Feces forced drainage device and closet with same

A technology for feces and toilets, which is applied to the field of feces forced drainage devices, can solve the problems of inability to meet the water consumption for flushing, excessive water for flushing, limited penetration rate, etc., and achieves reduction in size, water consumption for flushing, and reduction in water volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

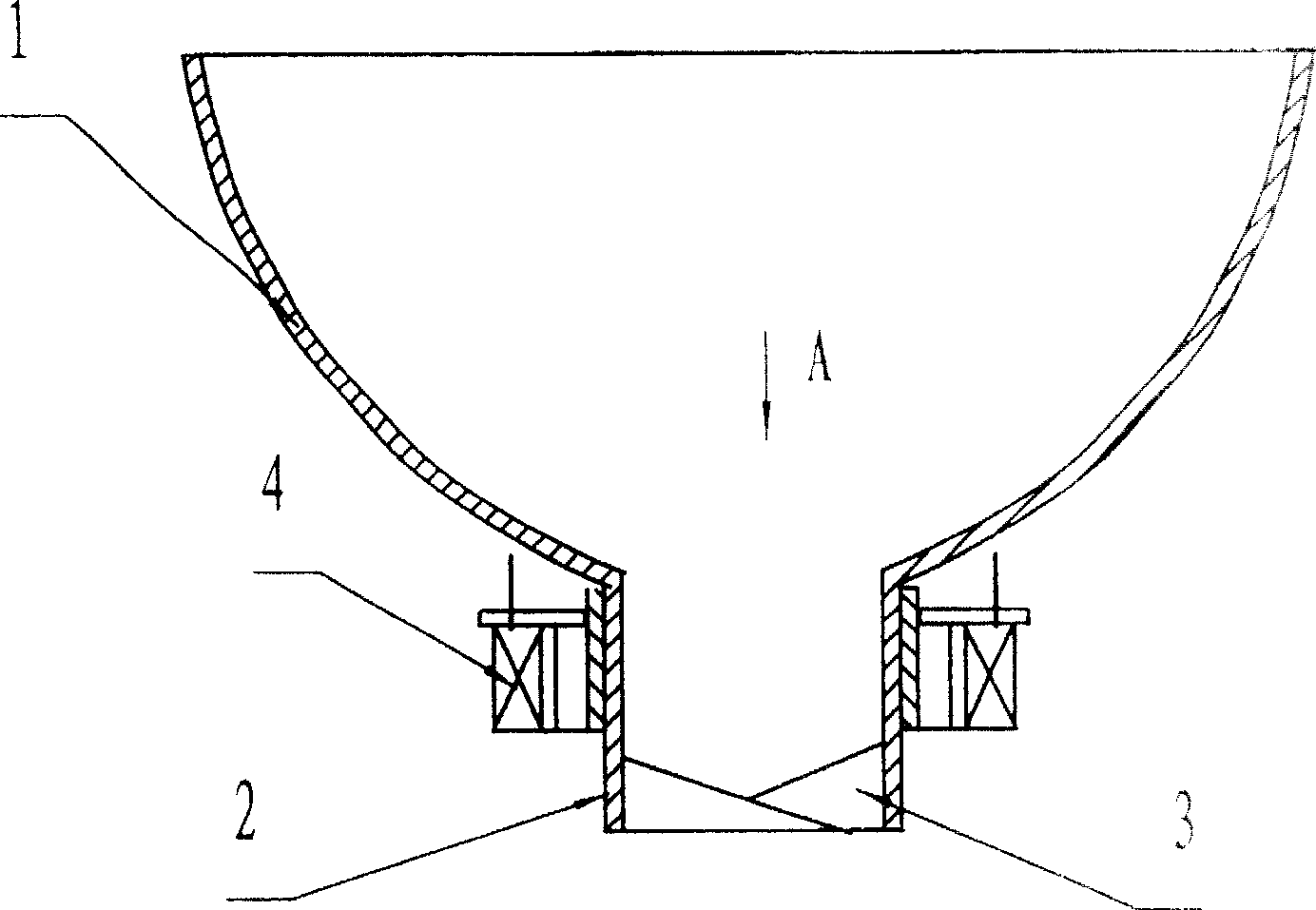

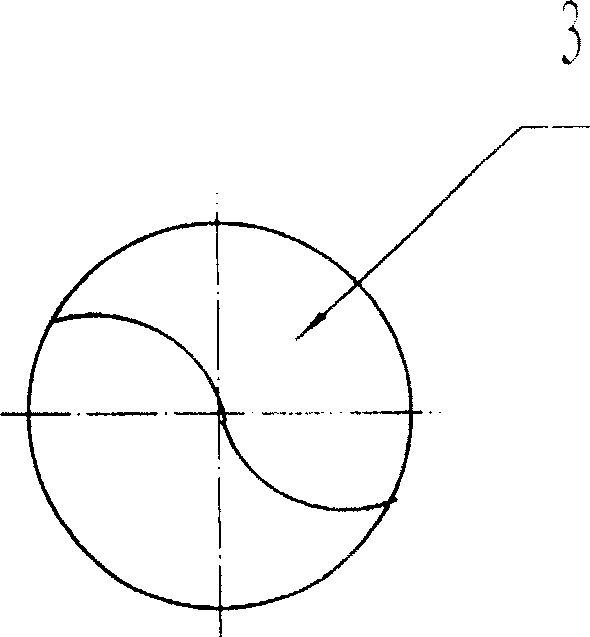

[0015] see figure 1 and figure 2 , reflecting the specific structure of the forced excretion device of the present invention. It has a rotatable closet 1, the bottom of the closet 1 is a through pipe 2, and two blades 3 are fixed in the through pipe 2, and the outer set of the through pipe 2 is a motor 4 that drives the closet to rotate. The mandrel of the motor 4 adopts a hollow shaft with a thick pipe diameter. When the motor 4 drives the toilet 1 to rotate, the blades 3 fixed in the through pipe 2 quickly chop the feces in the toilet 1, and form a vortex under the action of water to discharge , Flush away the feces in a few seconds, with very little water consumption.

Embodiment 2

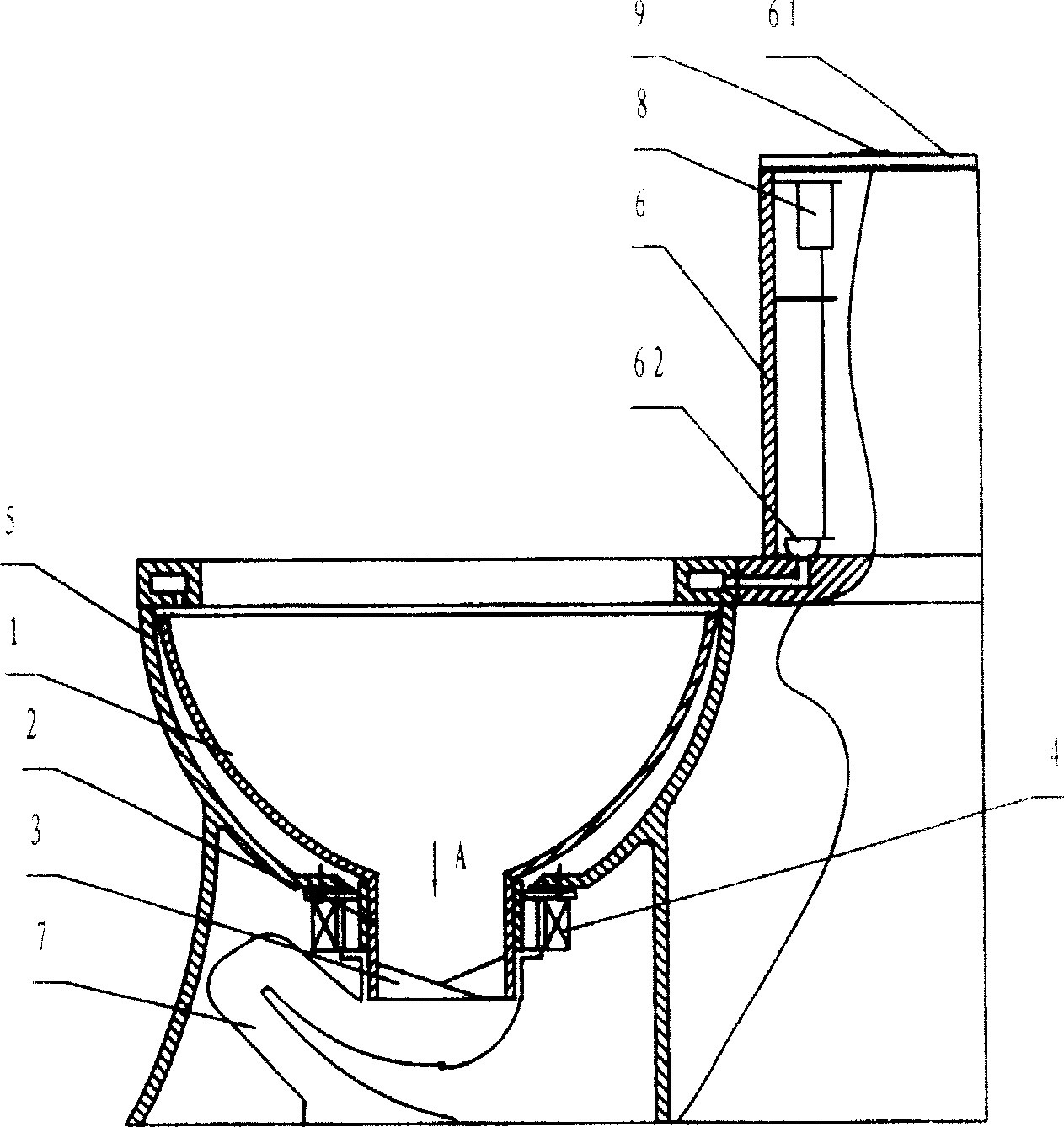

[0017] see image 3 and Figure 4 , this is an example that embodiment one is used for the toilet seat of manufacture, it still needs to use the fixed staving 5, water tank 6 and first siphon 7 of traditional toilet, but the size of first siphon 7 can be done smaller. Put the excrement forced discharge device mentioned in Embodiment 1 in the fixed barrel body 5, make the upper part of the toilet 1 communicate with the water of the water channel of the fixed barrel body 5, and connect the lower part of the through pipe 2 with the first siphon tube 7. The switch of the power supply of motor 4 adopts touch switch 9, and this switch is installed on the water tank cover 61, and a telescopic electromagnet 8 is housed above the beat cover 62 in the water tank 6, and this solenoid valve links to each other with the chain of beat cover 62, drives the beat cover 62 or up or down, to realize the closing or opening of the water tank outlet, the power supply of the telescopic electromagne...

Embodiment 3

[0019] see Figure 5 , Figure 6 , which is an embodiment in which Embodiment 1 is used to manufacture a squatting pan. As can be seen from the figure, we have still utilized the fixed basin 10 and the second siphon 11 on the top of the existing squatting pan, but require that the water outlet of the fixed basin 10 can be inserted into the closet 1, and the second siphon 11 can also be integrated with the toilet 1. Through pipe 2 sockets. Flush valve 12 can adopt electromagnetic valve, and this valve can share a power switch 13 with motor 4 (see Figure 6 ), when the switch is turned on, the flush valve 12 and the motor 4 work at the same time, at this time, the water flows into the toilet 1, and the motor 4 rotates to force the stool liquid to be discharged. Its working principle is the same as that of the above-mentioned embodiment, and the amount of water used Similarly, if we store the water for washing our hands and face, we can fully meet the required amount of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com