Triphenyl phosphite processing and tail gas treating technology based on graphite condenser

A technology of triphenyl phosphite and graphite condenser, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as side reactions, failure to reach customers, air pollution, etc., and achieve improved recovery Effects of reusing, reducing energy consumption, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

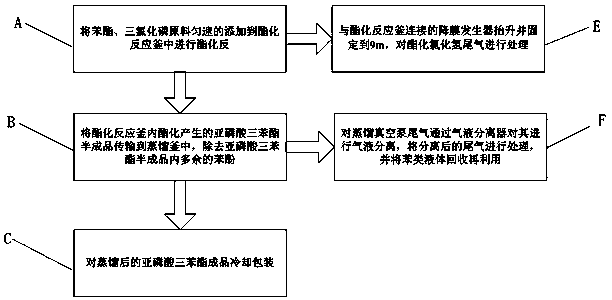

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 Shown, the processing and tail gas treatment technology of the triphenyl phosphite based on graphite condenser of the present invention comprise the following steps,

[0031] In step (A), the phenyl ester and phosphorus trichloride raw materials are added to the esterification reaction kettle at a uniform speed to carry out the esterification reaction. The esterification reaction kettle is equipped with a graphite condenser, and the esterification reaction kettle is in a vacuum environment. The reaction time is 15-16h, the temperature is 140-160°C, the feed rate is 300Kg / h, the esterification reaction produces esterified hydrogen chloride tail gas,

[0032] Among them, the added graphite condenser replaces the traditional stainless steel condenser, which can ensure that the semi-finished triphenyl phosphite produced by the lactonization of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com