Preparation method of phlogopite powder

A technology of phlogopite powder and phlogopite, which is applied in the direction of aluminum silicate, silicate, etc., can solve the problems of low purity of phlogopite powder, insufficient cleaning of impurities, and low production efficiency, so as to improve filtration efficiency and facilitate recycling , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

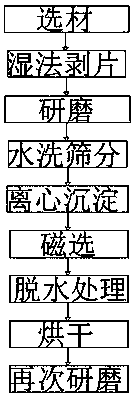

[0024] refer to figure 1 , a preparation method of phlogopite powder, comprising the following steps:

[0025] S1: material selection, manually screen the phlogopite ore, and wash and dry the screened phlogopite ore;

[0026] S2: wet flaking, the selected high-quality phlogopite ore raw materials are wet flaked, washed, removed, soaked, and rolled to form a flaky primary material A;

[0027] S3: Grinding, drying and dehydrating the flake raw material A at low temperature, rolling it with a wheel mill, and then grinding it with a grinder to produce phlogopite particles B;

[0028] S4: Washing and screening, put the phlogopite particles B into the separation sieve, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com