Tube plate condenser for refrigerators and/or freezers

A refrigeration device and refrigeration device technology, which is applied in the direction of evaporator/condenser, refrigeration and liquefaction, refrigerator, etc., and can solve problems such as heat dissipation limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

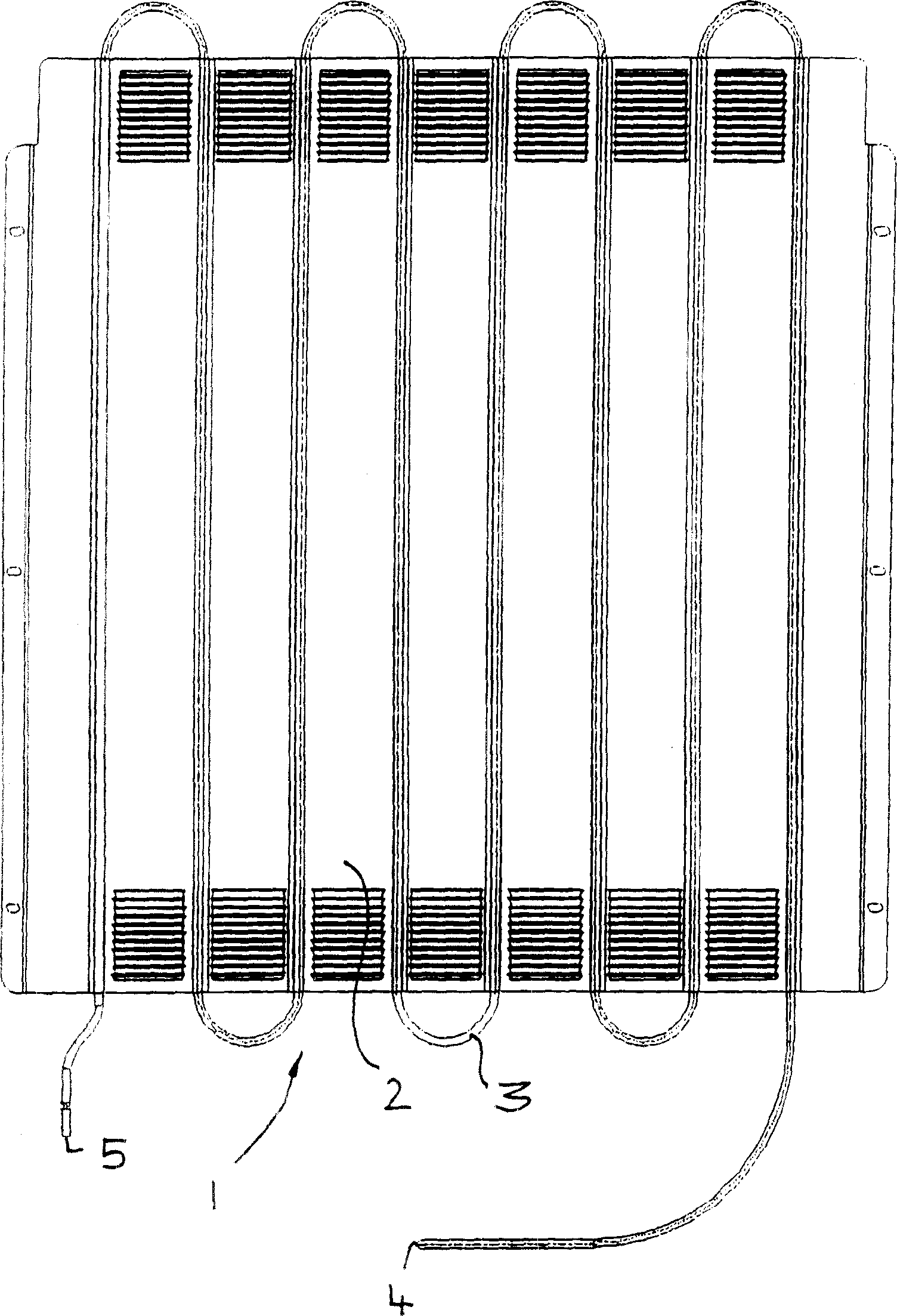

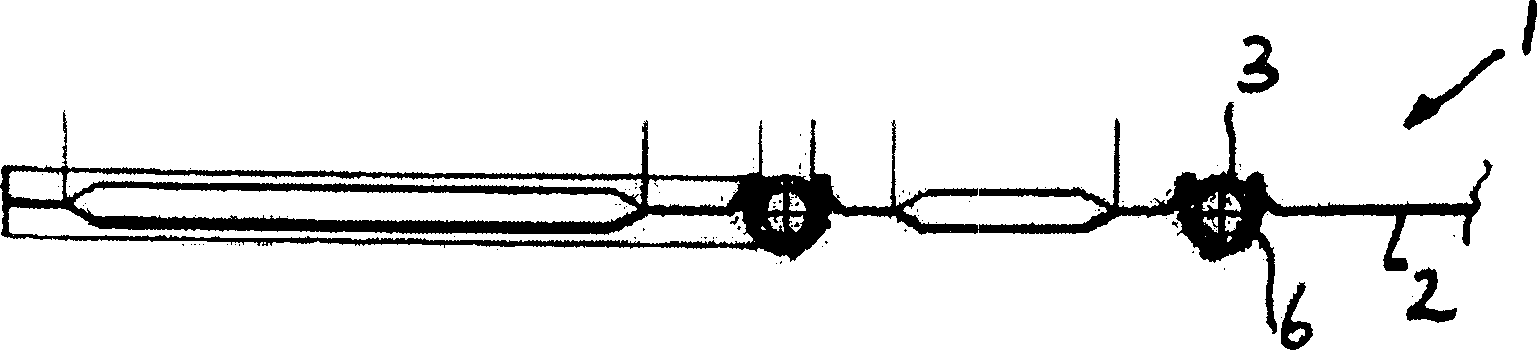

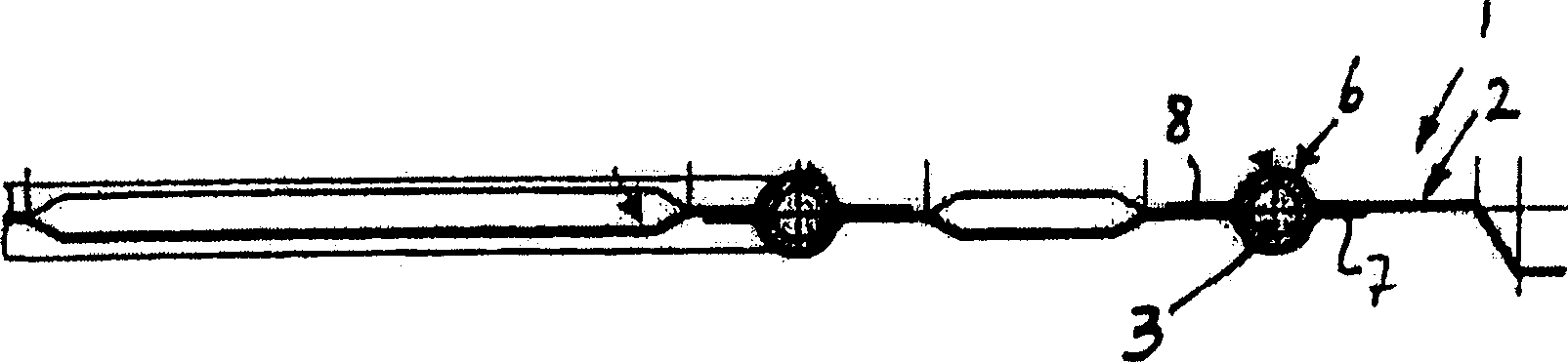

[0017] figure 1 The illustrated condenser 1 comprises a substantially plate-shaped carrier panel 2 and a condenser tube 3 connected thereto, which extends back and forth in a serpentine bend and has an inlet 4 and an outlet 5 . When the refrigerant flows through the condenser tubes extending in a serpentine manner, the refrigerant releases absorbed heat to the bearing panel 2 through the condenser tube 3, and releases heat to the surrounding environment through the bearing panel 2, so the evaporator medium or the The refrigerant is cooled down and condensed again until it is reintroduced via outlet 5 to subsequent functional units of the refrigeration circuit.

[0018] The bearing panel 2 is made of aluminum or aluminum alloy sheet metal. According to an embodiment of the present invention, the condenser tube 3 is similarly constructed of aluminum or an aluminum alloy. Alternatively, steel pipes can be used as condenser tubes 3, which steel pipes can be galvanized according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com