Patents

Literature

31results about How to "Reduce tube length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

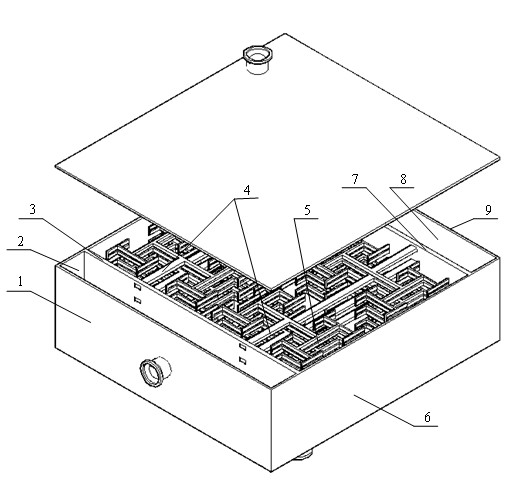

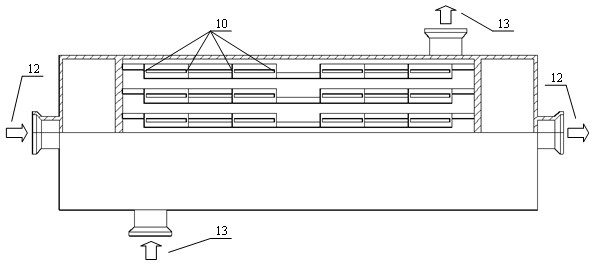

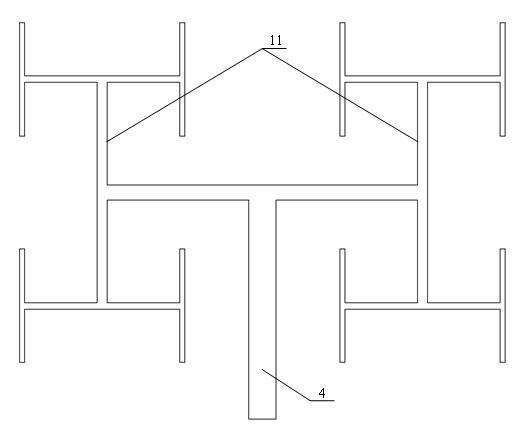

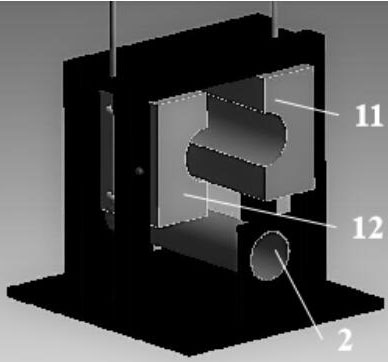

I-shaped tree type cross flow heat exchanger

InactiveCN102080937AIncrease the heat exchange areaImprove heat transfer coefficientHeat exchanger casingsStationary tubular conduit assembliesUnit structureEngineering

The invention discloses an I-shaped tree type cross flow heat exchanger which comprises a heat exchange tube bundle, a shell, a tube box and a tube plate, wherein the tube box and the tube plate are positioned at two sides of the shell; two ends of the heat exchange tube bundle are fixed on the tube plate, and are communicated with the tube box after penetrating through the tube plate; the heat exchange tube bundle is of the I-shaped tree structure; the I-shaped tree structure at least comprises one tree unit structure, wherein each tree unit structure comprises heat exchange tube bundles with two layers of tree structures and tail end communicating pipelines, and the last stage branch ports of the heat exchange tube bundles of the two layers of tree structures are communicated by the tail end communicating pipelines. According to the invention, the shell space is fully utilized, the heat exchange area required by the heat exchange of fluid is increased greatly, the path optimization functions of fluid transportation and energy transmission are realized, the power consumption of a fluid flow pump can be decreased effectively, and the flow heat exchange can be intensified, and the aim of efficient heat exchange and energy conservation is achieved.

Owner:SOUTHEAST UNIV

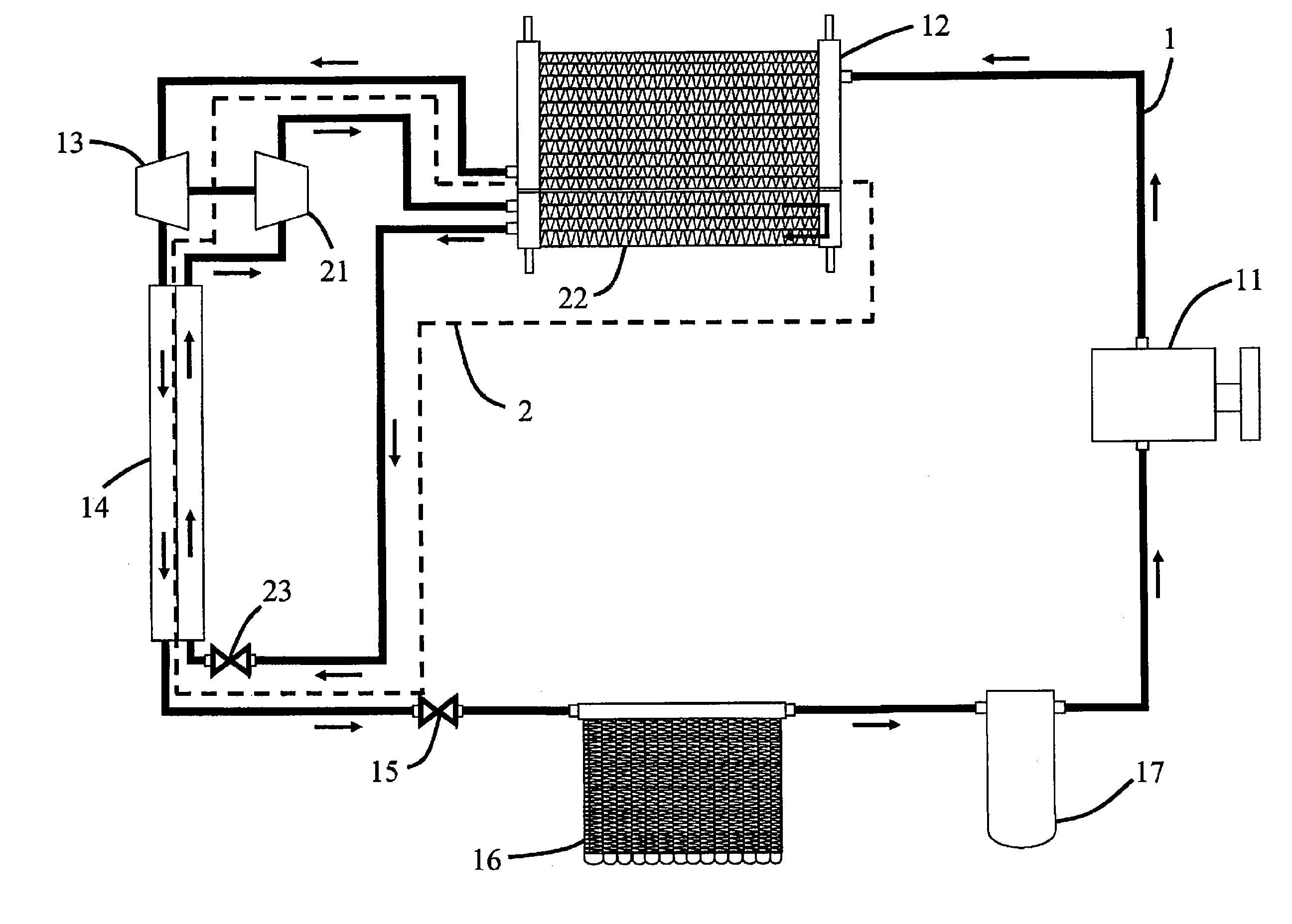

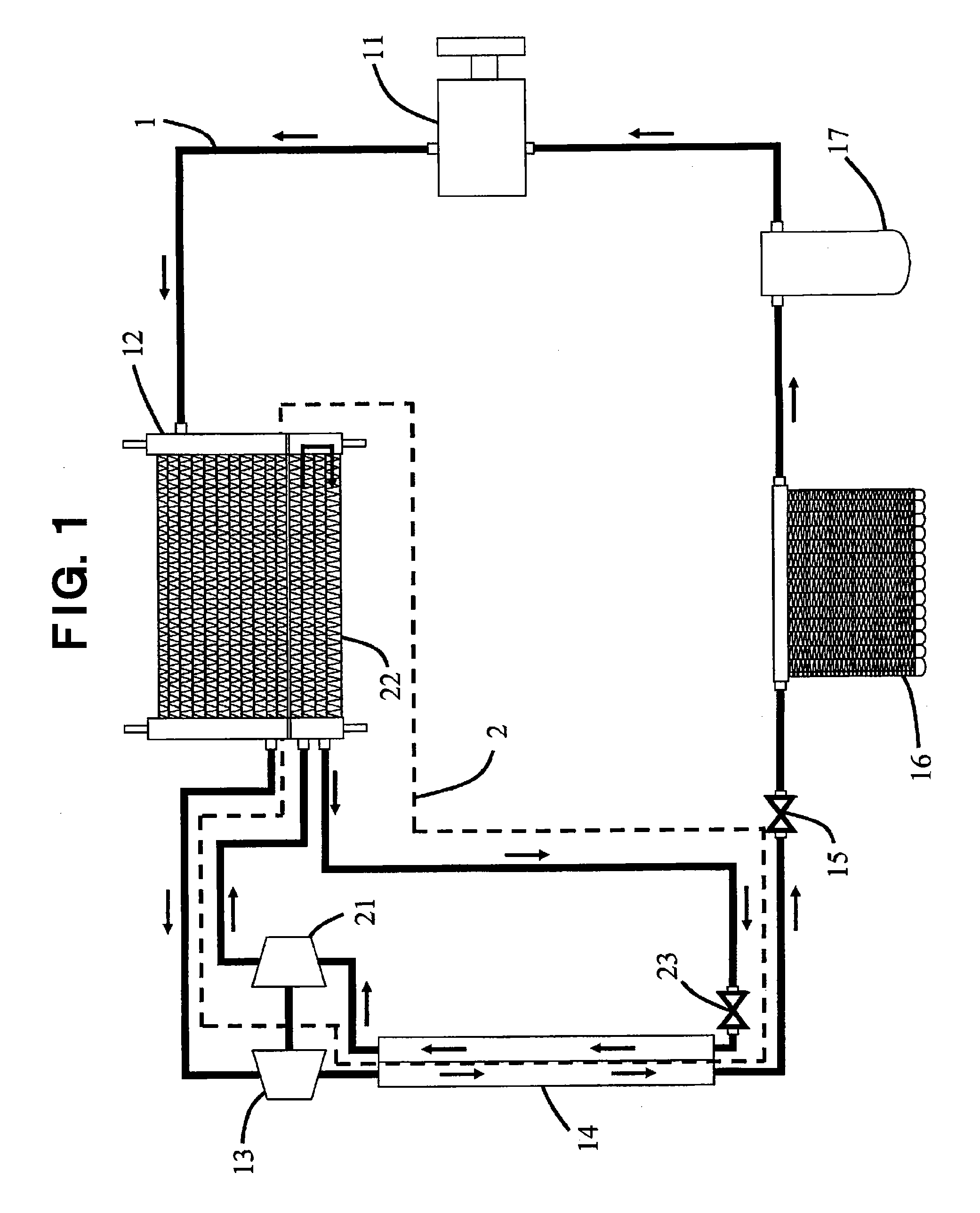

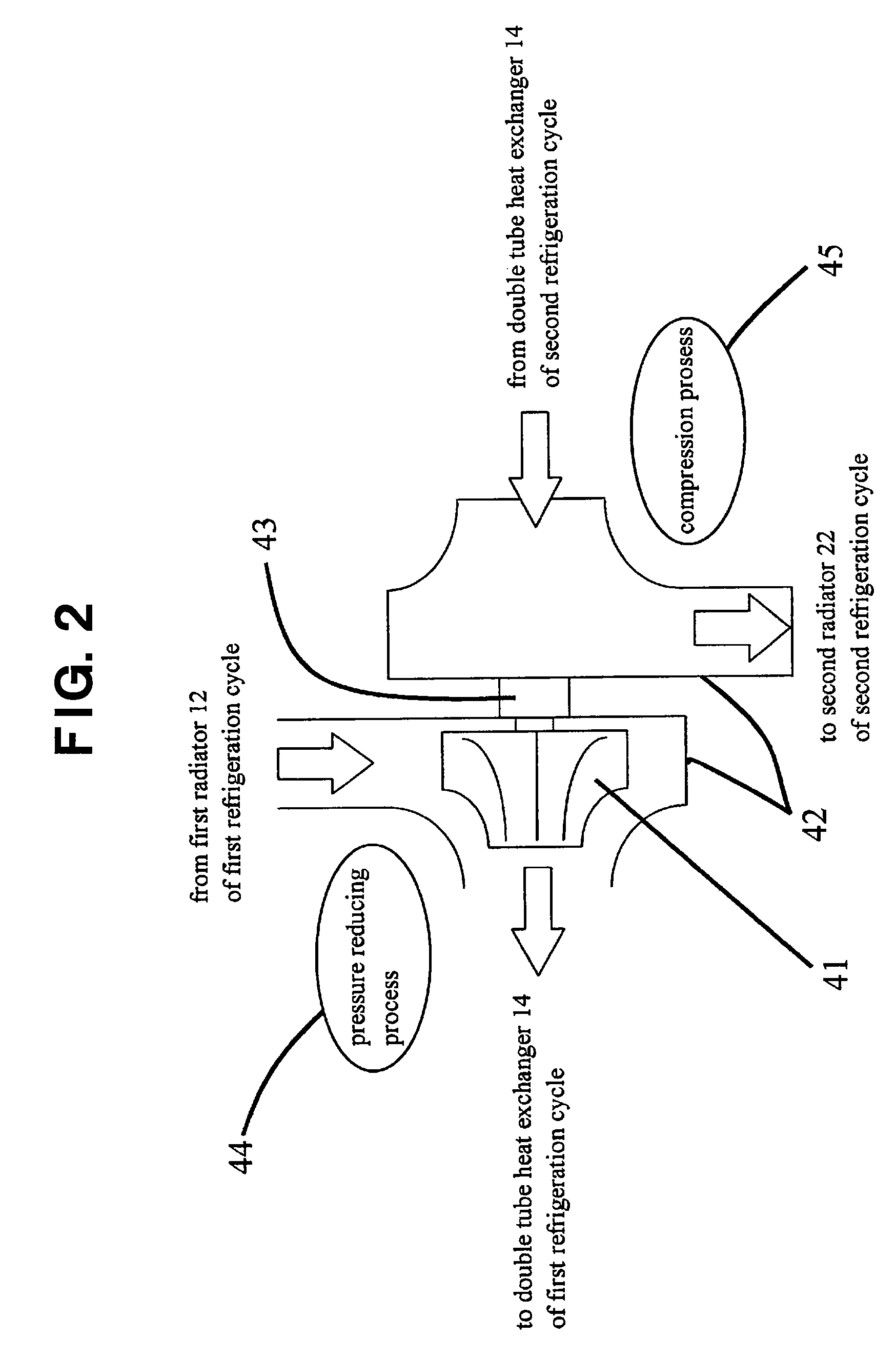

Air conditioning systems for vehicles

InactiveUS20070144201A1Reduce pressureImprove energy efficiencyAir-treating devicesCompression machines with non-reversible cycleEngineeringReducer

An air conditioning system for a vehicle includes a first refrigeration cycle, an expander, and a second refrigeration cycle. The first refrigeration cycle includes a first compressor, a first radiator, a first pressure reducer, an evaporator, and a gas / liquid separator. The expander is disposed on a first fluid communication path between the first radiator and the first pressure reducer. The second refrigeration cycle, which is provided as a cascade cycle, includes a second compressor powered by energy harnessed from adiabatic expansion of the refrigerant at the expander, thereby obviating the need for an additional power source for the second refrigeration cycle. A heat exchanger further is provided on a second fluid communication path in the second refrigeration cycle. The heat exchanger is configured to provide a heat exchange between refrigerant disposed within each of the respective first and second fluid communication paths.

Owner:SANDEN CORP

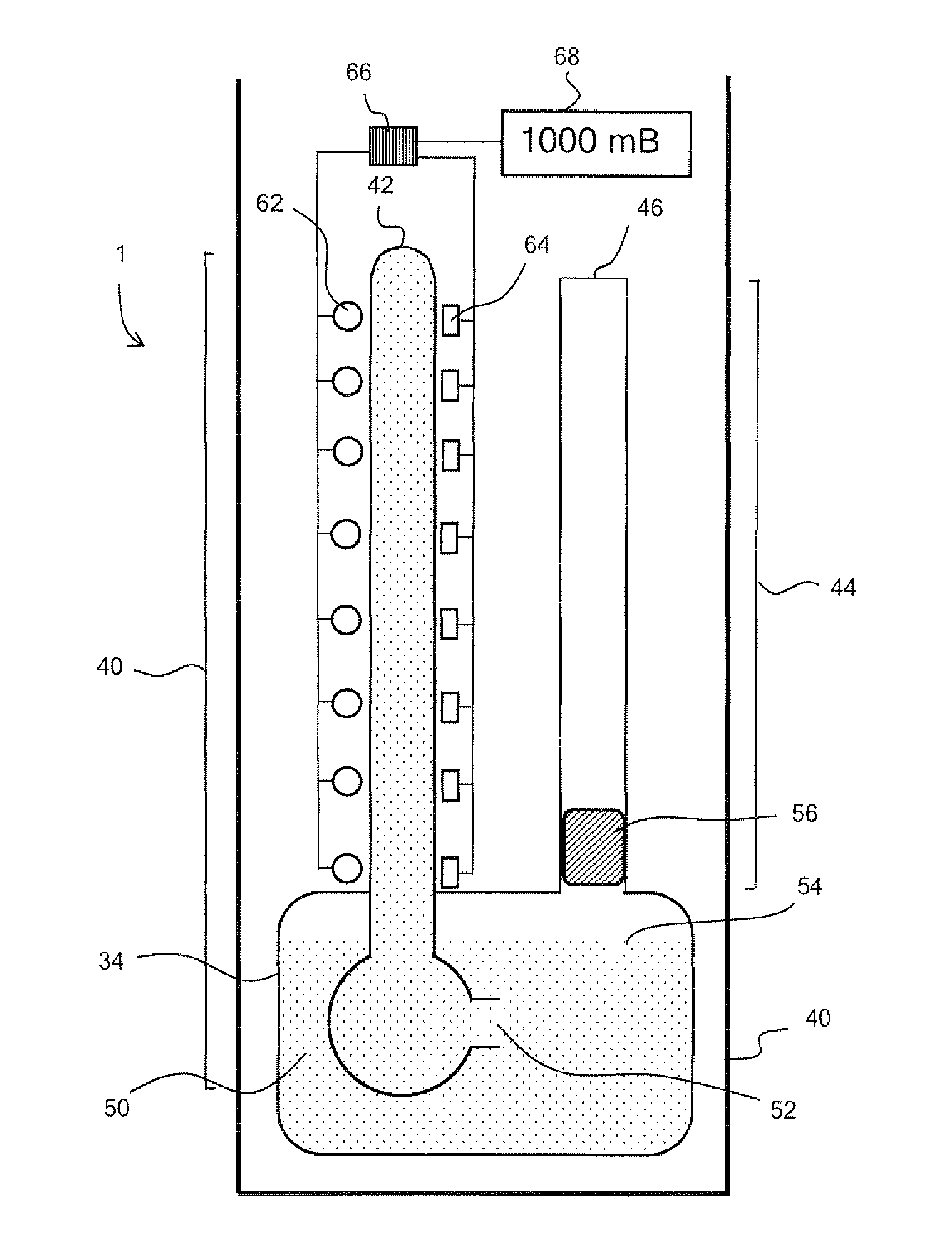

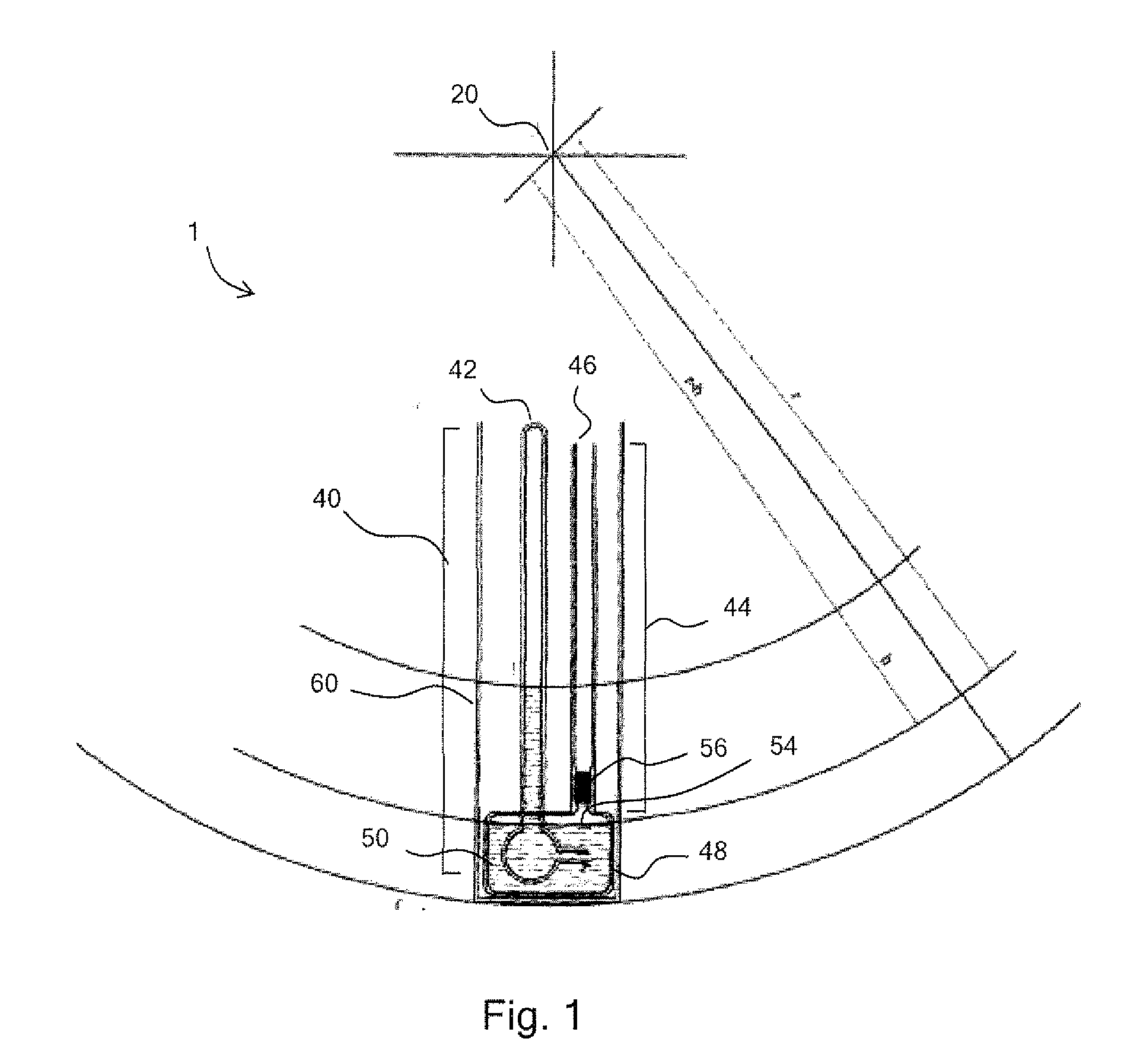

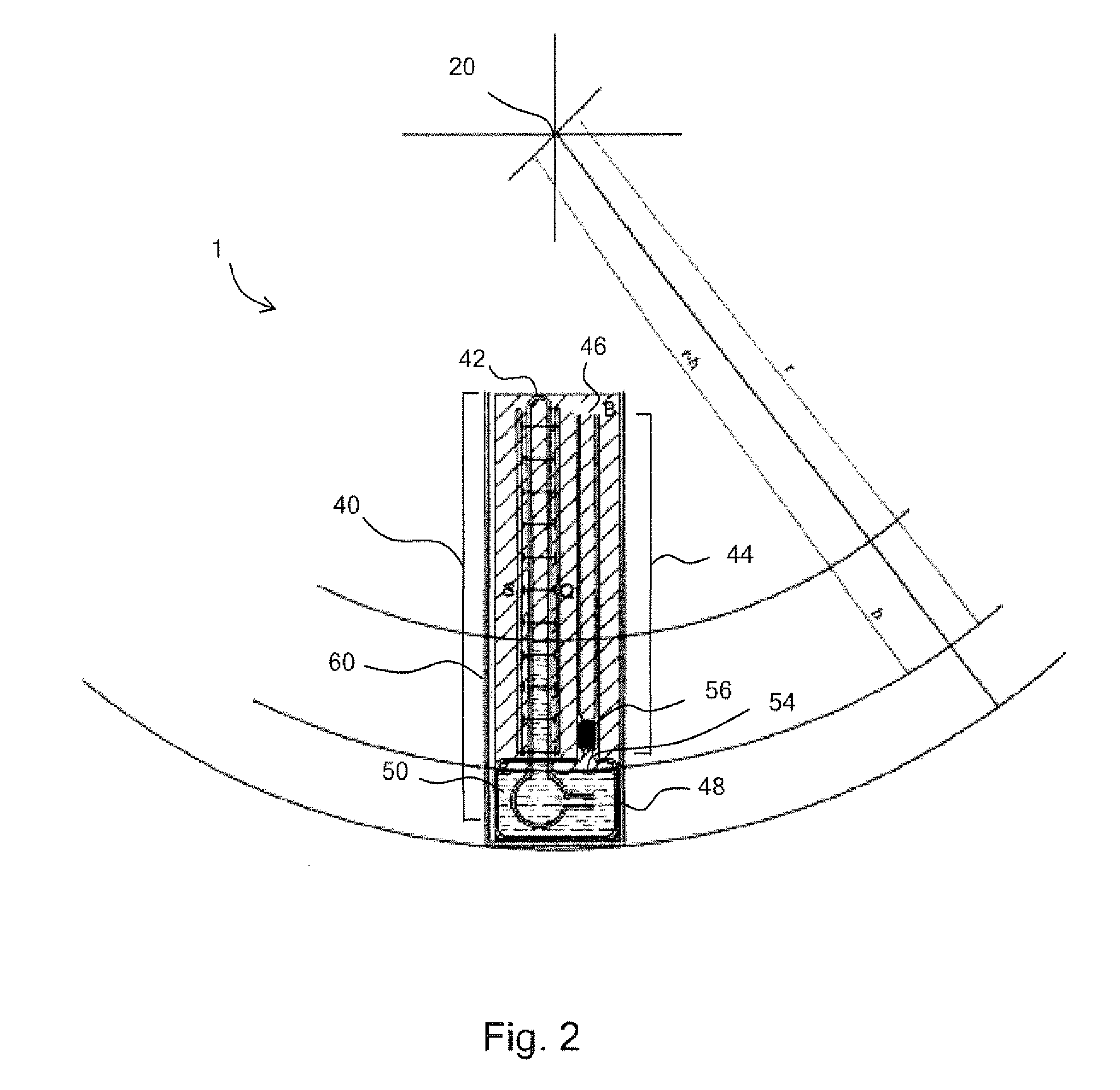

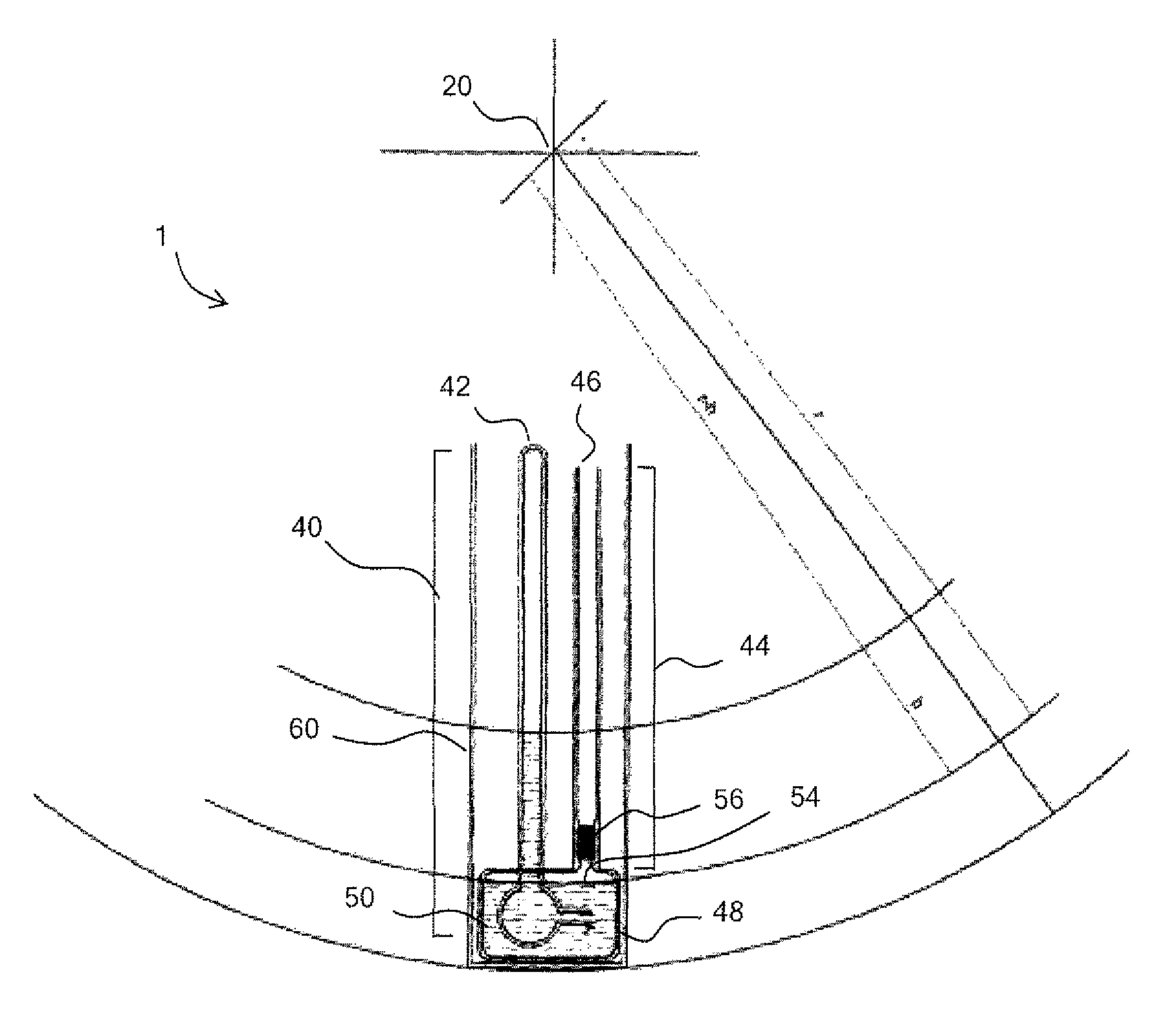

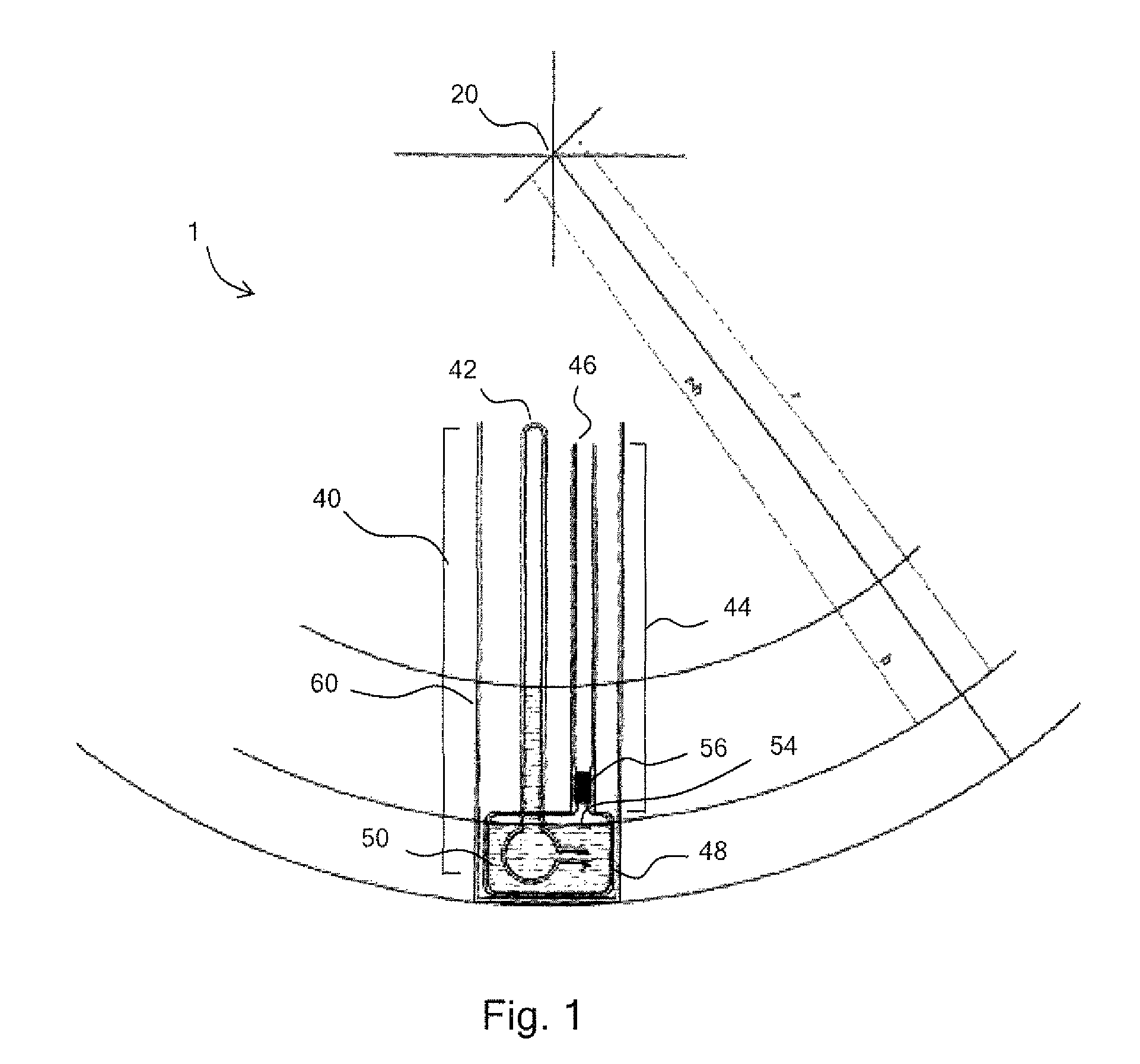

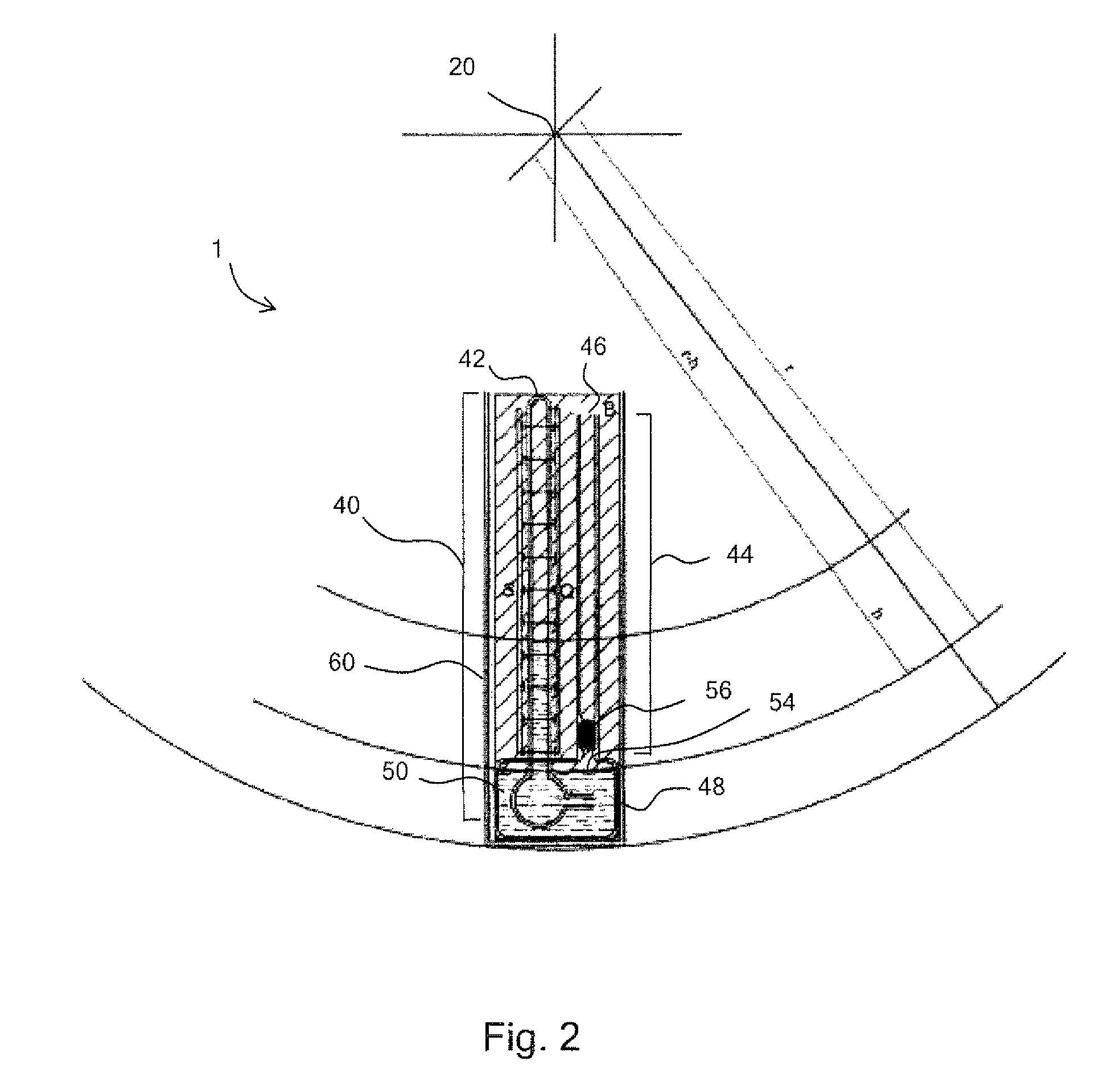

Barometer

InactiveUS20110247412A1Prevent capillary actionHigh surface tensionFluid pressure measurement using pressure-sensitive liquidEngineeringBarograph

A barometer which is rotatable and a method of using a barometer which is rotatable is presented comprising a barometer tube retaining barometric fluid that is shorter than that required by non-rotatable barometers. The provision of a rotatable barometer allows the use of a barometric fluid of a density lower than that of mercury to be used, thereby enabling the use of mercury to be avoided.

Owner:SCOTT KEVIN FRANCIS

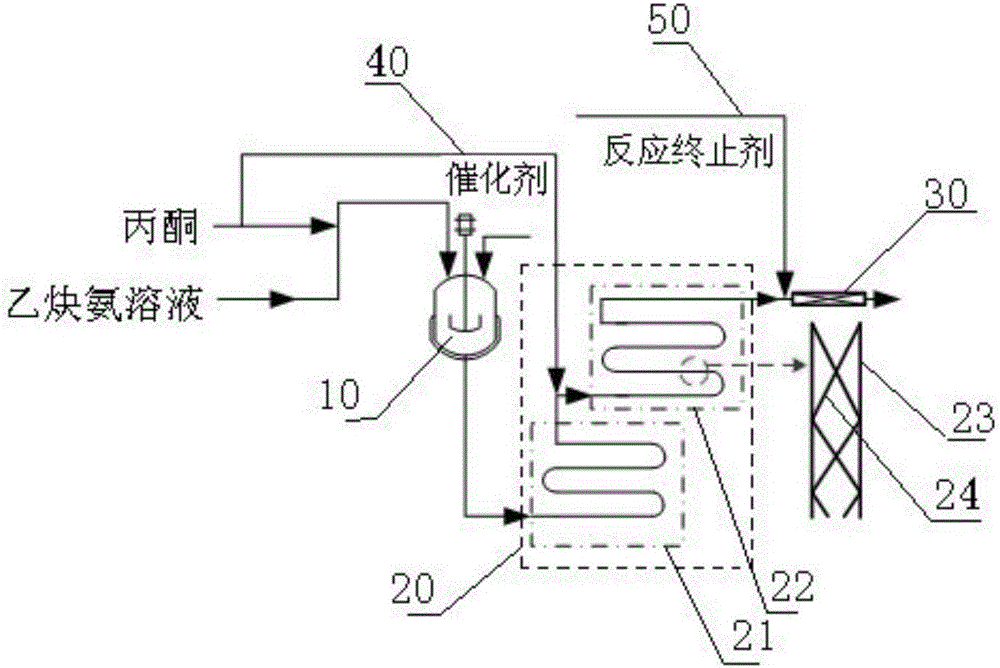

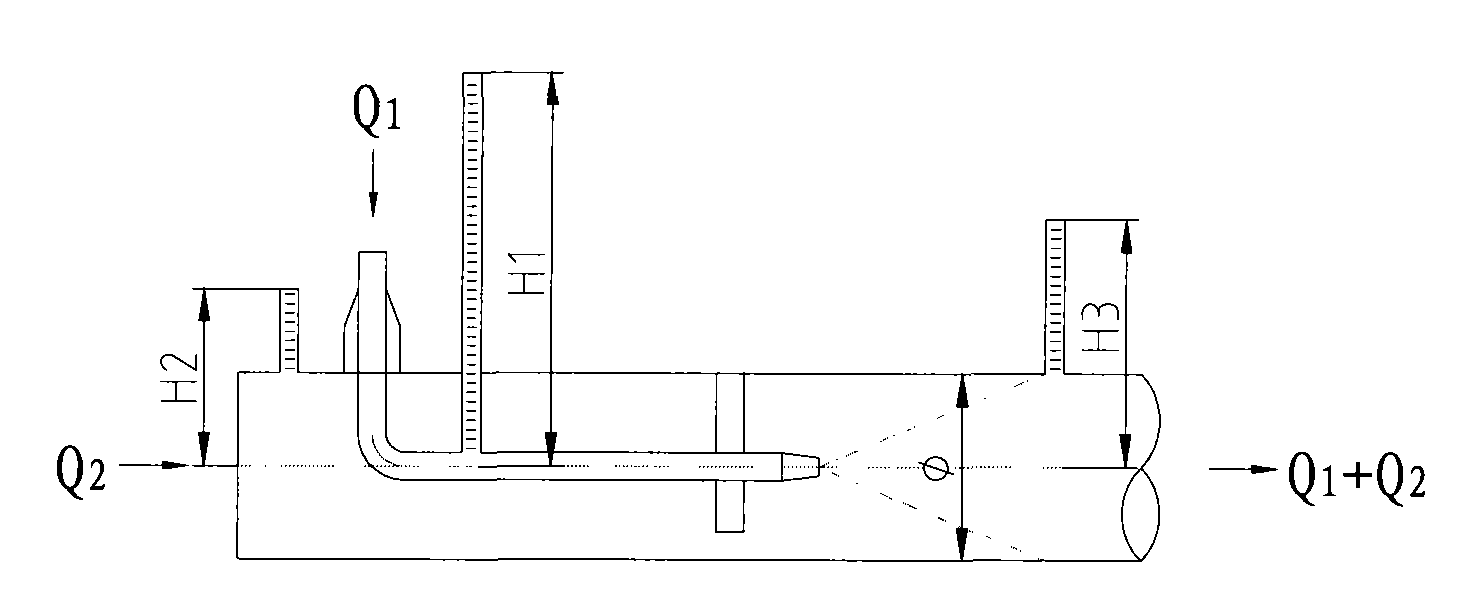

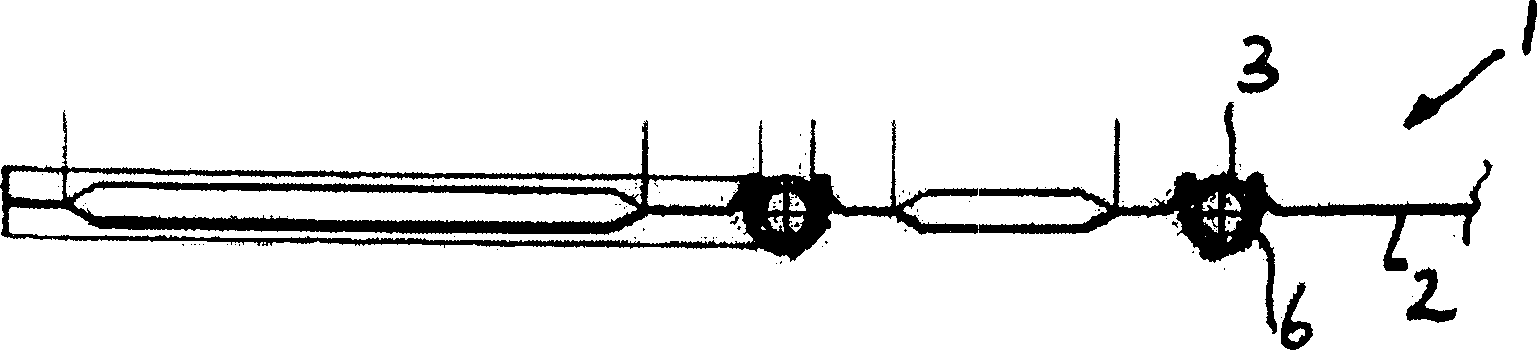

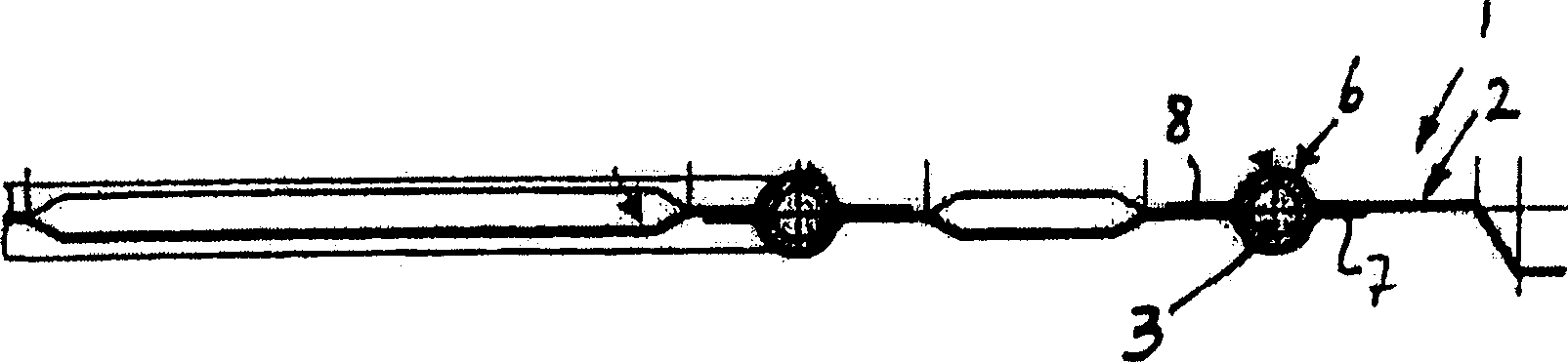

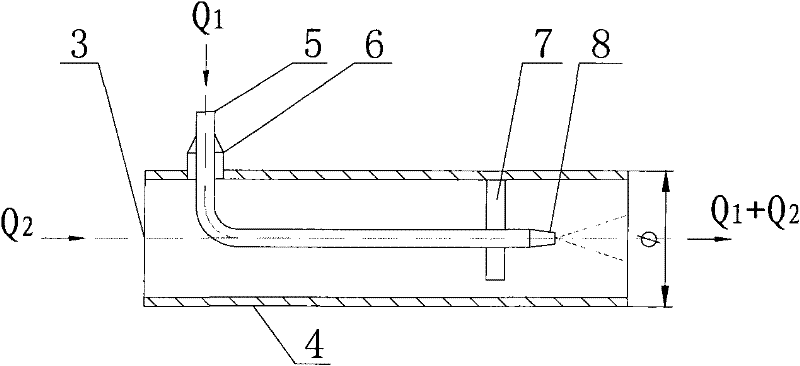

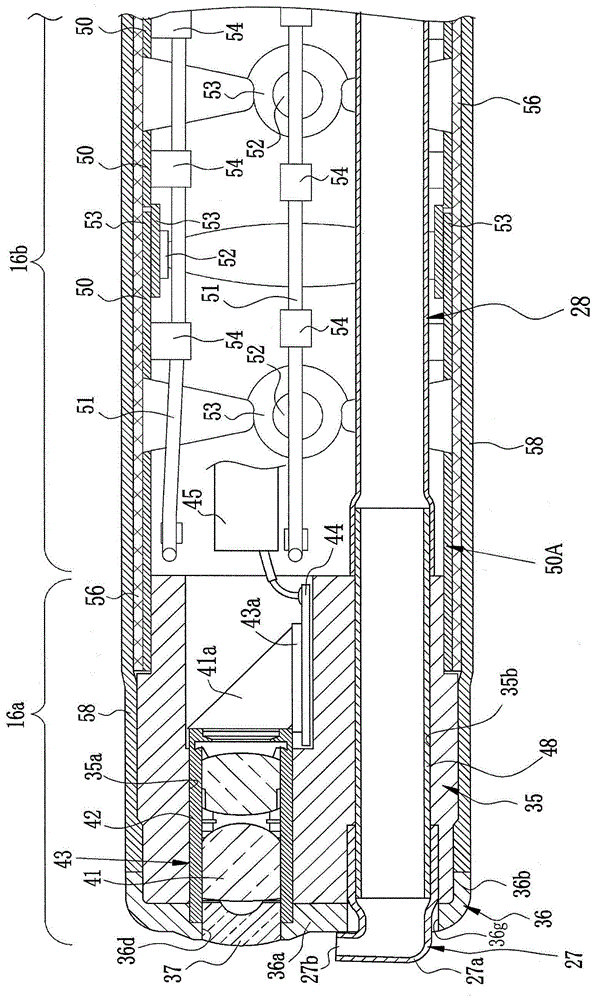

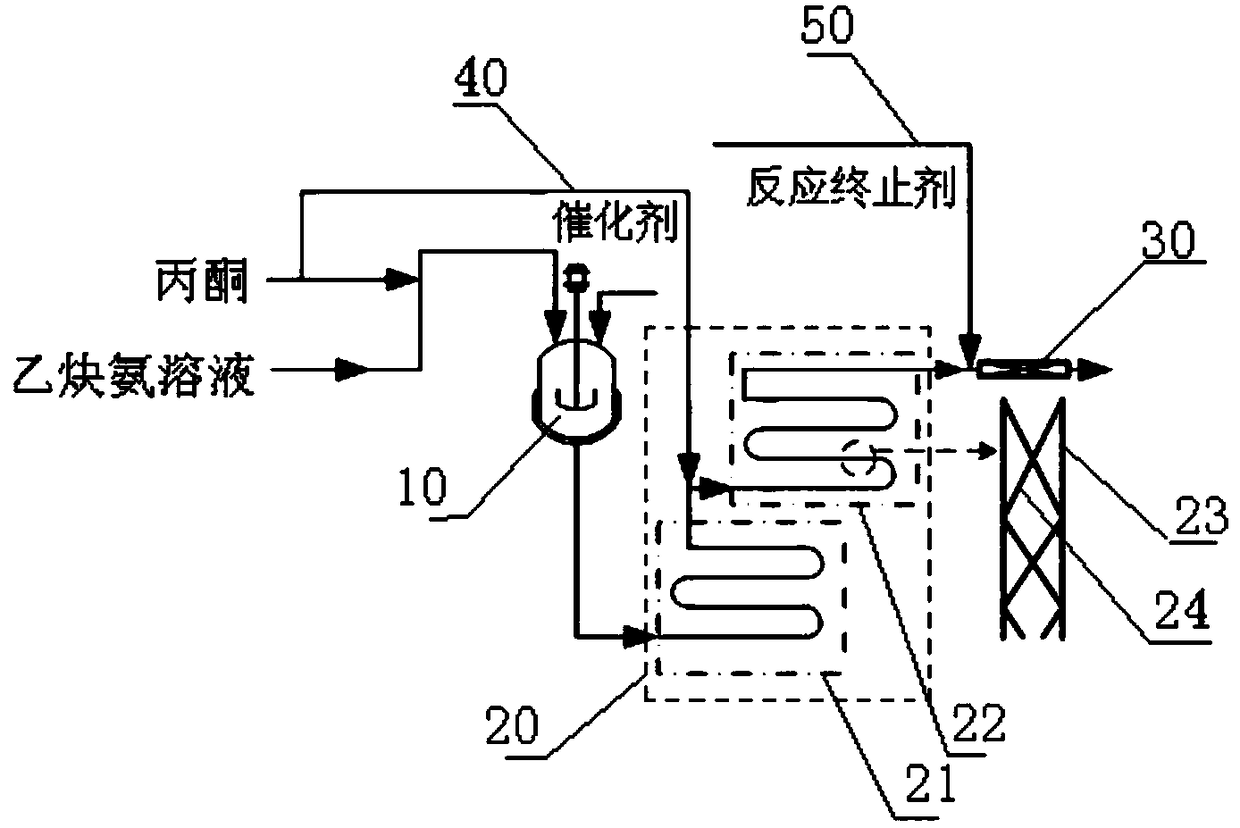

Reactor and reaction system for synthesizing methylbutynol

ActiveCN105924330AReduce tube lengthEfficient mixingOrganic compound preparationHydroxy compound preparationStatic mixerSide reaction

The invention discloses a reactor and reaction system for synthesizing methylbutynol. The reactor comprises a first-stage tubular reactor and a second-stage tubular reactor, which are connected sequentially, wherein each of the first-stage tubular reactor and the second-stage tubular reactor comprises a tubular reactor and a static mixer arranged in the tubular reactor. The reaction system comprises a stirring reaction kettle, a reactor and a termination mixer which are connected in a proper sequence by virtue of pipelines, wherein the reactor adopts the above reactor for synthesizing methylbutynol, a discharge port of the stirring reaction kettle is connected with a feed port of the first-stage tubular reactor, and a discharge port of the second-stage tubular reactor is connected with a feed port of the termination mixer. The reactor and the reaction system for synthesizing methylbutynol, disclosed by the invention, not only greatly shorten the tube pass length of the reactor, but also realize effective mixing of materials, avoid occurrence of side reactions, and greatly improve the product yield in comparison with an early process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

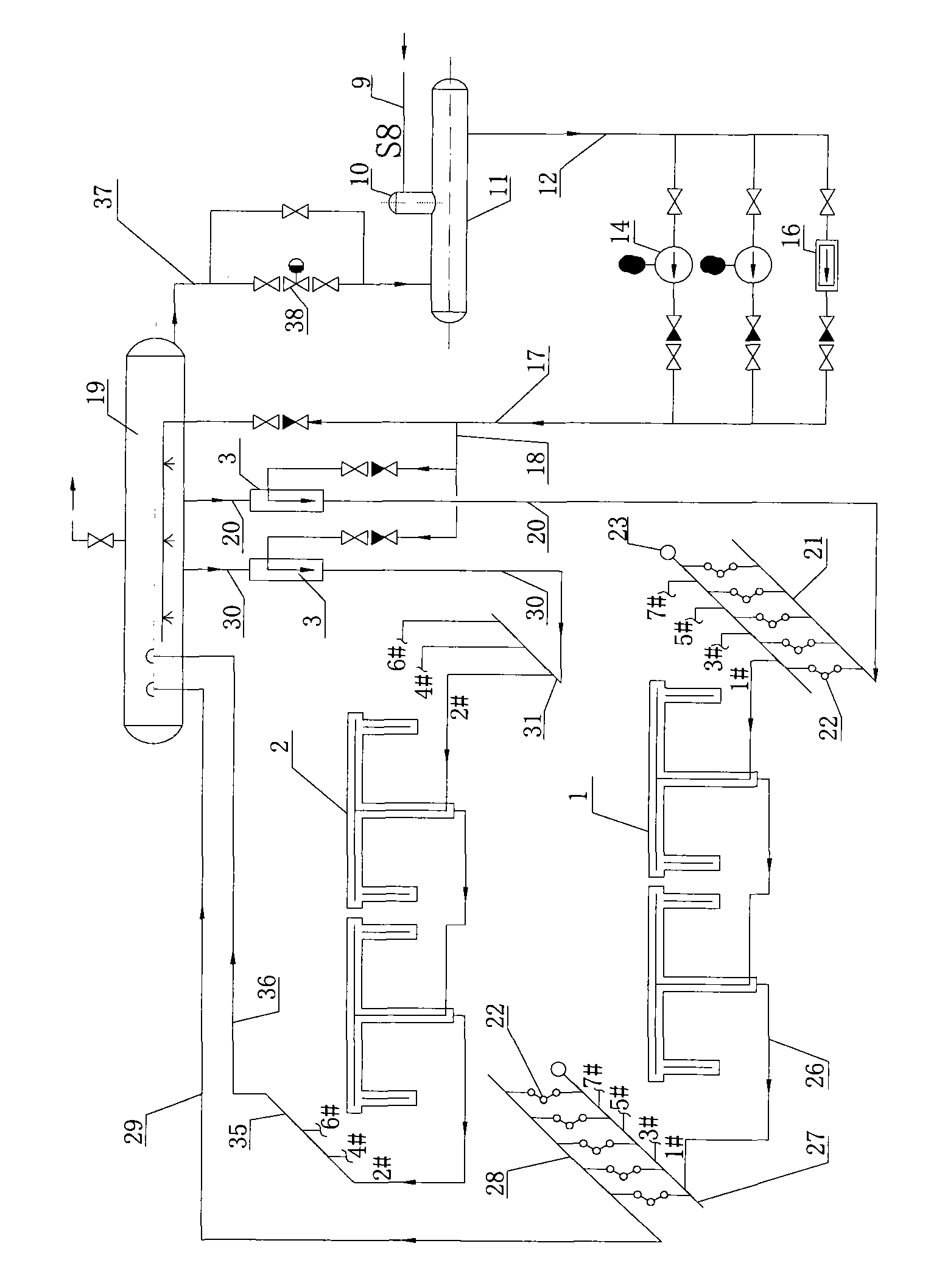

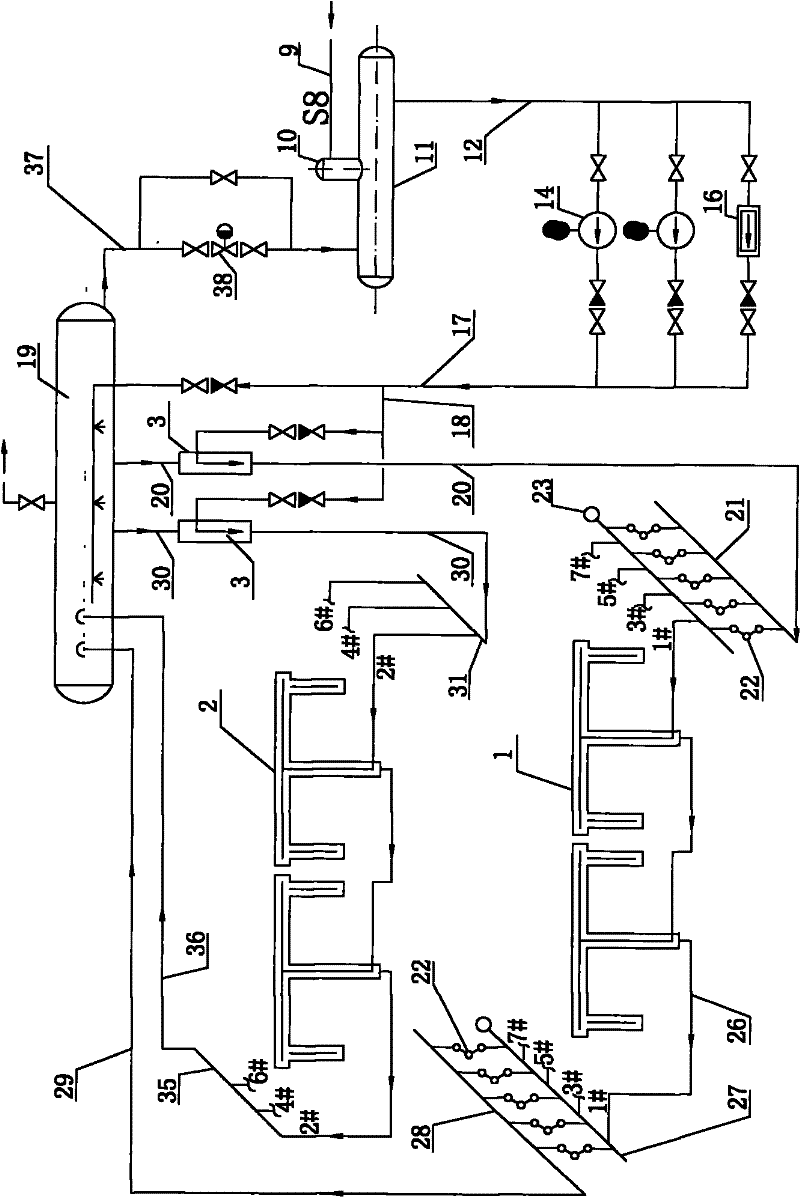

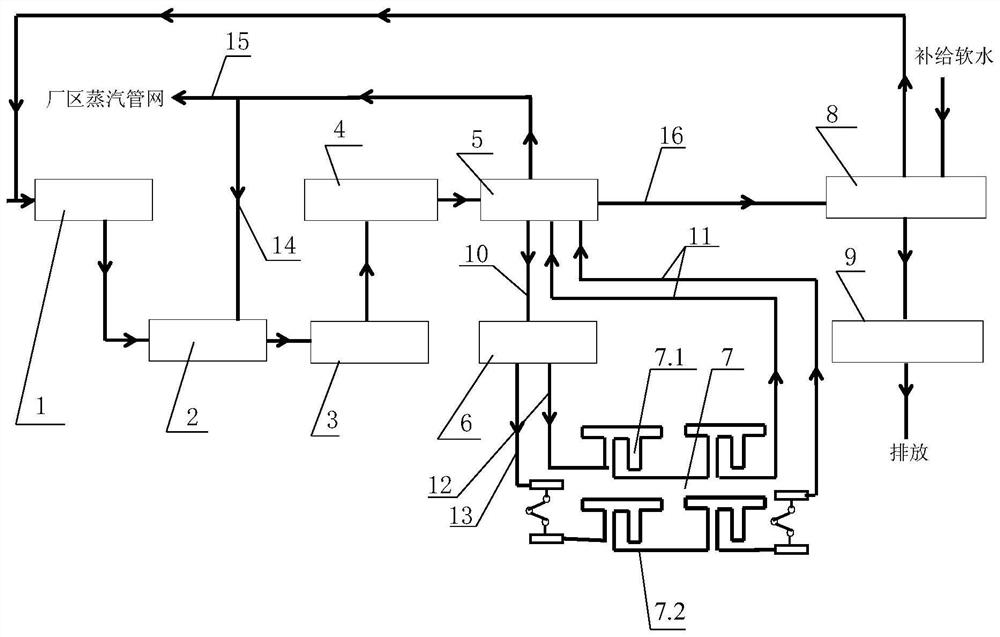

Simplified water beam vaporization cooling system of steel-rolling stepping heating furnace

InactiveCN102071304AMaximize energy efficiencyInvestment reductionFurnace typesFurnace coolingEnergy transferVaporization

The invention relates to a simplified water beam vaporization cooling system of a steel-rolling stepping heating furnace. The system comprises a stepping beam circulation loop, a fixed beam circulation loop and a water supply loop, wherein the water supply loop comprises an atmospheric thermal deaerator, a deoxidization water tank arranged at the lower part of the atmospheric thermal deaerator, and an electric water supply pump, which is connected in series to a deoxidization downcomer pipe at the lower part of the deoxidization water tank and connected to a steam pocket through a high-pressure water supply pipe, the high-pressure water supply pipe is provided with a high-pressure water supply branch pipe, and a stepping circulation loop downcomer pipe in the stepping beam circulation loop and a fixed circulation loop downcomer pipe in the fixed beam circulation loop are provided with efflux energy transfer devices which are respectively connected to the high-pressure water supply branch pipe. The simplified water beam vaporization cooling system of the steel-rolling stepping heating furnace, which is provided by the invention, integrates the three independent processes of deoxidization, water supply and circulation into a continuous process with low energy consumption to reduce the loading capacity, shorten the power consumption time, and has the advantages of high efficiency and energy saving.

Owner:BEIJING MINGCHENG TECH DEV

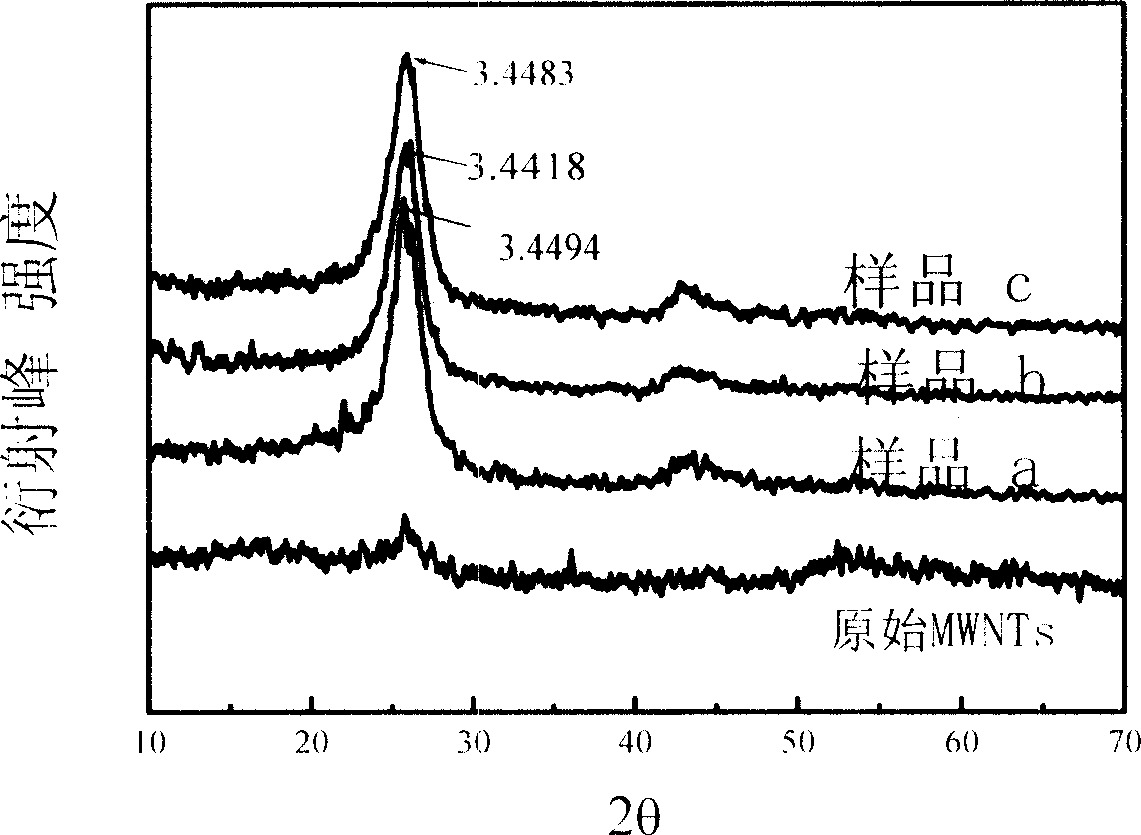

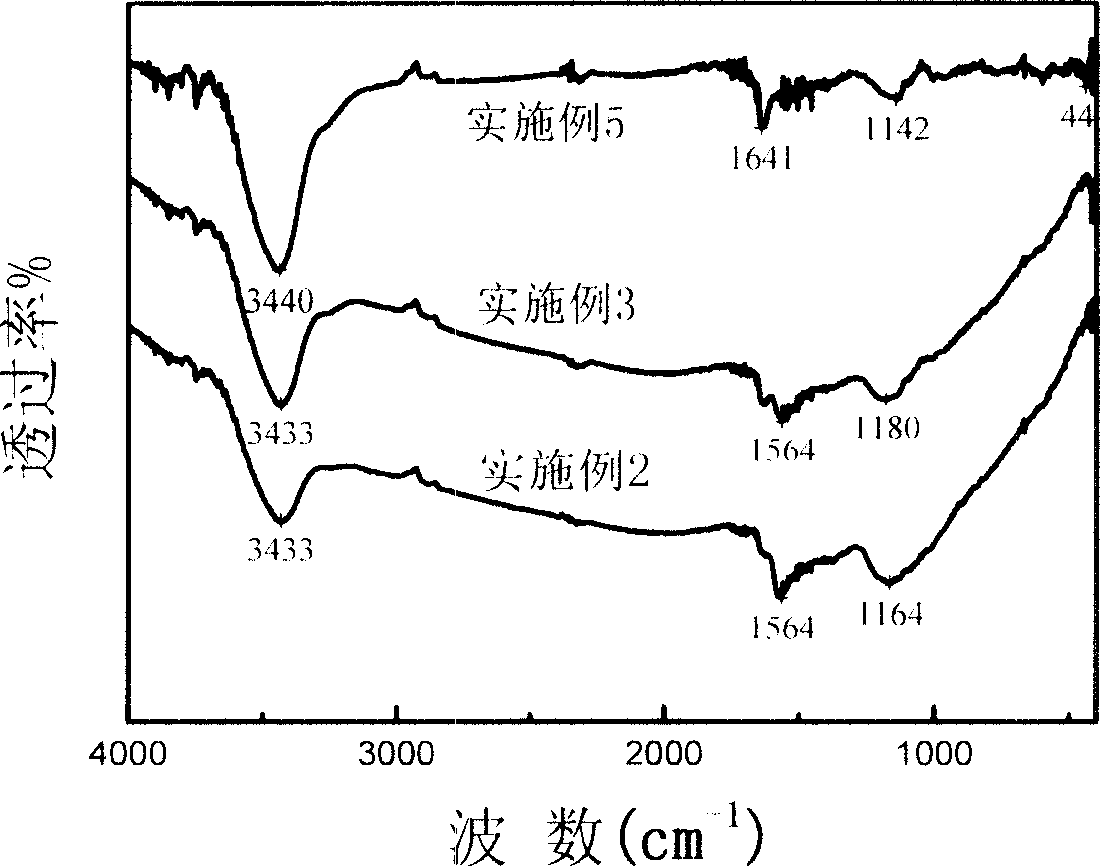

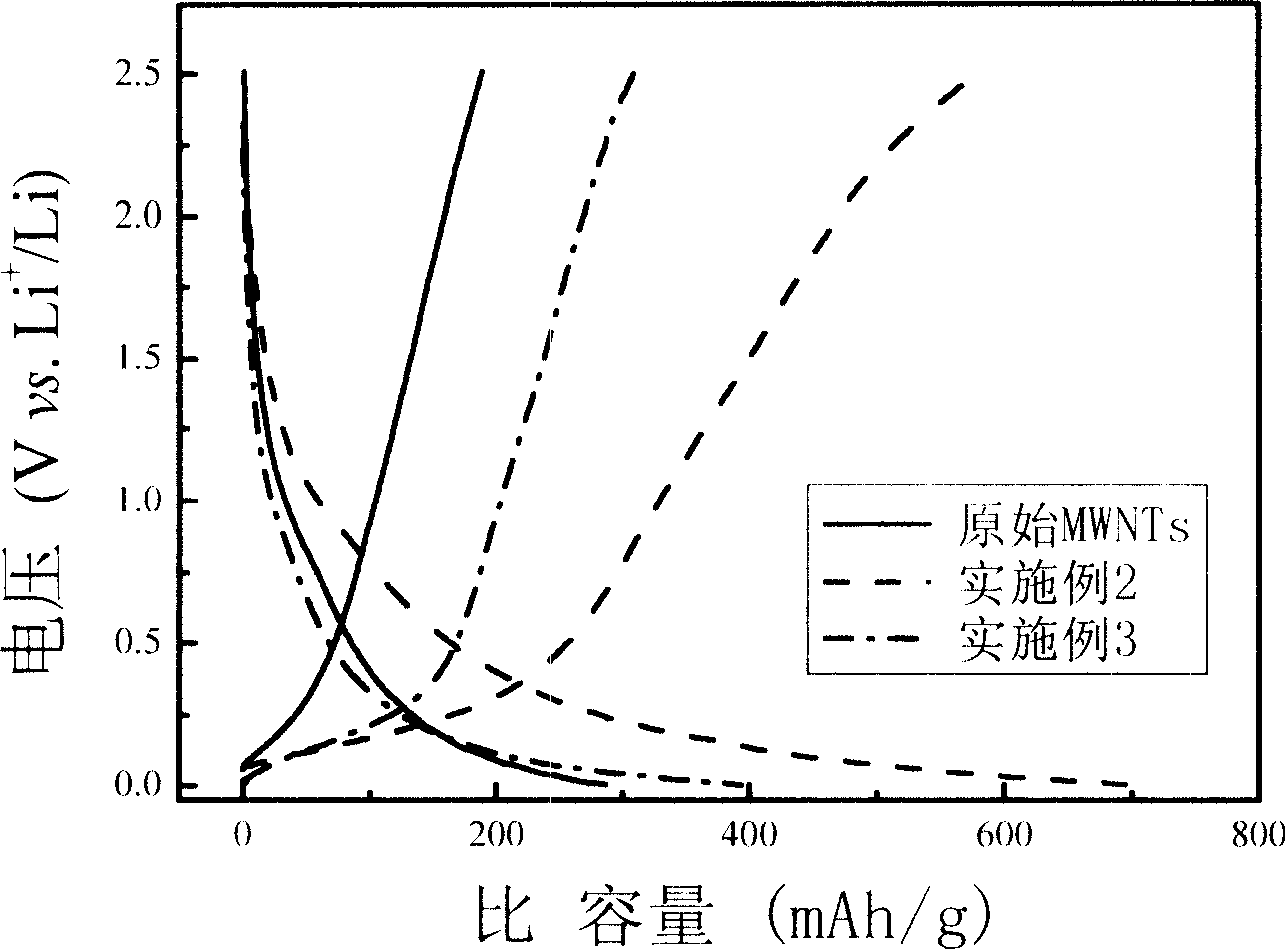

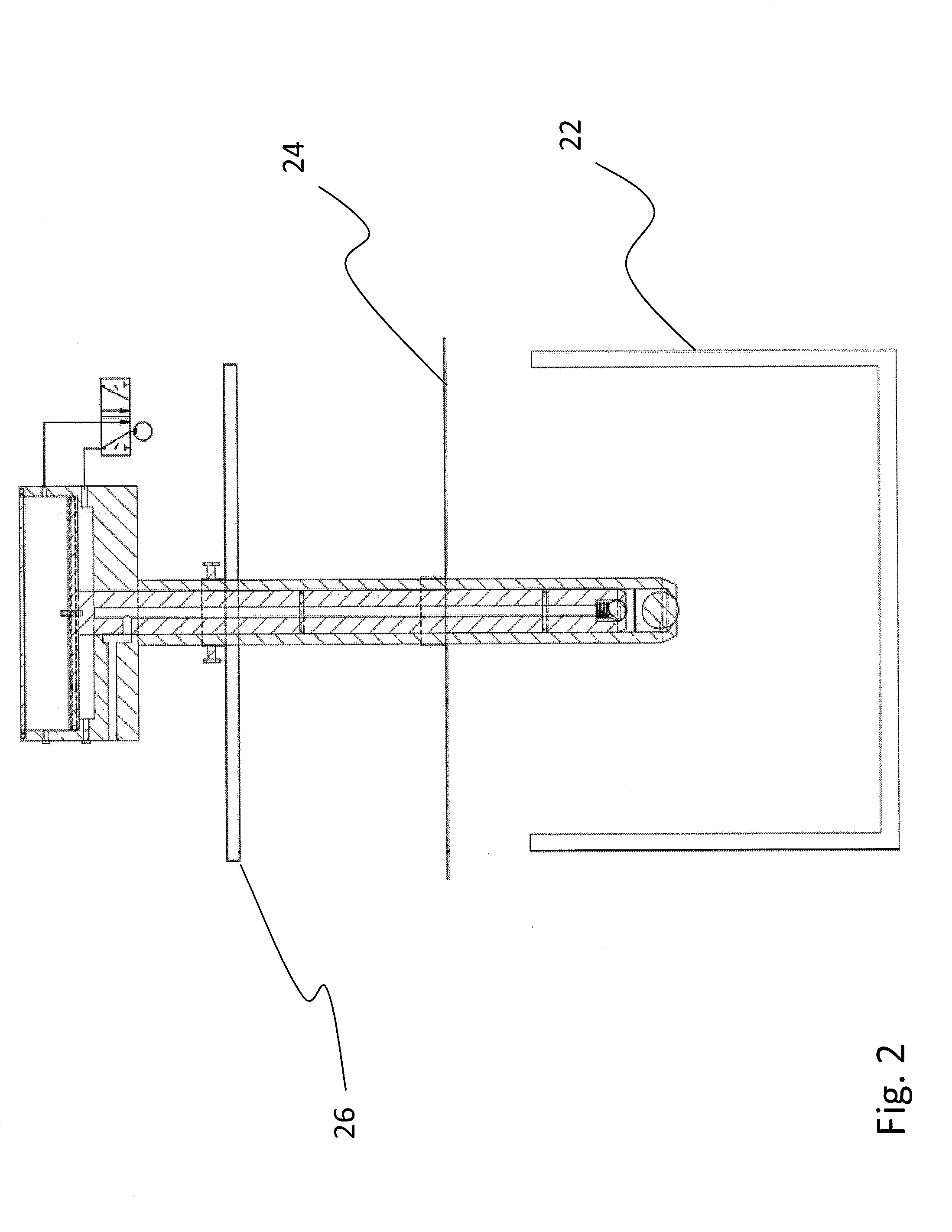

Method for increasing electrochemical lithium storage content of nano-carbon tube

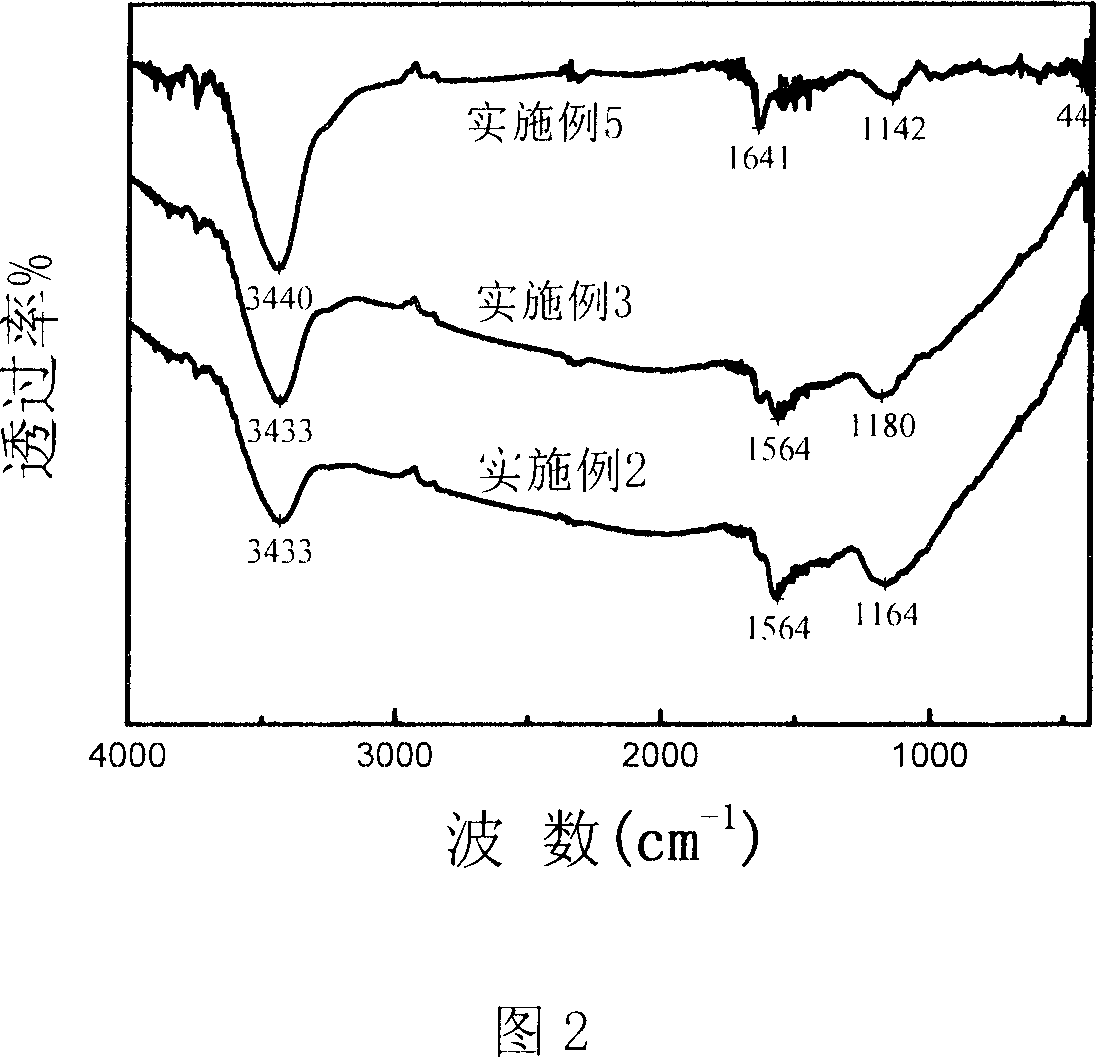

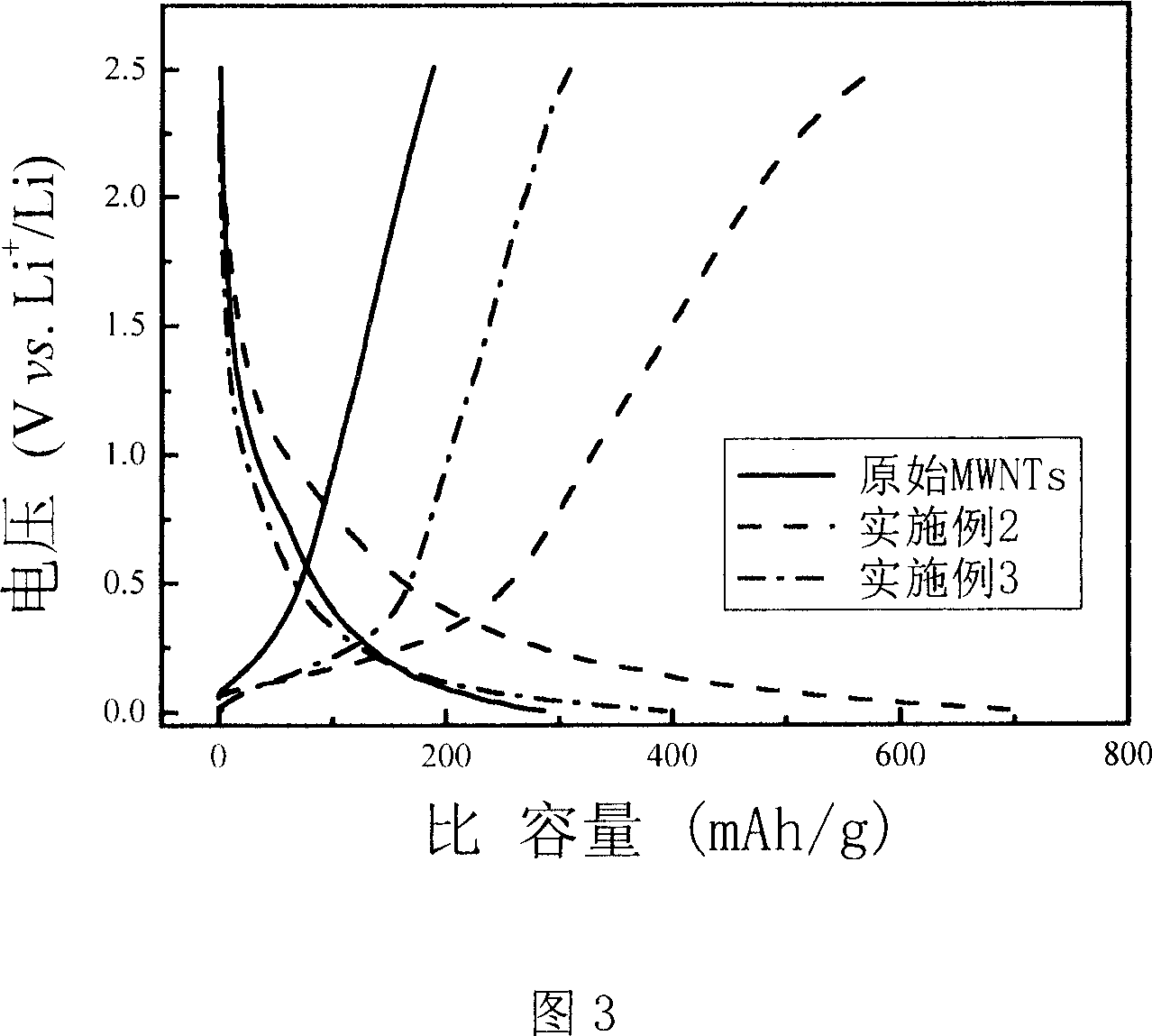

InactiveCN1688046AIncrease spacingIncrease profitElectrode manufacturing processesGas phaseCarbon nanotube

This invention discloses a method for increasing electrochemical Li-storage capacity of carbon nm tubes, which processes the original MWNTS raw material prepared with chemical gas phase deposition method including: first of all, the original MWNTS is supersonic-vibrated, mechanical mixed and dipped under room temperature in different matched volumes of H2SO4 and HNO3 mixed solution, the reacted product is cleaned with deionized water to neutral and put in a tube oven to be heated under 200-500deg.C to be cooled and dipped in Li2CO3 or LiOH solution, the obtained sample is cleaned with deionized water, filtered and dried in vacuum. The gap of quasigraphite layer of the processed MWNTS is expanded, the electrochemical Li capacity is increased.

Owner:TSINGHUA UNIV

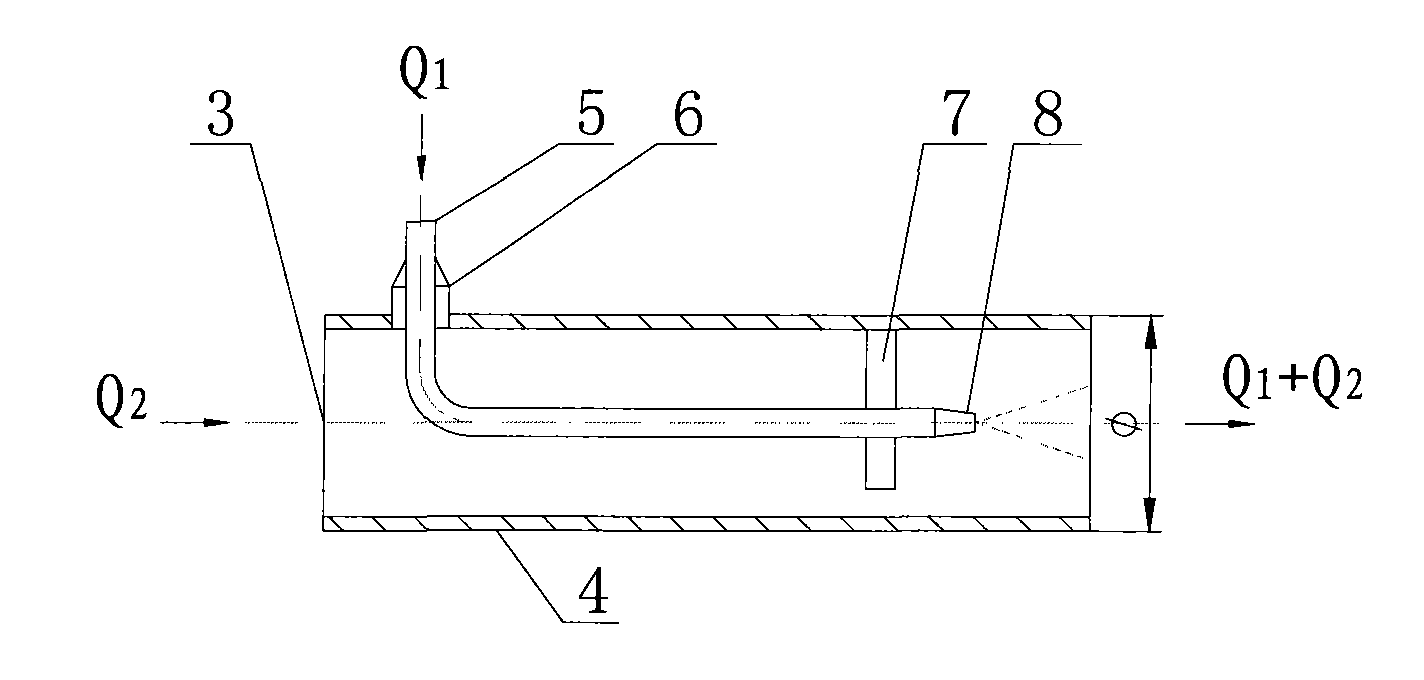

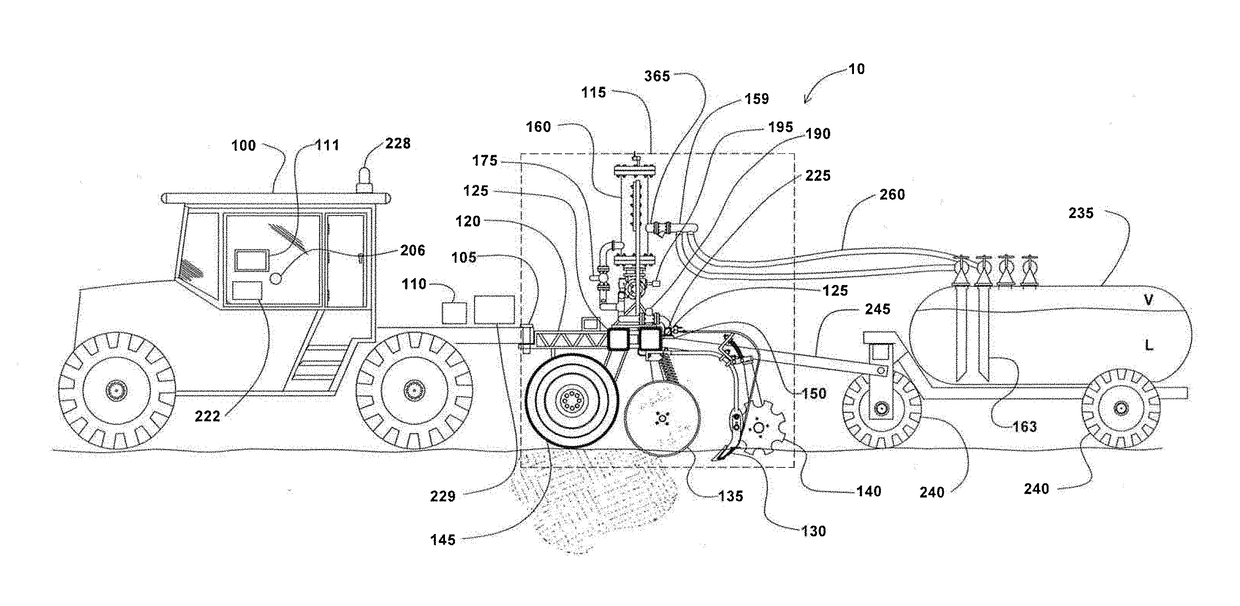

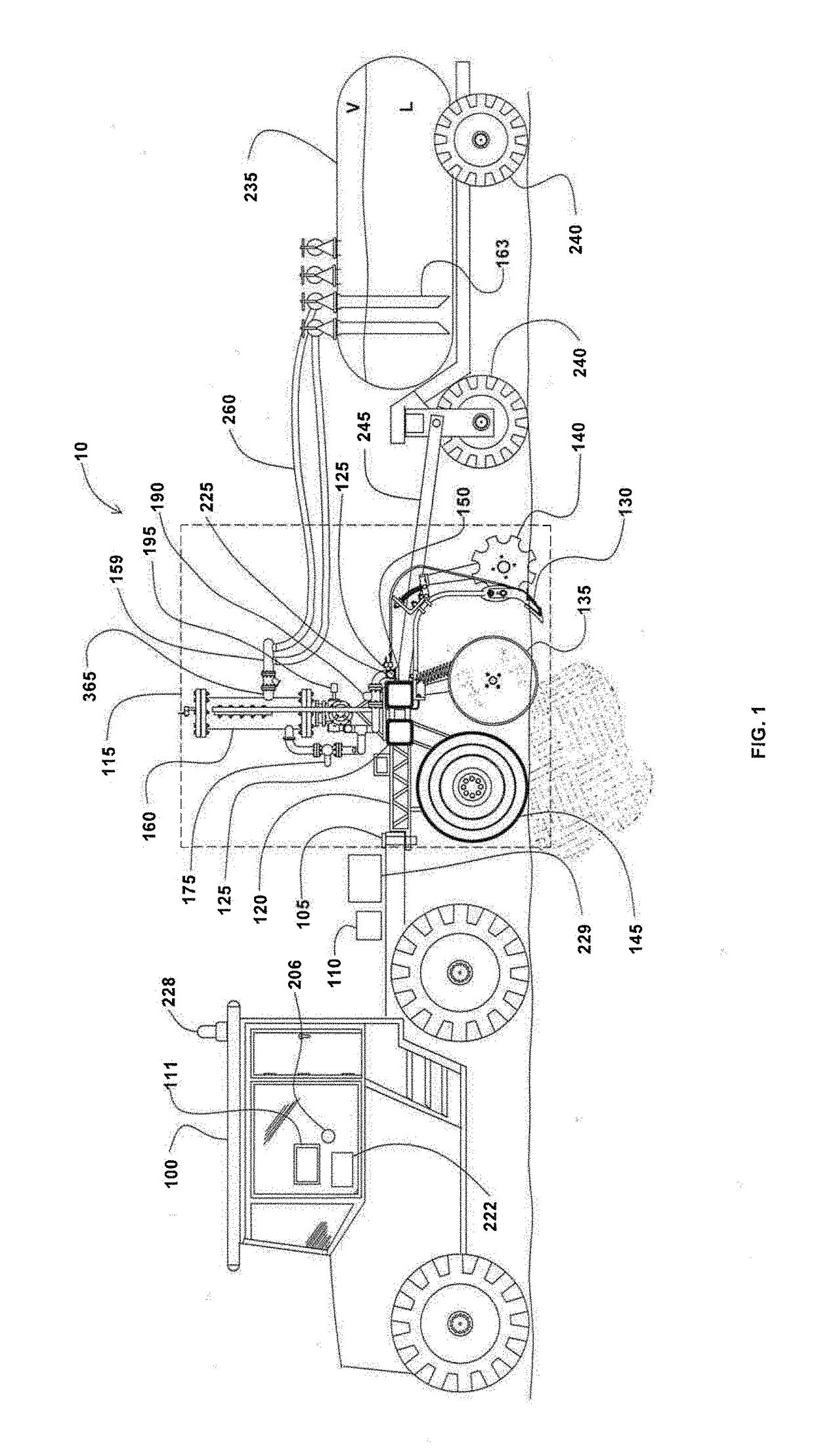

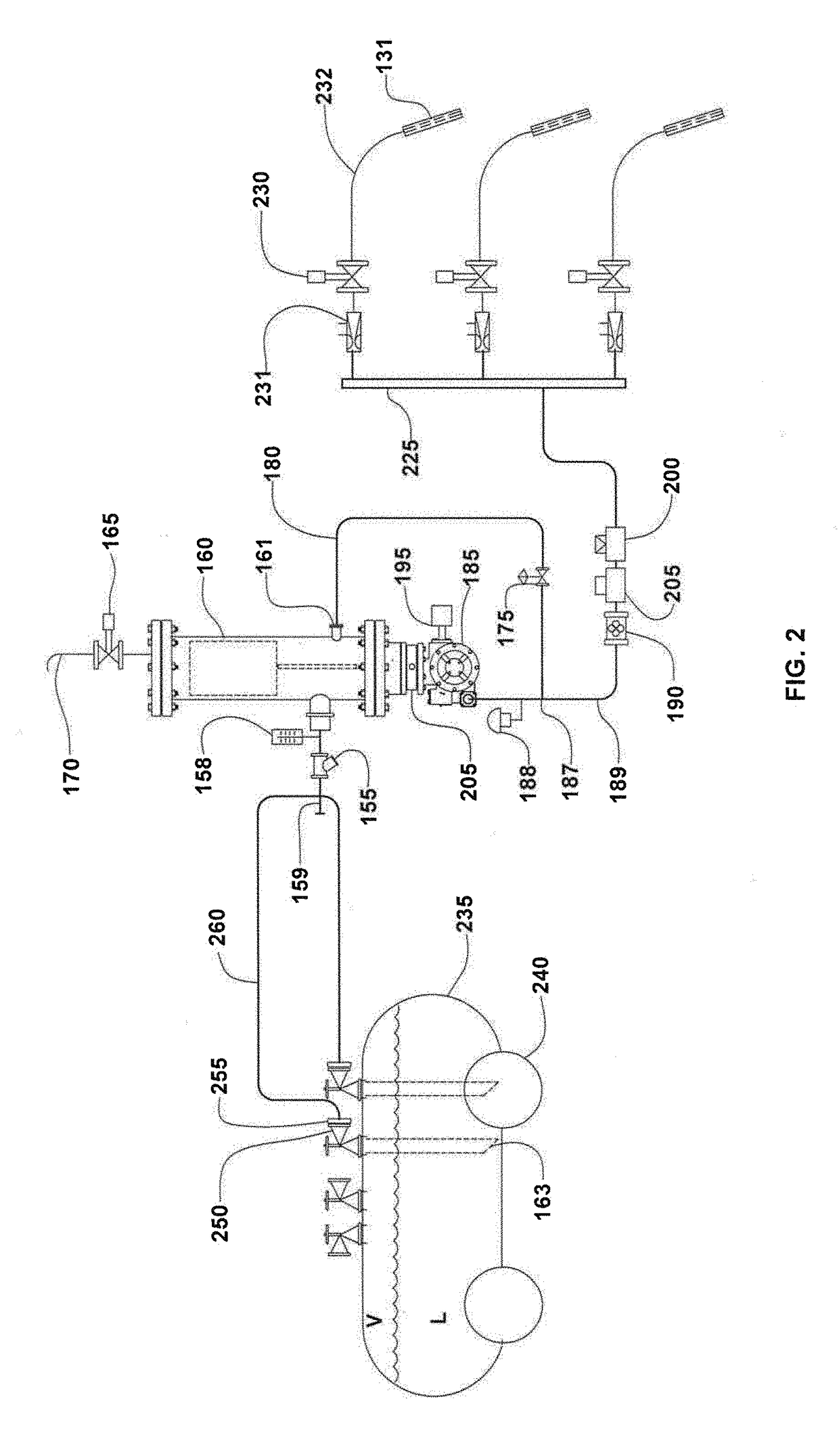

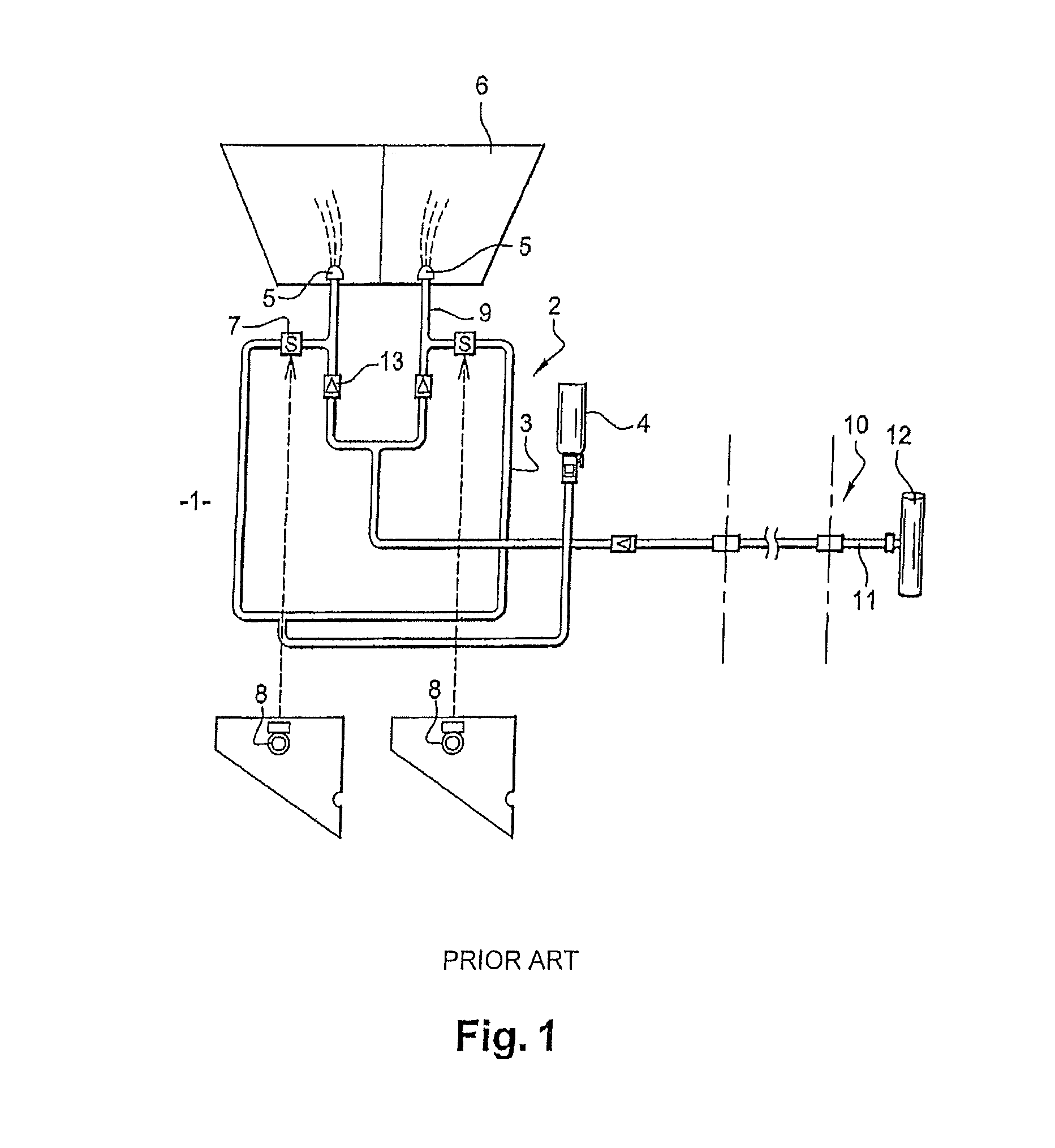

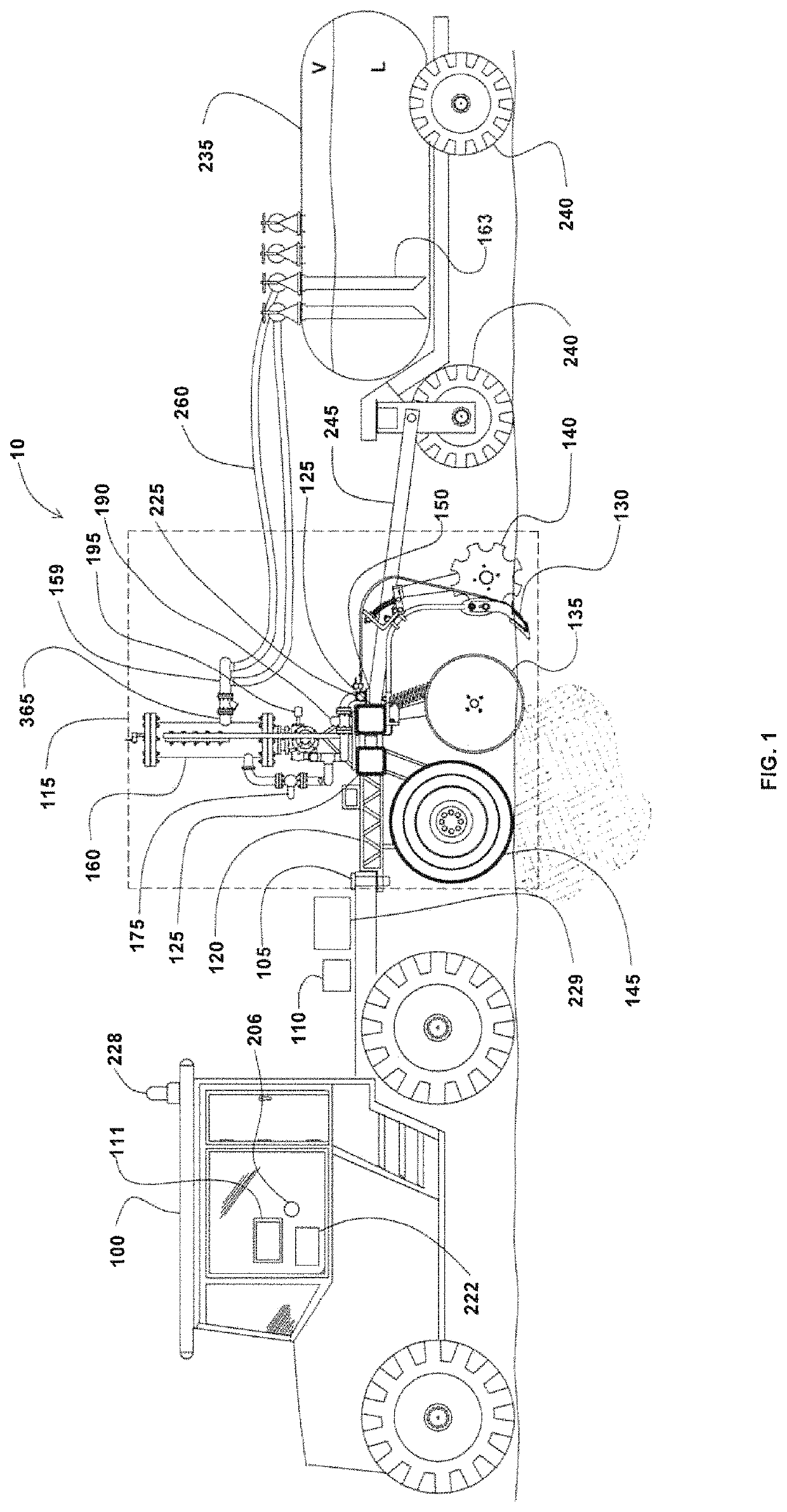

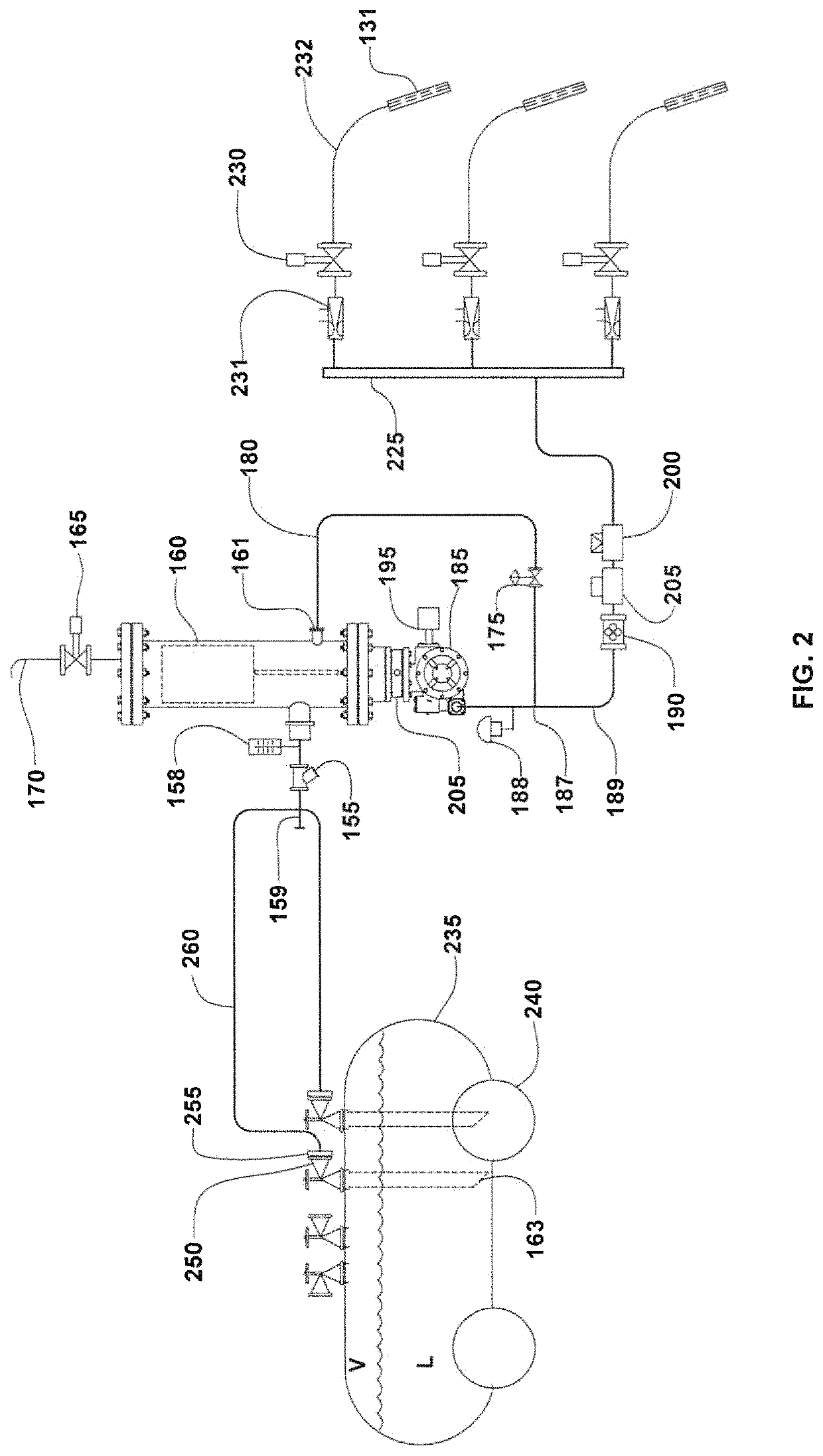

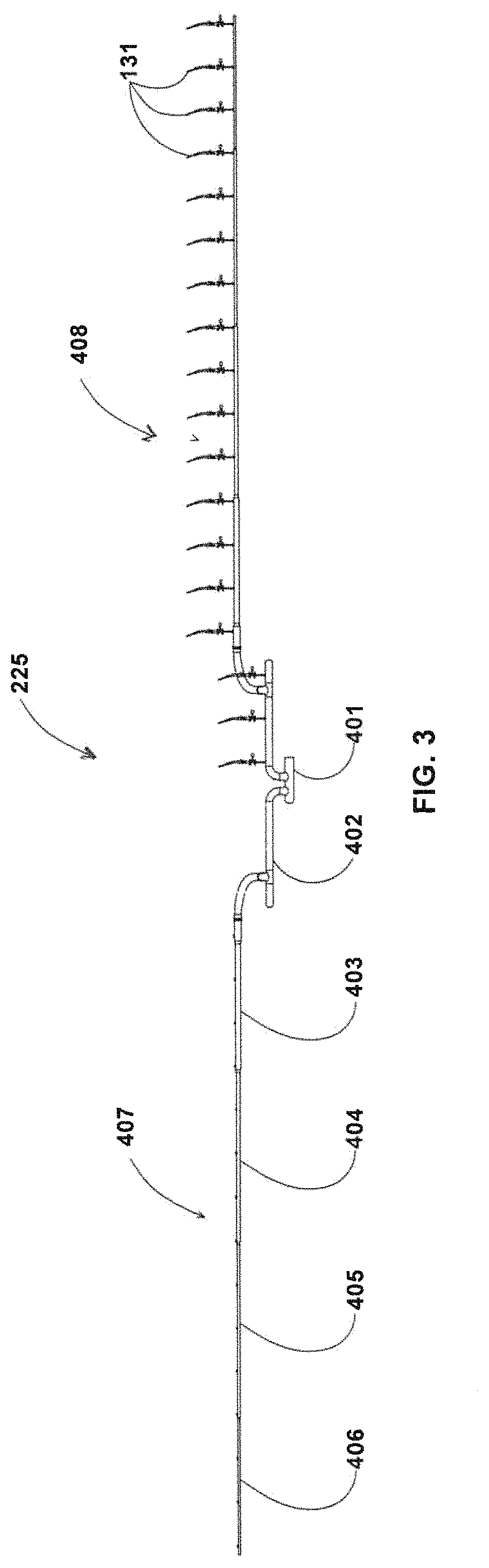

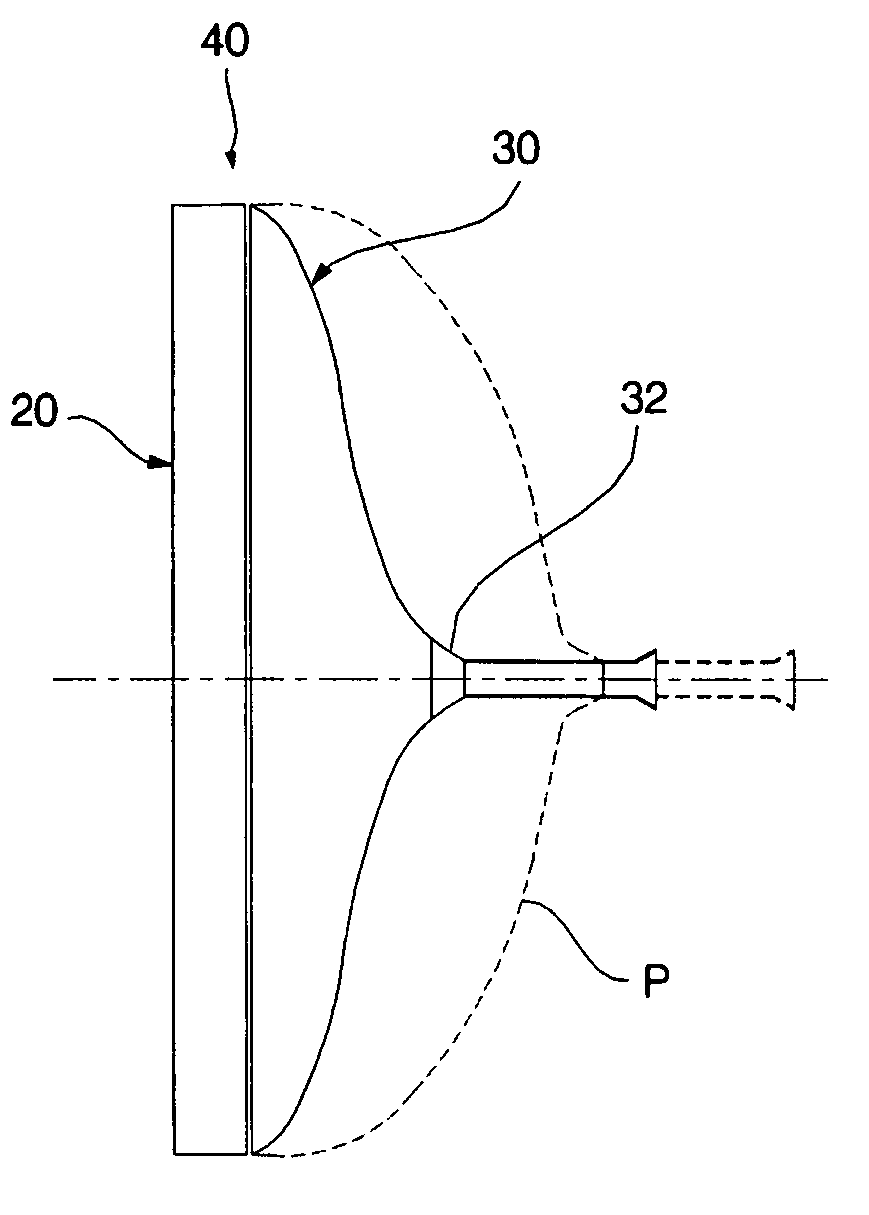

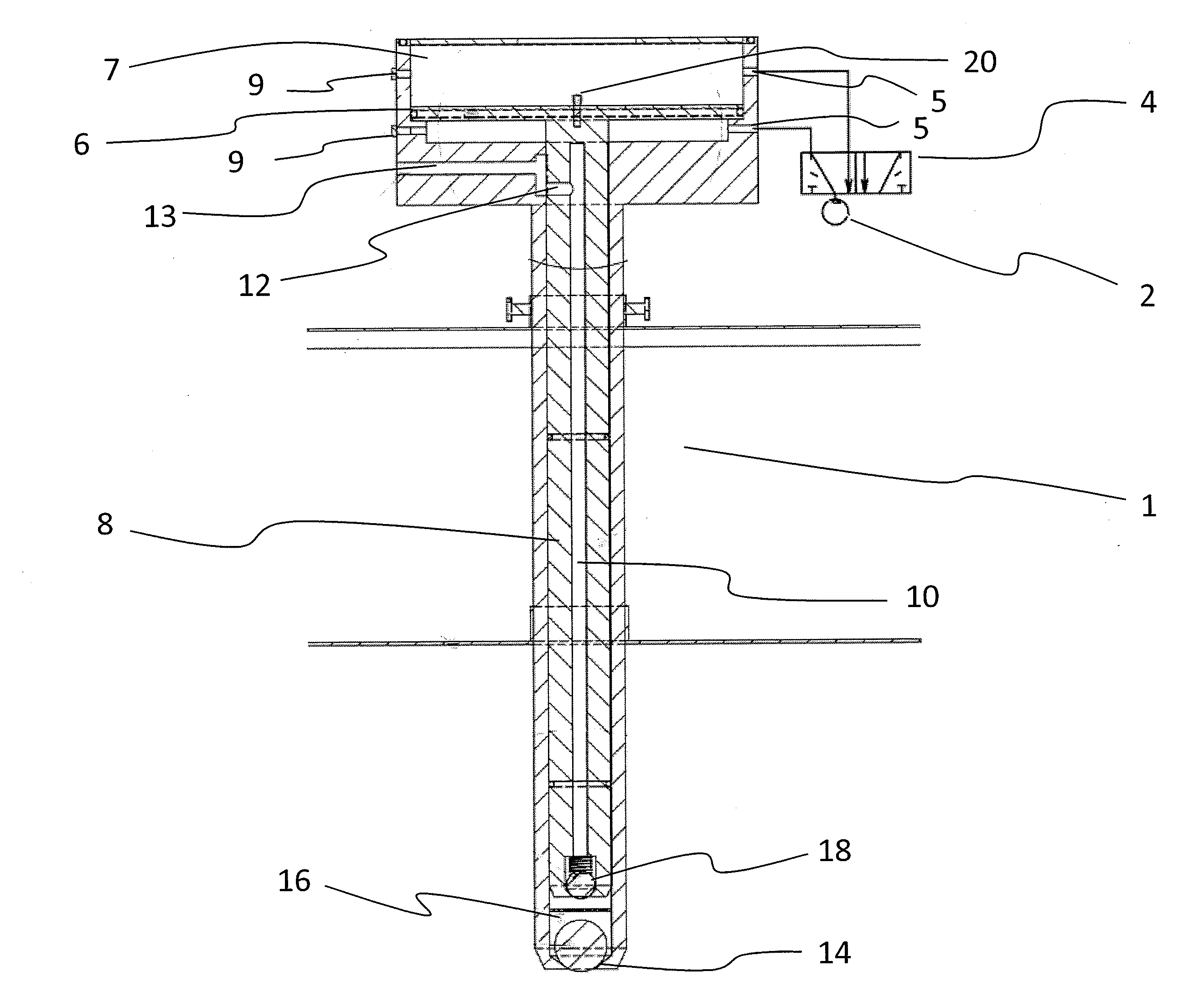

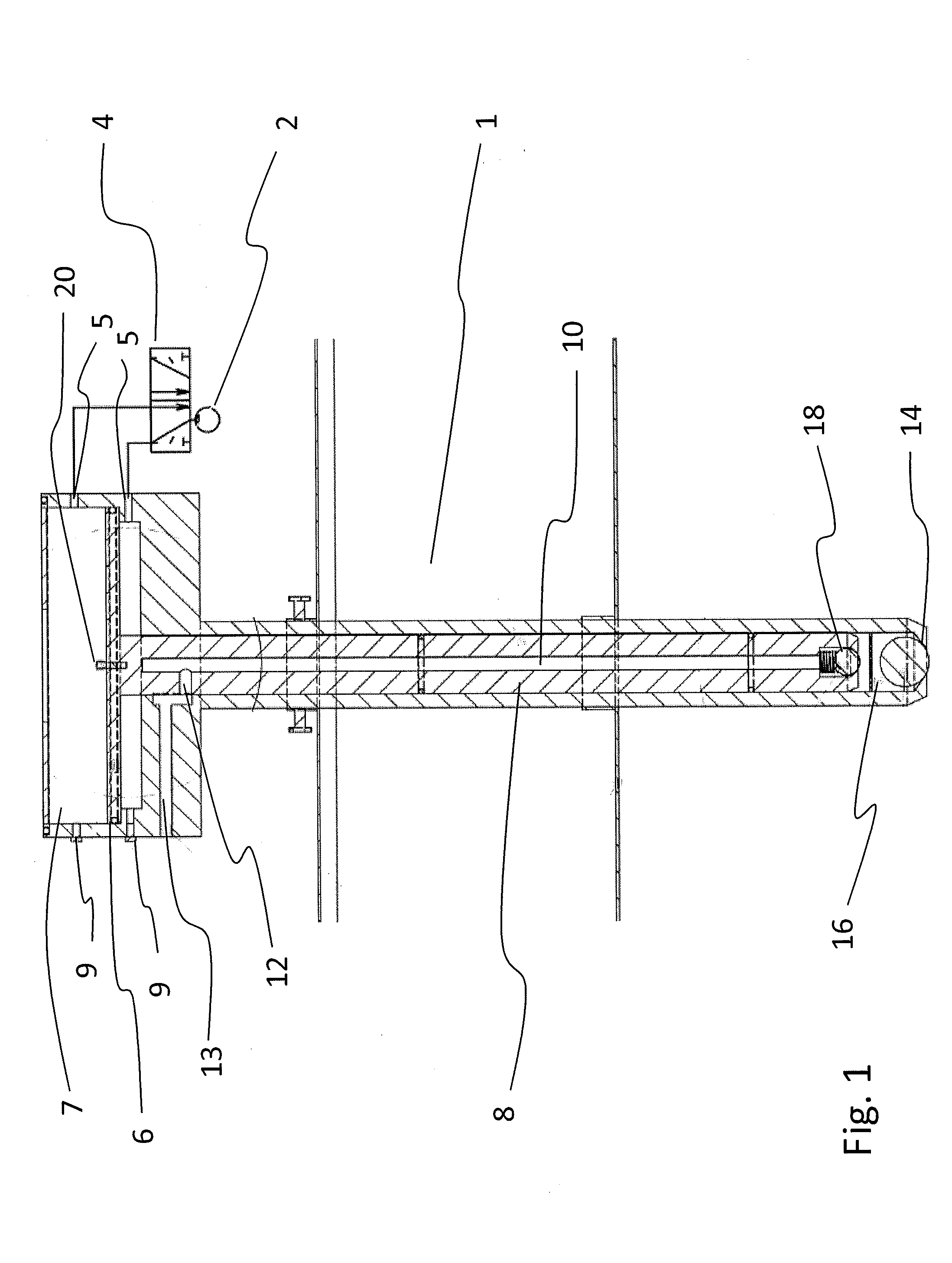

System, apparatus and method for applying anhydrous ammonia (NH3) to the soil

ActiveUS20180139895A1Reduce tube lengthLiquid fertiliser regulation systemsSpray nozzlesEngineeringAmmonia

An applicator for applying anhydrous ammonia, NH3, to an agricultural field is provided. The applicator includes a distribution rail for receiving and out letting a flow of the NH3 The distribution rail has a decreasing inner diameter from an inlet of the distribution rail to distal ends of the distribution rail.

Owner:AG AUTOMATION INC

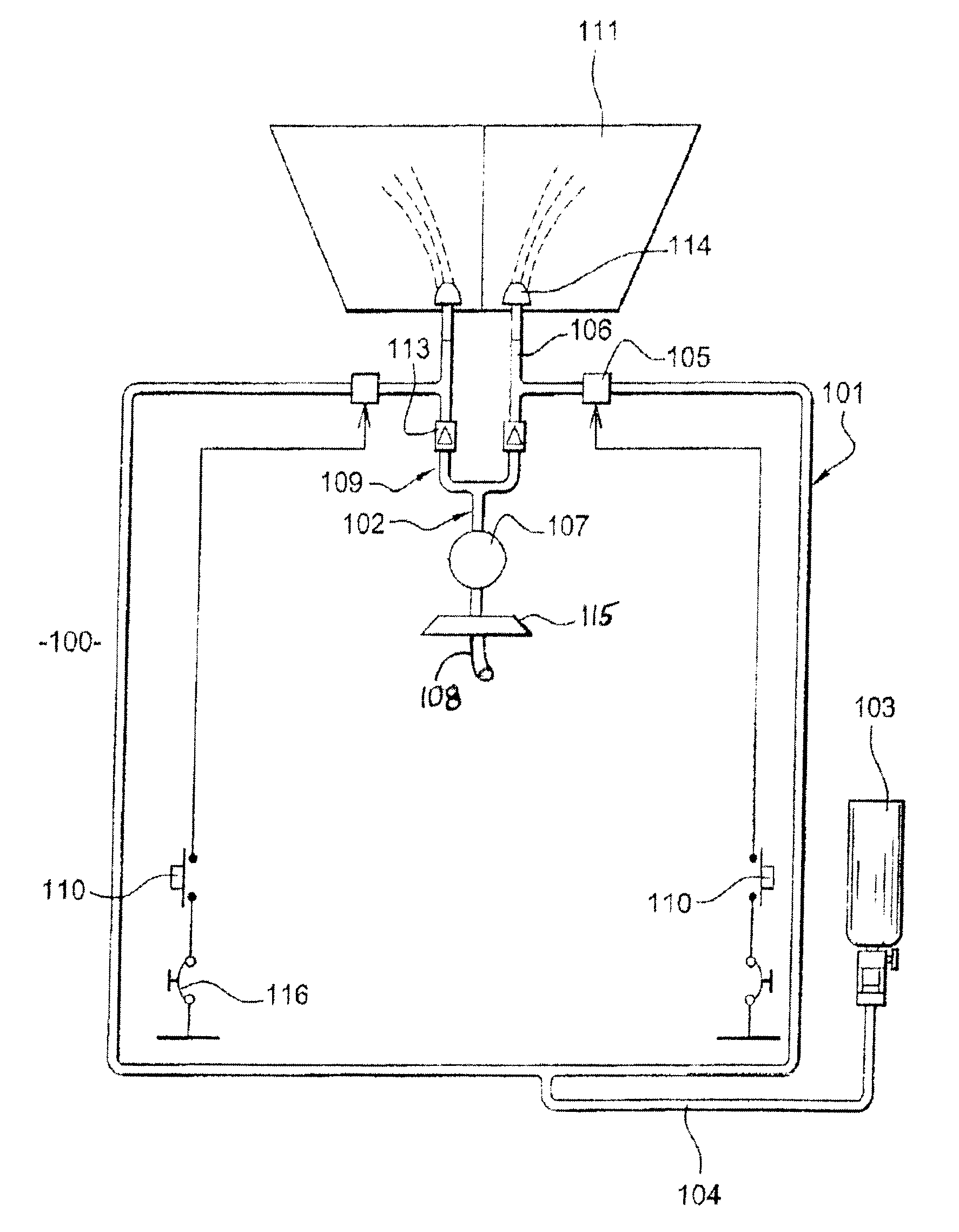

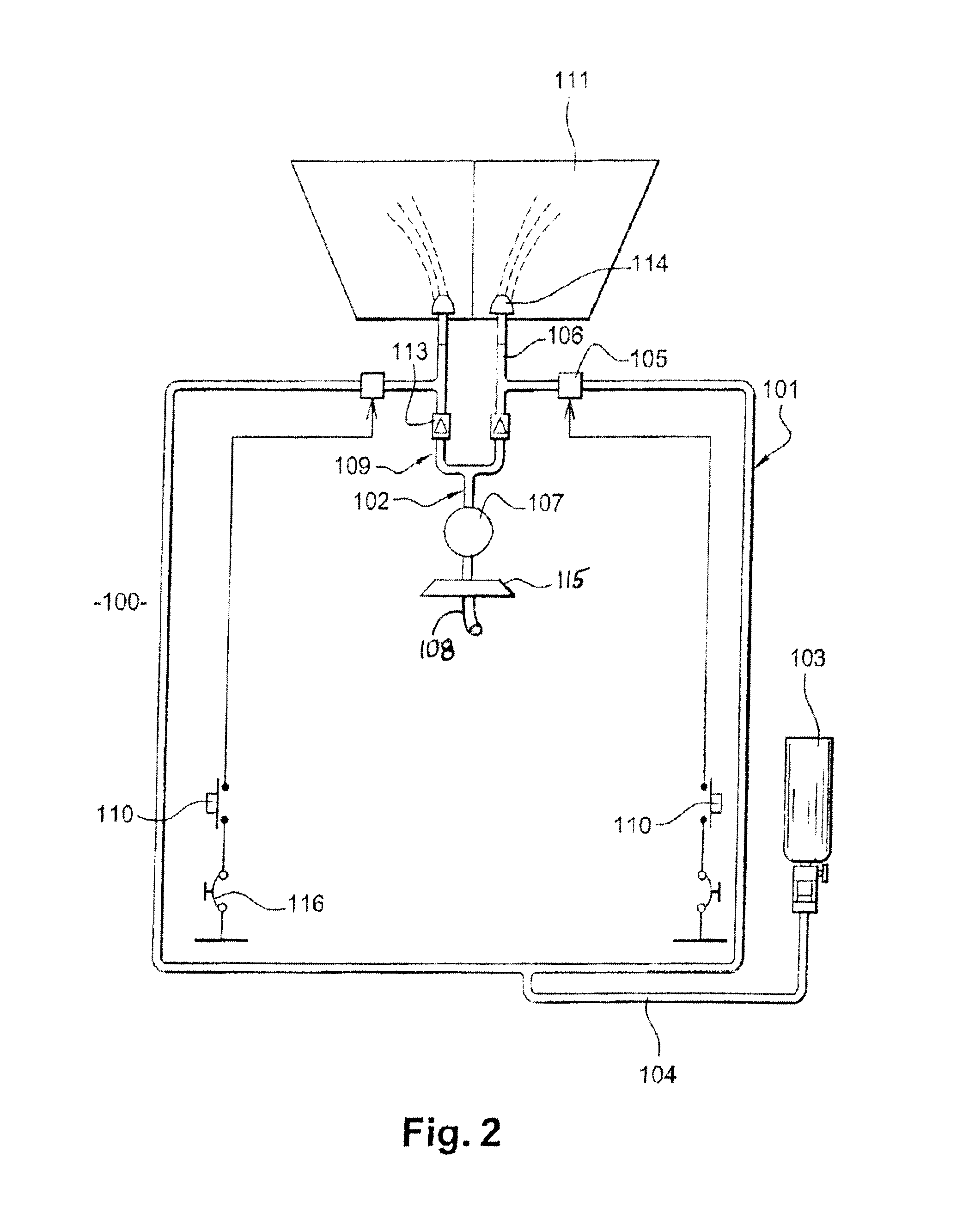

System for the spraying of spray liquid for aircraft windshield, and cockpit provided with such a spraying system

A system for spraying liquid (100) for a windshield (111) of an aircraft including a spray-liquid supply circuit (101), a pressurized-gas supply circuit (102) designed to purge the spray-liquid supply circuit, and at least one nozzle (114) disposed downstream from the circuits and designed to spray the spray liquid and pressurized gas on a windshield, characterized in that the system includes an auxiliary means of compression (107) ready to compress gas designed to circulate in the pressurized-gas supply circuit, the auxiliary means of compression being positioned near the nozzle. Also, an aircraft cockpit provided with at least such a spray system.

Owner:AIRBUS OPERATIONS (SAS)

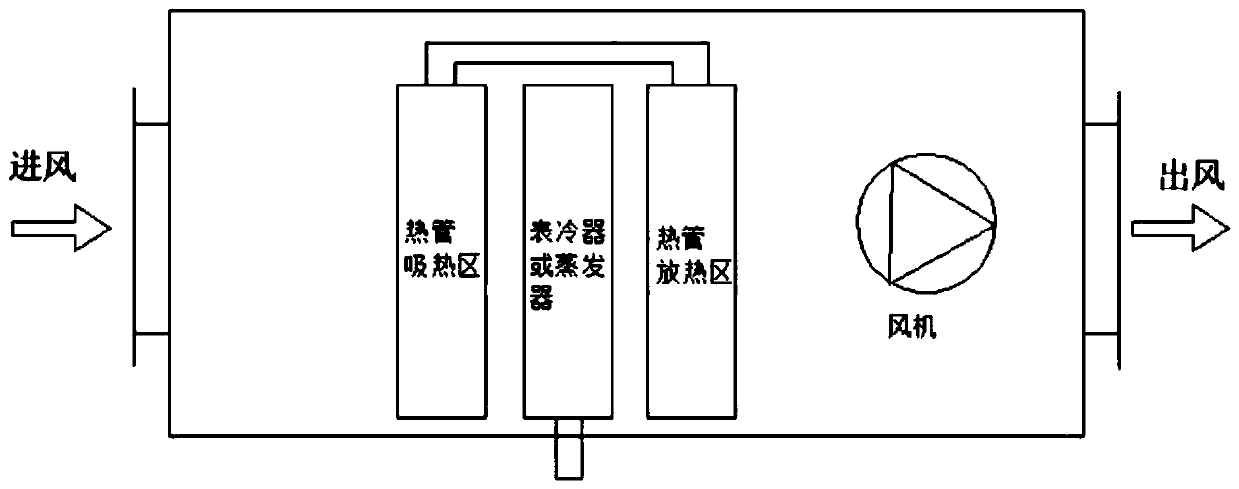

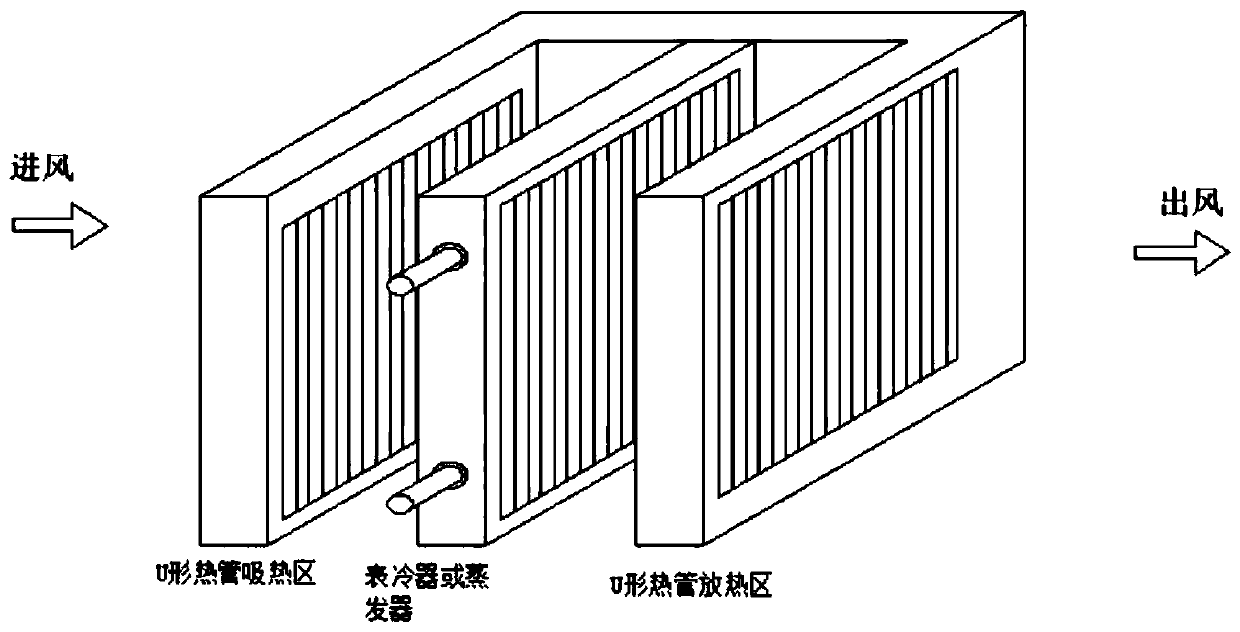

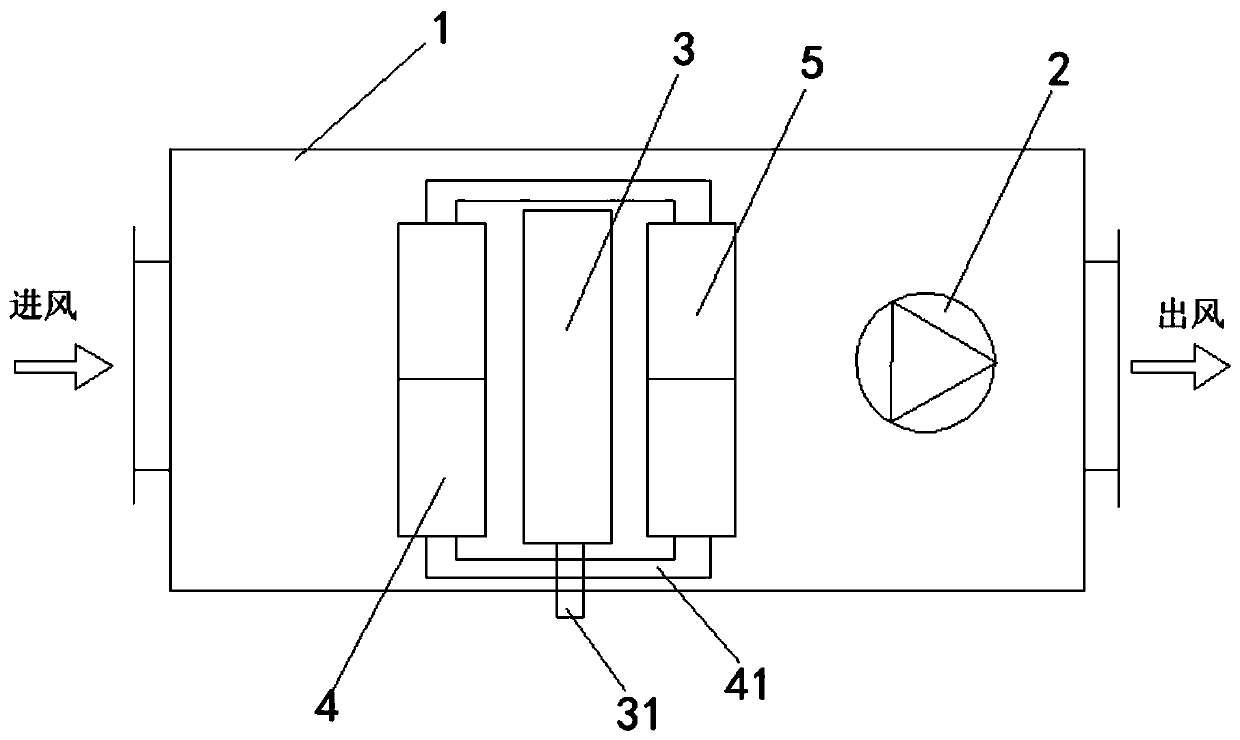

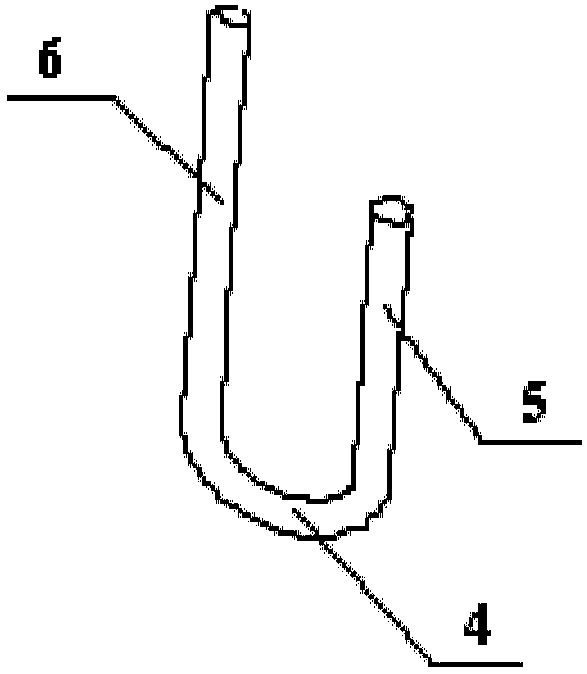

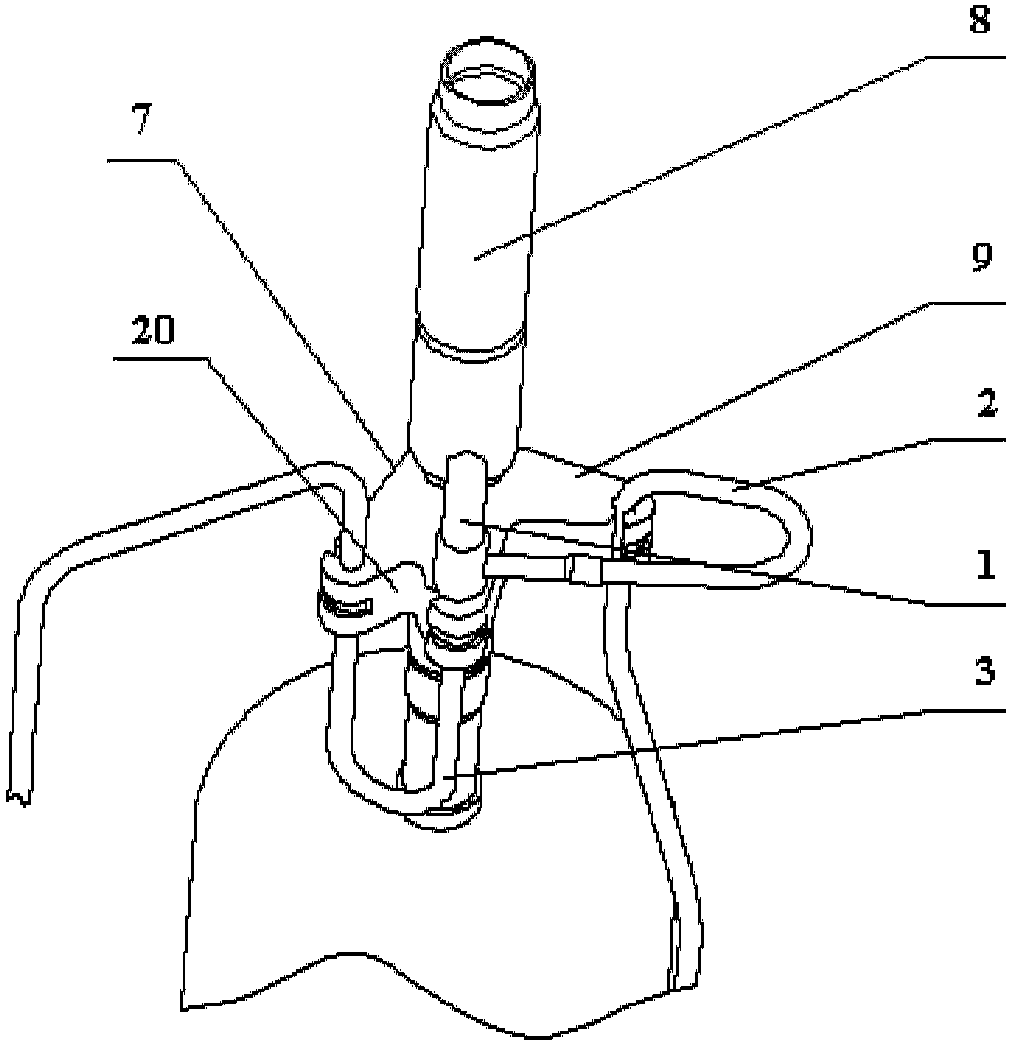

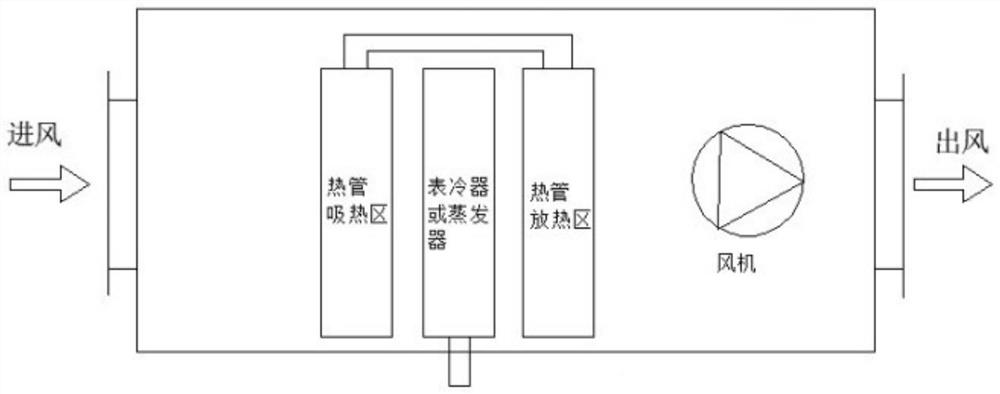

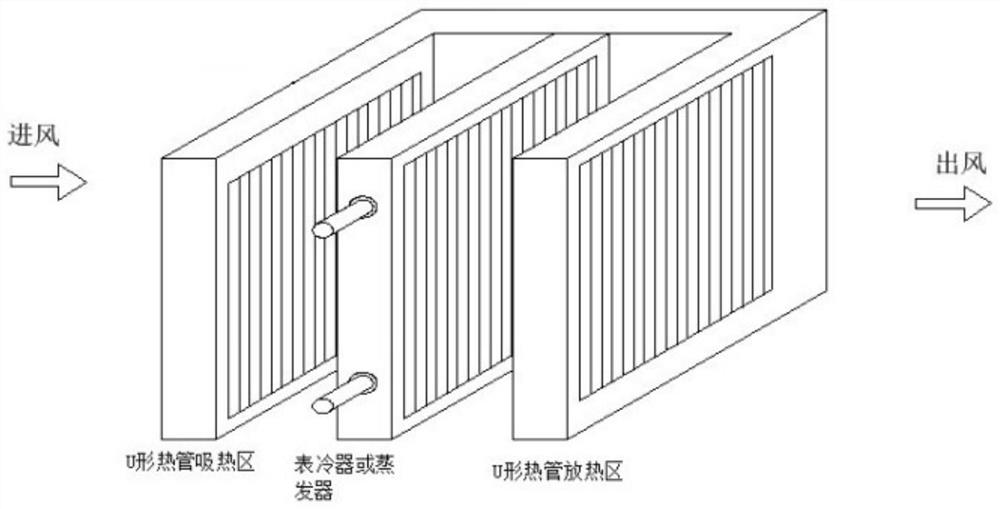

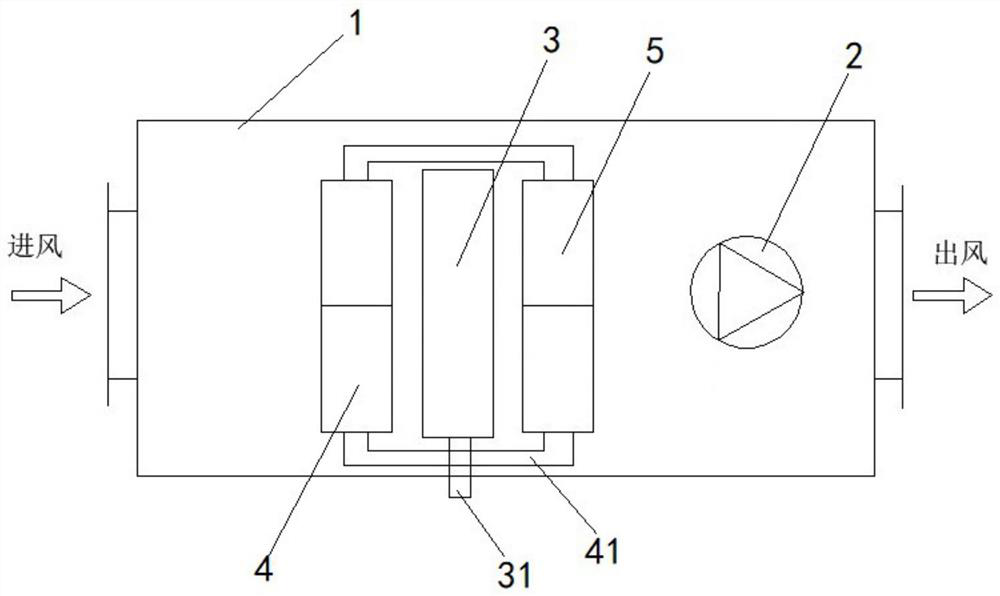

Dehumidification heat exchange device

ActiveCN110345573AReduce retrofit riskImprove performanceLighting and heating apparatusSpace heating and ventilation detailsHeat pipe heat exchangerEvaporator

The invention discloses a dehumidification heat exchange device. The dehumidification heat exchange device comprises an air duct, a surface cooler or an evaporator, a first U-shaped heat pipe heat exchanger and a second U-shaped heat pipe heat exchanger, wherein the air duct comprises an air inlet and an air outlet; the surface cooler or the evaporator is arranged in the air duct, the surface cooler or the evaporator (3) is larger than or equal to 600 mm, and an external pipeline is arranged on one side of the surface cooler or the evaporator; the first U-shaped heat pipe heat exchanger is arranged on one side of the external pipeline of the surface cooler or the evaporator, an interval is formed between the first U-shaped heat pipe heat exchanger and the connecting pipeline of a heat insulation area, and the interval is used for being connected with the outside through an external pipeline of the surface cooler or the evaporator; and the second U-shaped heat pipe heat exchanger and the first U-shaped heat pipe heat exchanger are arranged on the other side of the surface cooler or the evaporator in an opposite installation mode, and the pipe diameter of heat exchange pipelines of the first U-shaped heat pipe heat exchanger and the heat exchange pipeline of the second U-shaped heat pipe heat exchanger is 7.0-9.52mm. According to the dehumidification heat exchange device, the structure of the air duct does not need to be changed, so that the transformation risk is reduced, and the modification cost and period are shortened.

Owner:沈珂

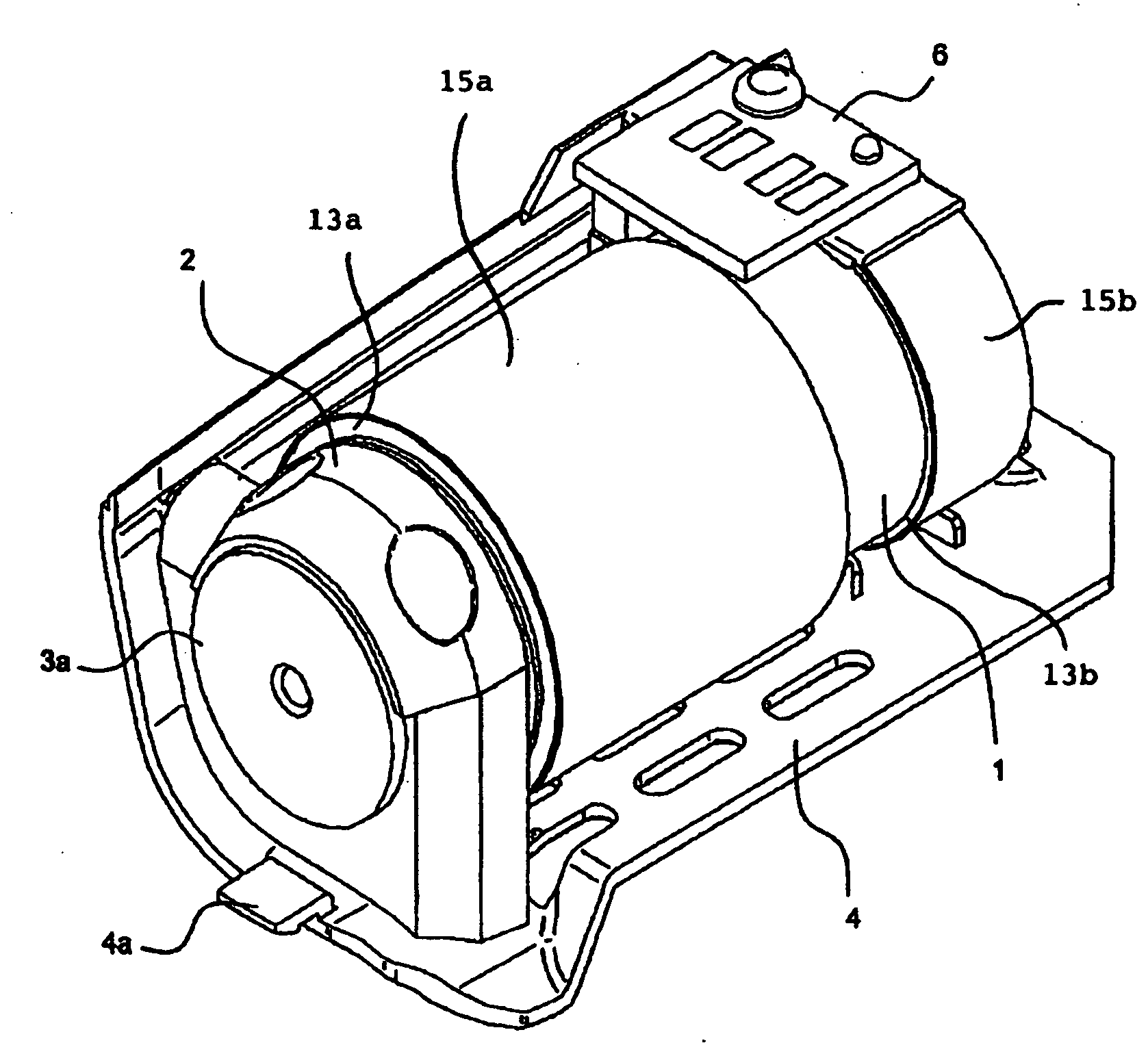

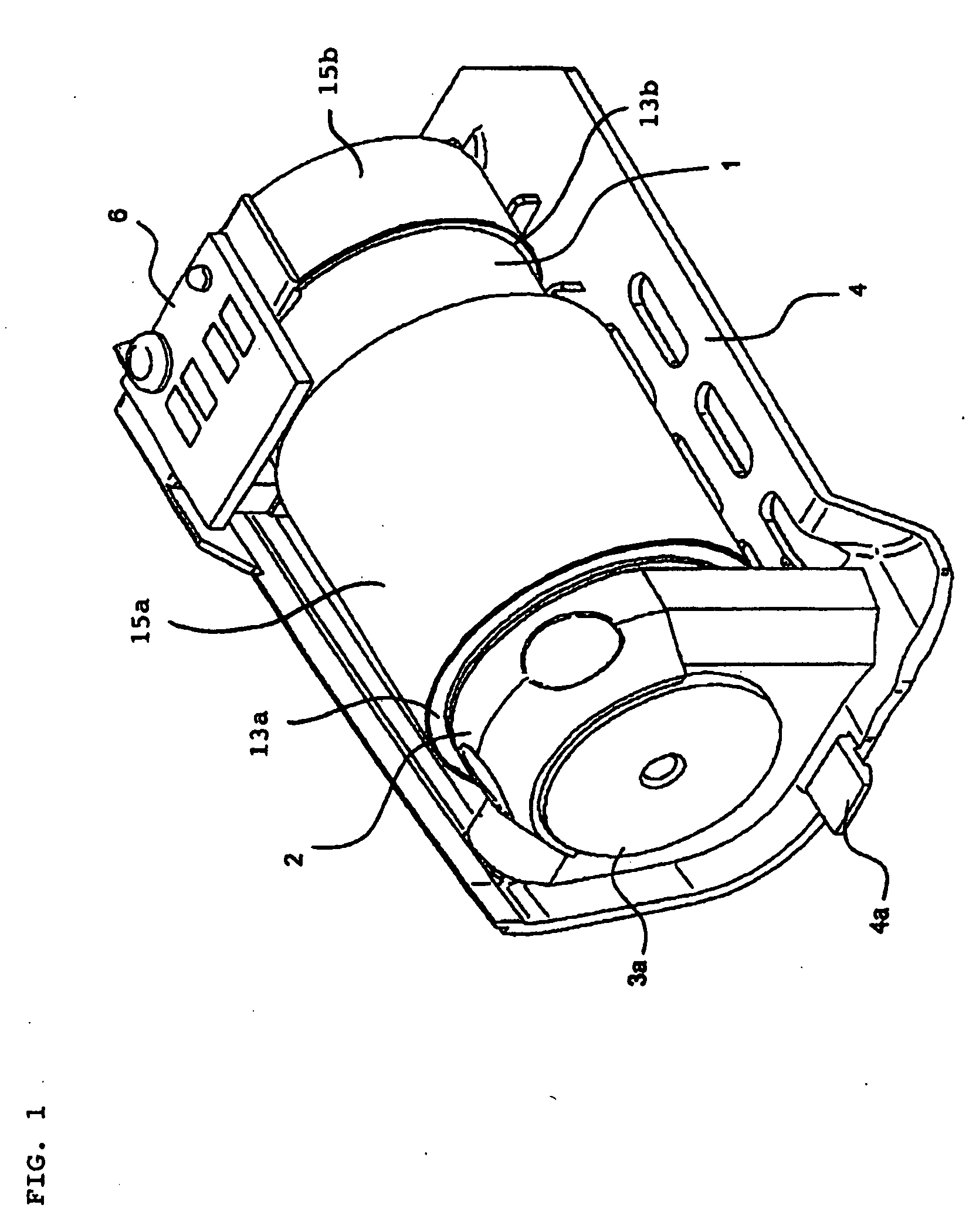

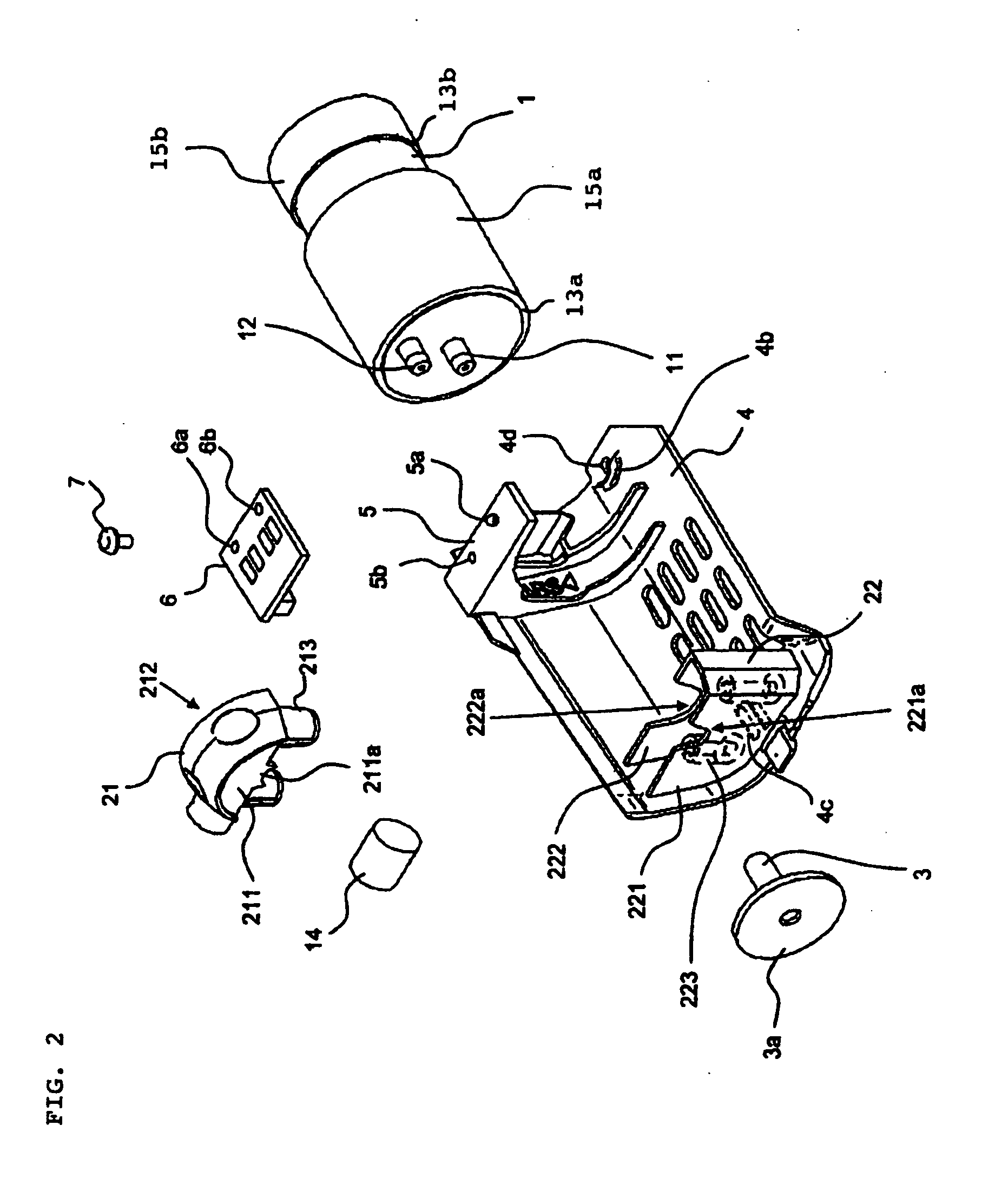

Cooling pump unit and projection display apparatus including the same

InactiveUS20110063582A1Reduce tube lengthReduce the cushioning forcePositive displacement pump componentsFlexible member pumpsElastomerEngineering

Generation of noise is suppressed by solving the problems of crushing and wear of a cushion caused by thermal expansion of a communicating tube. A pump unit includes main pump body 1 for discharging compressed air, a communicating tube made of an elastomer and having its one end fitted to a discharge opening of the main pump body 1, pump fixing portion 2 for holding a part of a portion of the communicating tube other than its portion fitted to the discharge opening, cushions 13a and 13b arranged on an outer circumferential surface of main pump body 1, and films 15a and 15b arranged on surfaces of cushions 13a and 13b. Films 15a and 15b have smooth surfaces, and friction coefficients of the smooth surfaces are smaller than those of cushions 13a and 13b.

Owner:NEC DISPLAY SOLUTIONS LTD

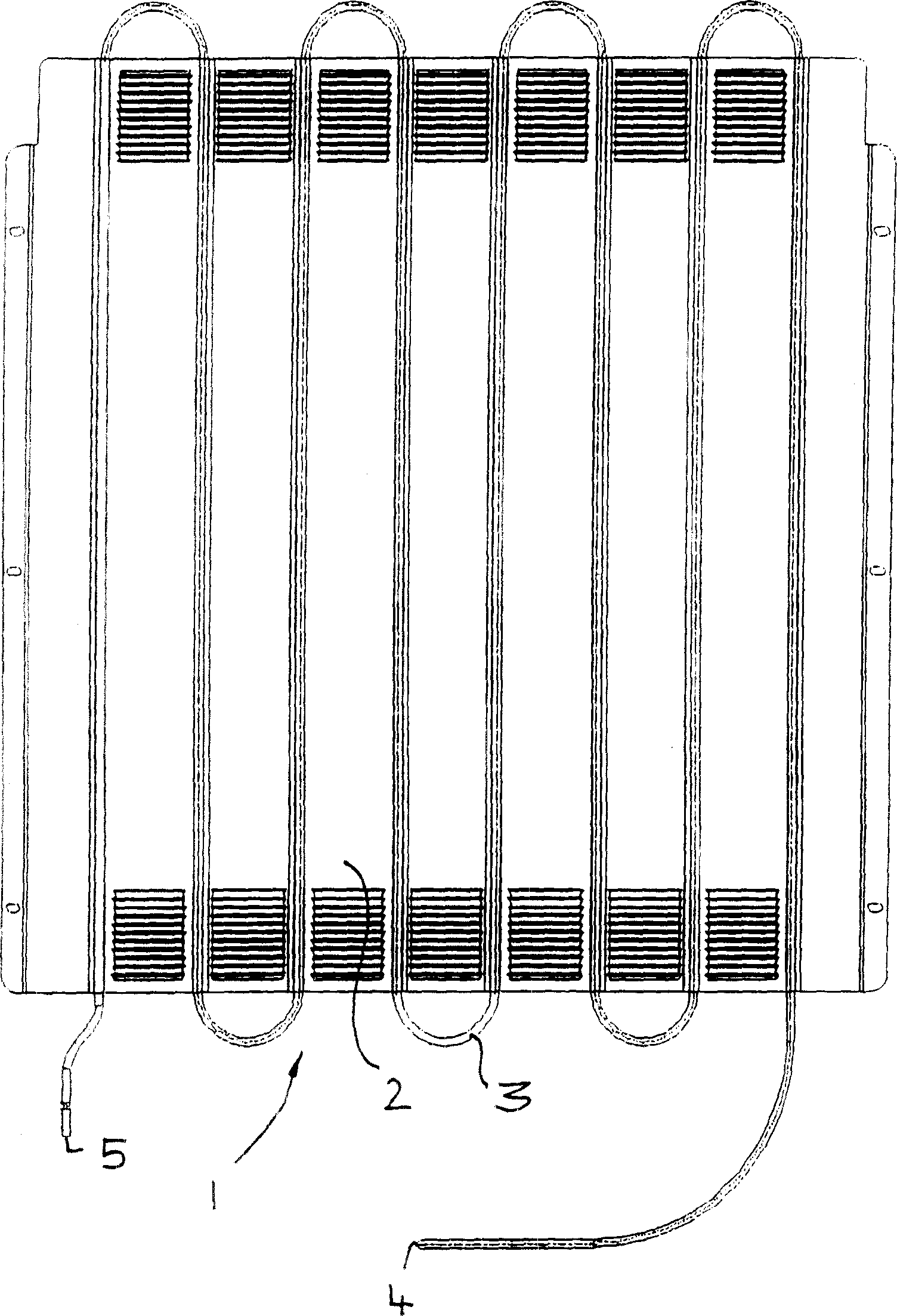

Tube plate condenser for refrigerators and/or freezers

InactiveCN1900631AImprove cooling effectImprove thermal conductivityEvaporators/condensersMetal sheetRefrigerated temperature

The present invention relates to a tube / plate condenser for a cooling circuit of a refrigerator and / or freezer comprising a bent tube in which the cooling circuit medium can be condensed as well as a carrier panel of sheet metal to which the tube is secured. In accordance with the invention, the tube / plate condenser is characterized in that the carrier panel consists of an aluminum sheet and the tube is a steel tube. The present invention further relates to a refrigerator and / or freezer comprising a tube / plate condenser of this type.

Owner:利布赫尔家用器具奥克森豪森有限责任公司

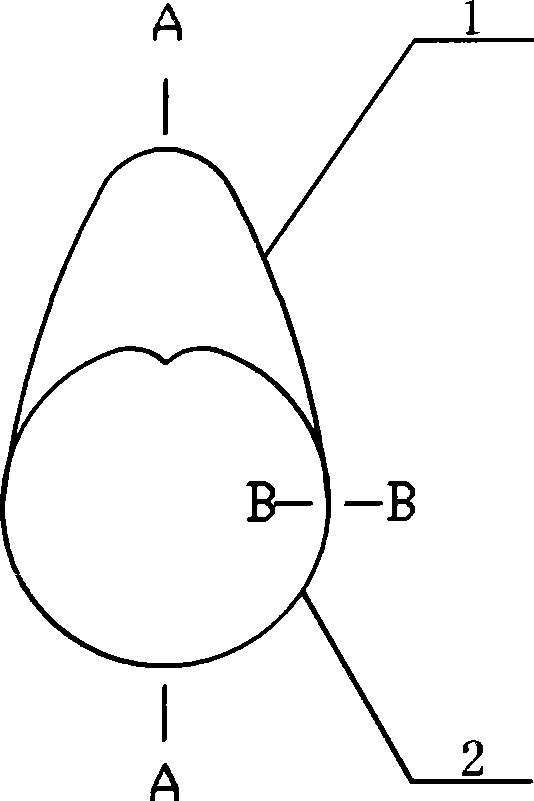

Novel contraceptive cap

The invention relates to a novel contraceptive cap which relates to the field of sexual products, in particular to a novel contraceptive cap. The cap comprises a latex casing body (1), an elastic ring (2), wherein the elastic ring (2) is arranged at the opening end of the latex casing body (1), the shape of the an elastic ring (2) is similar with the shape of the coronary sulcus of male external genital organs, and the cross section of the elastic ring (2) takes the shape of an oblong oval. The invention adopts the following methods that the pipe length of a condom is reduced and the elastic ring is added through making use of the coronary sulcus of male external genital organs, as the pipe length of the condom is reduced, and a sperm reservoir of the traditional condom, not only the contraception can be achieved, but also the full joy and comfort during sexual intercourse between the sexes.

Owner:陈天恩

Simplified water beam vaporization cooling system of steel-rolling stepping heating furnace

InactiveCN102071304BAvoid round-trip routingReduce tube lengthFurnace typesFurnace coolingEnergy transferVaporization

The invention relates to a simplified water beam vaporization cooling system of a steel-rolling stepping heating furnace. The system comprises a stepping beam circulation loop, a fixed beam circulation loop and a water supply loop, wherein the water supply loop comprises an atmospheric thermal deaerator, a deoxidization water tank arranged at the lower part of the atmospheric thermal deaerator, and an electric water supply pump, which is connected in series to a deoxidization downcomer pipe at the lower part of the deoxidization water tank and connected to a steam pocket through a high-pressure water supply pipe, the high-pressure water supply pipe is provided with a high-pressure water supply branch pipe, and a stepping circulation loop downcomer pipe in the stepping beam circulation loop and a fixed circulation loop downcomer pipe in the fixed beam circulation loop are provided with efflux energy transfer devices which are respectively connected to the high-pressure water supply branch pipe. The simplified water beam vaporization cooling system of the steel-rolling stepping heating furnace, which is provided by the invention, integrates the three independent processes of deoxidization, water supply and circulation into a continuous process with low energy consumption to reduce the loading capacity, shorten the power consumption time, and has the advantages of high efficiencyand energy saving.

Owner:BEIJING MINGCHENG TECH DEV

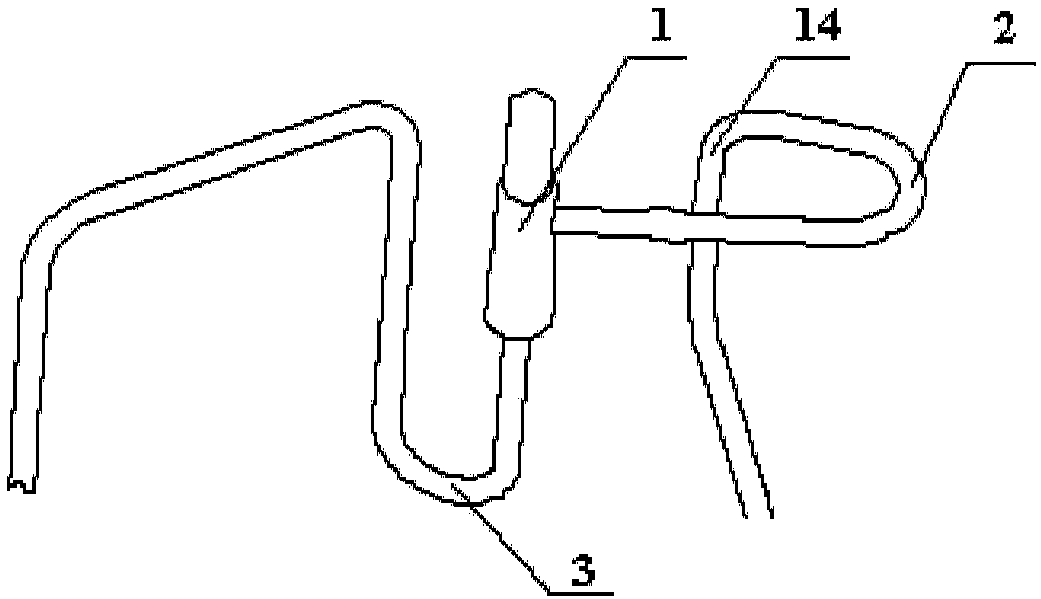

Pipeline, pipeline system and air conditioner

ActiveCN108151378ASimple structureEasy to operateMechanical apparatusFluid circulation arrangementEngineering

The invention provides a pipeline, a pipeline system and an air conditioner. The pipeline comprises an electromagnetic valve, a first U-shaped bend connected with the electromagnetic valve, and a second U-shaped bend connected with the electromagnetic valve. The plane where the first U-shaped bend is located and the horizontal plane form a first included angle alpha 1 which is not smaller than 0 degree and smaller than 90 degrees. The plane where the second U-shaped bend is located and the horizontal plane form a second included angle alpha 2 which is not smaller than 30 degrees and smaller than or equal to 90 degrees, and alpha 1 is not equal to alpha 2. According to the pipeline, the pipeline system and the air conditioner, the structure is simple, the cost is low, assembling is convenient, the damping effect is good, the reliability is high, and production efficiency is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

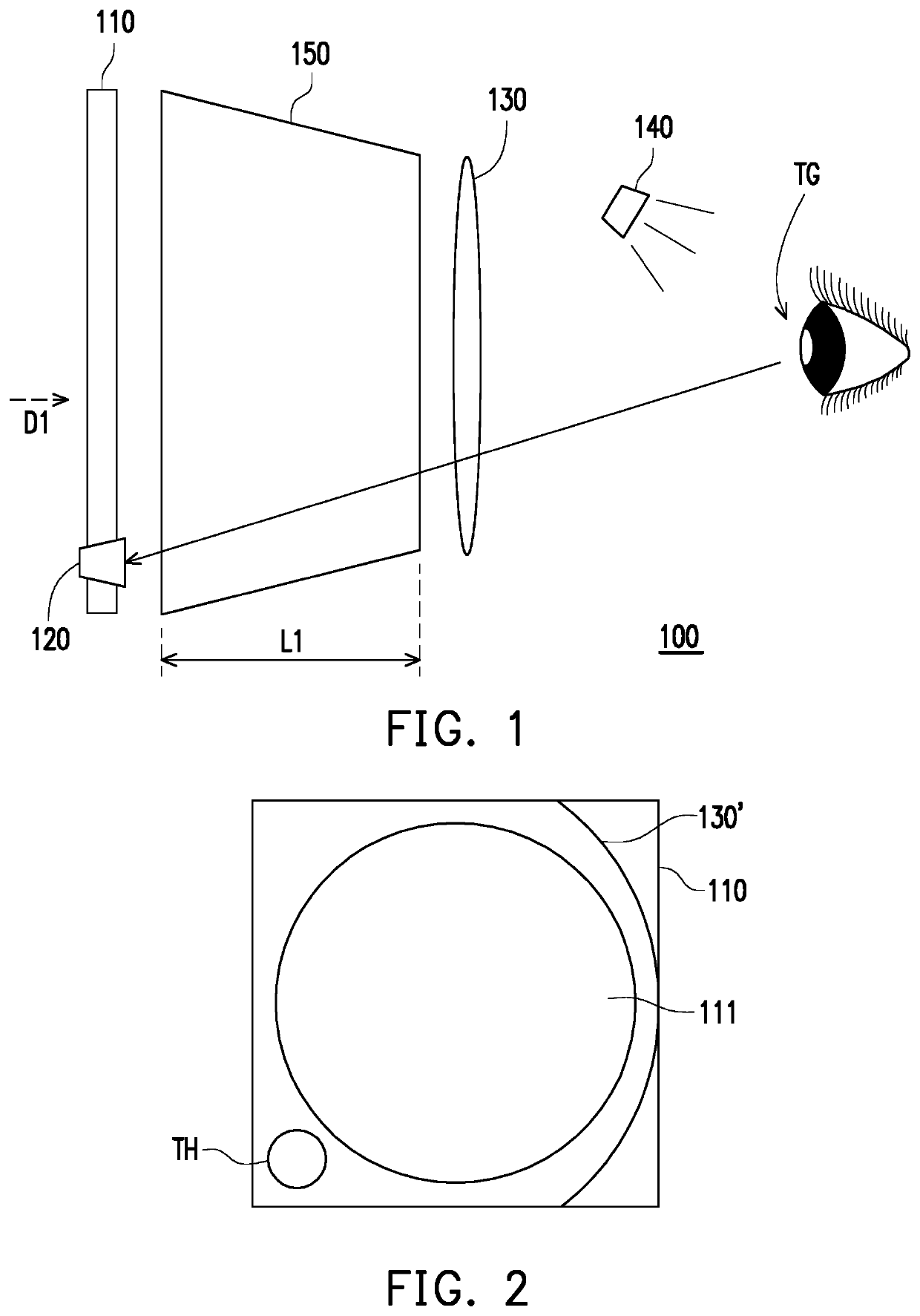

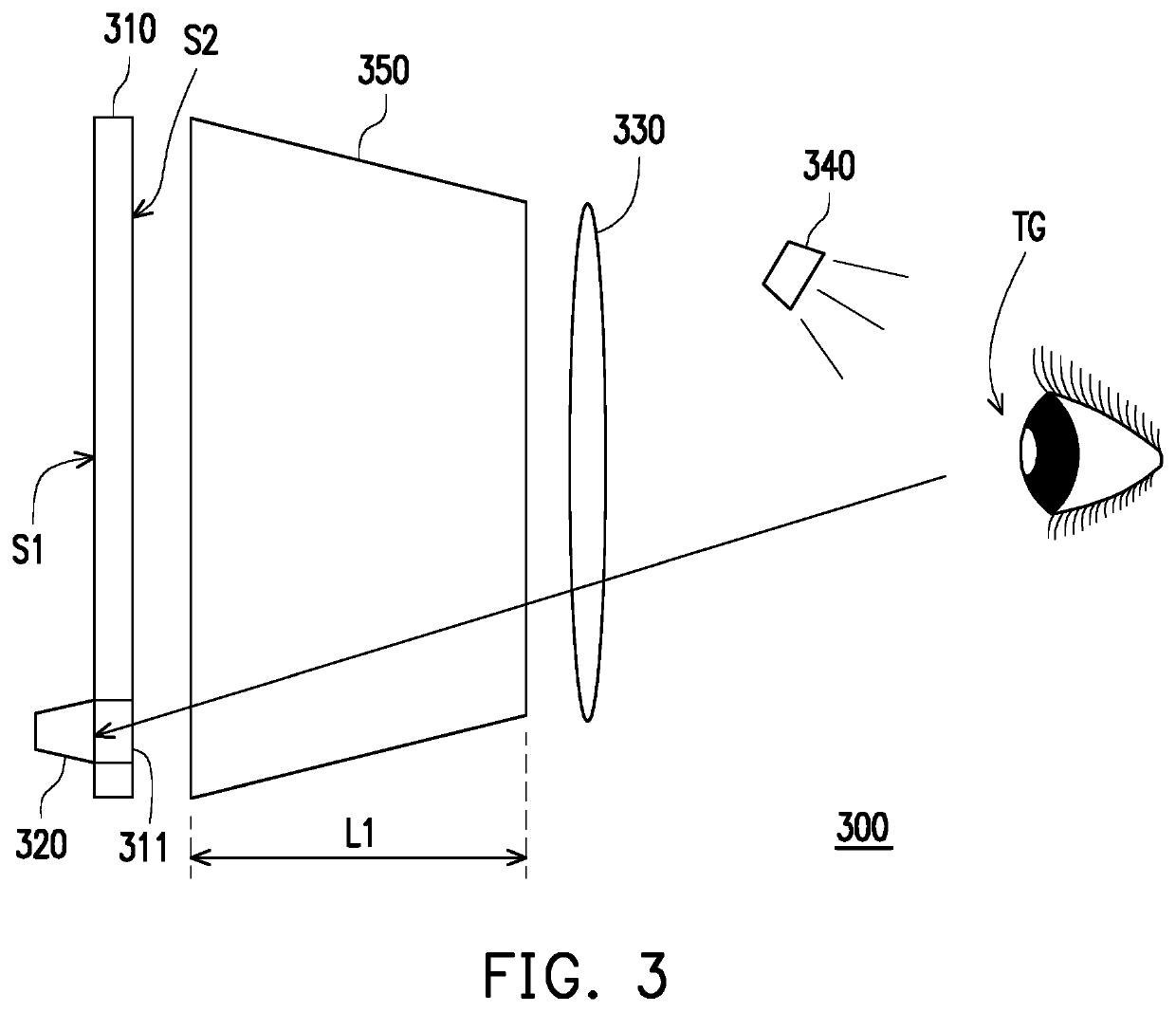

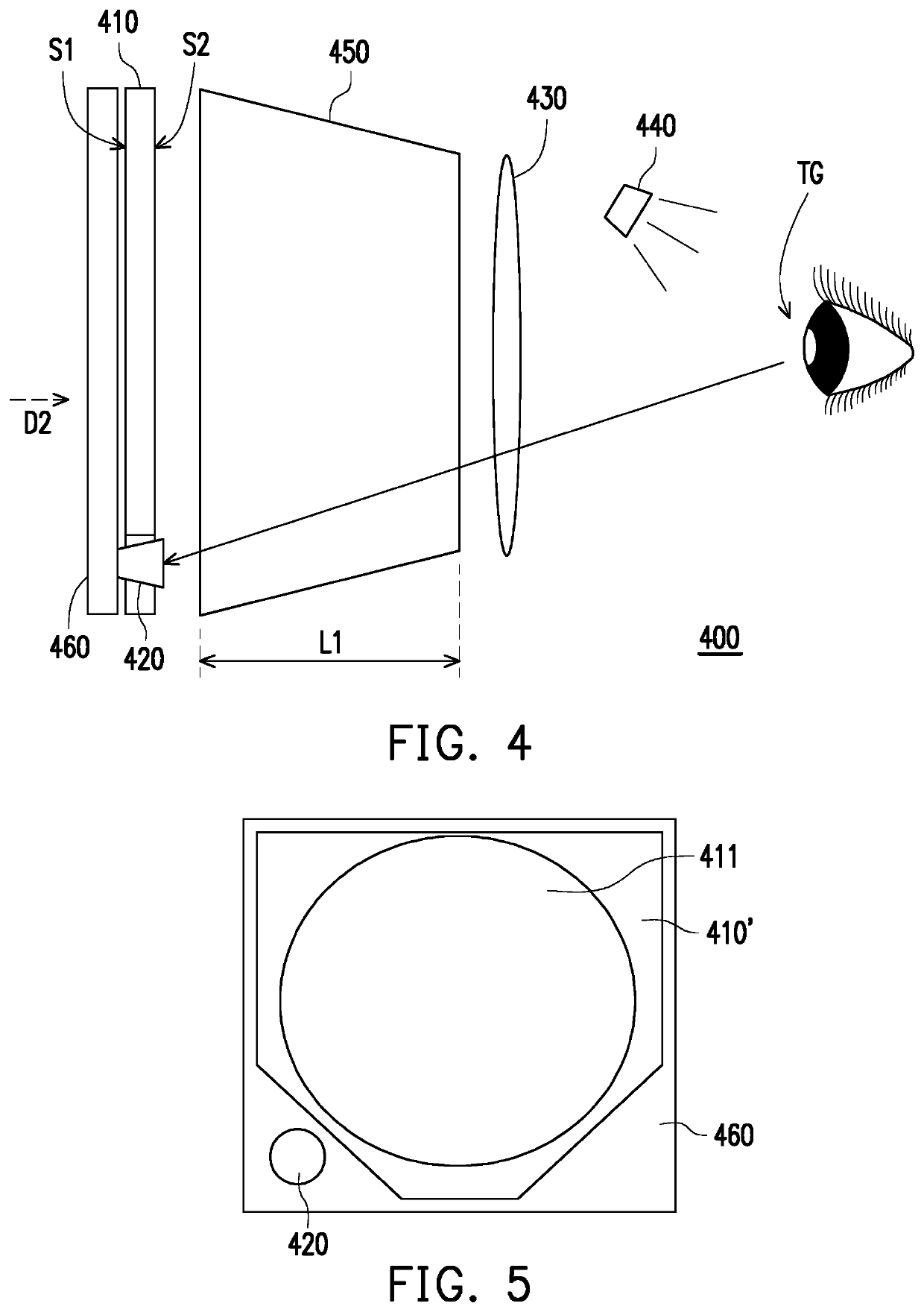

Head mounted display apparatus

ActiveUS10816810B1Reduce in quantityReduce head sizeTelevision system detailsCharacter and pattern recognitionCamera lensComputer graphics (images)

A head mounted display apparatus is provided, including a display, at least one image capturing device and an imaging device. The display provides a display image and projects the display image to a target region. The image capturing device is disposed adjacent to the display, and a camera lens of the image capturing device is oriented toward the target region. The imaging device is disposed between the target region and the display.

Owner:HTC CORP

System, apparatus and method for applying anhydrous ammonia (NH3) to the soil

ActiveUS10925209B2Reduce tube lengthLiquid fertiliser regulation systemsSpray nozzlesSoil scienceEngineering

Owner:AG AUTOMATION INC

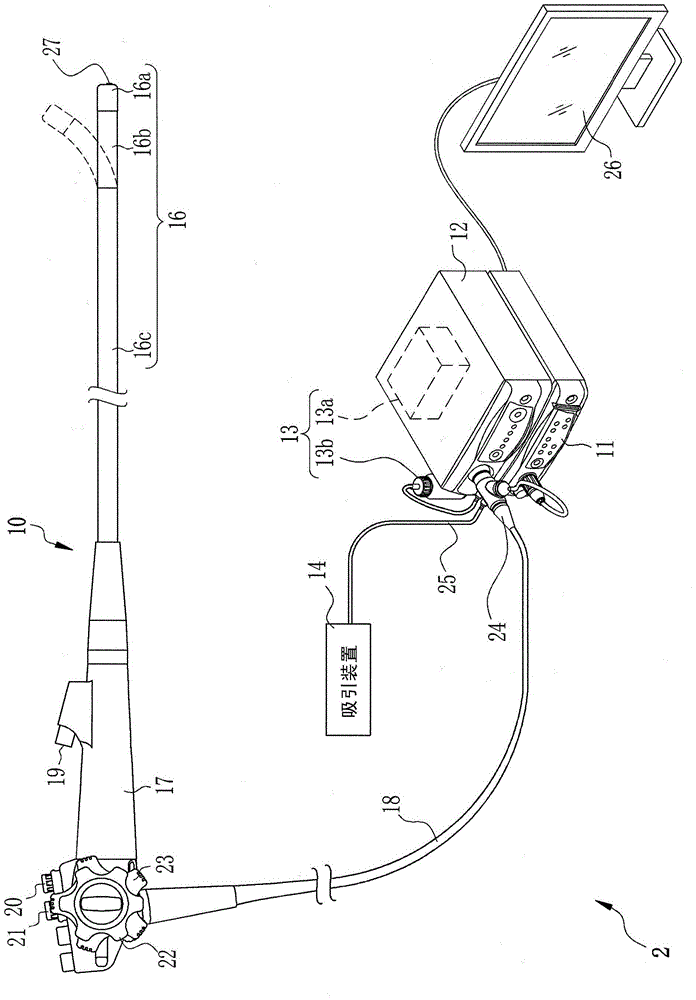

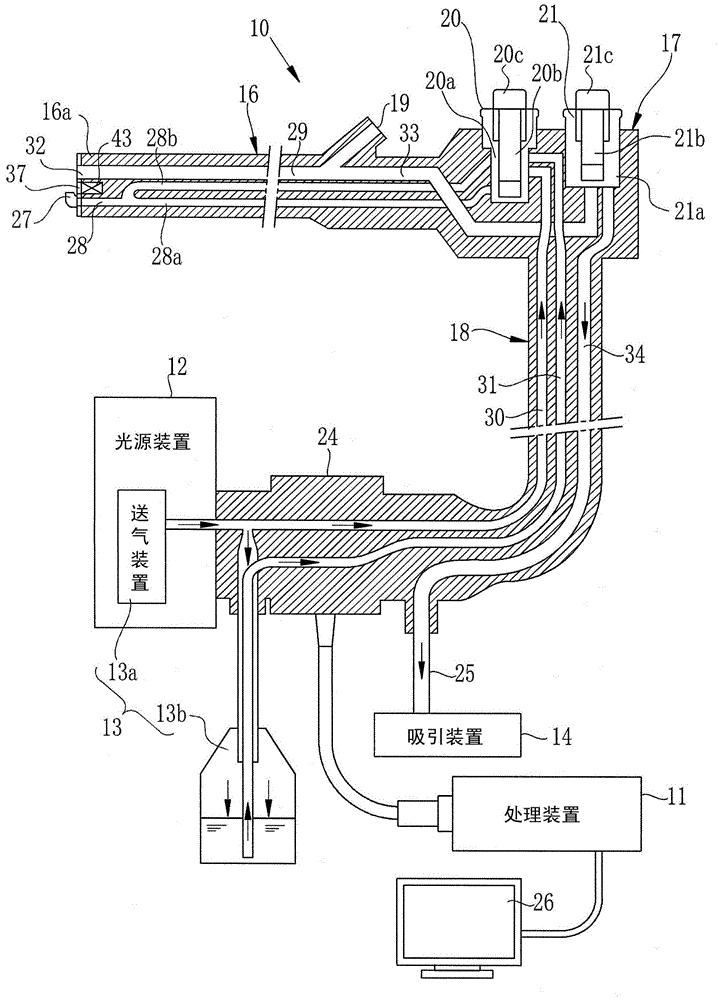

Insertion part for endoscope and endoscope

Owner:FUJIFILM CORP

A kind of reactor and reaction system for synthesizing methyl butynol

ActiveCN105924330BReduce tube lengthEfficient mixingOrganic compound preparationHydroxy compound preparationStatic mixerSide reaction

The invention discloses a reactor and reaction system for synthesizing methylbutynol. The reactor comprises a first-stage tubular reactor and a second-stage tubular reactor, which are connected sequentially, wherein each of the first-stage tubular reactor and the second-stage tubular reactor comprises a tubular reactor and a static mixer arranged in the tubular reactor. The reaction system comprises a stirring reaction kettle, a reactor and a termination mixer which are connected in a proper sequence by virtue of pipelines, wherein the reactor adopts the above reactor for synthesizing methylbutynol, a discharge port of the stirring reaction kettle is connected with a feed port of the first-stage tubular reactor, and a discharge port of the second-stage tubular reactor is connected with a feed port of the termination mixer. The reactor and the reaction system for synthesizing methylbutynol, disclosed by the invention, not only greatly shorten the tube pass length of the reactor, but also realize effective mixing of materials, avoid occurrence of side reactions, and greatly improve the product yield in comparison with an early process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

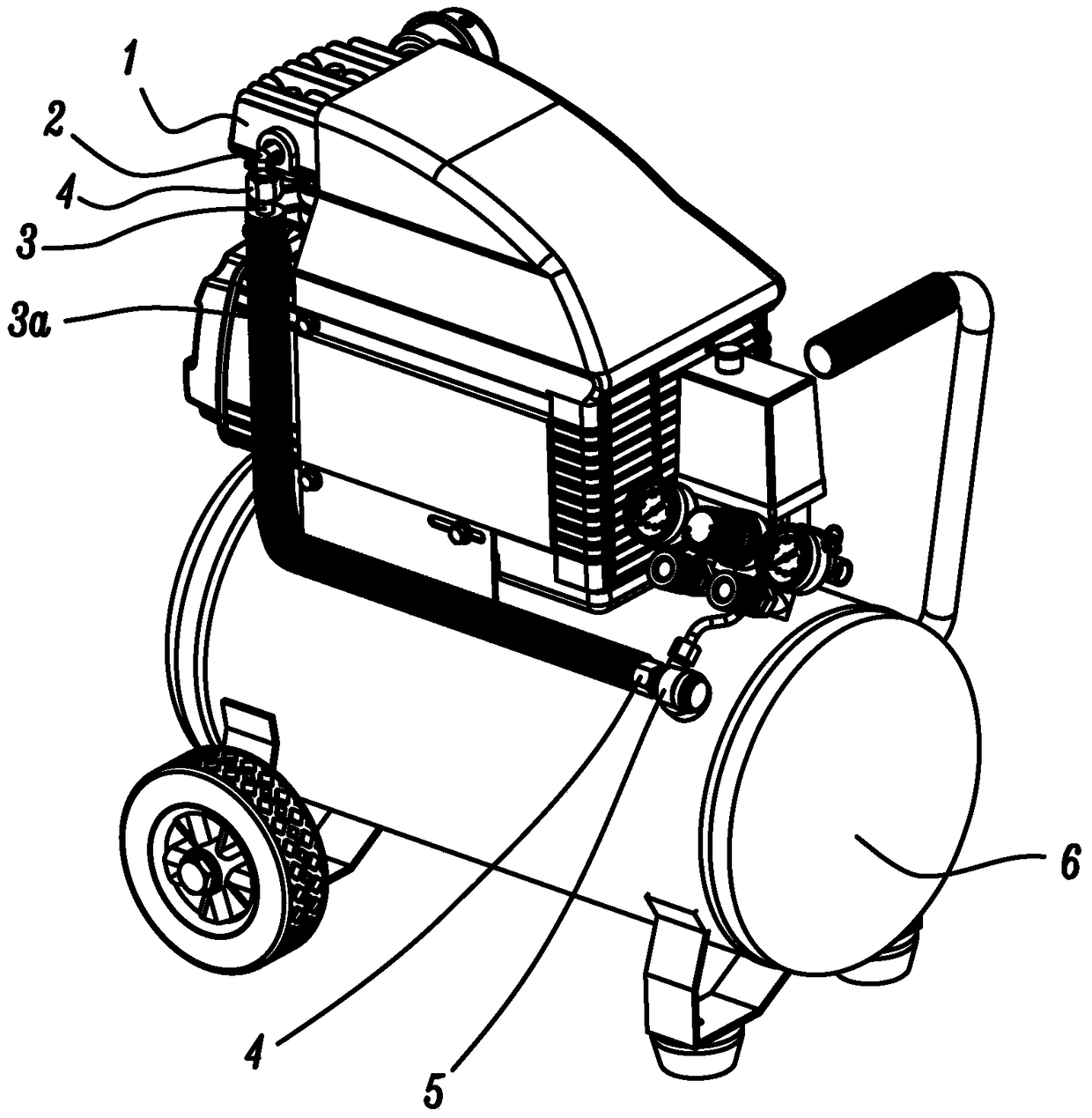

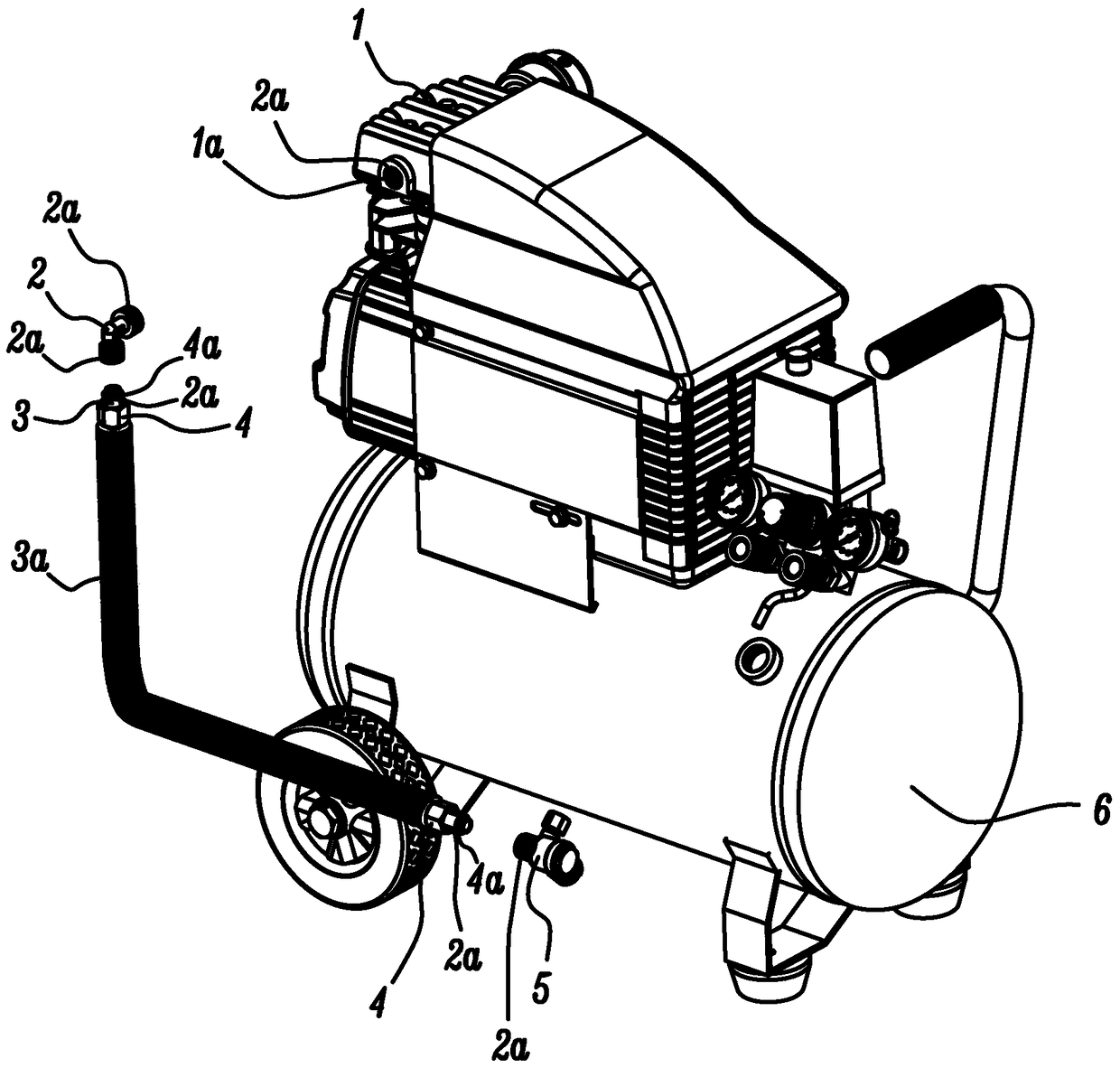

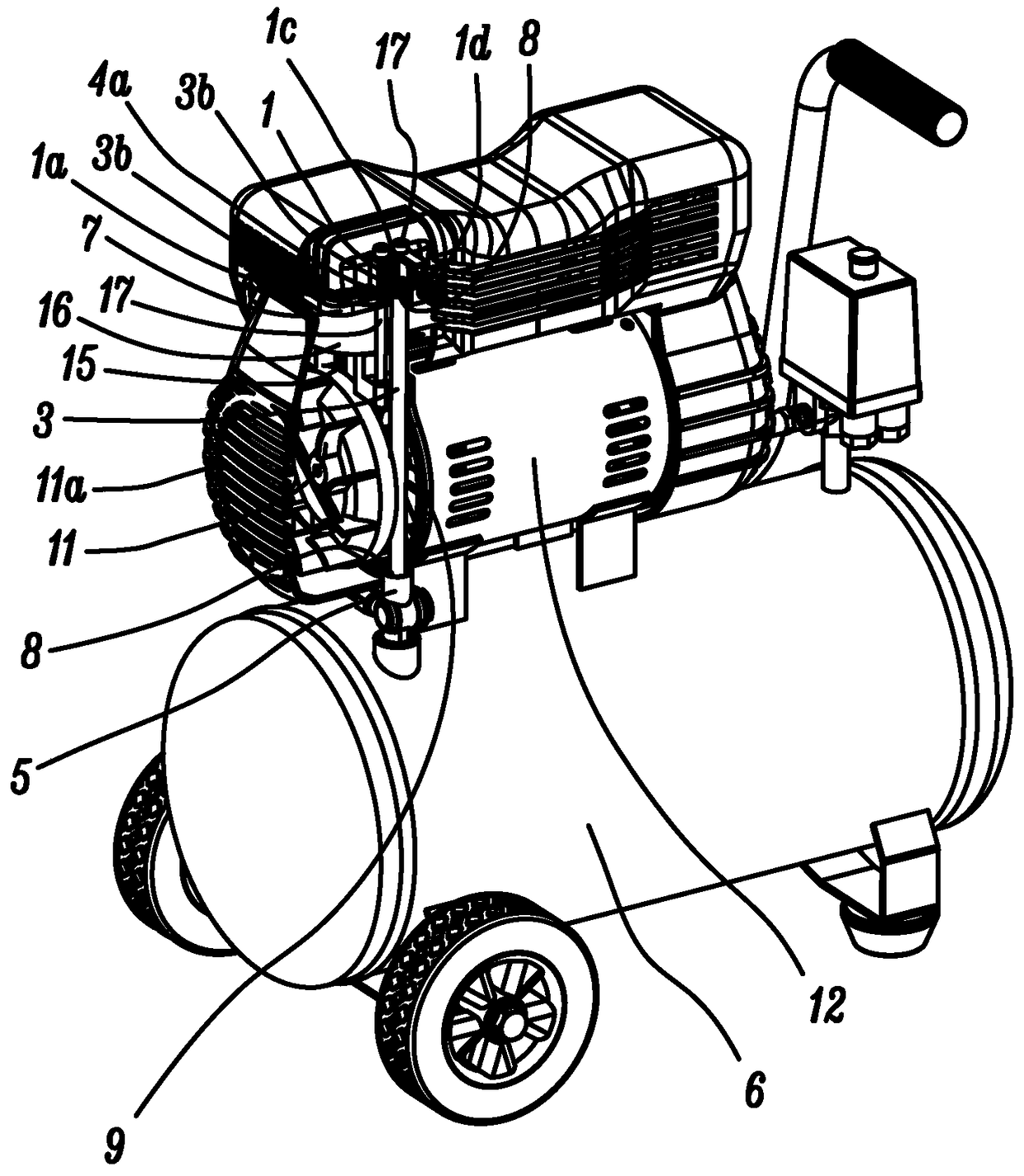

A thread-free connection structure and layout of an air compressor exhaust pipe

ActiveCN105370546BReduce tube lengthReduce the number of partsPositive displacement pump componentsPump installationsAir compressorExhaust pipe

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

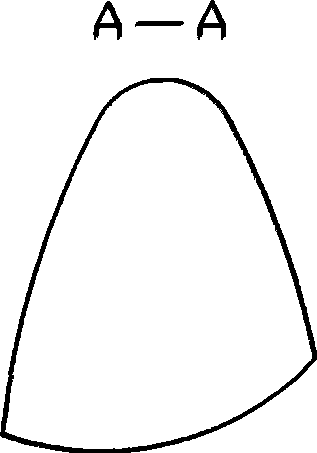

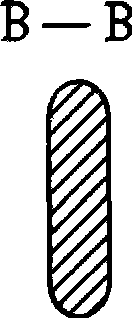

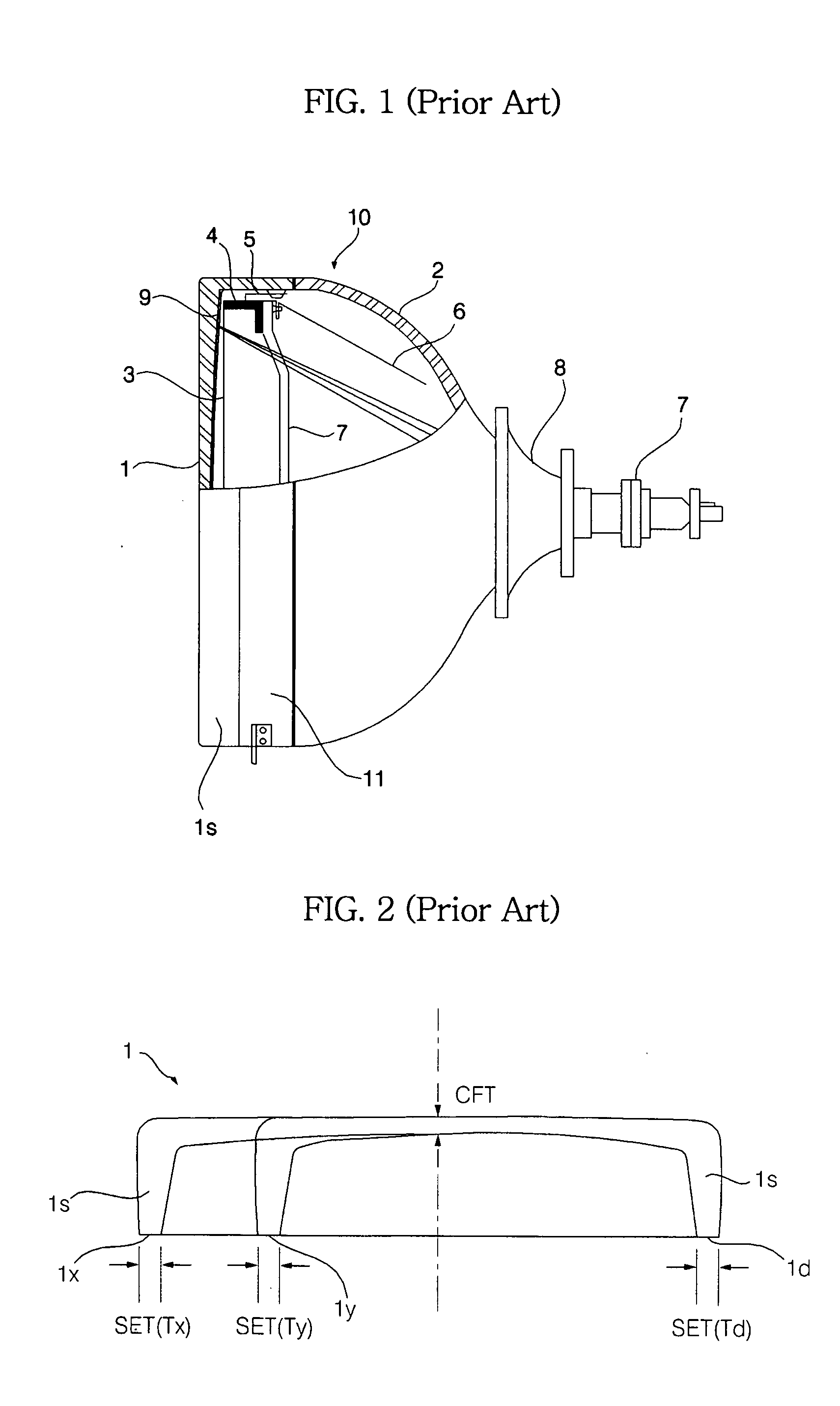

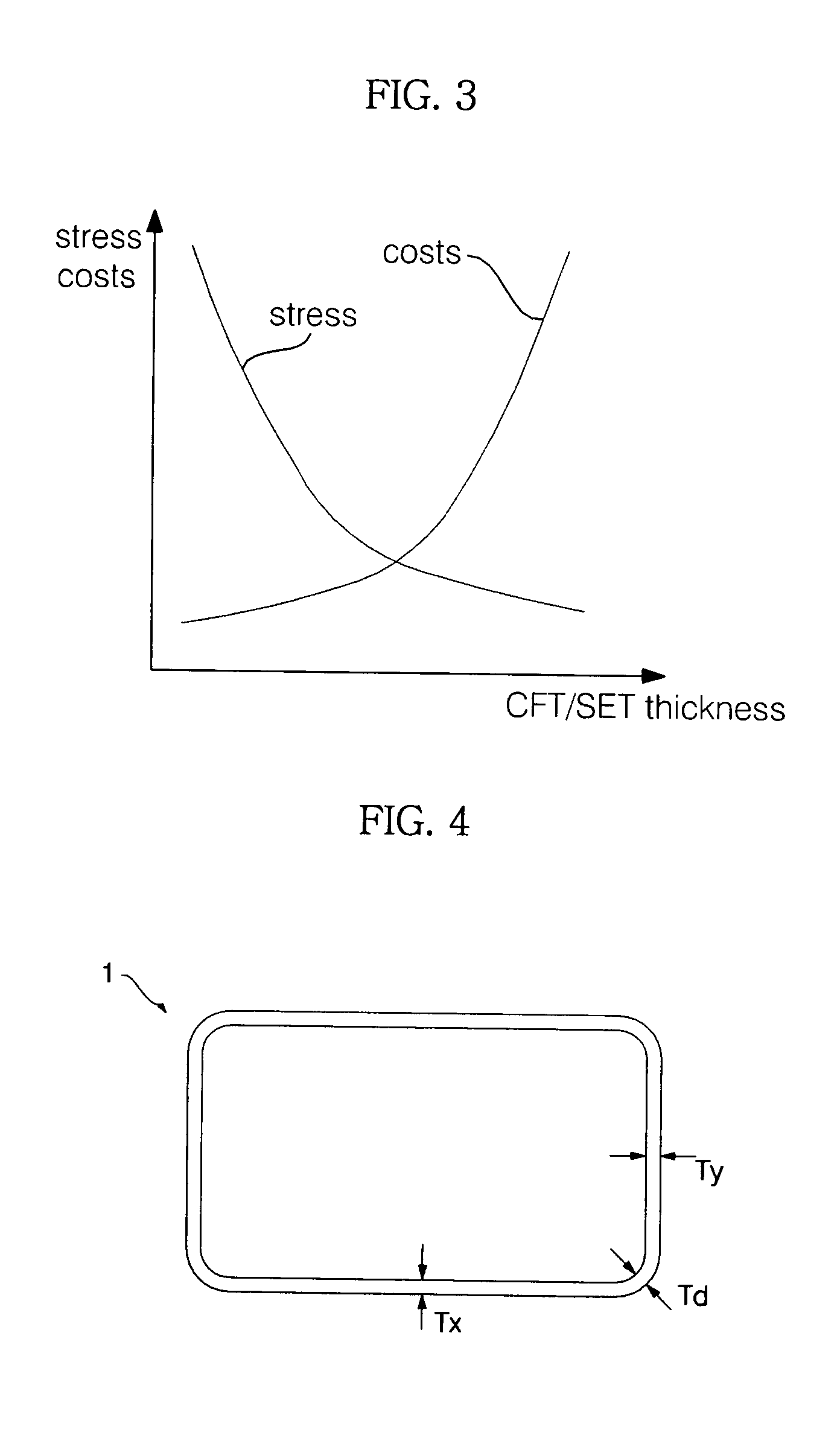

Panel for slim cathode ray tubes

InactiveUS20060186783A1Improving explosion-resistance characteristicRigid enoughCathode-ray/electron-beam tube vessels/containersDiagonalCathode ray

Disclosed herein is a panel of a slim cathode ray tube constructed such that the deflection angle of an electron beam is 110 degrees or more. The slim cathode ray tube includes a tube part constituted by joining the panel and a funnel with each other. The panel includes a face part, a side wall disposed around the face part such that the side wall is bent toward the funnel, and a seal edge formed at the side wall, the panel being joined with the funnel at the seal edge. On the assumption that the thickness of the center of the face part is Tc, the thickness of the long side of the seal edge is Tx, the thickness of the short side of the seal edge is Ty, and the thickness of the diagonal part of the seal edge is Td, the panel is constructed such that the following inequalities are satisfied: 0.8≦Tc / Ty≦Tc / Tx≦1.0≦Tc / Td and Td<Tx<Ty, and the side wall has an outer skirt angle of 0.5 to 1.5 degrees.

Owner:MERIDIAN SOLAR & DISPLAY

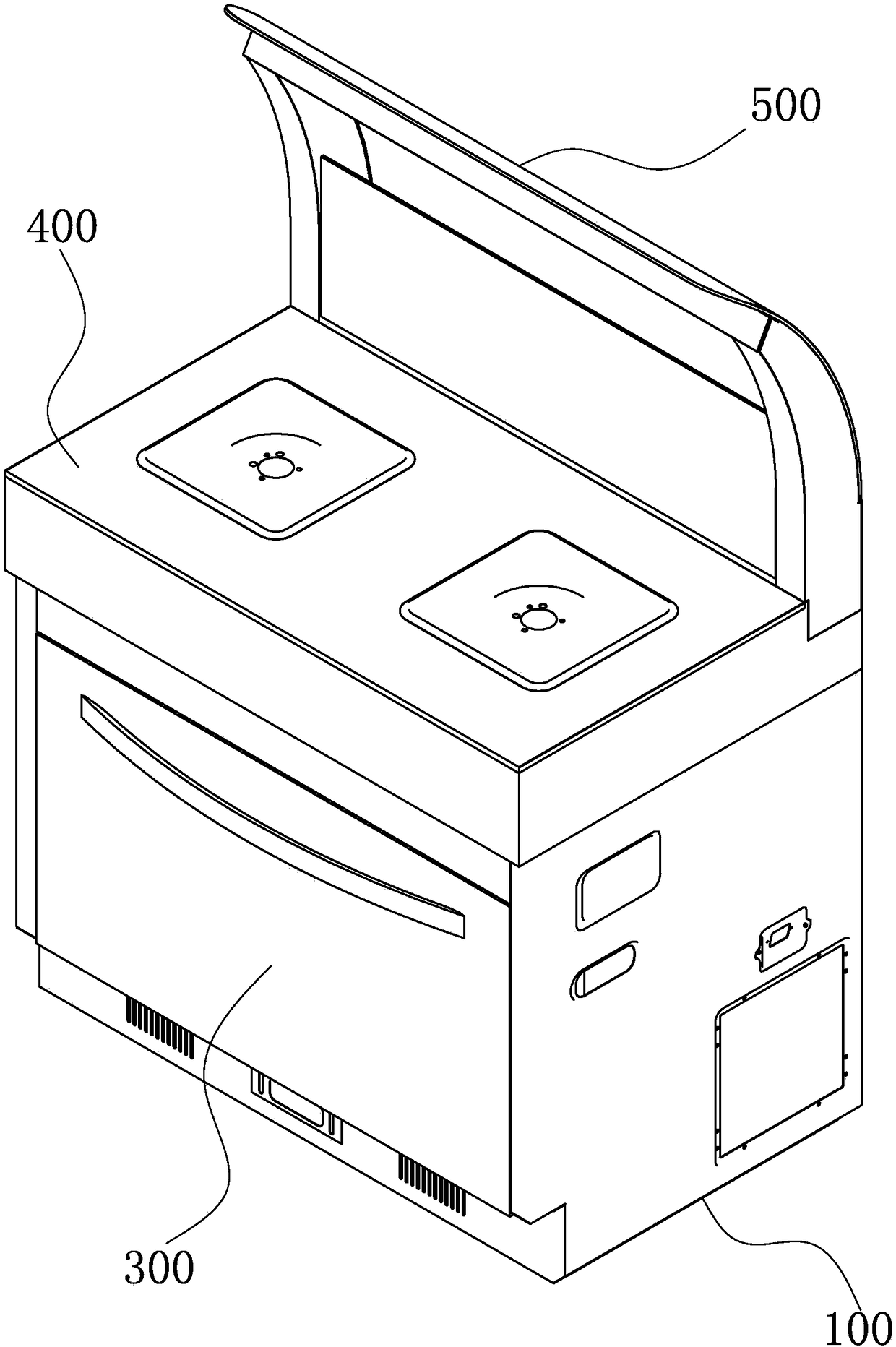

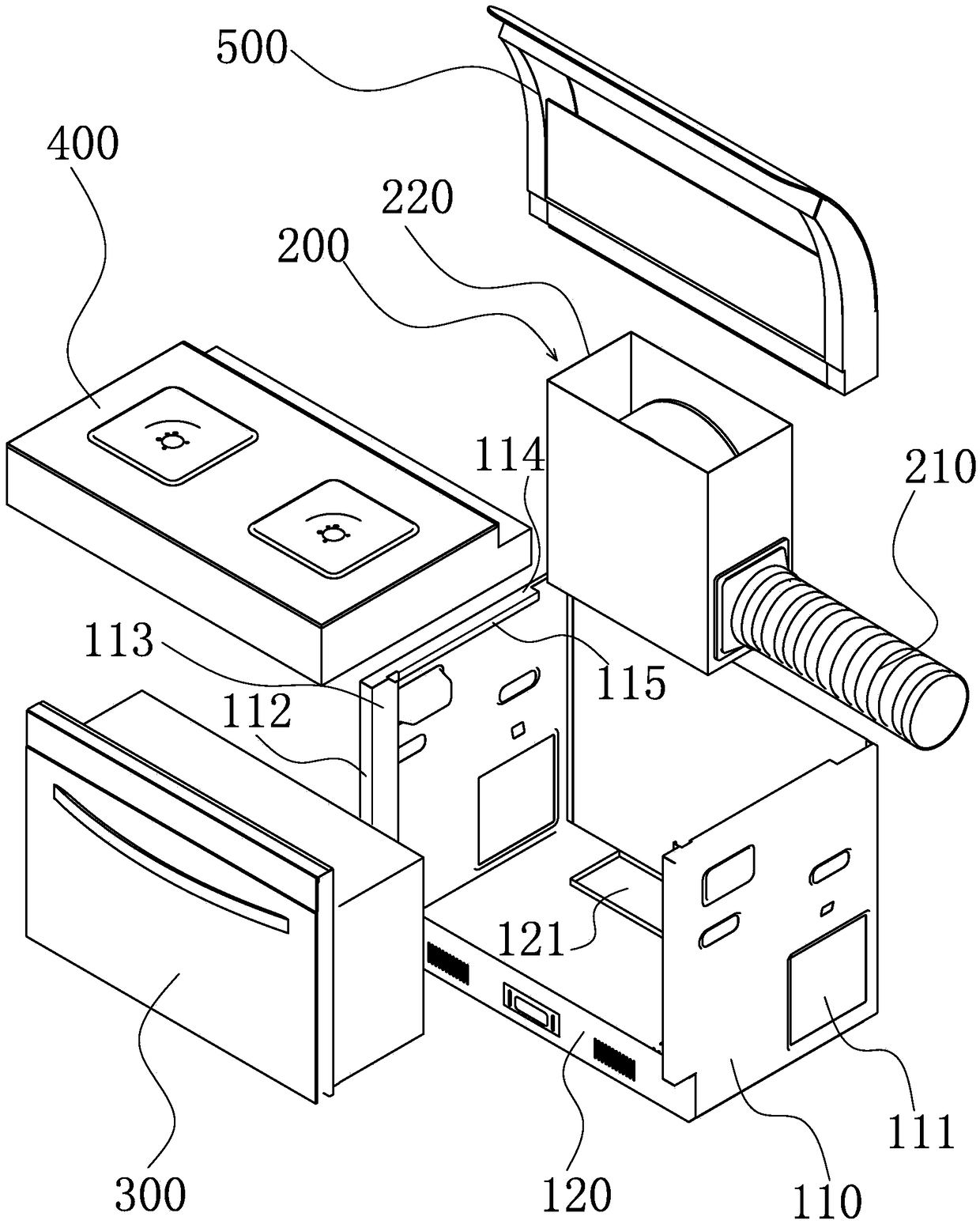

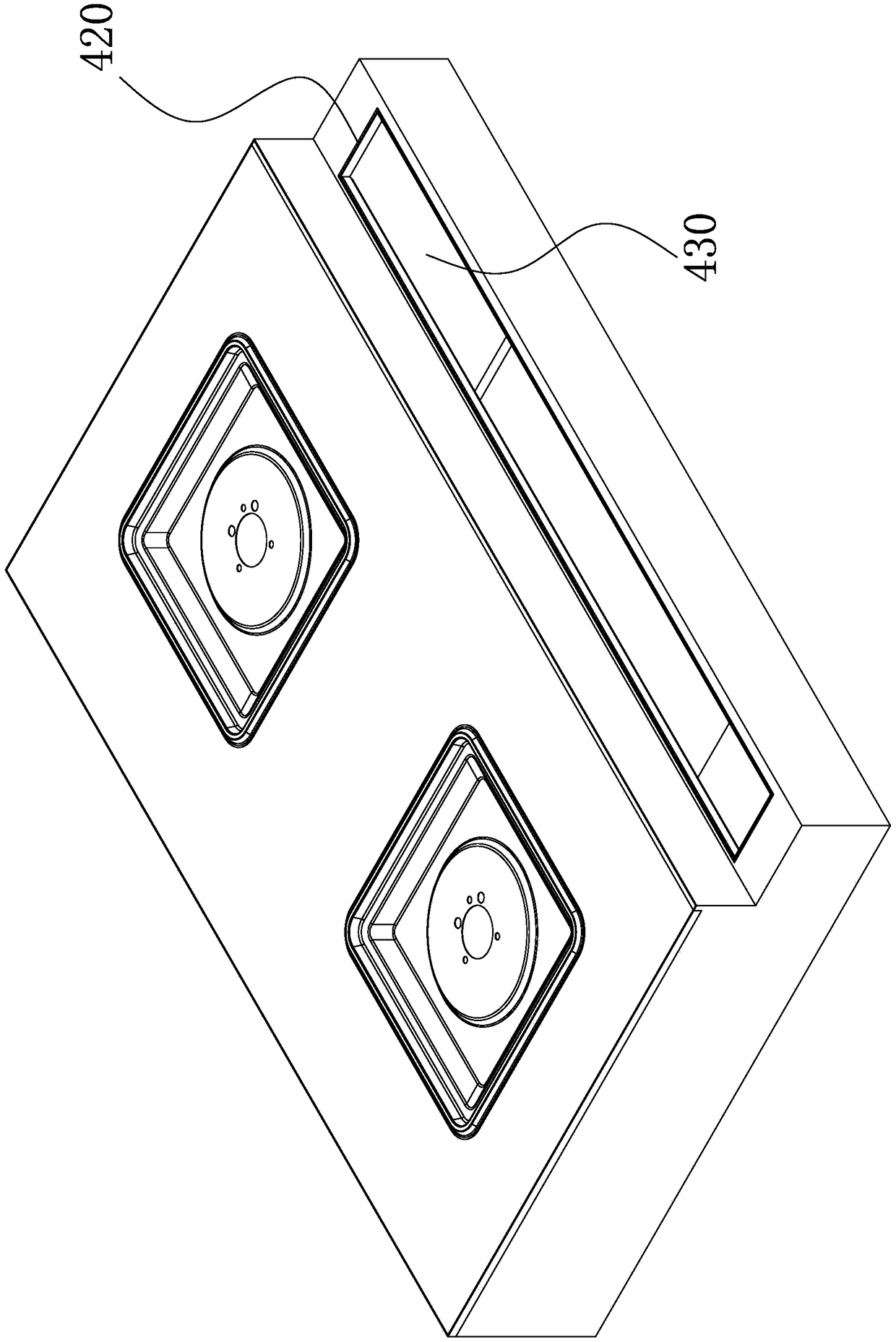

Modular combination spliced-type integrated stove

PendingCN109373382AEasy to disassembleEasy to maintain laterDomestic stoves or rangesLighting and heating apparatusModular compositionComputer module

The invention provides a modular combination spliced-type integrated stove. The modular combination spliced-type integrated stove comprises a frame and a fan module. The frame comprises a U-shaped coaming and a cork base which is connected to the lower side of the U-shaped coaming. The two sides of the U-shaped coaming are each provided with an air outlet. The fan module is embedded into the frameand further comprises an exhaust pipe. According to the smoke exhaustion orientation, the exhaust pipe can communicate with one of the air outlets. According to the modular combination spliced-type integrated stove provided by the invention, the fan module is detachably connected into the frame, the proper air outlets can be selected according to the smoke exhaustion orientation, and therefore the length of the exhaust pipe can be decreased, wind resistance is reduced, and the smoke exhaustion effect is improved; and in addition, the fan module is directly embedded into the frame, the fan module and the frame are arranged in a split mode, disassembling and later-period maintenance of the fan module can be facilitated and maintenance convenience is improved.

Owner:ZHEJIANG OULIN HEALTHY LIFE TECH CO LTD

A dehumidification heat exchange device

ActiveCN110345573BImprove performanceReduce tube lengthLighting and heating apparatusSpace heating and ventilation detailsEngineeringHeat pipe heat exchanger

The invention discloses a dehumidification heat exchange device. The dehumidification heat exchange device comprises an air duct, a surface cooler or an evaporator, a first U-shaped heat pipe heat exchanger and a second U-shaped heat pipe heat exchanger, wherein the air duct comprises an air inlet and an air outlet; the surface cooler or the evaporator is arranged in the air duct, the surface cooler or the evaporator (3) is larger than or equal to 600 mm, and an external pipeline is arranged on one side of the surface cooler or the evaporator; the first U-shaped heat pipe heat exchanger is arranged on one side of the external pipeline of the surface cooler or the evaporator, an interval is formed between the first U-shaped heat pipe heat exchanger and the connecting pipeline of a heat insulation area, and the interval is used for being connected with the outside through an external pipeline of the surface cooler or the evaporator; and the second U-shaped heat pipe heat exchanger and the first U-shaped heat pipe heat exchanger are arranged on the other side of the surface cooler or the evaporator in an opposite installation mode, and the pipe diameter of heat exchange pipelines of the first U-shaped heat pipe heat exchanger and the heat exchange pipeline of the second U-shaped heat pipe heat exchanger is 7.0-9.52mm. According to the dehumidification heat exchange device, the structure of the air duct does not need to be changed, so that the transformation risk is reduced, and the modification cost and period are shortened.

Owner:沈珂

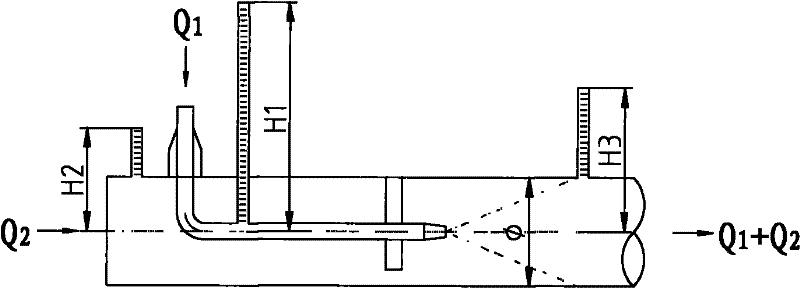

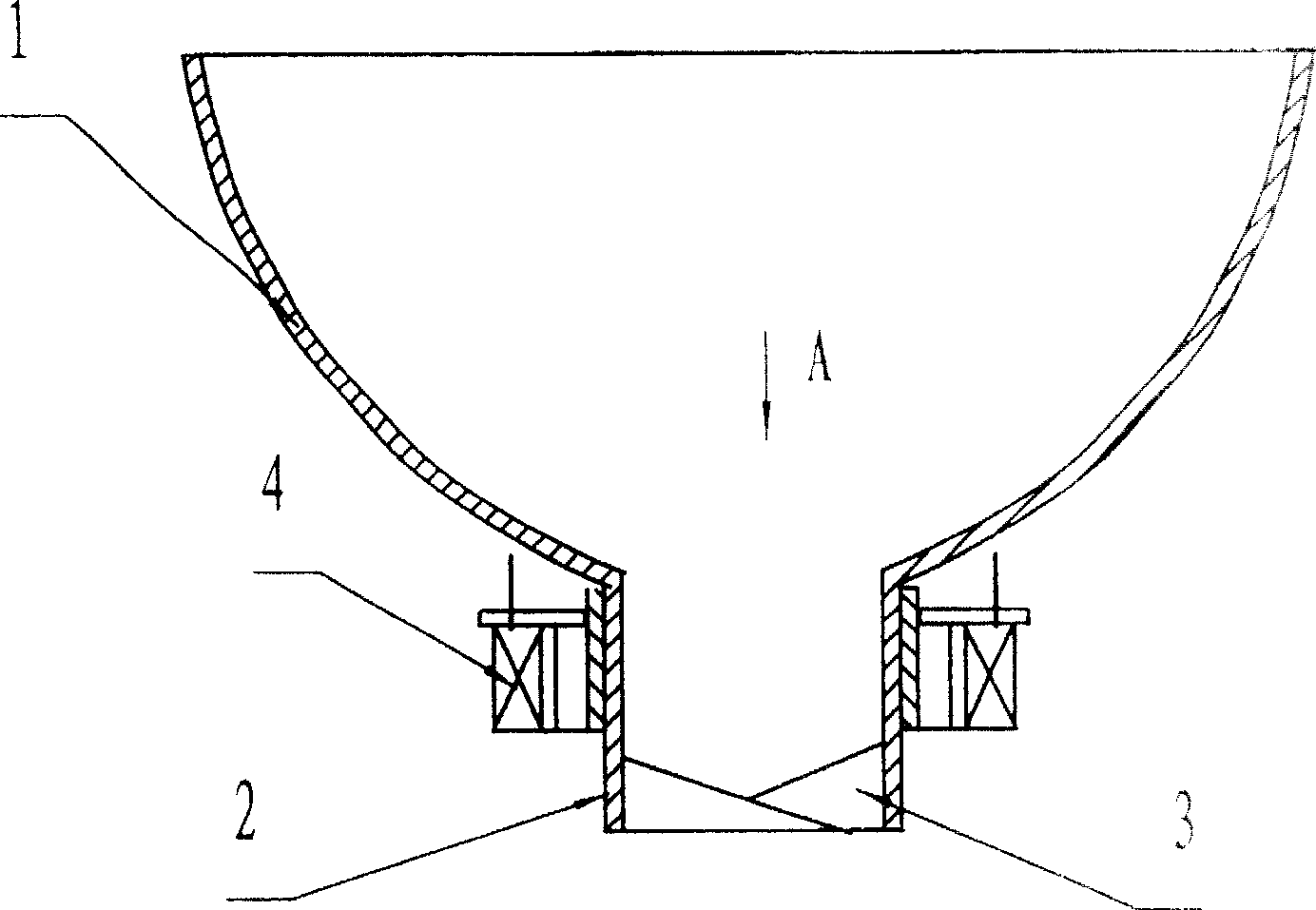

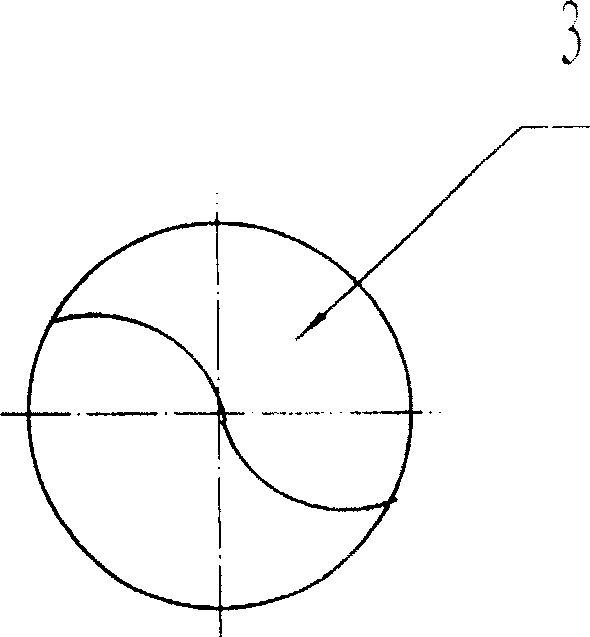

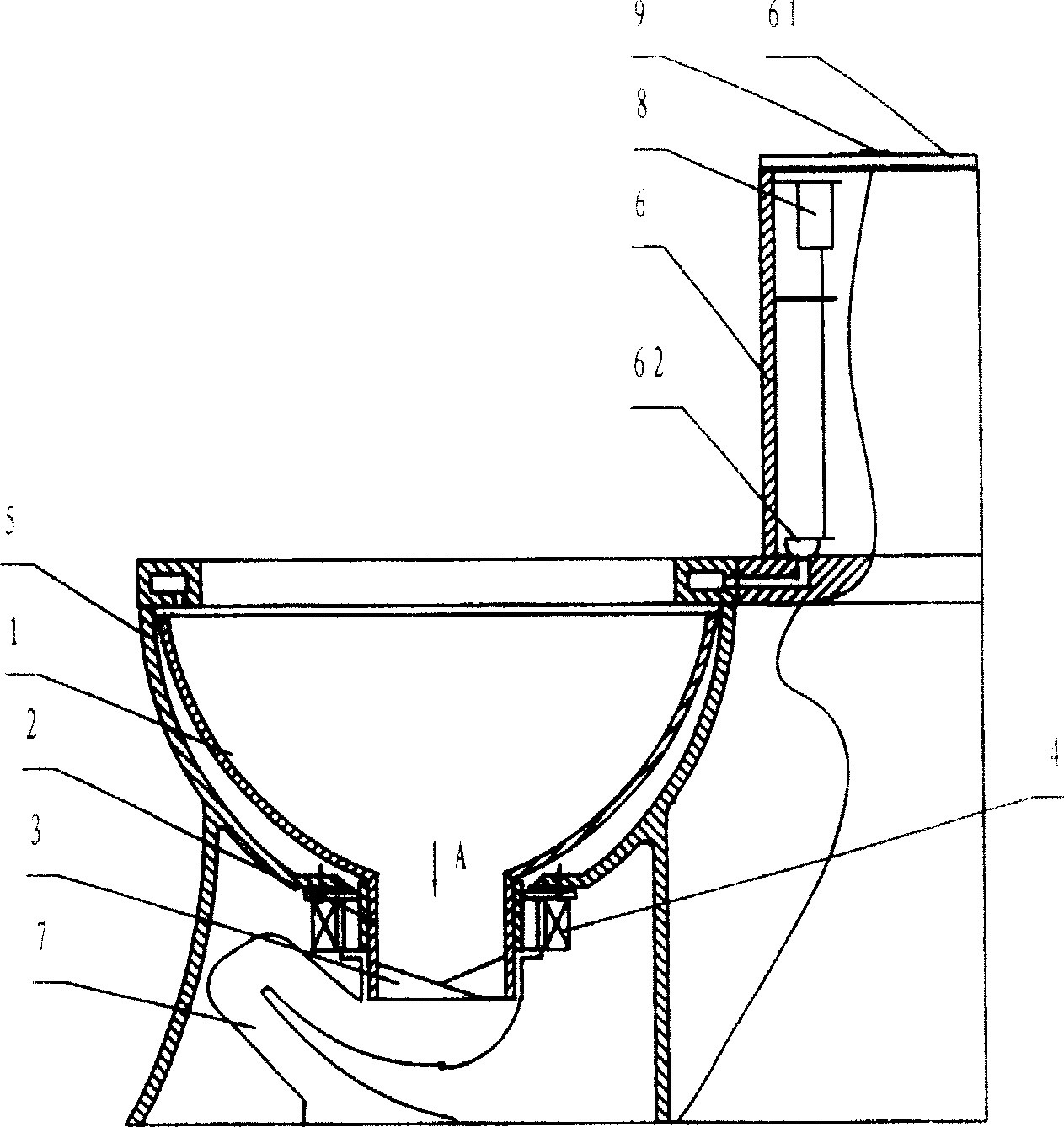

Feces forced drainage device and closet with same

InactiveCN100469982CReduce tube lengthReduce the amount of waterFlushing devicesSiphonTelecommunications

The invention relates to a fecal discharge device and relative toilet seat, wherein said fecal discharge device comprises one rotational chamber pot; the lower part of chamber pot is channel fixed with blades; the channel is sheathed with hollow motor rotating the chamber port; said toilet seat comprises fixed chamber, siphon tube, water tank cover, hit cover. And the invention is fixed inside fixed chamber; the upper part of toilet seat sheathes the fixed chamber; the siphon tube is at the lower of channel to connect the channel. The invention can save water and clean completely.

Owner:才教立

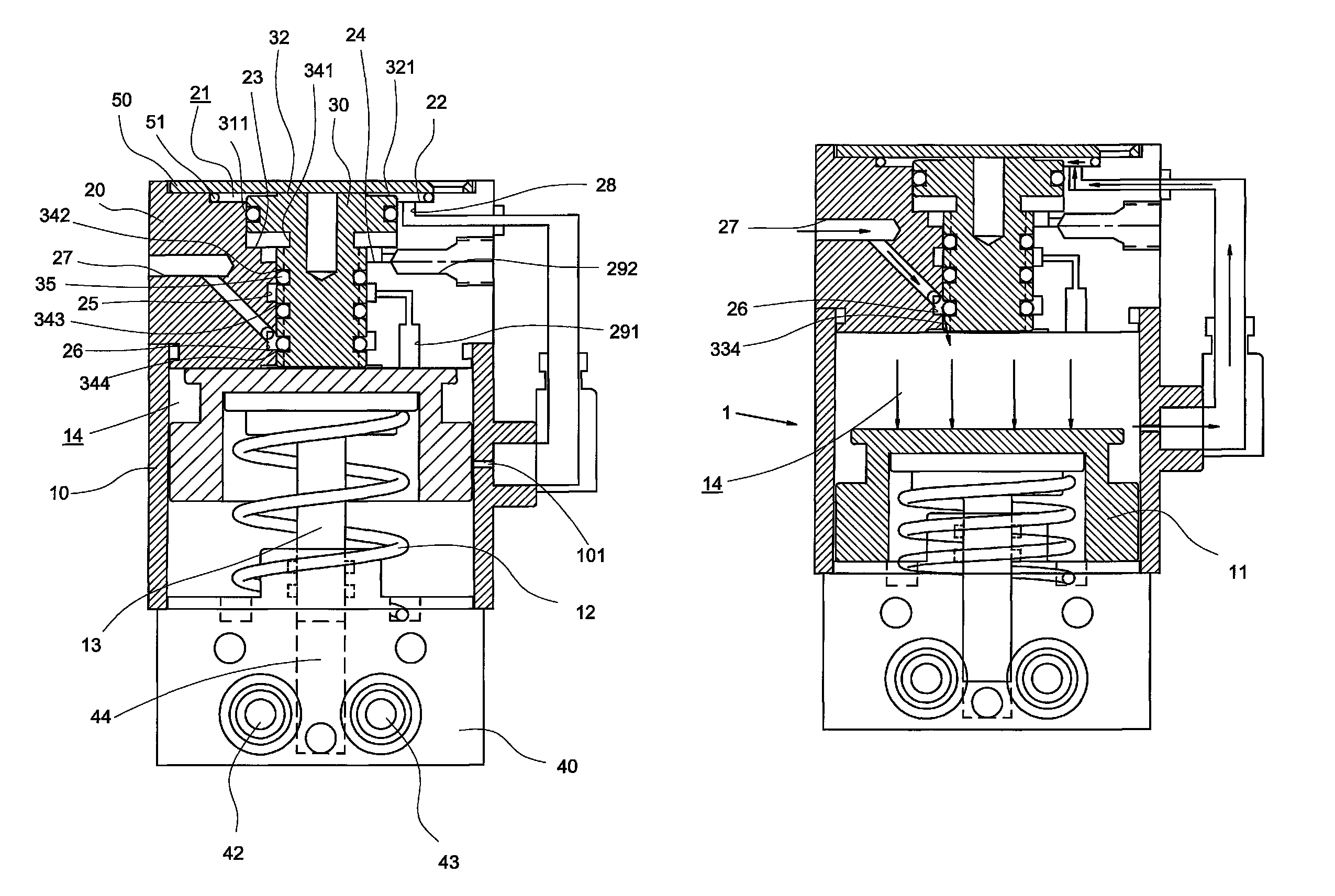

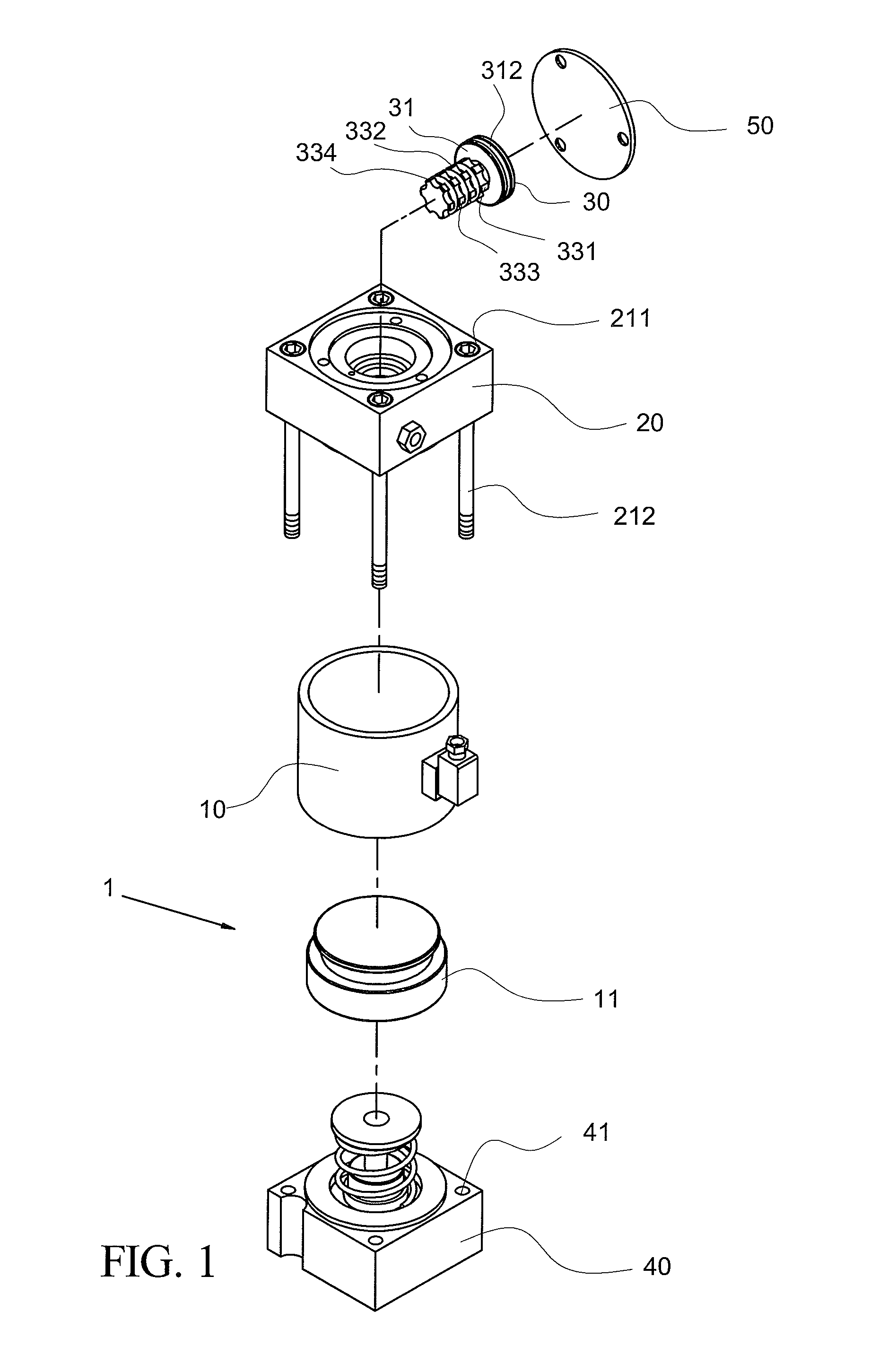

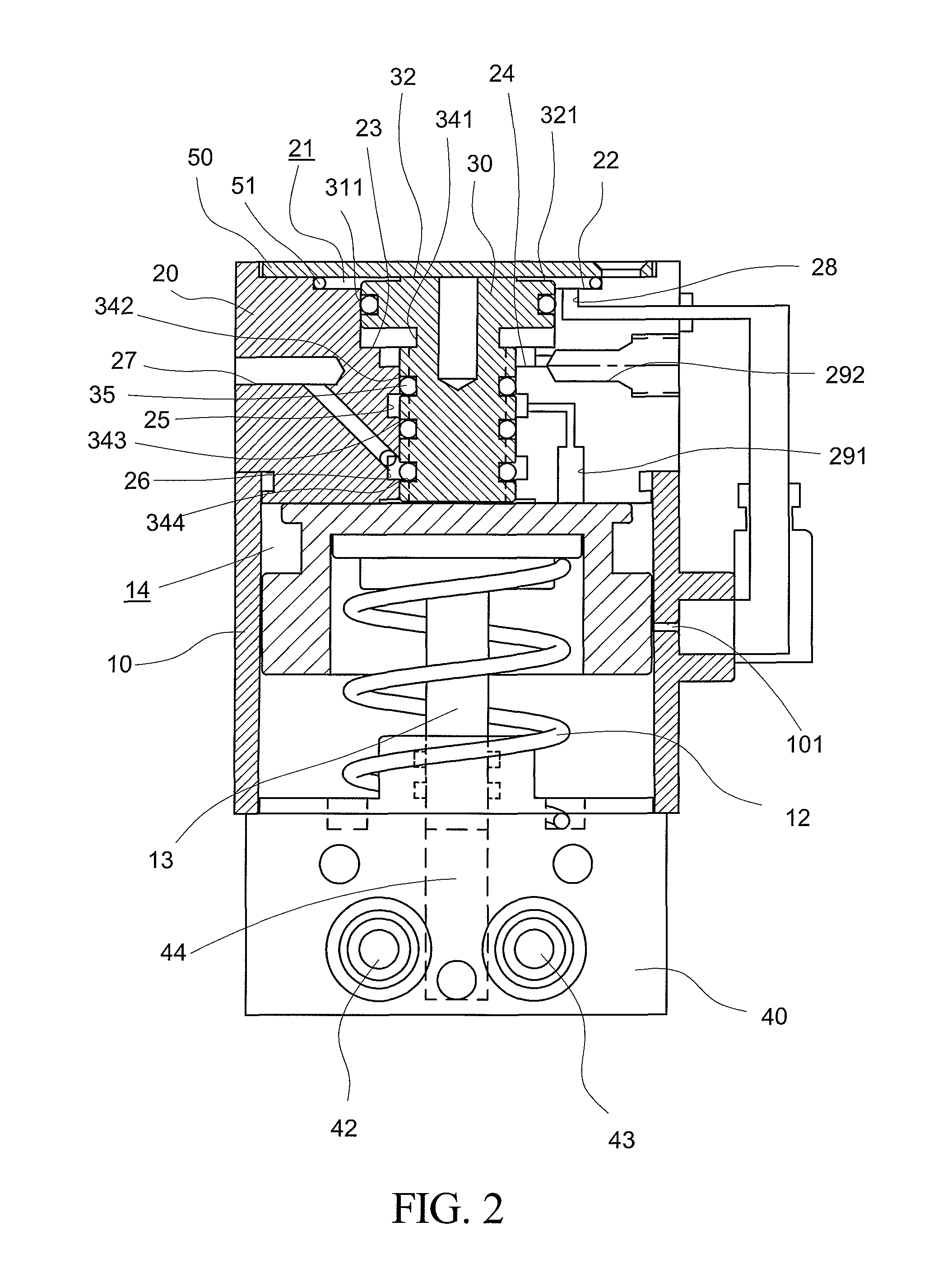

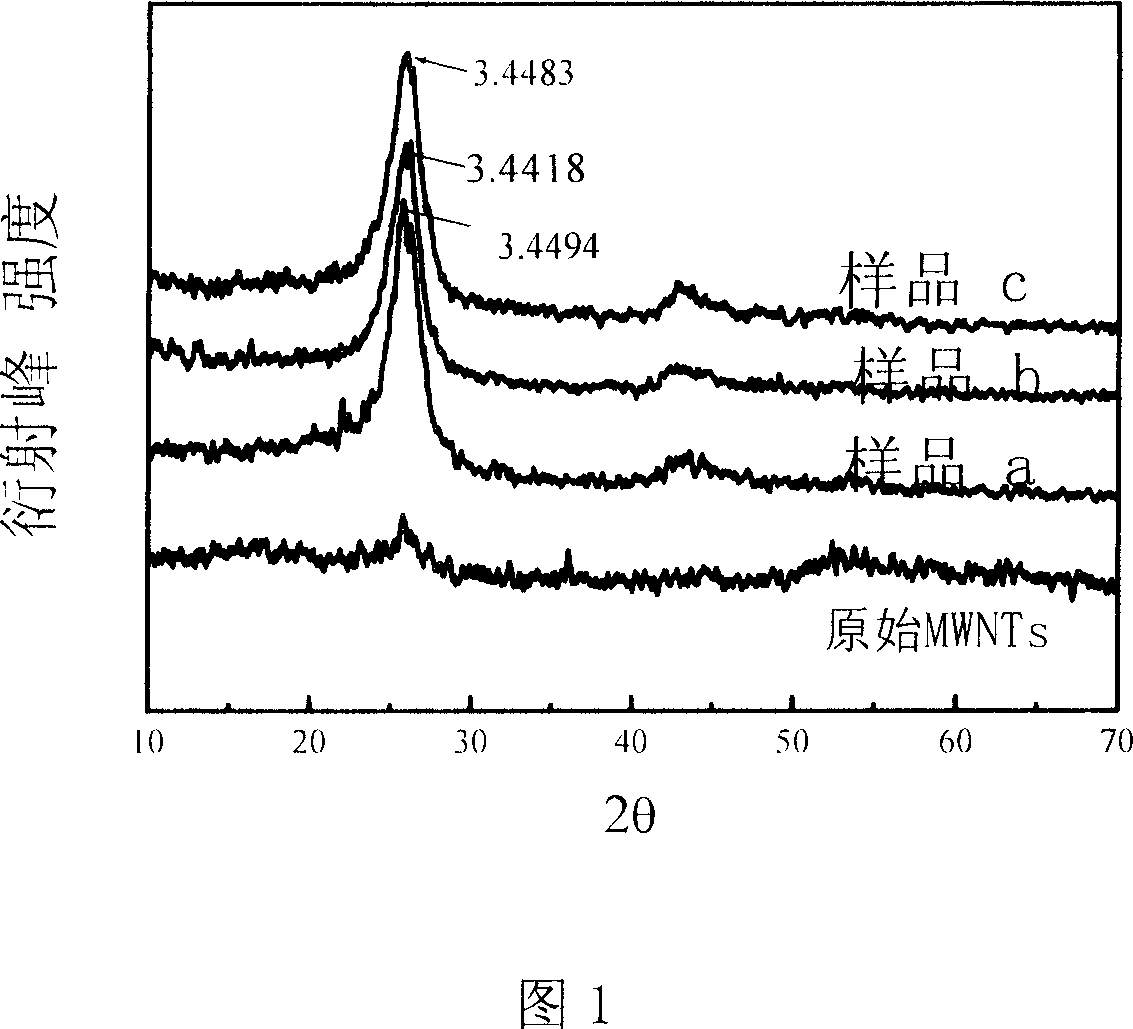

Pneumatic control device for supplying hydraulic fluid

ActiveUS8262371B2Reduce component countReduce tube lengthServomotor componentsValve drivesEngineeringHydraulic fluid

A pneumatic control device includes a base comprising a reservoir, a first check valve for only allowing hydraulic fluid to flow into the reservoir, and a second check valve for only allowing the fluid to flow out of the reservoir; a hollow cylinder comprising a spring biased piston; a body mounted to the cylinder thereunder and releasably secured to the base, the body comprising a stepped-diameter passageway with a poppet mounted therein; and a cover releasably secured onto the poppet. In response to feeding pressurized air into the cylinder, the fluid in the reservoir flows out during a first stroke of the piston, and the fluid is sucked back into the reservoir during an opposite second stroke of the piston. In one embodiment, the fluid is for actuating a machine vise.

Owner:WANG WEN FENG

Metering device for delivery of a liquid or viscous substance

InactiveUS20160231157A1Residue reductionDirect contact guaranteePositive displacement pump componentsVolume measurement and fluid deliveryEngineeringRisk stroke

A device for metered delivery of a liquid or viscous substance comprising a casing, a reciprocating differential piston able to slide in said casing, a metering chamber and at least one outlet for media delivery, the volume of the metering chamber varying during the piston stroke and comprising an inlet communicating with the outside of the casing via a first non-return valve, said piston comprising a central bore connecting said metering chamber by way of a central bore inlet and said at least one outlet via a passage, said central bore inlet being provided with a second non-return valve, said first non-return valve and second non-return valve being arranged face to face, piston stroke length being able to adjust the volume of the metering chamber.

Owner:OPTIMOL TRIBOTECHN +2

Method for increasing electrochemical lithium storage content of nano-carbon tube

InactiveCN1309104CIncrease spacingIncrease profitElectrode manufacturing processesGas phaseCarbon nanotube

This invention discloses a method for increasing electrochemical Li-storage capacity of carbon nm tubes, which processes the original MWNTS raw material prepared with chemical gas phase deposition method including: first of all, the original MWNTS is supersonic-vibrated, mechanical mixed and dipped under room temperature in different matched volumes of H2SO4 and HNO3 mixed solution, the reacted product is cleaned with deionized water to neutral and put in a tube oven to be heated under 200-500deg.C to be cooled and dipped in Li2CO3 or LiOH solution, the obtained sample is cleaned with deionized water, filtered and dried in vacuum. The gap of quasigraphite layer of the processed MWNTS is expanded, the electrochemical Li capacity is increased.

Owner:TSINGHUA UNIV

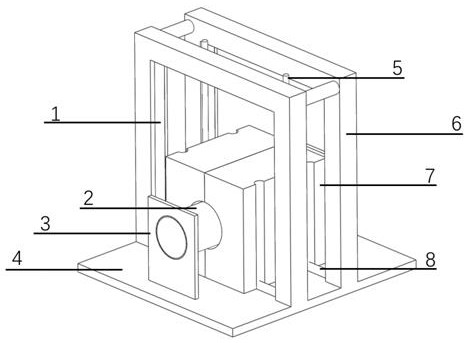

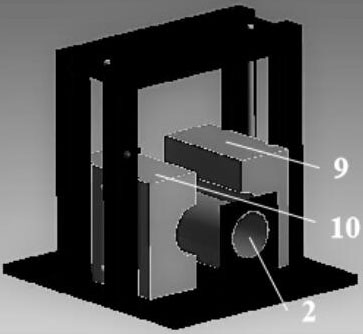

Novel graphene growth device capable of vertical lifting and rapid cooling

The invention discloses a novel graphene growth device capable of vertical lifting and rapid cooling. The device comprises an 8-inch quartz tube for CVD (chemical vapor deposition) growth of graphene, a vacuum tube type electric furnace for controlling the CVD growth temperature of the graphene, a lifting frame, a metal bottom plate, two parallel guide rails and other supporting structures. The quartz tube is fixed at the central position of the vacuum tube furnace through a supporting structure. A guide rail and an electric lifting frame are used for controlling horizontal and vertical displacement of the vacuum tube type electric furnace, so that closing and opening of the vacuum tube type electric furnace are automatically controlled. By means of the design, the occupied area of the graphene CVD device can be reduced, and the cooling time in the CVD process is shortened.

Owner:深圳华梦通讯技术有限公司

A walking heating furnace vaporization cooling system and method thereof

ActiveCN111926173BClear arrangementReduce tube lengthLiquid degasificationScale removal and water softeningDeaeratorSteam drum

The invention relates to the field of vaporization cooling systems, in particular to a walking heating furnace vaporization cooling system and a method thereof. A vaporization cooling system for a walking heating furnace of the present invention comprises a soft water tank, a deaerator, a feed water pump and a circulation cooling system composed of a steam drum, a downcomer, an upcomer and a circulating pump, which are sequentially connected by pipelines, and it also includes A waste heat recovery system consisting of the first steam pipeline, the second steam pipeline, the hot water pipeline, and the heat exchanger; the steam and water outlet of the steam drum is connected to the deaerator through the first steam pipeline, and connected to the factory area through the second steam pipeline. The steam pipe network is connected, the other is connected to the heat medium inlet of the heat exchanger through the hot water pipe, the cold water inlet of the heat exchanger is connected to the supply soft water, the soft water outlet of the heat exchanger is connected to the soft water tank, and the heat medium outlet of the heat exchanger The sewage is discharged outward through the expansion vessel; the invention reduces the flow resistance by optimizing the layout of the pipeline and improves the recovery and utilization rate of the waste heat by adding a waste heat recovery system.

Owner:武汉钢铁有限公司

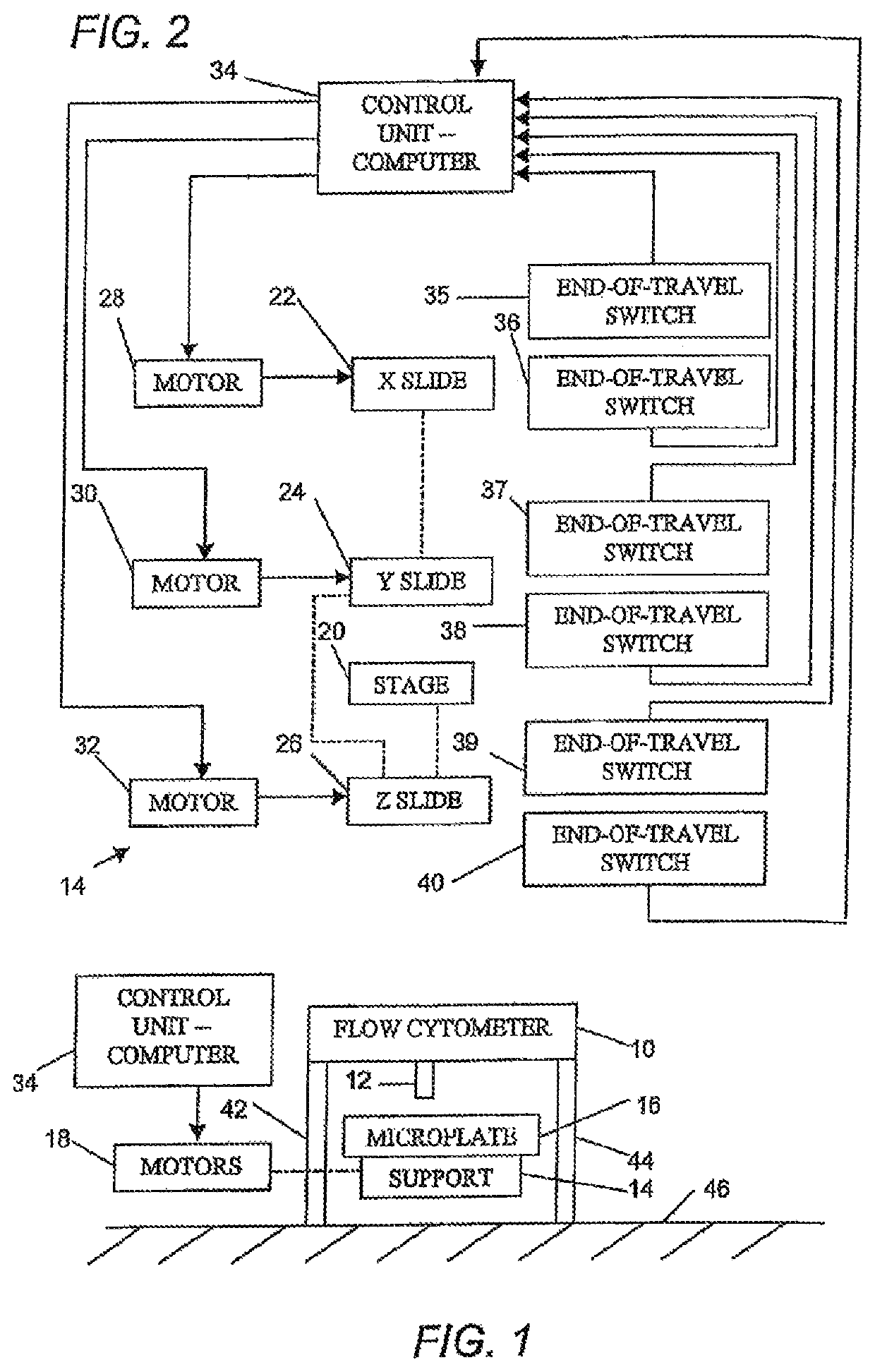

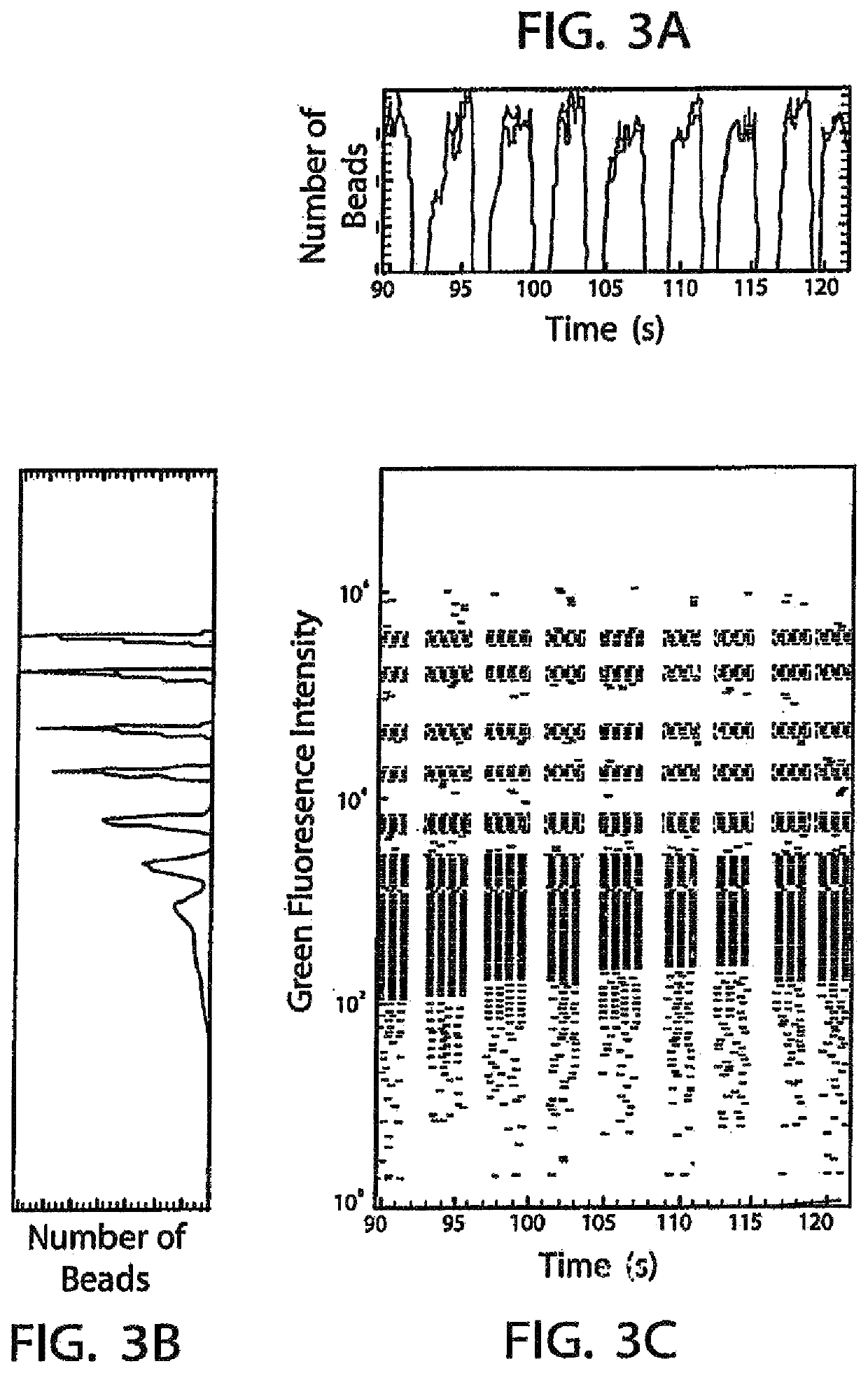

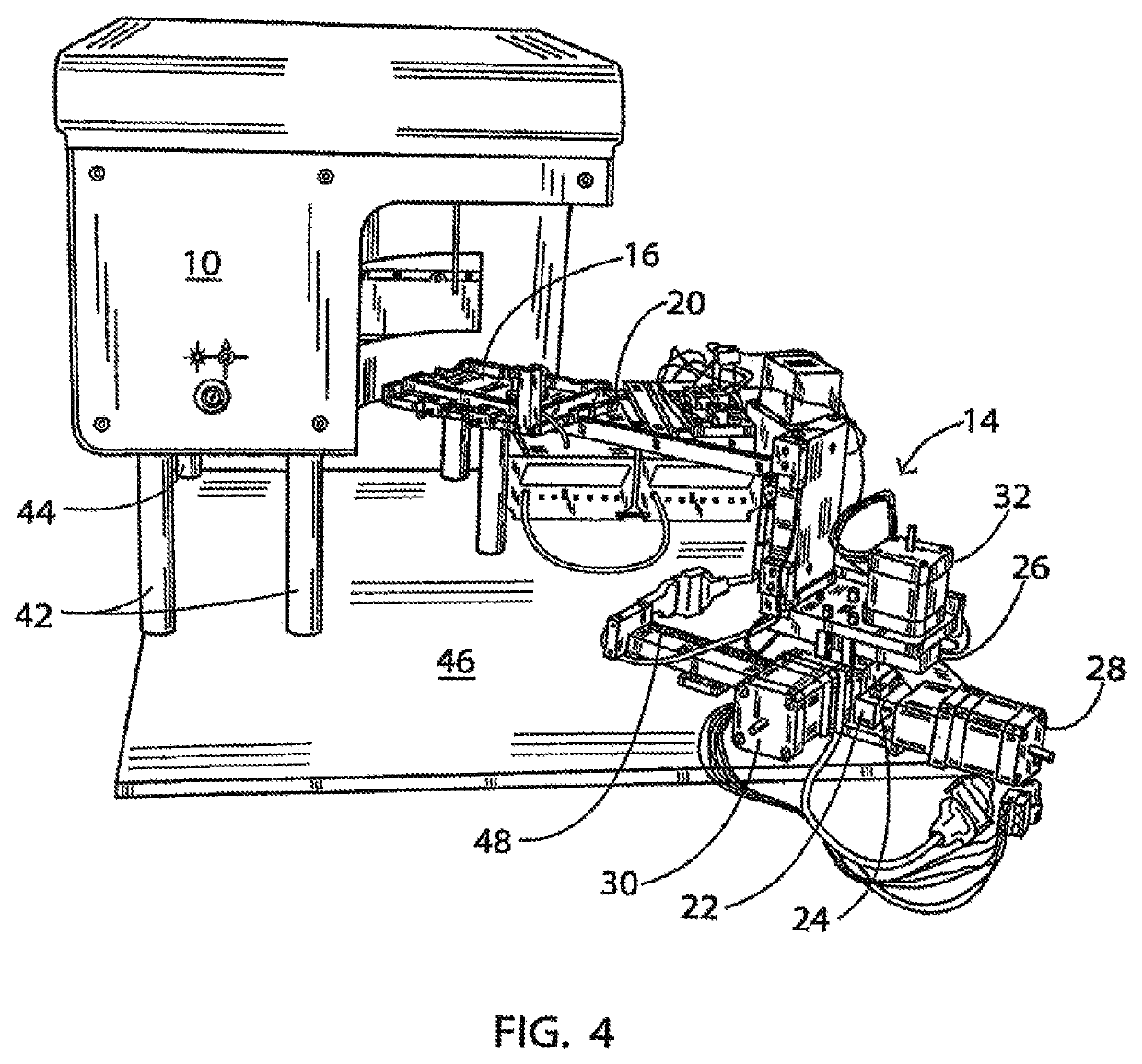

Flow cytometry apparatus pulling sample stream through observation chamber

ActiveUS10884007B1Reduce tube lengthEliminate needWithdrawing sample devicesMaterial analysis by optical meansEngineeringMechanical engineering

A flow cytometry apparatus includes a flow cytometer having a suction or negative-pressure intake probe, a support for a microplate having a plurality of sample wells, and motive elements operatively connected to at least one of the probe and the support for moving the intake probe and the support relative to one another so that the intake probe is sequentially aligned with different sample wells of the microplate. The apparatus has no fluid pumping elements between the support and the flow cytometer so that a bubble-separated sample stream is forced to the flow cytometer solely by virtue of a negative pressure communicated via the intake probe.

Owner:UNM RAINFOREST INNOVATIONS

Barometer

InactiveUS8915135B2Increase heightReduce tube lengthFluid pressure measurement using pressure-sensitive liquidEngineeringVolumetric Mass Density

A barometer which is rotatable and a method of using a barometer which is rotatable is presented comprising a barometer tube retaining barometric fluid that is shorter than that required by non-rotatable barometers. The provision of a rotatable barometer allows the use of a barometric fluid of a density lower than that of mercury to be used, thereby enabling the use of mercury to be avoided.

Owner:SCOTT KEVIN FRANCIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com