Preparation method of pig manure activated carbon electrode material

A technology of electrode material and activated carbon, which is applied in the field of preparation of pig manure activated carbon electrode materials, to achieve the effects of increasing wettability, improving transmission speed and storage, and good charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

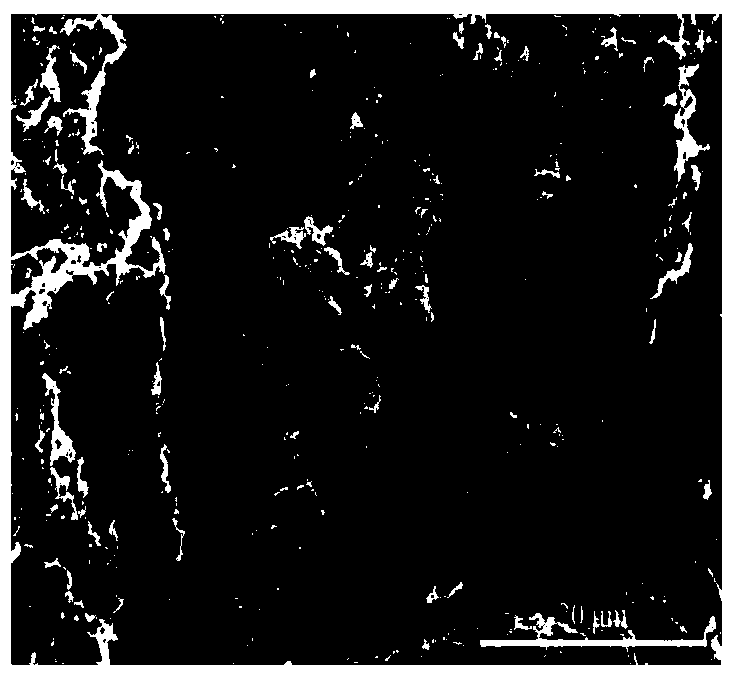

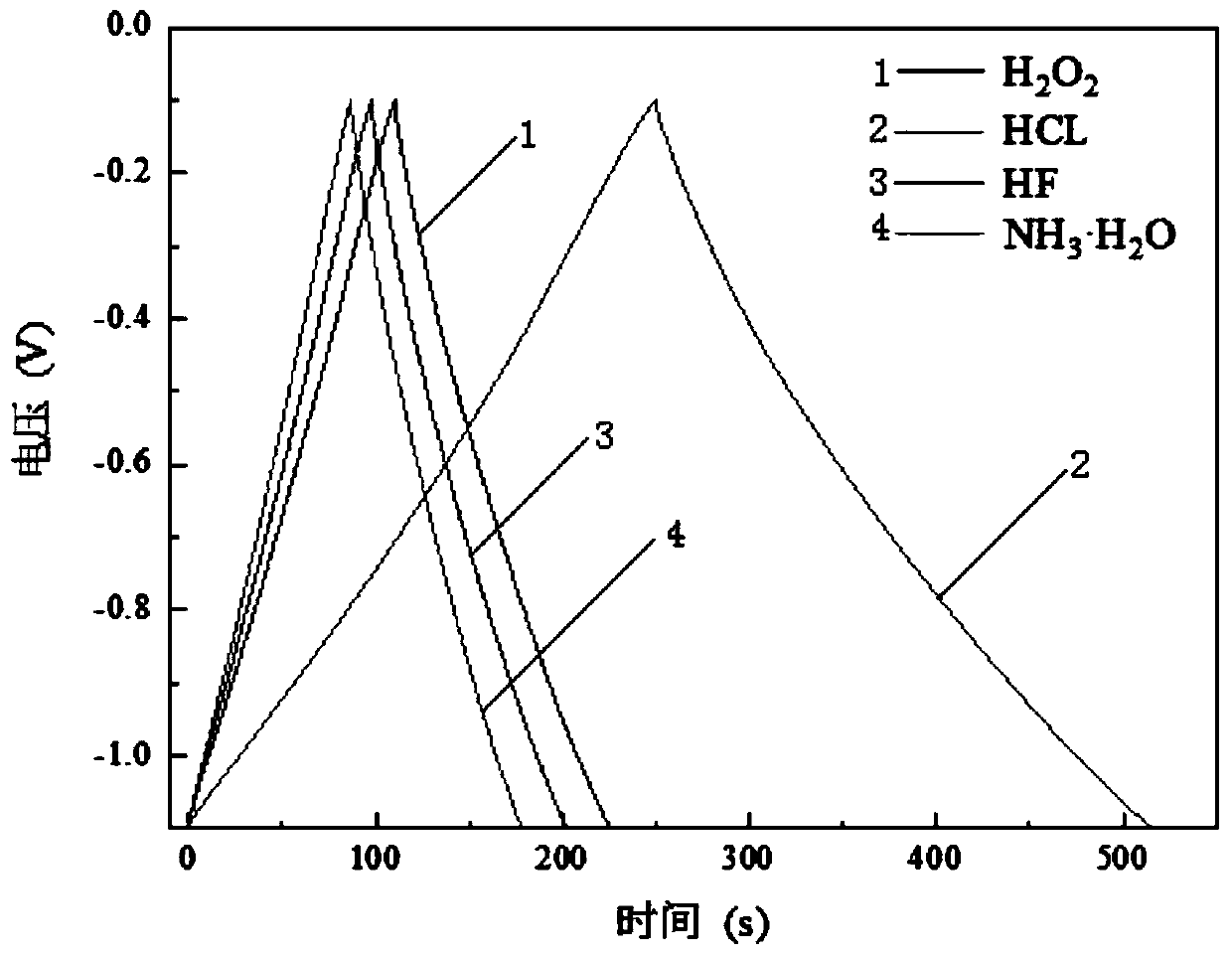

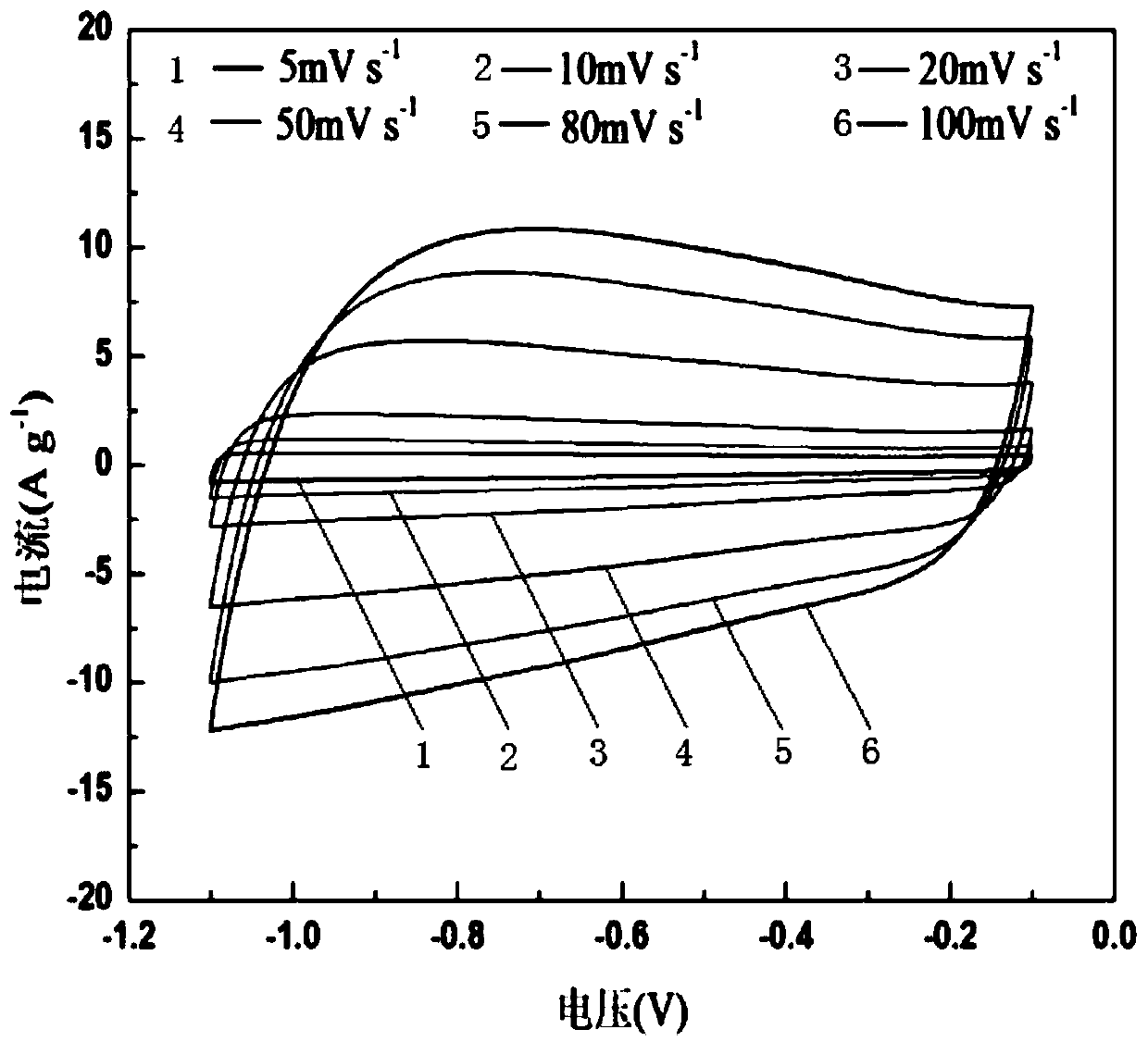

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation method of pig manure activated carbon electrode material is carried out according to the following steps in the present embodiment:

[0035] Step 1. Pretreatment: Add a hydrochloric acid solution with a concentration of 1mol / L to the dried pig manure, soak for 1.5 hours at room temperature, then wash with deionized water until neutral, and dry at 100°C to constant weight;

[0036] Step 2, then put it in a pyrolysis furnace, perform high temperature pyrolysis for 0.5h in a nitrogen atmosphere at 500°C, and cool down to room temperature with the furnace to obtain pyrolytic carbon, which is marked as PMB;

[0037] Step 3: Add 100ml of water to 10g of pyrolytic charcoal and a ratio of 4:1 to the pyrolytic charcoal obtained in step 2. Add KOH solution to the pyrolytic charcoal obtained in step 2, mix well, soak for 24 hours, and dry at 100°C to constant weight ;

[0038] Step 4, then under the protection of nitrogen, activate at 800°C for 1.5h ...

Embodiment 2

[0042]Embodiment 2: different from embodiment 1: the soaking treatment time is 2.0h in step one. Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com