Concrete anti-freezing and anti-cracking agent

An anti-cracking agent and concrete technology, applied in the field of concrete anti-freezing and anti-cracking agent, can solve problems such as poor anti-freezing and anti-cracking performance, and achieve the effects of improving waterproof and impermeability, improving compactness and strength, and increasing compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The first step, drying: Weigh an appropriate amount of muscovite powder (or phlogopite, which has the same effect as muscovite), and dry it in an oven at 105 °C for 48 hours to remove moisture; the above muscovite powder is a commercially available micron-sized flake powder material, where SiO 2 The content is 62.4%, Al 2 o 3 The content is 20.4%.

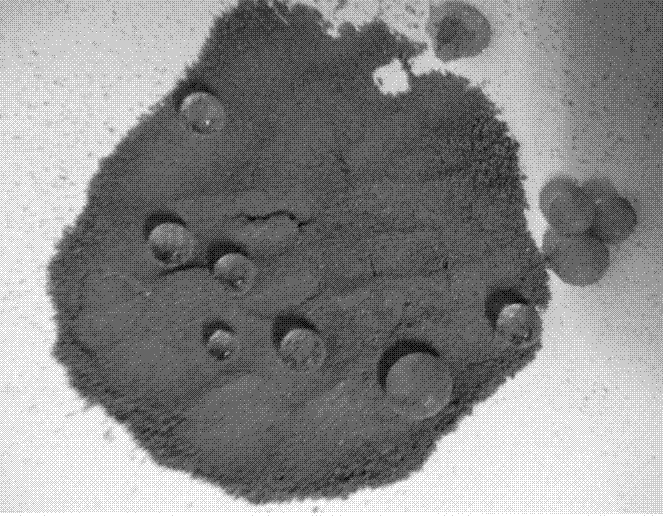

[0021] The second step, pulverization: further pulverize the above-mentioned dried muscovite powder with a high-fineness pulverizer to obtain a flake micropowder with a thickness of about 2.5 μm in a microscopic state. When sieved with an 80 μm cement negative pressure sieve, the remaining Below 15%.

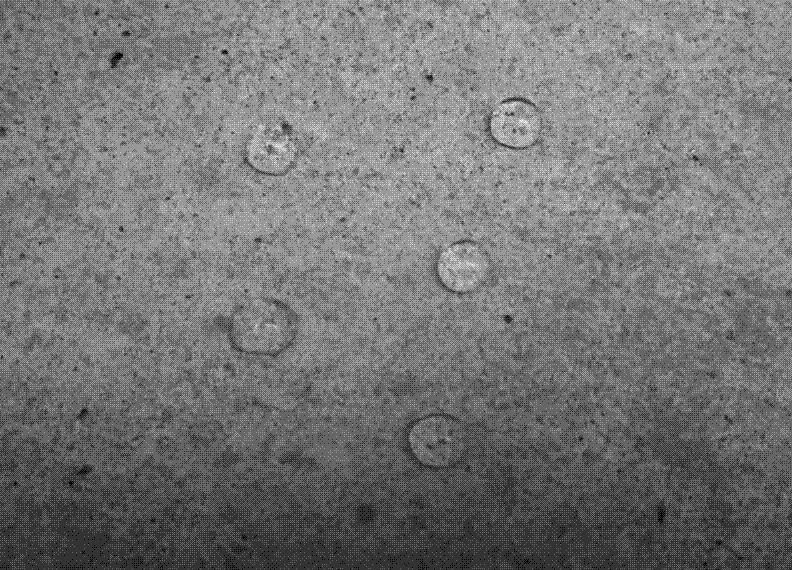

[0022] The third step, hydrophobic modification treatment: take 98 parts by weight of the muscovite powder prepared in the second step, add 1 part by weight of KH-550 silane coupling agent and 1 part by weight of methyl silicone oil, and send it to 150 ° C Perform high-temperature modification treatment in the powder surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com