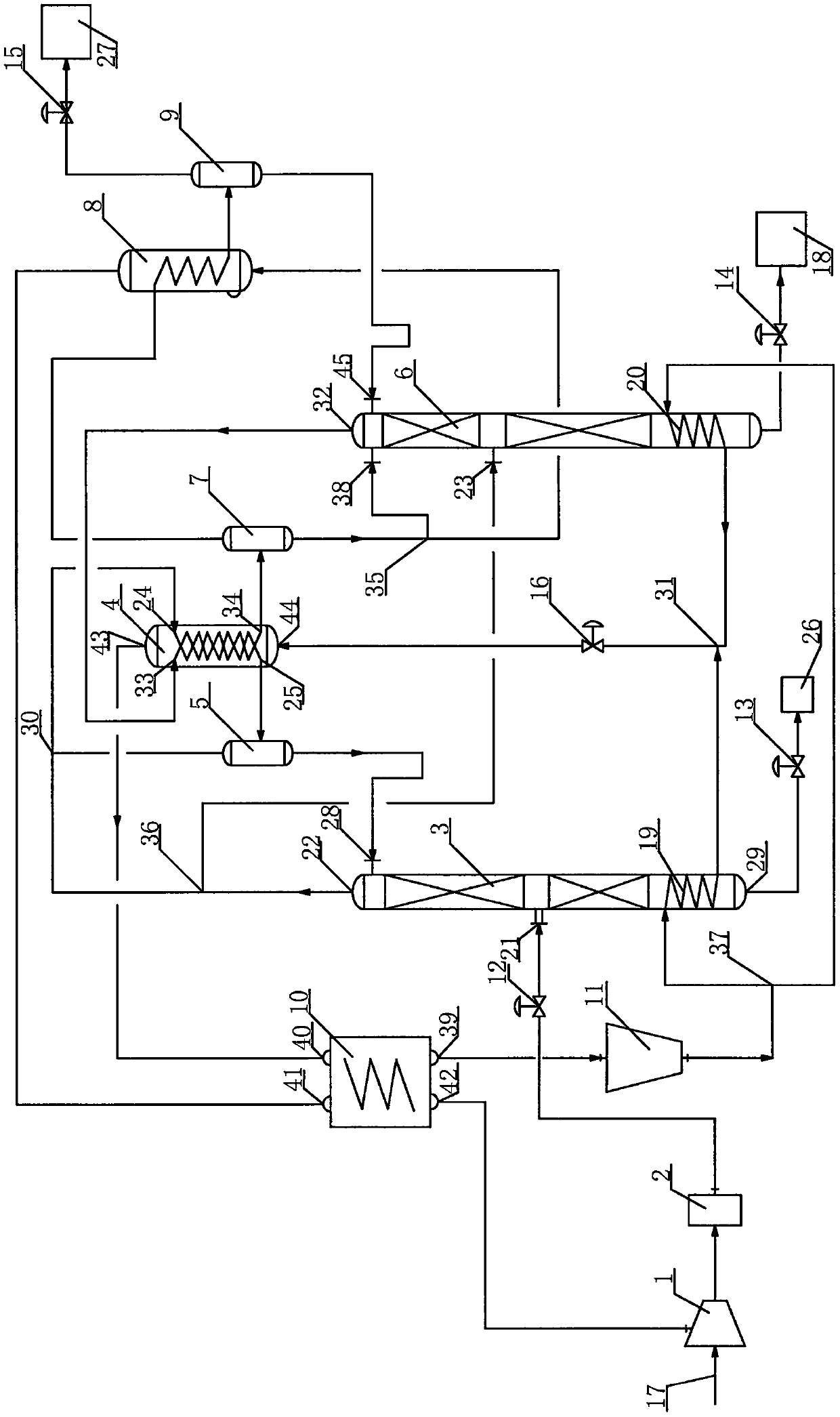

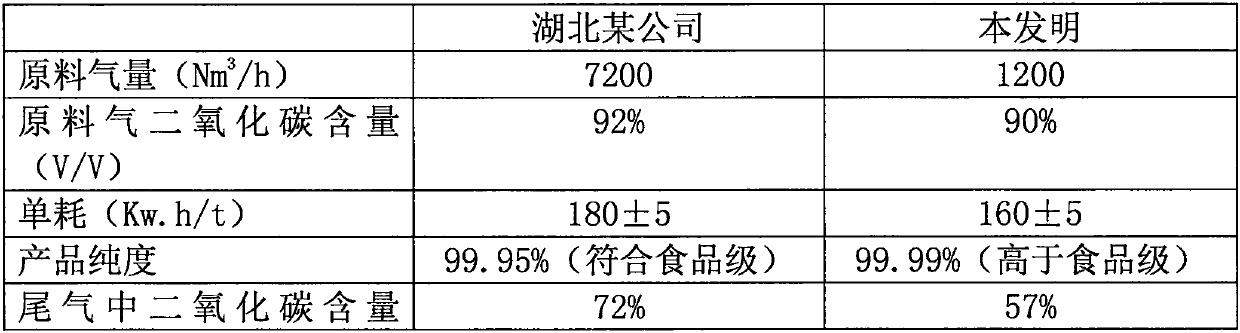

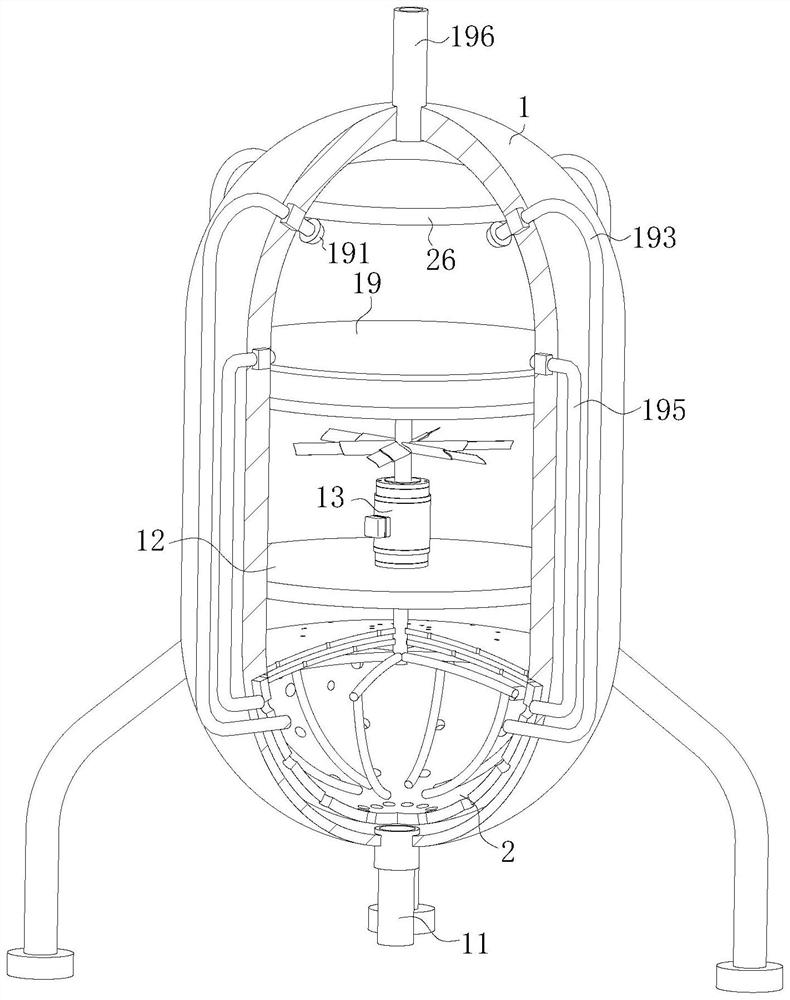

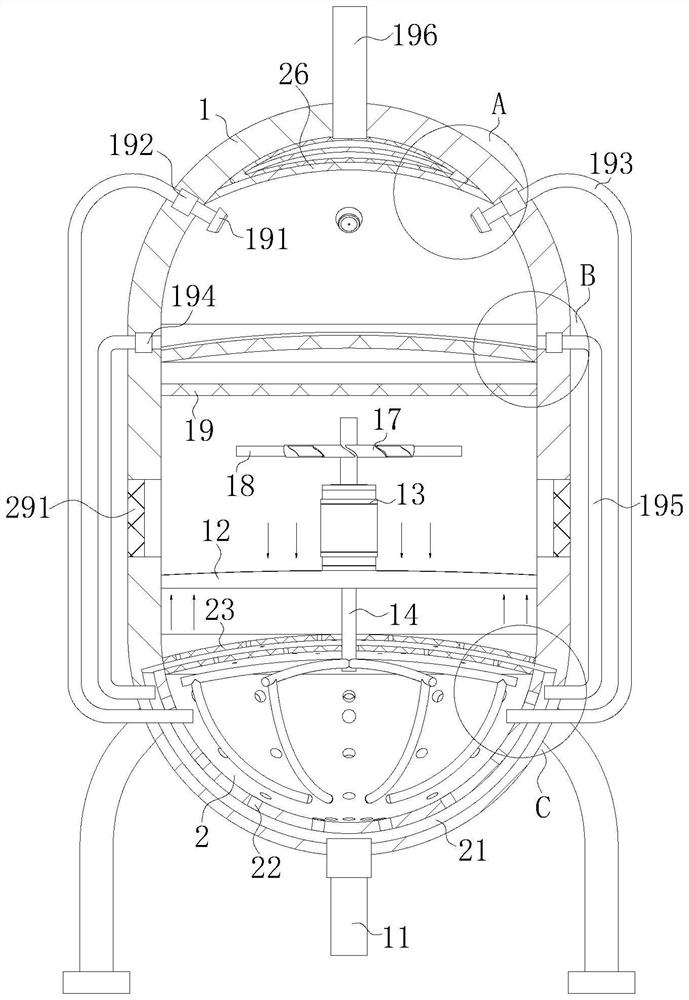

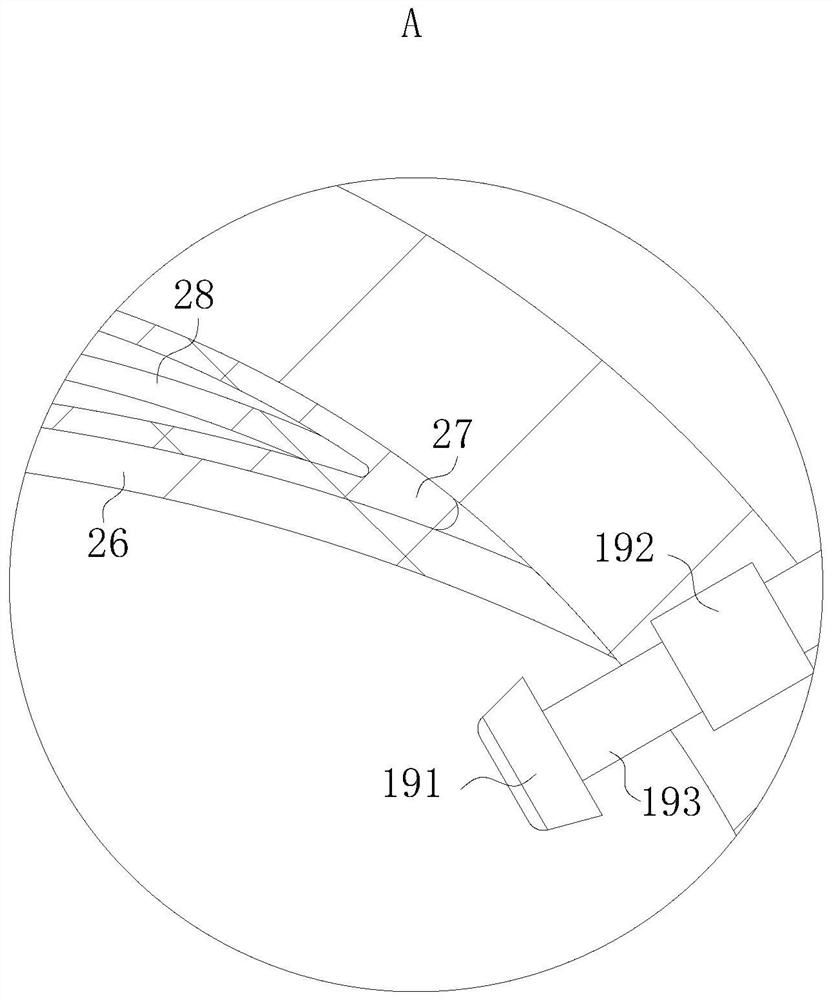

A device and production method for producing food-grade CO2 using nh3/co2 cascade refrigeration

The invention belongs to a kind of adopting NH 3 / CO 2 Cascade refrigeration produces food grade CO 2 A device and a production method; comprising a compressor connected to a feed gas pipeline, the outlet of the compressor is connected to the first feed gas inlet of the first flash tower through a drier, and the gas phase outlet at the top of the first flash tower is connected to the first tee through a first tee The first raw material gas inlet of the second flash tower is connected, and the liquid phase outlet at the bottom of the second flash tower is connected with food grade CO 2 The storage tanks are connected; it has the advantages of being able to reduce the energy consumption of food-grade carbon dioxide produced by the same type of raw material gas by 10%, and the emission content of carbon dioxide in the tail gas to less than 60%.

Owner:陈剑军

A solid waste three-bed combined pyrolysis gasification and tar cracking integrated system

ActiveCN105885950BEmission reductionReduce emission contentGasifier feeding meansBiofuelsCycloneFluidized bed

Owner:BEIJING UNIV OF CHEM TECH

Device for producing food-grade CO2 through NH3/CO2 cascade refrigeration and production method

The invention belongs to the field of a device for producing food-grade CO2 through NH3 / CO2 cascade refrigeration and a production method. The device comprises a compressor which is connected with a raw material gas pipeline, an outlet of the compressor is connected with a first raw material gas inlet of a first flash tower through a drier, a gas phase outlet at the top of the first flash tower is connected with a first raw material gas inlet of a second flash tower through a first tee, and a liquid phase outlet at the bottom of the second flash tower is connected with a food-grade CO2 storage tank. The device and the production method have the advantages that the energy consumption for producing the food-grade carbon dioxide through the same-type raw material gas can be reduced by 10%, and the emission content of the carbon dioxide in tail gas can be reduced to 60% or below.

Owner:陈剑军

Three-stage tail gas purification tower for high-concentration nitric oxide

PendingCN111603923AAdd process stepsSimple processCombination devicesNitrogen oxidesElectric machine

The invention belongs to the technical field of nitric oxide tail gas purification towers, and particularly relates to a three-stage tail gas purification tower for high-concentration nitric oxide. The tower comprises a tower body; a gas inlet pipe is fixedly connected to the center line of the tower body and in the inner wall below the tower body; a filter plate is fixedly connected into the inner wall of the tower body, and a purification cavity is formed below the filter plate; an adsorption liquid is contained in the purification cavity; blocky flourishing carbon is contained in the purification cavity; and a motor is fixedly connected to the upper end surface of the filter plate and located at the center line of the filter plate, and the motor is electrically connected with a controller through a wire. The tower is mainly used for solving the problems that a nitric oxide purification tower device in the prior art is large in occupied area, moving and overhauling are inconvenient,meanwhile, high-concentration NOx treatment needs to be supplemented with air to be diluted, the process steps of the nitric oxides are increased, waste water and waste residues are prone to being generated, the generated waste water and waste residues need to be subjected to secondary treatment, and the process steps of nitric oxide purification are increased.

Owner:朱文艳

A metal reshaping assembly line

ActiveCN111748692BReduce emission contentReduce pollutionCharge treatment typeCrucible furnacesImaging processingProcess engineering

The invention provides a metal reshaping assembly line, which is characterized in that it includes several interconnected smelting furnaces and casting chambers and a drainage groove for draining molten metal into the casting chamber; the smelting furnace is provided with a smelting chamber ; One end of the drainage groove communicates with each smelting chamber, and the other end communicates with the casting chamber; along the flow direction of the molten metal, the casting chamber is located downstream of the smelting furnace; a workbench is provided in the casting chamber; There are conveying components and several groups of workstation modules; the workstation modules include imaging workstation blocks, deburring workstation blocks and image processing components; The components are connected in communication; the deburring station block includes a deburring gun and a driving device that drives the deburring gun to move relative to the conveying component, and the driving device communicates with the image processing component. The invention has the advantages of improving production efficiency, reducing labor force and high degree of automation and intelligence.

Owner:FOSHAN NANHAI HUITAI TECH MACHINE

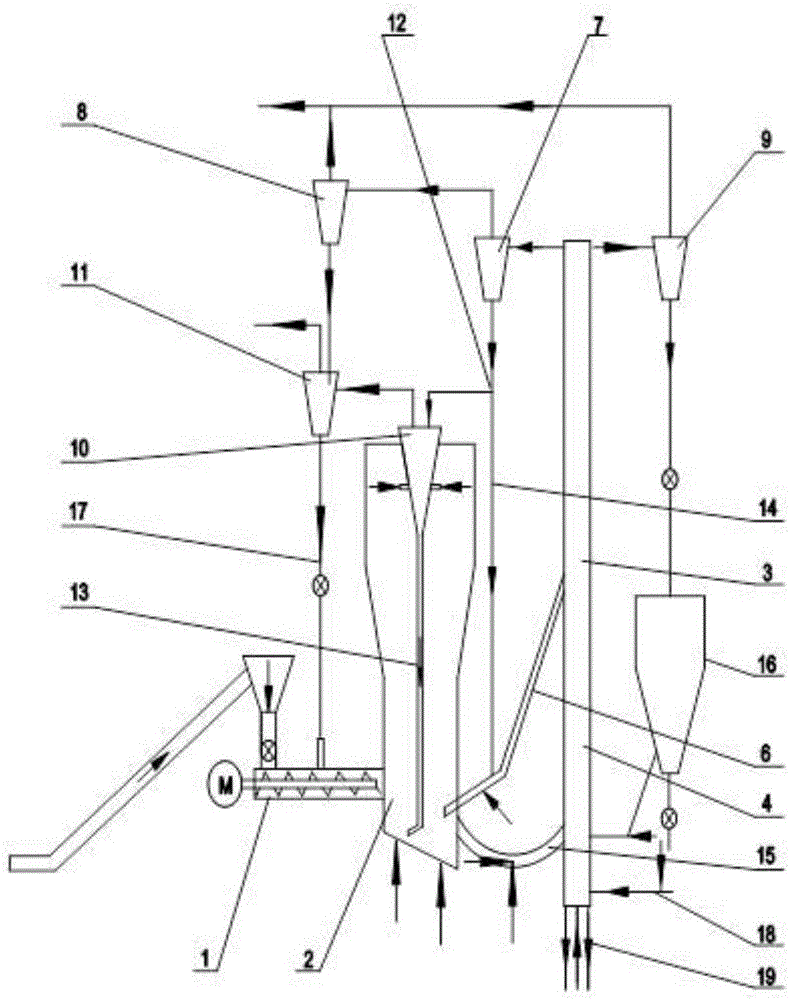

A two-stage pyrolysis gasification system for solid waste

ActiveCN105419878BFully lysedEasy to operateGasification processes detailsGranular/pulverulent flues gasificationCycloneGas solid

The invention relates to a two-section pyrolysis and gasification system of solid waste. The two-section pyrolysis and gasification system is provided with a solid waste material feeding system, a pyrolysis device, a circulating fluidized bed oxidization gasification device system, an oxidization gasification device cyclone separator and a cyclone separation type reactor. Two-section pyrolysis and gasification is realized by utilizing a circulating fluidized bed oxidization gasification device combining a gas stripping pipe and a sedimentation pipe and a pyrolysis reactor combining a moving bed and a fluidized bed, and hot bed materials and pyrolyzed gas are sufficiently mixed by using the cyclone separation type reactor, so that tar cracking and gas purification are greatly accelerated; synthetic gas and pyrolyzed gas can be produced simultaneously through an optimized design of the structures of the oxidization gasification device and the pyrolysis reactor, mixed use of the different bed materials, improvement of a material bed circulating flowing system and a gas-solid mixing level, and improvement of the feeding system, so that the whole pyrolysis and gasification efficiency and the heat value of the pyrolyzed gas are greatly improved and the content of tar in the synthetic gas and the pyrolyzed gas is reduced, and furthermore, the clean synthetic gas and pyrolyzed gas, which have high quality, are prepared.

Owner:代建军 +1

Moulded coal used for decoupling burning and method of producing the same

InactiveCN101130704BSolve the problems existing in useSolve the real problemSolid fuelsAdjuvantSoluble glass

The invention discloses a combustion decoupling coal and preparing method, which comprises the following parts: fire coal made of bituminite and anthracite with weight rate at 70-80: 30-20, stable composite liquid composed of stabilizer solution and soluble glass with weight rate at 17-23: 83-77 and the weight percentage density of the stabilizer at 0. 08%-0. 12%, methyl hydroxypropylcellulose asthe stabilizer; using calcium lime as sulfur fixing agent with content as 1. 4-1. 8 times as fire coal, 1%-2% potassium nitrate combustion adjuvant. The invention has stable source for raw material ofmolded coal, good using and storing property, low preparing cost, which realizes desulfurizing, denitrating, dedusting and environment protection, which can replace fuel to reduce combusting cost greatly and release insufficiency of the fuel.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recovering and extracting hydrogen based on discharged torch waste gas

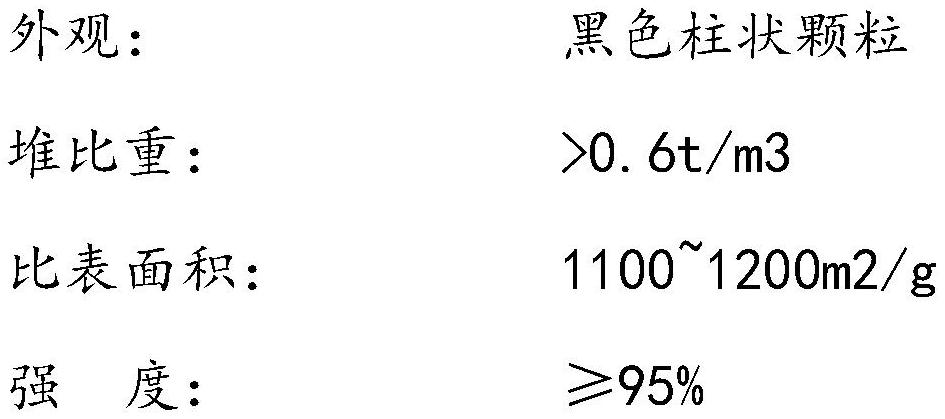

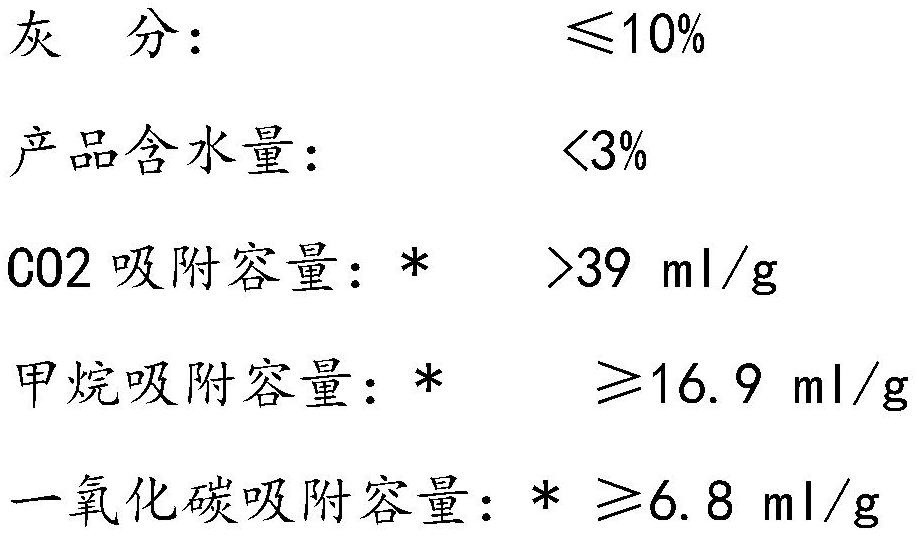

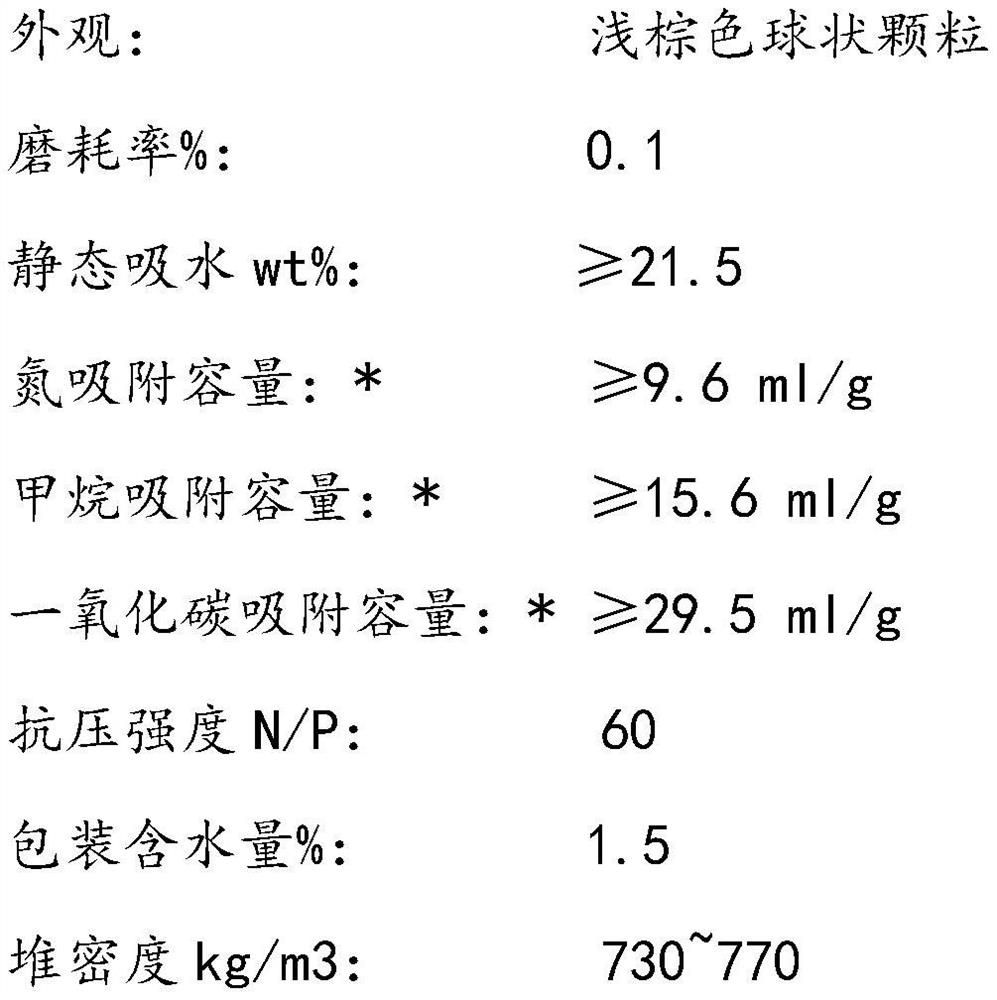

PendingCN114348962ALow running costReduce C emission content and comprehensive energy consumption of the production lineHydrogen separation using solid contactChemistryActivated carbon

The invention relates to a method for recovering and extracting hydrogen based on discharged torch waste gas, which comprises the following steps: 1) transformation: carrying out transformation treatment on the waste gas by using a sulfur-tolerant cobalt transformation catalyst, mixing steam and the waste gas in a mixing tank, entering a transformation bed to carry out transformation reaction, and converting CO into hydrogen through the transformation reaction; 2) decarburization: entering an adsorption bed for decarburization, removing most of ineffective components in the converted gas, and performing high-pressure adsorption and low-pressure desorption; and 3) separation and purification: separating the decarbonized waste gas, adopting a single-bed adsorption procedure, and filling adsorbents activated aluminum oxide, activated carbon and molecular sieves in an adsorption bed. The method is free of raw material cost, a novel catalyst and an adsorbent are used according to the composition of the waste gas, and hydrogen with the purity larger than or equal to 99.8% is extracted. The C emission content and the comprehensive energy consumption of the production line are reduced while the operation cost of the production line is reduced. The economic and social benefits are obvious.

Owner:甘肃银光聚银化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com