Antibacterial wear-resistant transparent glaze

A transparent glaze and ball milling technology, which is applied in the field of ceramic glaze processing, can solve the problems of no obvious improvement in the antibacterial and wear resistance of the ceramic tile surface, the influence of the appearance of ceramic products, and the surface of the tile is easy to be scratched, so as to increase the glaze The fluidity of the material, the avoidance of discoloration and scratches, and the effect of a wide range of firing temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

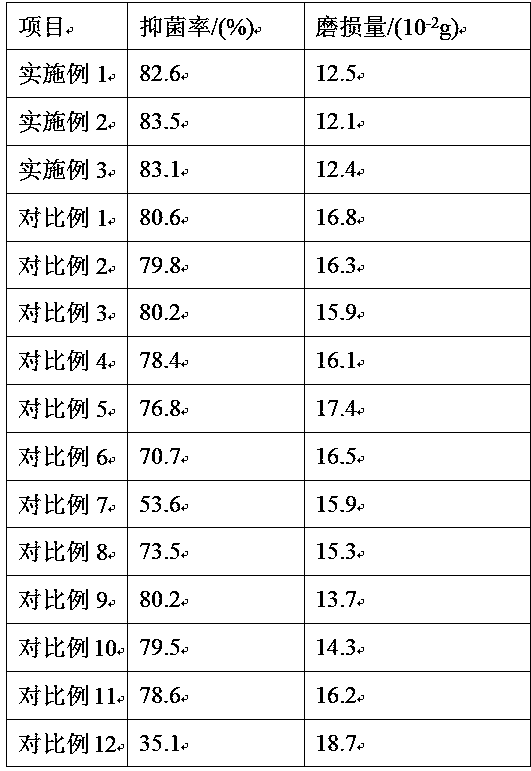

Examples

Embodiment 1

[0021] An antibacterial and wear-resistant transparent glaze is made of the following raw materials in parts by weight: 35 parts by weight of feldspar, 24 parts of dolomite, 21 parts of talc, 20 parts of limestone, 17 parts of phlogopite, 4 parts of niobium pentoxide and 3 parts of anatase titanium dioxide.

[0022] The feldspar is made of the following raw materials in parts by weight: albite 25, anorthite 17, barium feldspar 12, barium ice feldspar 6, microplagioclase 3.

[0023] A preparation method for antibacterial wear-resistant transparent glaze, comprising the following steps:

[0024] (1) Crush phlogopite to 140 mesh to obtain phlogopite powder;

[0025] (2) Add sodium carbonate solution equal to the weight of phlogopite powder to phlogopite powder with a concentration of 82 mg / L, freeze at -10°C for 2 hours, take it out, ball mill to 350 mesh, and calcine to promote the formation of sodium carbonate and phlogopite. Particles are combined to improve the alkali resist...

Embodiment 2

[0032] An antibacterial and wear-resistant transparent glaze is made of the following raw materials in parts by weight: 36 feldspar, 25 dolomite, 22 talc, 21 limestone, 18 phlogopite, 5 niobium pentoxide, and 4 anatase titanium dioxide.

[0033] The feldspar is made of the following raw materials in parts by weight: albite 26 , anorthite 18 , barium feldspar 13 , barium ice feldspar 7 , and microplagioclase 4 .

[0034] A preparation method for antibacterial wear-resistant transparent glaze, comprising the following steps:

[0035] (1) Crush phlogopite to 170 mesh to obtain phlogopite powder;

[0036] (2) Add sodium carbonate solution equal to the weight of phlogopite powder to phlogopite powder, the concentration is 84mg / L, freeze at -9°C for 2.5h, take it out, ball mill to 380 mesh, and calcine to promote the formation of sodium carbonate and gold The combination of mica particles improves the alkali resistance and wear resistance of phlogopite, reduces the elasticity and s...

Embodiment 3

[0043] An antibacterial and wear-resistant transparent glaze is made of the following raw materials in parts by weight: feldspar 37, dolomite 26, talc 23, limestone 22, phlogopite 19, niobium pentoxide 6, and anatase titanium dioxide 5.

[0044] The feldspar is made of the following raw materials in parts by weight: albite 27 , anorthite 19 , barium feldspar 14 , barium ice feldspar 8 , and microplagioclase 5 .

[0045] A preparation method for antibacterial wear-resistant transparent glaze, comprising the following steps:

[0046] (1) Crush phlogopite to 200 mesh to obtain phlogopite powder;

[0047] (2) Add sodium carbonate solution equal to the weight of phlogopite powder to phlogopite powder, the concentration is 86mg / L, freeze at -8°C for 3 hours, take it out, ball mill to 400 mesh, and calcine to promote the formation of sodium carbonate and gold The combination of mica particles improves the alkali resistance and wear resistance of phlogopite, reduces the elasticity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com