Patents

Literature

62 results about "Phlogopite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phlogopite is a yellow, greenish, or reddish-brown member of the mica family of phyllosilicates. It is also known as magnesium mica. Phlogopite is the magnesium endmember of the biotite solid solution series, with the chemical formula KMg₃AlSi₃O₁₀(F,OH)₂. Iron substitutes for magnesium in variable amounts leading to the more common biotite with higher iron content. For physical and optical identification, it shares most of the characteristic properties of biotite.

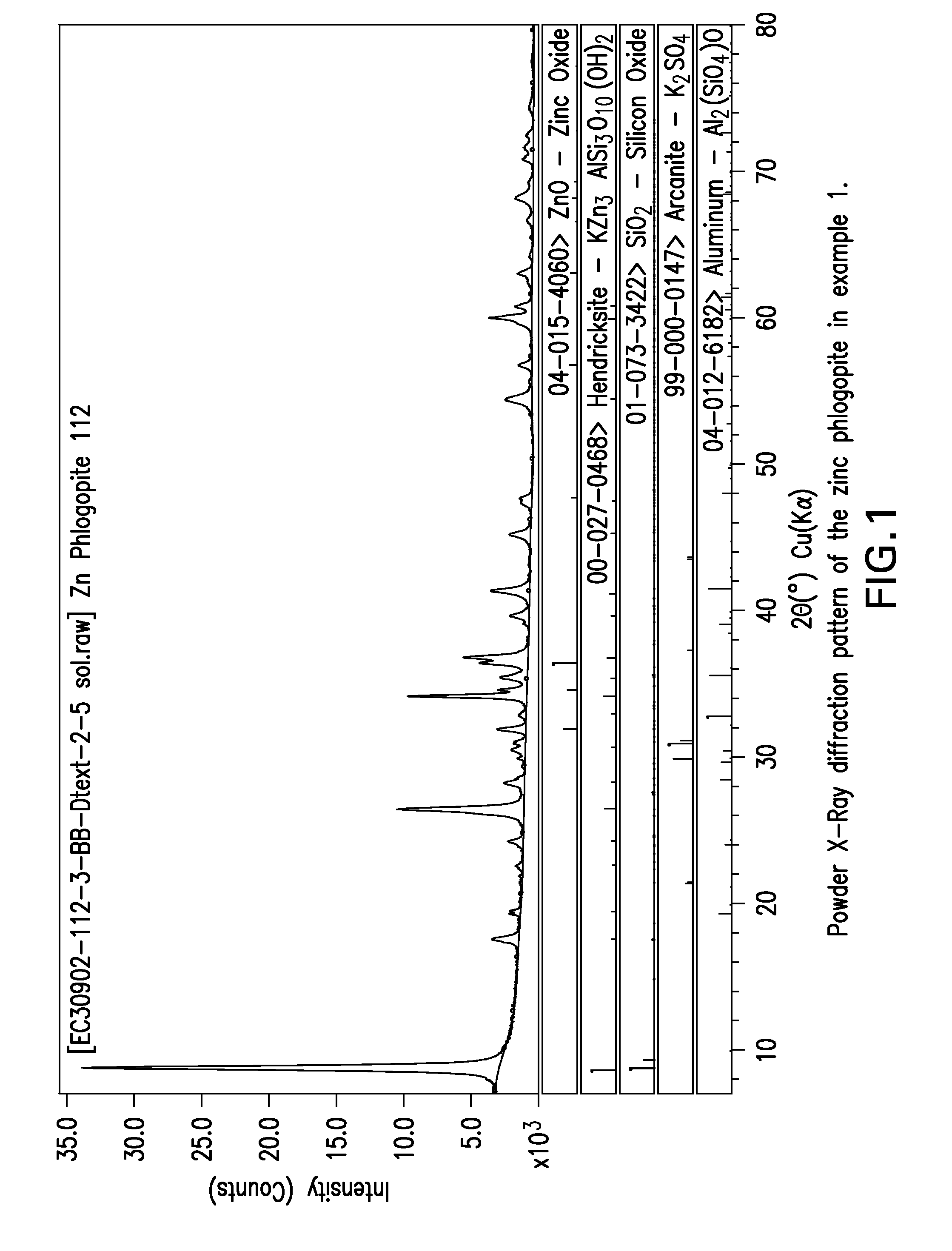

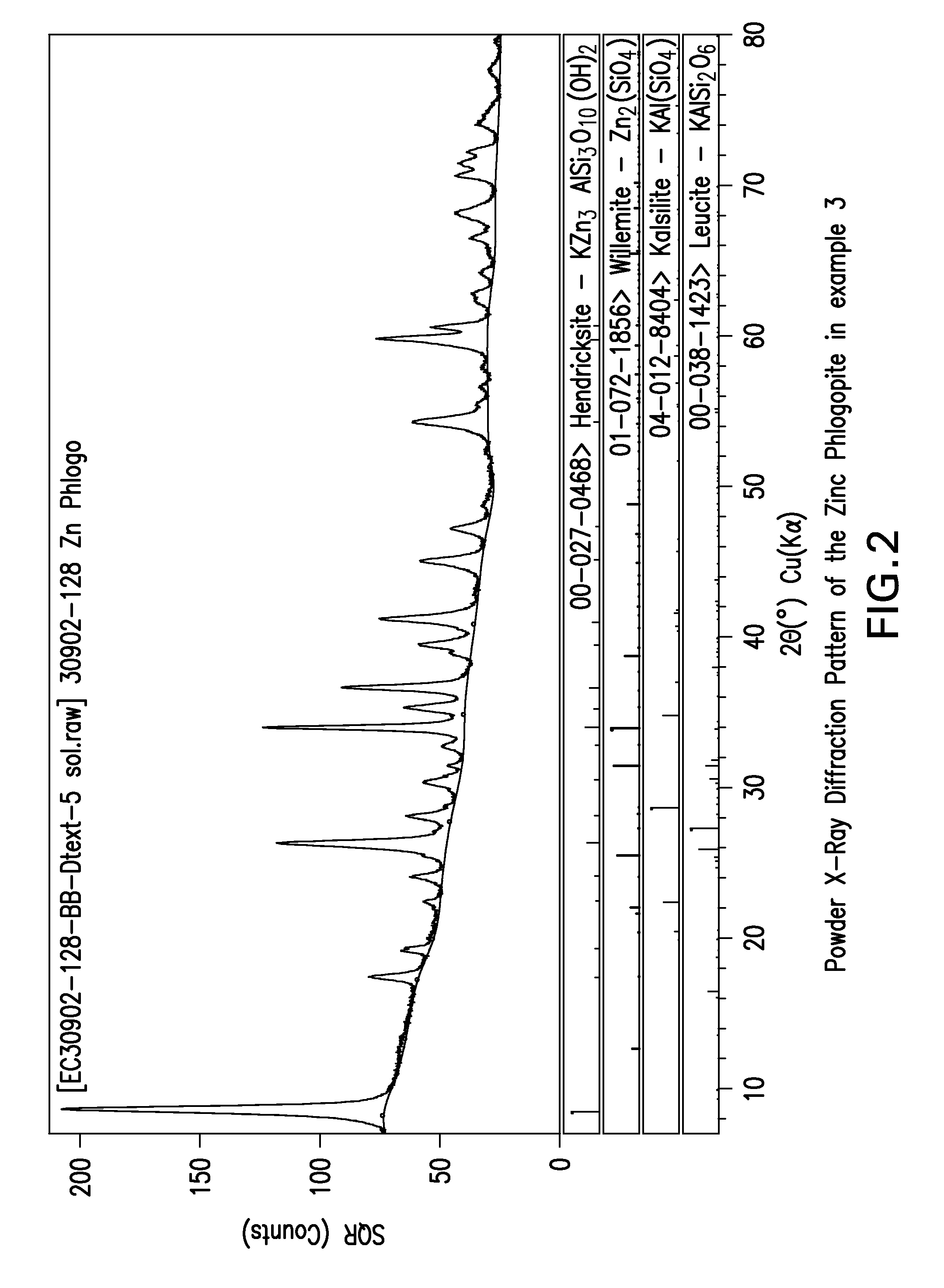

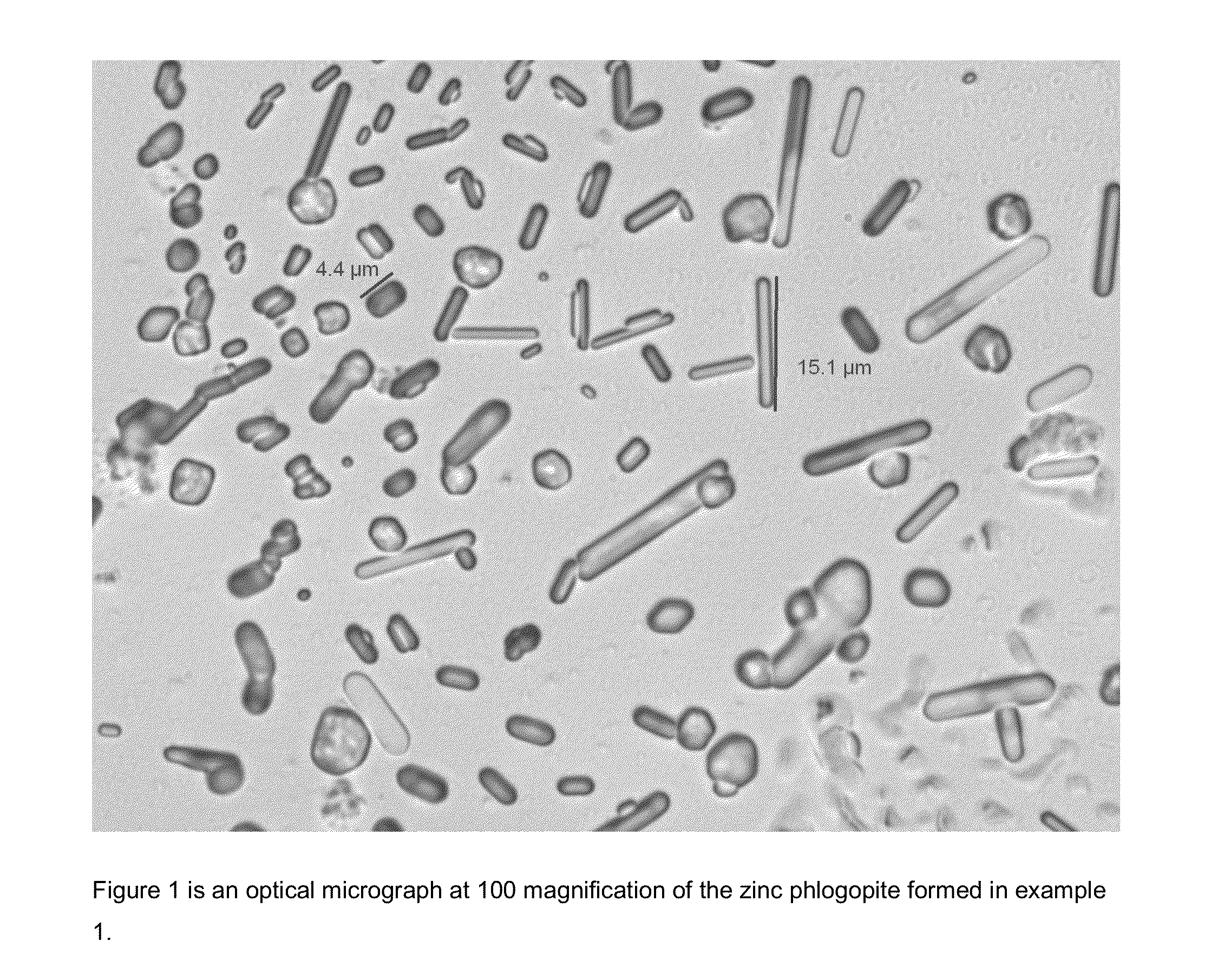

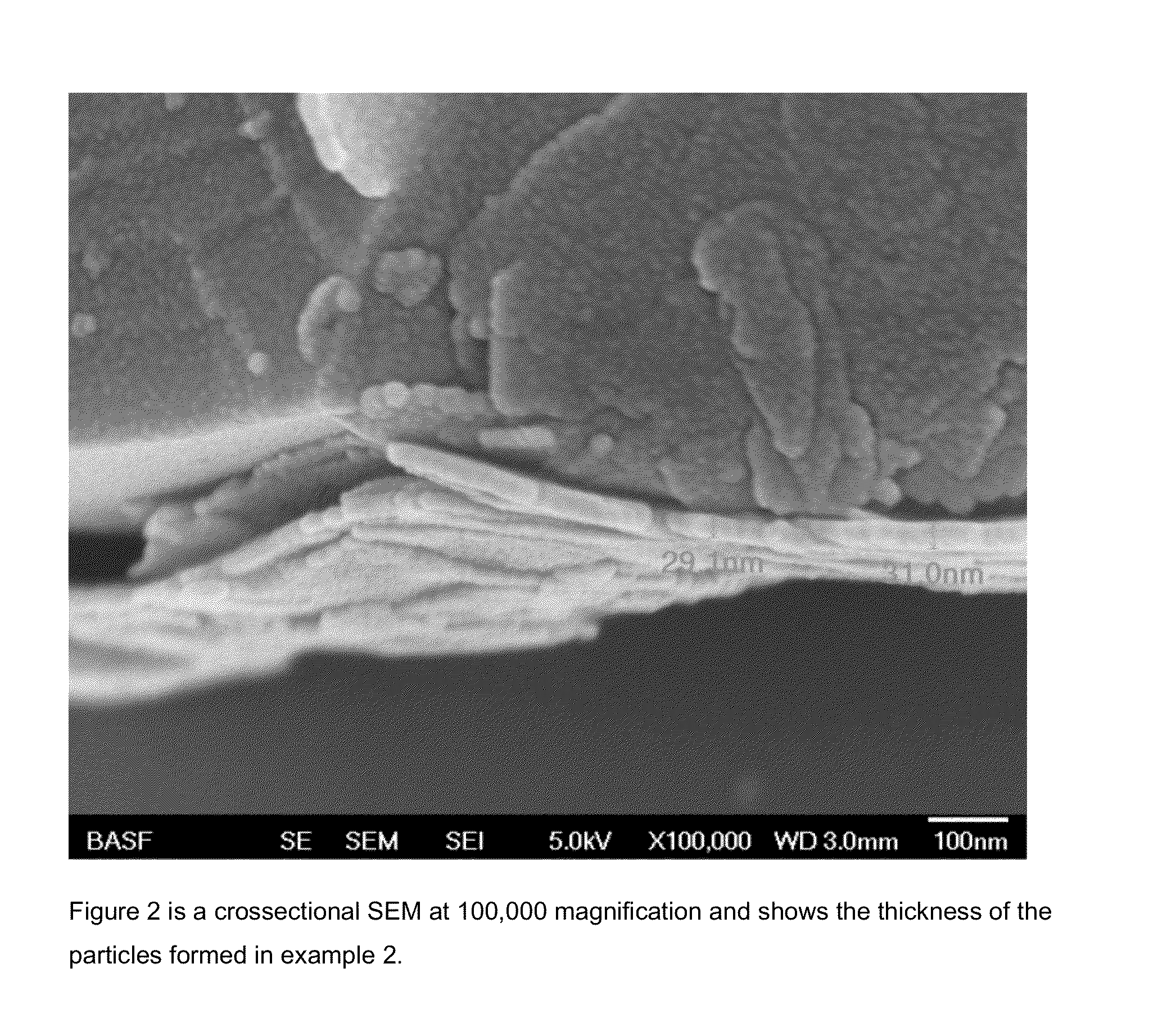

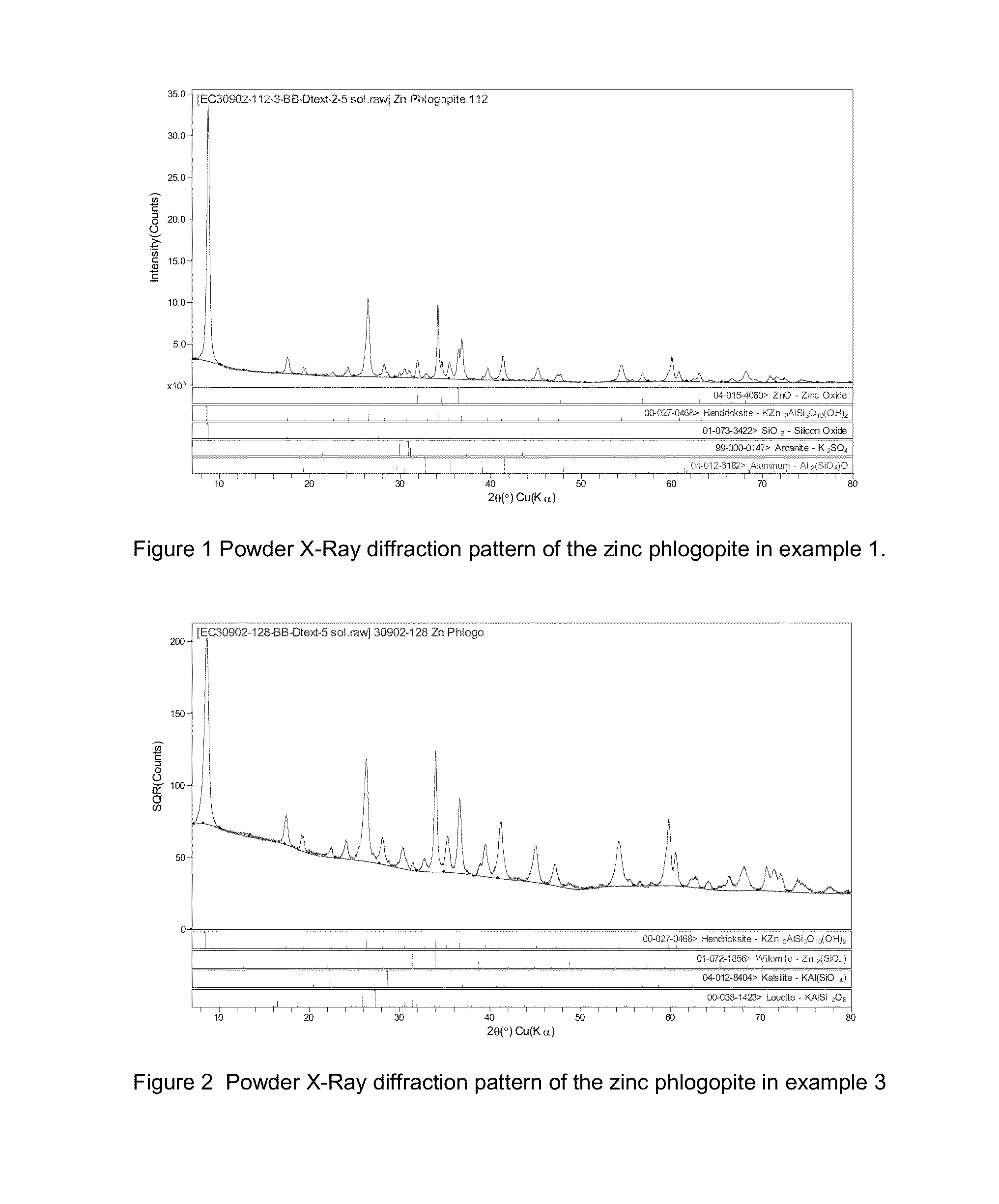

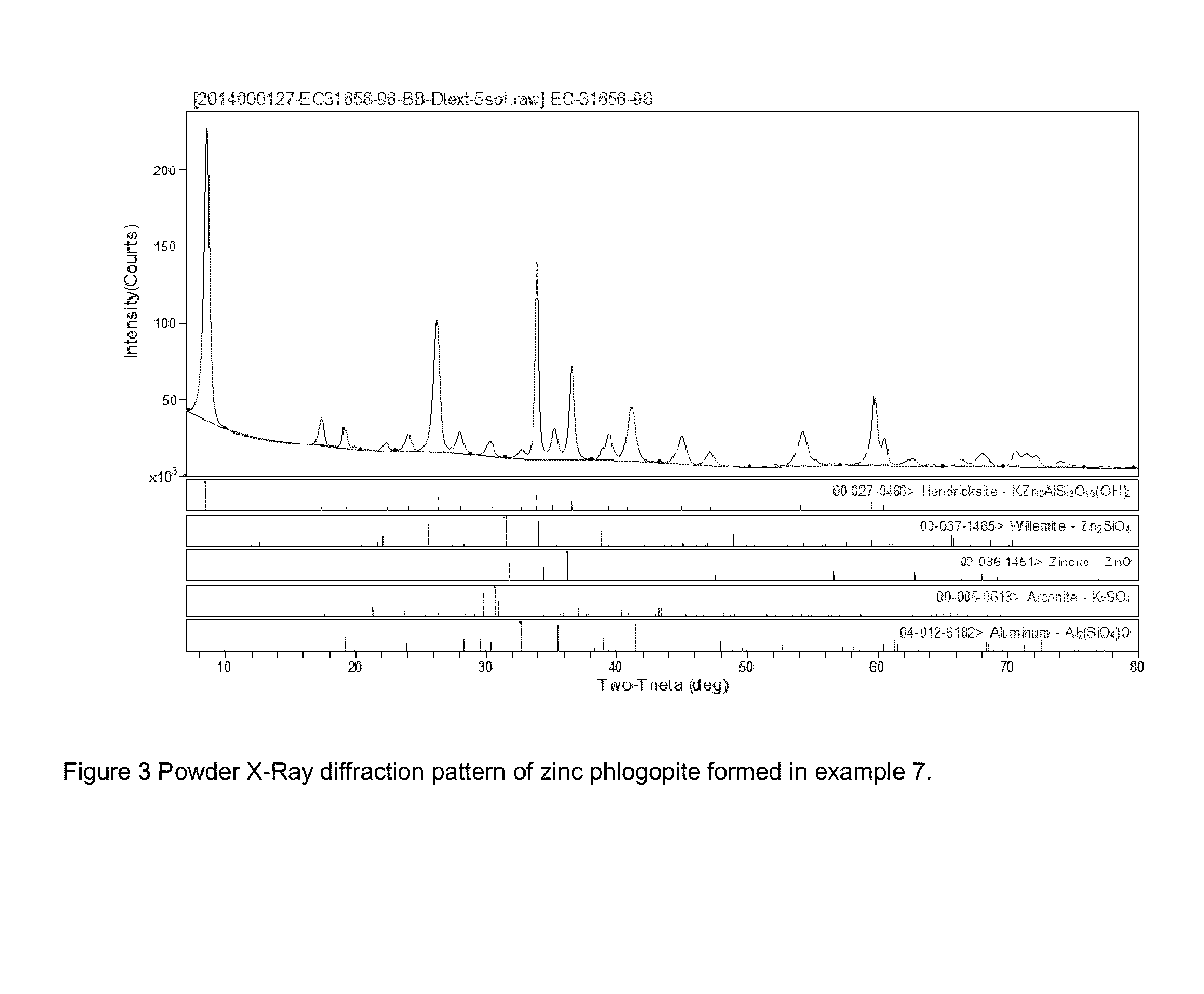

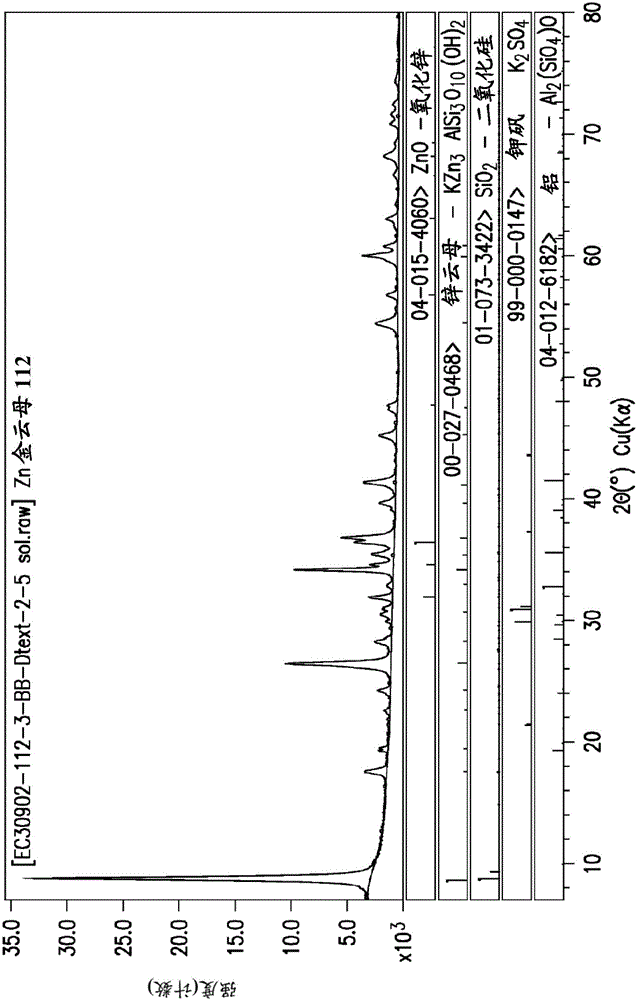

Synthetic Zinc Phlogopite via Hydrothermal Preparation

This invention relates to synthetically derived zinc phlogopite platelets, of superior aspect ratio, effect pigments comprising such synthetically derived platelets and methods of forming said platelets. More specifically the disclosure describes an improved hydrothermal synthesis of zinc phlogopite suitable as a platelets for interference pigments, barrier and flame retardant applications.

Owner:BASF AG

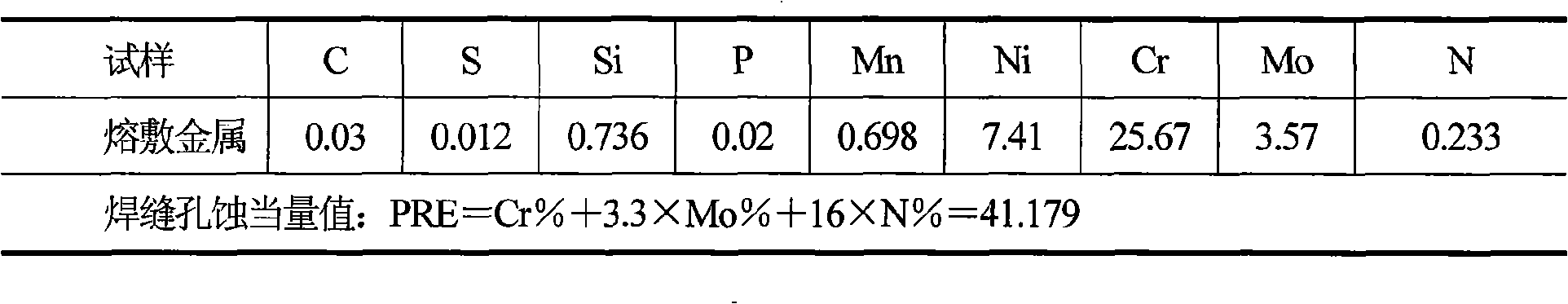

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

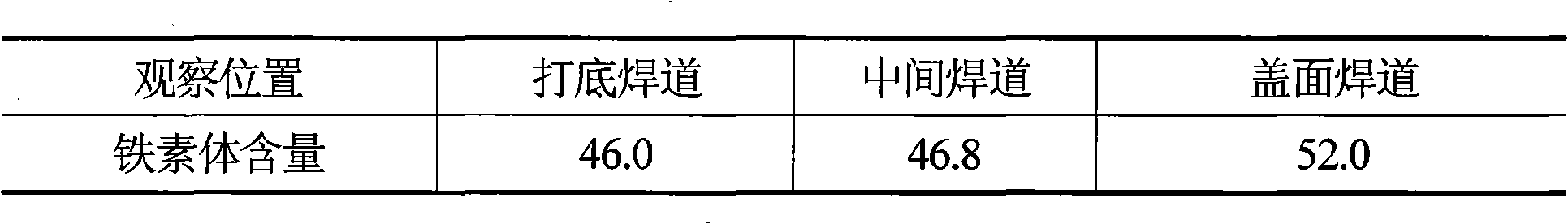

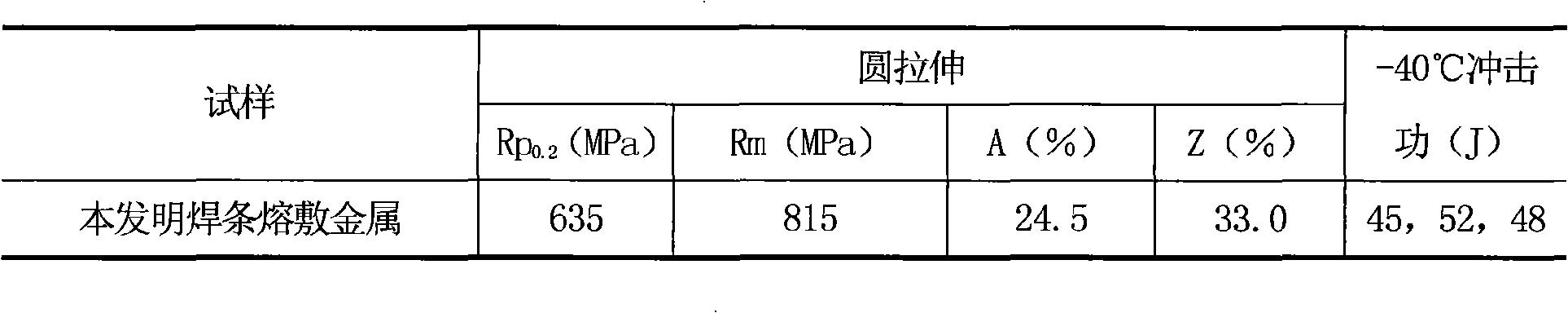

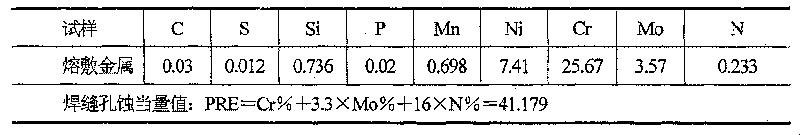

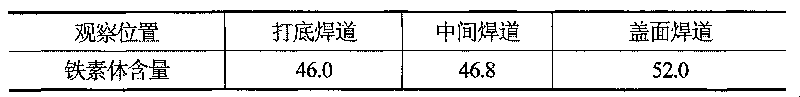

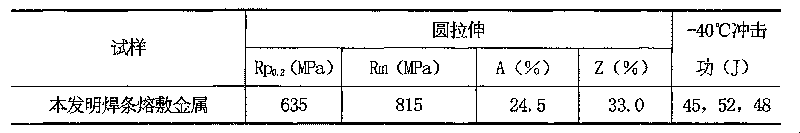

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Riser heating and insulating agent

InactiveCN101798233AHas the double effect of heat preservationWith feverFoundry mouldsFoundry coresCarbon graphiteSteel casting

The invention discloses a riser heating and insulating agent, which comprises the following components in percentage by weight: 5 to 35 percent of Al, 10 to 25 percent of AlN, 3 to 20 percent of low-carbon graphite, 5 to 25 percent of magnesia-alumina spinel, 5 to 15 percent of quartz, 10 to 30 percent of ferric oxide powder, 5 to 20 percent of corundum, 5 to 10 percent of organosilicon phlogopite, and 1 to 10 percent of MgO; and the riser heating and insulating agent is prepared by the following processes: crushing, pulverizing, mixing, pelletizing, drying, and the like. The riser heating and insulating agent has double effects of heating and insulating, and has good insulating effect. Because the riser heating and insulating agent has a granular appearance, dust and smoke are not generated in the using process, and the environment is not polluted. Due to the adoption of the low-carbon graphite, castings do not have carburizing phenomenon, and the molten steel is not polluted. The riser heating and insulating agent is particularly applied to open risers of low carbon steel large-scale steel castings and stainless steel castings with the weight of over 80 tons.

Owner:HENAN UNIV OF SCI & TECH

Fluoro phlogopite pearlescent pigment and method for making same

Disclosed is a kind of fluorine bronze mica nacreous pigments produced by artificial synthetic fluorine bronze mica, hydrolyzing the titanium dioxide completely and covering on the mica cloth in the glass lining autoclave, burning and getting the extraordinary nacreous pigments with high weatherability. The product is characterized by the high brightness, fire resistance which can reach as high as 1100DEG C, chemical stability, non-toxic, non-odour, flame-proof, acid and alkali-resisting, resistance to ultraviolet radiation, resistance to chemical solvent, non-conductive, and is adapted for special functionality textured paint application in space, navigation, automobile, ceramics and cosmetics and so on.

Owner:刘国忠

Welding electrode for welding -50 DEG C low-temperature pressure container steel

InactiveCN104400246AStable mechanical propertiesImprove toughnessWelding/cutting media/materialsSoldering mediaFerrosiliconRutile

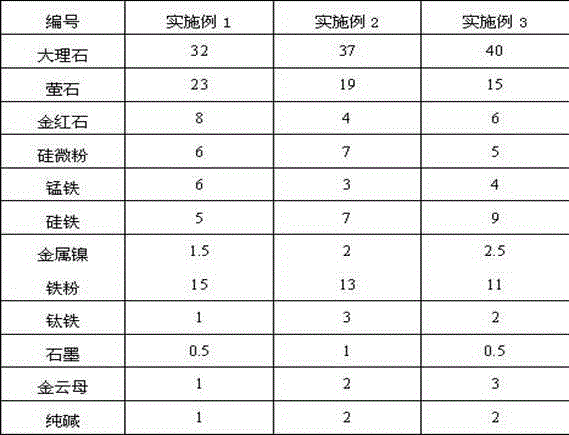

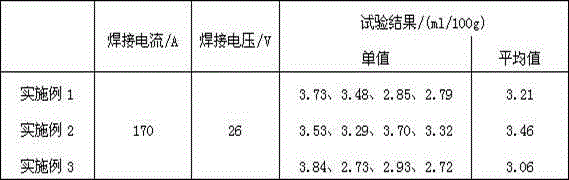

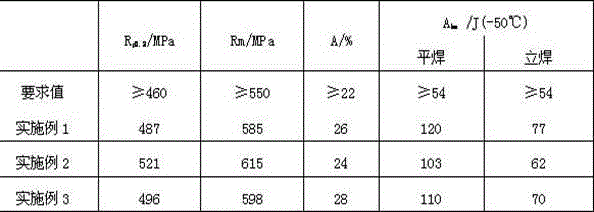

The invention discloses a welding electrode for welding -50 DEG C low-temperature pressure container steel. A core wire of the welding electrode is H08E of low S and P; a cover is prepared by the following components in parts by weight: 32-40 parts of marbles, 15-23 parts of fluorite, 4-8 parts of rutile, 5-7 parts of silica powder, 11-15 parts of iron powder, 5-9 parts of silicon iron, 3-6 parts of ferromanganese, 1-3 parts of ferrotitanium, 1.5-2.5 parts of metal nickel, 1-3 parts of phlogopite, 1-2 parts of sodium carbonate, and 0.5-1.0 part of graphite; all the components of the cover are evenly mixed, and 3.2 M pure sodium water glass of 24 weight% by the total weight of the components is added for mixing to prepare the cover; the rest production process of the welding electrode is performed by a conventional technology; the heat treatment is performed after the welding; and the temperature of 620 DEG C is keep for 1 hour, so that the mechanical performance is stable, the tensile strength reaches 560-620 Mpa at room temperature, and the -50 DEG C V-shaped gap impact power reaches above 110 J to satisfy the welding of the -50 DEG C low-temperature pressure container steel.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

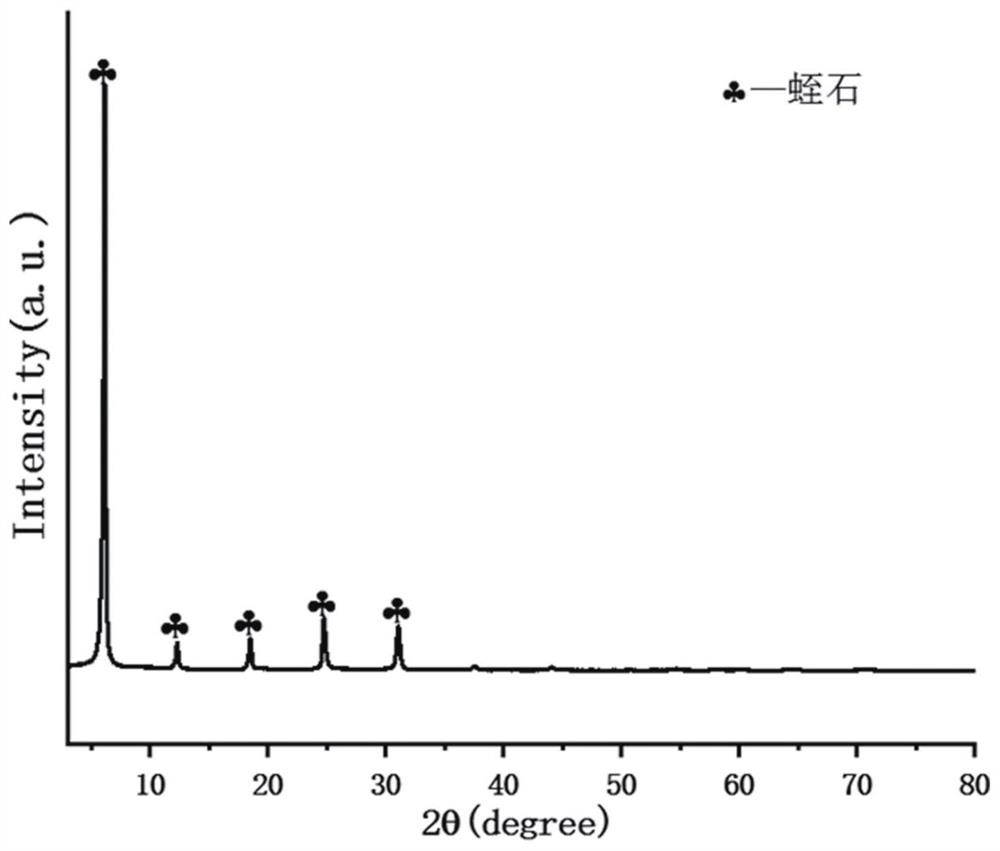

Process for producing KMg3(AlSi3O10)F2 crystal powder with wet-process synthesis

The invention discloses a method for preparing synthesized KMg3(AlSi3O10)F2 crystal powder through a wet process. The method comprises the following steps: (1) crushing synthesized fluorophlogopite with the particle diameter of more than 0.85 millimeters, and using an ore washer for scrubbing and sieving so as to remove impurities, wherein the scrubbing hydraulic pressure is between 0.15 and 0.2 MPa; (2) making the scrubbed materials enter a pulper for pulping, wherein the pulping hydraulic pressure is between 5 and 7 MPa; (3) performing sieve classification on the obtained materials by pulping into three materials with three kinds of particle diameter, namely the materials with the particle diameter of more than 0.25 millimeter, the materials with the particle diameter of between 0.25 and 0.125 millimeter and the materials with the particle diameter of less than 0.125 millimeter, and performing pressure filtration on the three materials respectively, wherein the water content of the materials after pressure filtration is between 31 and 40 weight percent; (4) using a wheel mill to perform fine grinding and sizing on the three materials respectively, wherein the rolling gap is between 10 and 40 millimeters, the sizing is performed in a group of sizing pools, the materials with the particle diameter of more than 0.25 millimeter are subjected to rolling and sizing to generate powder products with the particle diameter of less than 100 mu m, the materials with the particle diameter of between 0.25 and 0.125 millimeter are subjected to rolling and sizing to generate powder products with the particle diameter of less than 250 mu m, and the materials with the particle diameter of less than 0.125 millimeter are subjected to rolling and sizing to generate powder products with the particle diameter of less than 160 mu m; and (5) using a plate-and-frame filter press to perform pressure filtration on the products after sizing, making the water content of the products be less.

Owner:鹿寨七色珠光云母材料有限公司

Method for preparing brown mica powder

InactiveCN104609435APreserve lamellar structurePreserve the large diameter-thickness ratioAluminium silicatesPhlogopiteGranularity

The invention discloses a method for preparing brown mica powder, and belongs to the field of methods for preparing mica. The method for preparing brown mica powder comprises the following steps: (1), material selection, (2), wet splitting, (3), rolling crushing, (4), screening and flotation, and (5) filtering and drying. For the brown mica powder, the granularity D50 is 10 <+ / -2>(mum), the degree of whiteness is more than 60, the moisture is less than 1%, the PH value is 6 to 8, the bulk density is less than 0.17 g / cm<3>, the diameter-to-thickness ratio is more than 90; the content of heavy metals is as follows: Pb is less than 5, As is less than 1, Hg is ND, Cd is ND, Sb is ND, and Ni is ND. The method for preparing the brown mica powder has the advantages that the prepared brown mica powder has elasticity, remains the characteristics of sheet structure, large diameter-to-thickness ratio, high refractive index, high purity and high glossiness, and is fine in appearance, smooth in hand-feeling, and natural in color.

Owner:ANHUI HENGHAO SCI & TECH

A nickel-based welding rod

InactiveCN101745759BImprove pressure coatingIncrease the amount of controlWelding/cutting media/materialsSoldering mediaSolid componentArc stability

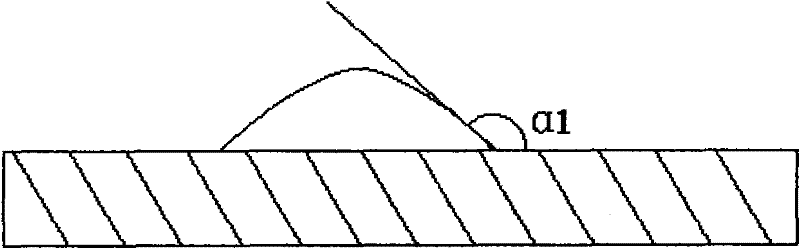

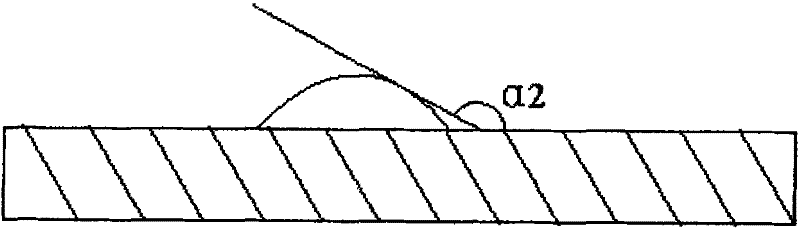

The invention relates to a welding material technology, and specifically introduces a nickel-based electrode. The electrode uses SNi6062 welding wire as the welding core, and the mass content of the solid component of the coating is: rutile: 36-50%, titanium dioxide: 2-7%, Fluorite: 20-30%, cryolite 3-8%, phlogopite: 2-4%, zircon sand: 2-4%, soda ash 0.5-1.5%, metal manganese: 5-10%, Ti 25- 35% ferro-titanium: 2-4%, ferro-niobium containing 50-60% Nb: 2-4%. The nickel-based electrode of the present invention has excellent production process performance, smooth electrode surface, high yield, and stable eccentricity; stable arc during welding, basically no spatter, good slag removal, and excellent electrode operability; beautiful weld shape and moderate bead height , moderate weld wetting angle; moderate strength and plasticity of deposited metal.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

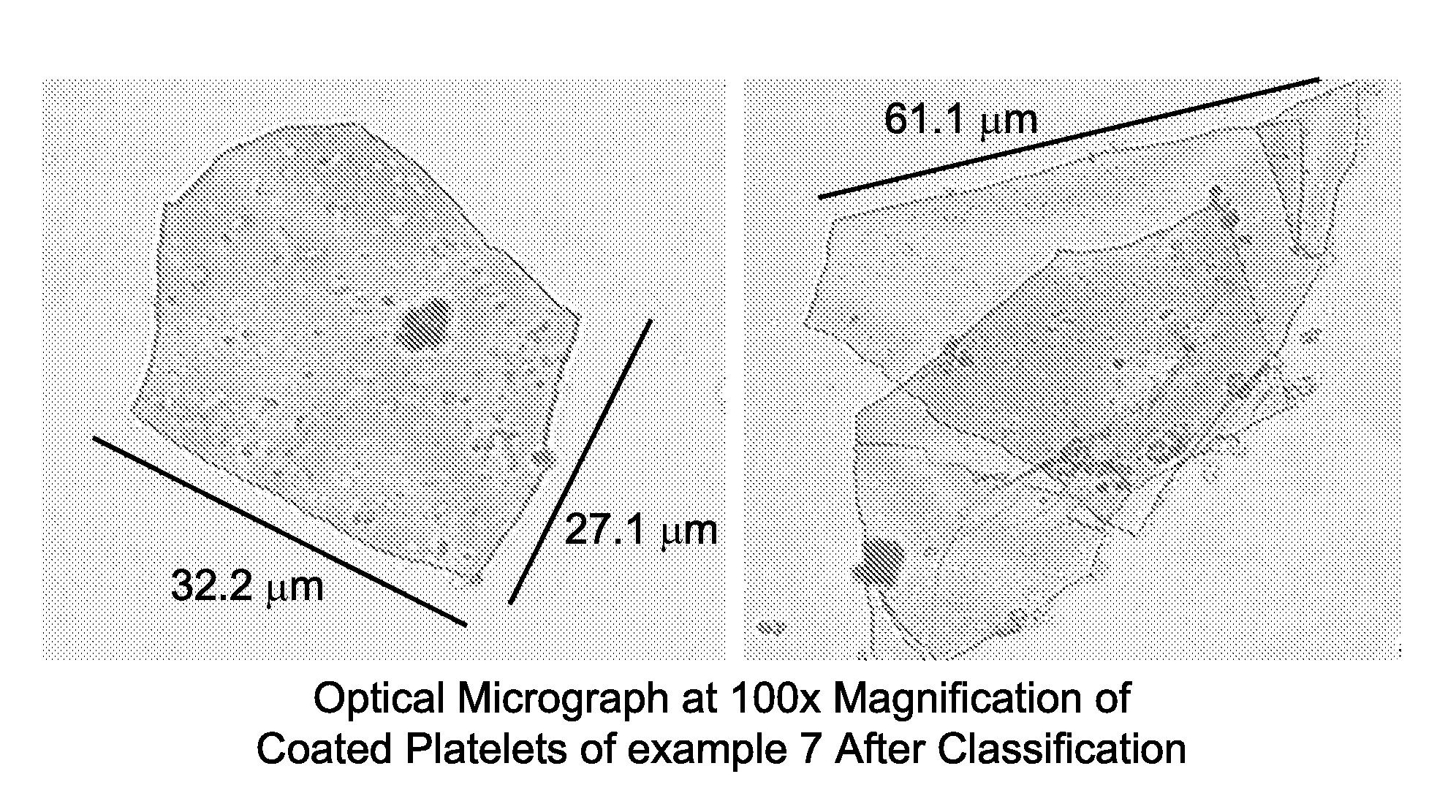

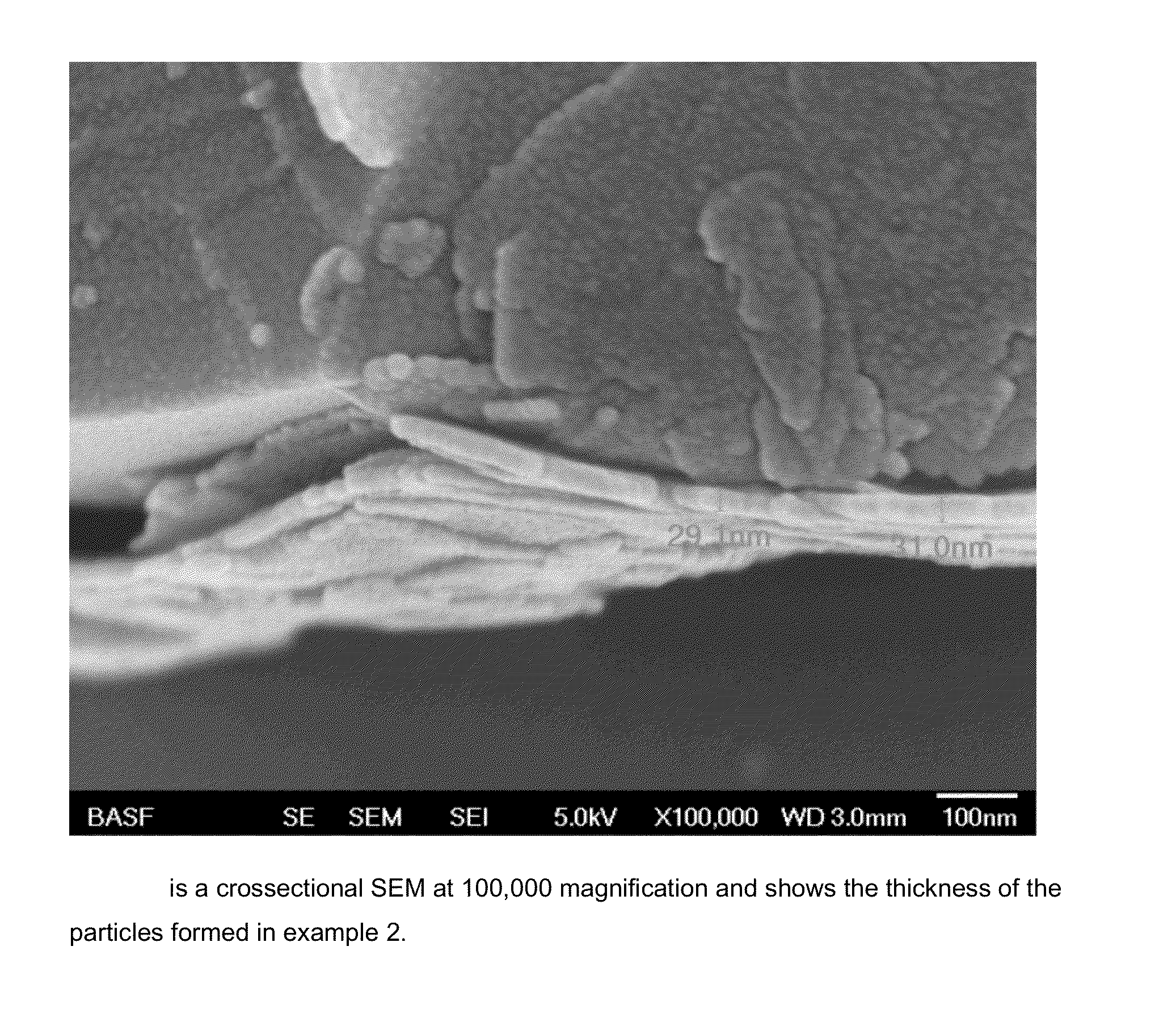

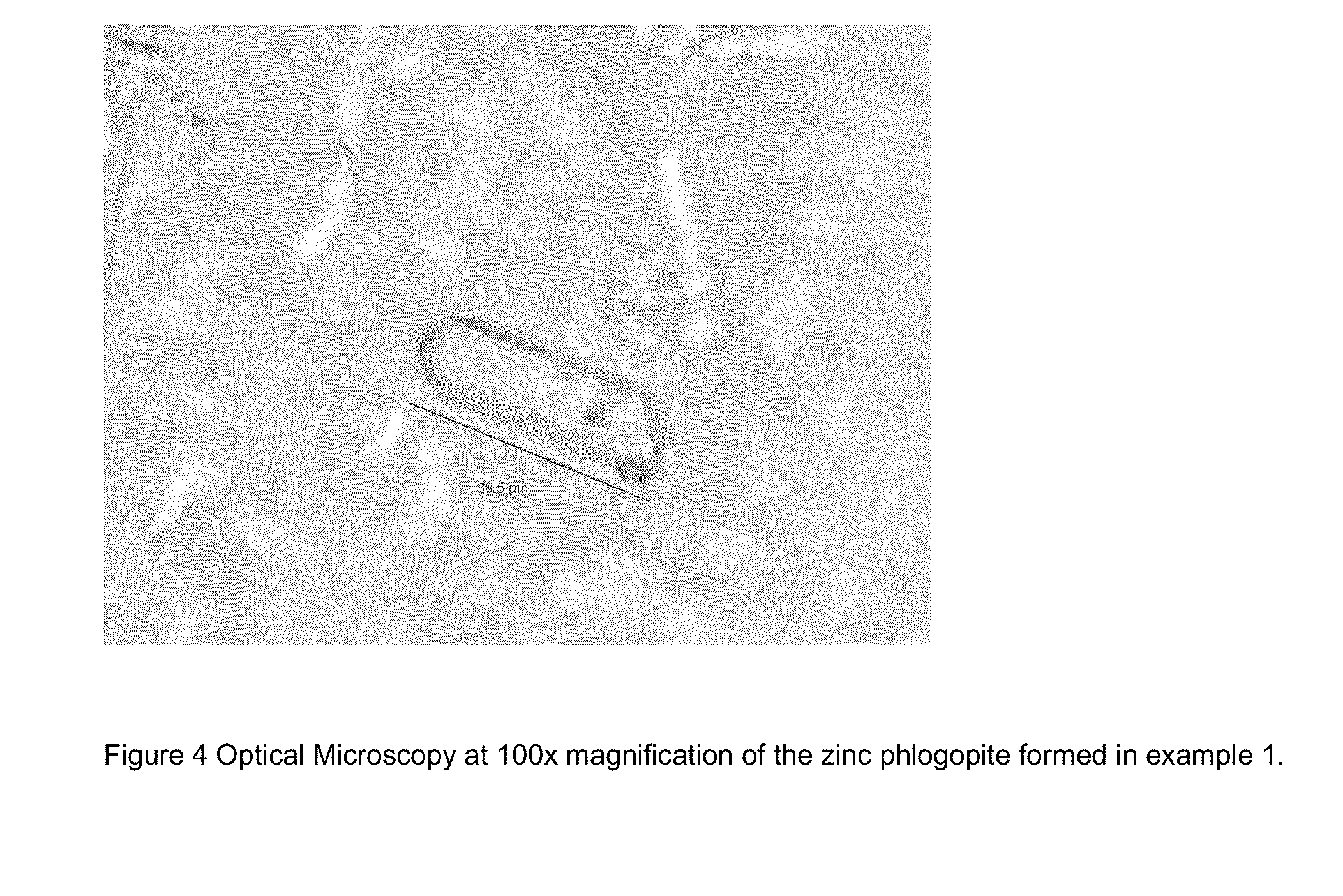

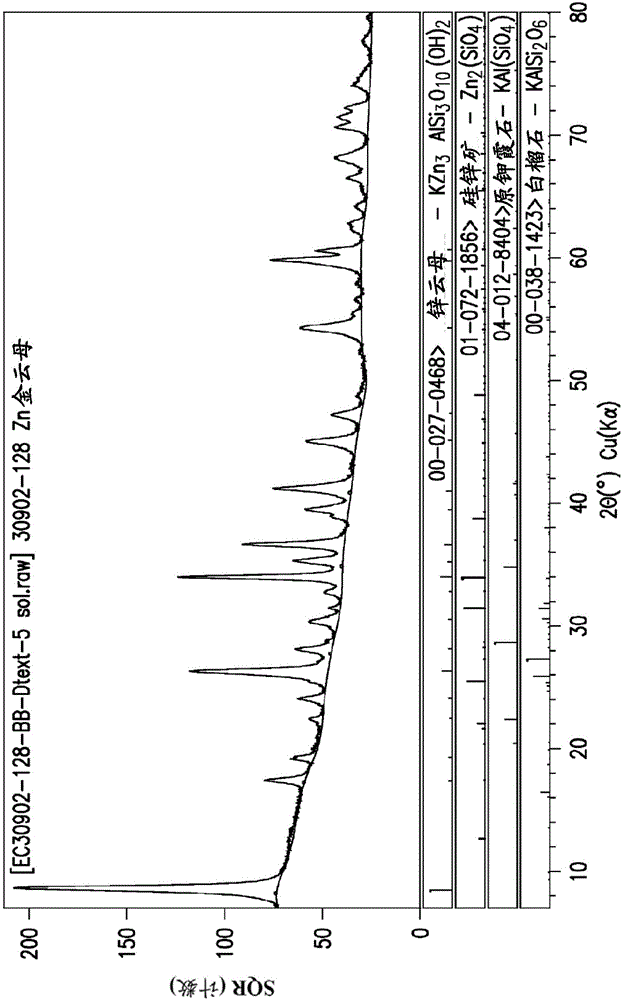

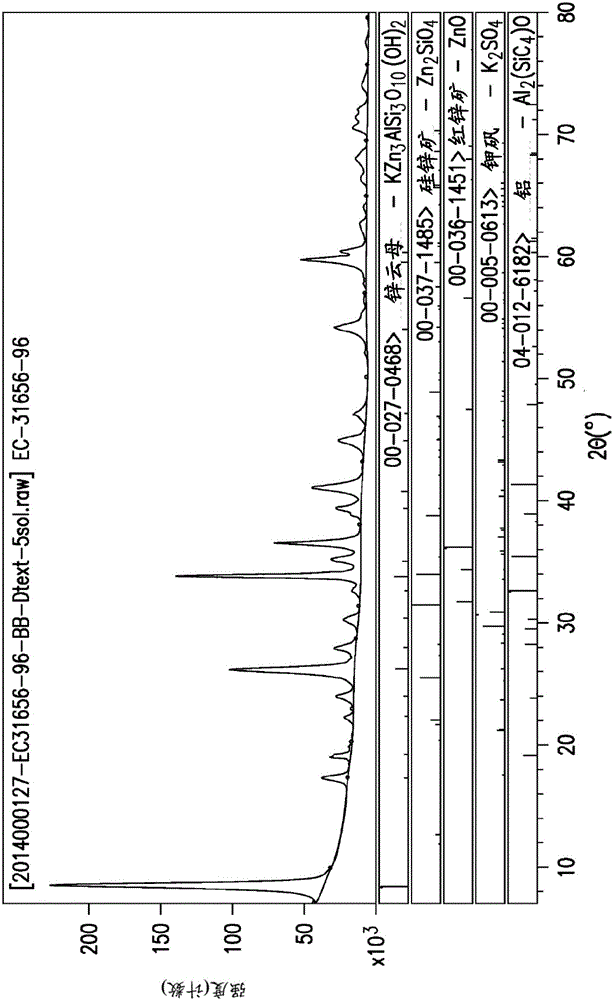

Hydrothermal Synthesis of Zinc Phlogopite

InactiveUS20140255328A1Meet needsPigmenting treatmentCosmetic preparationsPhlogopiteHydrothermal synthesis

This invention relates to a synthetically derived zinc phlogopite platelets, of superior platelet diameter, effect pigments comprising such synthetically derived platelets and methods of forming said substrates. More specifically the disclosure describes an improved hydrothermal synthesis of zinc phlogopite suitable as a platelets for interference pigments, barrier and flame retardant applications.

Owner:BASF AG

Synthetic Zinc Phlogopite via Hydrothermal Preparation

InactiveUS20140251202A1High aspect ratioPigmenting treatmentCosmetic preparationsPhlogopiteHydrothermal synthesis

This invention relates to synthetically derived zinc phlogopite substrates, of superior aspect ratio, effect pigments comprising such synthetically derived substrates and methods of forming said substrates. More specifically the disclosure describes an improved hydrothermal synthesis of zinc phlogopite suitable as a substrate for interference pigments, barrier and flame retardant applications.

Owner:BASF AG

Titanic-acid stainless steel welding electrode and manufacturing method thereof

InactiveCN105772990AReduce contentReduce surface tensionWelding/cutting media/materialsSoldering mediaElectrolysisManganese

The invention discloses a titanic-acid stainless steel welding electrode and a manufacturing method thereof. The titanic-acid stainless steel welding electrode comprises a core wire and a coating, wherein the coating comprises the following ingredients in parts by weight: 20-40 parts of rutile, 5-10 parts of marble, 5-10 parts of X-type titanium dioxide, 4-12 parts of fluorite, 10-20 parts of gold feldspar, 2-8 parts of ferrotitanium, 5-10 parts of phlogopite, 8-20 parts of micro-carbon ferrochrome, 0.1-1 part of antimony oxide, 3-10 parts of electrolytic manganese, 2-8 parts of potassium titanate and 3-10 parts of Haitai powder. The titanic-acid stainless steel welding electrode and the manufacturing method have the advantages that the surface tension of a molten drop is reduced, so as to achieve a fine molten drop spraying process; and not only is the welding efficiency improved, is the welding period shortened, and are the tendencies to redness and cracking reduced, but also the technological performance is improved.

Owner:NANTONG HAOTAI WELDING MATERIAL CO LTD

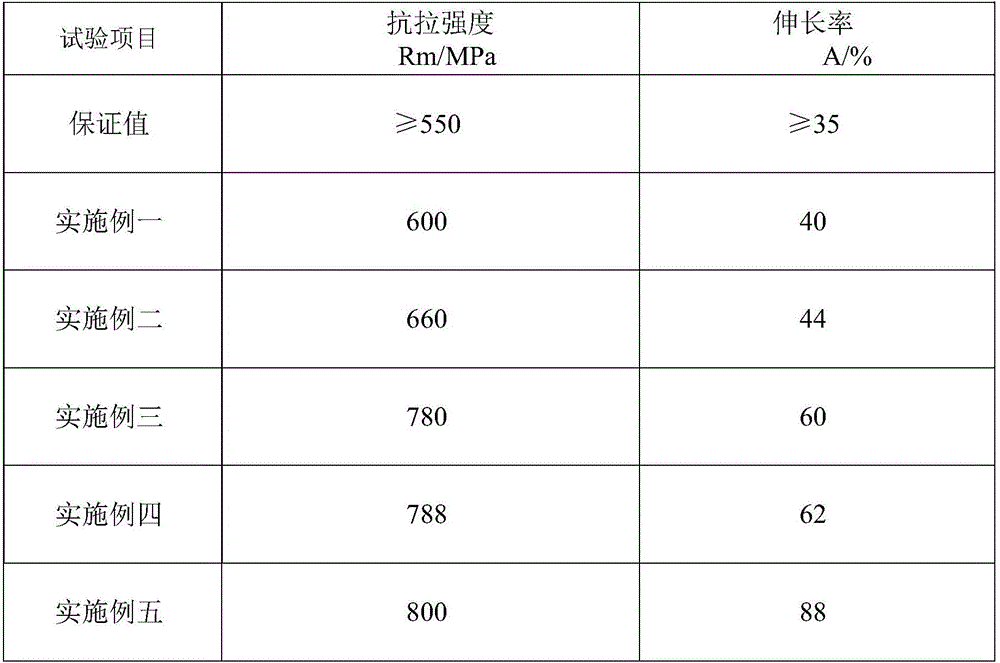

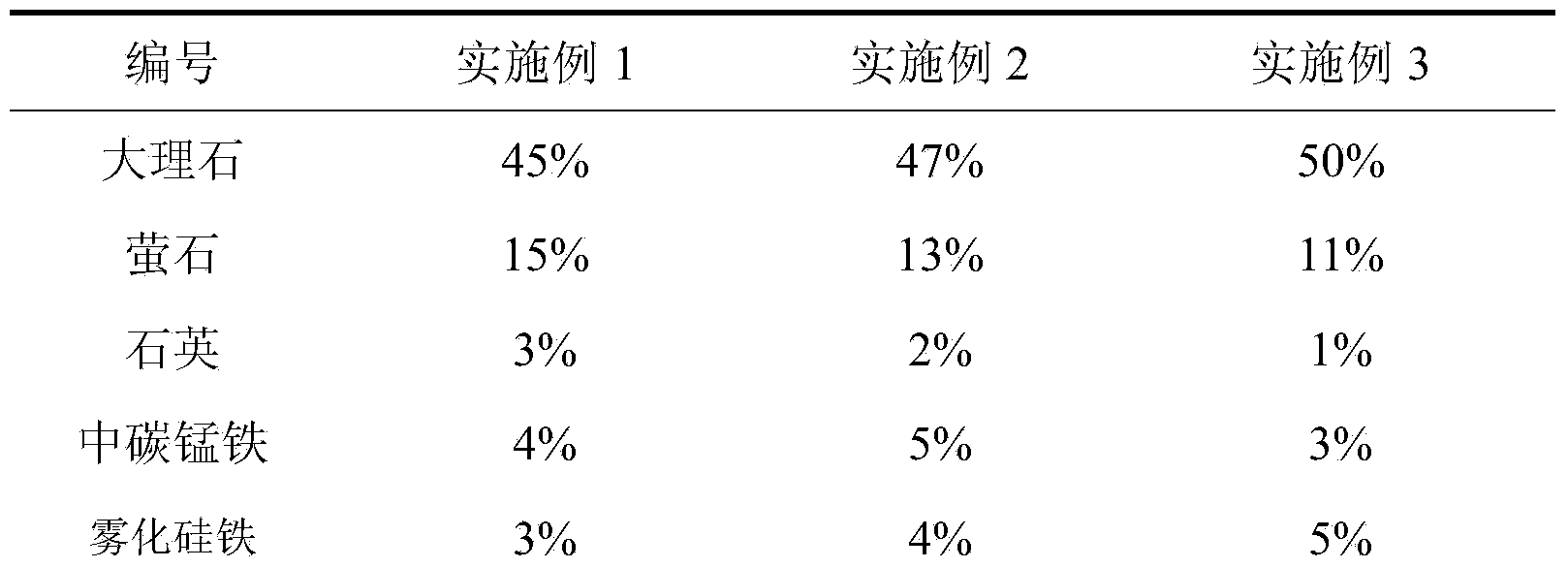

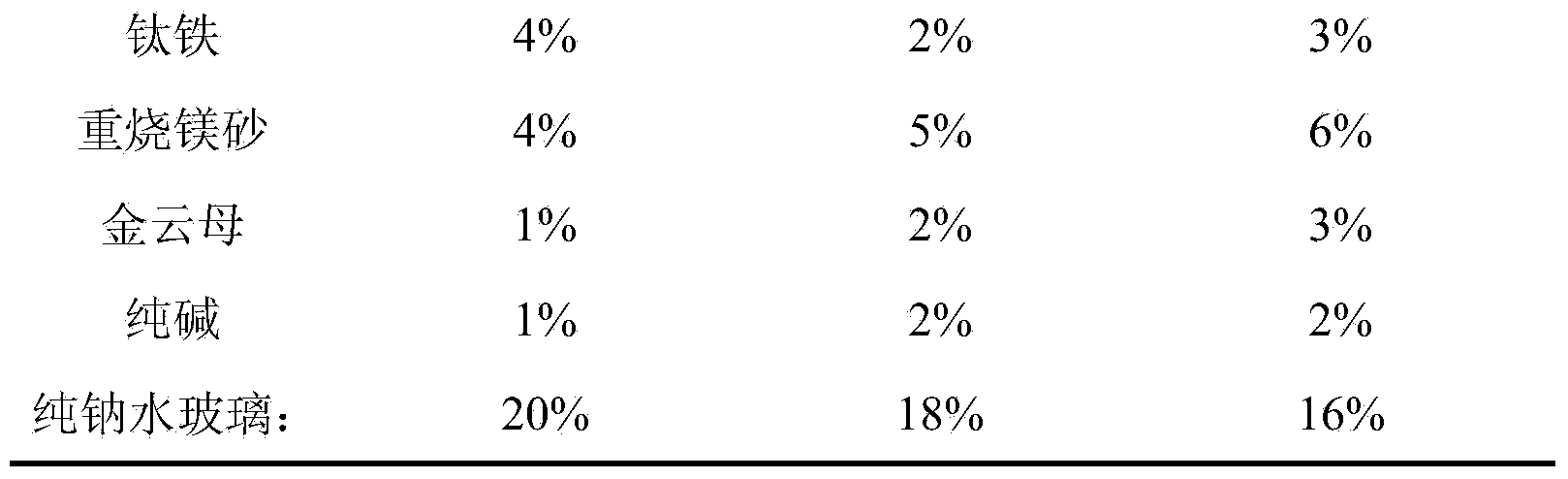

Root-welding welding rod capable of one-side welding and double-side forming

InactiveCN103878505AImprove pressure coatingGood formabilityWelding/cutting media/materialsSoldering mediaFerrosiliconOxygen

A root-welding welding rod capable of one-side welding and double-side forming comprises an H08E welding core and a coating. The coating is prepared by components including, by weight, 45-50% of marbles, 11-15% of fluorite, 1-2% of sodium carbonate, 3-5% of atomized ferrosilicon, 1-3% of flogopite, 3-5% of mid-carbon ferromanganese, 4-6% of dead-burned magnesite, 2-4% of terrotitanium, 1-3% of quartze and 16-20% of pure sodium silicate. The welding rod coating contains the marbles, the fluorite and rutile which are capable of slagging and gas making, deoxidized alloy transition element including manganese metal and the atomized ferrosilicon, pure sodium silicate binder and the flogopite and the sodium carbonate which are capable of improving compressive property. The root-welding welding rod is good in one-side welding and double-side forming, low in welding defect, stable in impact toughness and good in welding technology.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for preparation of machinable mica glass ceramic insulating material from waste glass and phlogopite

The invention relates to a method for preparation of machinable mica glass ceramic insulating material from waste glass and phlogopite. The method specifically includes the steps of: washing the waste glass and phlogopite repeatedly, and conducting breaking, crushing and sieving for standby use; mixing the above two powder according to a mass ratio (with the mica accounting for 50-75%), performing grinding, adding 4-5wt% of polyvinyl alcohol as a binder, carry out dry pressing and cold isostatic pressing molding, placing the molded sample into a muffle furnace to perform pressureless sintering at 800DEG C-1500DEG C, carrying out heat preservation for 2h, performing natural cooling to room temperature, and then taking the sample out, thus obtaining the machinable mica glass ceramic insulating material prepared from waste glass and phlogopite. The material has the advantages of low cost, high strength and good electrical insulation properties, etc.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Composite heating agent for die steel

InactiveCN107312503ABurn fasterHigh calorific valueHeat-exchange elementsSodium bicarbonateVolume variation

The invention relates to a composite heating agent for die steel, made from, by weight, 7-8 parts of aluminum powder, 6-9 parts of activated calcium oxide, 4-6 parts of bauxite, 3-4 parts of magnesium chloride, 2-3 parts of potassium nitrate, 6-8 parts of phlogopite, 2-3 parts of sodium chloride, 5-7 parts of boron nitride, 5-7 parts of zinc silicate, 4-6 parts of vermiculite, 3-5 parts of quartz sand, 9-10 parts of diatomite, 3-4 parts of acidified graphite, 2-4 parts of silicon-calcium powder, 3-4 parts of sodium bicarbonate, and 4-5 parts of potassium chloride. The composite heating agent has a volume variation rate of 15% and below in a high-temperature environment so that the heating agent has high burning speed and more concentrated heat generation; the heating generation of the composite heating agent is increased by 35% and above as compared to traditional heating agents; less heating agent is used, production cost is reduced, and pollution emission is decreased.

Owner:晋江市池店镇泉捷鞋机设计服务部

Friction material composition, friction material, and friction member

ActiveUS20190024744A1Excellent friction coefficient stability and crack resistance and abrasion resistanceSuppress low frequency noiseOther chemical processesBraking discsPhlogopiteFiber

Provided is a friction material composition including: a binder; an organic filler; an inorganic filler; and a fiber substrate, in which a content of copper as an element is 0.5% by mass or less, the friction material composition contains at least one of phlogopite or biotite in a total of from 3% by mass to 9% by mass, and a graphite in an amount of from 2% by mass to 6% by mass, as the inorganic fillers, the at least one of phlogopite or biotite has an average particle size of from 340 μm to 1,500 μm, and the graphite has an average particle size of from 450 μm to 1,100 μm.

Owner:RESONAC CORP

Fluorophlogopite prepared by using molybdenum tailings and method thereof

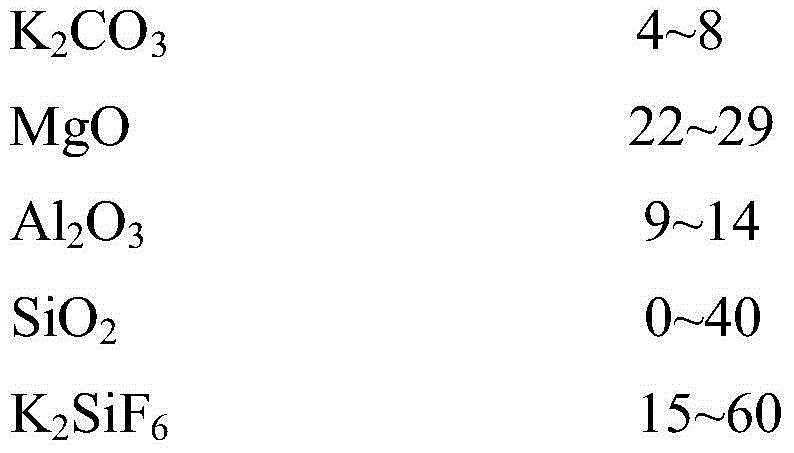

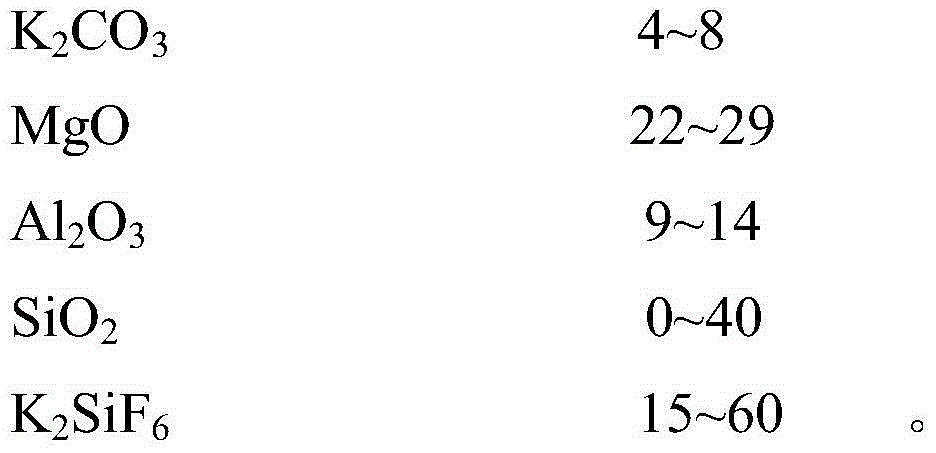

The invention discloses a production formula of fluorophlogopite and a method for preparing the fluorophlogopite. The formula concretely comprises the following components by weight percent: 40-71% of molybdenum tailings and 29-60% of powder batch, wherein the powder batch comprises the following components by weight percent: 4-8% of K2CO3, 22-29% of MgO, 9-14% of Al2O3, 0-40% of SiO2 and 15-60% of K2SiF6. The fluorophlogopite produced according to the formula disclosed by the invention forms a flake structure and is easy to separate, the color is brown, the whiteness range is 30-55%, and the dielectric constant range is 6-10. Compared with artificial fluorine phlogopite produced at home and abroad at present, fluorophlogopite prepared according to the formula by the method disclosed by the invention has the advantages that the production cost of an enterprise can be greatly reduced, the phenomenon of molybdenum tailings as waste slag is effectively solved, and the technique and the product developed by the method have broad development prospects and markets.

Owner:DALIAN POLYTECHNIC UNIVERSITY

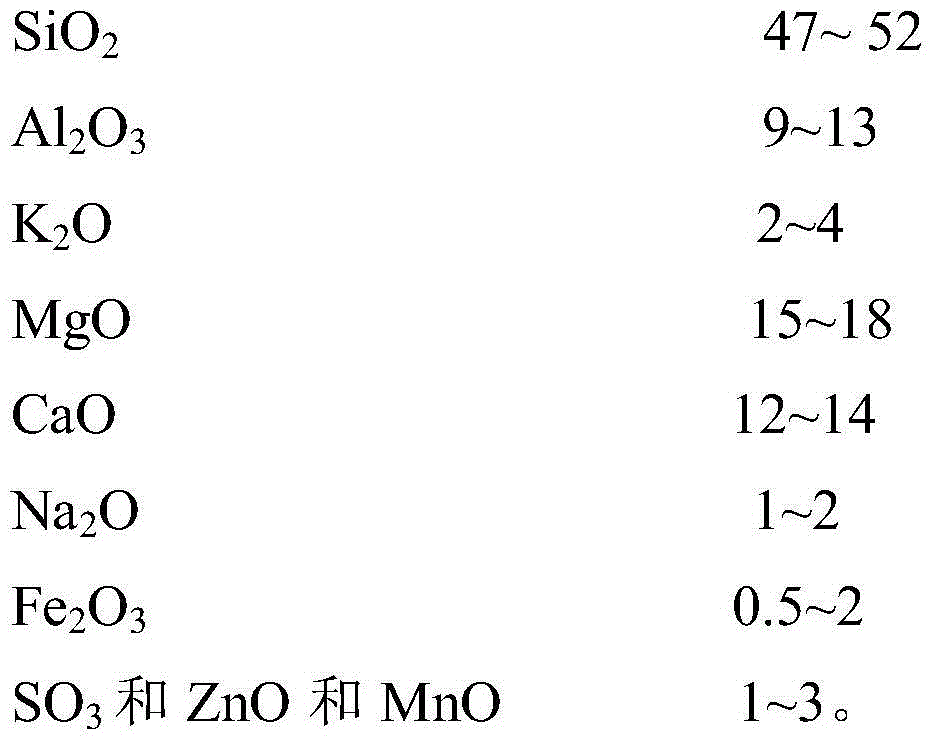

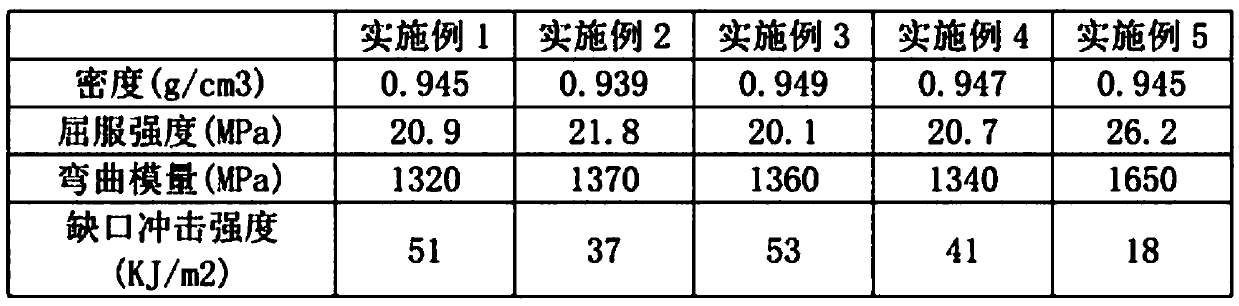

Propylene material with high modulus and high rigidity for light automobile door panel and preparation method thereof

The invention discloses a propylene material with high modulus and high rigidity for a light automobile door panel and a preparation method thereof. According to the key point of the technical scheme,the propylene material is prepared from the following raw materials in parts by weight: 78-88 parts of polypropylene, 4-8 parts of ultrafine inorganic filler, 6-12 parts of flexibilizer, 0.2-0.5 partof thermal stabilizer, 0-0.2 part of other additives, 1-2 parts of crystal whiskers and 1-2 parts of phlogopite. The preparation method comprises the following steps performing dry mixing on raw materials in a high-speed mixer for 2-10 minutes; putting into a twin-screw extruder; melting, extruding, cooling and granulating. The propylene material has excellent performance, and can meet the strength requirement for automobile door panels.

Owner:SUZHOU SUNWAY POLYMER

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058BSimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioMechanical property

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the weldedwelding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Synthetic zinc phlogopite via hydrothermal preparation

InactiveCN105121344AHigh aspect ratioPigmenting treatmentCosmetic preparationsPhlogopiteHydrothermal synthesis

This invention relates to a synthetically derived zinc phlogopite platelets, of superior platelet diameter, effect pigments comprising such synthetically derived platelets and methods of forming said substrates. More specifically the disclosure describes an improved hydrothermal synthesis of zinc phlogopite suitable as a platelets for interference pigments, barrier and flame retardant applications.

Owner:BASF SE

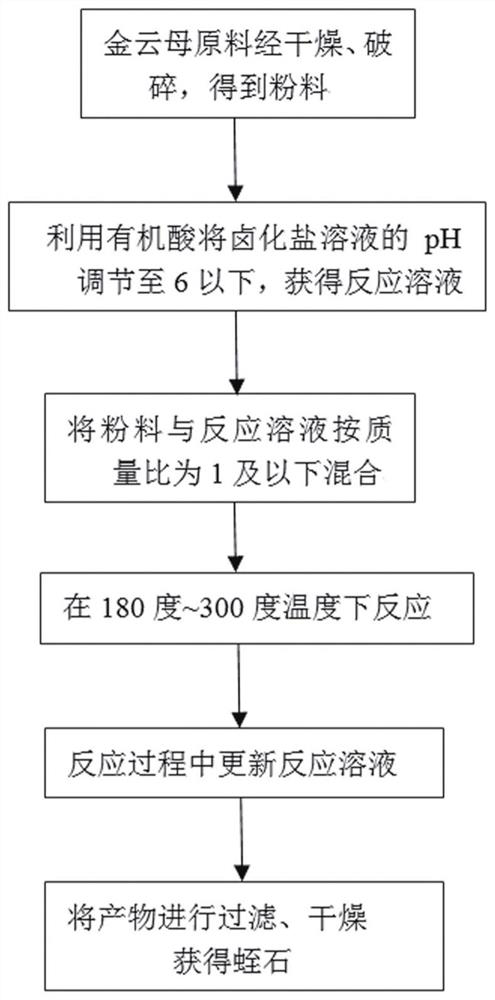

Vermiculite synthesized by phlogopite hydrothermal reaction and preparation method thereof

The invention provides vermiculite synthesized by a phlogopite hydrothermal reaction and a preparation method thereof. The method comprises the following steps: drying and crushing a phlogopite raw material to obtain powder; adjusting the pH value of a halide salt solution to 6 or below by utilizing organic acid to obtain a reaction solution, the halide salt solution being a non-potassium halide halide metal salt solution, and the concentration of the halide salt solution being 0.5 to 3 mol / L; mixing the powder with the reaction solution according to a mass ratio of 1 or less, then carrying out a reaction at 180 to 300 DEG C, and updating the reaction solution in the reaction process; and after the reaction is finished, carrying out filtering and drying to obtain the vermiculite. The vermiculite synthesized by the hydrothermal reaction comprises the vermiculite prepared by the method. According to the method, the technological process is remarkably simplified, and the vermiculite synthesized through the hydrothermal reaction has the advantages of being uniform in particle, high in purity and excellent in expansion performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

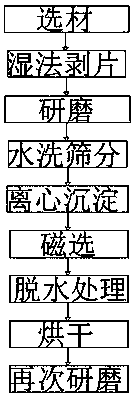

Preparation method of phlogopite powder

The invention discloses a preparation method of phlogopite powder. The preparation method comprises the following steps of selecting materials; artificially screening phlogopite ore; performing flushing and drying treatment on the screened phlogopite ores; peeling the sheets by a wet process; using wet sheet peeling on the picked high-quality phlogopite ore raw materials; performing water washing,impurity removal, soaking and milling to prepare flaky primary materials A; performing grinding; performing low-temperature drying dewatering on the flaky primary materials; performing milling by using a wheel milling machine; next, performing grinding by a grinding machine; preparing phlogopite particles B; performing water washing screening; feeding the phlogopite particles B into a separationsieve; injecting a proper amount of pure water; removing floating impurities. The impurities with small density can be conveniently removed; acid soluble impurities such as calcium carbonate can be removed; the impurities of the phlogopite powder can be favorably improved; the product quality is improved; the recovery is convenient; the yield is improved; the production cost is reduced; the filtering efficiency is improved; the work efficiency is improved.

Owner:ANHUI HENGHAO SCI & TECH

High-performance heating agent

InactiveCN107298967ABurn fasterHigh calorific valueHeat-exchange elementsSodium bicarbonateBoron nitride

The invention relates to a high-performance heating agent. The high-performance heating agent is prepared from the following raw materials in parts by weight: 9 to 10 parts of diatomite, 4 to 6 parts of bauxite, 3 to 4 parts of magnesium chloride, 2 to 3 parts of potassium nitrate, 6 to 8 parts of potassium chlorate, 2 to 3 parts of sodium chloride, 5 to 7 parts of boron nitride, 7 to 8 parts of iron powder, 5 to 7 parts of zinc silicate, 4 to 6 parts of vermiculite, 3 to 5 parts of quartz sand, 6 to 9 parts of cryolite, 3 to 4 parts of expanded graphite, 2 to 4 parts of silicon and calcium powder, 3 to 4 parts of sodium bicarbonate, and 4 to 5 parts of phlogopite. The high-performance heating agent has the advantages that the volume change rate is controlled within 15% under the high temperature environment, the combustion speed is high, the heat is centrally generated, and the heating amount is increased by 35% or more in comparison with the traditional heating agent; the usage amount of the heating agent is smaller, the production cost is reduced, and the pollution emission is reduced.

Owner:晋江市池店镇泉捷鞋机设计服务部

Friction material composition, friction material, and friction member

ActiveUS10570975B2Excellent friction coefficient stability and crack resistance and abrasion resistanceSuppress low frequency noiseOther chemical processesBraking discsFiberPhlogopite

Provided is a friction material composition including: a binder; an organic filler; an inorganic filler; and a fiber substrate, in which a content of copper as an element is 0.5% by mass or less, the friction material composition contains at least one of phlogopite or biotite in a total of from 3% by mass to 9% by mass, and a graphite in an amount of from 2% by mass to 6% by mass, as the inorganic fillers, the at least one of phlogopite or biotite has an average particle size of from 340 μm to 1,500 μm, and the graphite has an average particle size of from 450 μm to 1,100 μm.

Owner:RESONAC CORP

Modification method of diaphragm with polymethyl methacrylate-mica coating agent

InactiveCN108963157ALow costImprove discharge capacityCell component detailsViscous liquidHexafluoropropylene

The present invention relates to a modification method of a diaphragm with a polymethyl methacrylate-mica coating agent. The method for modifying a diaphragm with a mica coating agent is characterizedin that low-carbon ketone, coating agent and polyvinylidene fluoride are respectively added into a reaction kettle to prepare the diaphragm, wherein the low-carbon ketone, coating agent and polyvinylidene fluoride are respectively added into the reaction kettle. Hexafluoropropene, polymethyl methacrylate and the like, to obtain a viscous liquid. A substrate film is discharge, coated with a viscous liquid, and dry to obtain a coating film. The coating agent is sericite, muscovite, synthetic mica, conductive mica or phlogopite. The compatibility of the coating film with the positive electrode,negative electrode and electrolyte is obviously improved, and the cycle performance of the battery is improved.

Owner:FUJIAN NORMAL UNIV

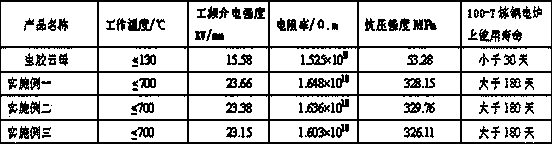

Formula of material for making high-strength fire-resistant electric furnace insulating mat by hot molding

The invention relates to a formula of a material for making a high-strength fire-resistant electric furnace insulating mat by hot molding, which is formed by mixing phlogopite powder, talcum powder, kaolin, alkali-free glass fiber and an adhesive. The mixture is characterized by comprising the following components in percentage by weight: 30-40% of phlogopite powder, 23-32% of talcum powder, 23-30% of kaolin, 6-10% of alkali-free glass fiber and 8-12% of adhesive. The phlogopite in the material has the characteristic of high melting point; the kaolin has favorable plasticity, high binding property and favorable fire resistance; the talcum powder is beneficial to the shape stability of the product, has favorable flowability, and is convenient for stripping; the alkali-free glass fiber has very high tensile strength; and therefore, the material for making a high-strength fire-resistant electric furnace insulating mat by hot molding has the overall characteristics of the materials above.

Owner:JIAXING UNIV

Heat insulating plate

Owner:ZHENGZHOU ZHENDONG TECH

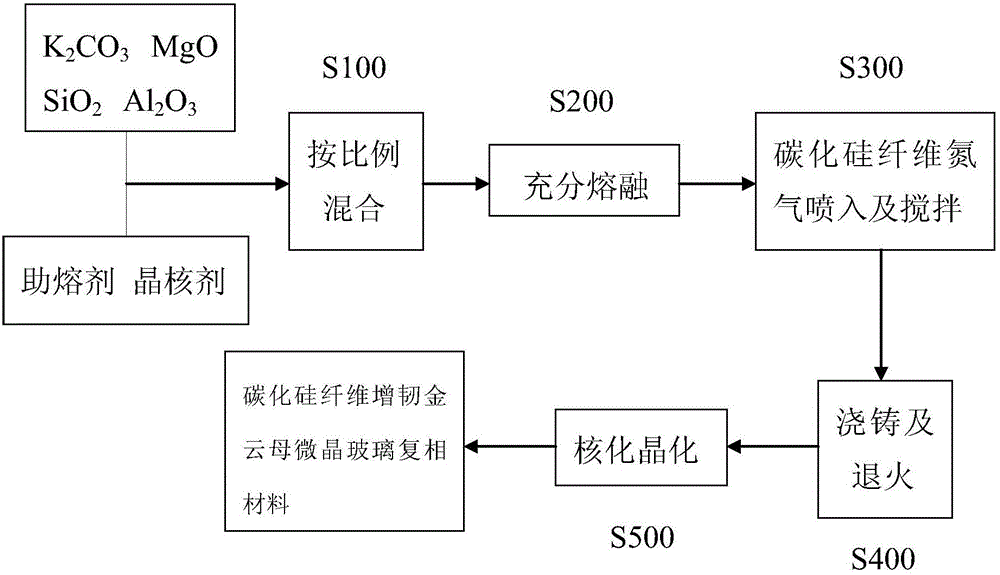

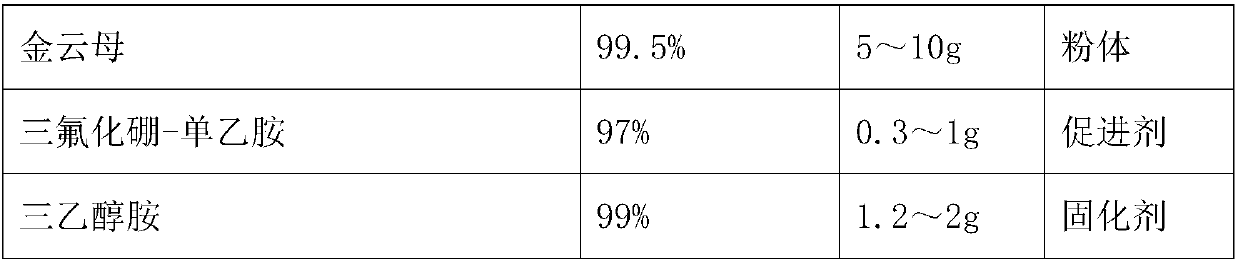

Silicon carbide fiber toughened phlogopite glass-ceramic multi-phase material and preparation method thereof

The invention discloses a preparation method of a silicon carbide fiber toughened phlogopite glass-ceramic multi-phase material. The preparation method comprises the following steps: mixing K2CO3 powder, MgO powder, SiO2 powder, Al2O3 powder, a fluxing agent and a nucleating agent in proportion to form a uniform mixture; melting and heating the mixture; spraying silicon carbide fibers into a melting tank through nitrogen gas at the final period of a melting process, and sufficiently mixing to form a uniform melted mixture; pouring the melted mixture into a pre-heated mold; annealing the melted mixture poured into the mold; and nucleating basic glass which is obtained by annealing and contains the silicon carbide fibers, and crystallizing to obtain the silicon carbide fiber toughened phlogopite glass-ceramic multi-phase material. The invention further provides the multi-phase material prepared by the method, and the multi-phase material comprises K2CO3, MgO, SiO2, Al2O3, B2O3, Cr2O3, TiO2 and the silicon carbide fibers.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

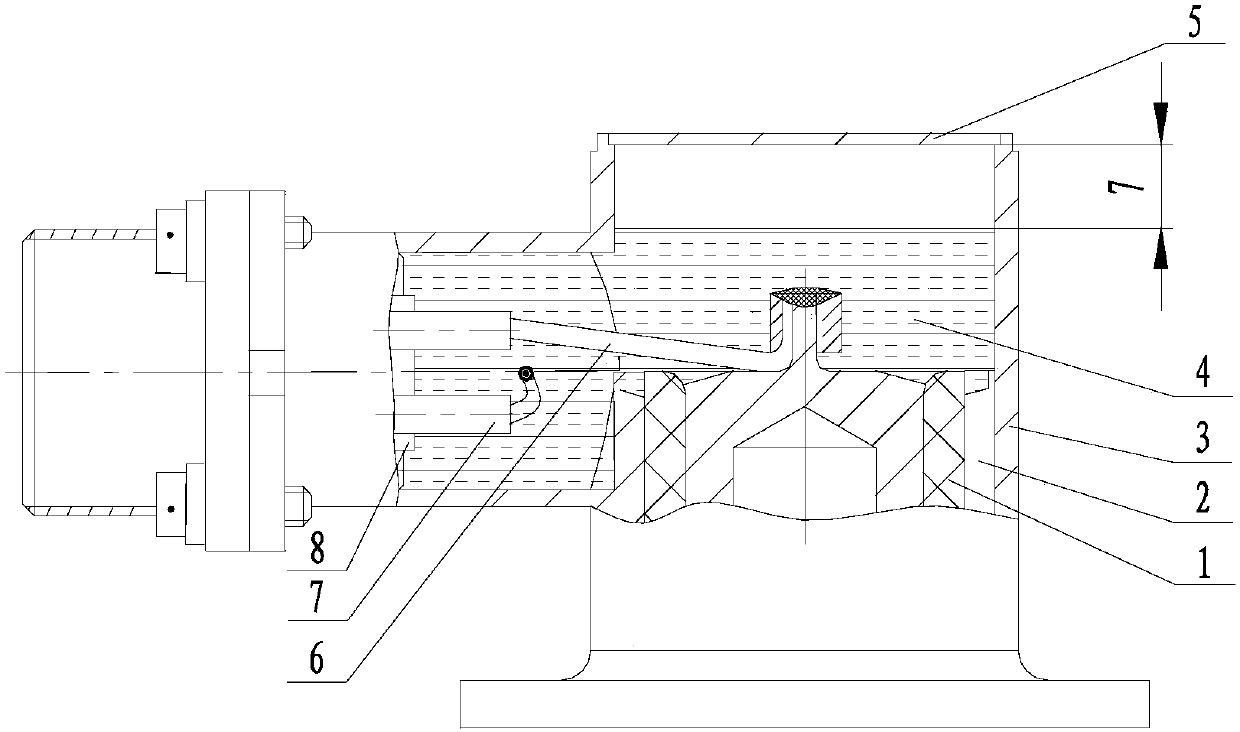

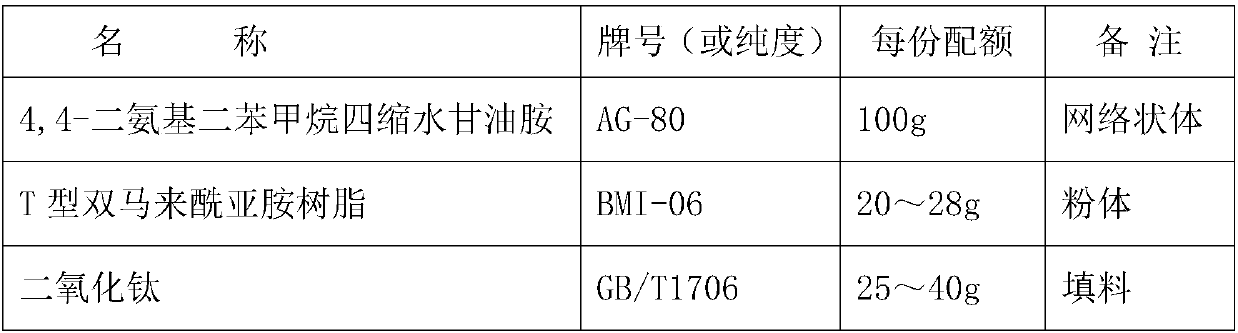

Preparation method of epoxy resin matrix composite material

Belonging to the technical field of composite materials, the invention relates to an epoxy resin matrix composite material and a preparation method thereof. According to the invention, 4, 4-diaminodiphenylmethane tetraglycidylamine is adopted to achieve good heat resistance; T type bismaleimide resin is taken as the toughening agent, and titanium dioxide and phlogopite are employed as the filler to enhance the hardness and adjust the thermal expansion coefficient so as to match with a stainless steel cavity and improve the thermal shock resistance and heat resistance; boron trifluoride-ethylamine is adopted as the accelerant, and triethanolamine is taken as the curing agent to adjust the viscosity and curing crosslinking speed. The epoxy resin matrix composite material prepared by the method provided by the invention solves the problems of unsmooth surface, cracking, block fall and other problems after potting of an epoxy potting material used by ion flame detectors, the heat resistance is raised from the original 361DEG C to 408DEG C, the thermal expansion coefficient matches with a potting cavity material, and the material performance meets the requirements of supporting products. The epoxy resin matrix composite material is successfully applied to potting and filling materials of various aviation ion flame detectors already, and has great economic and social benefits.

Owner:SHAANXI AVIATION ELECTRICAL

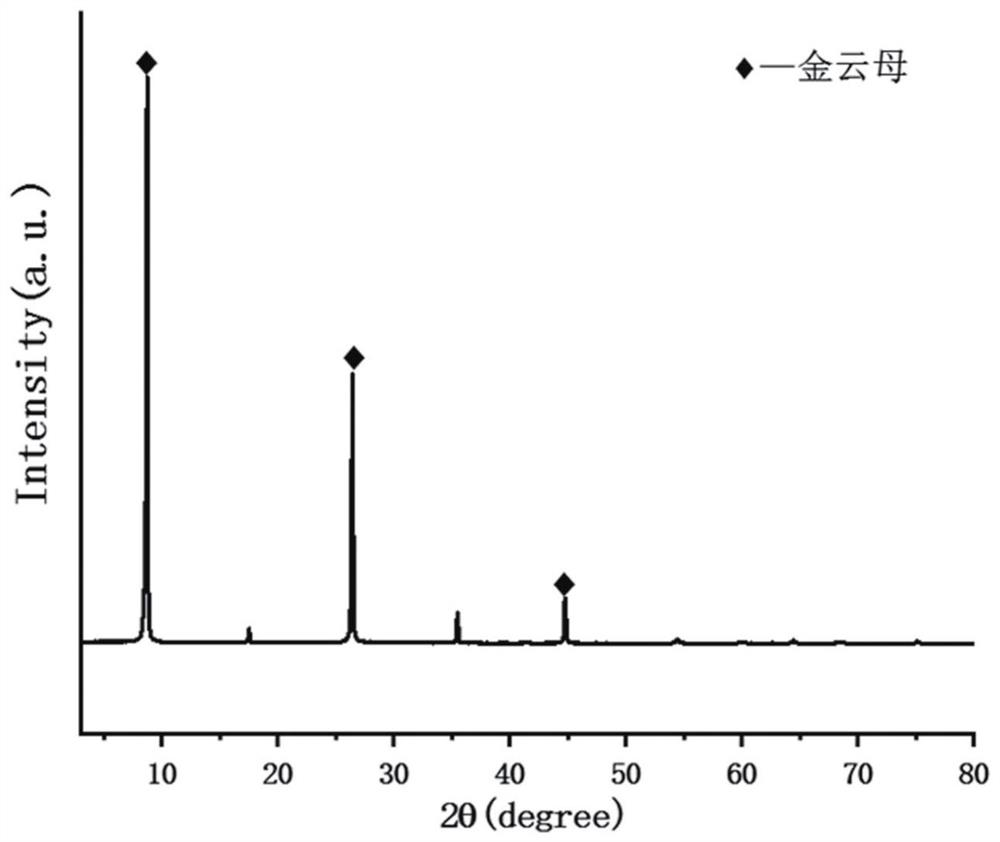

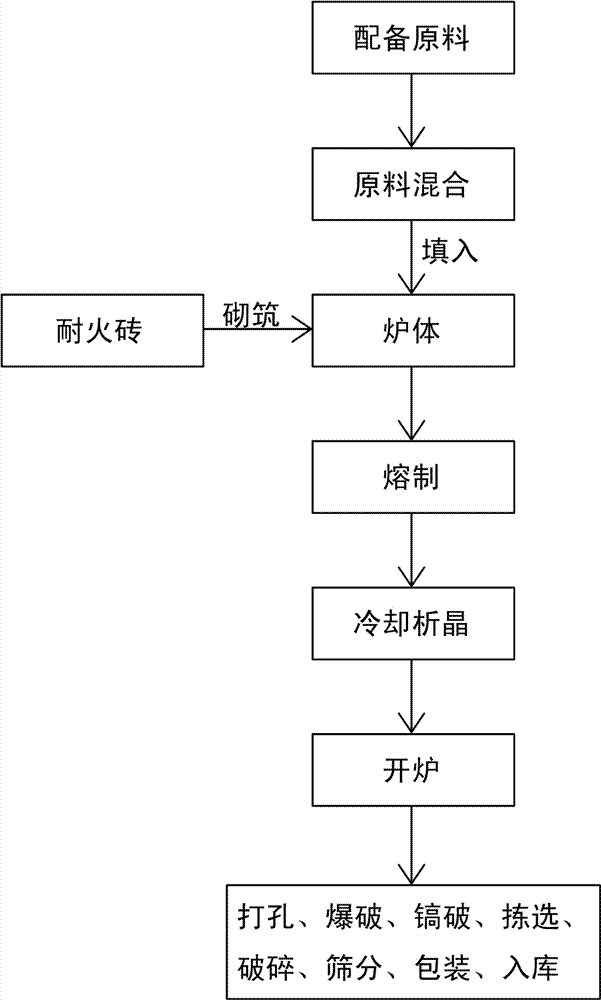

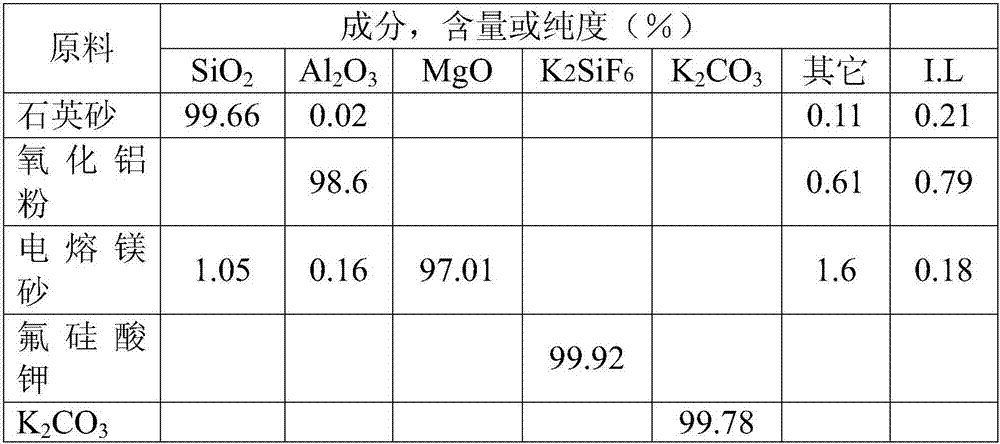

A kind of preparation method of synthetic fluorine phlogopite

The invention relates to a preparation method for manually synthesized fluorophlogopite. The preparation method comprises the following steps: (1) preparing raw materials, wherein the molar ratio of SiO2, MgO, Al2O3, K2CO3 and K2SiF6 in the raw materials is as follows: SiO2: MgO: Al2O3: K2CO3: K2SiF6=(16-a): 18: 3: (1-a): (2+a), and a is greater than or equal to 0.1 but less than or equal to 0.5; (2) bricking a furnace body and mounting an electrode; (3) filling the uniformly mixed raw materials into the furnace body; (4) electrifying to smelt the raw materials in the furnace body; (5) cutting off power and naturally cooling and separating out crystals; and (6) opening the furnace and taking out manually synthesized fluorophlogopite. By optimizing the raw material formula, the high-quality manually synthesized fluorophlogopite is synthesized; and the prepared manually synthesized fluorophlogopite does not contain other crystals, meets the pearl package requirement, and is clear, transparent, flexible, complete in crystal, large in crystal plates and good in dielectric properties.

Owner:梅州市三宝光晶云母科技有限公司

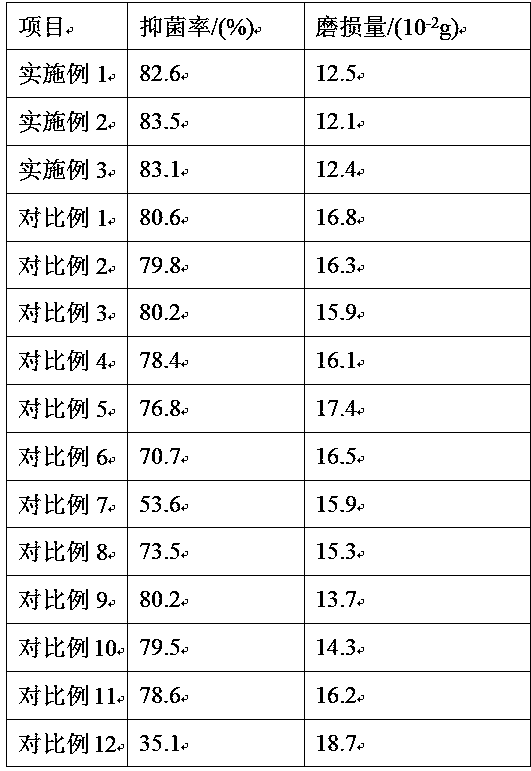

Antibacterial wear-resistant transparent glaze

The invention mainly relates to the technical field of ceramic glaze processing,and discloses an antibacterial wear-resistant transparent glaze. The glaze is prepared from 35-37 parts of feldspar,24-26 parts of dolomite,21-23 parts of talcum,20-22 parts of limestone,17-19 parts of phlogopite,4-6 parts of niobium pentoxide and 3-5 parts of anatase titanium dioxide. The antibacterial wear-resistanttransparent glaze is bright,transparent and light yellow in luster,has relatively good antibacterial property and wear resistance,can effectively avoid color changing and scratches of ceramic productsin the use process,keeps the ceramic products attractive,and prolongs the service life of the ceramic products. The phlogopite is crushed and added into a sodium carbonate solution,and the mixture isfrozen and then subjected to high-temperature calcination,so that combination of sodium carbonate and phlogopite particles is promoted,the alkali resistance and wear resistance of phlogopite are improved,the elasticity and the sliding property are reduced,then the transparent glaze can be tightly attached to ceramic,the sintering temperature after glazing is reduced,and a large amount of energy is saved.

Owner:合肥汉甲陶瓷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com