A walking heating furnace vaporization cooling system and method thereof

A step-by-step heating furnace and vaporization cooling technology, applied in the field of vaporization cooling system, can solve the problems of reducing the operation efficiency of vaporization cooling system, increasing the tube length and flow resistance, and complicated piping arrangement, so as to improve the recycling of waste heat. The effect of utilization rate, shortening tube length and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

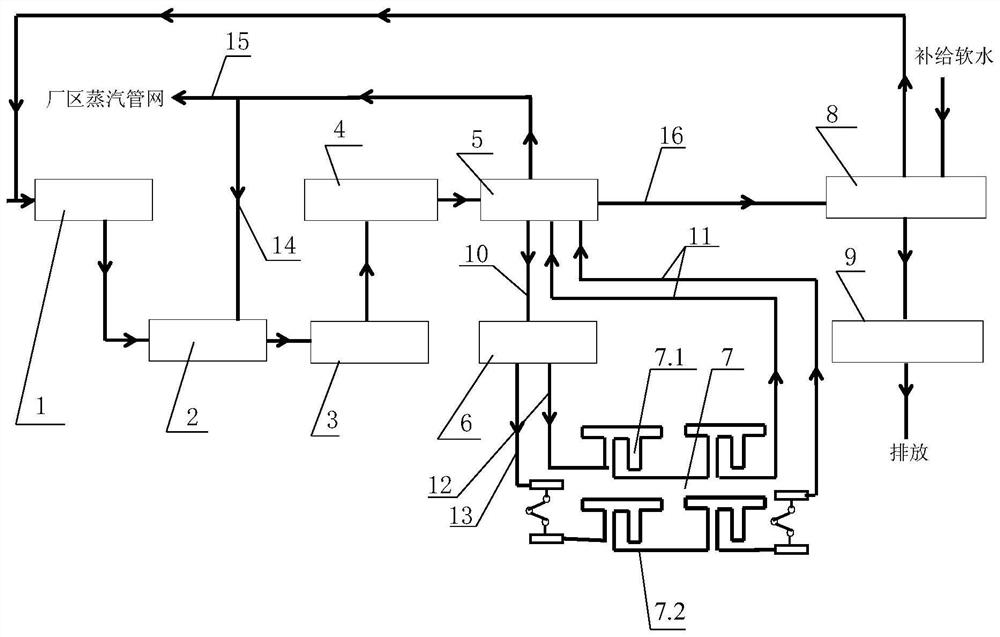

[0024] A walking heating furnace vaporization cooling system includes a water supply system, a circulating cooling system and a waste heat recovery system. In this embodiment, the water beam 7 of the heating furnace is a fixed beam 7.1 and a movable beam 7.2 connected in parallel.

[0025] The water supply system includes a soft water tank 1, a deaerator 2, a feed water pump 3, and a dosing device 4, and the soft water tank 1, the deaerator 2, the feed water pump 3, and the dosing device 4 are connected in sequence through pipelines. Among them, a 0.005mol / L trisodium phosphate solution is prepared in the dosing device 4. Adding the trisodium phosphate solution to the soft water can form soft slag with the calcium and magnesium ions in the soft water in the steam drum 5, which is easy to discharge with the steam drum 5. Discharge, play a role in preventing system equipment pipeline fouling, improve the operating efficiency of the system.

[0026] The circulating cooling syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com