Method for increasing electrochemical lithium storage content of nano-carbon tube

A carbon nanotube, electrochemical technology, applied in the direction of circuit, electrode manufacturing, electrical components, etc., can solve the problems of low output voltage, small output, high cost, etc., achieve large output current, improve utilization rate, and increase diffusion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

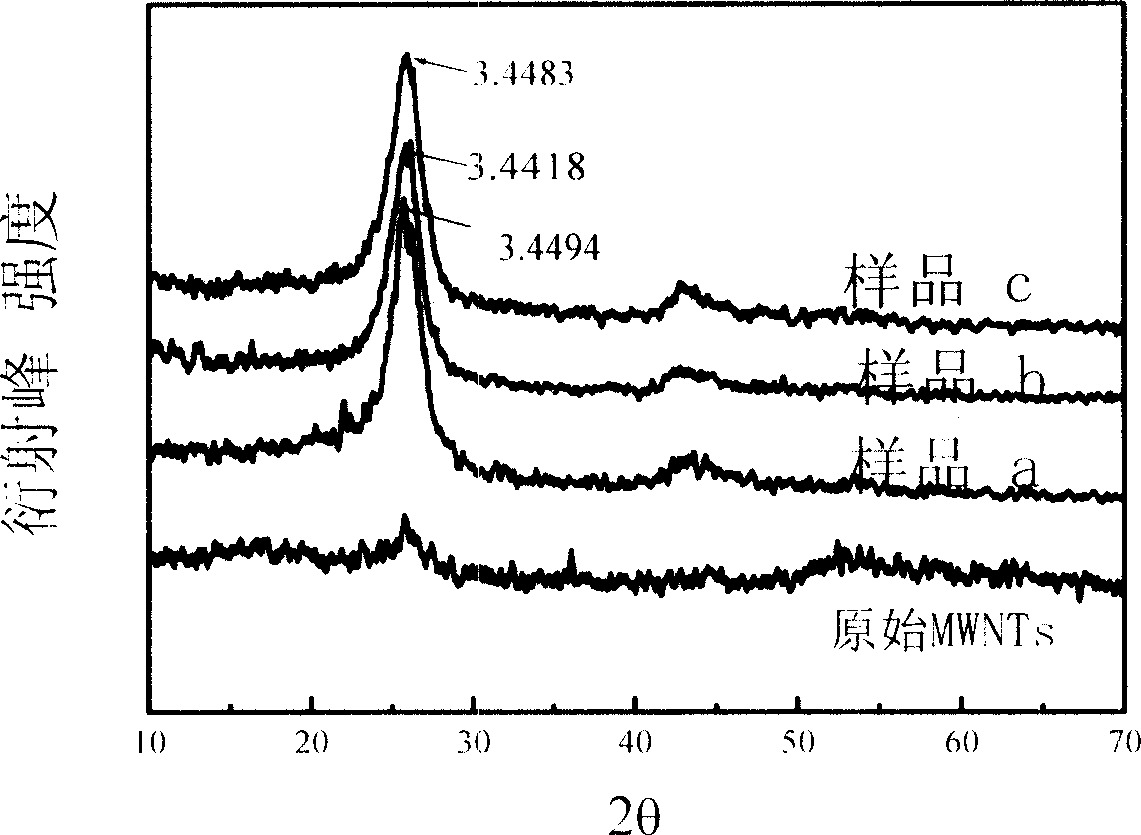

Embodiment 1

[0015] Immerse 500mg of native MWNTs in 40ml of H with different volume ratios 2 SO 4 : HNO 3 = 8:2 mixed solution, ultrasonic vibration for 0.5h, mechanical stirring for 0.5h, soaking treatment for 10h, temperature 60°C. The reaction product was washed with deionized water until it was neutral, heated at 500°C for 2 hours in an air atmosphere, and then cooled and allowed to stand for 10 hours. The product was soaked in 2wt% LiOH solution for 10 hours, and the obtained sample was washed with deionized water, filtered, and vacuum-dried, and then assembled into a button battery for electrochemical performance testing.

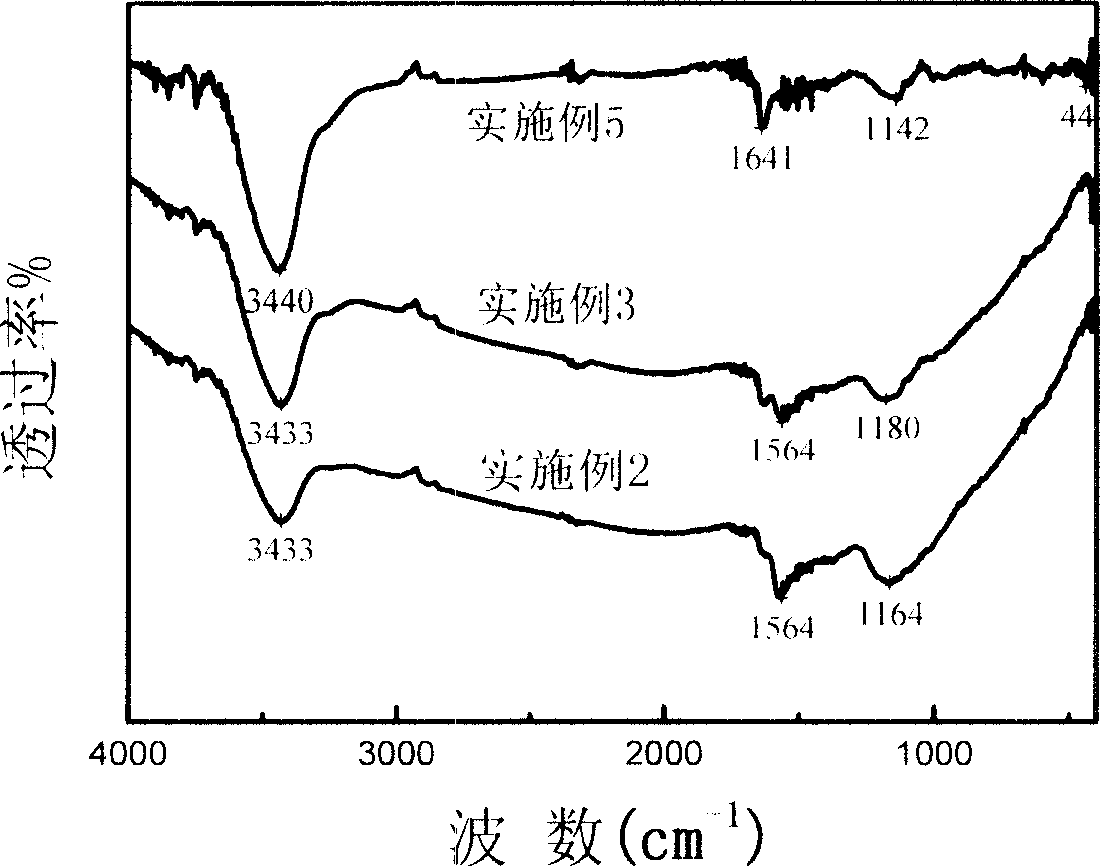

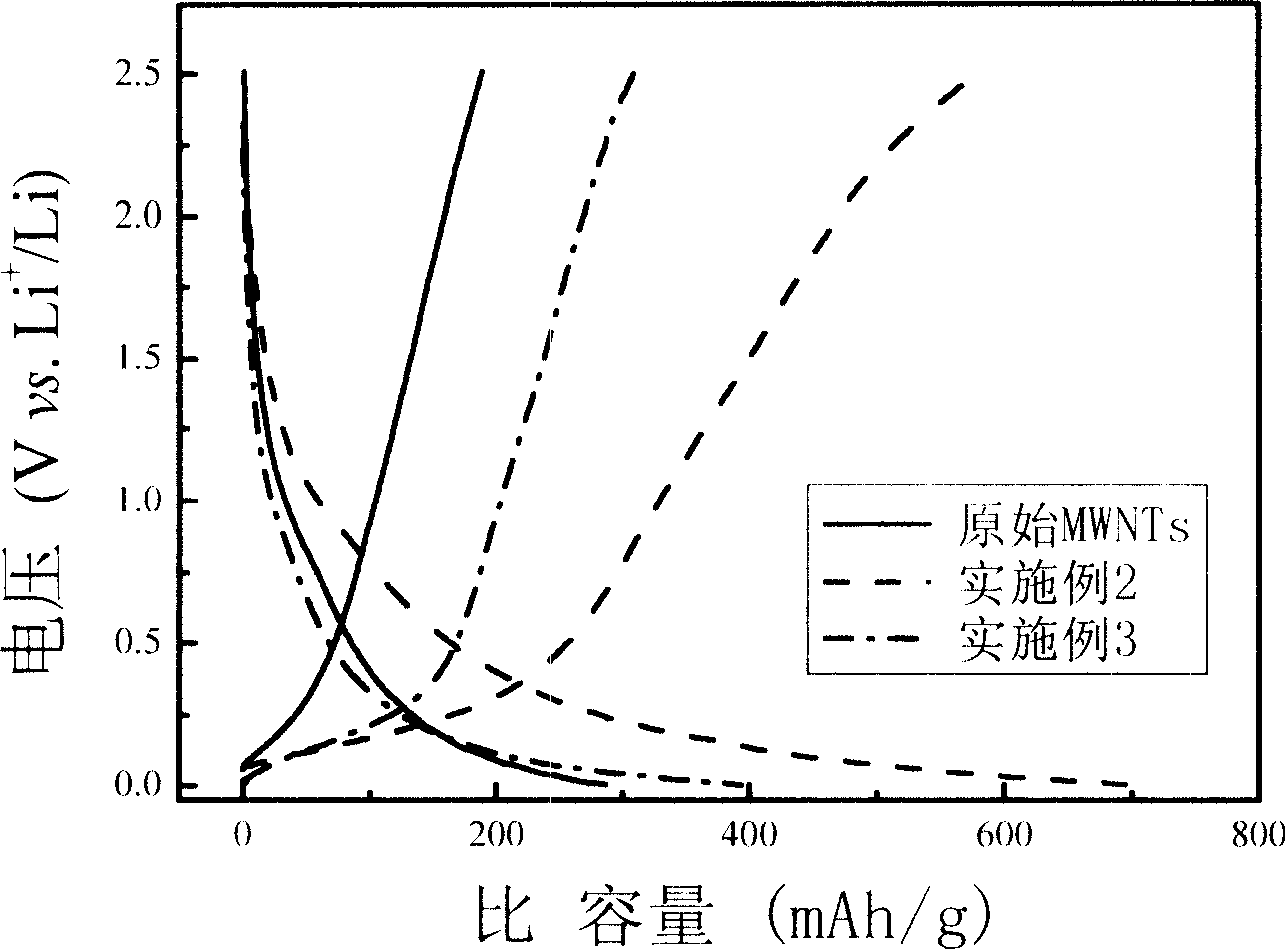

Embodiment 2

[0017] Immerse 300mg of native MWNTs in 30ml of H with different volume ratios 2 SO 4 : HNO 3 = 8:2 mixed solution, ultrasonic vibration for 2.5h, mechanical stirring for 2.5h, soaking treatment for 10h, temperature 60°C. The reaction product was washed with deionized water until neutral, heated at 350° C. for 2 h under an air atmosphere, and then cooled and allowed to stand for 10 h. Products with saturated Li 2 CO 3 The solution was soaked for 4 hours, and the obtained samples were washed with deionized water, filtered, dried in vacuum and then assembled into button batteries for electrochemical performance testing.

Embodiment 3

[0019] Immerse 1g of native MWNTs in 40ml of H with different volume ratios 2 SO 4 : HNO 3 = 6:4 mixed solution, ultrasonic vibration for 2h, mechanical stirring for 1.5h, soaking treatment for 10h, temperature 50°C. The reaction product was washed with deionized water until it was neutral, heated at 500°C for 1.5h under an air atmosphere, and cooled for 10h. The product was soaked in 2wt% LiOH solution for 16 hours, and the obtained sample was washed with deionized water, filtered, dried in vacuum, and then assembled into a button battery for electrochemical performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com