Silicon carbide fiber toughened phlogopite glass-ceramic multi-phase material and preparation method thereof

A silicon carbide fiber and glass-ceramic technology, applied in the field of silicon carbide fiber-toughened phlogopite glass-ceramic composite materials and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

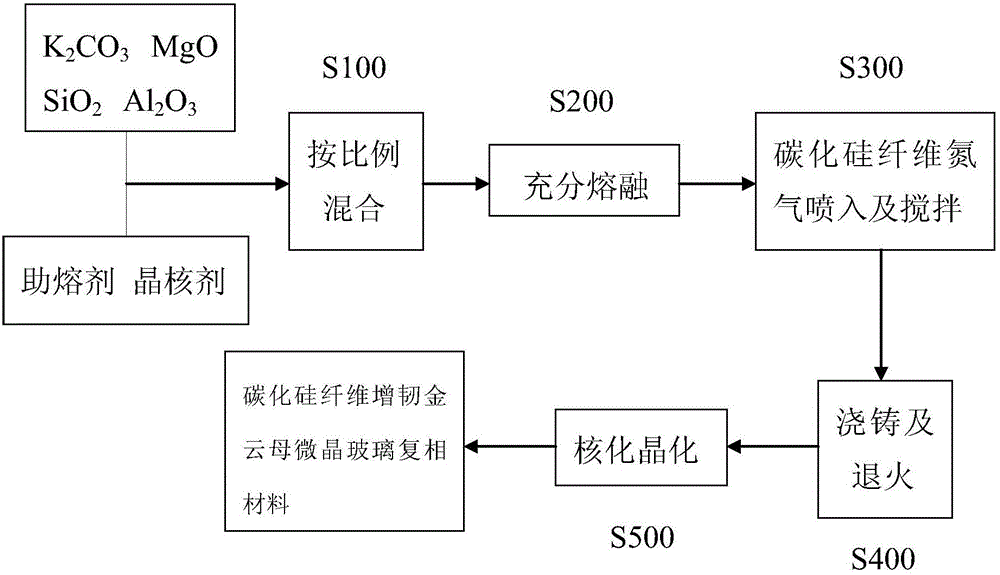

[0031] refer to figure 1 , in step S100, 5 parts by weight of K 2 CO 3 powder, 16 parts by weight of MgO powder, 47 parts by weight of SiO 2 powder, 11 parts by weight of Al 2 o 3 powder and 4 parts by weight of flux B 2 o 3 Powder, respectively 2 parts by weight of crystal nucleating agent Cr 2 o 3 Powder and TiO 2 The powders are blended into a homogeneous mixture. Then in step S200, the above mixture is melted at 1550° C. for 4 hours to ensure sufficient melting of the mixture. Then, at the end of the melting stage in step S200, as shown in step S300, 13 parts by weight of powdered silicon carbide fibers are sprayed into the molten pool through nitrogen flow and fully stirred, so that the silicon carbide fibers are evenly distributed in the molten mixture. A molten mixture containing evenly distributed silicon carbide fibers was obtained. As shown in step S400, the molten mixture obtained in step S300 is poured into a mold fully preheated at 590°C, and annealed a...

Embodiment 2

[0033] refer to figure 1 , in step S100, 6 parts by weight of K 2 CO 3 powder, 16 parts by weight of MgO powder, 45 parts by weight of SiO 2 powder, 10 parts by weight of Al 2 o 3 powder and 5 parts by weight of flux B 2 o 3 Powder, respectively 2 parts by weight of crystal nucleating agent Cr 2 o 3 Powder and TiO 2 The powders are blended into a homogeneous mixture. Then in step S200, the above mixture is melted at 1480° C. for 3 hours to ensure sufficient melting of the mixture. Then, at the end of the melting stage in step S200, as shown in step S300, 11 parts by weight of powdered silicon carbide fibers are sprayed into the molten pool through nitrogen flow and fully stirred, so that the silicon carbide fibers are evenly distributed in the molten mixture. A molten mixture containing evenly distributed silicon carbide fibers was obtained. As shown in step S400, the molten mixture obtained in step S300 is poured into a mold fully preheated at 580°C, and annealed a...

Embodiment 3

[0035] refer to figure 1 , in step S100, 4 parts by weight of K 2 CO 3 powder, 10 parts by weight of MgO powder, 44 parts by weight of SiO 2 powder, 17 parts by weight of Al 2 o 3 powder and 3 parts by weight of flux B 2 o 3 Powder, the crystal nucleating agent Cr of 1 weight part respectively 2 o 3 Powder and TiO 2The powders are blended into a homogeneous mixture. Then in step S200, the above mixture is melted at 1480° C. for 2 hours to ensure sufficient melting of the mixture. Then, at the end of the melting stage in step S200, as shown in step S300, 19 parts by weight of powdered silicon carbide fibers are sprayed into the molten pool through nitrogen flow and fully stirred, so that the silicon carbide fibers are evenly distributed in the molten mixture. A molten mixture containing evenly distributed silicon carbide fibers was obtained. As shown in step S400, the molten mixture obtained in step S300 is poured into a mold fully preheated at 450°C, and annealed at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com