Self-lubricating solid composite material and preparation method of self-lubricating solid coating

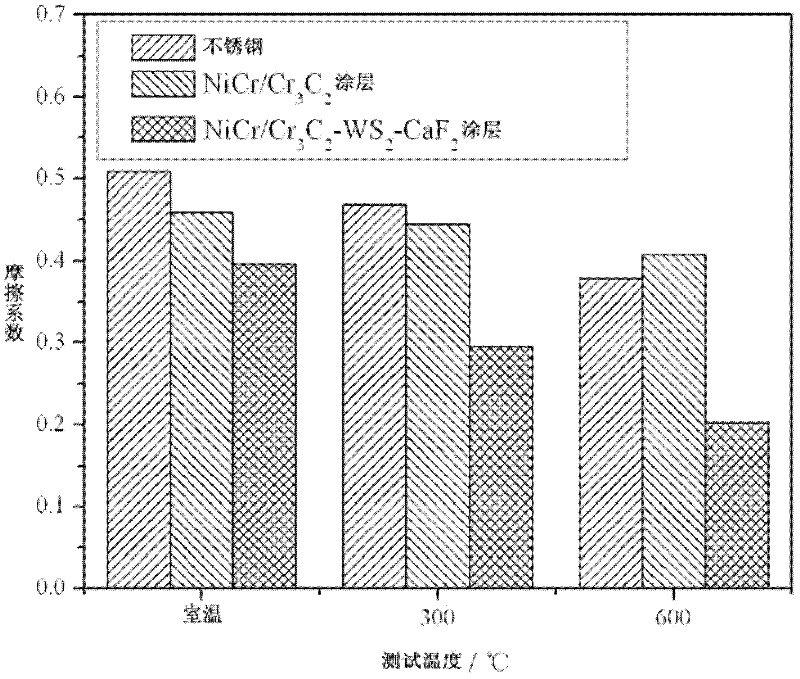

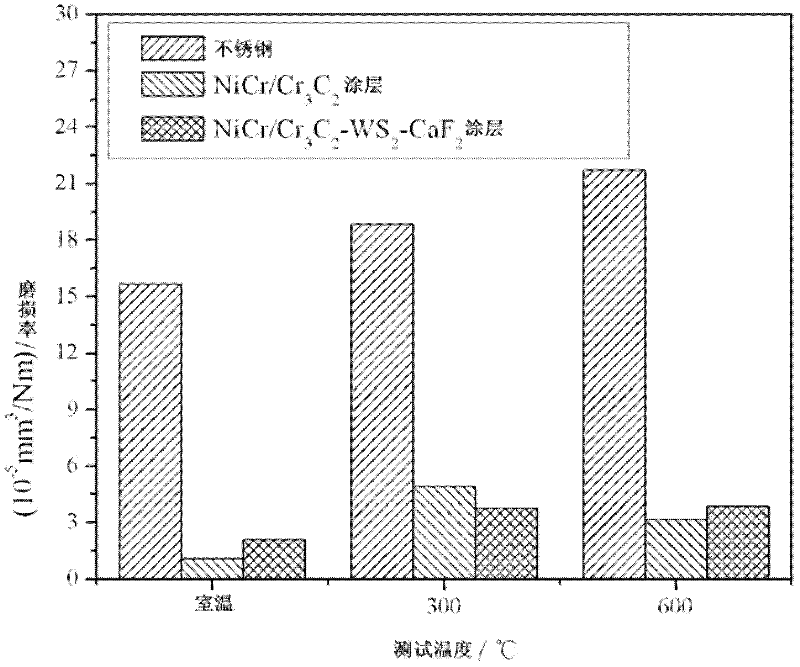

A solid self-lubricating, composite material technology, applied in metal material coating process, coating and other directions, can solve problems such as poor lubrication performance, achieve low friction coefficient and wear rate, improve comprehensive performance, and excellent high temperature wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention has no special limitation on the preparation method of the solid self-lubricating composite material, and is preferably prepared according to the following method:

[0046] The chromium carbide, nickel-chromium alloy, tungsten disulfide and calcium fluoride are mechanically ball-milled, mixed, dried, and melted to obtain a solid self-lubricating composite material.

[0047] The present invention has no special limitation on the melting method, and methods such as laser cladding, plasma spraying, and powder metallurgy can be used to form a coating on the substrate while melting the mixture.

[0048] In the present invention, the chromium carbide endows the composite material with good wear resistance; tungsten disulfide and calcium fluoride endow the composite material with good lubricity in a wide temperature range; The compatibility between tungsten and calcium fluoride makes the composite material have good comprehensive performance. The solid s...

Embodiment 1

[0088]Mix 21g of nickel-chromium alloy with a particle size of 30 μm to 45 μm, 49 g of chromium carbide with a particle size of 30 μm to 45 μm, 15 g of tungsten disulfide with a particle size of 1 μm to 2 μm, and 15 g of calcium fluoride with a particle size of 10 μm to 25 μm, and mix and bake After drying, the mixture is obtained;

[0089] Dissolving methyl cellulose in ether, adding the mixture to make a paste, coating the obtained paste on the surface of the austenitic stainless steel substrate, and drying to obtain a pre-coat;

[0090] Under the protection of nitrogen, the laser beam with a power density of 1.2kW is used to scan and irradiate the pre-coated coating to obtain a solid self-lubricating coating; wherein the laser beam is a carbon dioxide gas laser beam with a size of The length is 6 mm, the width is 3 mm, and the scanning speed is 4 mm; the overlapping rate of the multiple overlapping is 50%.

Embodiment 2

[0092] Mix 18g of nickel-chromium alloy with a particle size of 30 μm to 45 μm, 55 g of chromium carbide with a particle size of 30 μm to 45 μm, 13 g of tungsten disulfide with a particle size of 1 μm to 2 μm, and 14 g of calcium fluoride with a particle size of 10 μm to 25 μm, mix and bake After drying, the mixture is obtained;

[0093] Under nitrogen protection, a laser beam with a power density of 1.2kW is used to irradiate the 1Cr18Ni9Ti stainless steel base material to form a molten pool, and then the mixture is fed into the molten pool by nitrogen synchronous powder feeding, and nitrogen is used to protect the molten pool Avoid molten pool oxidation; Wherein, the laser beam is a carbon dioxide gas laser beam, the size is 6mm long, 3mm wide, and the scanning speed is 4mm; the feeding speed is 25g / min;

[0094] Continue to adopt the laser beam with a power density of 1.2kW to irradiate the solid self-lubricating composite material with multiple overlapping laser scans to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com