Method for preparation of machinable mica glass ceramic insulating material from waste glass and phlogopite

A mica glass and ceramic insulation technology, applied in the field of engineering ceramic materials, can solve the problems of high cost, high energy consumption, high cost of mica glass ceramics, etc., and achieve the effects of low cost, good electrical insulation performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

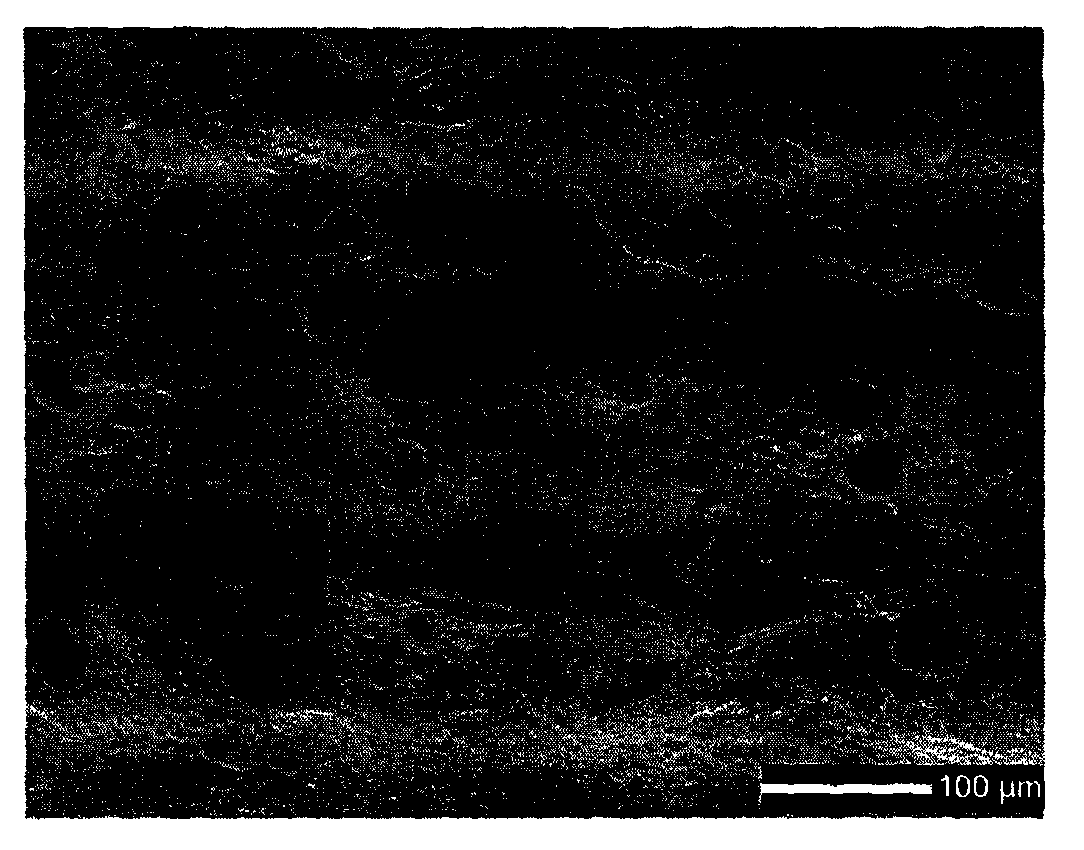

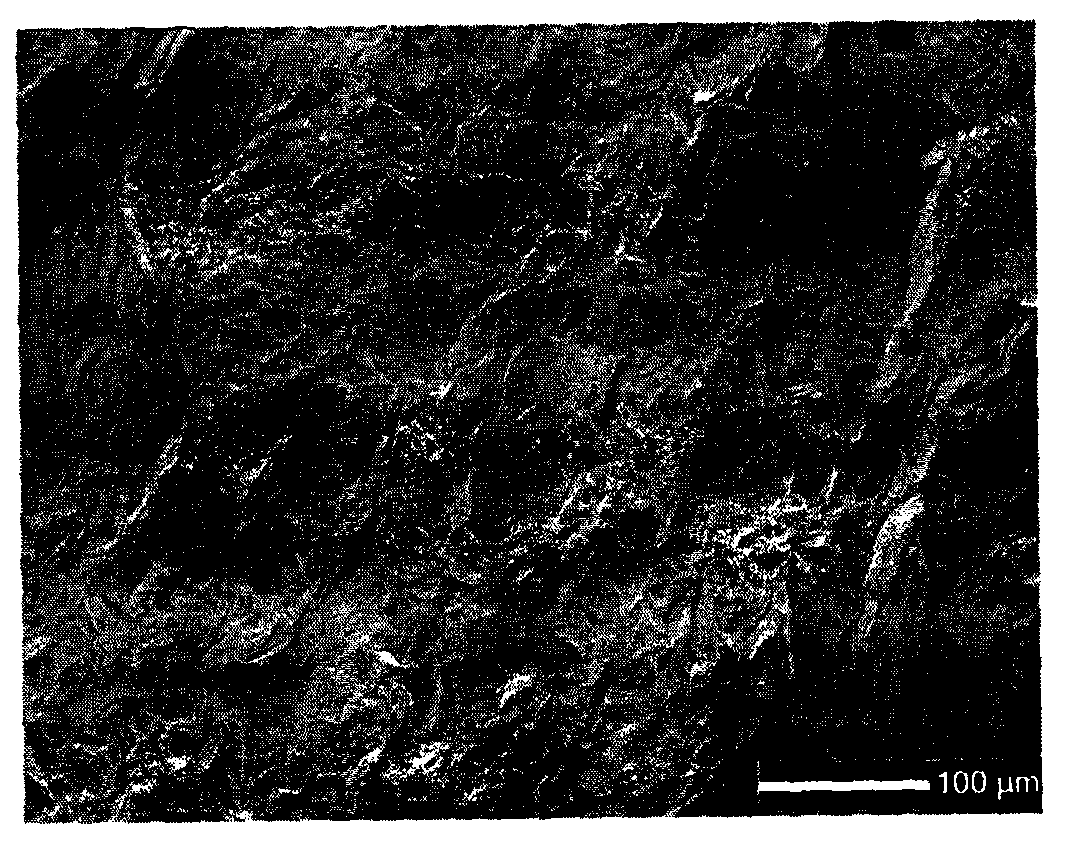

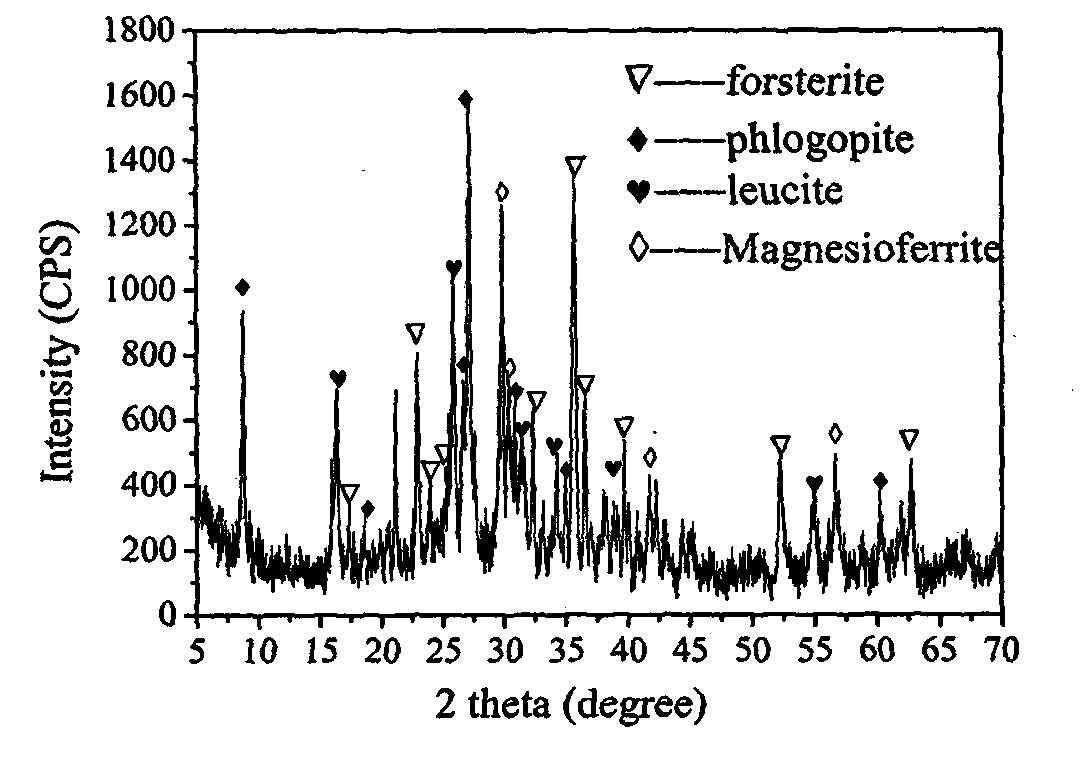

Embodiment 1

[0020] First, the waste glass is repeatedly cleaned, dried naturally at room temperature, then crushed, pulverized, sieved with 100 mesh, and then used; the phlogopite is crushed, crushed, and sieved with 100 mesh, and the obtained mica powder is used. The glass powder and the mica powder are mixed and ground according to the mass ratio (the mica accounts for 65%) to obtain the mixed powder. Add 4-5wt% polyvinyl alcohol as a binder to the mixture of glass powder and mica powder, grind again, then weigh about 3.5g of ingredient powder, put it into a mold, and place it on a powder tablet press for dry pressing. The pressure used is 20MPa, and the holding time is about 40s. Cold isostatic pressing is performed immediately after dry pressing. Before isostatic pressing, carefully put the strips of samples into rubber gloves, vacuumize the rubber gloves and tie them tightly, then place them in a cold isostatic press, pressurize to 120MPa at a certain speed, Keep the pressure for 9...

Embodiment 2

[0023] First, the waste glass is repeatedly cleaned, dried naturally at room temperature, then crushed, pulverized, sieved with 100 mesh, and then used; the phlogopite is crushed, crushed, and sieved with 100 mesh, and the obtained mica powder is used. The glass powder and the mica powder are mixed and ground according to the mass ratio (the mica accounts for 65%) to obtain the mixed powder. Add 4-5wt% polyvinyl alcohol as a binder to the mixture of glass powder and mica powder, grind again, then weigh about 3.5g of ingredient powder, put it into a mold, and place it on a powder tablet press for dry pressing. The pressure used is 20MPa, and the holding time is about 40s. Cold isostatic pressing is performed immediately after dry pressing. Before isostatic pressing, carefully put the strips of samples into rubber gloves, vacuumize the rubber gloves and tie them tightly, then place them in a cold isostatic press, pressurize to 120MPa at a certain speed, Keep the pressure for 9...

Embodiment 3

[0026] First, the waste glass is repeatedly cleaned, dried naturally at room temperature, then crushed, pulverized, sieved with 100 mesh, and then used; the phlogopite is crushed, crushed, and sieved with 100 mesh, and the obtained mica powder is used. The glass powder and the mica powder are mixed and ground according to the mass ratio (the mica accounts for 70%) to obtain the mixed powder. Add 4-5wt% polyvinyl alcohol as a binder to the mixture of glass powder and mica powder, grind again, then weigh about 3.5g of ingredient powder, put it into a mold, and place it on a powder tablet press for dry pressing. The pressure used is 20MPa, and the holding time is about 40s. Cold isostatic pressing is performed immediately after dry pressing. Before isostatic pressing, carefully put the strips of samples into rubber gloves, vacuumize the rubber gloves and tie them tightly, then place them in a cold isostatic press, pressurize to 120MPa at a certain speed, Keep the pressure for 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com