Gel battery electrolyte and preparation method therefor

A colloidal battery and electrolyte technology, applied in the direction of lead-acid batteries, etc., can solve the problems of uneven electrolyte, low discharge capacity, short deep cycle service life, etc., achieve superior charge and discharge performance, solve sulfuric acid stratification, and cycle life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

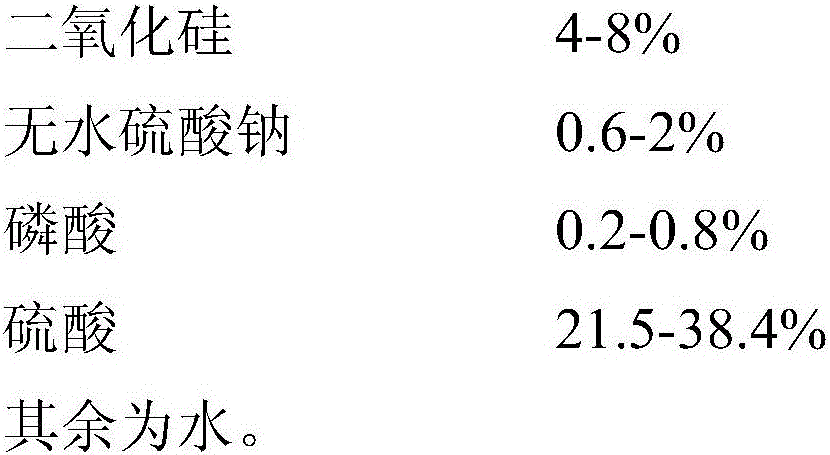

[0041] Gel battery electrolyte, the mass percentage is composed of:

[0042]

[0043] The silicon dioxide is prepared by a gas phase method, and the particle size of the silicon dioxide is 10-50nm.

[0044] Specifically prepared by the following steps:

[0045] (1) Mix silica and water, the mass ratio of silica and water is 1:5, configure colloidal mother liquor under high-speed shearing, the speed of high-speed shearing is 3500 rpm, and the shearing time is 5min ;

[0046] (2) the concentrated sulfuric acid that mass fraction is 98% is slowly added in water, the density of gained dilute sulfuric acid aqueous solution is 1.15g / ml, adds required amount of anhydrous sodium sulfate and phosphoric acid to obtain mixed solution;

[0047] (3) Add the obtained colloidal mother liquor into the mixed solution, stir rapidly at 4500 rpm for 10 minutes to obtain a finished product, and the density of the obtained finished colloidal battery electrolyte is 1.20 g / ml.

Embodiment 2

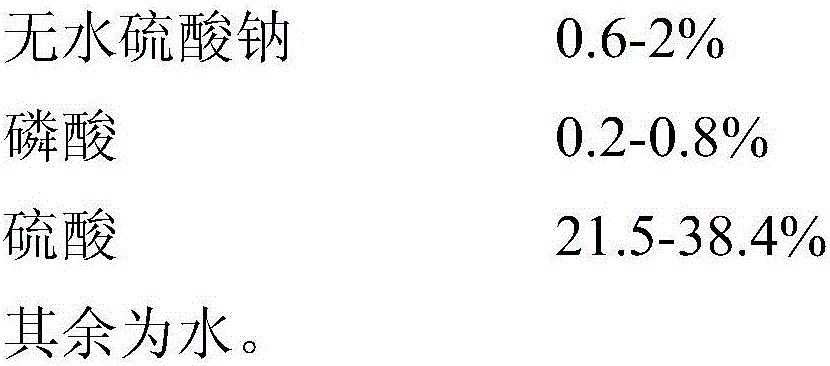

[0049] Gel battery electrolyte, the mass percentage is composed of:

[0050]

[0051] The silicon dioxide is prepared by a gas phase method, and the particle size of the silicon dioxide is 20-60nm.

[0052] Specifically prepared by the following steps:

[0053] (1) Mix silica and water, the mass ratio of silica and water is 1:6, configure the colloidal mother liquor under high-speed shearing, the speed of high-speed shearing is 4000 rpm, and the shearing time is 15min ;

[0054](2) the concentrated sulfuric acid that mass fraction is 98% is slowly added in water, the density of gained dilute sulfuric acid aqueous solution is 1.19g / ml, adds required amount of anhydrous sodium sulfate and phosphoric acid to obtain mixed solution;

[0055] (3) Add the obtained colloidal mother liquor into the mixed solution, stir rapidly at 5000 rpm for 15 minutes to obtain a finished product, and the density of the obtained finished colloidal battery electrolyte is 1.22 g / ml.

Embodiment 3

[0057] Gel battery electrolyte, the mass percentage is composed of:

[0058]

[0059] The silicon dioxide is prepared by a gas phase method, and the particle size of the silicon dioxide is 15-38nm.

[0060] Specifically prepared by the following steps:

[0061] (1) Mix silica and water, the mass ratio of silica and water is 1:8, configure the colloidal mother liquor under high-speed shearing, the speed of high-speed shearing is 4500 rpm, and the shearing time is 25min ;

[0062] (2) the concentrated sulfuric acid that mass fraction is 98% is slowly added in water, the density of gained dilute sulfuric acid aqueous solution is 1.19g / ml, adds required amount of anhydrous sodium sulfate and phosphoric acid to obtain mixed solution;

[0063] (3) Add the obtained colloidal mother liquor into the mixed solution, stir rapidly at 5000 rpm for 15 minutes to obtain a finished product, and the density of the obtained finished colloidal battery electrolyte is 1.25 g / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com