Titanic-acid stainless steel welding electrode and manufacturing method thereof

A manufacturing method and stainless steel technology, applied in the direction of manufacturing tools, welding media, welding equipment, etc., can solve the problems of easy redness and cracking of welds, long welding time, and low welding efficiency, so as to reduce the tendency of redness and cracking and improve welding efficiency. Efficiency, surface tension reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

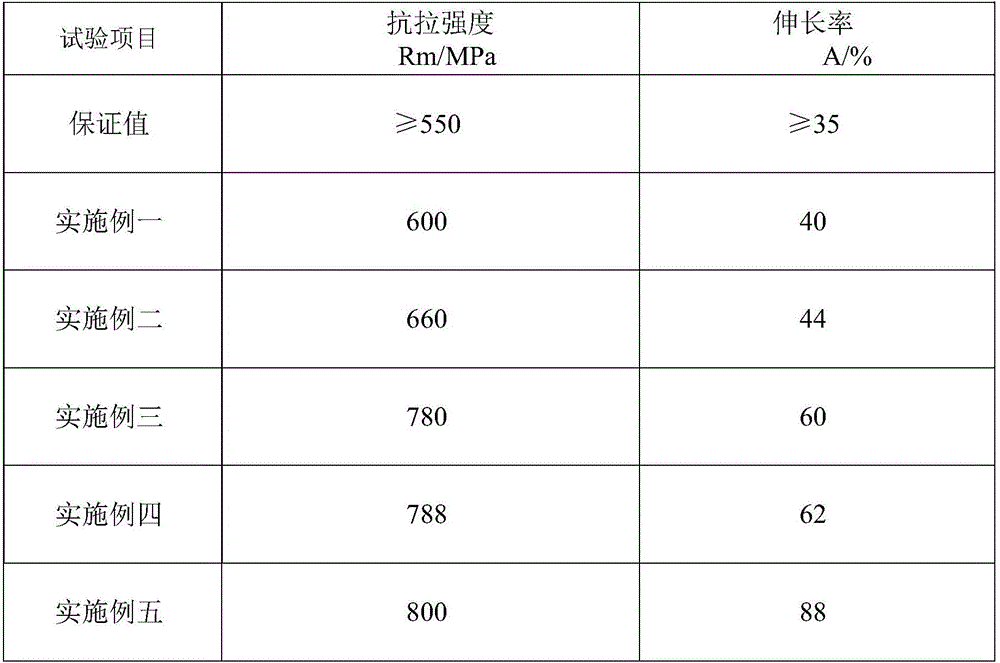

Examples

Embodiment 1

[0034] In parts by weight, the following components are obtained:

[0035] Rutile: 20 parts, marble: 5 parts, X-type titanium dioxide: 5 parts, fluorite: 4 parts, chrysoplast: 10 parts, titanium iron: 2 parts, phlogopite: 5 parts, micro-carbon ferrochrome: 8 parts , antimony oxide: 0.1 parts, electrolytic manganese: 3 parts, potassium titanate: 2 parts, Haitai powder: 3 parts;

[0036] Dry mix the obtained components, then add 1:1 potassium sodium water glass, continue to stir, and make a drug skin;

[0037] Apply the stirred coating evenly on the welding core, and press the welding rod, wherein the welding core is H08Cr21Ni10 welding core, and the welding core contains the following components in parts by weight:

[0038] C: 0.030 parts, Si: 0.25 parts, Mn: 1.0 parts, Cr: 18 parts, Ni: 8 parts, S: 0.019 parts, P: 0.0:4 parts;

[0039] After natural drying, the pressed and formed electrodes are sent to a high-temperature drying furnace for baking at a temperature of 280 degr...

Embodiment 2

[0041] In parts by weight, the following components are obtained:

[0042] Rutile: 40 parts, marble: 10 parts, X-type titanium dioxide: 10 parts, fluorite: 12 parts, chrysoplast: 20 parts, titanium iron: 8 parts, phlogopite: 10 parts, micro-carbon ferrochrome: 20 parts , antimony oxide: 1 part, electrolytic manganese: 10 parts, potassium titanate: 8 parts, Haitai powder: 10 parts;

[0043] Dry mix the obtained components, then add 1:1 potassium sodium water glass, continue to stir, and make a drug skin;

[0044] Apply the stirred coating evenly on the welding core, and press the welding rod, wherein the welding core is H08Cr21Ni10 welding core, and the welding core contains the following components in parts by weight:

[0045] C: 0.080 parts, Si: 0.60 parts, Mn: 2.0 parts, Cr: 22 parts, Ni: 11 parts, S: 0.019 parts, P: 0.0:4 parts;

[0046] After natural drying, the pressed and formed electrodes are sent to a high-temperature drying furnace for baking at a temperature of 280...

Embodiment 3

[0048] In parts by weight, the following components are obtained:

[0049] Rutile: 29 parts, marble: 6 parts, X-type titanium dioxide: 7 parts, fluorite: 5 parts, chrysogenite: 13 parts, titanium-iron: 4 parts, phlogopite: 6 parts, micro-carbon ferrochrome: 10 parts , antimony oxide: 0.2 parts, electrolytic manganese: 4 parts, potassium titanate: 3 parts, Haitai powder: 5 parts;

[0050] Dry mix the obtained components, then add 1:1 potassium sodium water glass, continue to stir, and make a drug skin;

[0051] Apply the stirred coating evenly on the welding core, and press the welding rod, wherein the welding core is H08Cr21Ni10 welding core, and the welding core contains the following components in parts by weight:

[0052] C: 0.060 parts, Si: 0.40 parts, Mn: 1.5 parts, Cr: 20 parts, Ni: 10 parts, S: 0.019 parts, P: 0.0:4 parts;

[0053]After natural drying, the pressed and formed electrodes are sent to a high-temperature drying furnace for baking at a temperature of 280 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com