Preparation method of epoxy resin matrix composite material

A composite material and epoxy resin technology, applied in the field of composite materials, can solve the problems of mismatching linear expansion coefficients, falling blocks, cracks, etc., and achieve the effect of great economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

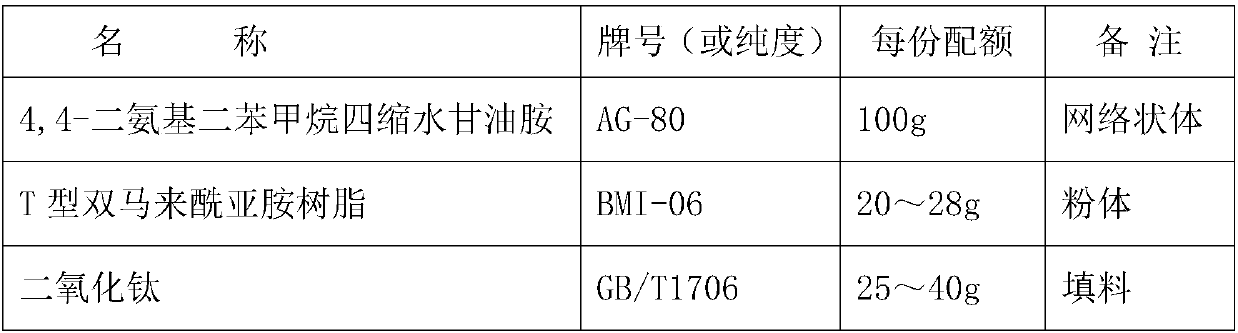

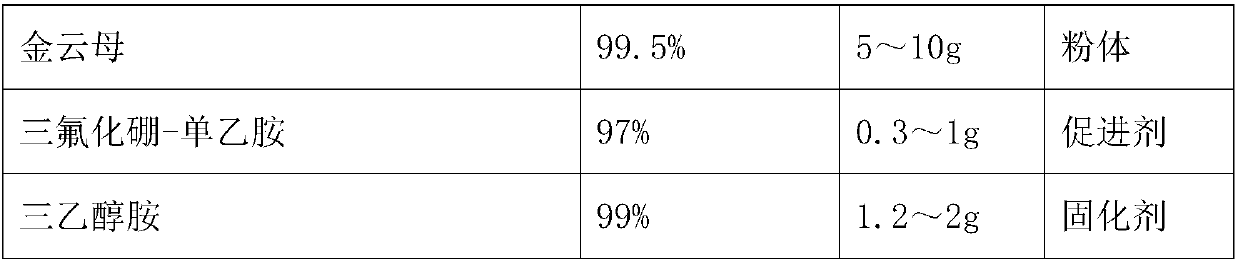

[0029] A preparation method of epoxy resin-based composite material, the method adopts the following steps:

[0030] 1) Pretreatment of titanium dioxide

[0031] Place the titanium dioxide in a high-temperature container and heat it at 950℃ for at least 2 hours to convert all the titanium dioxide into stable rutile titanium dioxide; ball mill the heat-treated rutile titanium dioxide on a ball mill to achieve a particle size of more than 200 mesh ;

[0032] 2) Pretreatment of phlogopite

[0033] Soak the phlogopite in a 10% dilute hydrochloric acid solution for 2 to 4 hours to remove the impurity iron of the phlogopite, fully wash the soaked phlogopite, and dry it, and ball mill it on a ball mill to achieve a particle size of more than 200 mesh. The phlogopite obtained is bottled for later use;

[0034] 3) Preparation of epoxy resin-based composite materials

[0035] The ratio of raw materials to 4,4-diaminodiphenylmethane tetraglycidol is 55%, the ratio of T-type bismaleimide resin is ...

Embodiment

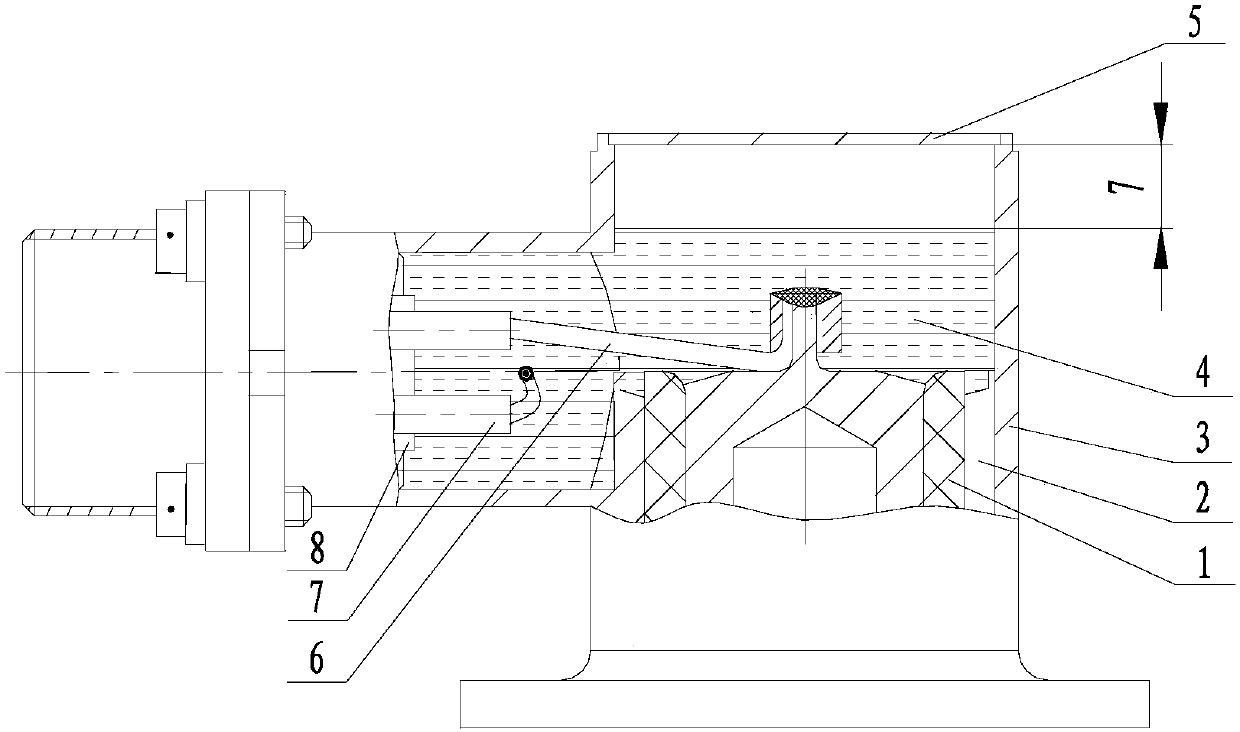

[0043] Taking a certain product (HTQ-17A) as an example, the product processing is as follows figure 1 After the cavity is formed, the epoxy resin-based composite material is filled into the cavity, and after curing and cross-linking, the cover plate 5 is welded to the shell assembly. The cover plate and the composite material surface have a cavity of about 7 mm. The preparation and construction methods of epoxy resin-based composite materials are as follows:

[0044] 1. Pretreatment of titanium dioxide.

[0045] Heat the titanium dioxide in a corundum crucible at 950℃ for 2h for heat treatment. The heat treatment temperature system is as follows: room temperature~600℃, 200℃ / h; 600℃~800℃, 150℃ / h; 800℃~950℃, 80℃ / h; 950 +10 ℃, keep for 2h.

[0046] The heat-treated gold-red titanium dioxide is ball milled on a planetary ball mill for 1 hour to achieve a 200-mesh sieve with no sieve residue.

[0047] 2. Pretreatment of phlogopite

[0048] Soak the phlogopite in a 10% dilute hydrochlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com