I-shaped tree type cross flow heat exchanger

A cross-flow, heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of pump power consumption and heat transfer performance mismatch, unreasonable fluid delivery path, etc. Achieve the effect of reducing pump power consumption, improving flow heat transfer efficiency, and offsetting flow length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

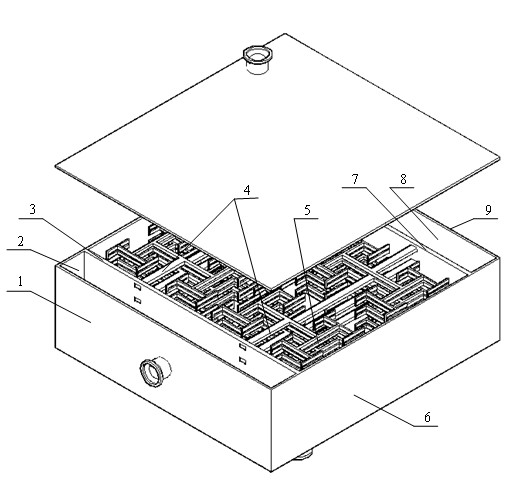

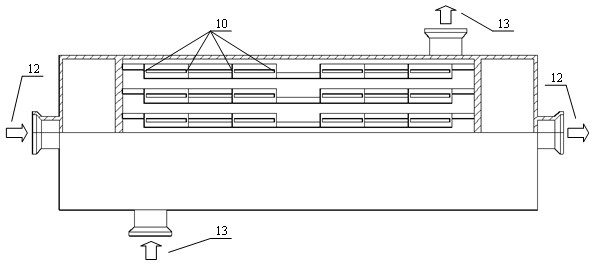

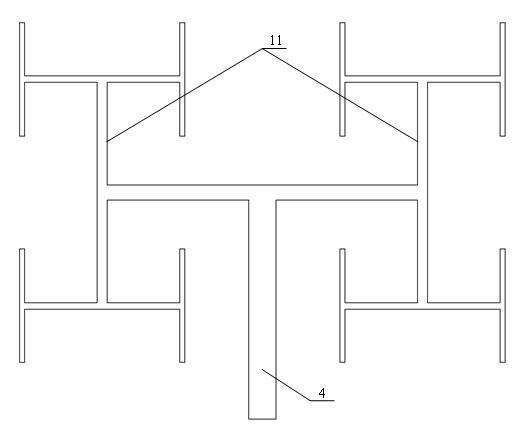

[0021] figure 1 , figure 2 A schematic structural view of the "I" shape tree cross-flow heat exchanger of the present invention is given. A cross-flow heat exchanger with a characteristic heat exchange tube bundle of "I" shape tree structure, which is composed of main parts such as "I" shape tree heat exchange tube bundle 5, a shell 6, a tube box, and a tube sheet. The cross-sectional shape of the shell 6 is generally rectangular, the tube box is divided into left tube box 2 and right tube box 8, the tube sheet is divided into left tube sheet 3 and right tube sheet 7, left tube box 2, right tube box 8 and left tube sheet 3. The right tube sheets 7 are respectively located on both sides of the shell 6, and the "I"-shaped tree-shaped heat exchange tube bundles 5 are spread out in a planar manner, and the main communication pipes 4 located on both sides of the "I"-shaped tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com