Patents

Literature

3164 results about "Touch switch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A touch switch is a type of switch that only has to be touched by an object to operate. It is used in many lamps and wall switches that have a metal exterior as well as on public computer terminals. A touchscreen includes an array of touch switches on a display. A touch switch is the simplest kind of tactile sensor.

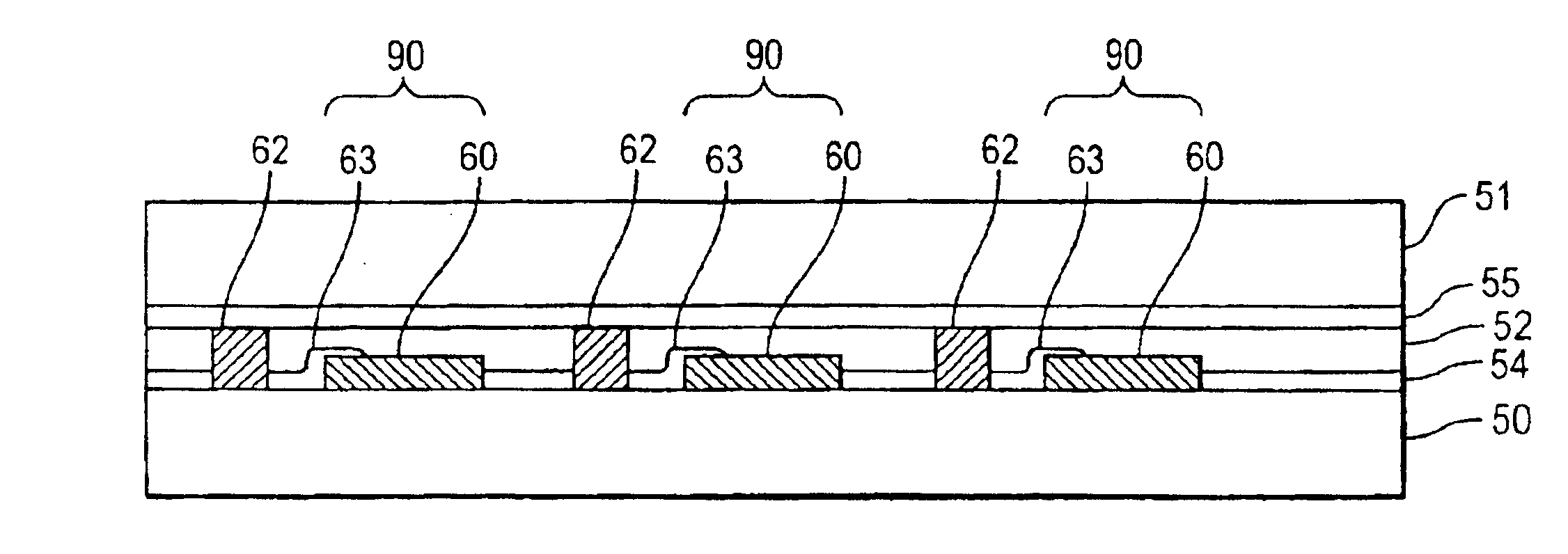

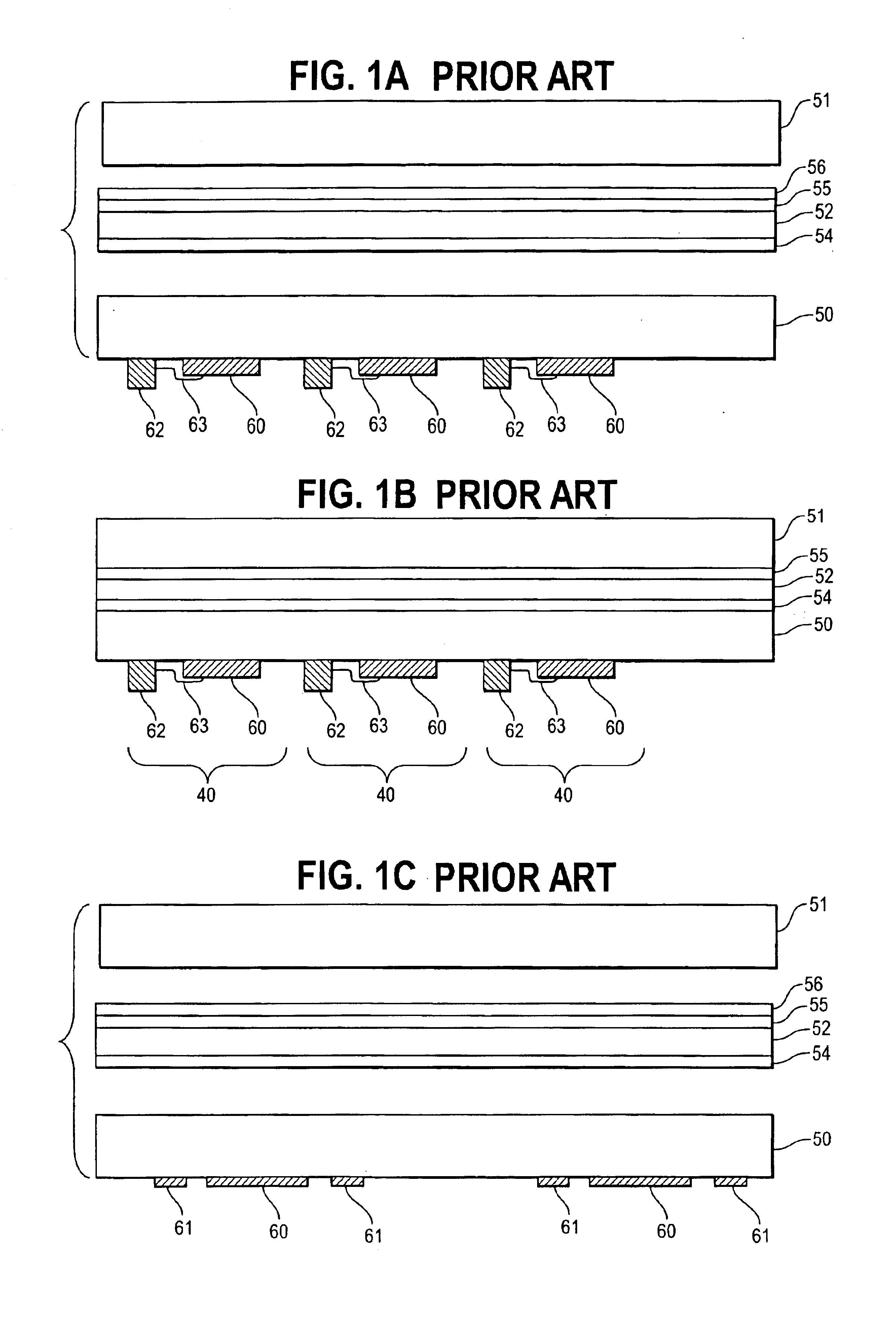

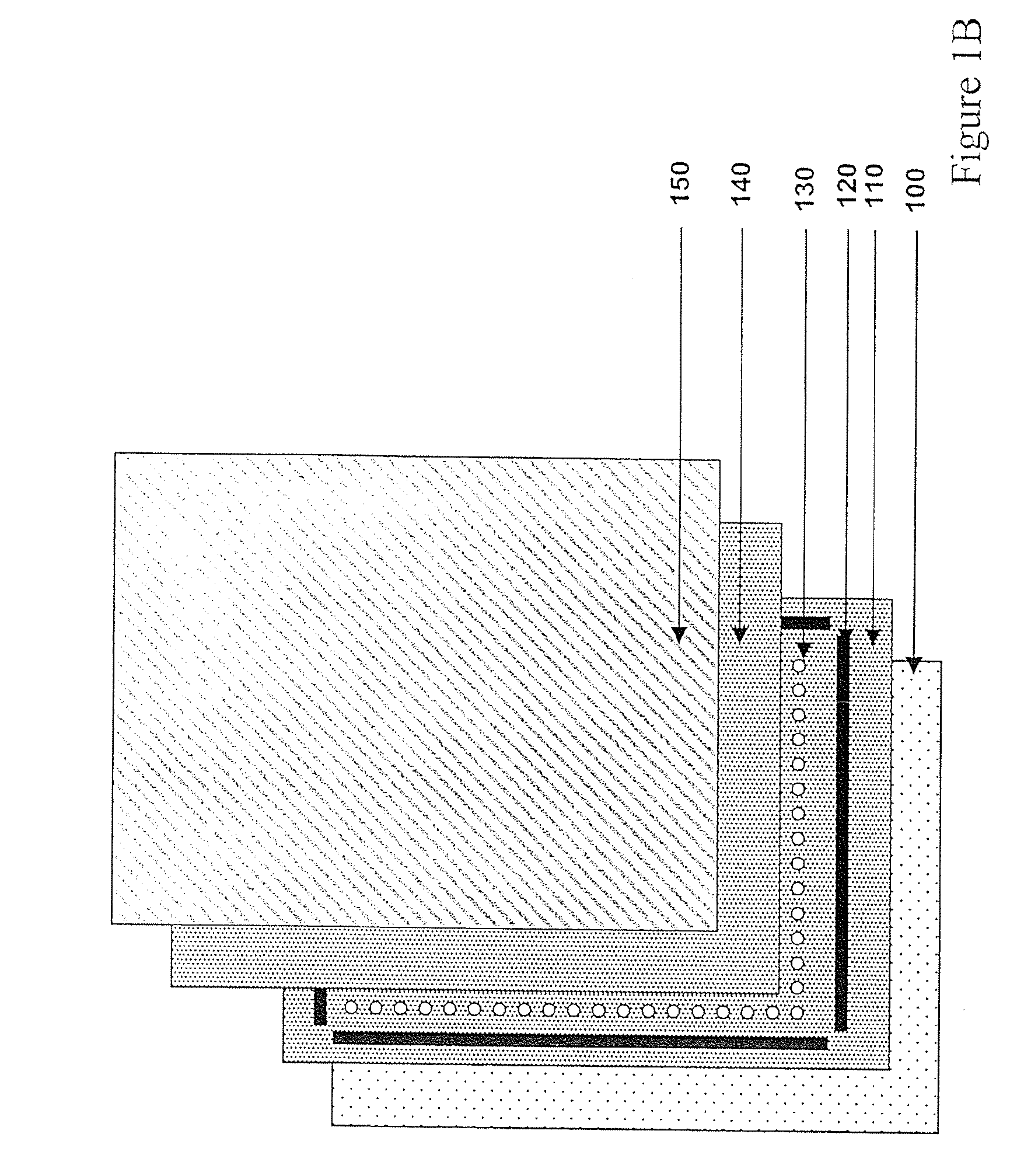

Planar element, and touch switch

InactiveUS20110102370A1Improve visibilityElectronic switchingInput/output processes for data processingVisibilityEngineering

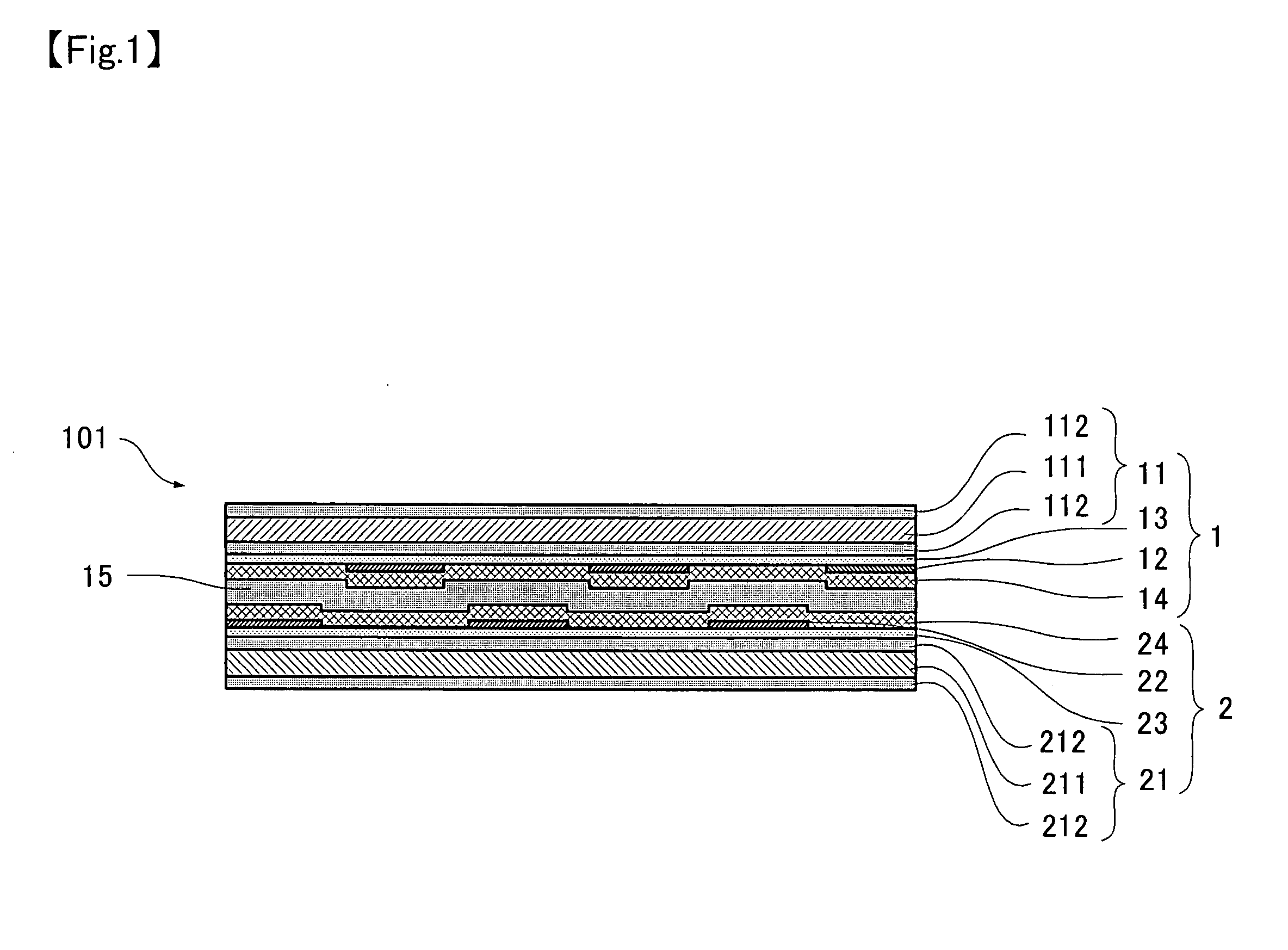

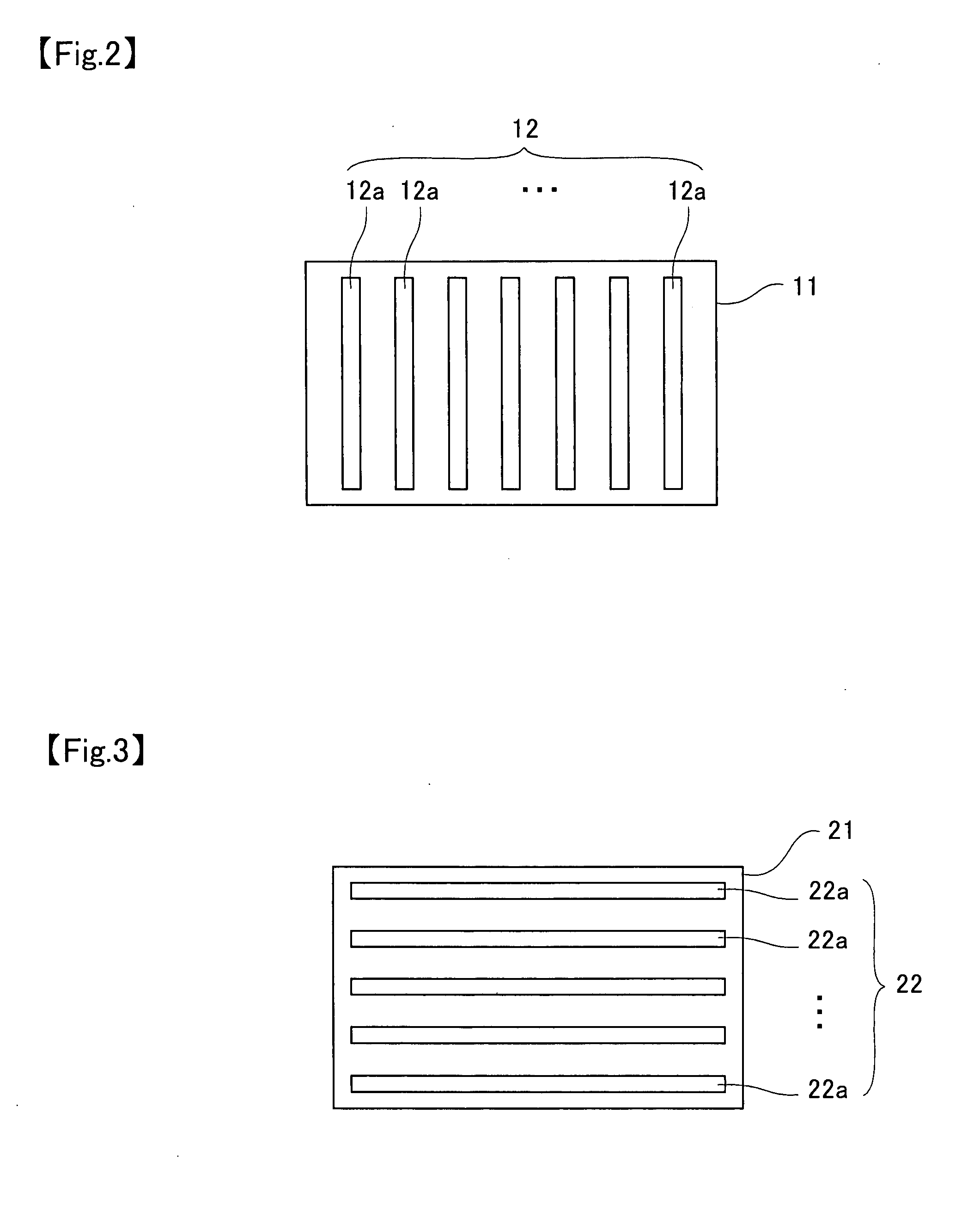

The present invention provides a touch switch having two ITO-free electrode layers that are bonded together, the touch switch having good visibility, and a planar body that forms such a touch switch. The planar body includes a mesh-like electrode formed in a mesh shape by multiple conductor lines L on one side of a substrate, in which the mesh-like electrode is separated into multiple conductive areas disposed at intervals, and non-conductive areas each disposed between each of the conductive areas; each non-conductive area has multiple cutting portions that cut the conductor lines L, and each non-conductive area insulates between the adjacent conductive areas by the cutting portions.

Owner:GUNZE LTD

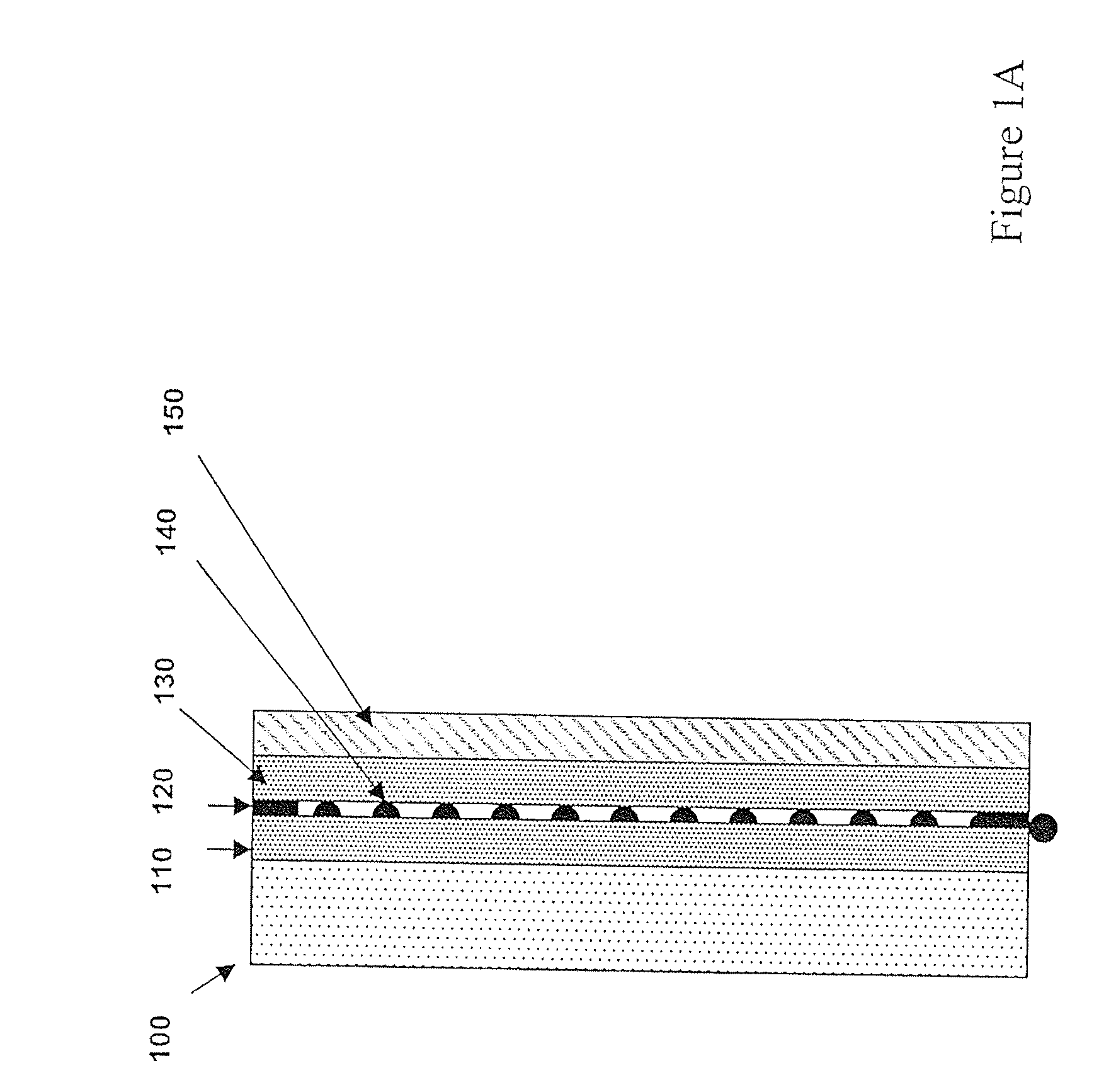

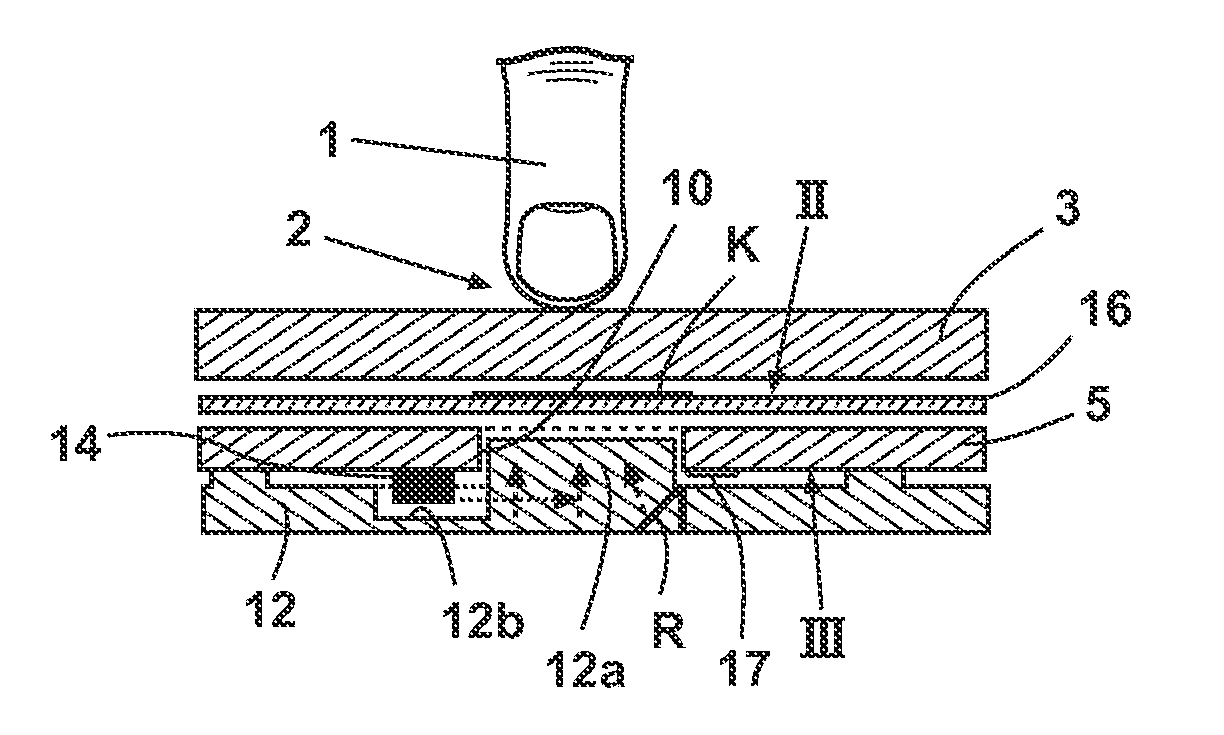

Transparent Planar Body and Transparent Touch Switch

ActiveUS20080138589A1Increase awarenessConductive layers on insulating-supportsDecorative surface effectsVisibilityTransmittance

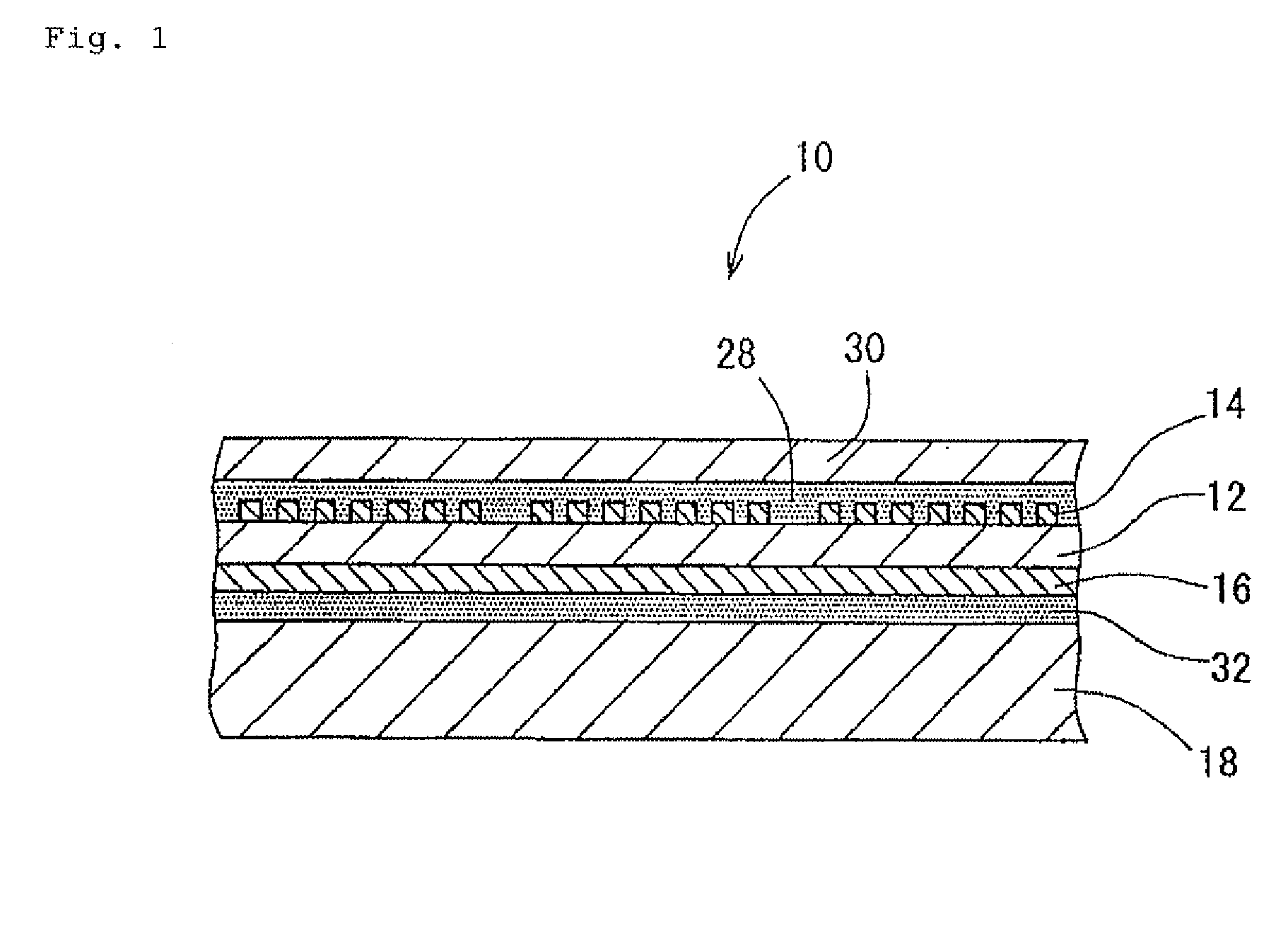

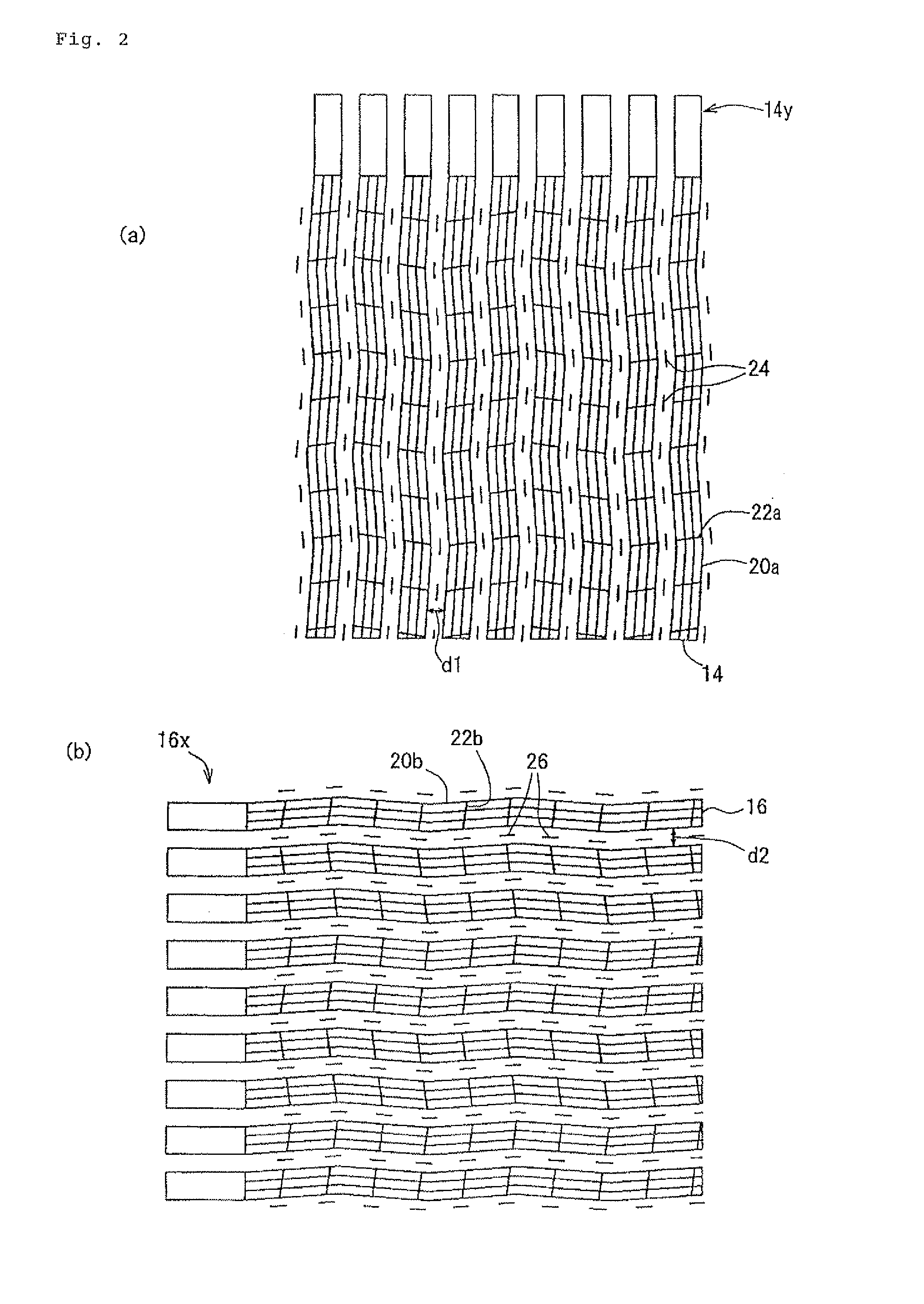

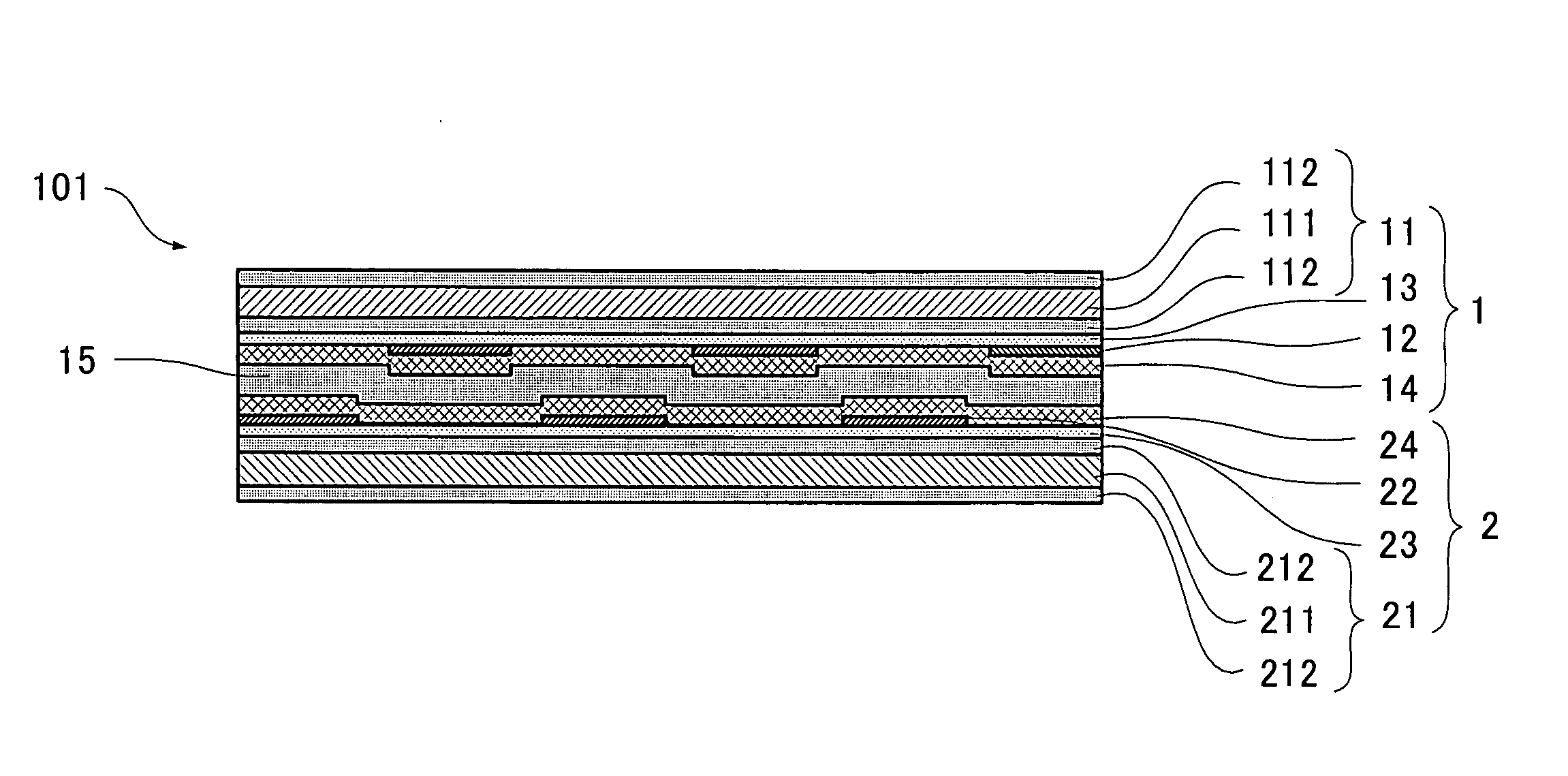

The present invention provides a transparent planar body and a transparent touch switch that can improve visibility. Specifically, the transparent planar body (1) has a patterned transparent conductive film (12) on at least one surface of a transparent substrate (11). This transparent planar body (1) comprises a transmittance-adjusting layer for equalizing the transmission spectrum of light transmitted through a patterned region wherein the transparent conductive film (12) is provided via the transparent substrate (11) with that transmitted through a non-patterned region wherein the transparent conductive film (12) is not provided via the transparent substrate (11).

Owner:GUNZE LTD

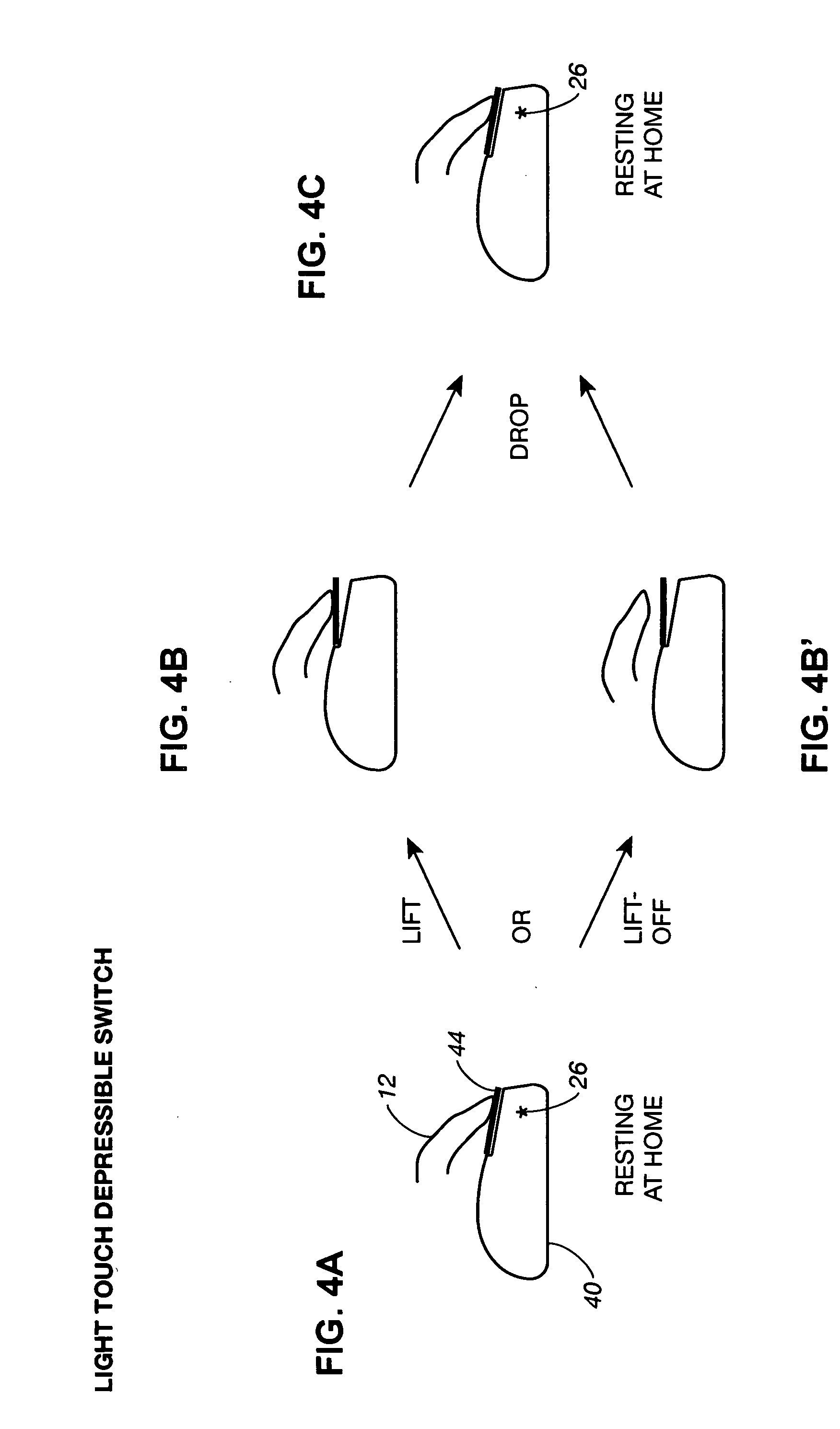

Ergonomic lift-clicking method and apparatus for actuating home switches on computer input devices

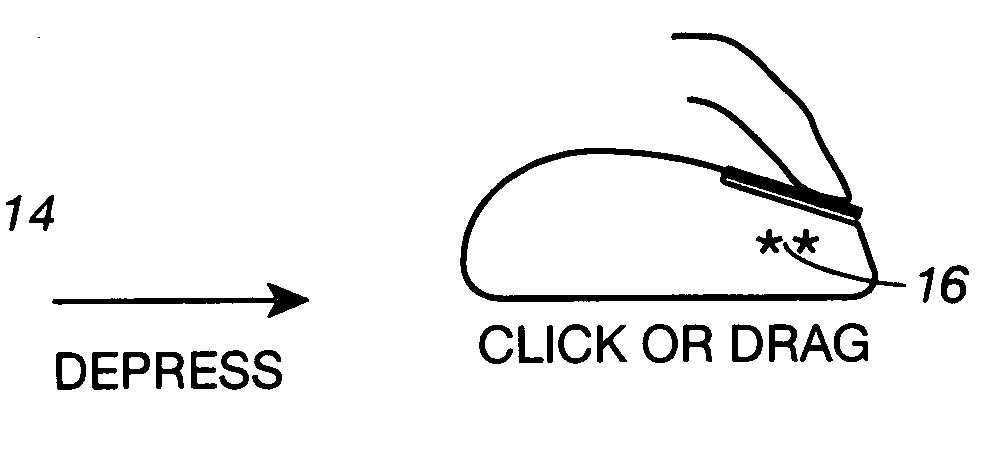

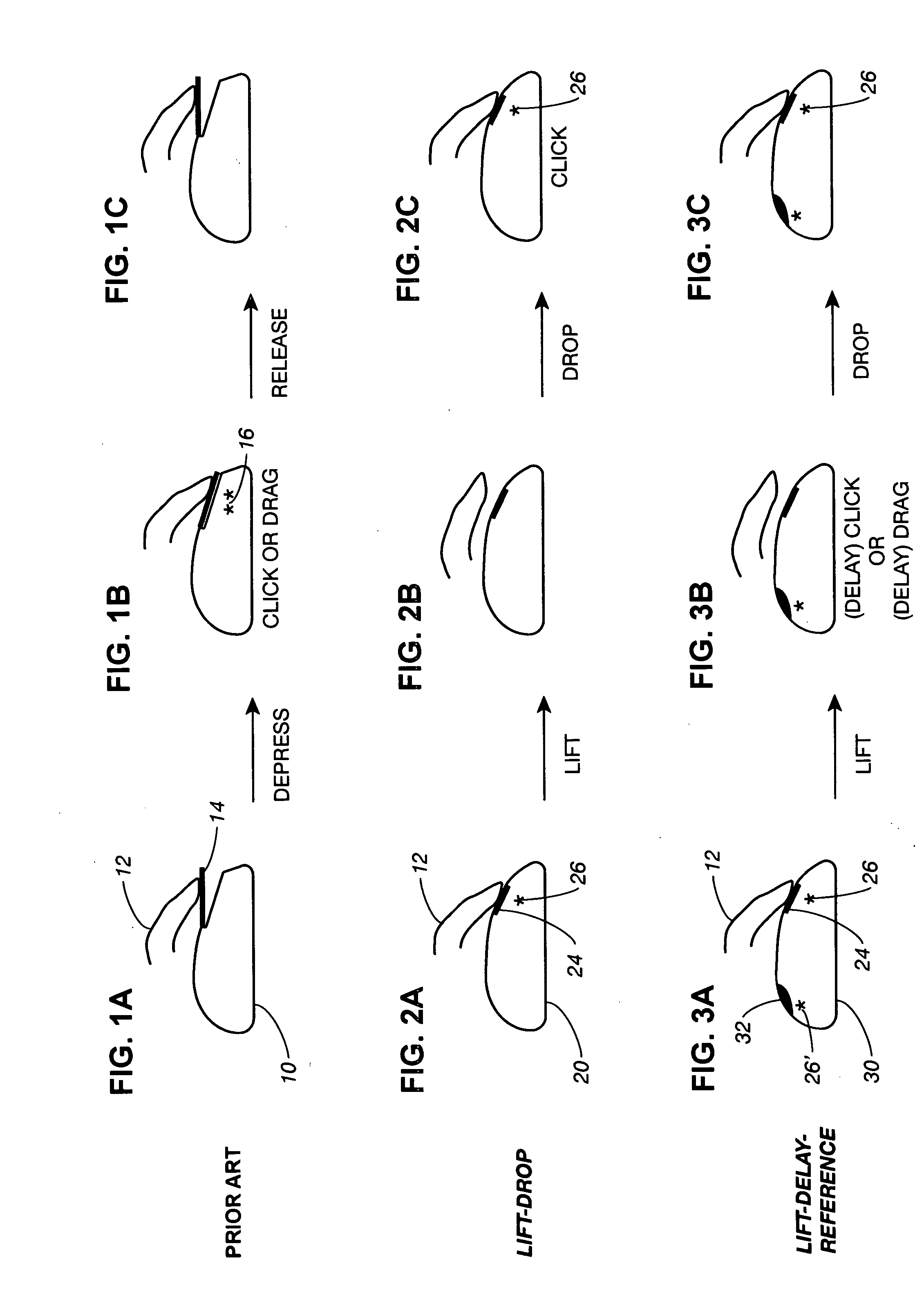

This invention introduces lift-clicking, a gentle method of clicking that utilizes light touch home sensors on the mouse and other computer input devices. It can be used either to replace the prior art depression-type mouse button with a home touch surface and a light touch or proximity sensor, or to add a touch / proximity sensor to an existing mouse button, providing three or more additional functions for each finger. It is a very ergonomic method that uses less force than the weight of the relaxed resting finger. It employs a finger lift, or a finger lift followed by a gentle drop, and utilizes unique combinations of windows, timing, hand presence reference, and logic sequences carefully designed to automatically prevent the production of unwanted clicks when the finger first arrives on or leaves the home sensor as the hand arrives or departs the input device. The initial condition is a finger resting on a touch switch / proximity sensor surface at a home resting position. A function is triggered either by lifting (or sliding) the finger away from its home touch surface (lift-delay-reference mode) or by dropping the finger back to the surface soon after the lift (lift-drop mode). Unwanted clicks do not occur because the function is triggered either by a lift after a very short delay with a requirement for hand presence reference, or by a drop within a time window opened by the previous lift. The gentle lift of the finger followed by a passive drop eliminates the push-down muscle twitch of prior art depression clicking, without any sacrifice of speed. Optionally included are click-inhibiting means so that unwanted clicks are not produced when a finger leaves a home sensor to actuate a non-home switch or scroll device. Momentary lifted modes can be used to enable scrolling with mouse motion, a fine cursor control feature, or to ignore all XY data so that the mouse can be repositioned without lifting it off the desktop and without moving the cursor (disengage clutch feature). Dragging can be accomplished with either the finger held lifted or with the finger resting at home. A single lift-click sensor can be used to trigger two different functions, the function chosen depending on the amount of time between the lift and the drop. The lift-click sensor can be piggybacked together with a prior art mouse button to provide lift-clicking while still allowing depression clicking, greatly increasing the number of triggerable functions. A lift-click sensor can be of a fixed type with no moving parts, (a zero button mouse) allowing the manufacture of pointing devices that are completely solid state, low in cost and sealed from the environment. The lift-click method makes it possible to replace the click buttons on a horizontal mouse with a programmable multi-point XY(Z) multi-functional touchpad which can be used to provide not only lift-clicks, but by toggling to new function sets, can also offer arrow / nudge key functions, page navigation, fine cursor control, and gesturing. Lift-clicking can greatly improve versatility and ease of use in most types of pointing devices.

Owner:CONRAD RICHARD H

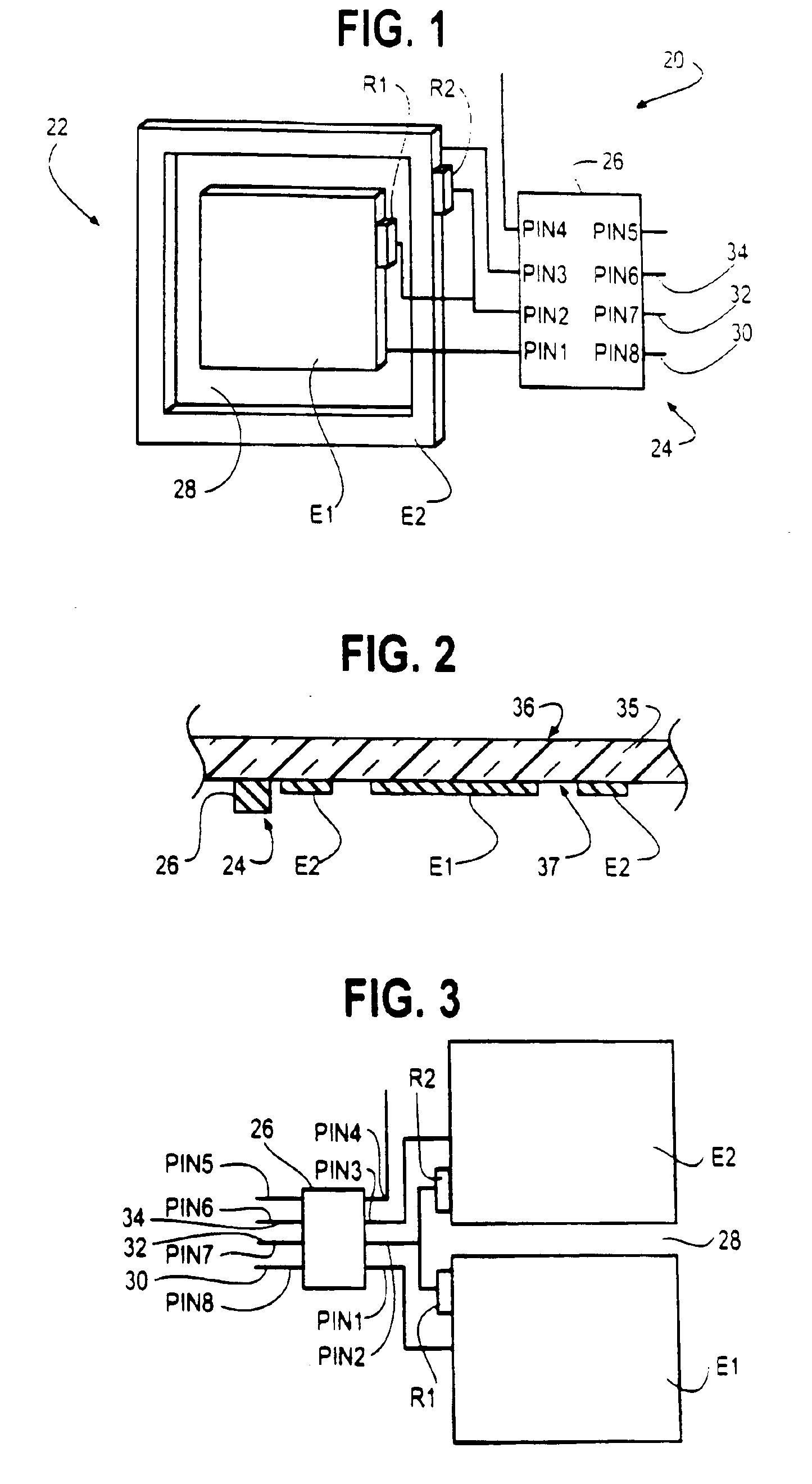

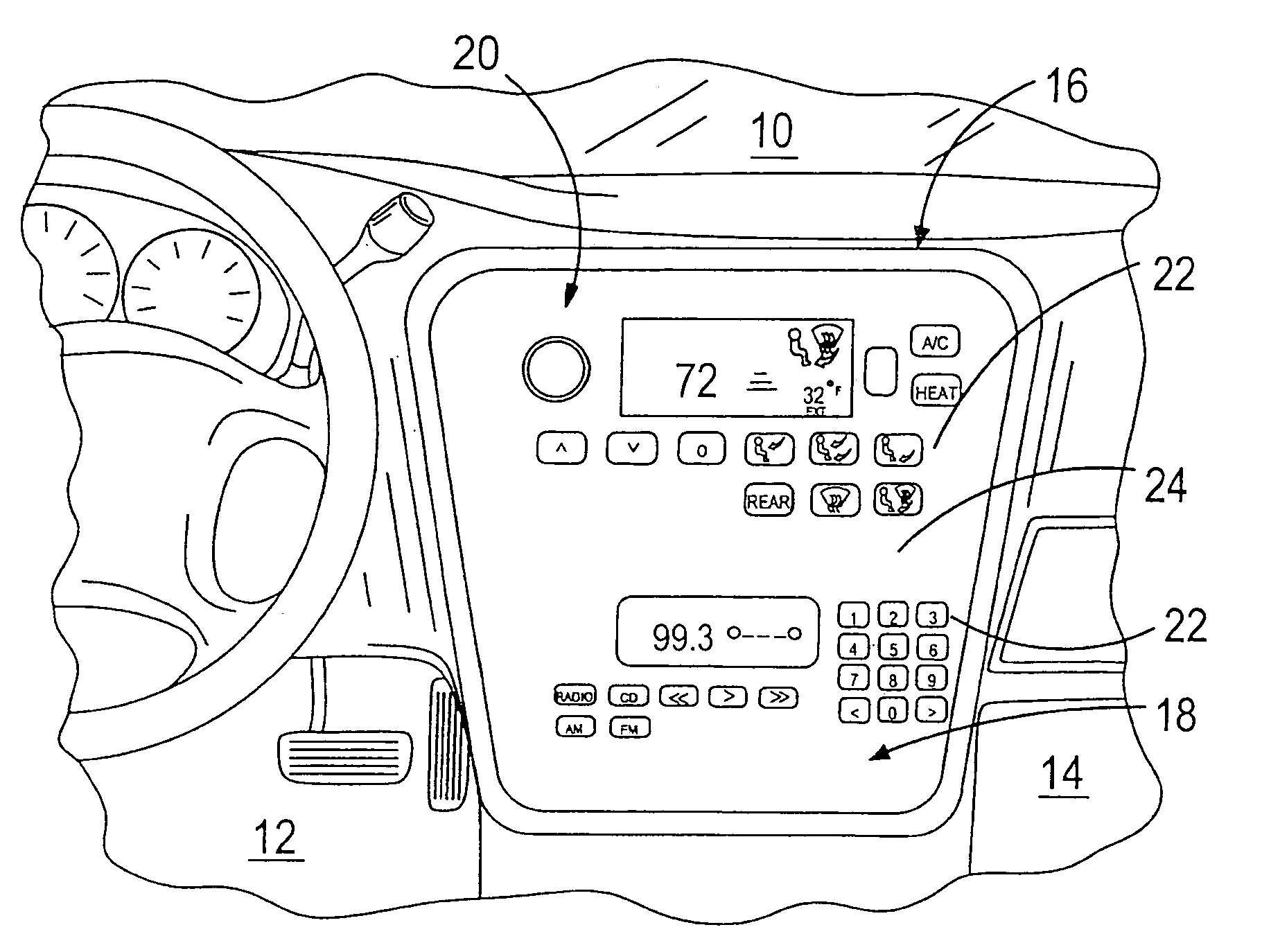

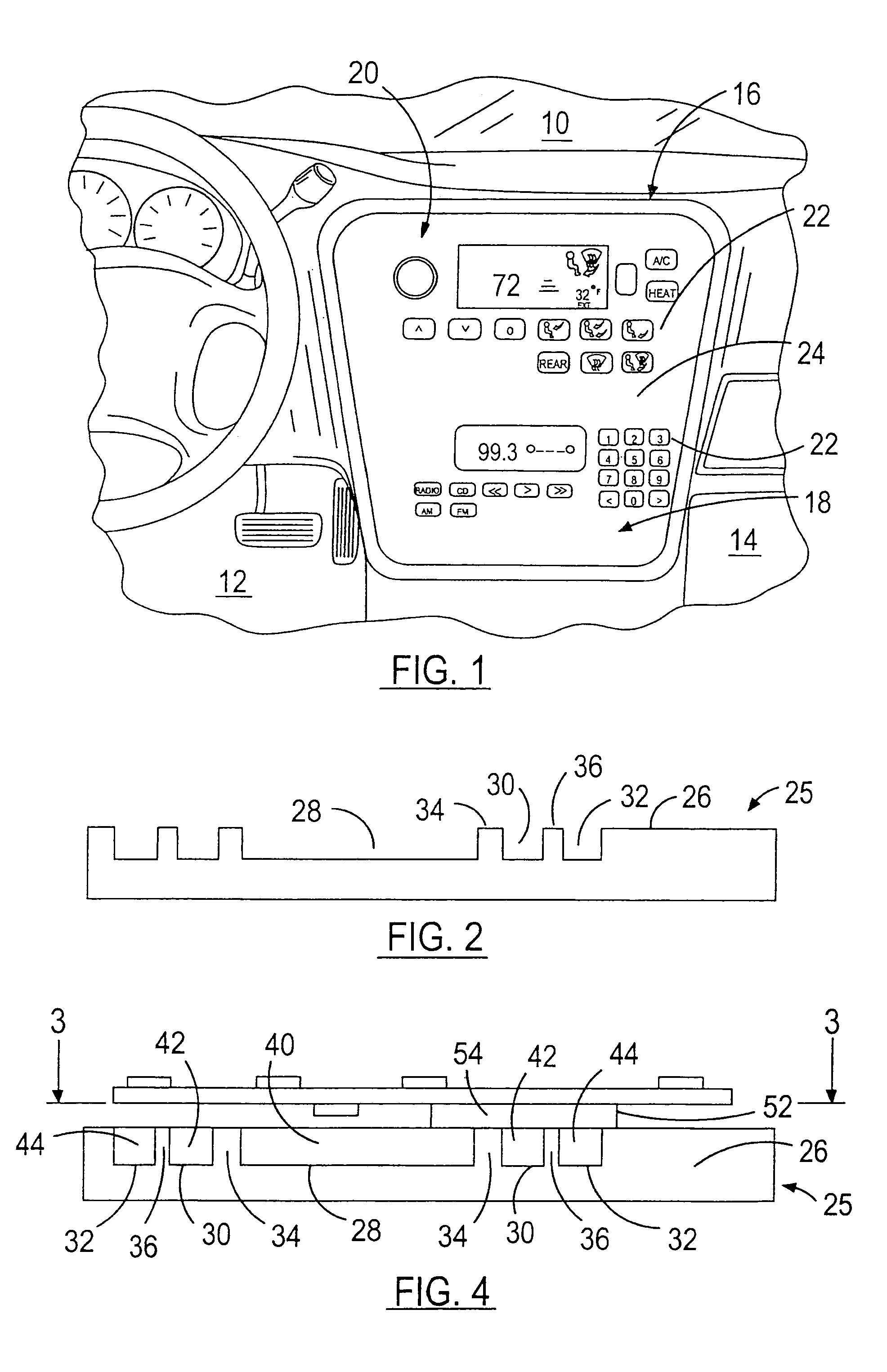

Molded/integrated touch switch/control panel assembly and method for making same

InactiveUS6897390B2Overcomes shortcomingSimple manufacturing processStampsContact surface shape/structureEngineeringInjection moulding

Touch switches are integrated with thermoformable, injection molded, and other substrates to yield integrated touch switch / control panel assemblies. The ensuant assemblies can include ridges, depressions, anchors, overlaps, rivets and bezels or other housings. They can have any combination of flat and curved surfaces. Further, such assemblies can be incorporated into components of other assemblies, such as automobiles.

Owner:TOUCHSENSOR TECH

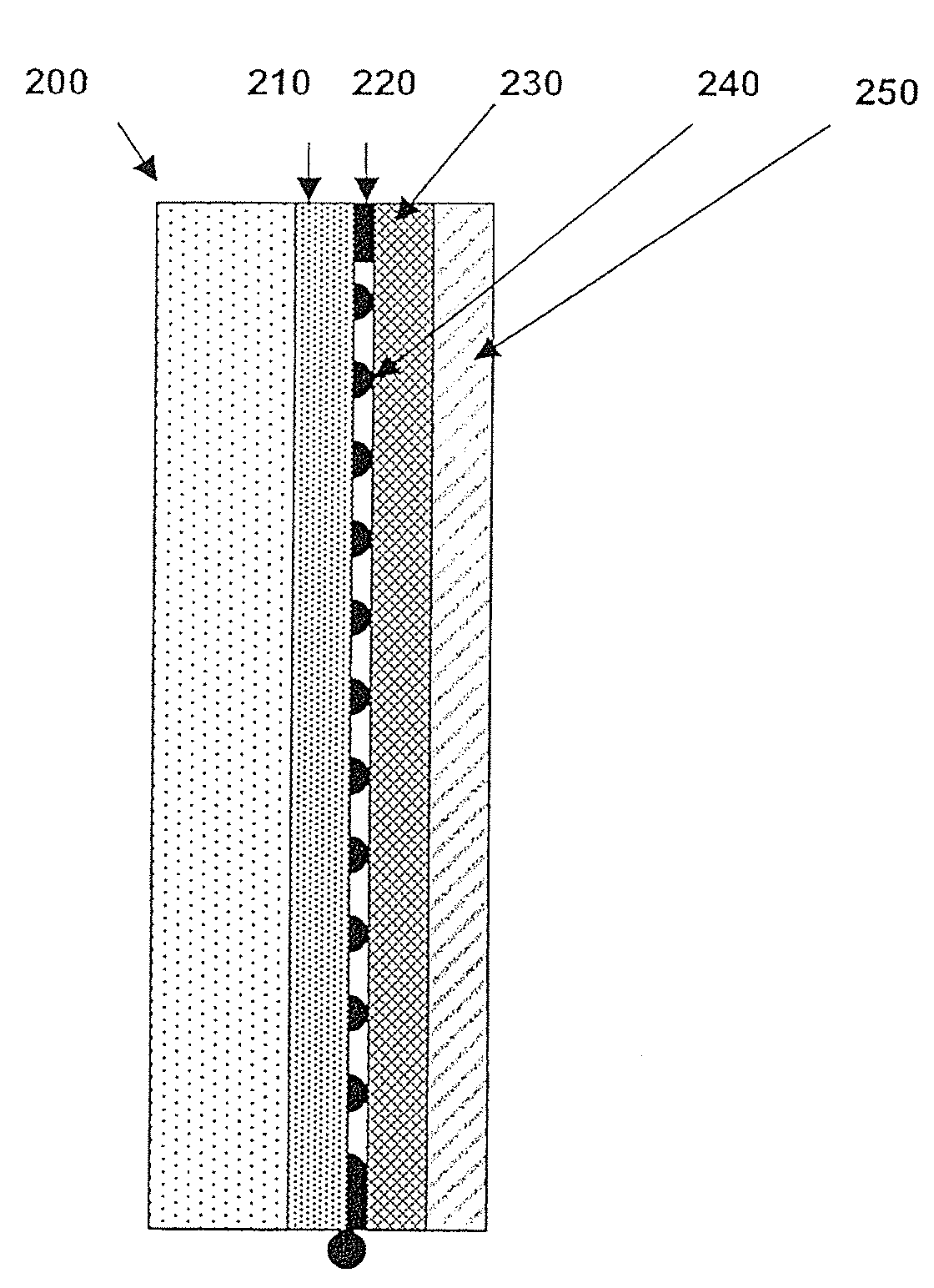

Symmetric touch screen system with carbon nanotube-based transparent conductive electrode pairs

InactiveUS20080238882A1Input/output processes for data processingElectricityElectrical resistance and conductance

A symmetric touch screen switch system in which both the touch side and panelside transparent electrodes are comprised of carbon nanotube thin films is provided. The fabrication of various carbon nanotube enabled components and the assembly of a working prototype touch switch using those components is described. Various embodiments provide for a larger range of resistance and optical transparency for the both the electrodes, higher flexibility due to the excellent mechanical properties of carbon nanotubes. Certain embodiments of the symmetric, CNT-CNT touch switch achieve excellent optical transparency (<3% absorption loss due to CNT films) and a robust touch switching characteristics in an electrical test.

Owner:NANTERO

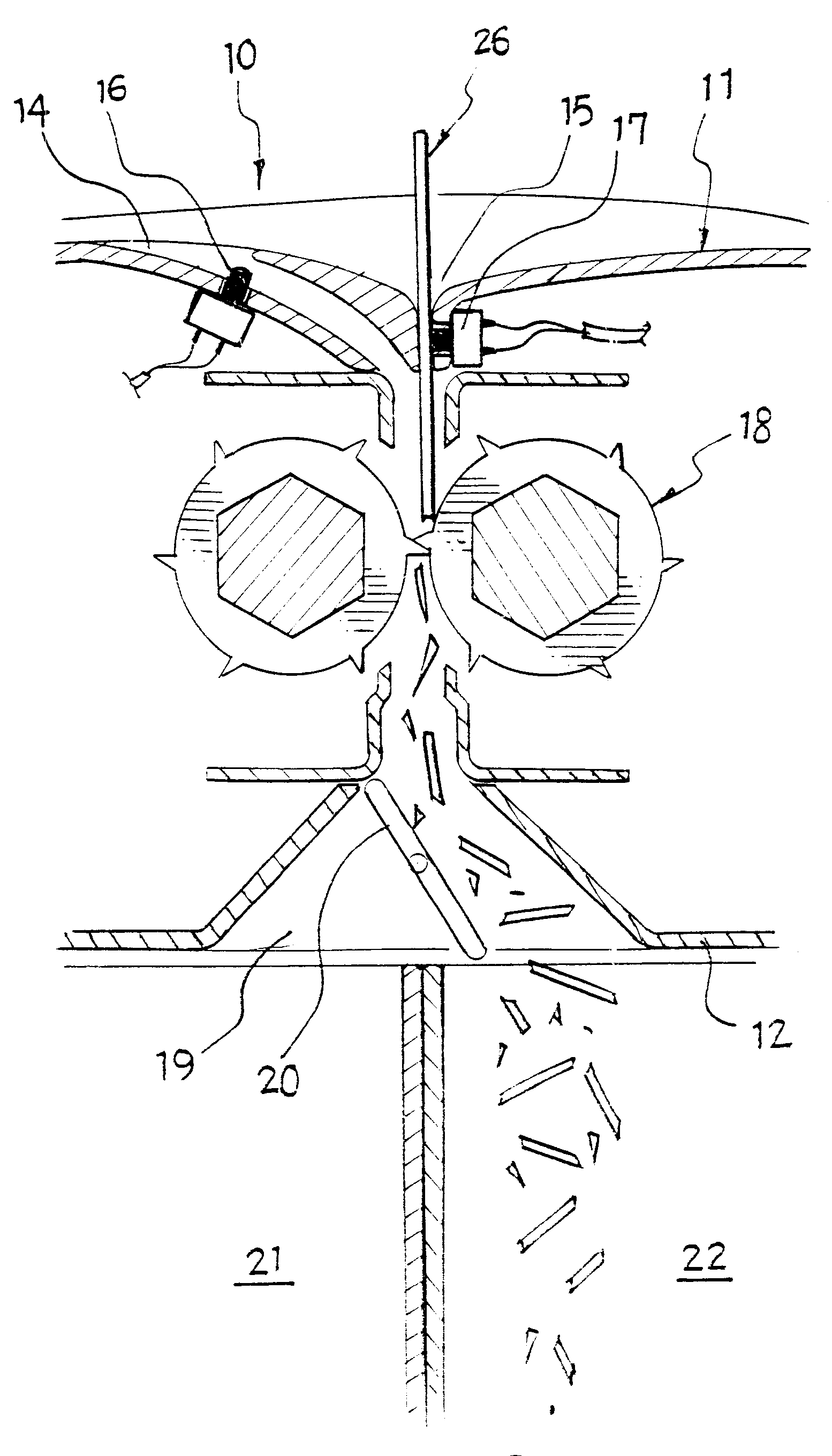

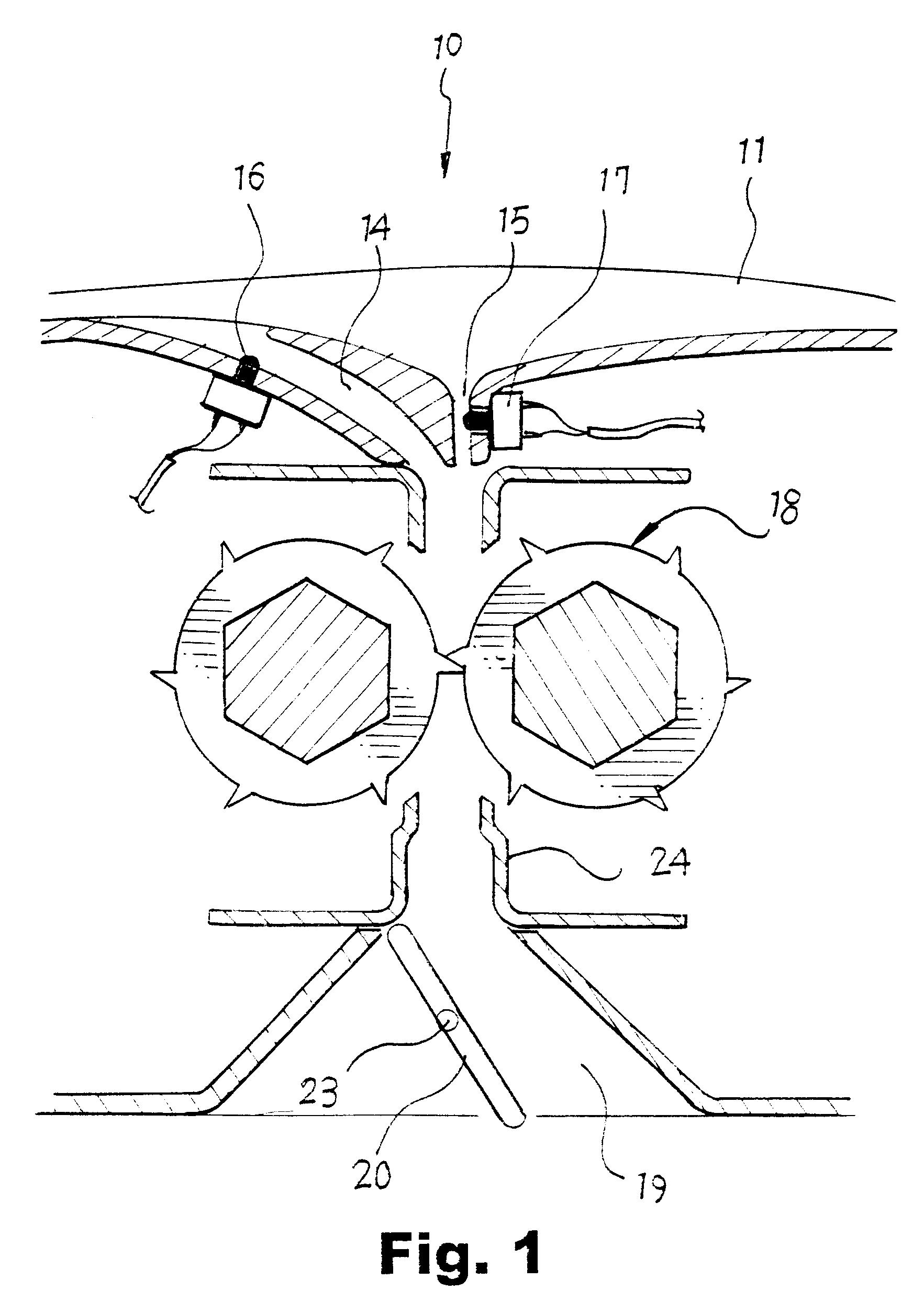

Dual-functional medium shredding machine structure

This invention is related to a dual-functional medium shredding machine structure, specifically designed for shredding or destroying paper printed with data to be destroyed, optical discs containing data to be destroyed, or expired credit cards. This invention mainly implements a pair of shredding roller blades with sharp teeth as shredding means, and is characterized by providing separate feeding inports, including a paper inport for feeding paper in an inclined orientation, and a disc inport for feeding discs in a vertical orientation, wherein the inports are each led to the same shredding roller blades such that, regardless of the type of substance being fed by the user, the paper or the discs can both be shredded by the shredding roller blades, and the shredded scraps are dispensed to separate collectors through an identical exit by means of an auto-revolving switch plate; and a touch switch at each of the inports such that, while feeding the paper or the discs, the touch switch activates the shredding roller blades to perform shredding task, and drives the switch plate so as to dispense shredded scraps of different substance into different collectors.

Owner:MICHILIN PROSPERITY

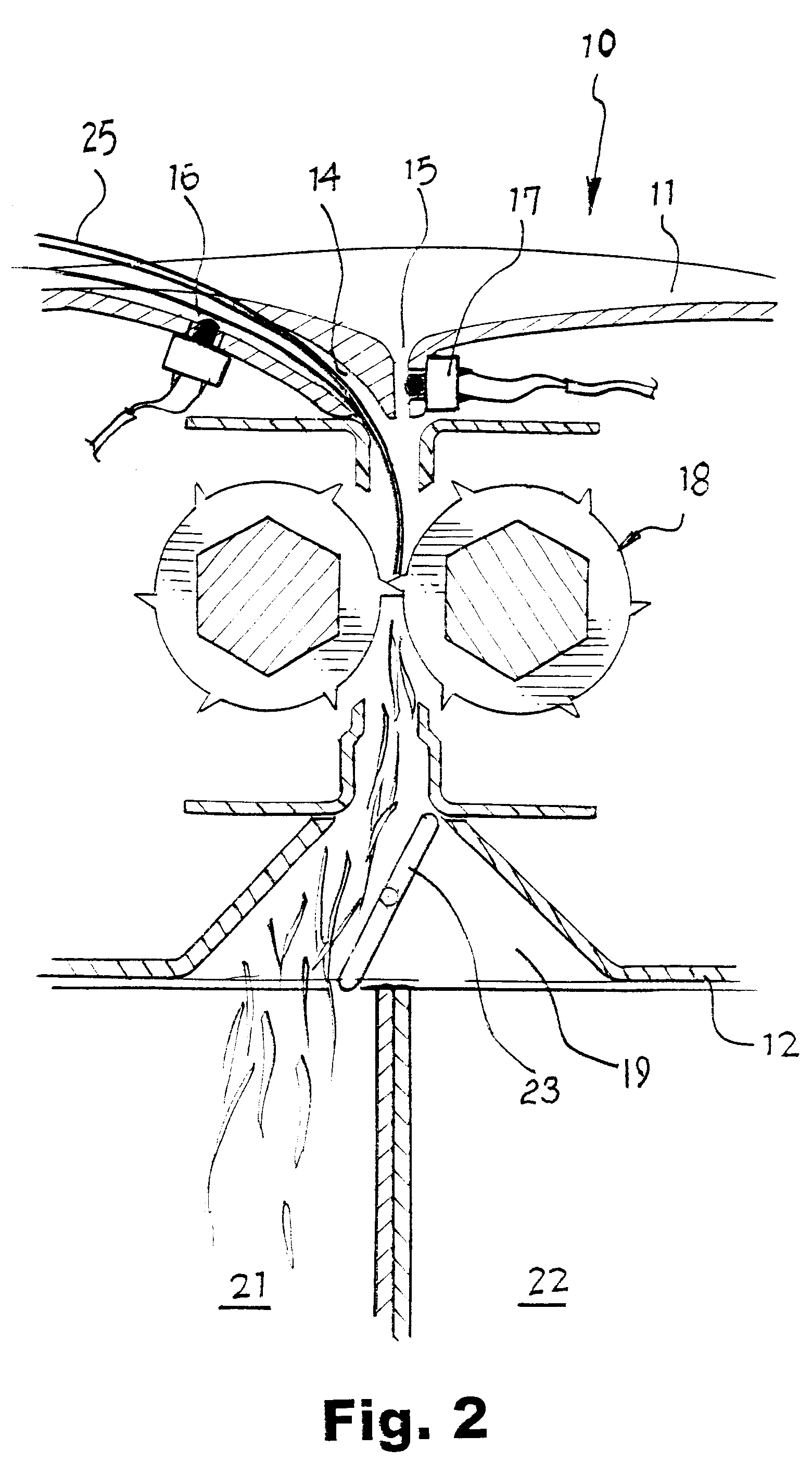

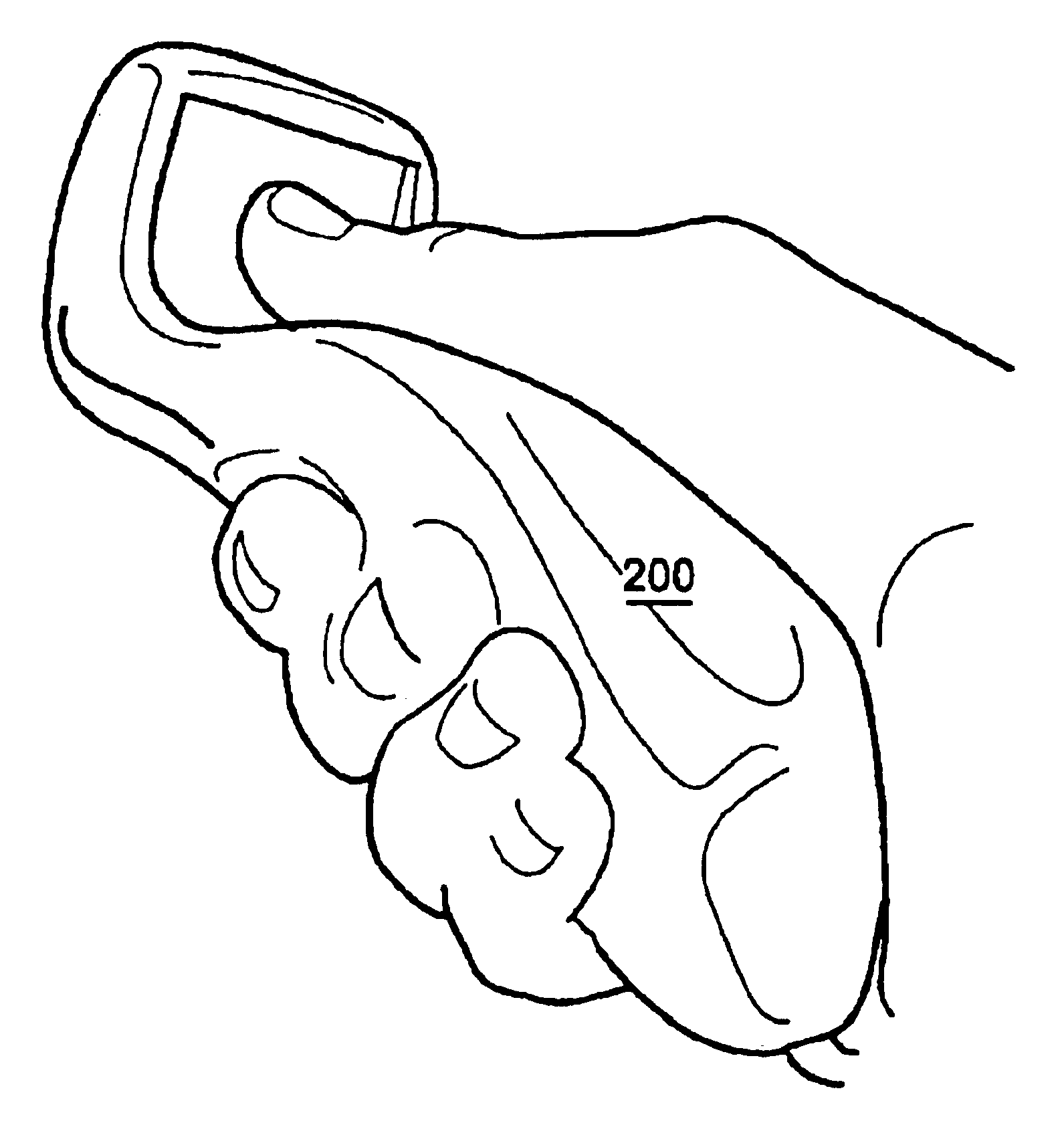

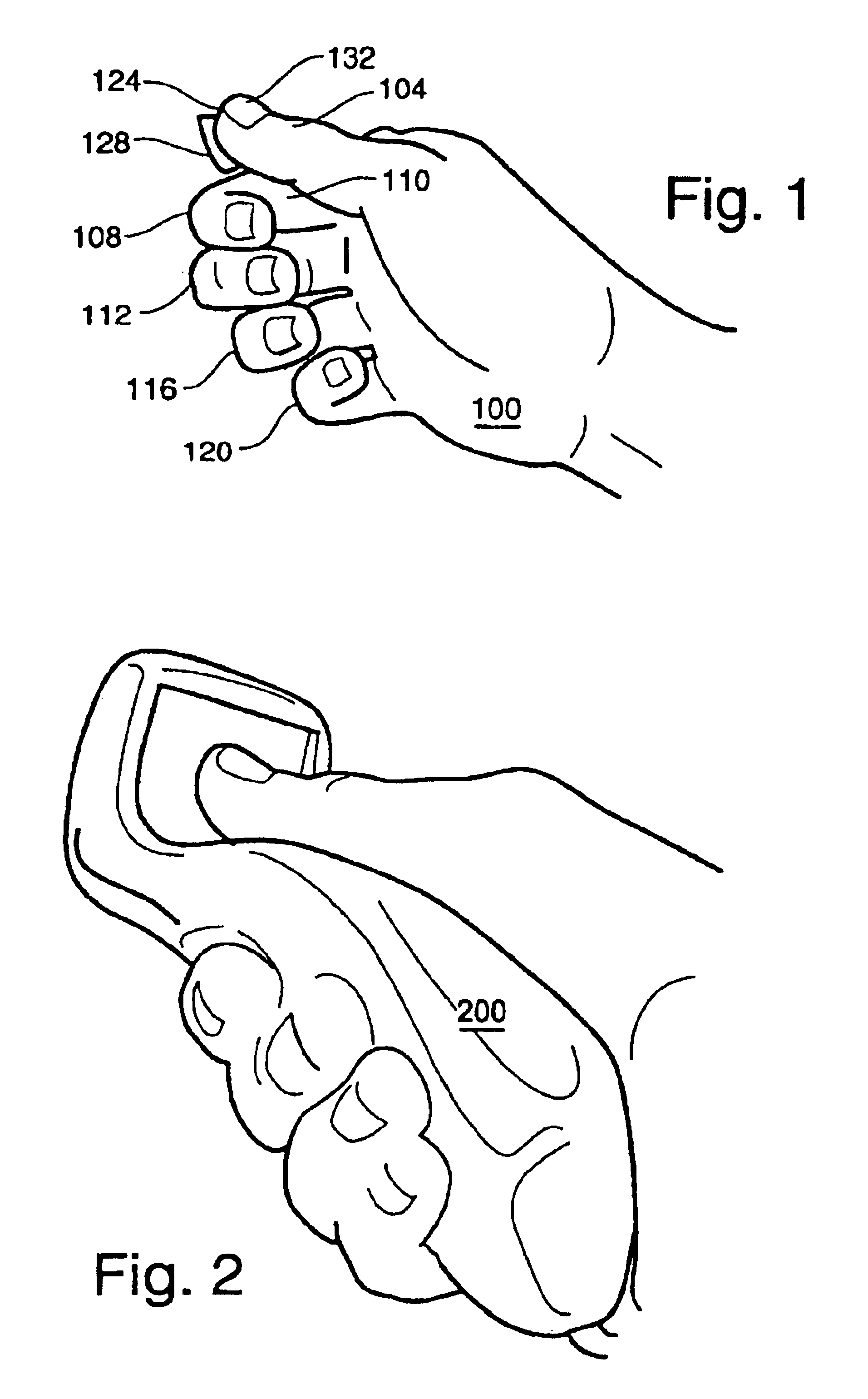

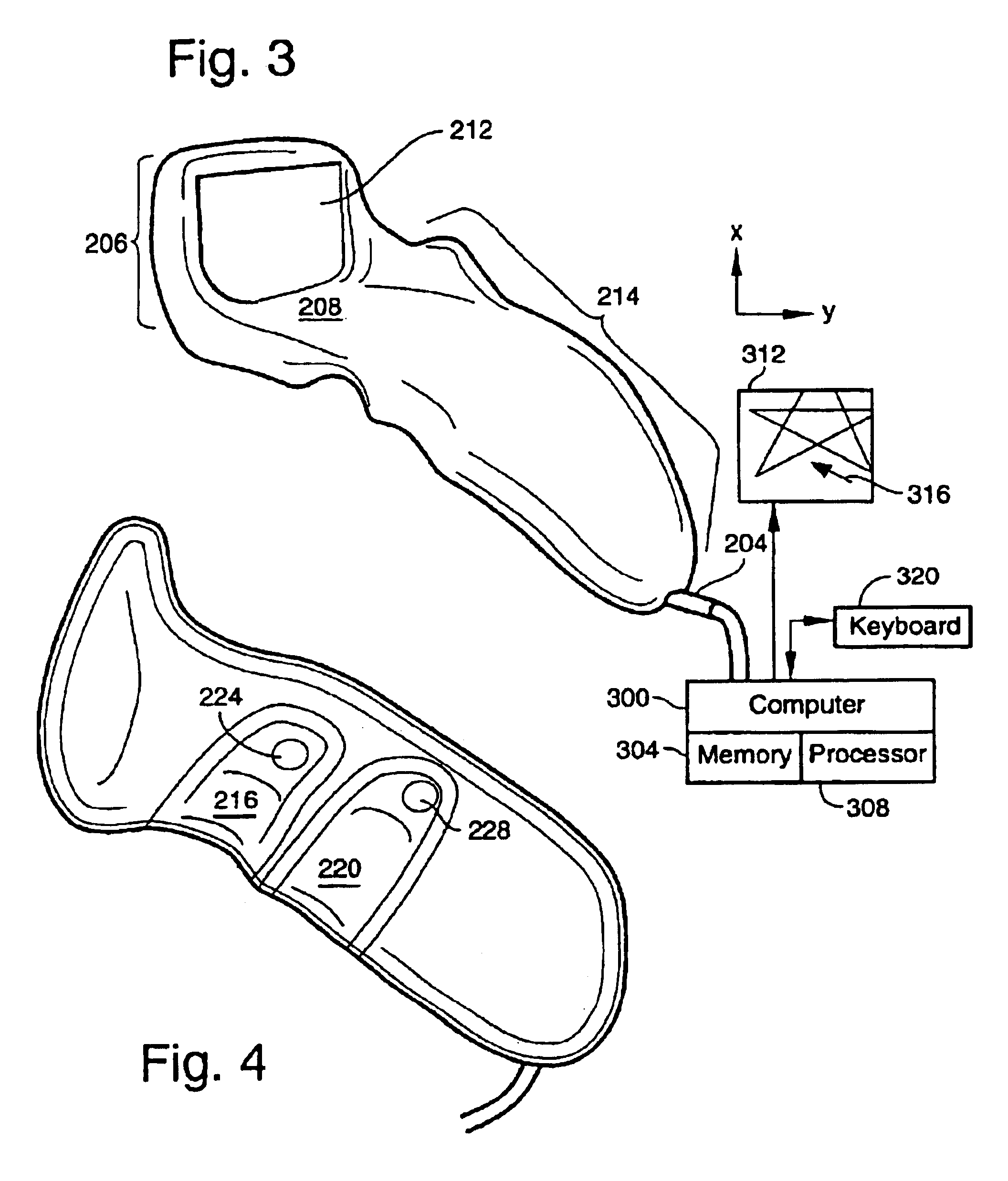

Thumb actuated X-Y input device

InactiveUSRE40324E1Effective applicationRelieve pressureTelevision system detailsColor signal processing circuitsHand sizeTouchpad

Various x-y input devices are disclosed that are adapted to allow a user to hold and operate the input device with a stress-reducing, open grip posture with the thumb pointing forward and on top of the device. One preferred embodiment discloses an input device for a computer comprising an x-y input sensor (such as a touchpad) positioned perpendicular to the thumb such that the user provides input with the thumb tip by using pivotal movement of the thumb. Various stress-reducing zero force touch switches are disclosed including zero force touch switches that can be adjusted to accommodate variations in user finger length. The mode of x-y cursor control can be altered through the use of x-y input sensor perimeter inputs. One preferred embodiment discloses a thumb actuated scroll select touch switch that alters the response to actuation of the finger actuated zero force touch switches from mouse button input to scroll wheel input. A unique fin-shaped feature of one preferred embodiment stabilizes the device within the relaxed hand and adapts the device to fit a range of user hand sizes.

Owner:PINEAPPLE34 LLC

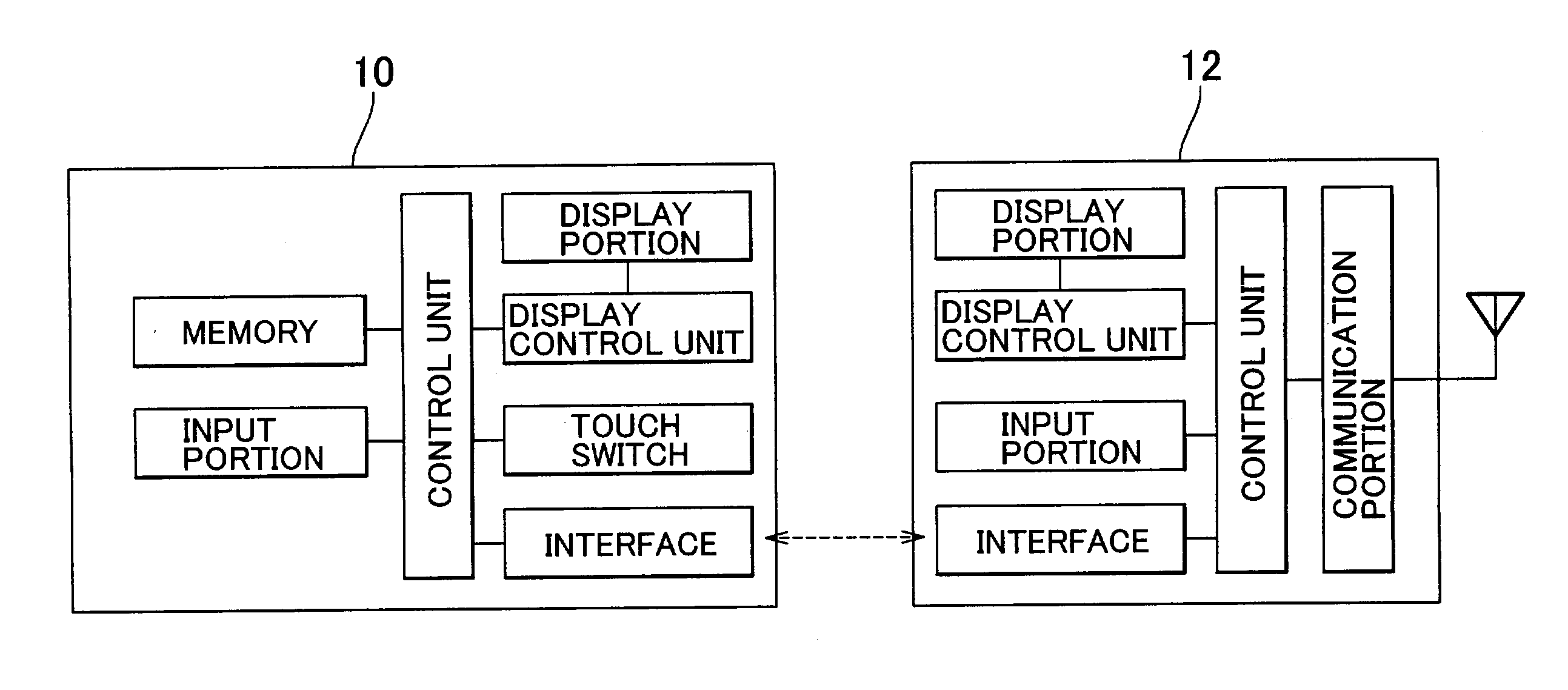

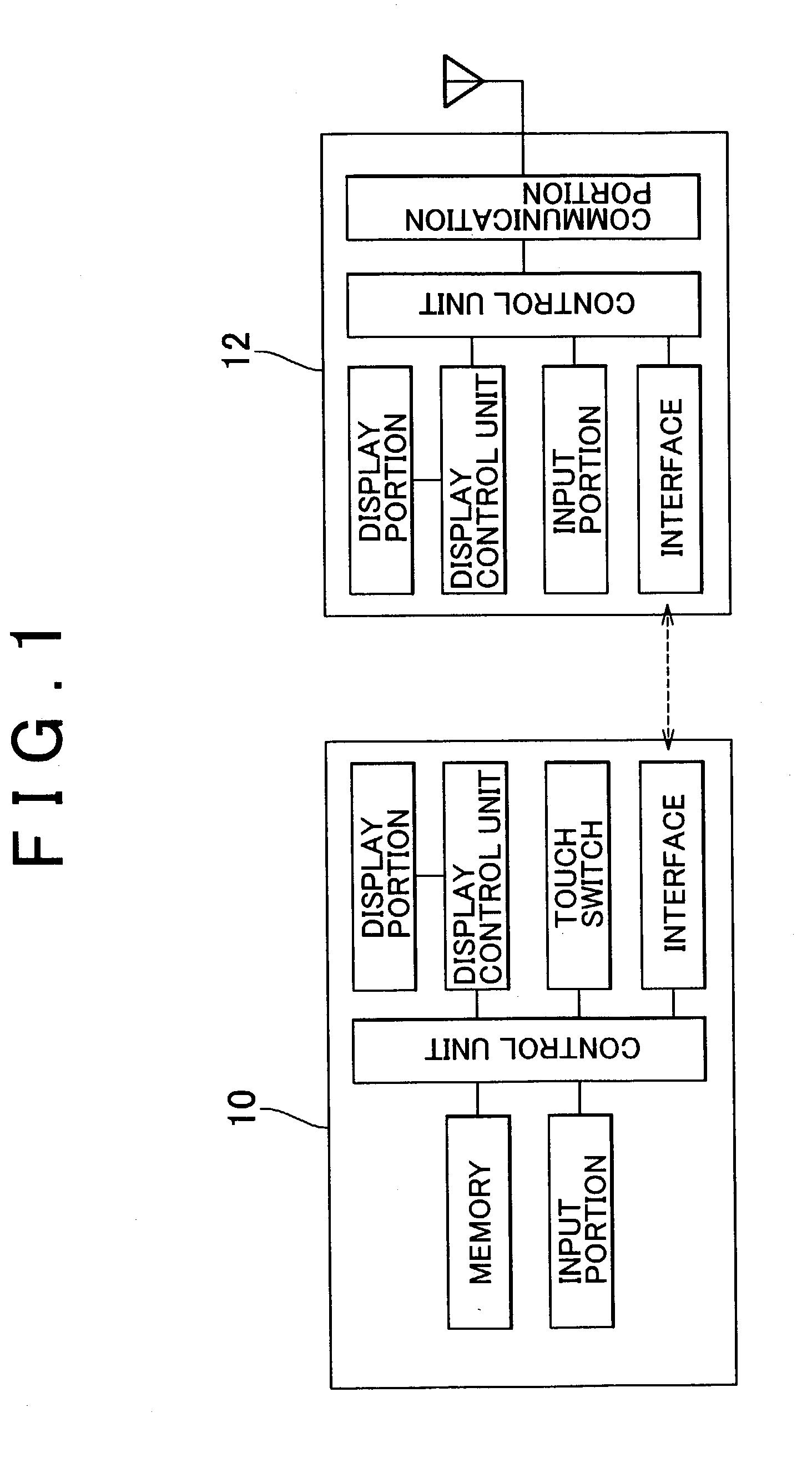

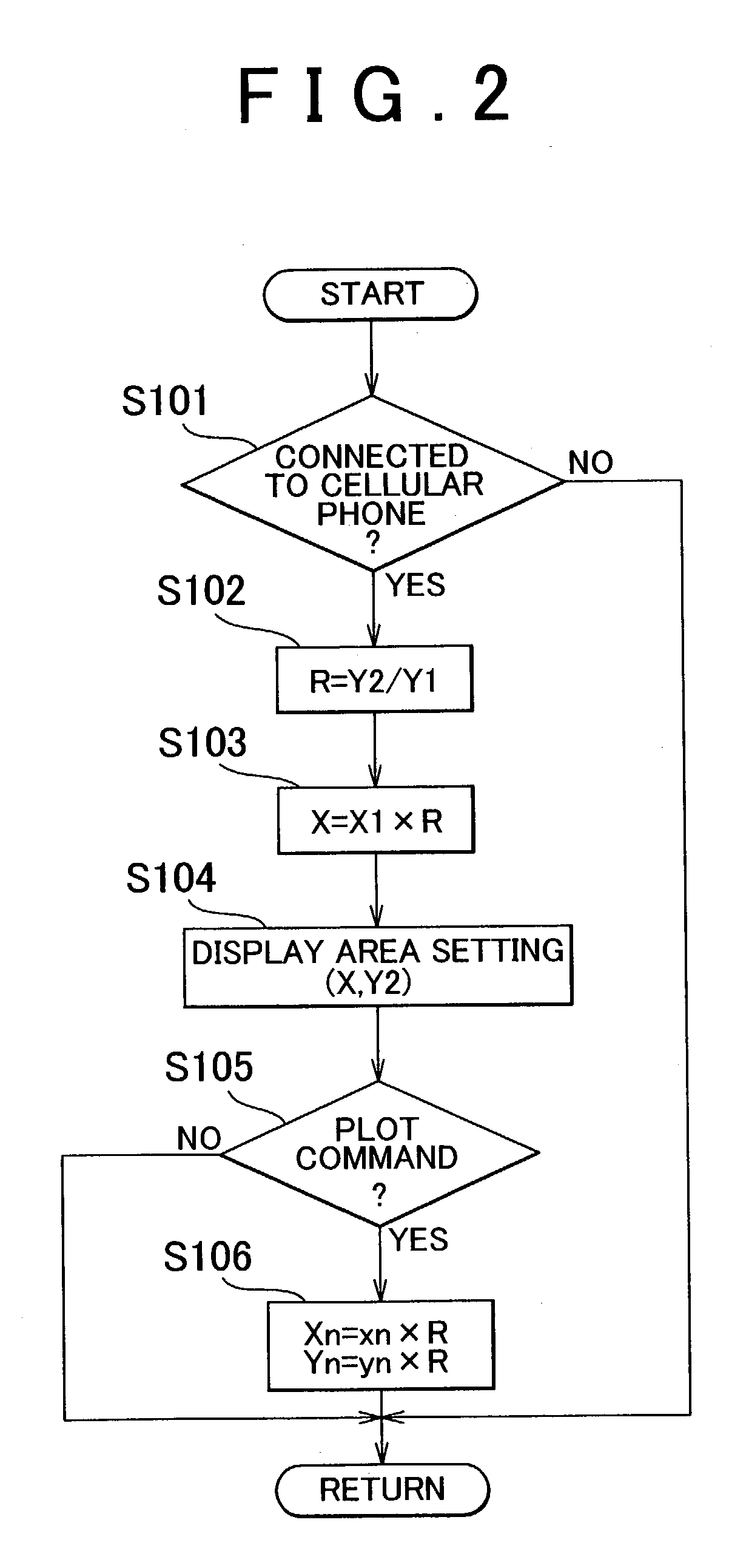

Display apparatus, portable terminal, data display system and control method of the data display system

InactiveUS20030156097A1Instruments for road network navigationTelephonic communicationData displayIn vehicle

A portable terminal such as a cellular phone and an in-vehicle device such as a vehicle navigation system are connected. After detecting the connection between the portable terminal and the in-vehicle device, a control unit of the cellular phone supplies display data to be displayed on its screen to the in-vehicle device. A control unit of the in-vehicle device displays on a screen the display data supplied from the portable terminal. Touch switches such as alphanumeric keys of the cellular phone are further displayed in the blank area of the screen of the in-vehicle device, enabling operation of the cellular phone from the in-vehicle device.

Owner:TOYOTA JIDOSHA KK

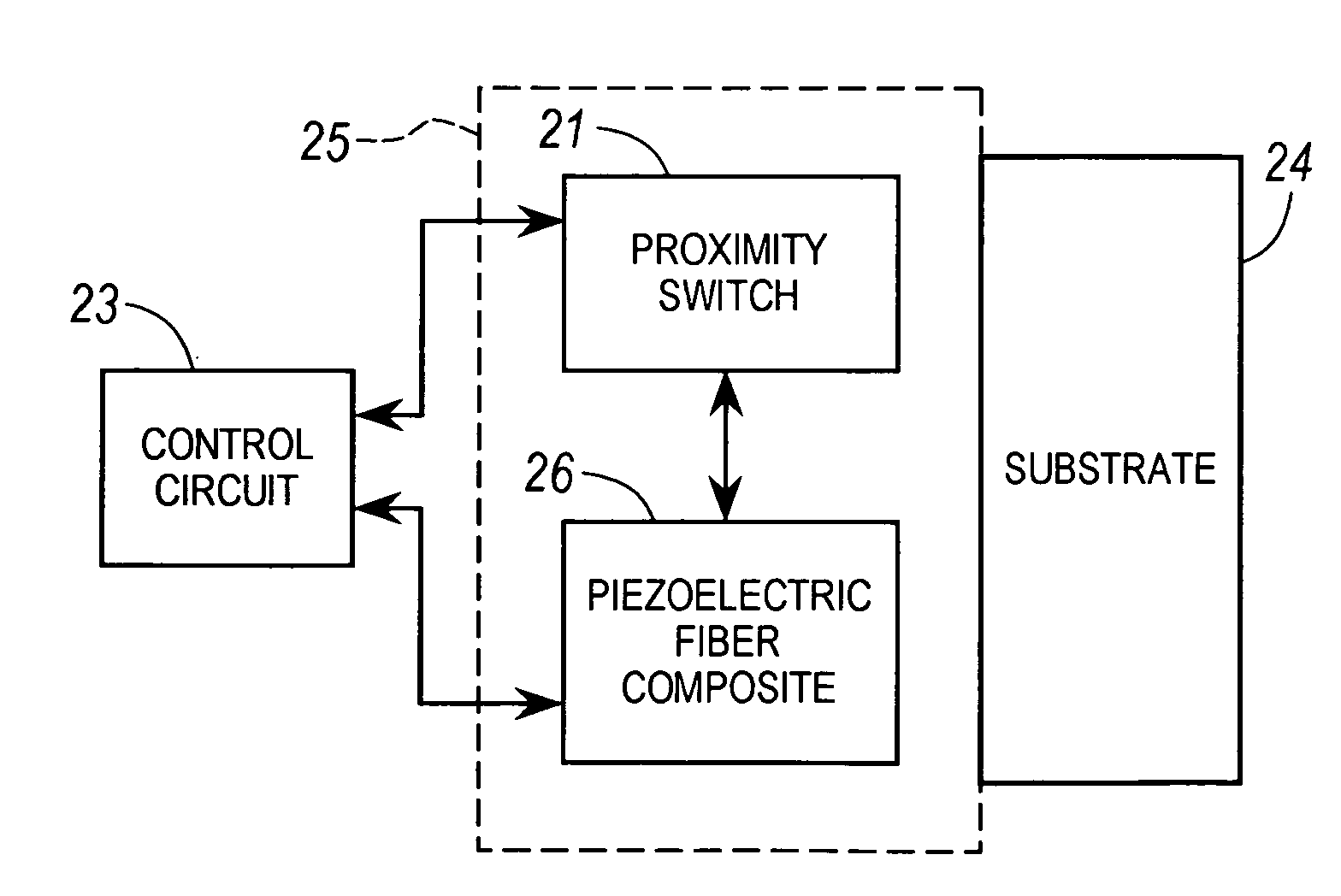

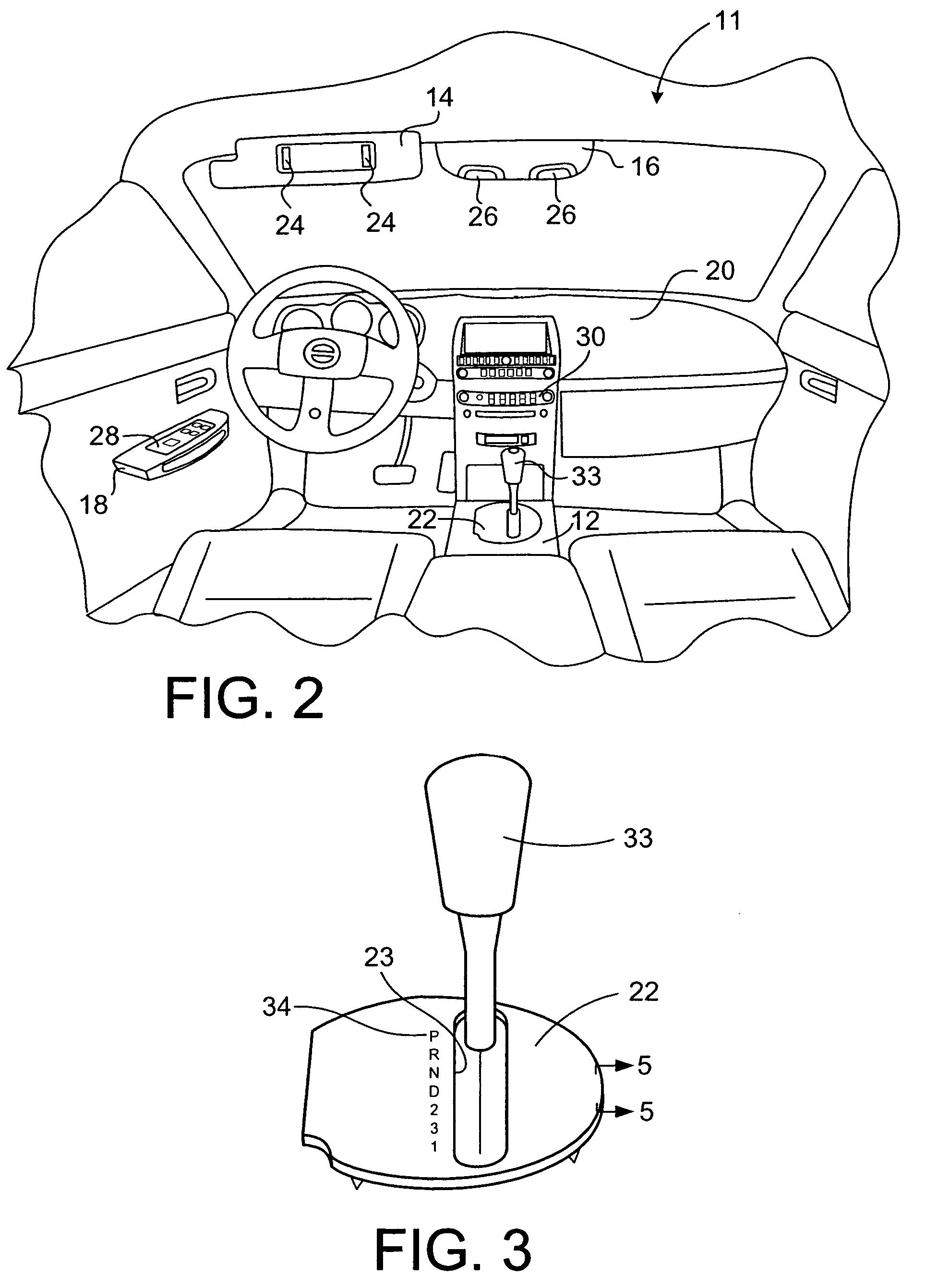

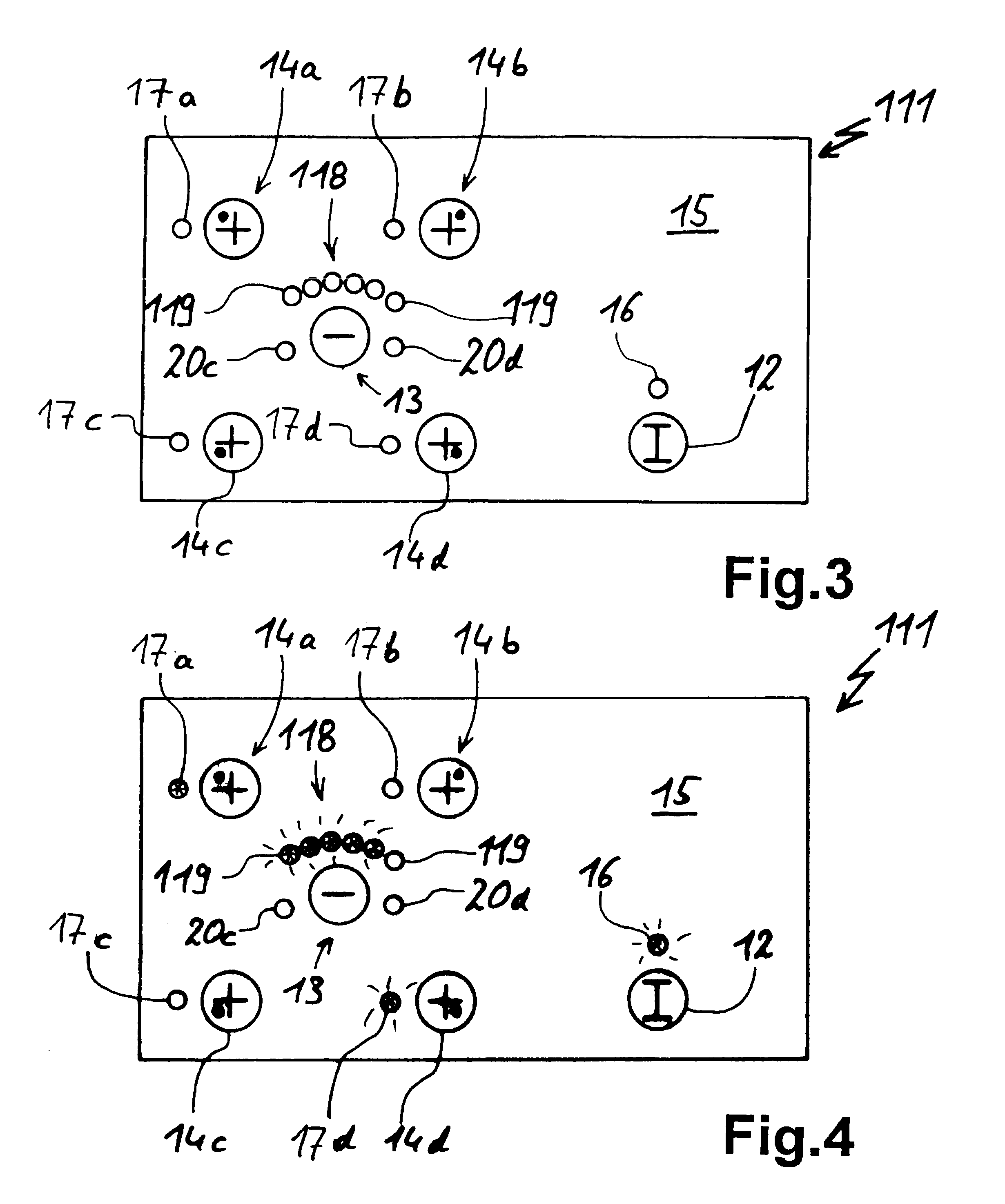

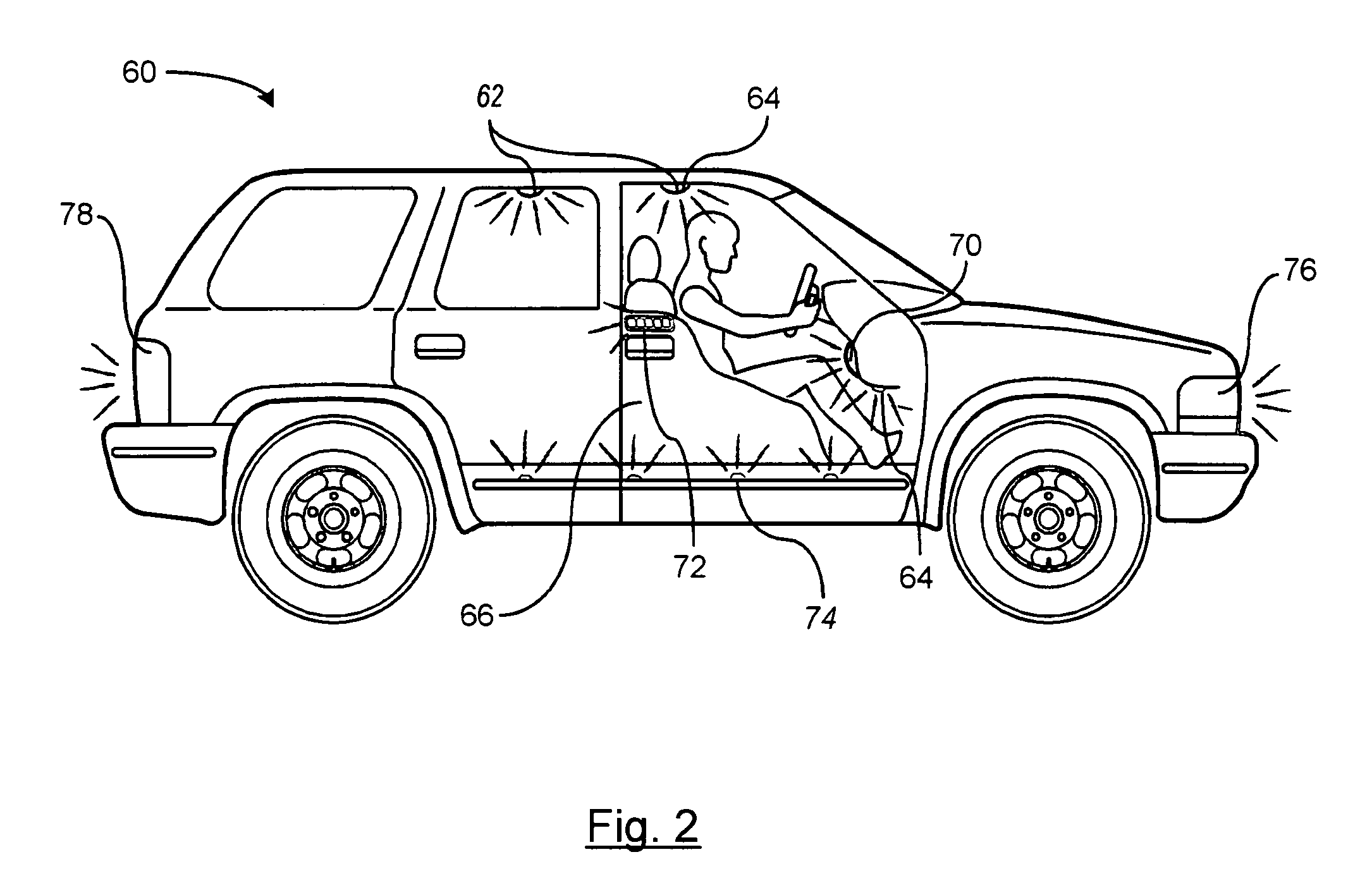

Vehicular touch switches with adaptive tactile and audible feedback

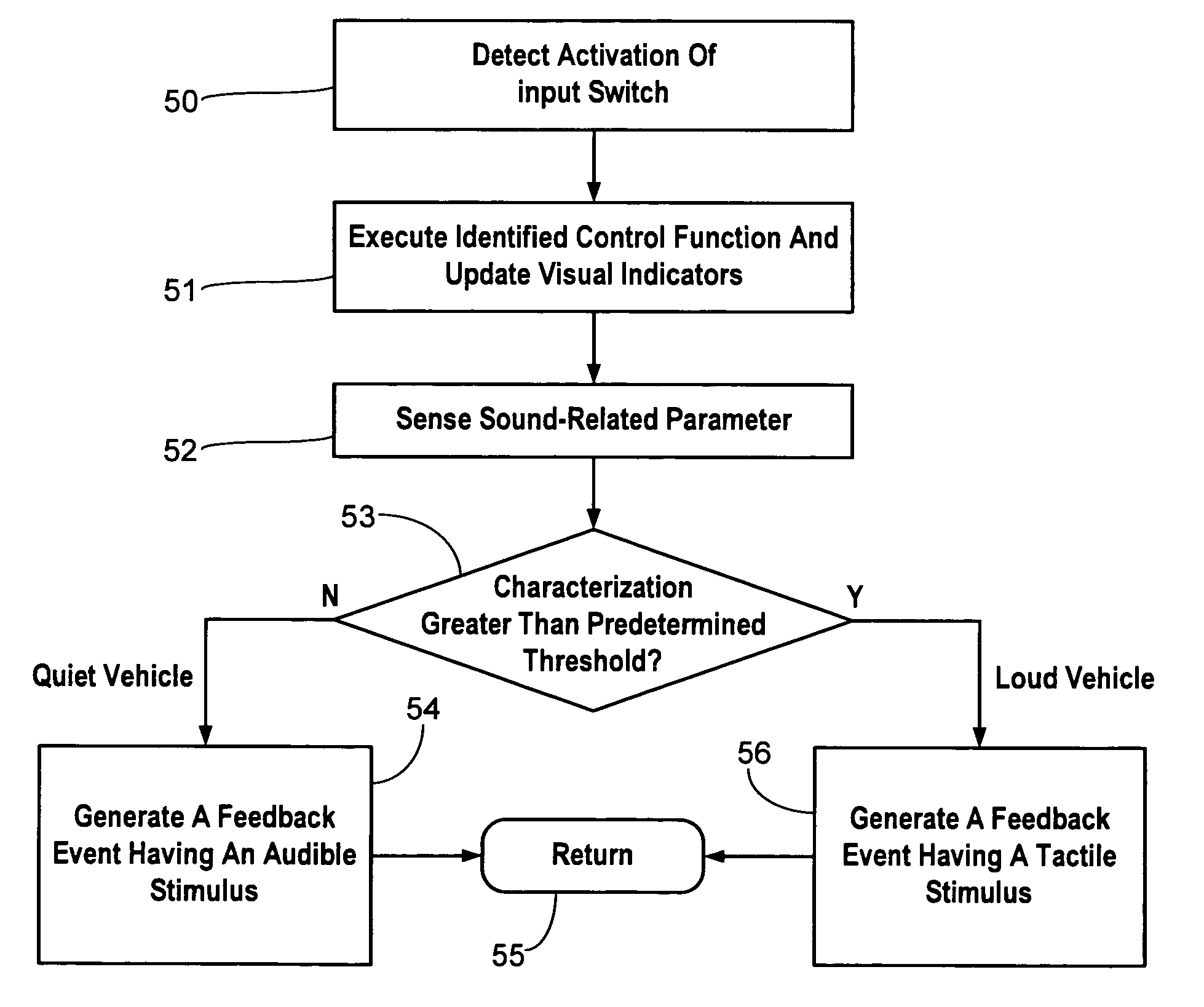

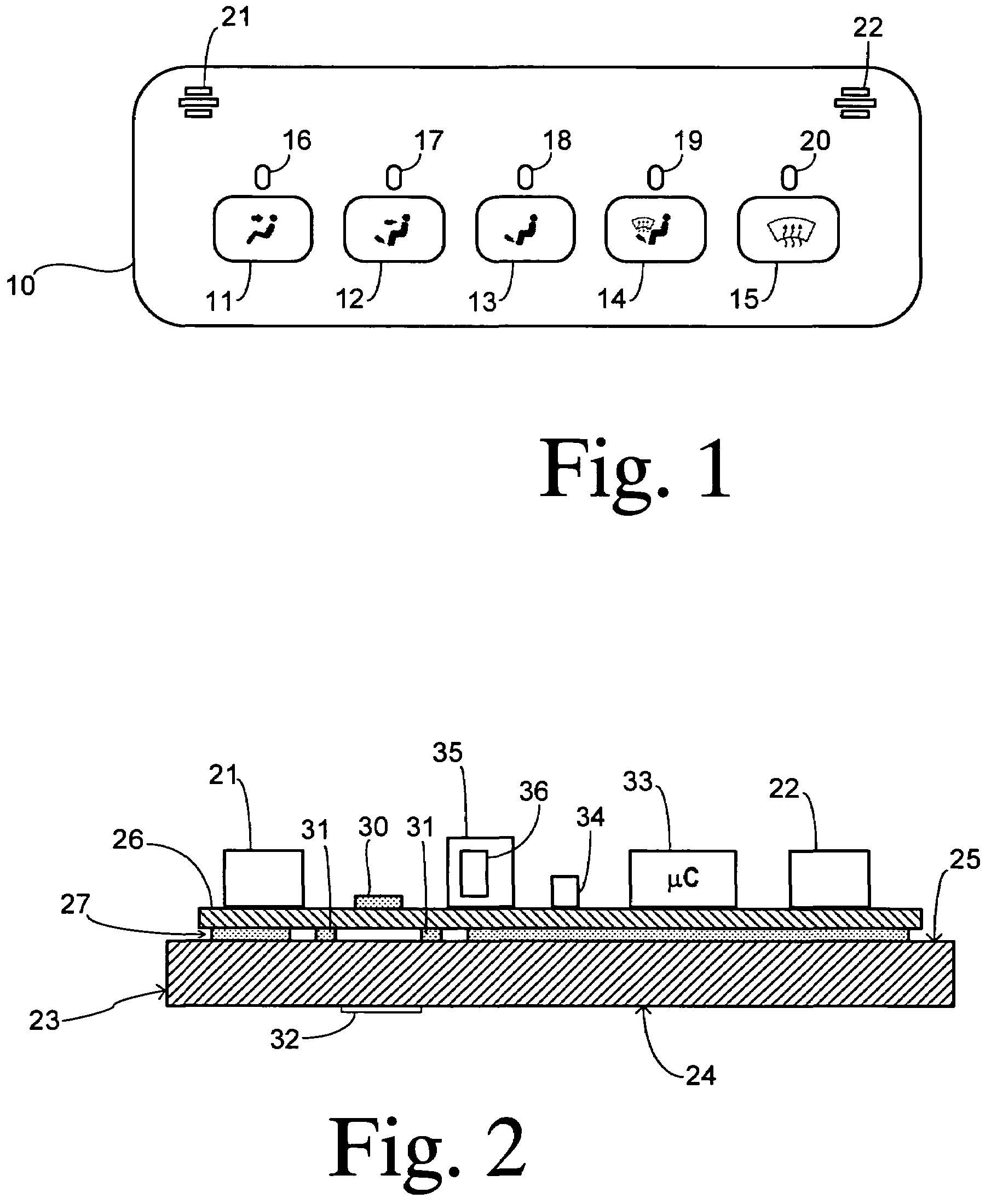

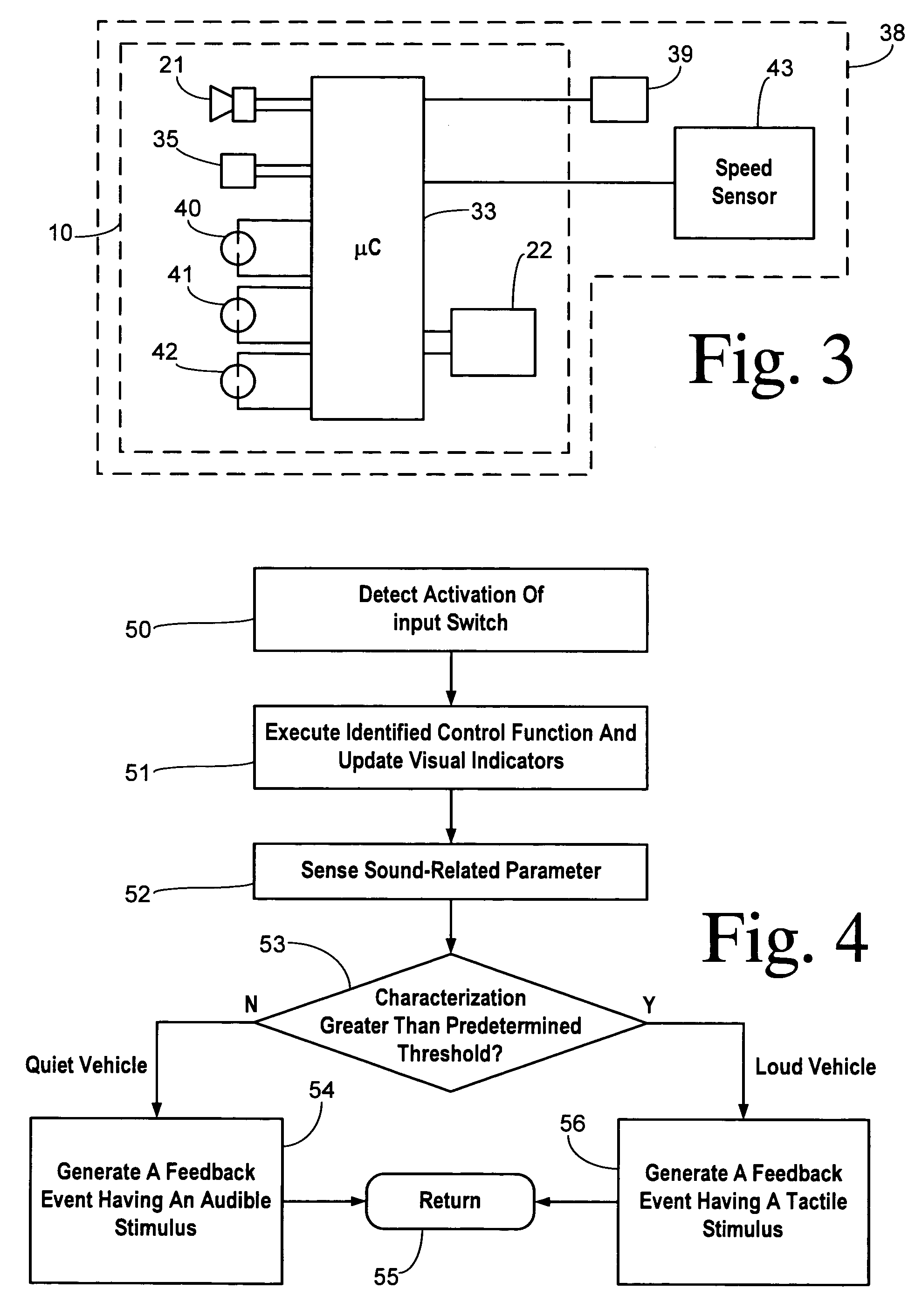

InactiveUS7269484B2Dashboard fitting arrangementsRoad vehicles traffic controlTouch PerceptionControl system

A manual control system for a vehicle includes a touch sensitive input element actuatable in response to proximity of a user's appendage. A tactile feedback generator produces a perceptible tactile stimulus. An audible feedback generator produces a perceptible audible stimulus. A sound level characterizer generates a sound characterization signal indicative of a sound-related parameter of the vehicle. A controller generates a feedback event in response to an actuation of the input element. The controller includes the perceptible tactile stimulus and the perceptible audible stimulus in the feedback event according to the sound characterization signal.

Owner:LEAR CORP

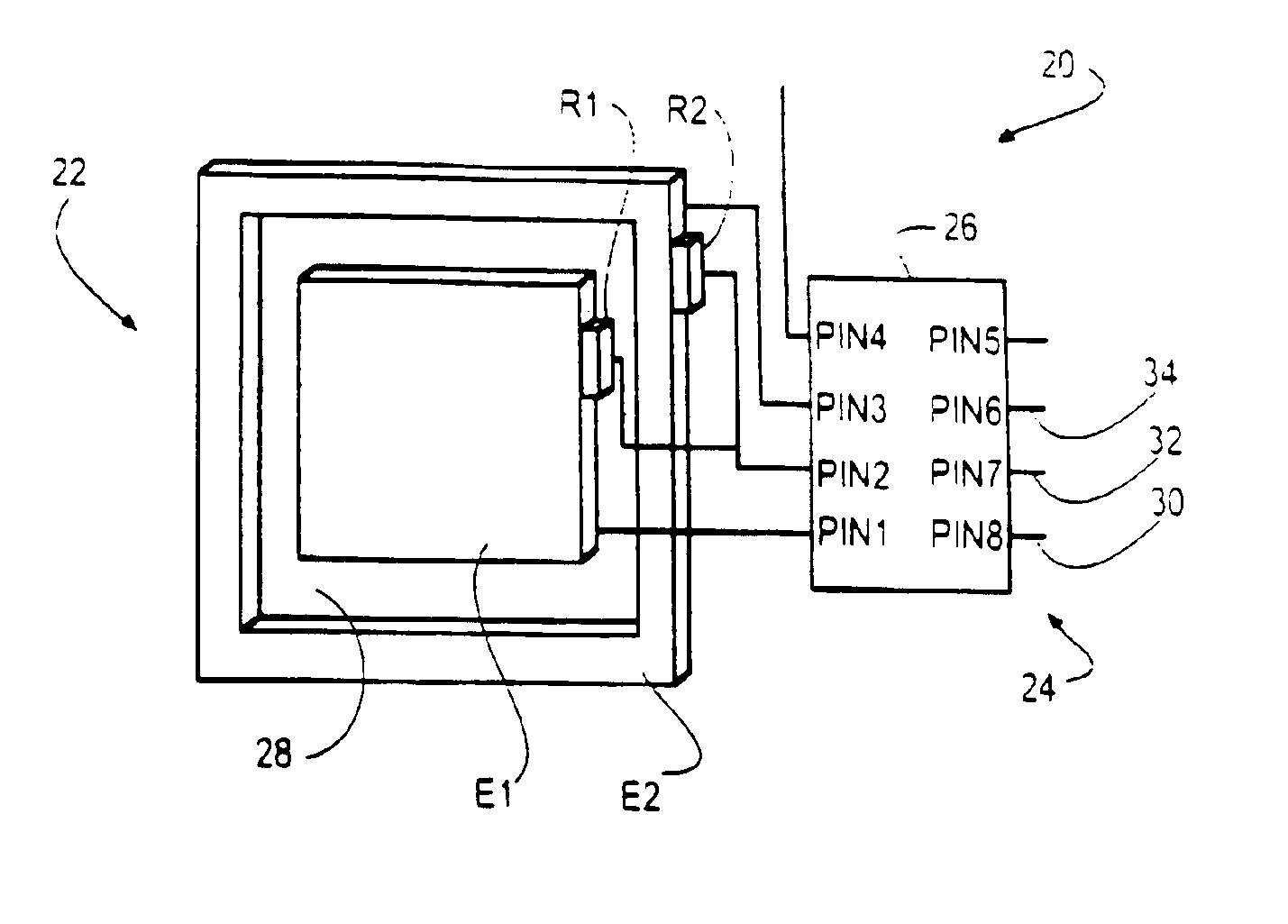

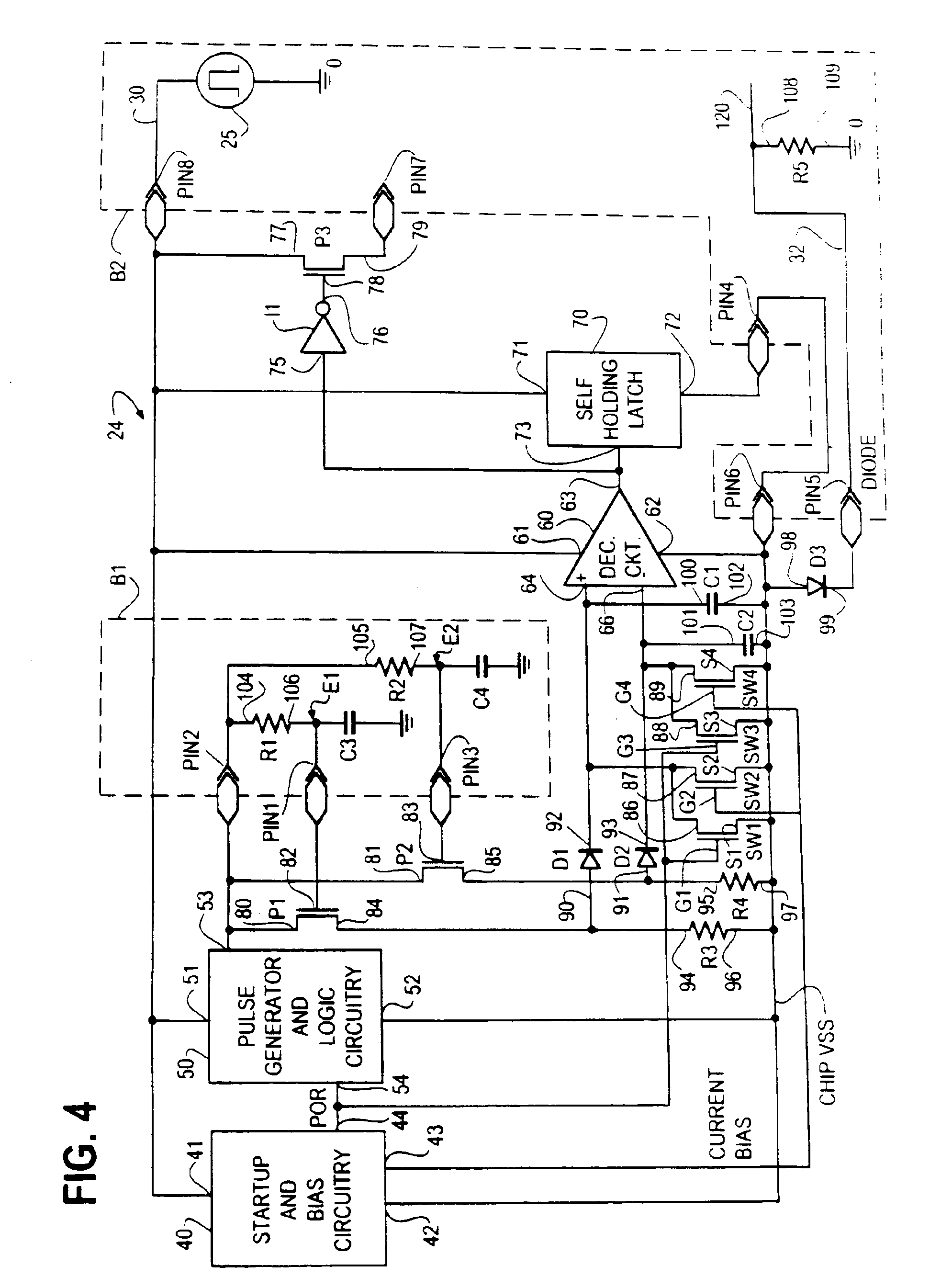

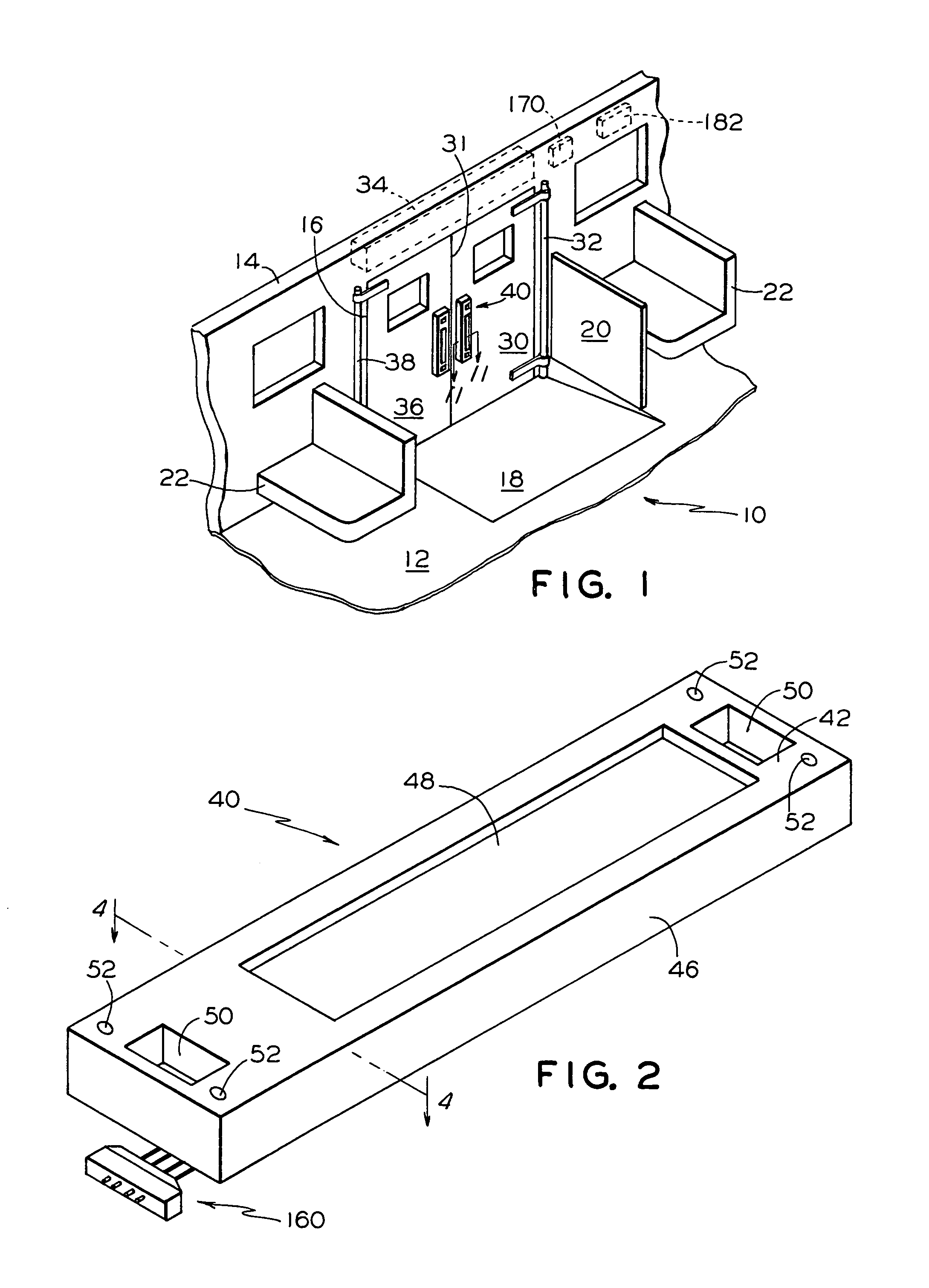

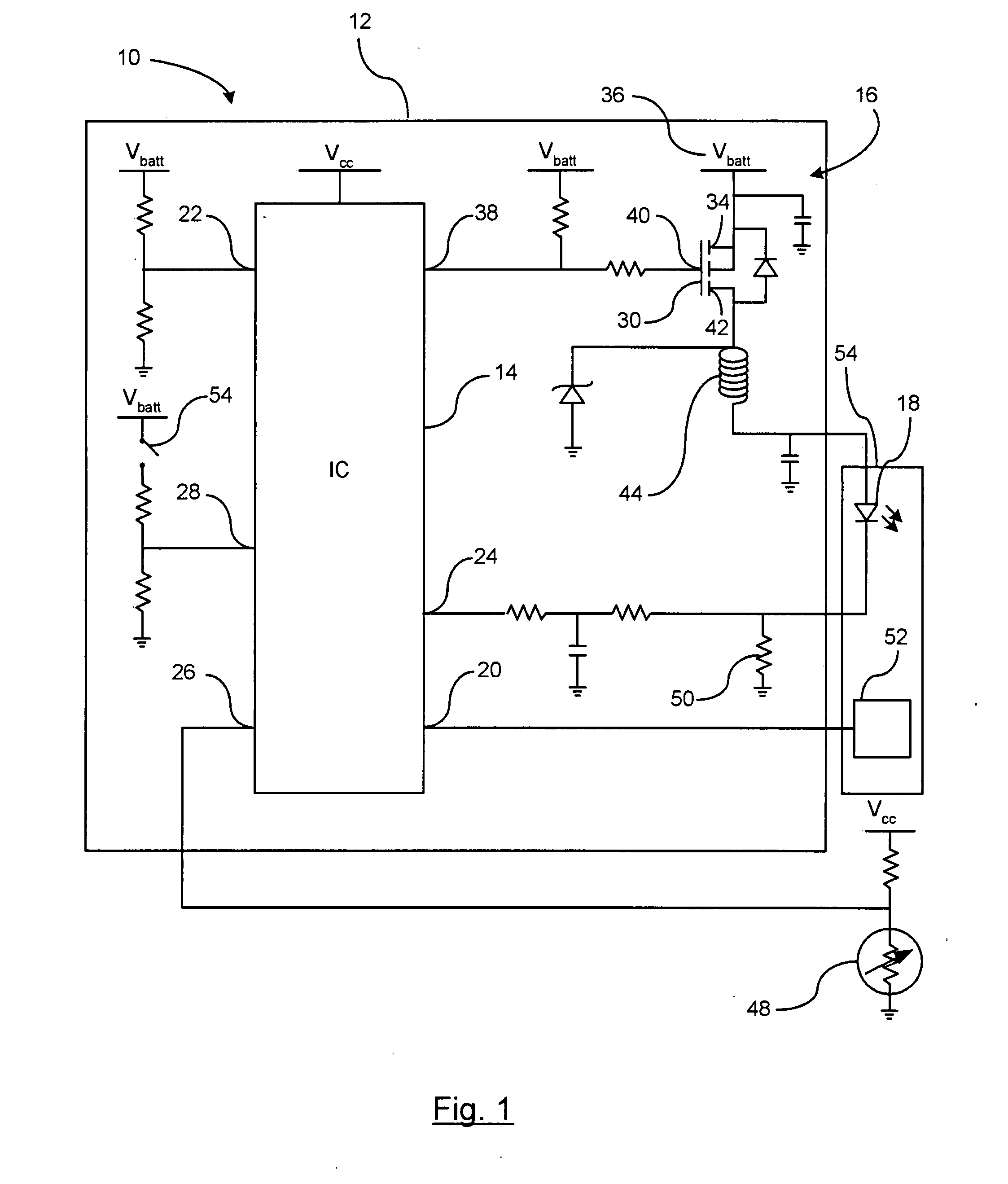

Touch switch with integral control circuit

InactiveUS7030513B2Prevent unintended switch actuationAvoid switchingInput/output for user-computer interactionBatteries circuit arrangementsControl signalTouchpad

A touch switch apparatus for detecting the presence of an object such as a human appendage, the apparatus having a touch pad and a local control circuit connected to the touch pad and to a controlled device. The touch pad preferable includes a first electrode and a second electrode spaced from and surrounding the first electrode. The control circuit is preferably in integrated circuit form. A signal is provided to the touch pad to generate an electric field thereabout. Introduction of a stimulus near the touch pad disturbs the electric field. The control circuit detects the electric field disturbance in and generates a control signal in response.

Owner:TOUCHSENSOR TECH

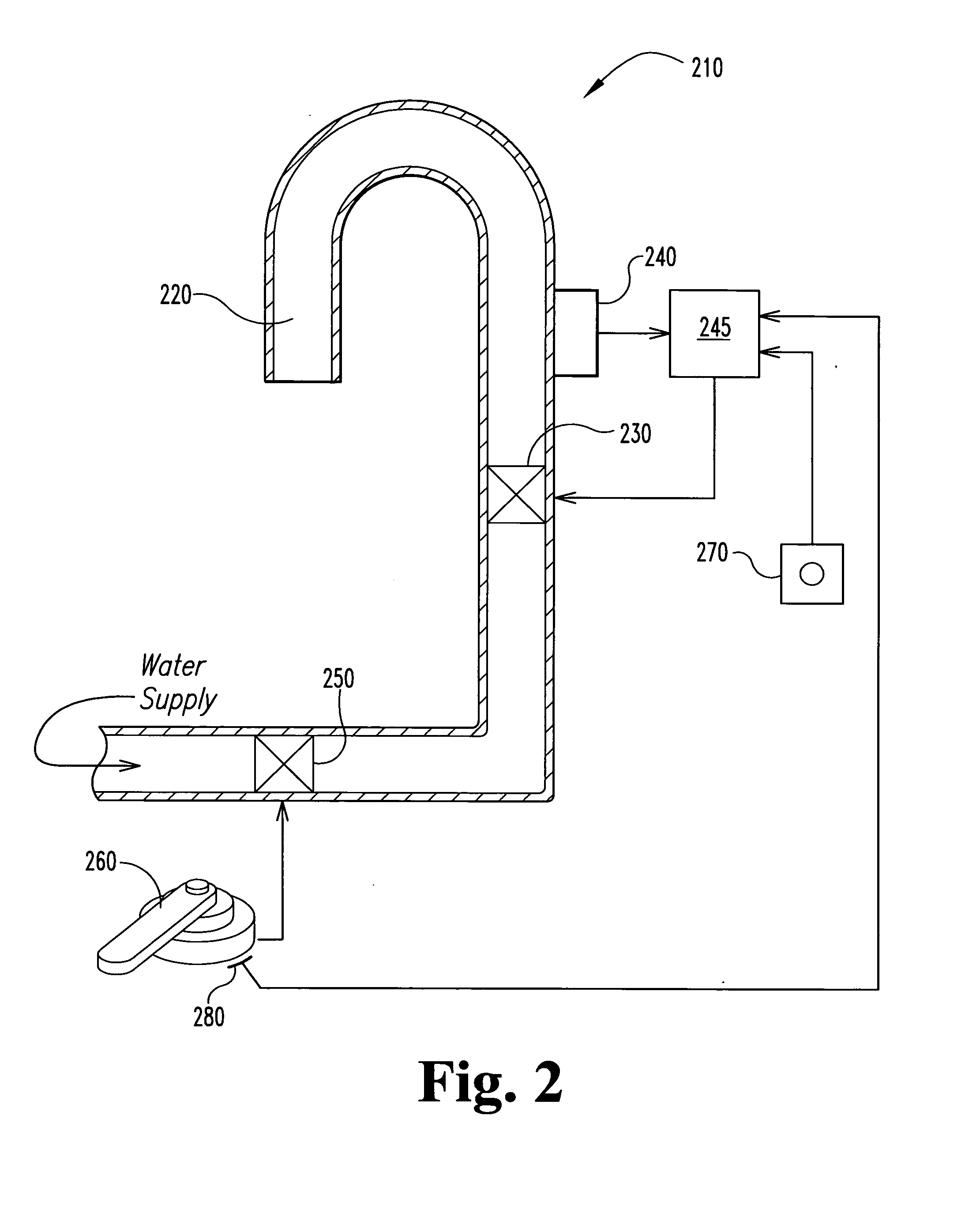

Flexible touch-sense switch

A flexible touch-sense switch includes a force sensitive composite and an at least one proximity sensor. The force sensitive composite includes a plurality of force sensors disposed between a first layer and a second layer of polymide film defining a displacement region. The at least one proximity sensor generates an electromagnetic field that defines a detection region. The force sensitive composite and the at least one proximity sensor are mounted to the first layer of the polymide film for forming a flexible printed circuit board. A control circuit is electrically connected to the force sensitive composite and the at least one proximity sensor for selectively controlling the touch-sense switch activation in response to coincident actuation thereof.

Owner:LEAR CORP

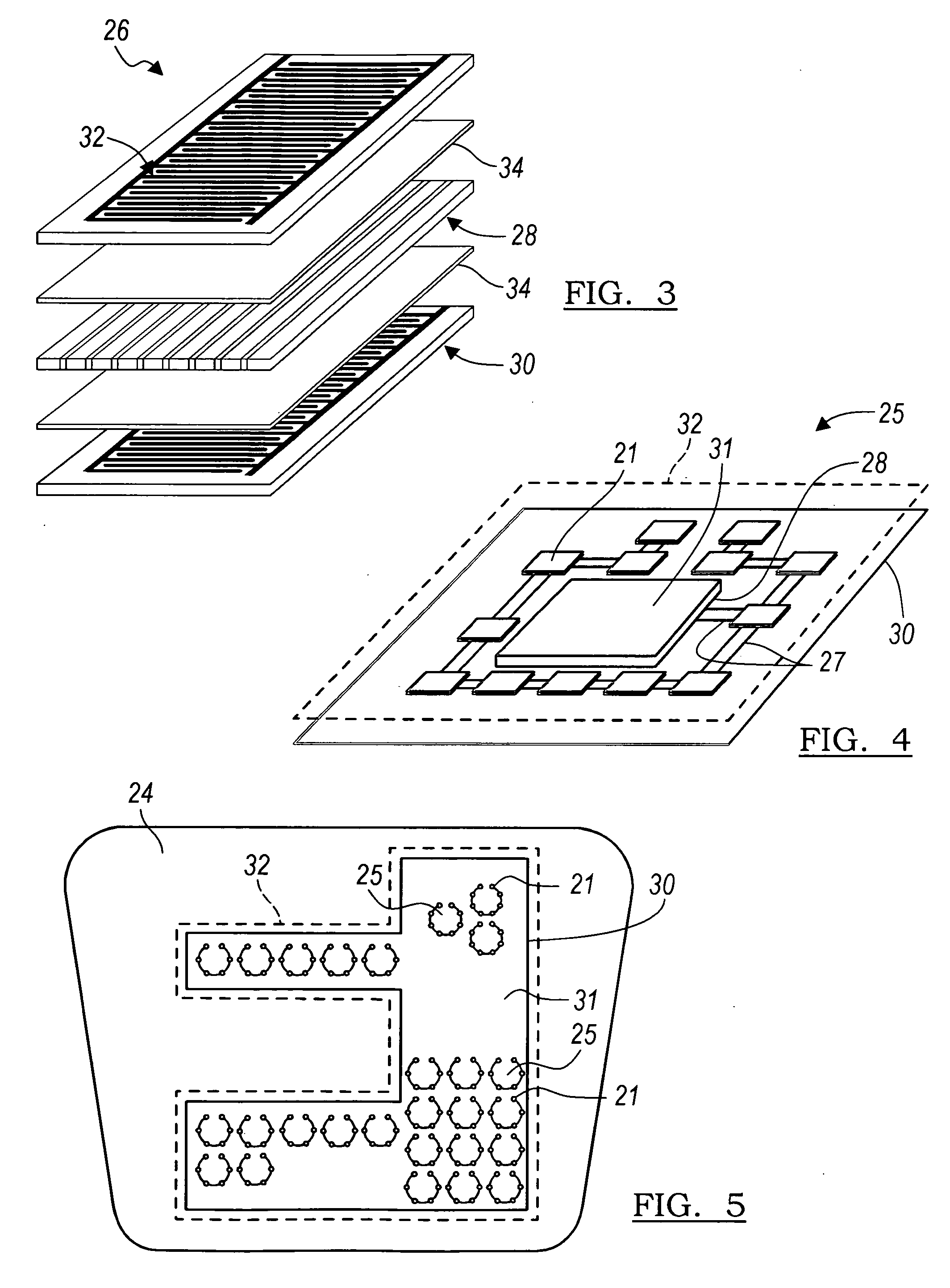

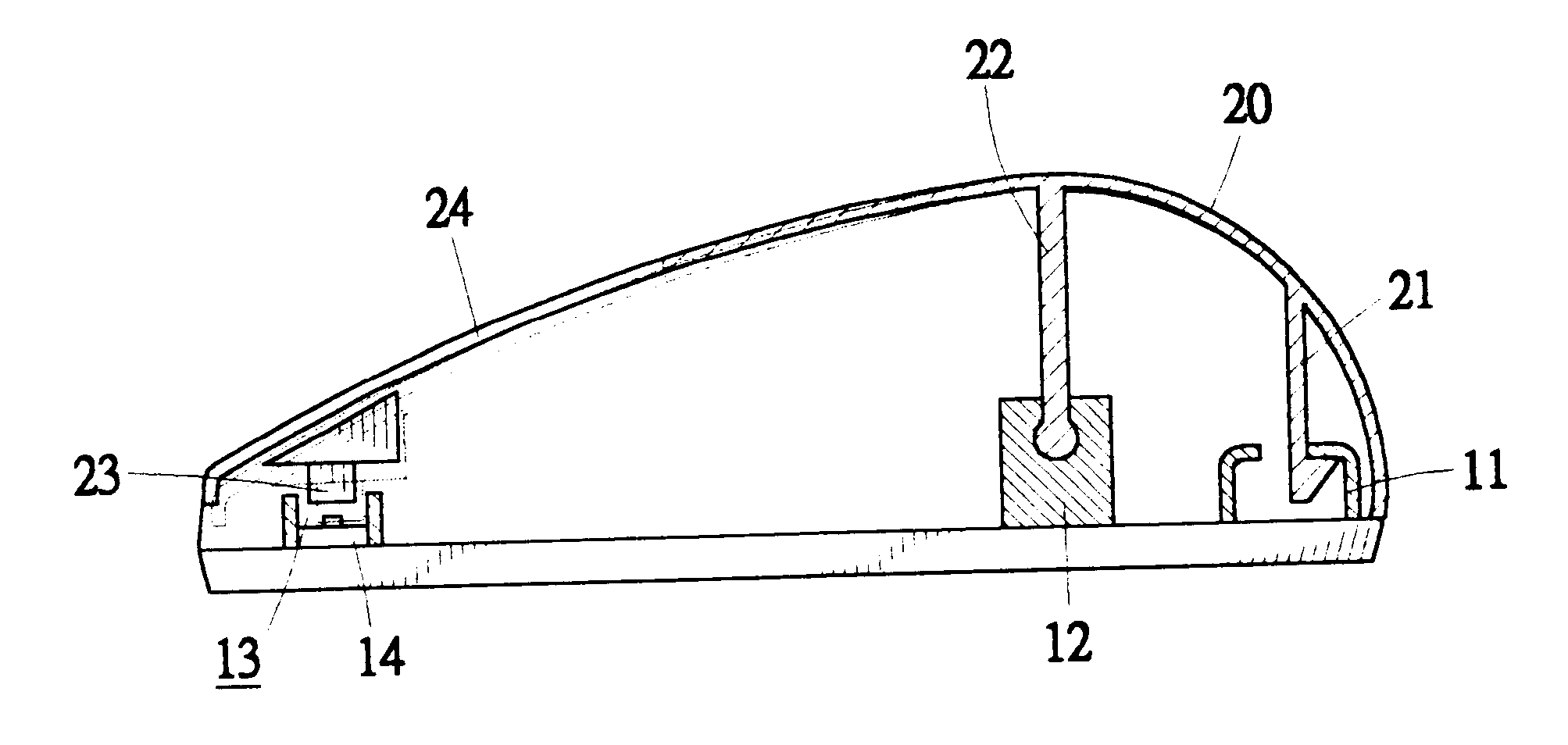

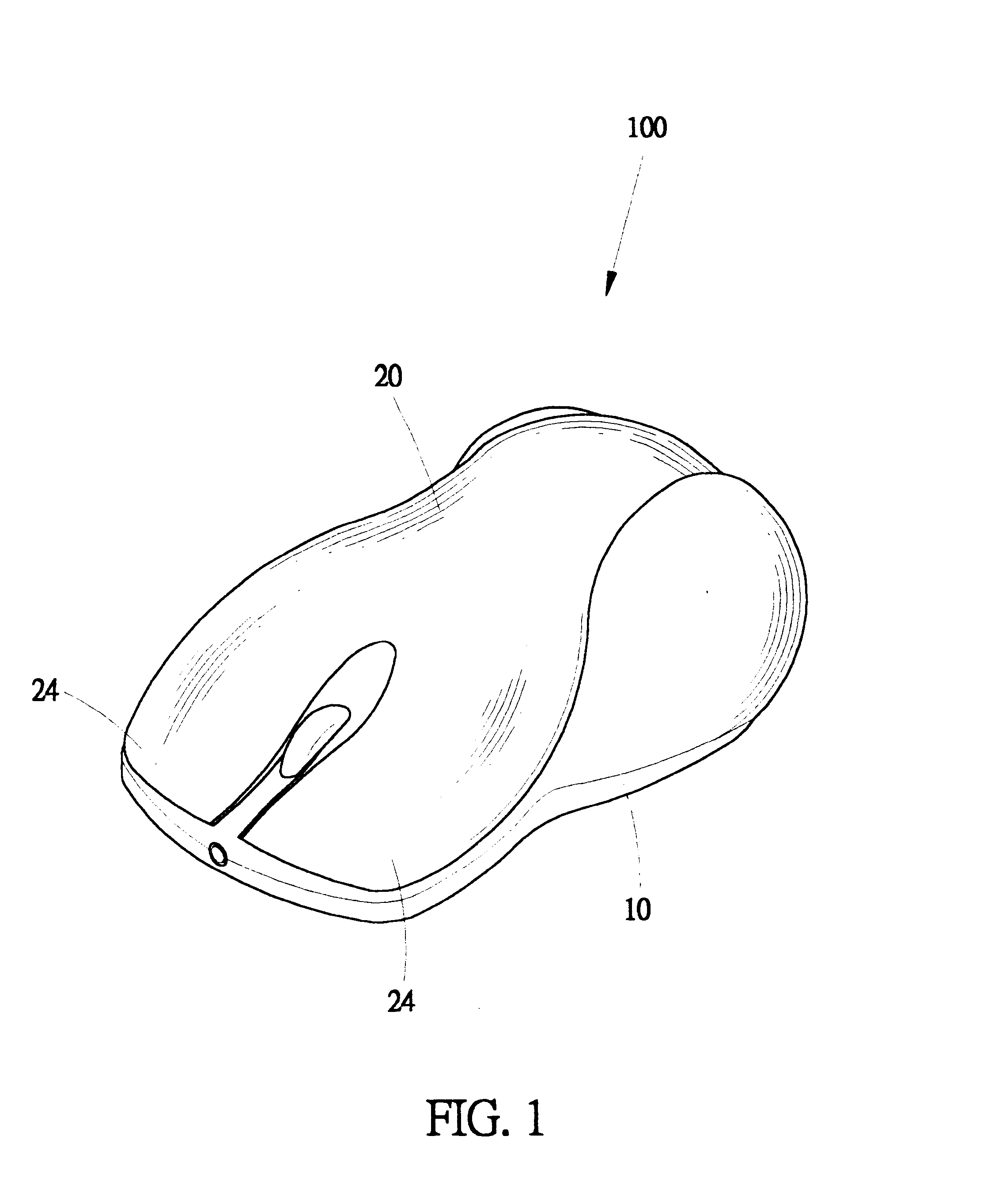

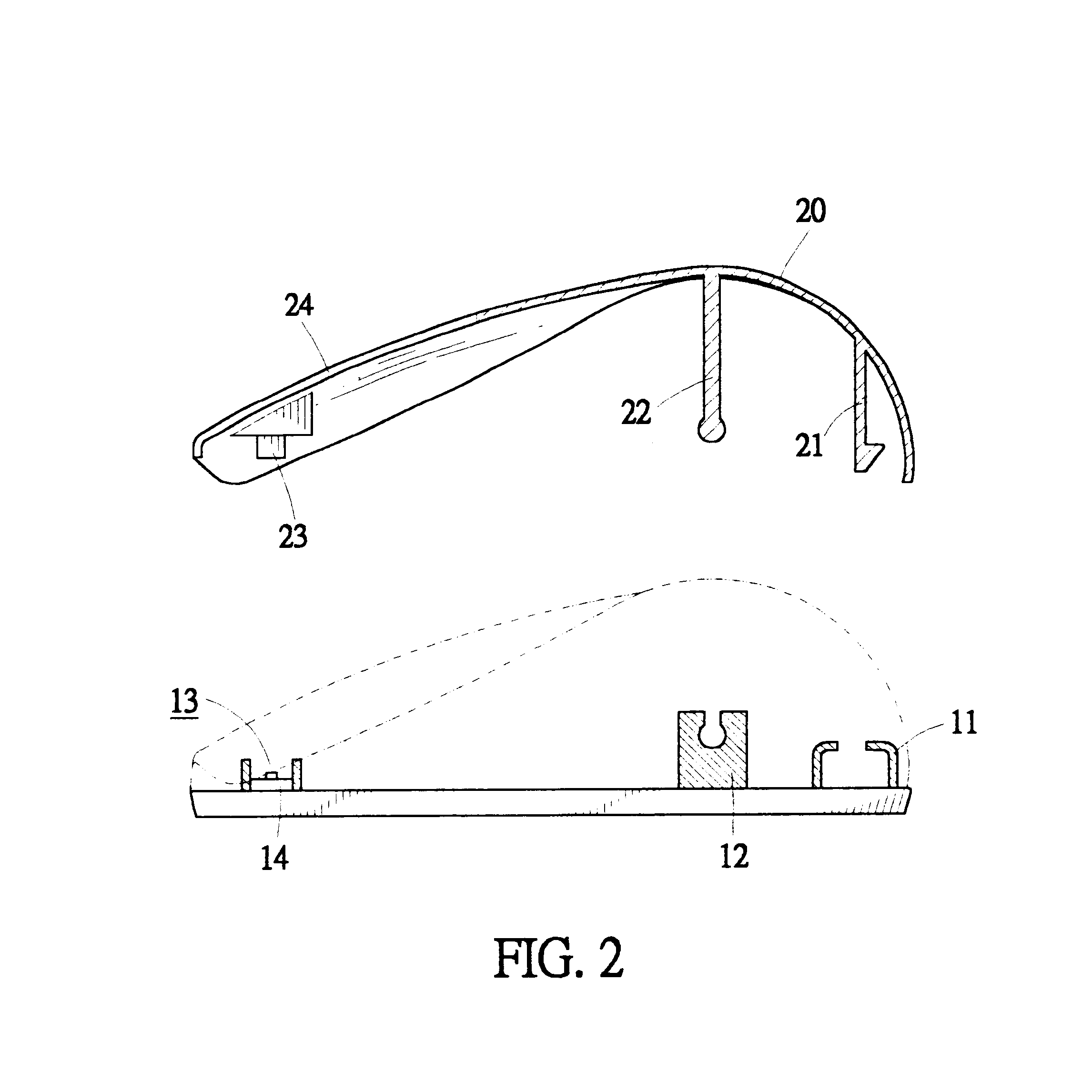

Seamless mouse

InactiveUS6791533B2Cathode-ray tube indicatorsInput/output processes for data processingKey pressingSoftware engineering

A seamless mouse comprising a base, with an embedding unit at the rear of the base, a coupling unit in it, a pair of activating troughs near its front, a touch switch in the activating trough, to receive command from the touch operation; and a top cover, at the rear of the top cover and opposite the embedding unit being a joining pin to insert into the embedding unit for fastening purpose, inside it and opposite the coupling unit being a coupling post to couple with the coupling unit, at its front and opposite the activating trough being a driving lever, and extending from the top cover itself being the formation of at least one push key. When the top cover is assembled to the base, the joining pin is fastened to the embedding unit, the coupling post is fastened to the coupling unit. When the push key is pressed, the driving lever activates the touch switch in the activating trough, to serve the function of the mouse. Furthermore, the mouse appears to have no seam, and its radial push key will have better control and operation performance.

Owner:MIND FUSION LLC

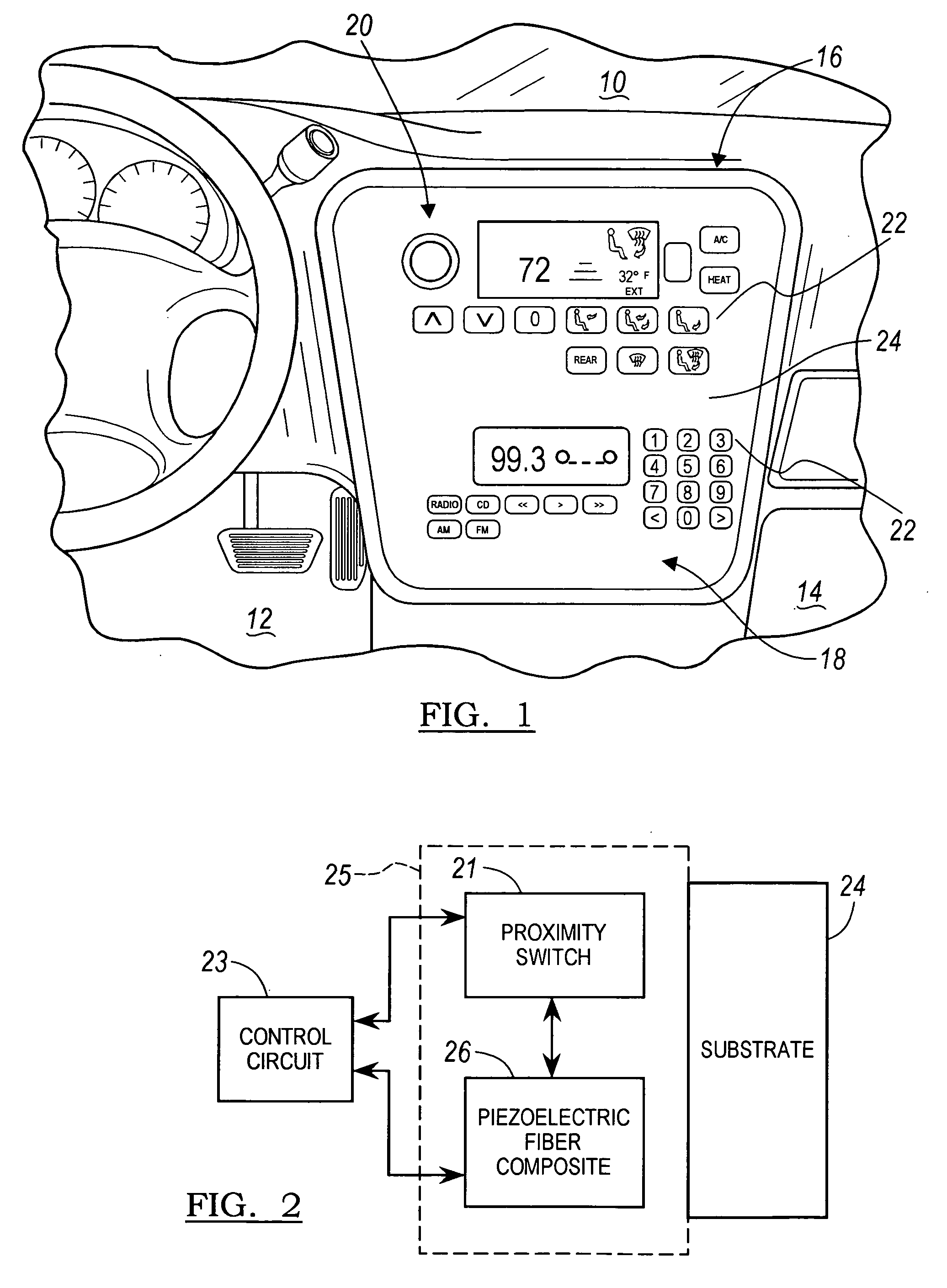

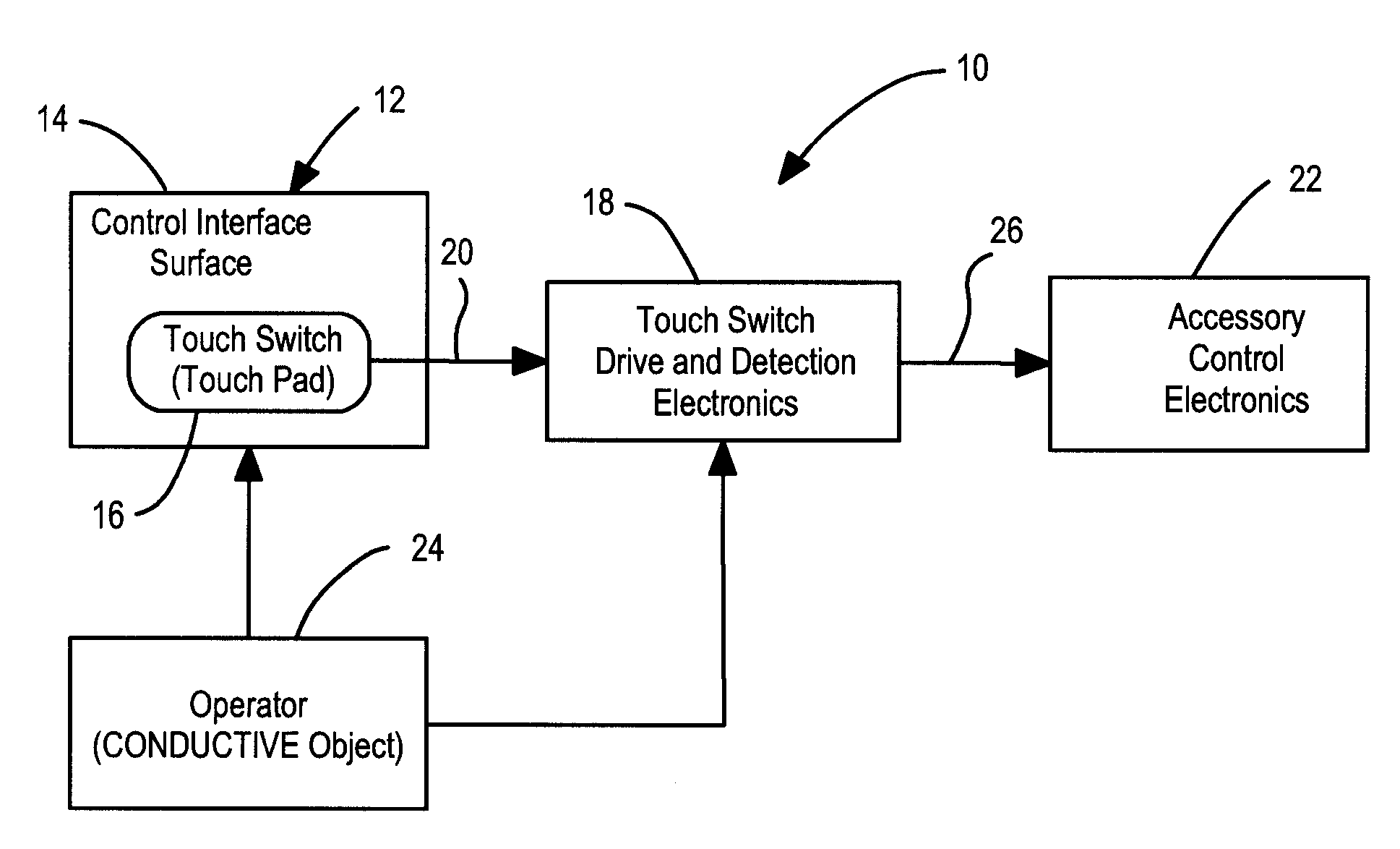

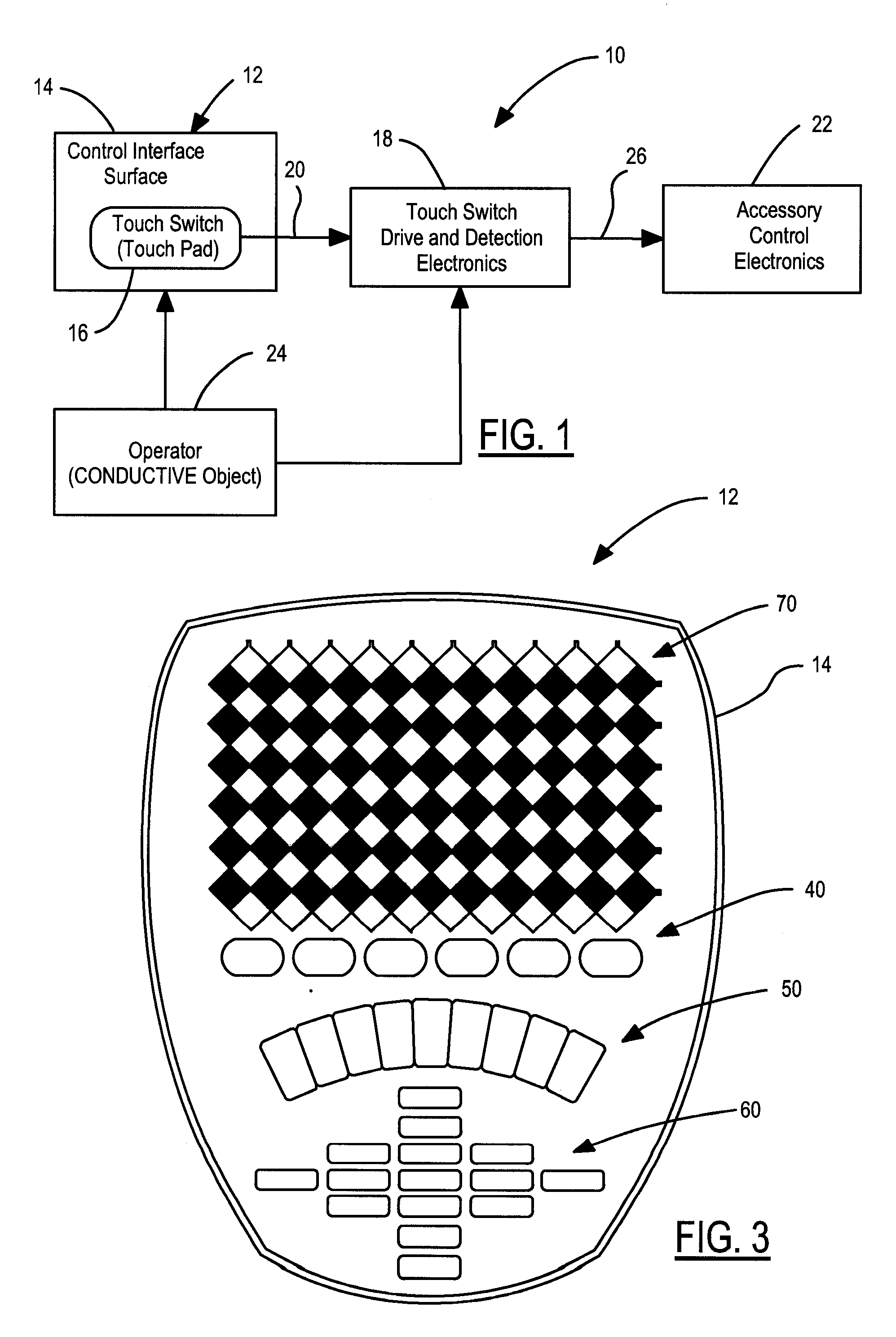

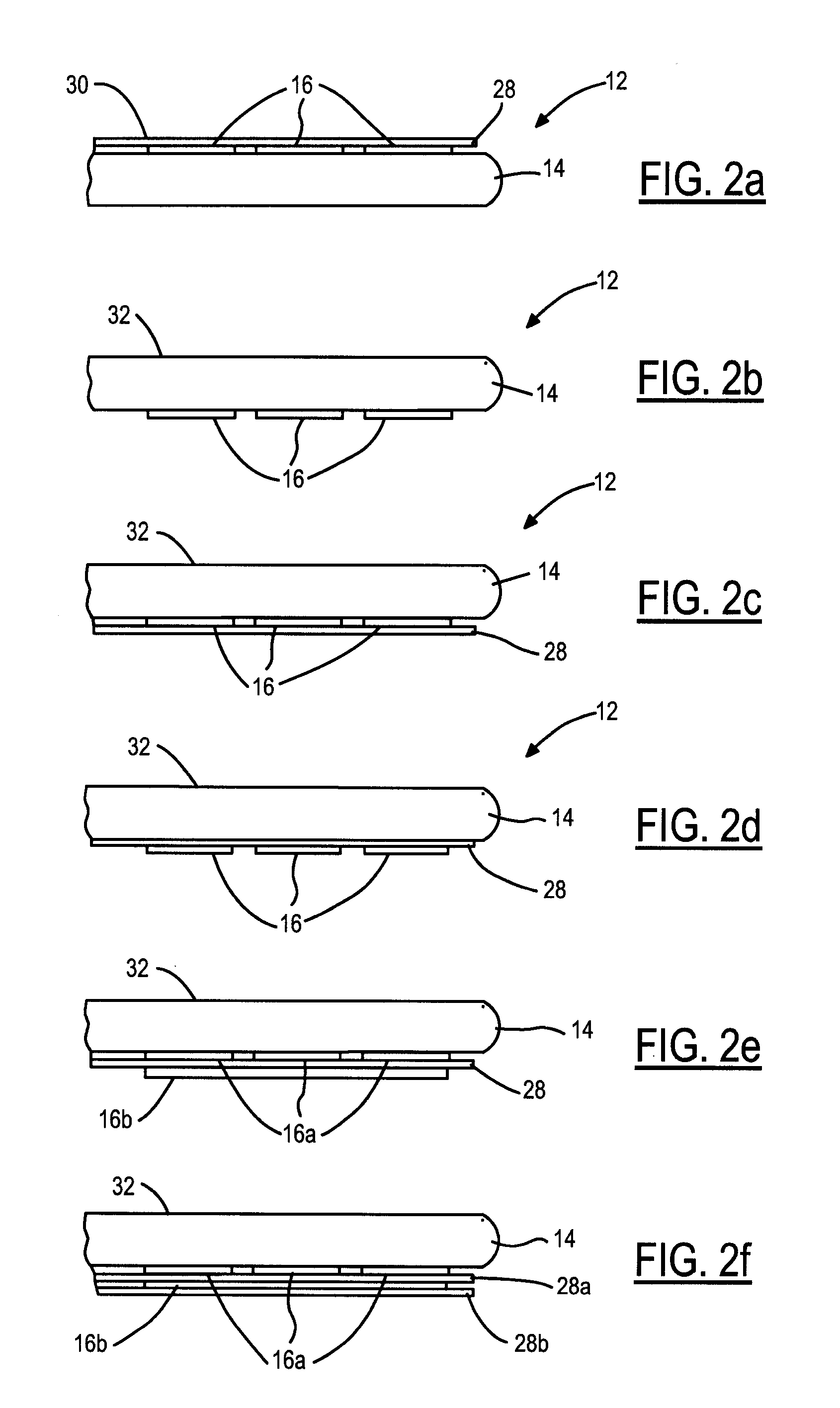

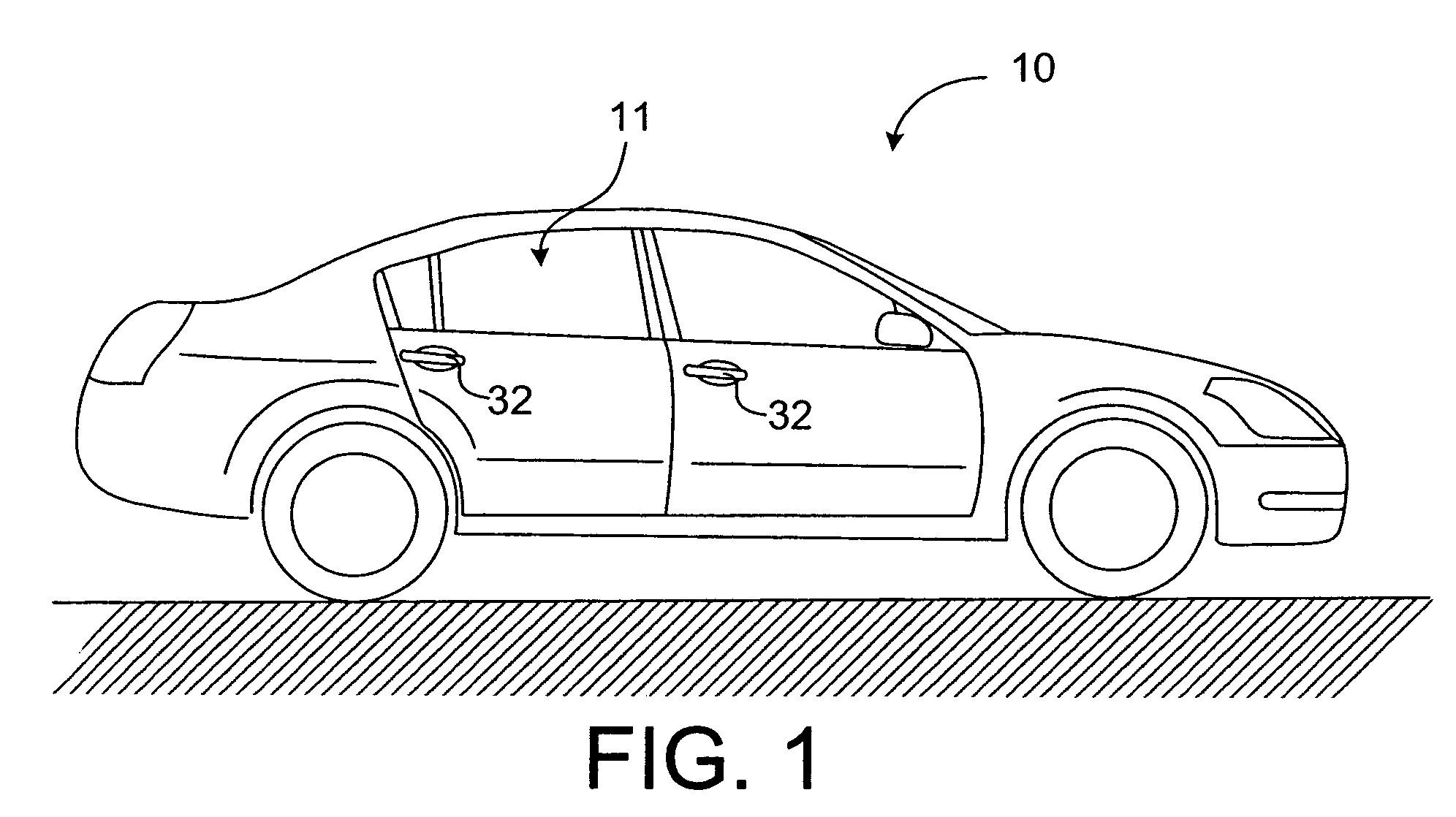

Vehicle accessory control interface having capactive touch switches

ActiveUS20110001722A1Improves human interactionEliminate Design ConstraintsInput/output processes for data processingCapacitanceCapacitive coupling

A system for enabling an operator to control a vehicle accessory includes a control interface and a processor. The control interface has a display surface and a touch area defined by an electrically conductive layer adjacent the display surface. The conductive layer capacitively couples to an electrically conductive object upon the object touching or being in proximity with the touch area while the conductive layer is driven with an electrical charge. The processor drives the conductive layer with the electrical charge, detects the capacitive coupling of the conductive layer to the object upon the object touching or being in proximity with the touch area while the conductive layer is driven, generates a signal indicative of the object touching or being in proximity with the touch area upon detecting the capacitive coupling of the conductive layer to the object, and provides the signal to the accessory for controlling the accessory accordingly.

Owner:UUSI

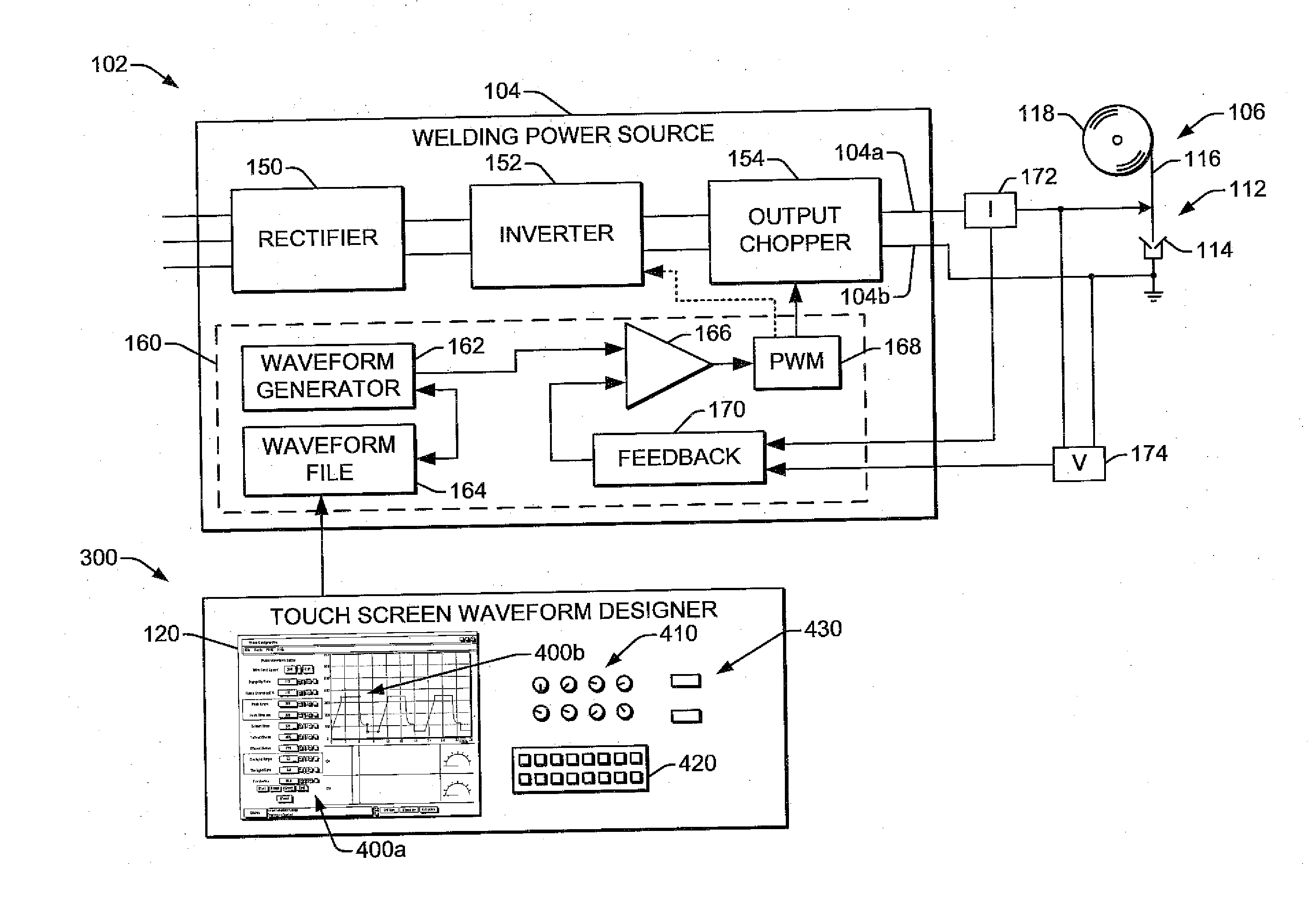

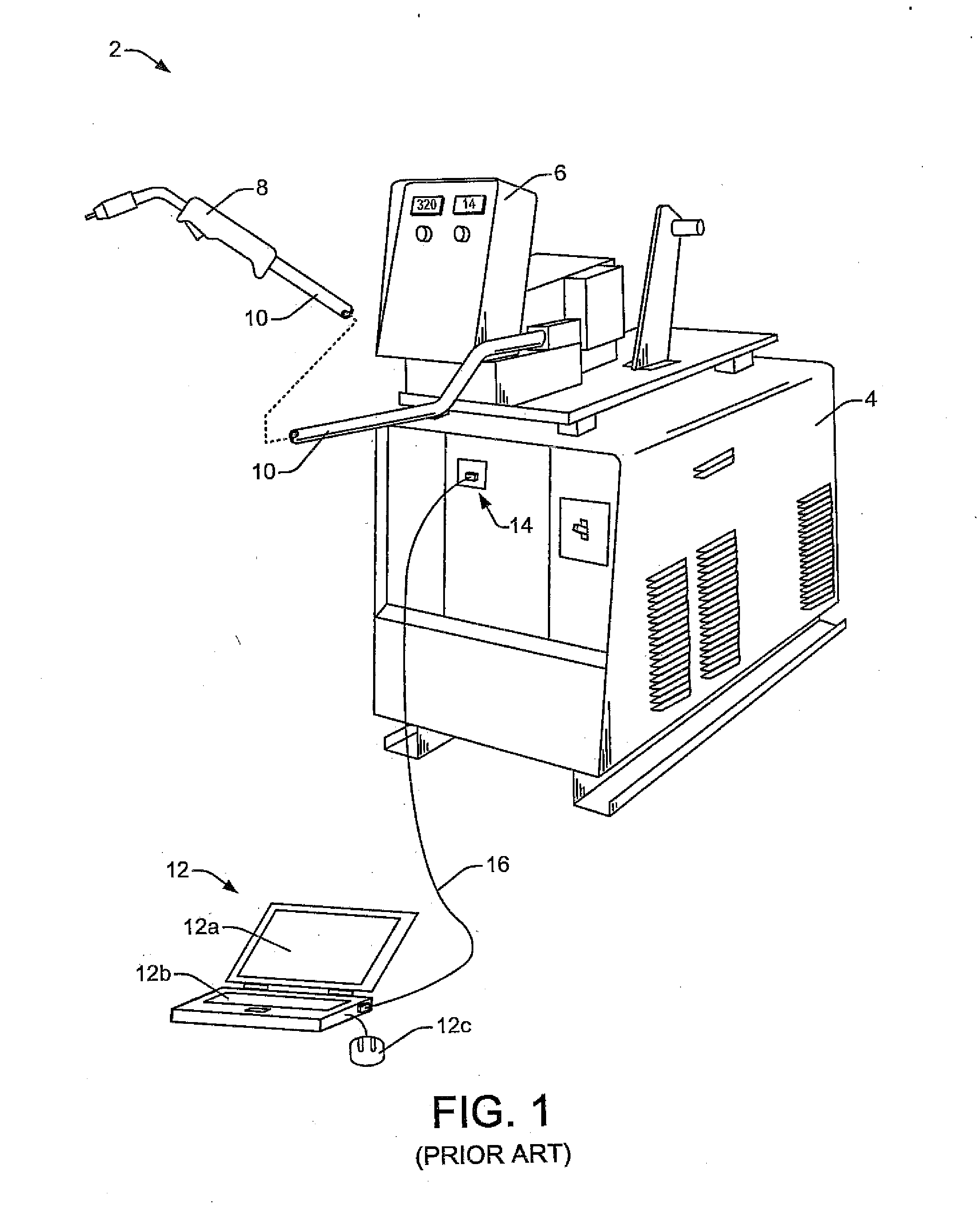

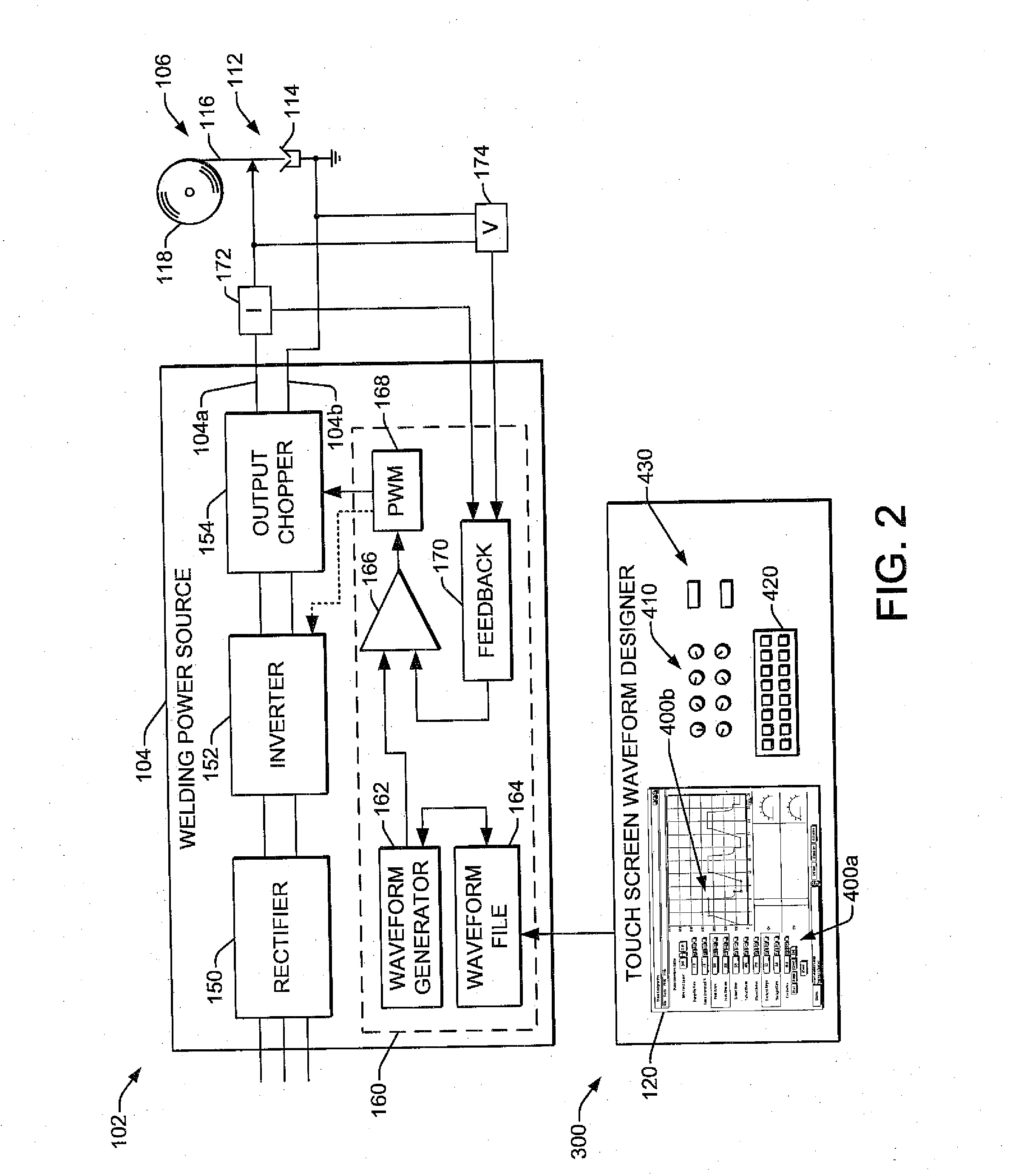

Touch screen waveform design apparatus for welders

Welding systems and programming tools are described, in which a touch screen-based welding system configuration tool is provided having a touch screen display for designing welding power source waveforms or for configuring a system sequence controller, where the touch screen may be integrated into a welding system component. The touch screen displays information related to a switching type welding power source and / or a welding system sequence controller, as well as one or more touch activation indicia to allow a user to numerically or graphically configure the power source or the sequence controller by touching the touch activation indicia.

Owner:LINCOLN GLOBAL INC

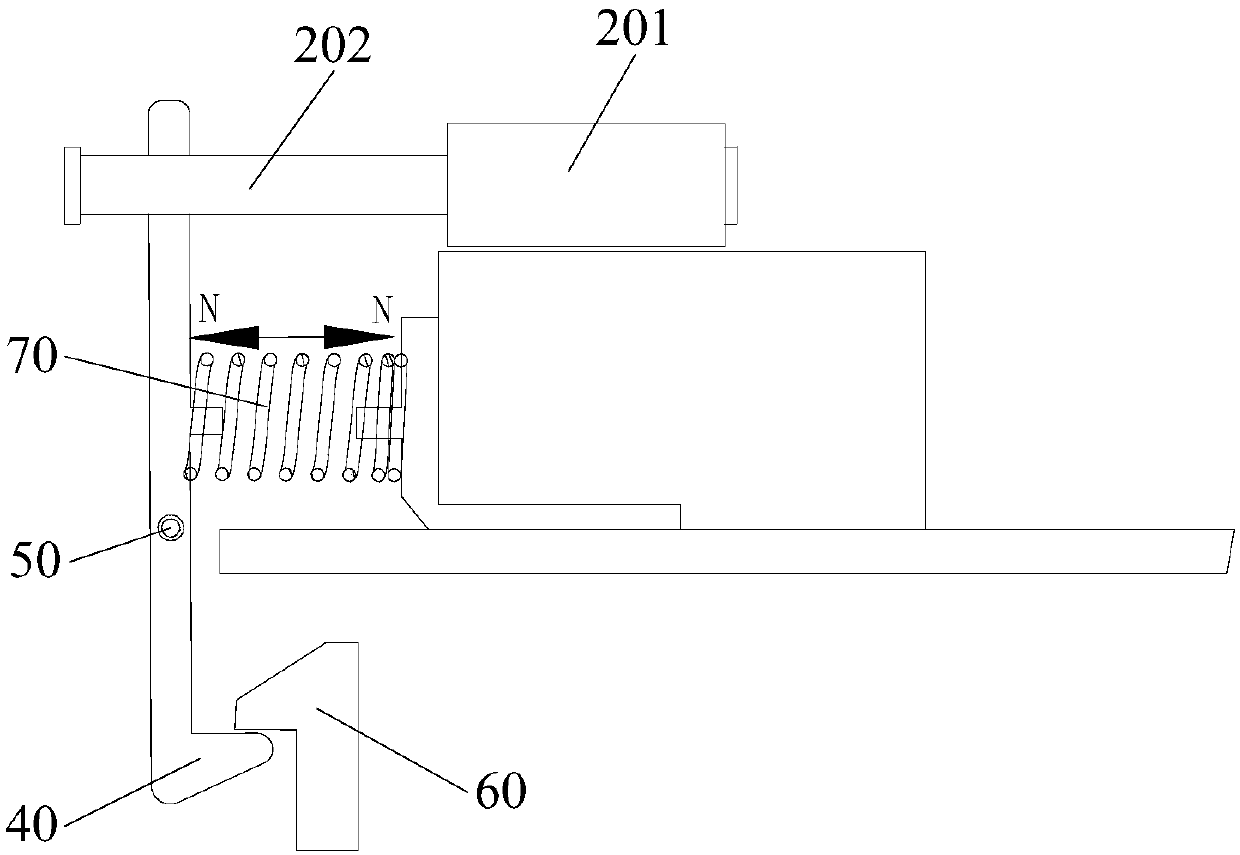

Cooking utensil

The invention provides a cooking utensil which comprises a touch switch, a driving part and a controller. The touch switch is arranged on the body or a cover body of the cooking utensil and used for sending an uncovering signal. The driving part is used for driving the cover body to open. The controller is electrically connected with the touch switch and the driving part and used for receiving theuncovering signal and controlling the driving part to move so as to open the cover body. When a user touches the touch switch, the driving part is driven through the controller for uncovering, a locking structure is loosened and breaks away from a fastened position, accordingly automatic uncovering is achieved, and an uncovering button structure conventionally exposed on the appearance face of the product is omitted in the uncovering way, so that a whole interface of the product is simpler. In addition, in this uncovering way, an uncovering operation can be selected or not according to the working environments in the cooking utensil, for example, pressure intensity, the cooking utensil has higher safety, and especially the risk is prevented that the cooking utensil is forcedly uncovered due to misoperation of a user during under-pressure work and accordingly explodes and scalds a user.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

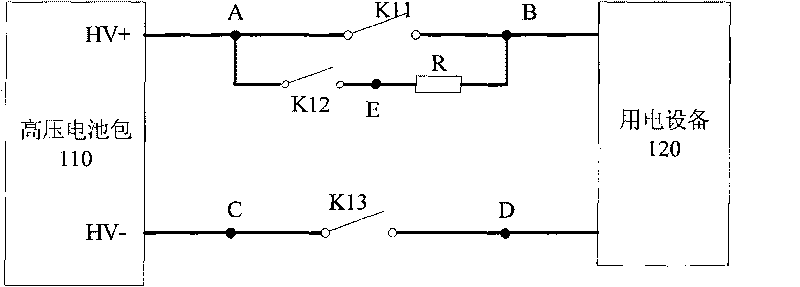

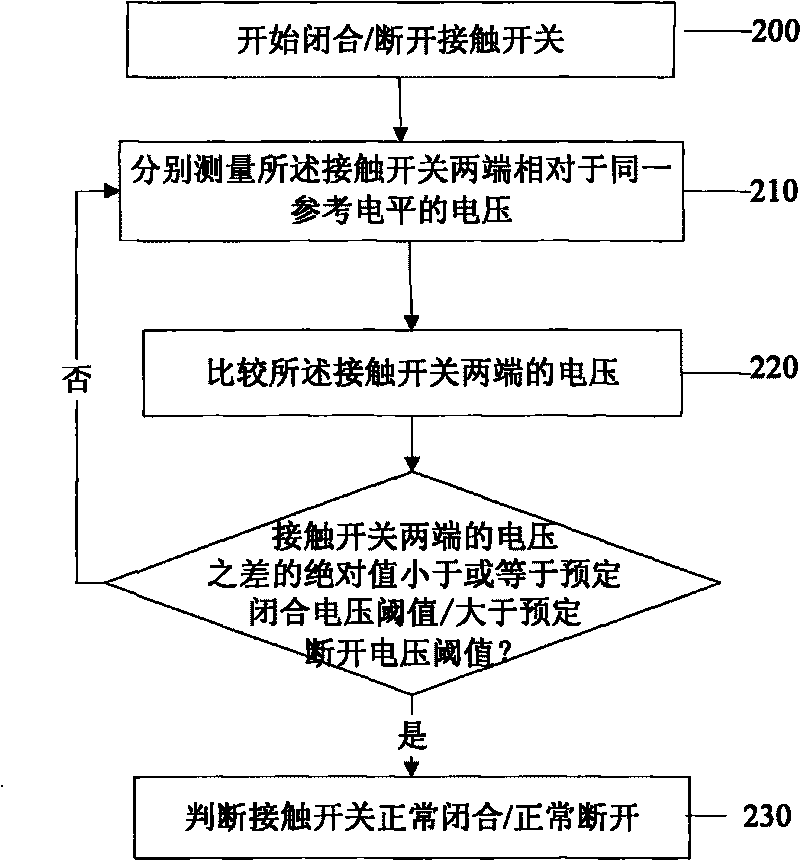

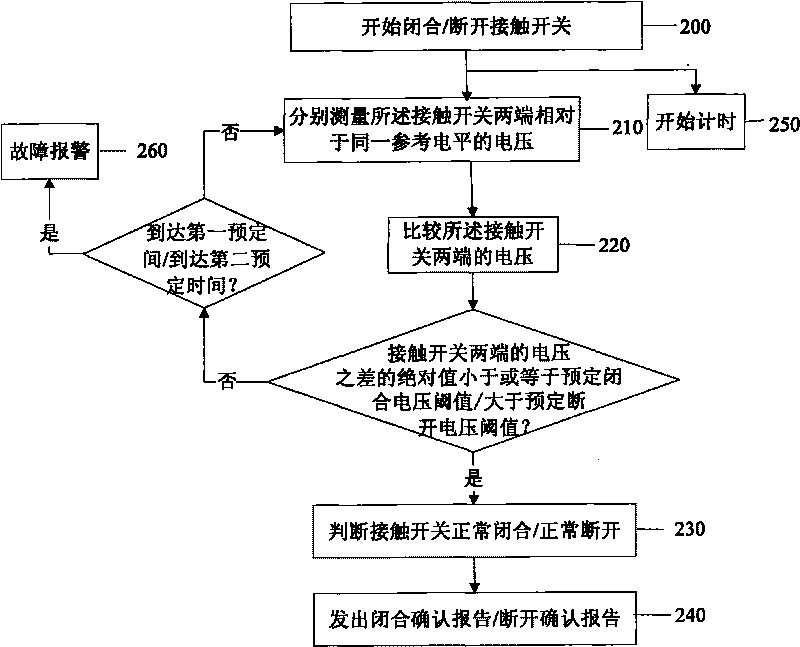

Monitoring method and monitoring system for touch switch

The invention provides a monitoring method and a monitoring system for a touch switch. The monitoring method comprises the following steps of: (1) during switching on the touch switch or switching off the touch switch, respectively measuring voltages of two ends of the touch switch relative to the same reference electrical level; (2) comparing the voltages of the two ends of the touch switch relative to the same reference electrical level; and (3) judging whether the touch switch is switched on or switched off normally or not according to a comparison result. By using the method and the device of the monitoring method and the monitoring system of the touch switch, the touch switch can be confirmed whether to be switched on normally or switched off normally through judging the voltages of the two ends of the touch switch relative to the same reference electrical level after the touch switch in a high voltage system of an elective vehicle receives a switching-on command or a switching-off command. The invention provides the effective and reliable monitoring method and the motoring system of the touch switch, thus the touch switch can be correctly judged whether to be switched on normally or switched off normally.

Owner:BEIQI FOTON MOTOR CO LTD

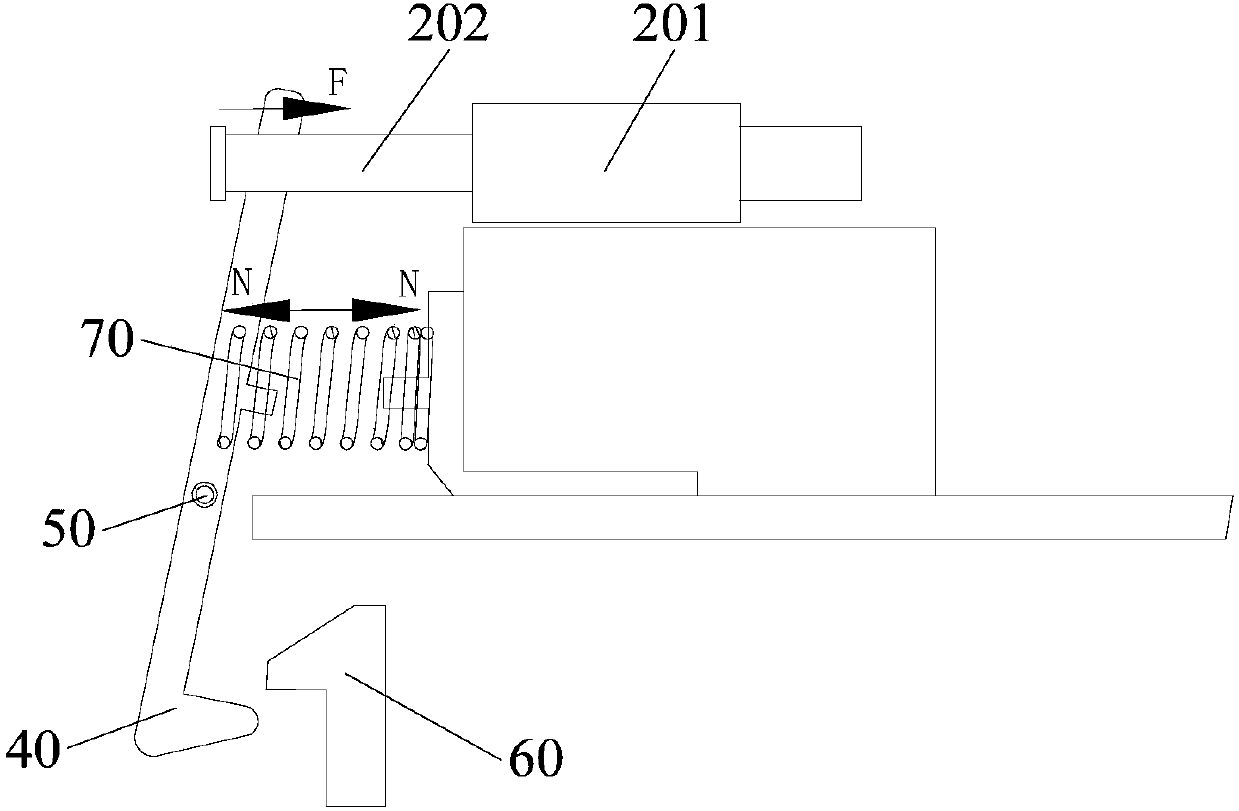

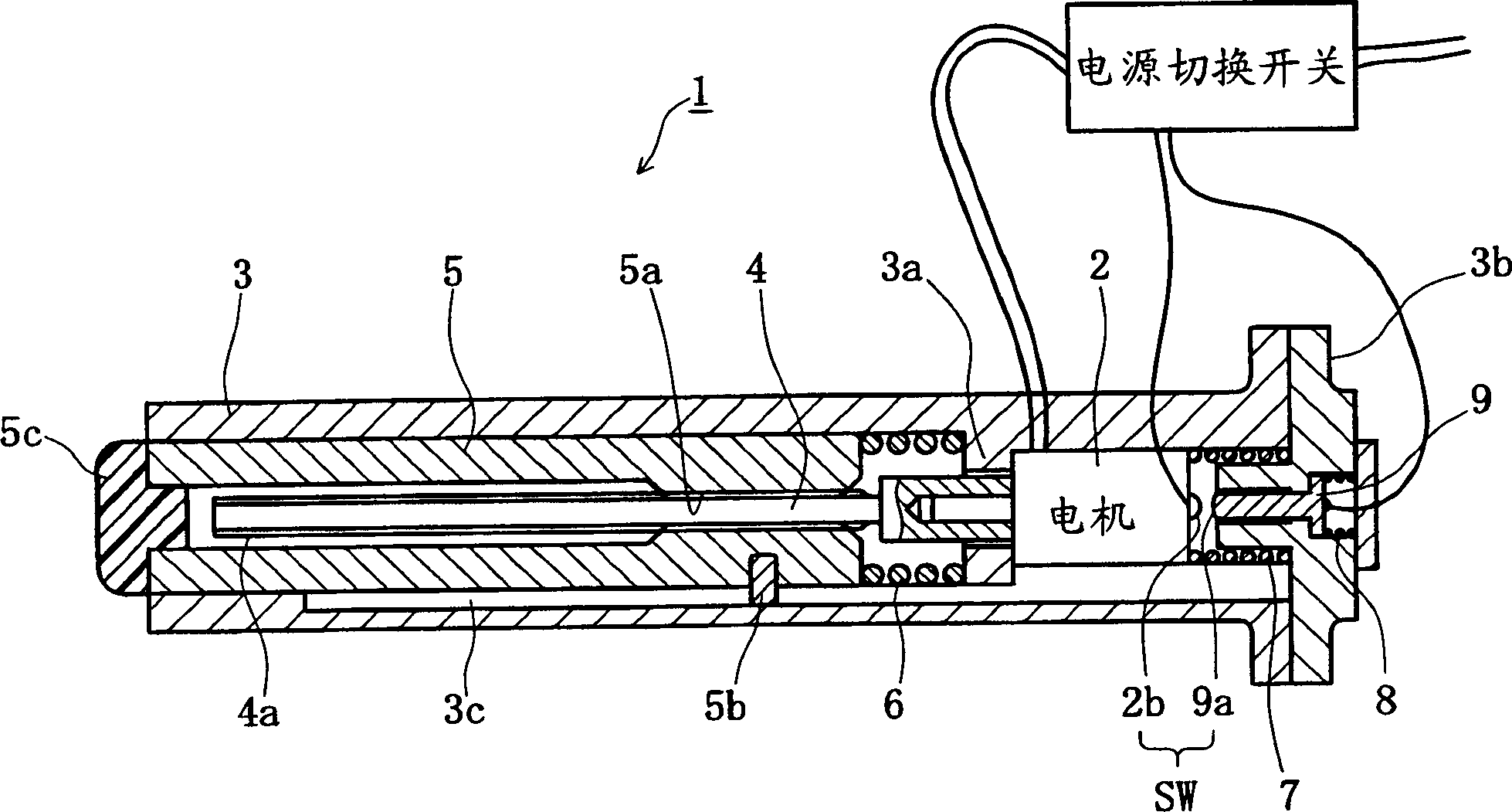

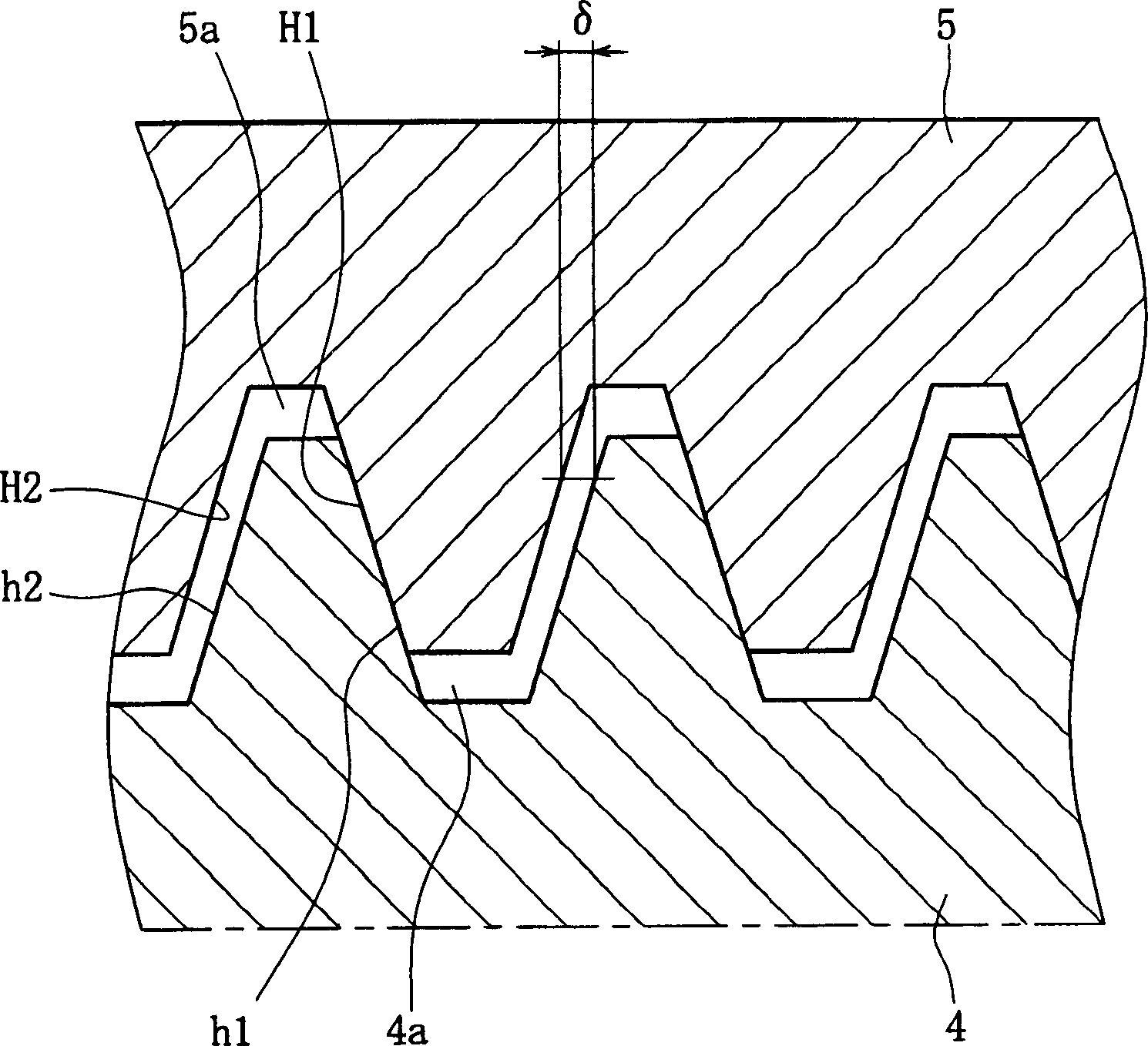

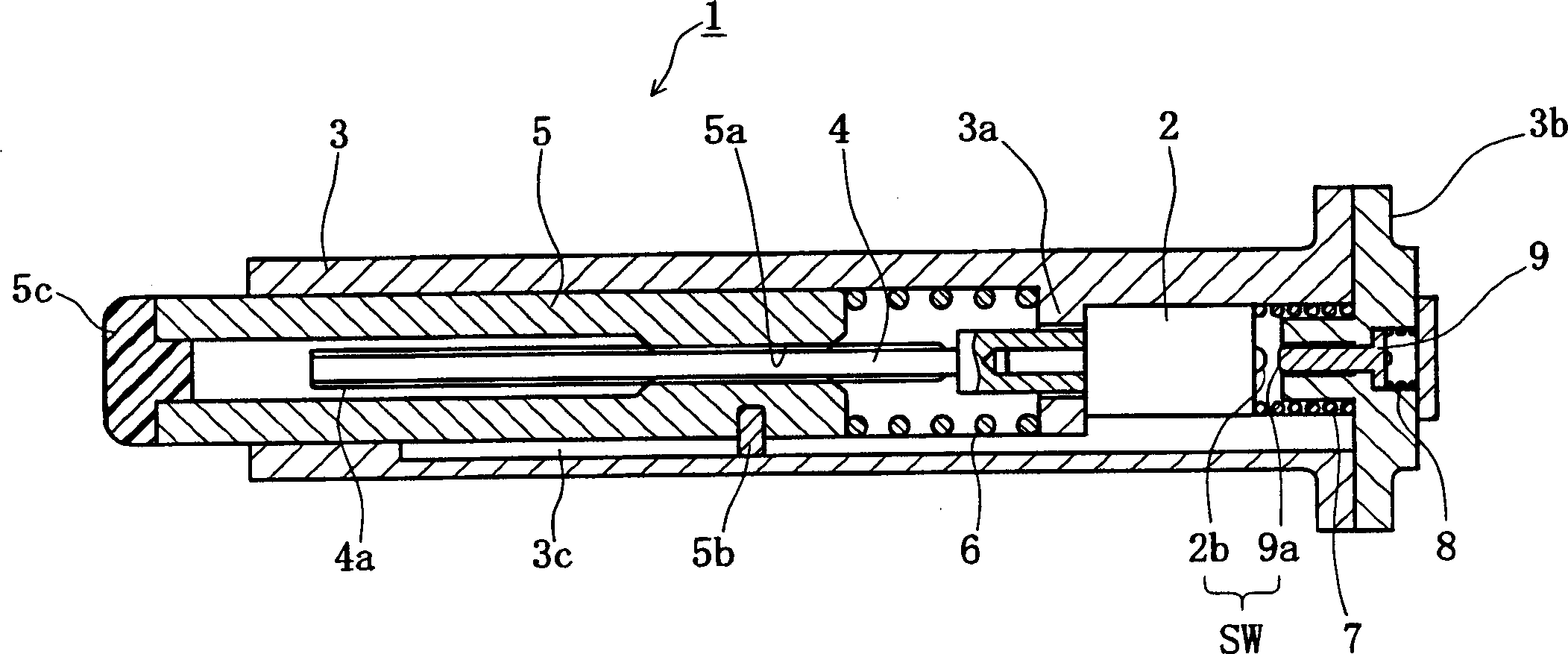

Door opening device

InactiveCN1397710APrevent overloadBig impactBuilding braking devicesPower-operated mechanismLinear motionEngineering

The present invention provided a door opener, by which a door open-close unit is miniaturized and lightened and a door can be opened efficiently by only one of the operation of a touch switch and which is silent. In the door opener 1 opening the rotary type door in which one end section is supported rotatably by a hinge, the door opener 1 has a motor 2 housed in a bottomed cylindrical housing 3, a screw shaft 4, to which the rotation of the motor 2 is transmitted, a nut 5 screwed to the screw shaft 4 and internally inserted into the housing 3, the first spring 6 housed between the nut 5 and the shoulder section 3a of the housing 3 and the second spring 7 housed between the bottom section 3b of the housing 3 and the motor 2, and the rotation of the motor 2 is converted into the linear motion of the nut 5. The nut 5 is formed to the housing 3 retractively and irrotationally and the screw shaft 4 is formed integrally with an output shaft for the motor 2.

Owner:PANASONIC CORP

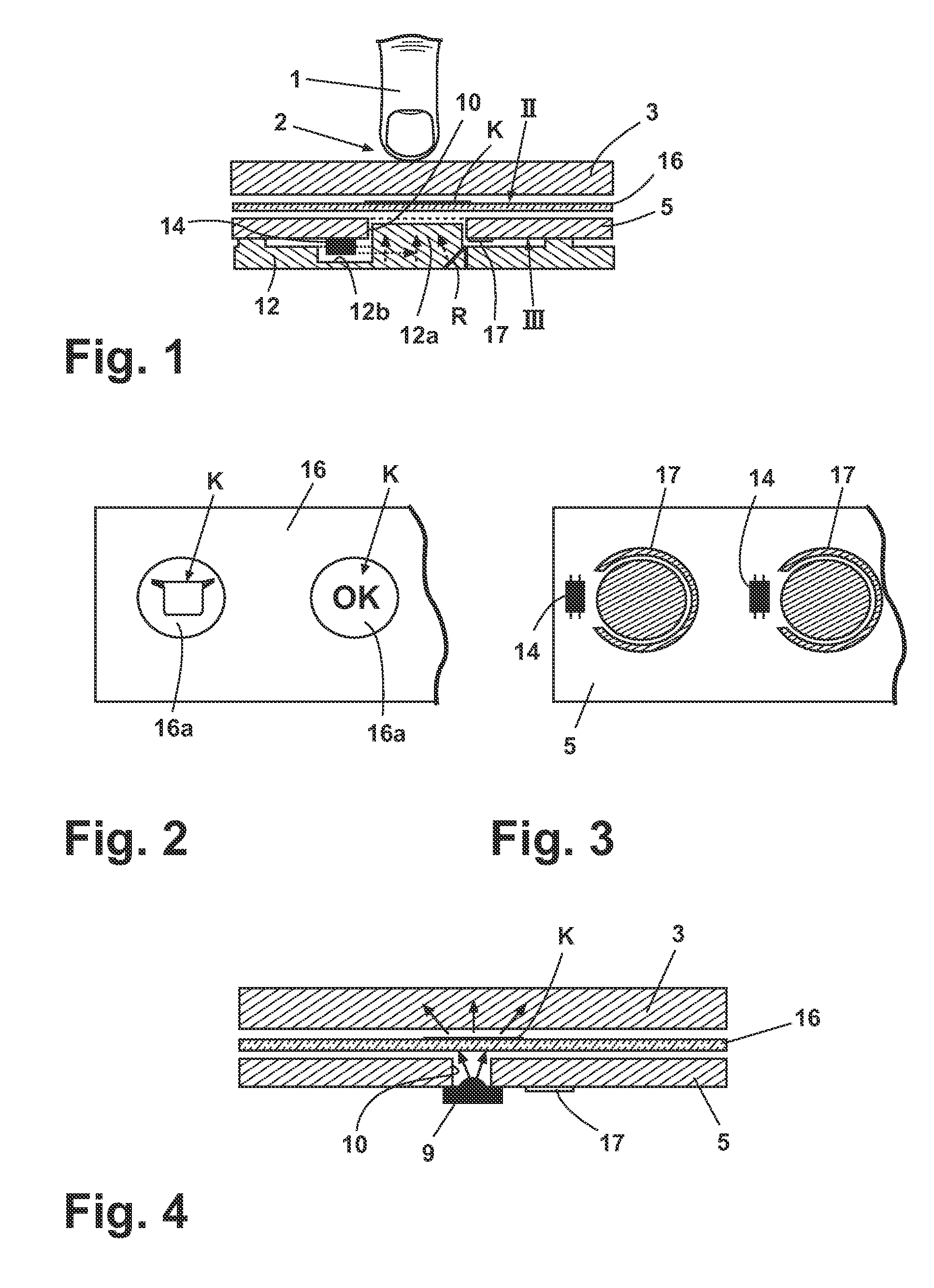

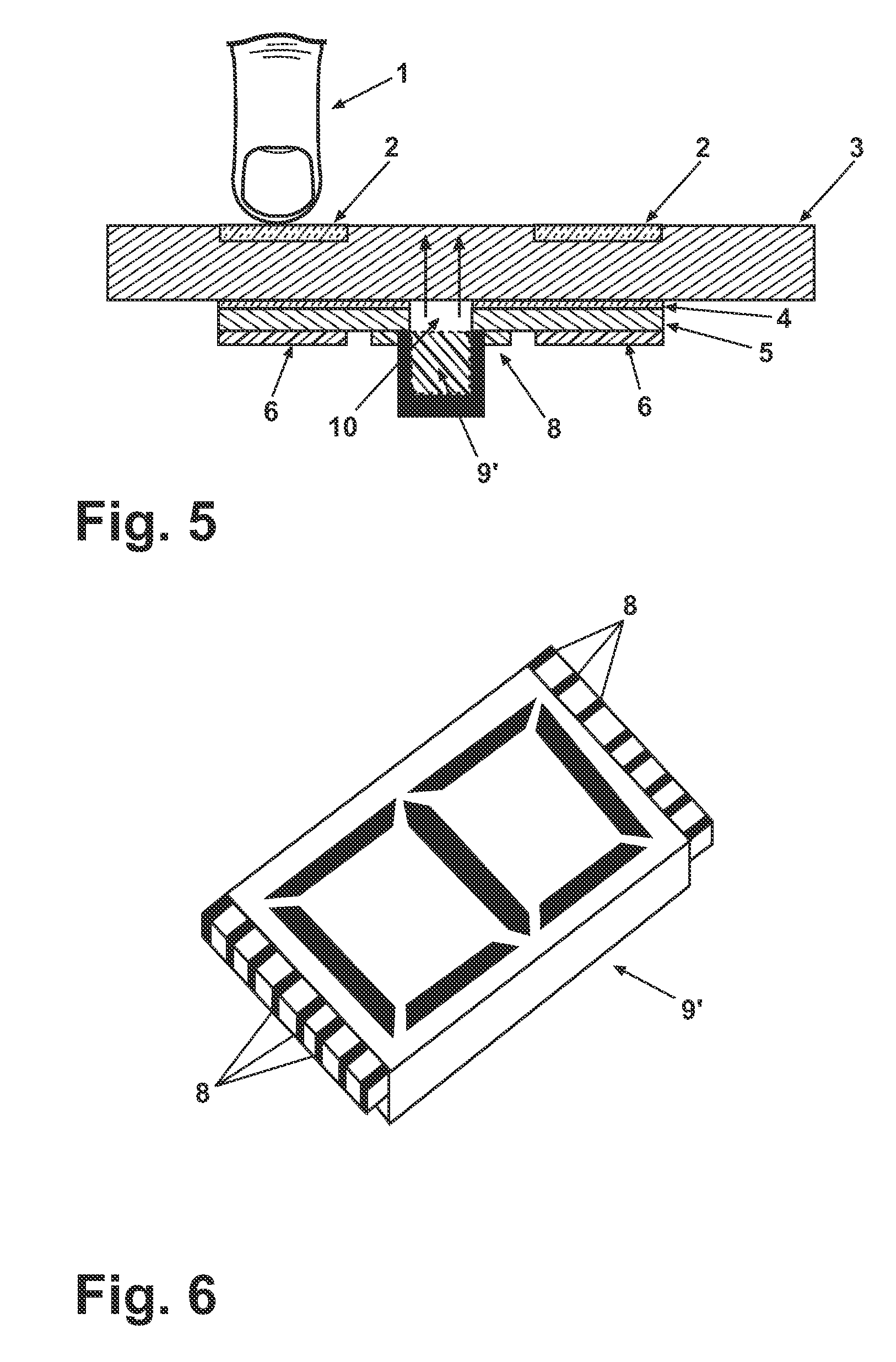

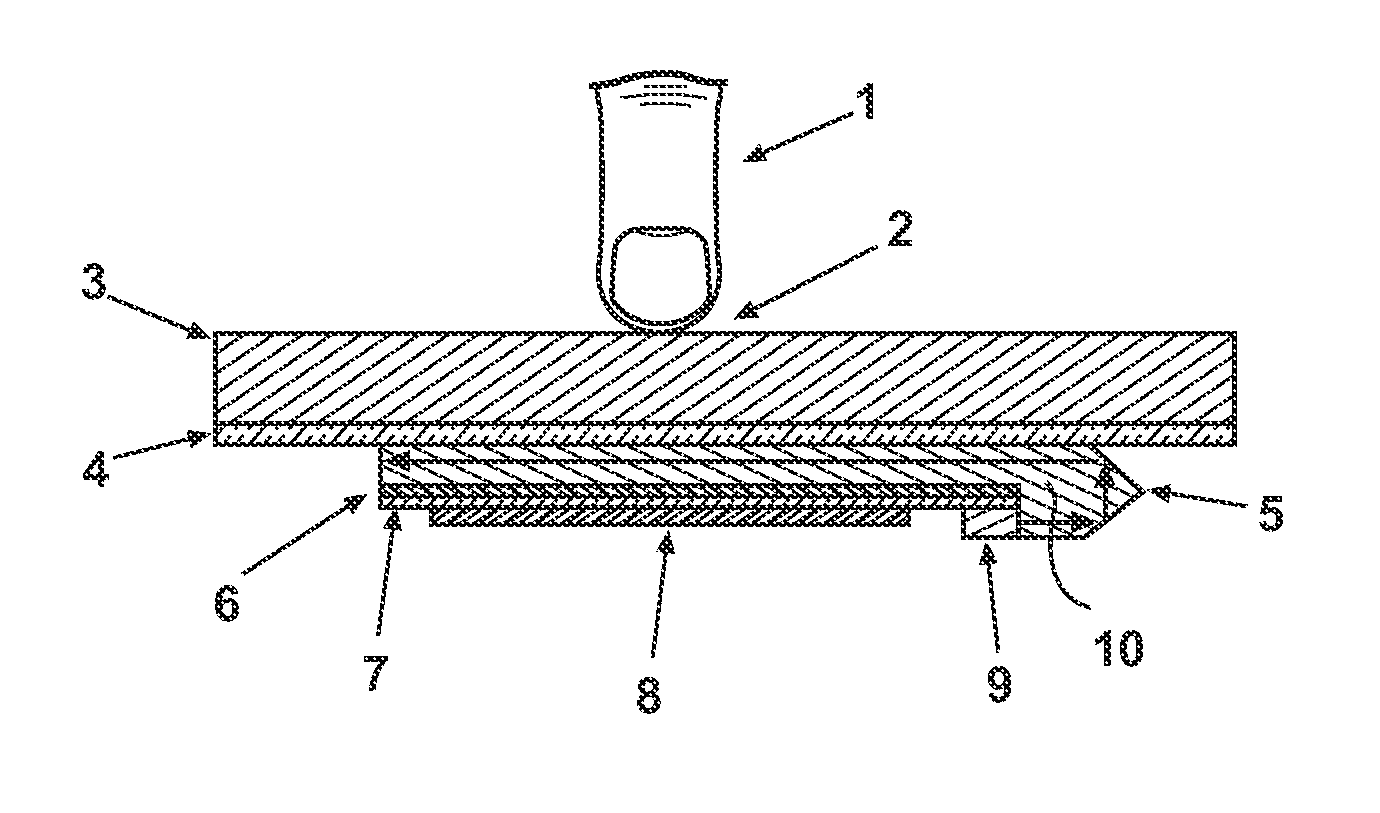

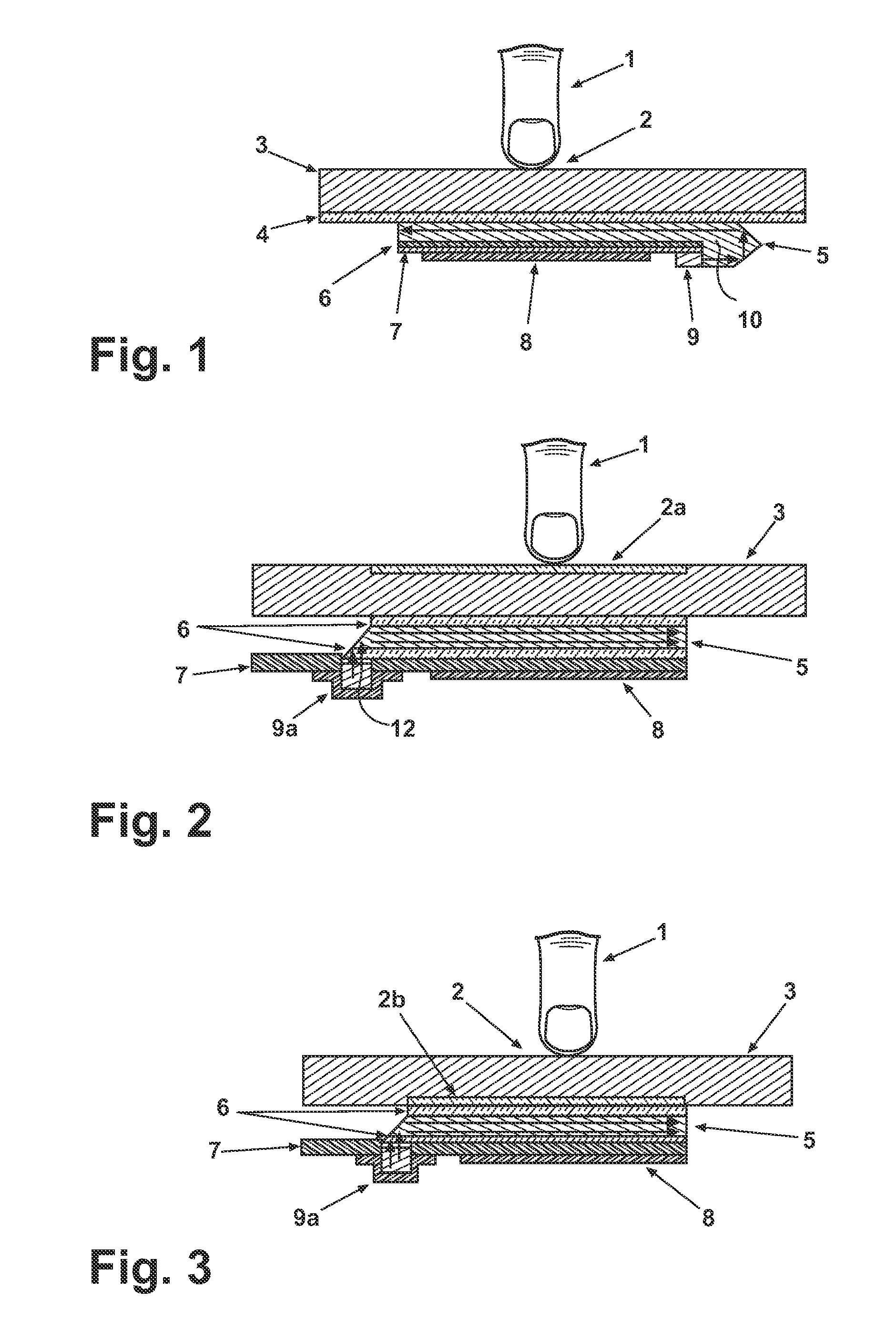

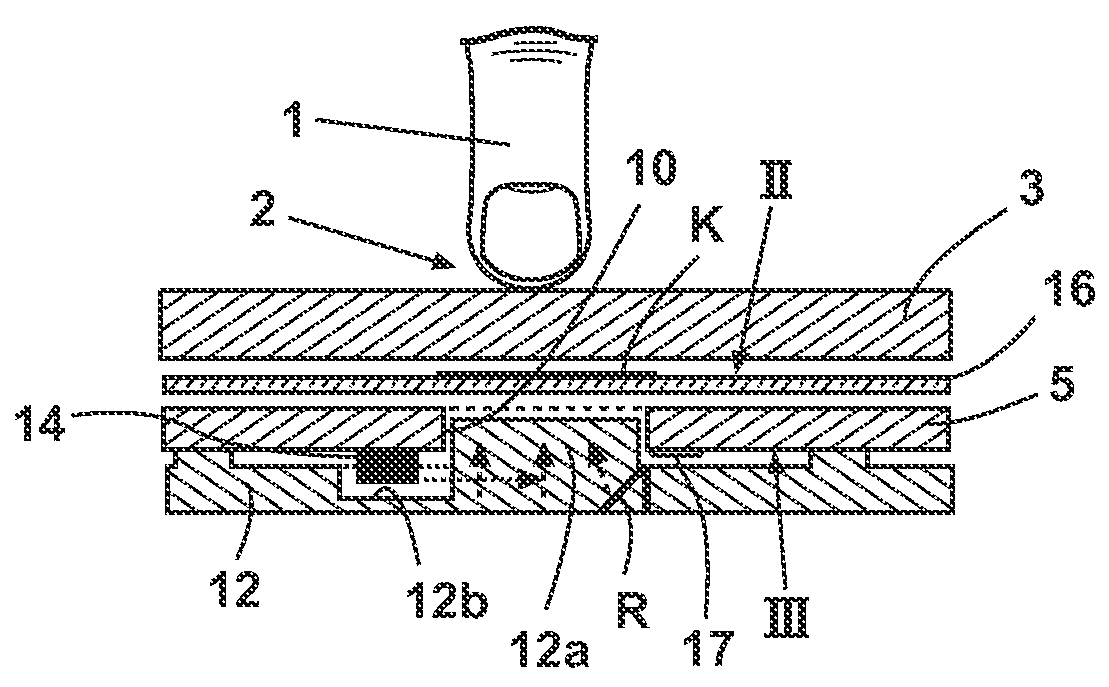

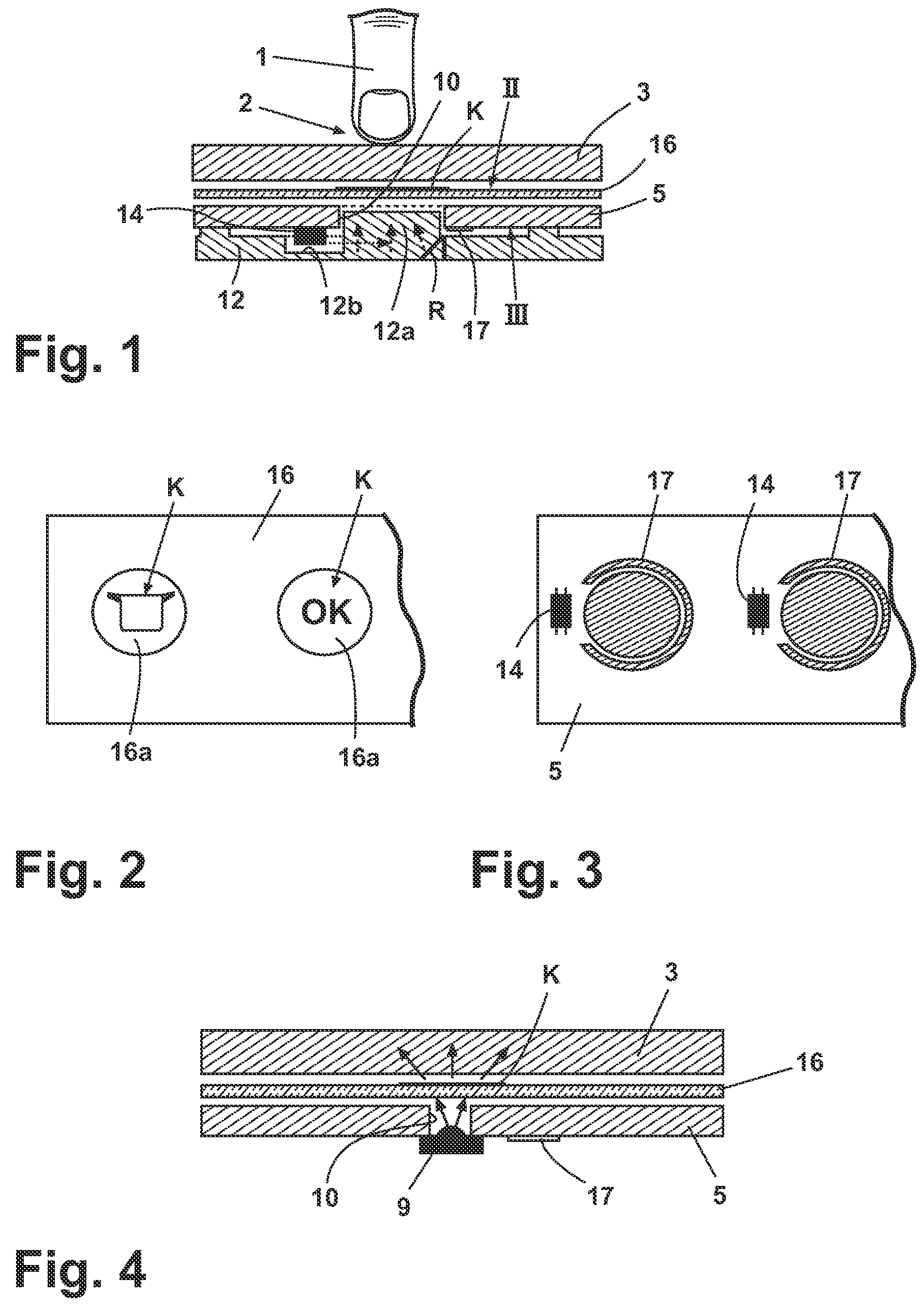

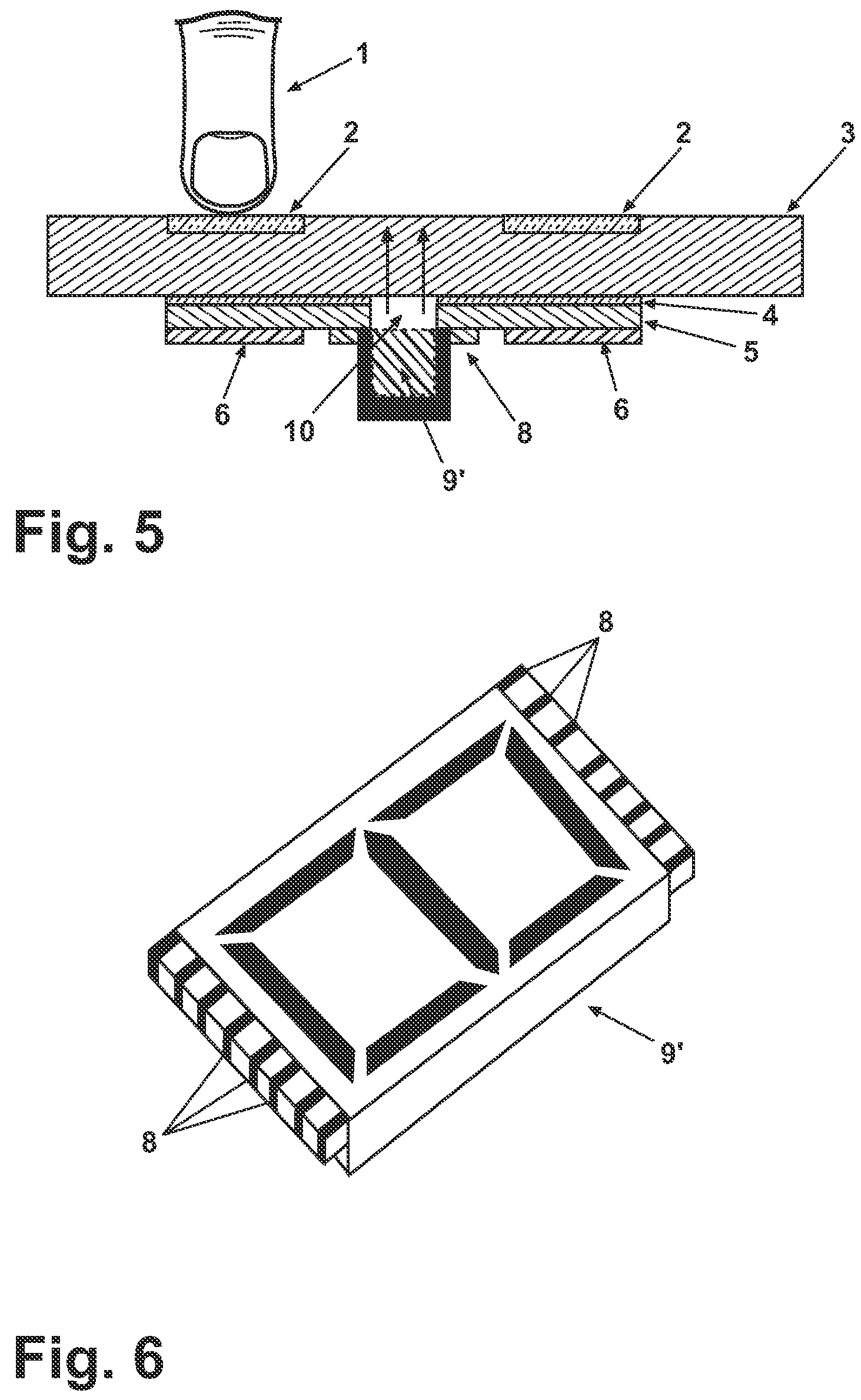

Touch switch for electrical appliances and electrical appliance provided with such switch

InactiveUS20090090605A1Big thicknessReduce physical sizeElectronic switchingElectric switchesPrinted circuit boardLight transmission

A touch switch for an electrical appliance having a capacitive flat electrode, a light source, a transparent cover and a printed circuit board connected to the electrode is disclosed. The light source is mounted on a face of the printed circuit board opposite the transparent cover and the printed circuit board presents a cut-out for allowing light transmission from the light source towards the transparent cover.

Owner:WHIRLPOOL CORP

Capacitive touch switch and domestic appliance provided with such switch

InactiveUS20090090611A1Increasing the thicknessControl thicknessElectronic switchingElectric switchesLight guideEngineering

A capacitive touch switch having a printed circuit board and capacitive electrode provided on a surface of the printed circuit board is disclosed. The printed circuit board is interposed between a transparent planar light guide and the electrode, the planar light guide being attached to a first face of a transparent cover whose second face is adapted to be touched by the user, a light source being connected to the printed circuit board and being able to convey light to the planar light guide.

Owner:WHIRLPOOL CORP

Touch switch for electrical appliances and electrical appliance provided with such switch

InactiveUS7705257B2Reduce physical sizeImprove versatilityElectronic switchingElectric switchesEngineeringPrinted circuit board

A touch switch for an electrical appliance having a capacitive flat electrode, a light source, a transparent cover and a printed circuit board connected to the electrode is disclosed. The light source is mounted on a face of the printed circuit board opposite the transparent cover and the printed circuit board presents a cut-out for allowing light transmission from the light source towards the transparent cover.

Owner:WHIRLPOOL CORP

Capacitive touch on/off control for an automatic residential faucet

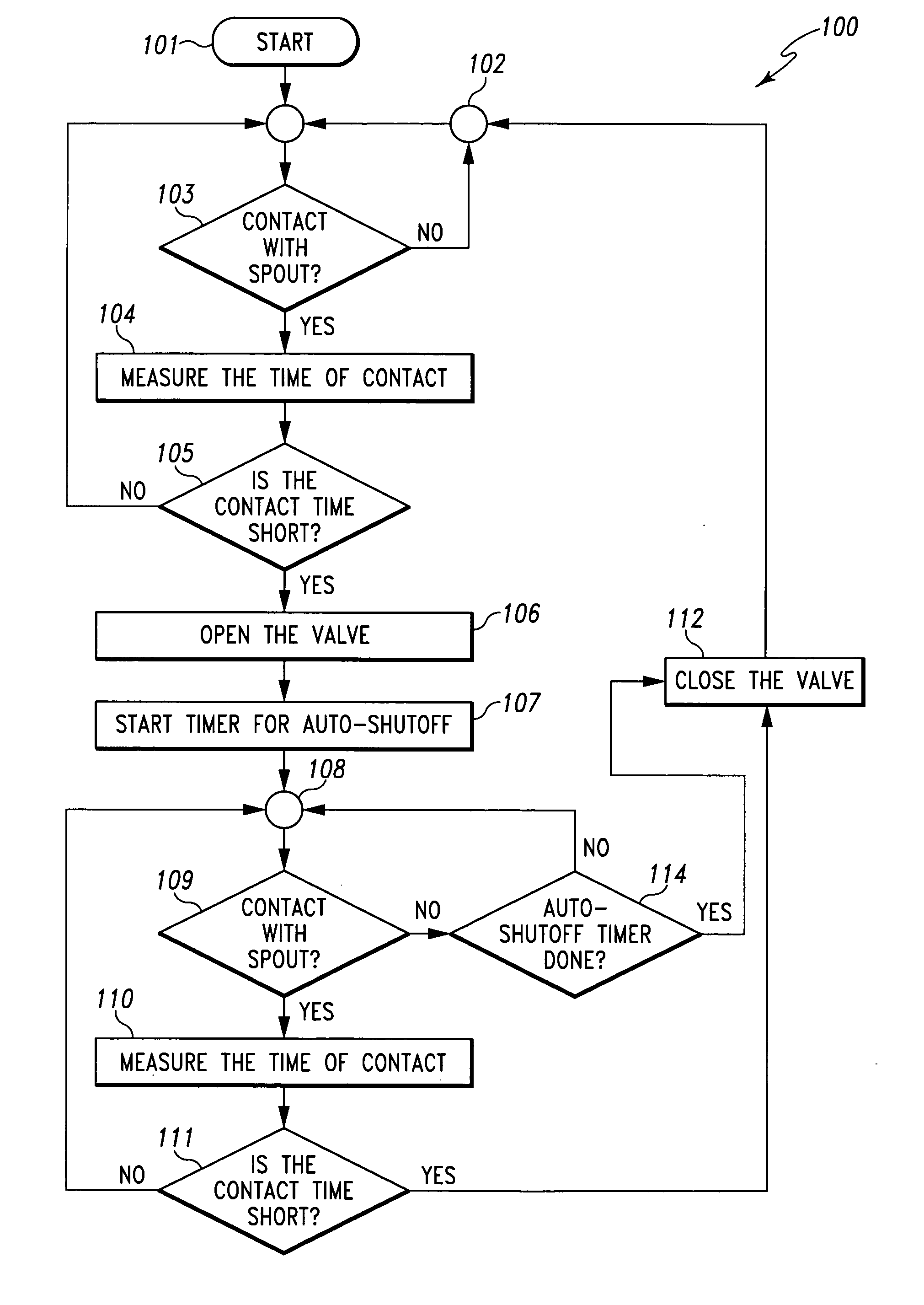

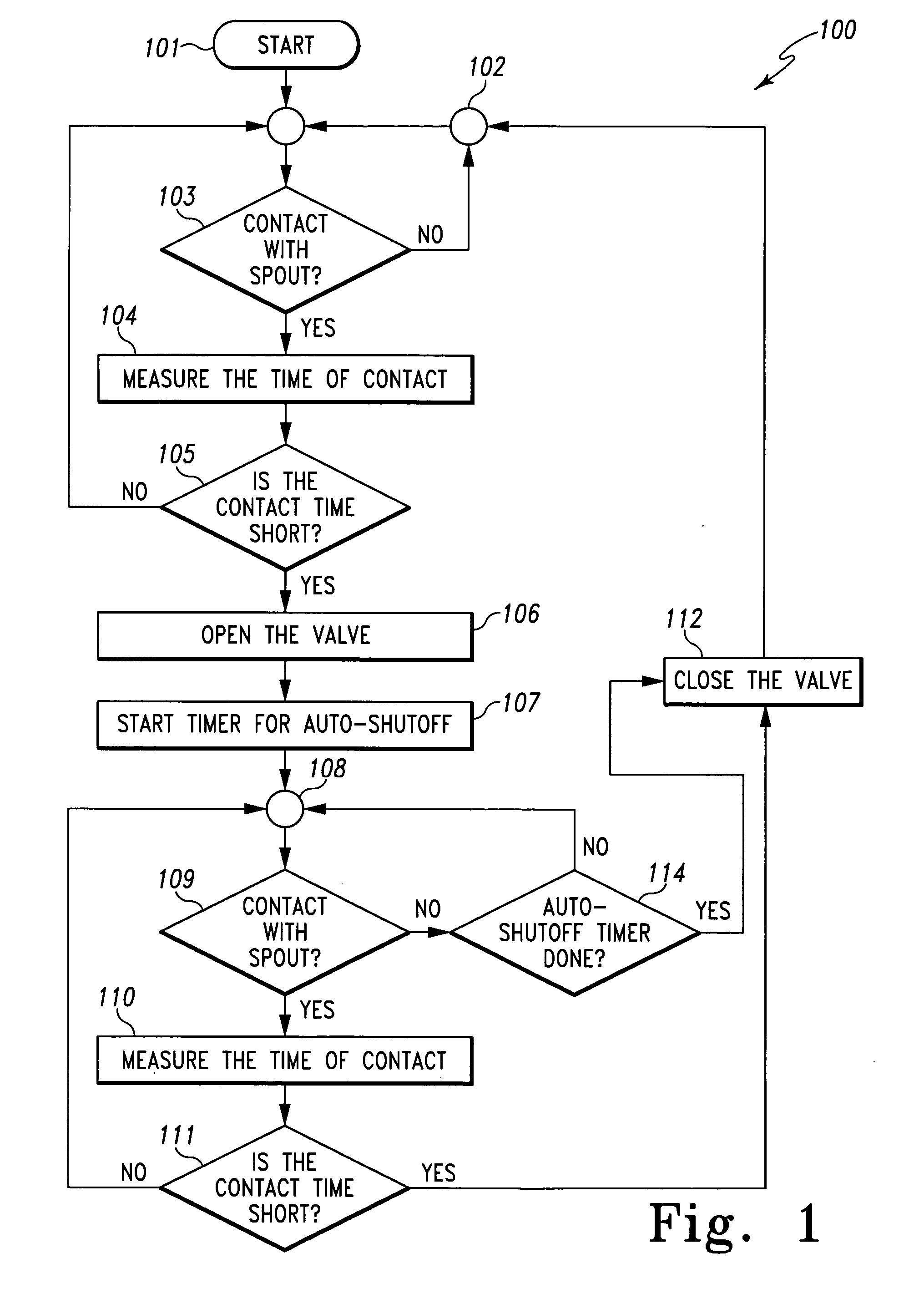

ActiveUS20050150557A1Operating means/releasing devices for valvesServomotor componentsProximity sensorTime segment

A capacitive touch-controlled automatic faucet comprises: a spout, a magnetically latching valve, a proximity sensor, a handle, a capacitive touch-control, and a logical control. The proximity sensor is sensitive to motion of objects within a detection zone of the proximity sensor. The handle determines a water flow rate and temperature. The capacitive touch-control is positioned in the spout and generates an output signal while the touch-control is in contact with a user. The logical control receives the output signal, and toggles the magnetically latching valve when the output signal begins and ends within a period of time less than a predetermined threshold, but does not toggle the magnetically latching valve when the output signal persists for a period longer than the predetermined threshold. The faucet has a manual mode, wherein the proximity sensor is inactive, and a hands-free mode, wherein water flow is toggled in response to the proximity sensor.

Owner:DELTA FAUCET COMPANY

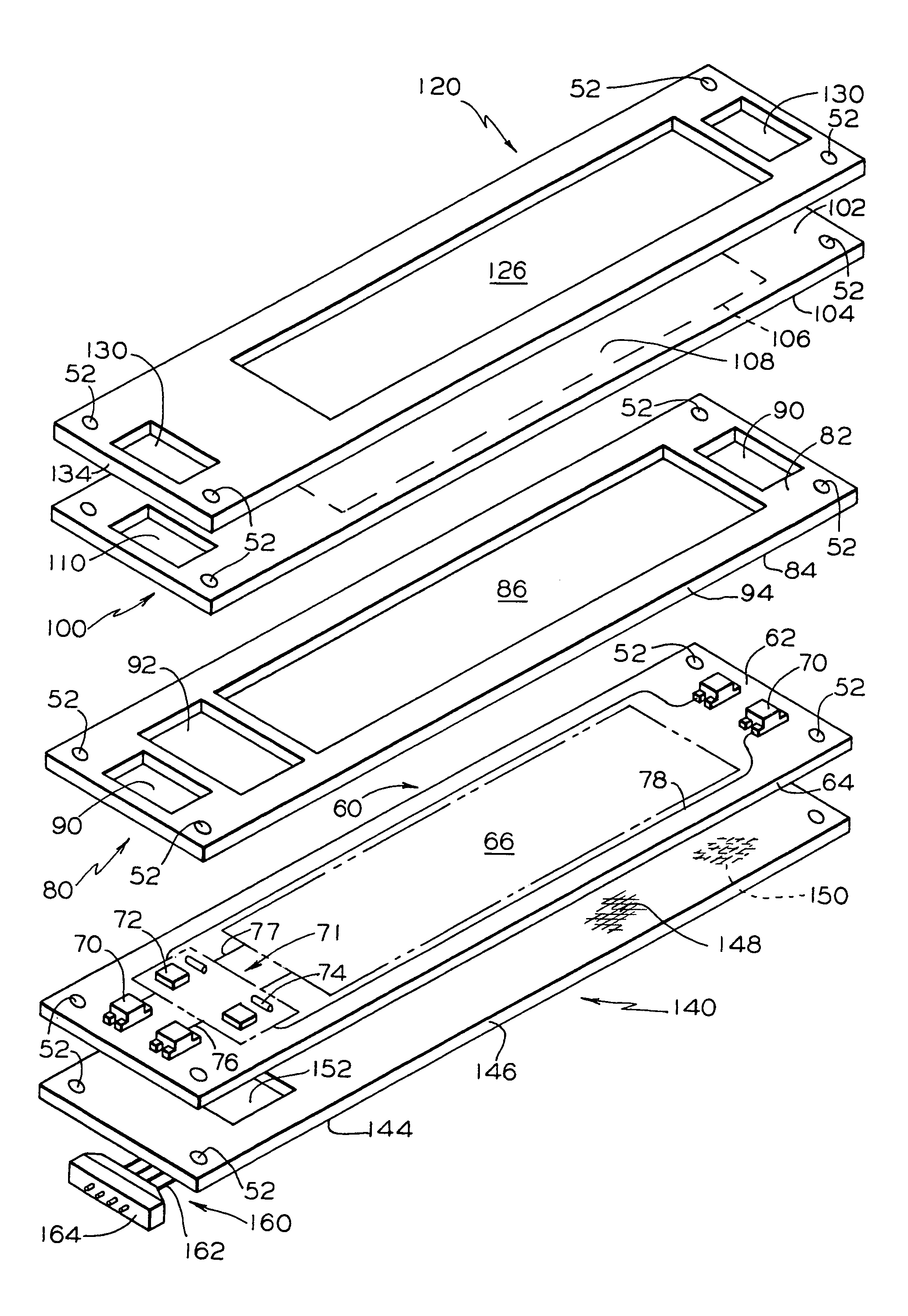

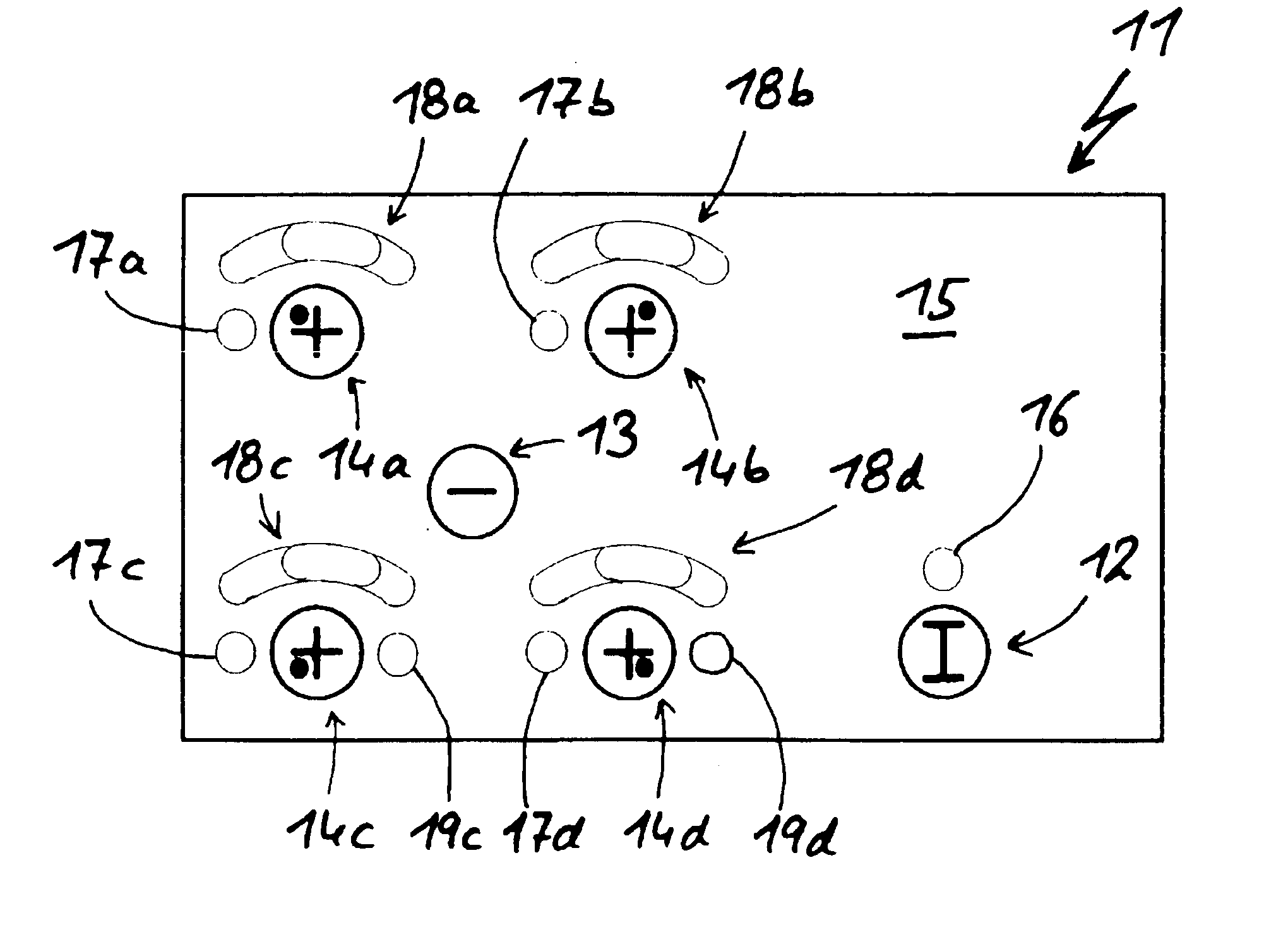

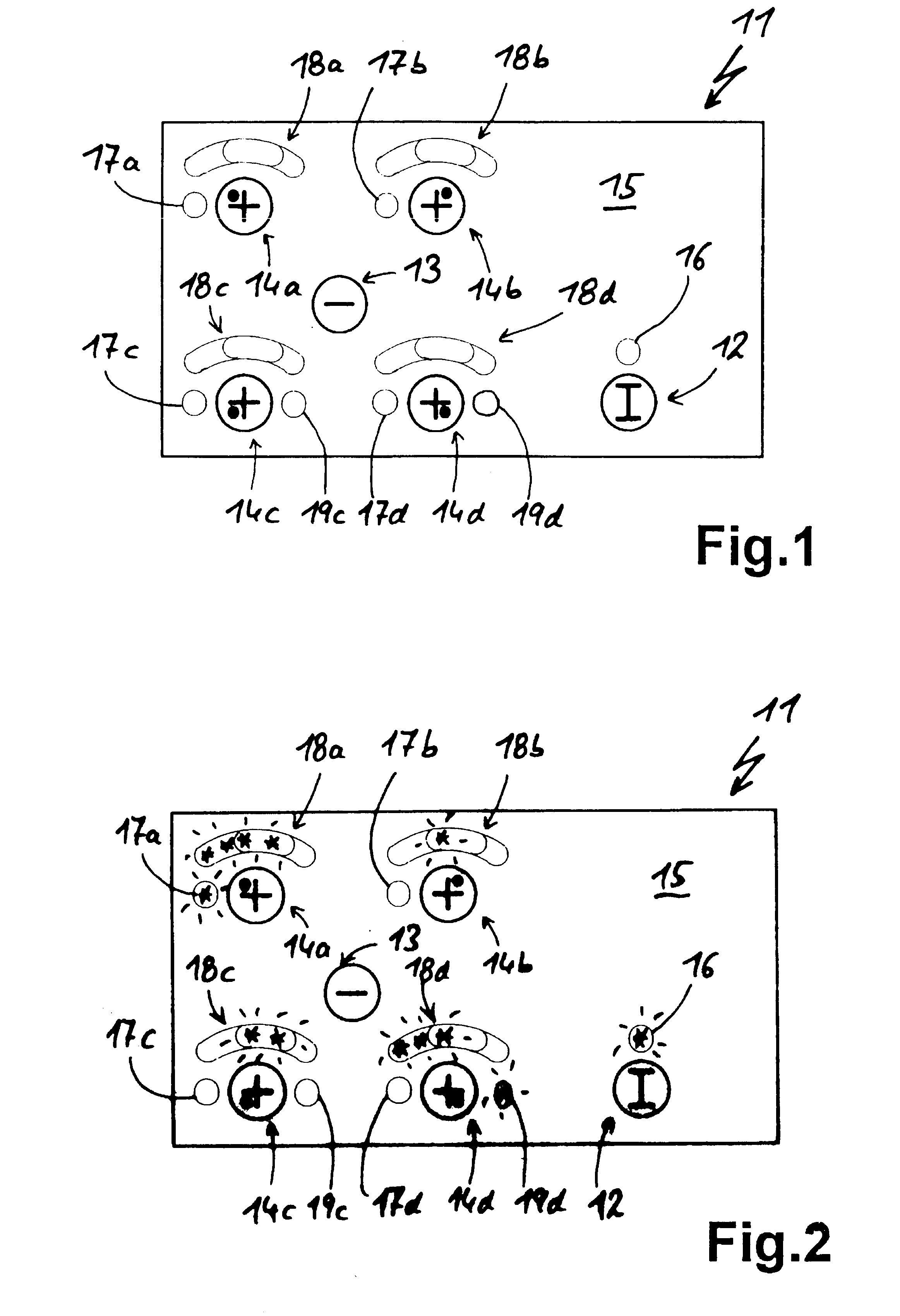

Interior/exterior component with electroluminescent lighting and soft touch switching

ActiveUS7445350B2Small sizeReduce spacingLighting circuitsElectric circuit arrangementsElectricityEffect light

A light panel includes an outer layer, a first proximity switch, an electroluminescent element and a base portion. The outer layer includes a translucent portion. The first proximity switch is disposed beneath the outer layer and has first and second electrically conductive switch portions that are arranged to form an electric field that emanates through the outer layer when the first proximity switch is energized. The electroluminescent element is disposed beneath the outer layer to provided backlighting to the outer layer. One of the first and second electrically conductive switch portions of the first proximity switch forms at least a portion of an electrode of the electroluminescent element. The base portion is disposed beneath the electroluminescent element and the first proximity switch.

Owner:NISSAN MOTOR CO LTD

Illuminated touch switch

An illuminated touch switch has a touch sensitive area and a plurality of light emitting diodes arranged in a predetermined pattern. The touch switch includes a first rigid circuit board with a first electrical conductor and a second flexible circuit board with a second electrical conductor separated by a spacer of a predetermined thickness. Both conductors are aligned with the touch sensitive area and are coupled from the applied pressure providing an output signal. Light emitting diodes illuminate a single color light to indicate an enabled condition of the touch sensitive area.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

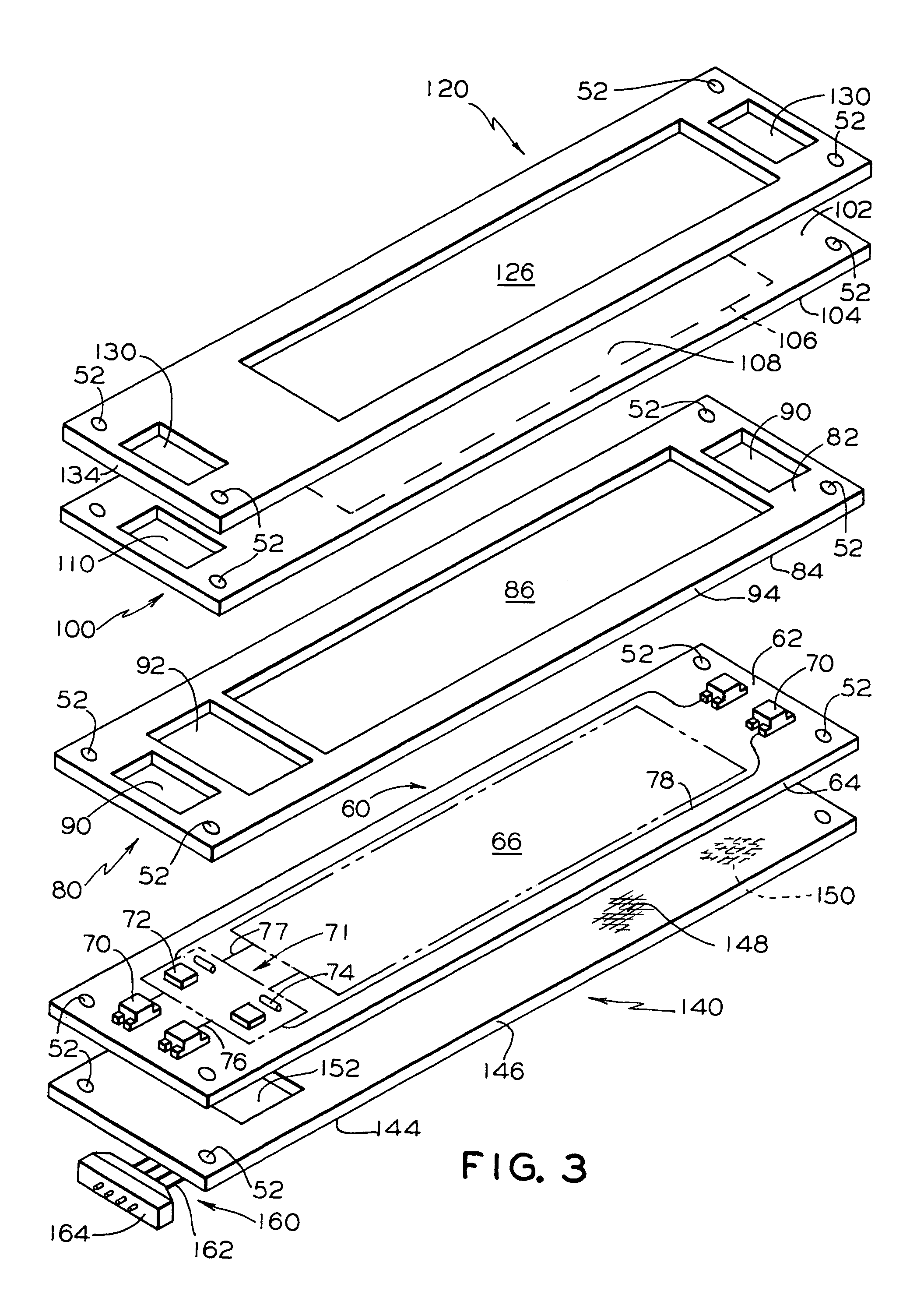

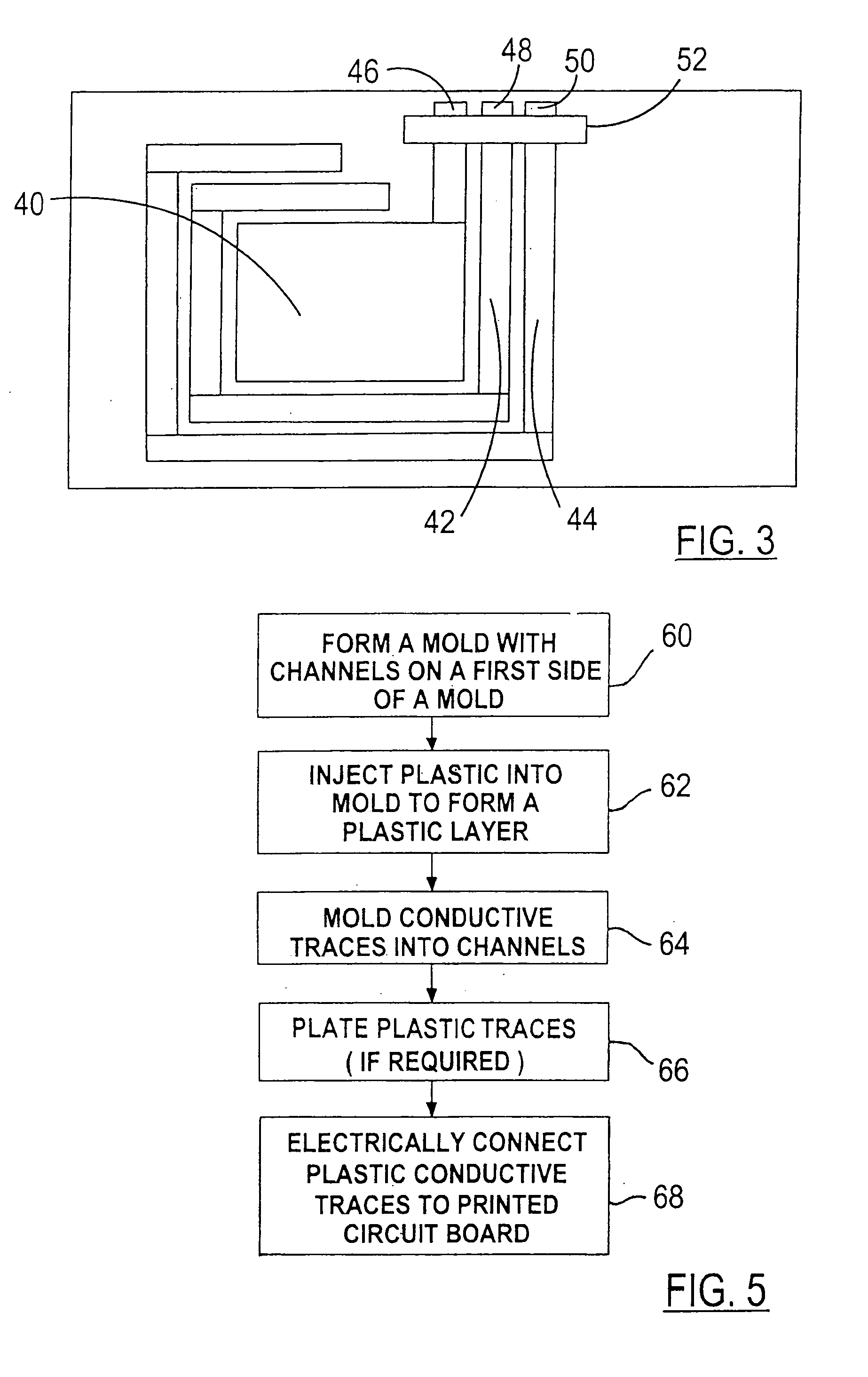

Multi-shot molded touch switch

A conductive plastic touch switch includes a plastic substrate having a first side surface including at least two channels formed within the first side surface and a second side surface including a manual activation region opposite of the at least two channels. At least two conductive traces are formed within the at least two channels, respectively. A printed circuit board is electrically attached to the at least two conductive traces. The plastic substrate is formed during a first mold process and said at least two conductive traces are in-molded during a second mold process.

Owner:LEAR CORP

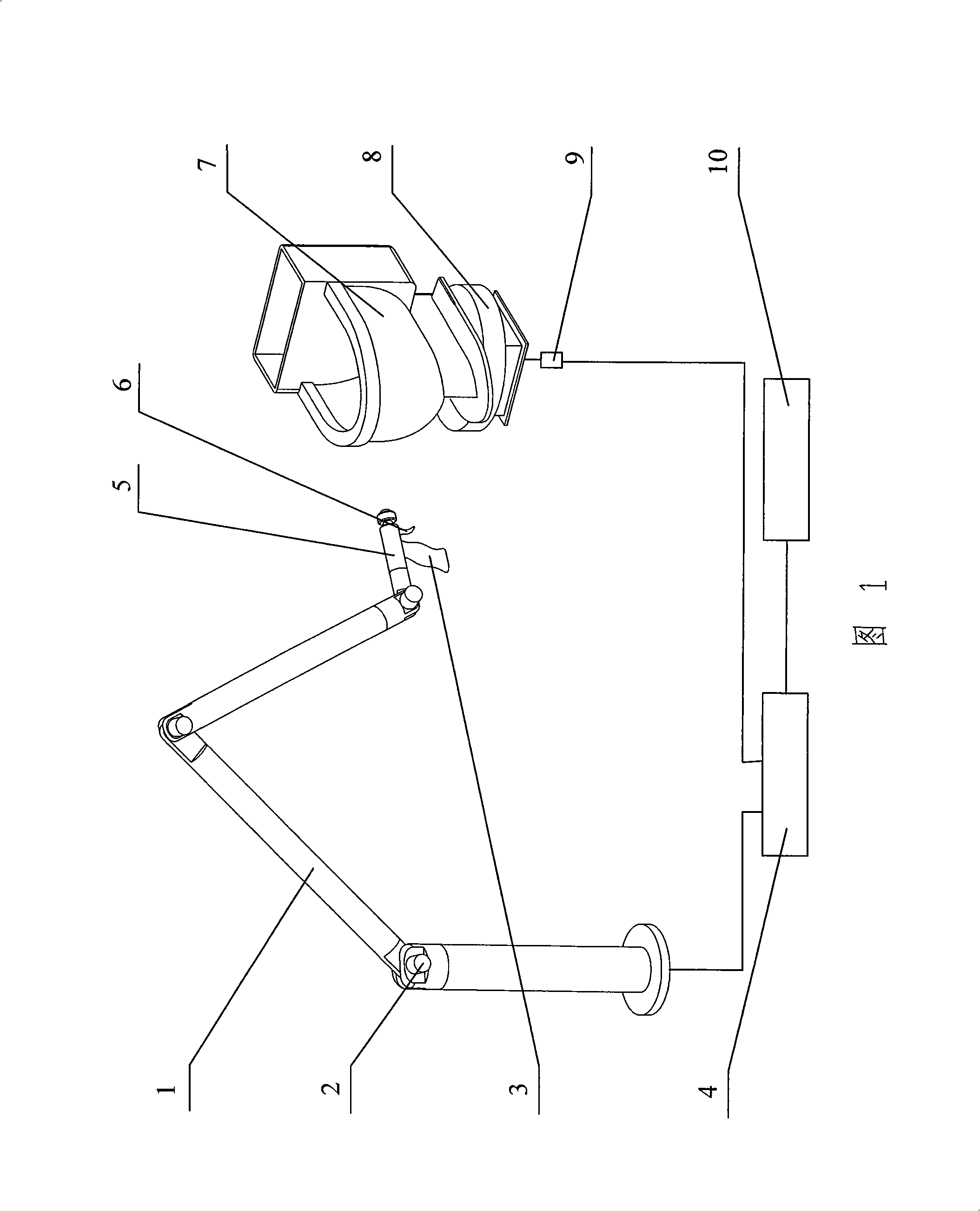

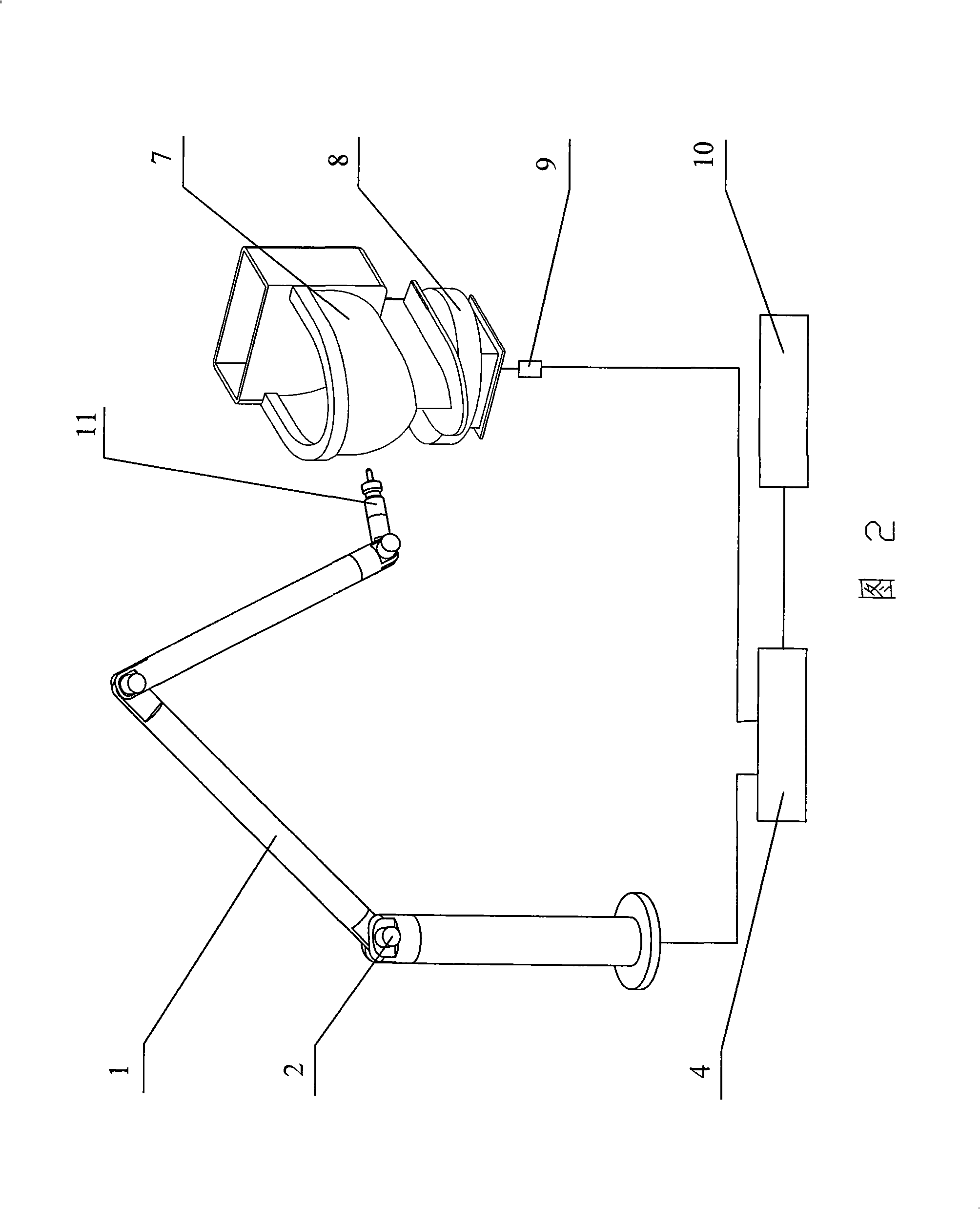

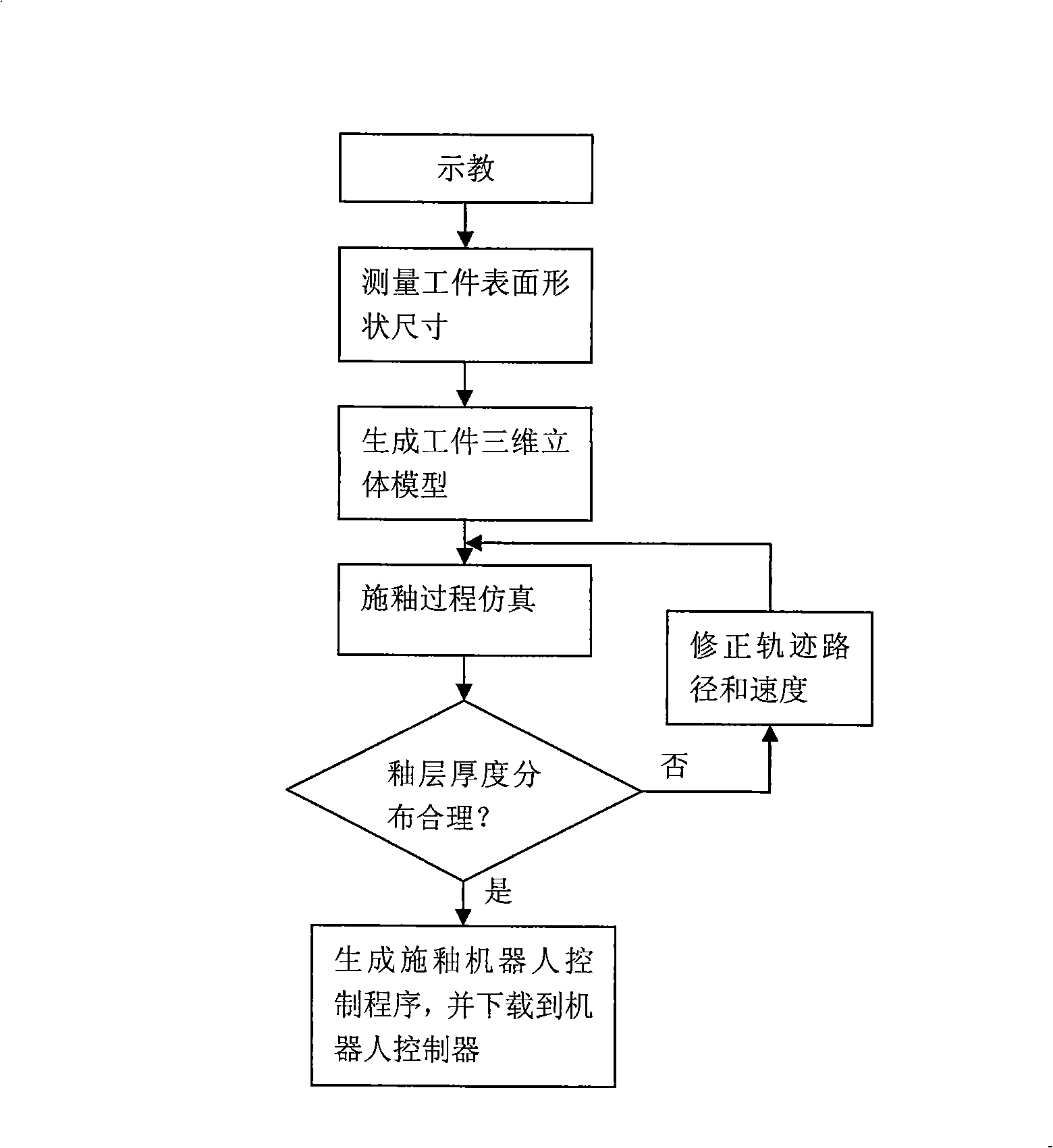

Glazing robot off-line teaching device and teaching method

InactiveCN101327590AEasy to programEasy to operateProgramme-controlled manipulatorSimulationProcess simulation

The present invention relates to an off-line glazing robot-demonstrating device, which belongs to the field of industrial robots. The demonstrating mechanism of the off-line glazing robot-demonstrating device has the same degree of freedom, the same type and number of hinges, the same mechanism size and the same operating space as the actual glazing robot does, joints are connected together by link rods, and the rotary shafts of the joints are respectively connected with an encoder. A demonstrating ejection gun is assembled on the end of the demonstrating mechanism and held by a hand in order to demonstrate, and a data-acquiring unit acquires and records the position and the speed of each joint and the on-off state of the ejection gun. A touch switch is assembled on the end of the demonstrating mechanism, the shape and the size of the surface of a workpiece are measured, and then the three-dimensional model of the workpiece is built in a computer. A glazing process simulation software simulates the piling process and the thickness distribution of glaze on the surface of the workpiece in the process of glazing. A data transmission unit converts the acquired data into a control program for the glazing robot, and then the glazing robot conducts a glazing action according to a data sequence. The off-line glazing robot-demonstrating device has the advantages of light weight, flexibility, high demonstration efficiency and convenient operation, and the glazing process simulation can forecast the thickness distribution of the glazed layer of the surface of the workpiece.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

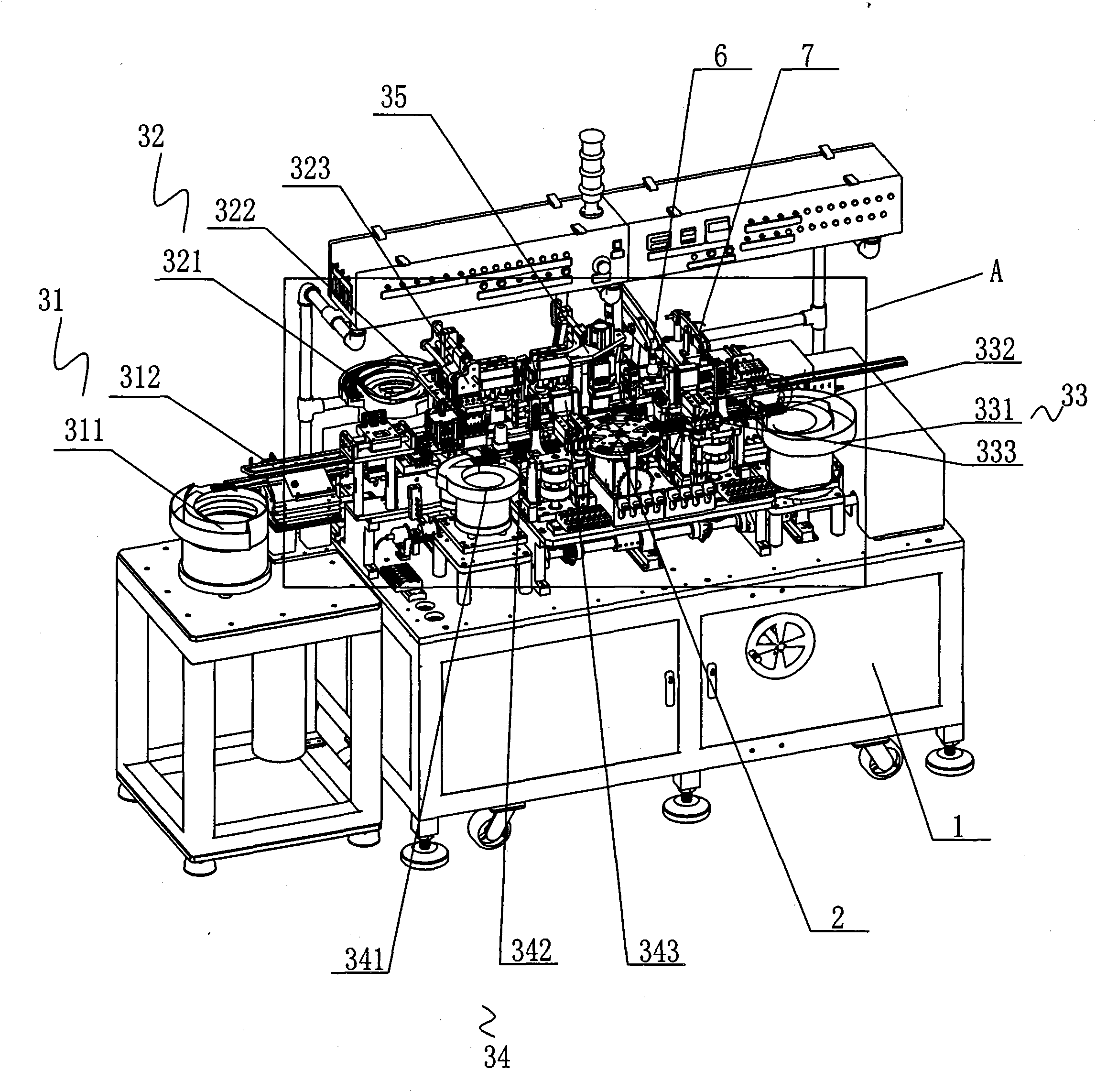

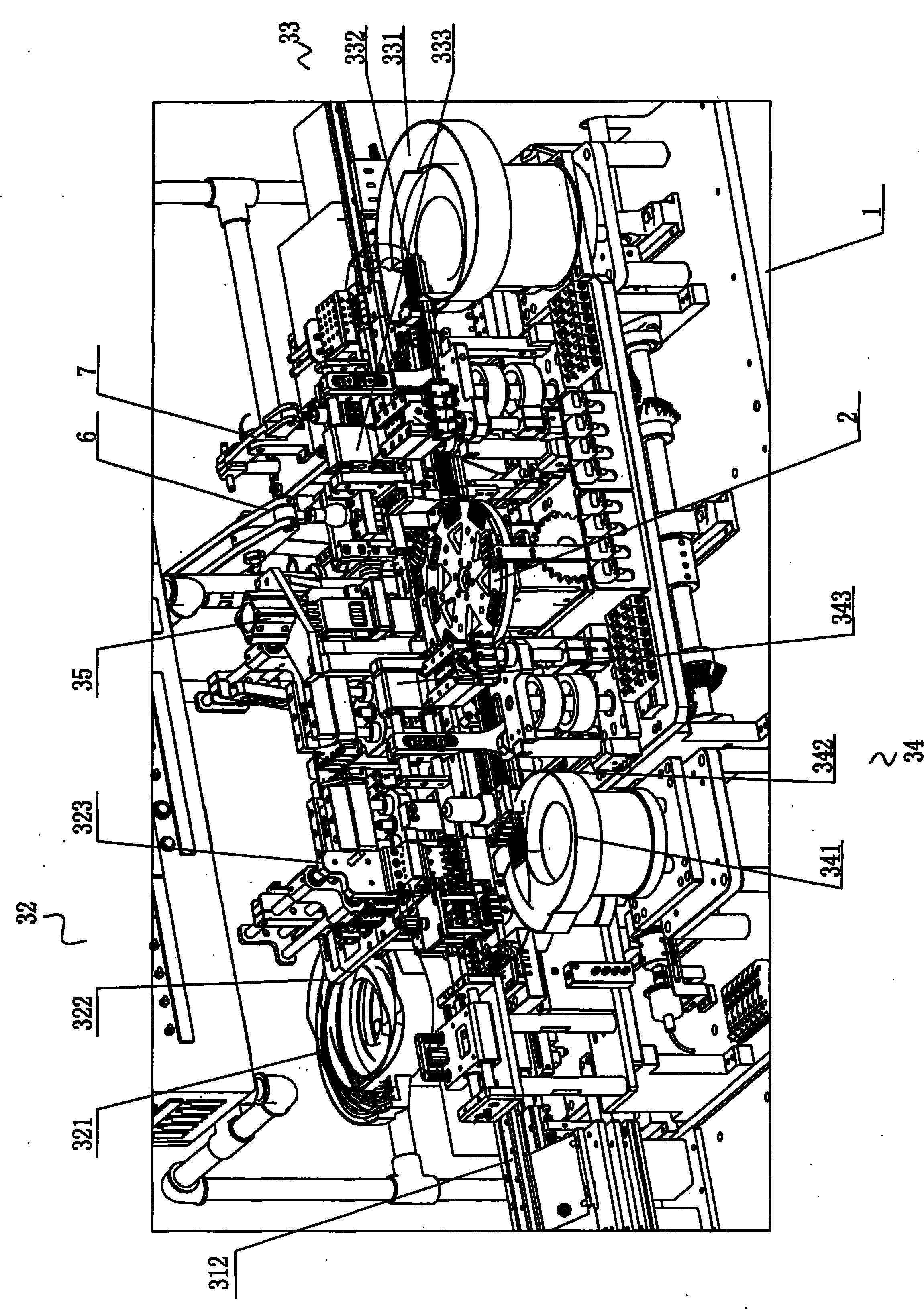

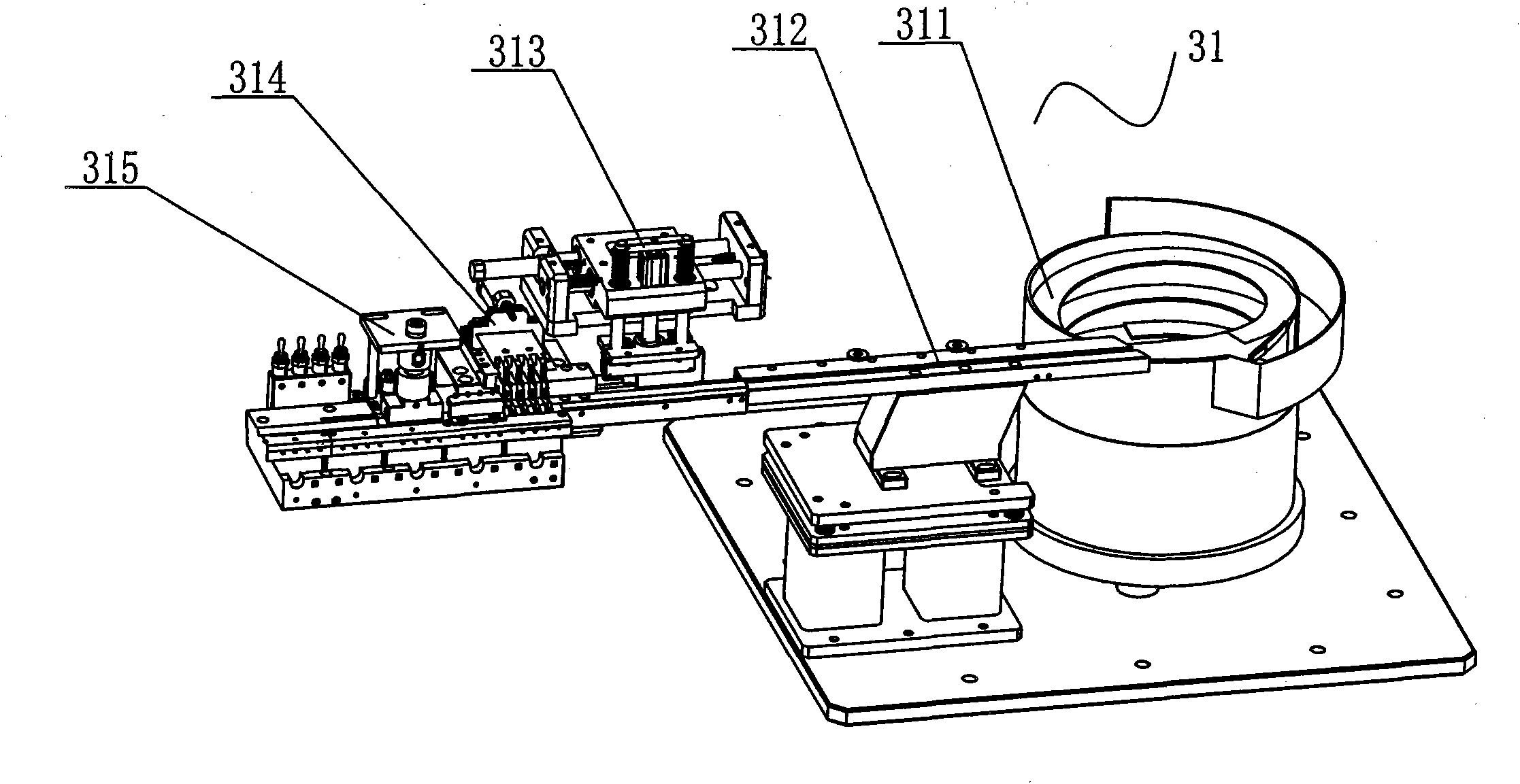

Automatic assembly machine for touch switch

InactiveCN101777448AAssembled preciselyRealize automatic assemblyElectric switchesEngineeringTransfer mechanism

The invention discloses an automatic assembly machine for a touch switch, which comprises a machine body. The machine body is provided with an assembly rotary disc and a feeding mechanism which feeds a body, an elastic sheet, a button and a cover plate assembly of the touch switch into assembly stations respectively. The automatic assembly machine also comprises a main conveying track for bearing the body, wherein a transferring mechanism which clamps the body and does regular vertical or horizontal feed movement is arranged below the main conveying track; a body feeding mechanism is arranged at the input end of the main conveying track; an elastic sheet feeding mechanism, a button feeding mechanism and a cover plate feeding mechanism are orderly arranged along the main conveying track; the assembly rotary disc is arranged between the button feeding mechanism and the cover plate feeding mechanism for assembling the button and the cover plate integrally; a third assembling mechanism is arranged on one side of the assembly rotary disc for assembling the touch switch assembly; and the mechanisms are connected with a main control circuit and is controlled by the main control circuit. The automatic assembly machine accurately and efficiently assemblies the touch switch through automatic assembling so as to save the production cost.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

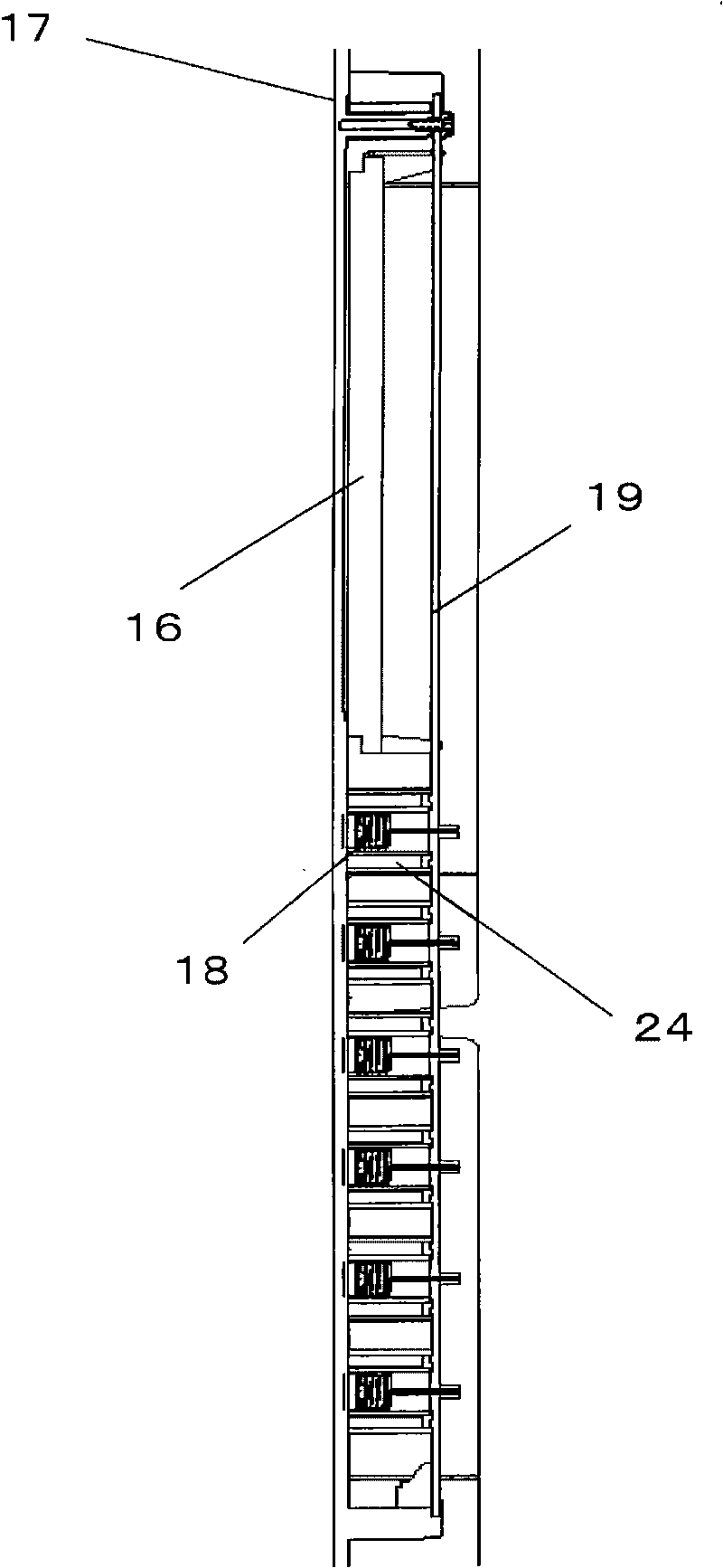

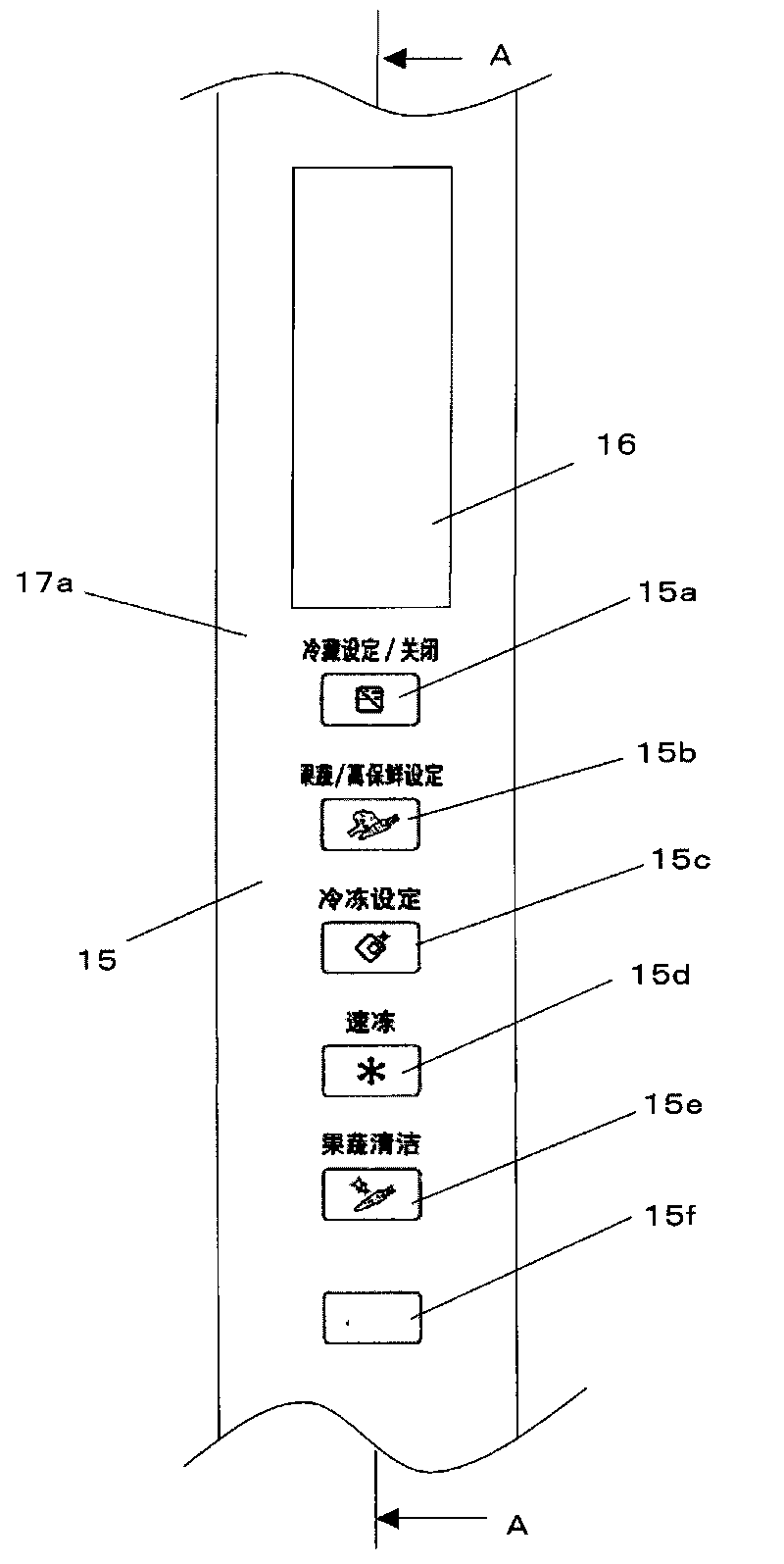

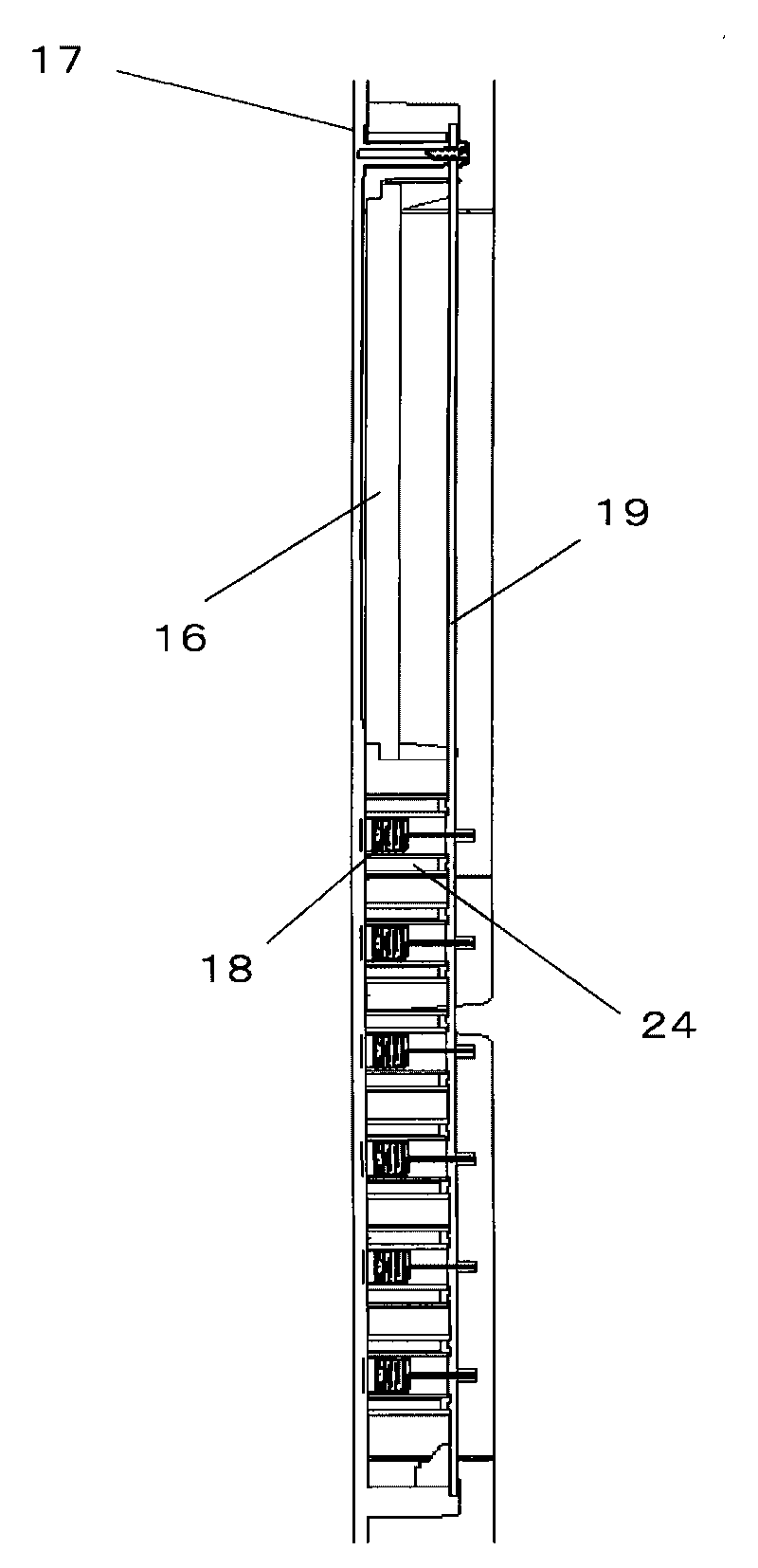

Touch switch

ActiveCN101741371AImprove reliabilityEasy to fixLighting and heating apparatusDomestic refrigeratorsEngineeringOperational stability

The invention provides a touch switch which can improve the operation stability and the reliability per se and also can ensure the operation convenience, the reliability and the appearance beauty of machinery equipment provided with the touch switch. The touch switch is internally provided with a box body (24) covering the periphery of an induction part (18), the induction part is connected with a connecting part (21) under a state that the upper surface (18a) of the induction part is higher than the upper surface (24c) of the box body, and the connecting part is an elastic part. After the box body is fixed on a printed substrate, the induction part after being connected with the connecting part is easy to be fixed on the printed substrate, and the difference of assembly operation also can be reduced. Because the induction part is arranged at the position protruding over the upper surface of the box body, tight attaching type fixation can be realized between a part arranged on the upper surface of the induction part and supplied for people to touch and the induction part, and the detection deviation of an electrostatic capacity can be lowered.

Owner:无锡松下冷机有限公司 +1

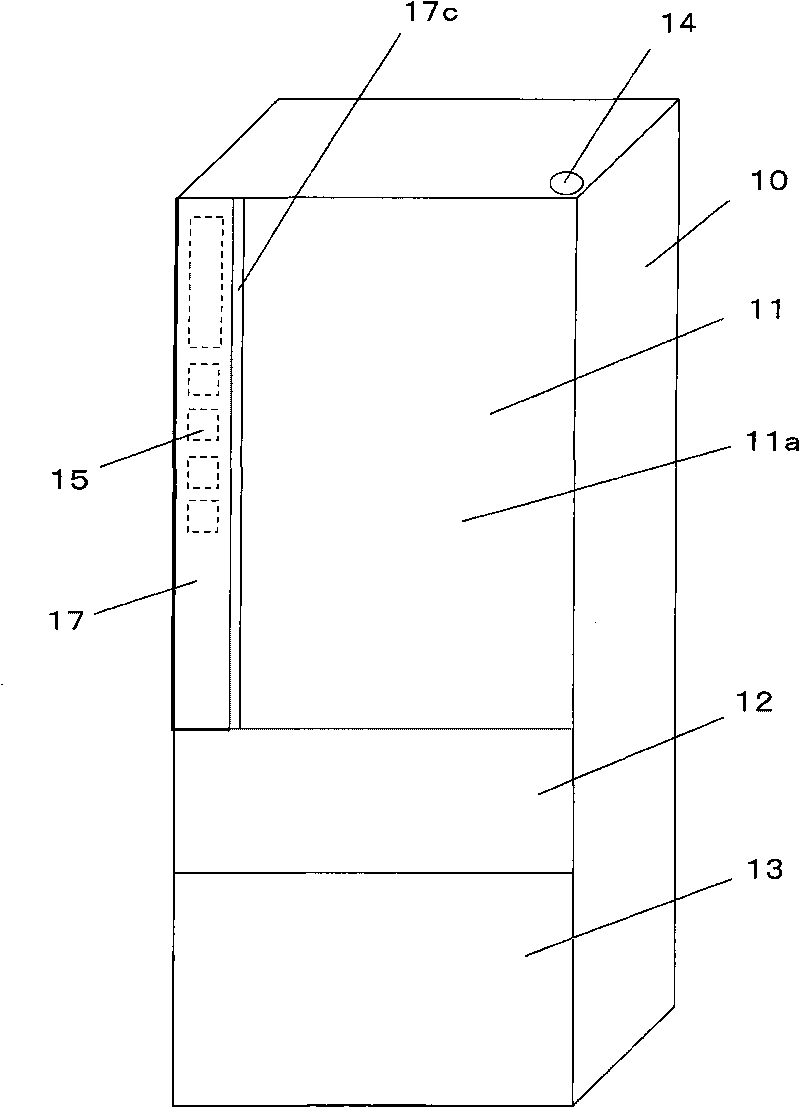

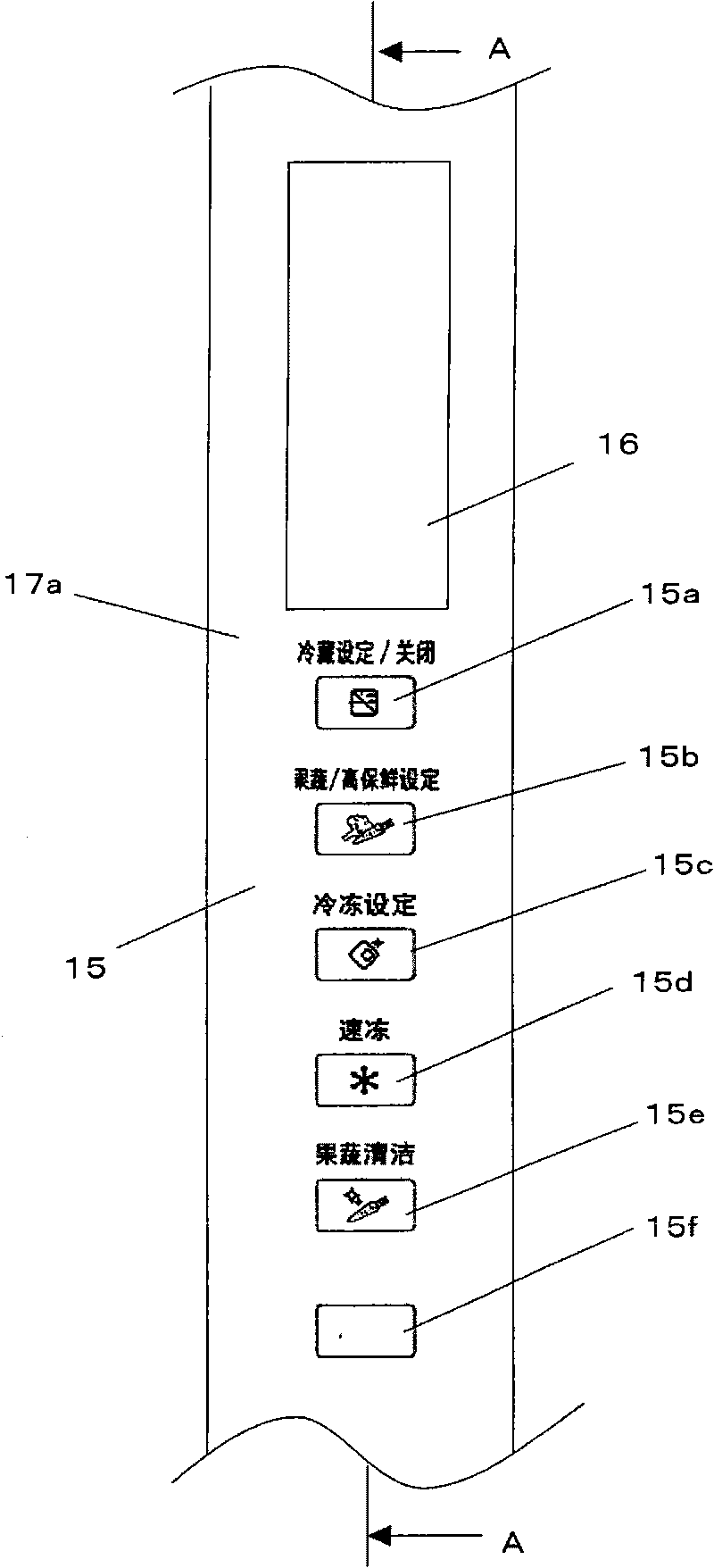

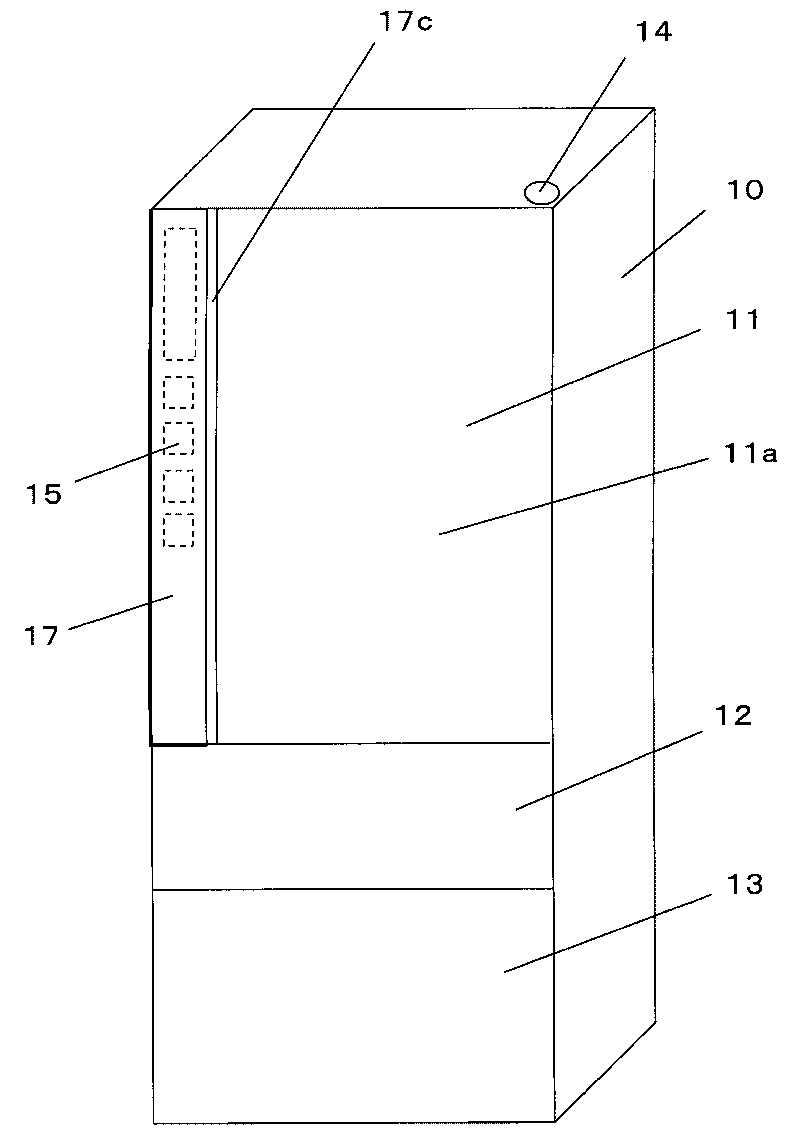

Refrigerator

ActiveCN101738051AEnsure operabilityEnsure reliabilityLighting and heating apparatusDomestic refrigeratorsRefrigerated temperatureTouch switch

The invention provides a refrigerator. Touch switches are arranged on a machine door of the refrigerator, the misoperation when the touch switches are touched with the contrary will of a user can be improved when the machine door is opened, and the operation when the touch switches are touched can be improved under the condition that the surface of the machine door is cleaned by cleaning cloth, and the like when the machine door is closed, therefore, the operation convenience and reliability as well as the appearance beauty can be ensured. In the refrigerator, a refrigerating chamber machine door (11) is provided with a plurality of touch switches (15) which set the chamber temperature and the functional operation by detecting the electrostatic capacity of a person; under the condition of touching the adjacent touch switches simultaneously within the set time, not all touched touch switches are available, however, the corresponding operation of the original touched touch switch is available, and the corresponding operation of the later touched touch switch is unavailable, therefore, the accurate operation control can also be carried out when the touch switches are touched by chance.

Owner:无锡松下冷机有限公司 +1

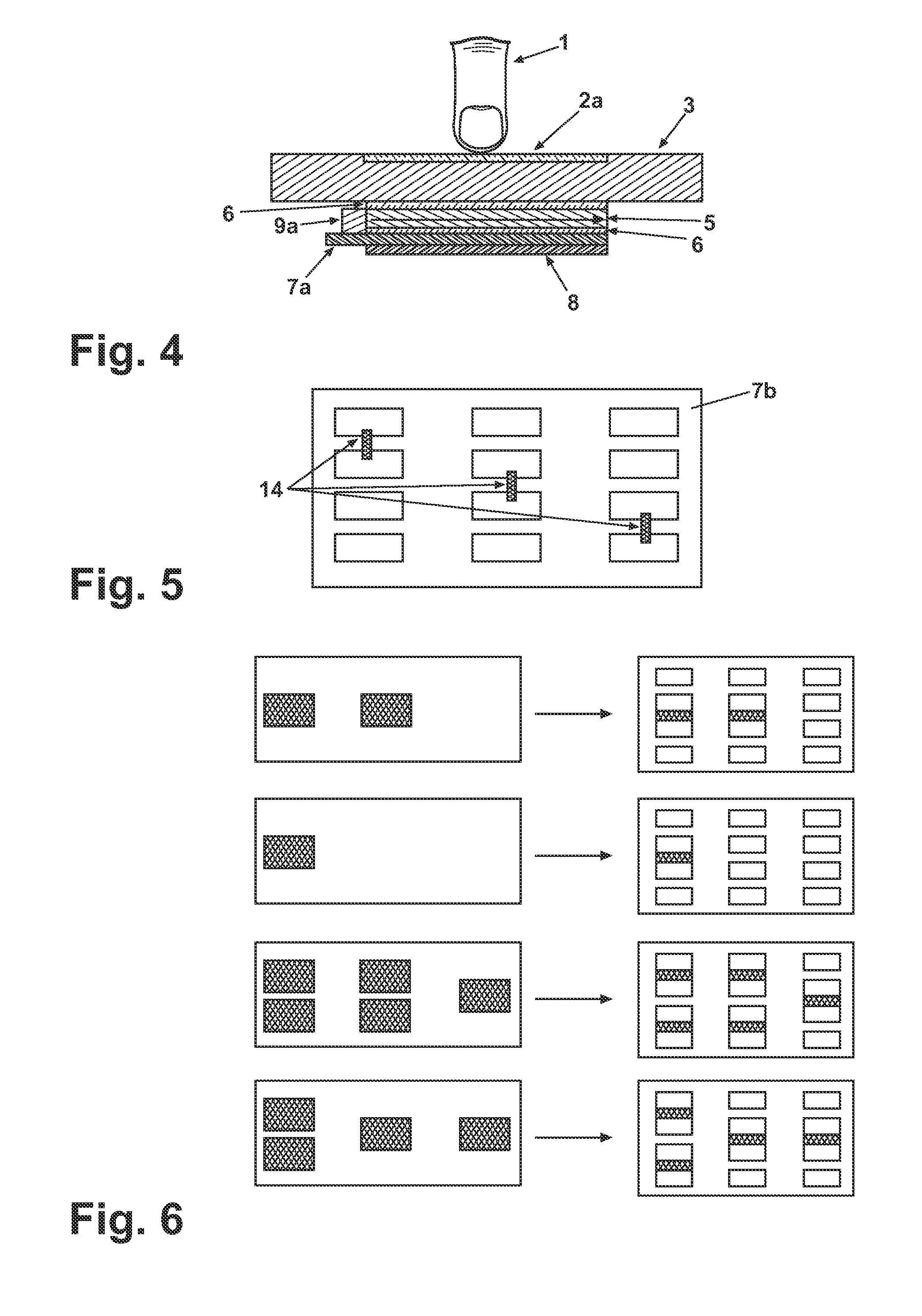

Touch switch layout and method for the control of a touch switch

InactiveUS6734377B2Low costCutting costsDomestic stoves or rangesLighting and heating apparatusTouch switchPower control

Owner:E G O ELEKTRO GERAETEBAU GMBH

LED driver touch switch circuit

InactiveUS20080198613A1Reduce in quantityLighting circuitsCompartment lightingDriver circuitUser input

A vehicular touch switch activated LED illumination circuit includes a LED illumination source for providing vehicle illumination. A touch switch antenna senses a user input for activating and deactivating the LED illumination source. An integrated circuit mounted to a printed circuit board for controlling the current provided to the LED illumination source. The integrated circuit is in communication with the touch switch antenna for detecting the user input. A driver circuit is mounted to the printed circuit board and is electrically coupled to the LED illumination source for driving the LED illumination source. The integrated circuit includes a battery voltage sensed input and a temperature sensed input for receiving sensed input signals to control a signal input to the driver circuit for variably controlling the current provided to the illumination source.

Owner:LEAR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com