Fluorophlogopite prepared by using molybdenum tailings and method thereof

A technology of fluorophlogopite and molybdenum tailings, applied in aluminum silicate, silicate and other directions, can solve many problems, such as not using molybdenum tailings to manufacture fluorophlogopite, and achieves a simple process and reduces manpower and material resources. Consumption, the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The production process flow of the present invention using molybdenum tailings to prepare fluorphlogopite is: molybdenum tailings iron removal, impurity removal treatment; ball milling; batching calculation and batching; high temperature melting and heat preservation; cooling and heat preservation; furnace cooling; pulverization; quality Inspection, product grading; packaging for factory sales.

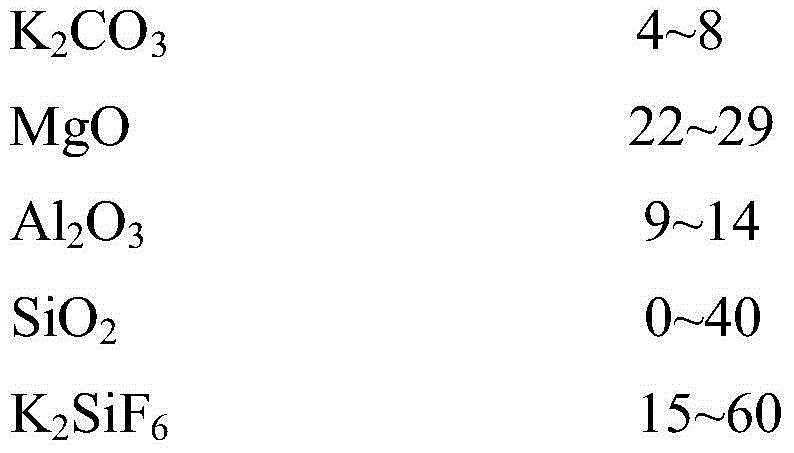

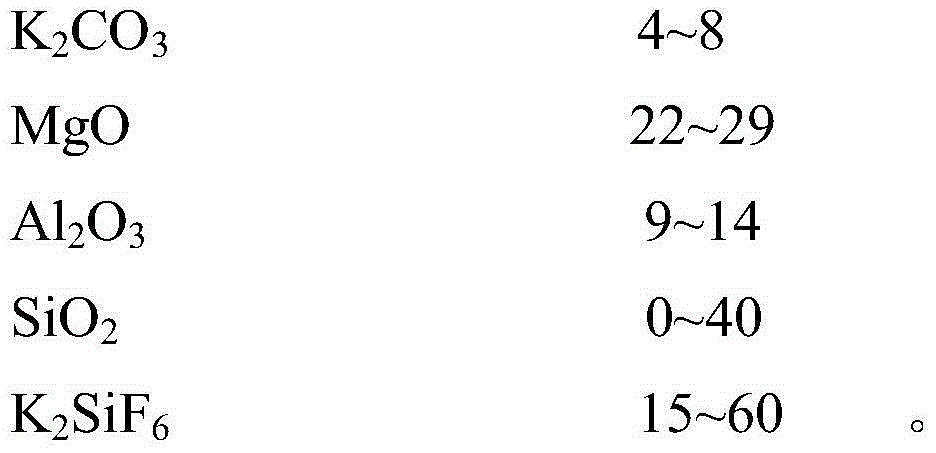

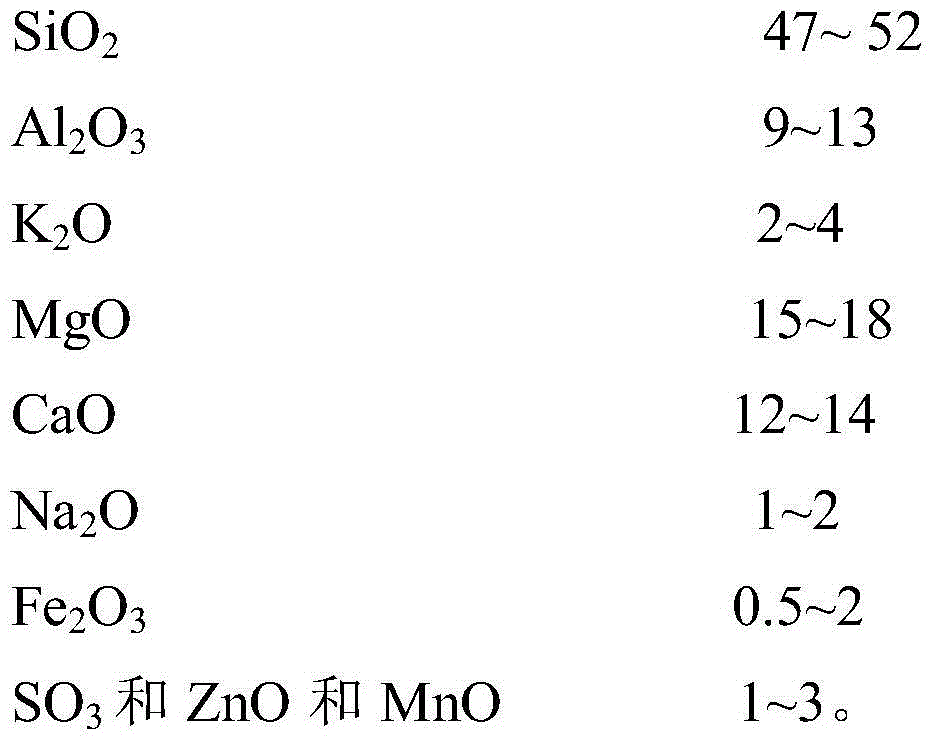

[0031] The raw material formula is shown in Table 3, and the calculated chemical composition of fluorophlogopite is shown in Table 4.

[0032] Raw material formula (kg) of table 3 embodiment 1

[0033] raw material

Molybdenum tailings

SiO 2

Al 2 o 3

K 2 CO 3

MgO

K 2 SiF 6

kg

50

11.1

5.9

2.9

13.5

16.6

[0034] The fluorophlogopite composition table (mass percentage) of the fluorine phlogopite of table 4 embodiment 1

[0035] composition

SiO 2

al 2 o 3

K 2 CO 3

...

Embodiment 2

[0052] The raw material formula of Example 2 is shown in Table 5, and the chemical composition of fluorophlogopite calculated therefrom is shown in Table 6.

[0053] The raw material formula (kg) of table 5 embodiment 2

[0054] raw material

Molybdenum tailings

SiO 2

Al 2 o 3

K 2 CO 3

MgO

K 2 SiF 6

kg

60

5.9

4.7

2.4

10.6

16.4

[0055] The fluorine phlogopite composition table (mass percentage) of the embodiment 2 of table 6

[0056] composition

SiO 2

Al 2 o 3

K 2 CO 3

MgO

K 2 SiF 6

mass percentage

35.9

11.4

4.3

29.4

16.4

[0057] One preparation process:

[0058] Raw material crushing, mixing, melting, annealing and sample processing are the same as in Example 1

[0059] Crystallization treatment: the crystallization holding temperature is 1250°C, hold for 2 hours, and the cooling rate from the melting temperature ...

Embodiment 3

[0067] The raw material formula of Example 3 is shown in Table 7, and the chemical composition of fluorophlogopite calculated therefrom is shown in Table 8.

[0068] The raw material formula (kg) of table 7 embodiment 3

[0069] raw material

Molybdenum tailings

SiO 2

al 2 o 3

K 2 CO 3

MgO

K 2 SiF 6

kg

71

0

3.4

1.9

7.4

16.4

[0070] The fluorophlogopite composition table (mass percentage) of the embodiment 3 of table 8

[0071] composition

SiO 2

Al 2 o 3

K 2 CO 3

MgO

K 2 SiF 6

mass percentage

35.5

11.4

4.1

29.7

16.4

[0072] One preparation process:

[0073] Raw material crushing, mixing, melting, annealing and sample processing are the same as in Example 1

[0074] Crystallization treatment: the crystallization holding temperature is 1300°C, hold for 2 hours, and the cooling rate from the melting temperature is abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com