Novel graphene growth device capable of vertical lifting and rapid cooling

A vertical lifting and rapid cooling technology, applied in the field of chemical production, can solve the problems of uneven temperature, safety, convenience and controllability, uneven airflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

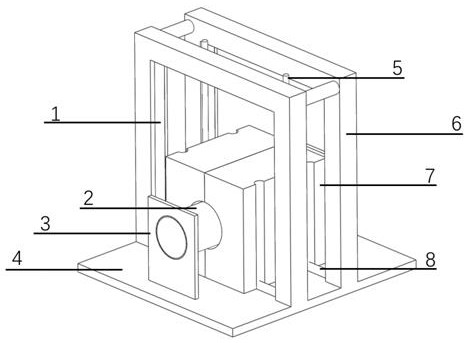

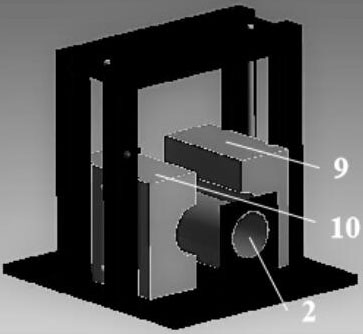

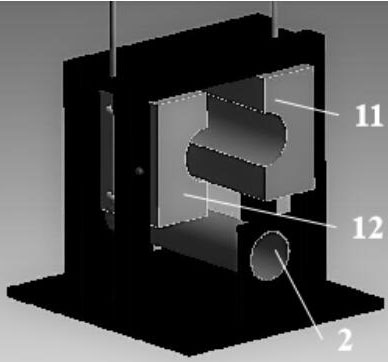

[0019] figure 1 It is a schematic diagram of a novel large-scale graphene CVD device of the present invention.

[0020] refer to figure 1 , a novel vertical lifting rapid cooling graphene growth device, characterized in that it includes a (2) 8-inch quartz tube for graphene CVD growth, a (7) vacuum tube electric furnace for controlling the graphene CVD growth temperature , (1) vertical rails, (3) brackets at both ends, (4) horizontal platform, (6) vertical lifting brackets, (8) horizontal rails and other supporting structures. The heating temperature and position of the electric furnace can be controlled by adding an intelligent control terminal, which is convenient for users to use.

[0021] In the present invention, the vertical lifting frame is installed on the guide rail, so that the vacuum tube electric furnace can perform vertical and horizontal displacement at the same time, and the movement is more flexible.

[0022] In the present invention, after the reaction is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com