Insertion part for endoscope and endoscope

A technology of endoscope and insertion part, applied in the direction of endoscope, application, medical science, etc., can solve the problems of increased filling rate, hindering the bending action of the bending part, etc., and achieve the effect of shortening the length of the tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

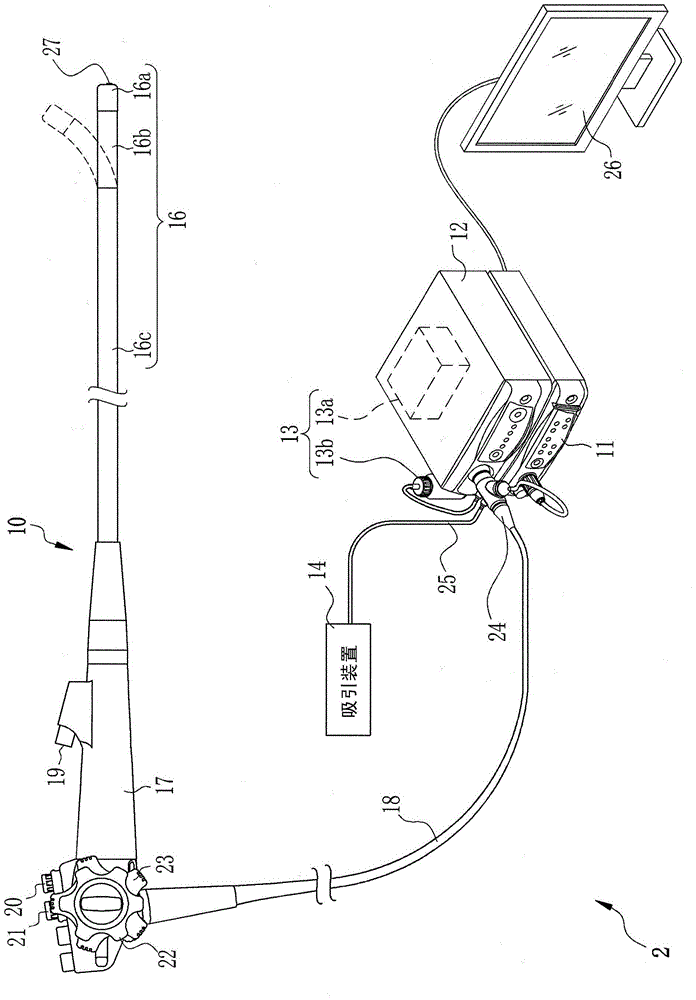

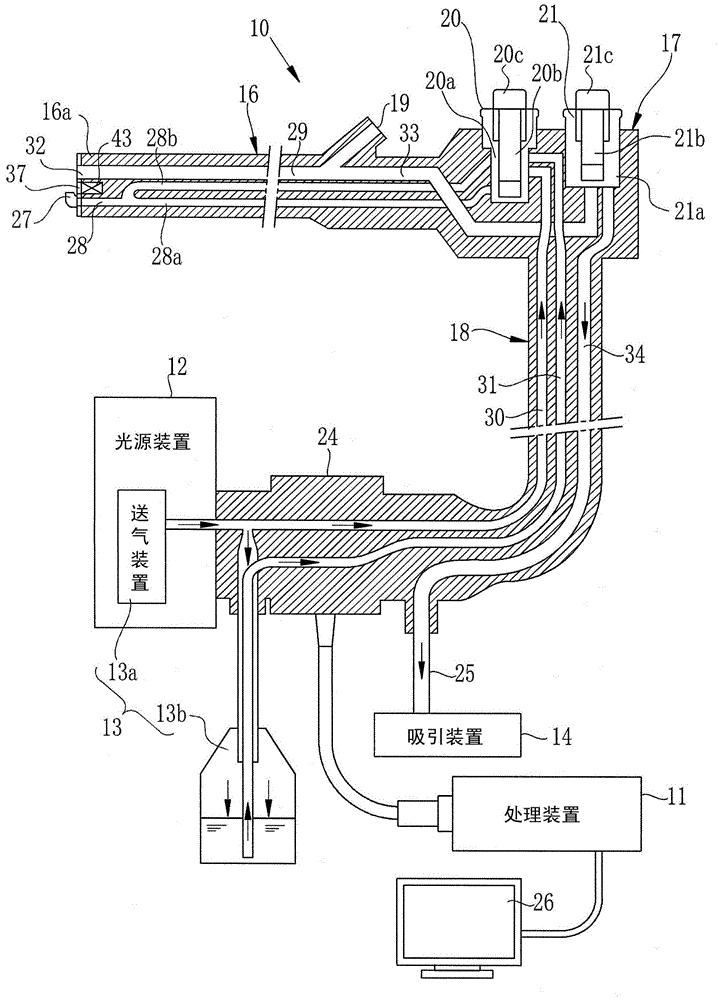

[0065] like figure 1 As shown, the endoscope system 2 includes an electronic endoscope 10 , a processing device 11 , a light source device 12 , an air and liquid feeding device 13 , and a suction device 14 . The gas and liquid feeding device 13 includes a known gas feeding device (pump, etc.) 13 a built in the light source device 12 to send gas, and a liquid tank 13 b provided outside the light source device 12 to store liquid. The electronic endoscope 10 has a flexible endoscope insertion portion (hereinafter referred to as an insertion portion) 16 inserted into the body, a manual operation portion 17 connected to the base end portion of the insertion portion 16, and a processing device 11, The universal cord 18 to which the light source device 12 is connected. Washing water is used as the liquid conveyed by the air and liquid feeding device 13 , and air and carbon dioxide gas are used as the conveyed gas.

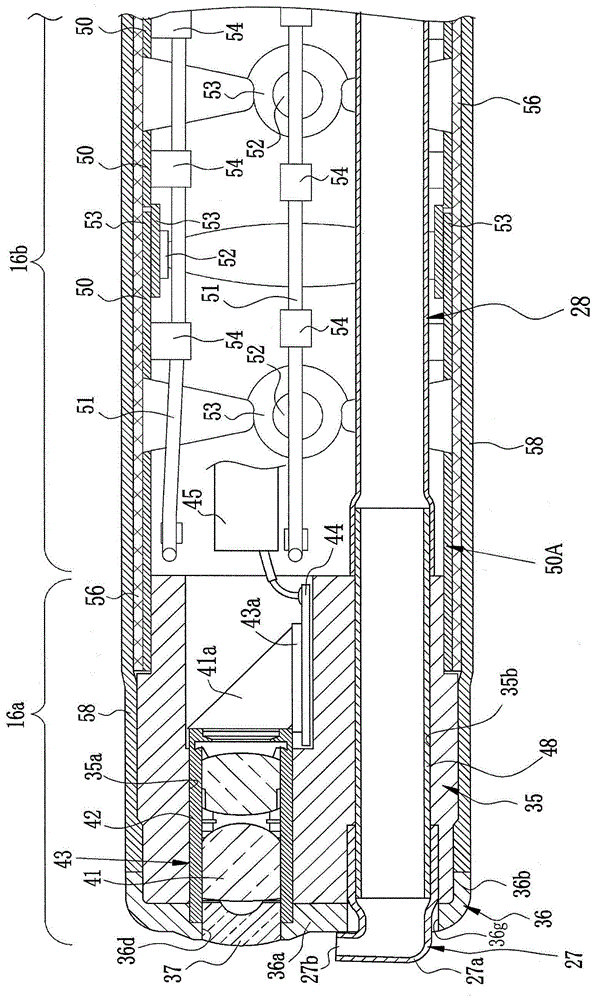

[0066] The insertion part 16 has a front end part 16a, a bent part...

no. 2 approach

[0102] In the above-mentioned first embodiment, the positions of the branch tube parts 71a and 71b are limited by the arrangement of built-in components such as the signal cable 45, the light guides 46a and 46b, the treatment instrument insertion tube 29, the coil tube 55, and the fixing part 60 as an example. Be explained. However, it is not limited to this, it can also be like Figure 9 Like the base end block 75 constituting the insertion portion of the second embodiment shown, the protruding portion 76 protruding from the fixing portion 60 toward the confluence member 70 is integrally formed. Since the contents in the insertion part 16 slightly move according to the bending operation of the bending part 16b and the insertion shape of the soft part 16c, in the above-mentioned first embodiment, there is a possibility that the branch pipe parts 71a, 71b may enter the proximal end. space within block 50B, but in this second embodiment, as Figure 10 As shown, by bringing the...

no. 3 approach

[0104] In addition, as another example of restricting the position of the branch pipe parts 71a, 71b, it is also possible to Figure 11 As in the third embodiment shown, a spring 80 as an urging member is provided between the coil tube 55 and the confluence member 70 . In this case, the spring 80 is attached so that one end is wound around the coil tube 55 and the other end is wound around the junction pipe part 72 . Thereby, when the confluence member 70 is pulled in by the bending of the bent portion 16b, the spring 80 biases the confluence member 70 toward the proximal end side of the soft portion 16c. By the action of the spring 80 , it is possible to restrict the entry of the branch pipe portions 71 a and 71 b into the base end block 50B and to return to the position of the confluence member 70 when the curved portion 16 b is in a straight state. It should be noted that, as the installation of the spring 80 toward the coil pipe 55 and the confluence member 70 , other ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com