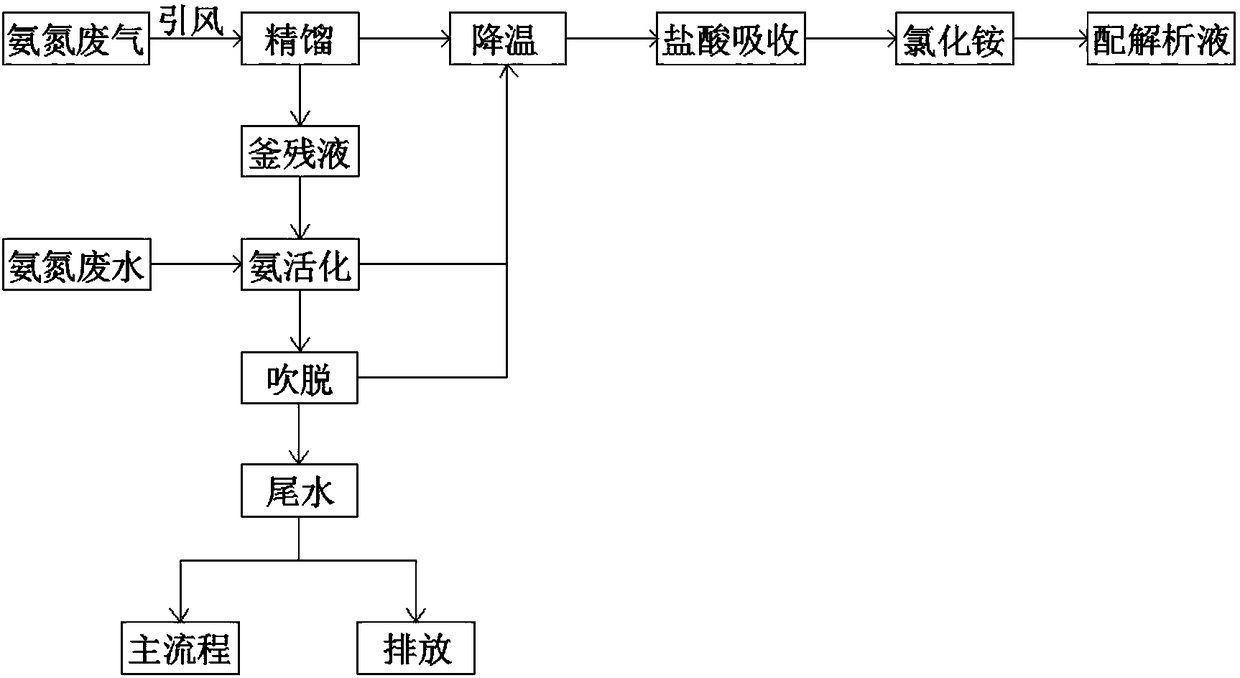

Ammonia recycling method and system in APT production process

A production process and ammonia recovery technology, applied in the field of ammonia recovery technology, can solve the problems of uncompetitiveness of enterprises, increased cost, and low available value, etc., to improve stripping efficiency, save energy consumption, and improve ammonia activation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

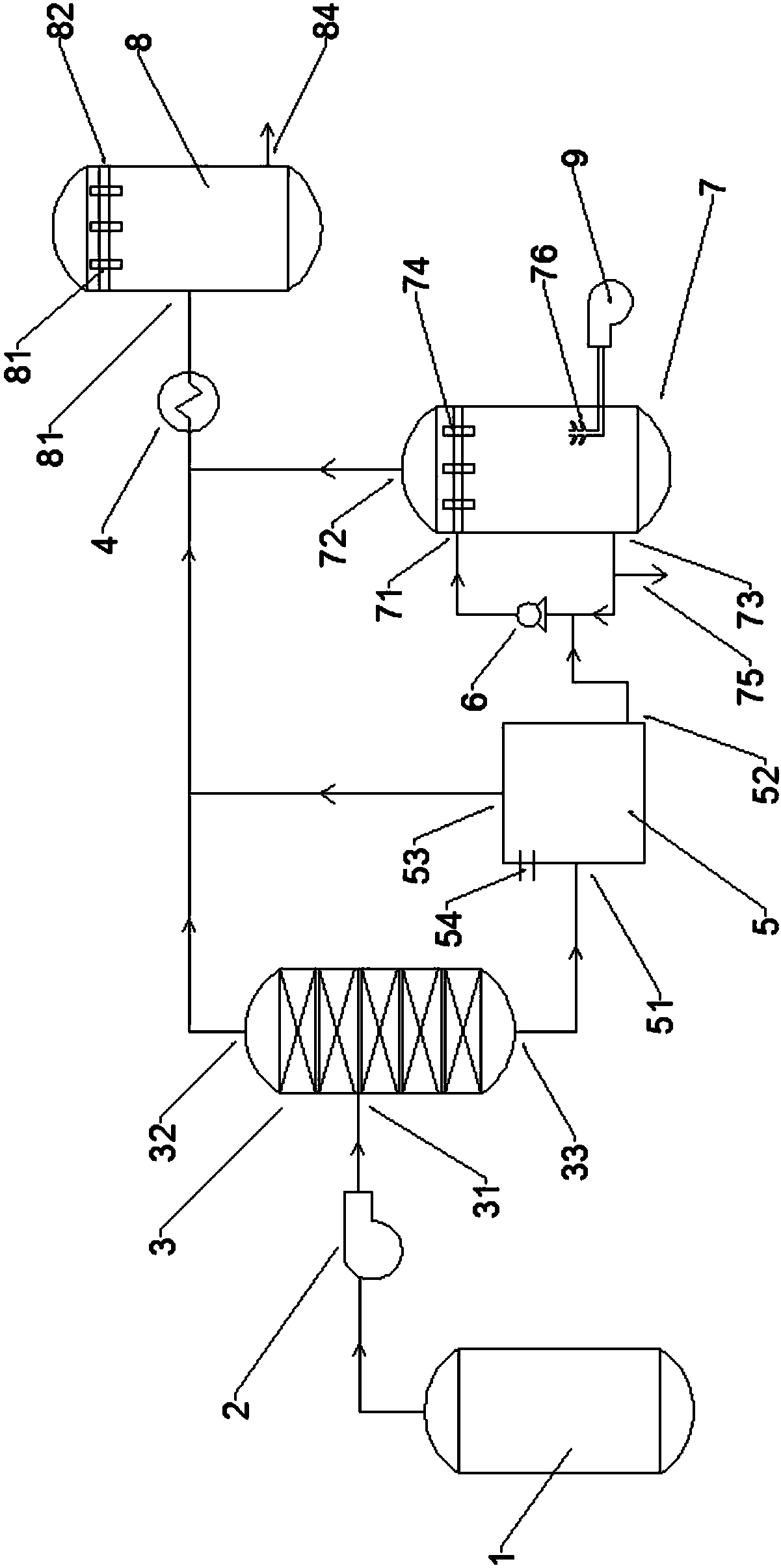

[0052] Such as image 3 As shown, the ammonia recycling system of the present embodiment includes an evaporation pot 1, a centrifugal blower 2, a rectification tower 3, a heat exchanger 4, a stirring tank 5, a stripping tower 7 and a hydrochloric acid absorption tower 8, wherein the centrifugal blower 2 The inlet of the inlet is connected to the hot state ammonia outlet of the evaporator 1, the outlet is connected to the gas inlet 31 of the rectifying tower 3, the ammonia tail gas outlet 32 of the rectifying tower 3 is connected to the inlet of the heat exchanger 4, and the outlet of the heat exchanger 4 is connected to the hydrochloric acid absorption tower The gas inlet 81 of 8; the outlet 33 at the bottom of the rectification tower 3 is connected to the inlet 51 of the stirring tank 5, and the waste water outlet 52 of the stirring tank 5 is connected to the liquid inlet 71 of the stripping tower 7 through the pump 6, and the waste gas outlet 53 is connected to the heat exc...

Embodiment 2

[0055] On the basis of Example 1, the device of the present invention is further described.

[0056] Such as image 3 As shown, the difference between the ammonia recycling system of this embodiment and that of Embodiment 1 is that the heat exchanger 4 is composed of a partitioned heat exchanger with high heat exchange efficiency; the stirring tank 5 adopts a mechanical stirring device with a large rotating speed, The solution is evenly dispersed, which can increase the activation rate of ammonia; the outlet 33 at the bottom of the rectification tower 3 and the position of the stripping tower 7 lower than the air outlet pipe 76 are equipped with ammonia nitrogen on-line monitors 34, 78, which accurately control the stillness after rectification. The residual liquid and the ammonia nitrogen content in the solution after stripping ensure that the ammonia nitrogen content of the waste water reaches the standard; the stripping tower 7 is also provided with a temperature controller...

Embodiment 3

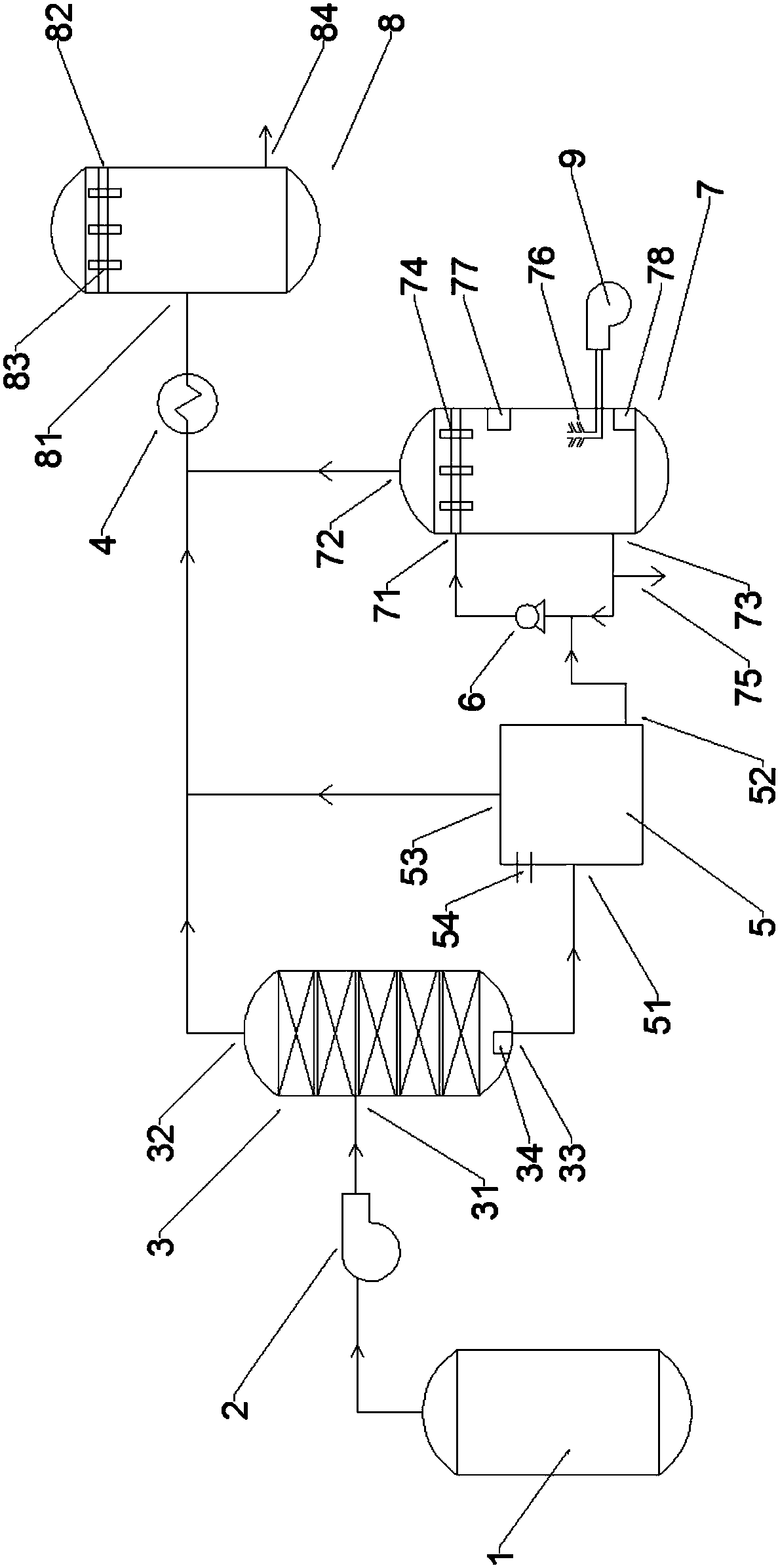

[0059] On the basis of Example 2, the device of the present invention is further described.

[0060] Such as image 3 As shown, the ammonia recycling system of the present embodiment differs from Embodiment 2 in that there are four air outlet pipes 76 on the stripping tower 7, and the hydrochloric acid absorption tower 8 adopts corrosion-resistant, large gas-liquid contact area, In the sieve tray tower with high absorption efficiency, its spray device 83 includes two spray heads 831, 832 arranged horizontally and vertically, such as Figure 5 As shown, wherein the horizontal shower head 831 is an annular shower head, and the annular shower head is provided with a plurality of nozzles 833, and the vertical shower head 832 includes at least two parallel shower heads, and the parallel shower head is provided with a plurality of nozzles 833; The spray structure is coordinated to ensure that the gas phase and the liquid phase can fully contact, improve the absorption efficiency, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com