Cast rolling composite production device and method of metal composite plate

A technology of metal composite panels and production methods, which is applied in the field of steel processing and manufacturing, can solve the problems of increasing the difficulty and production time of metal composite panels, the inability to continuously process sheets, and reducing the production efficiency of metal composite panels. Smooth and smooth, reduce difficulty, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

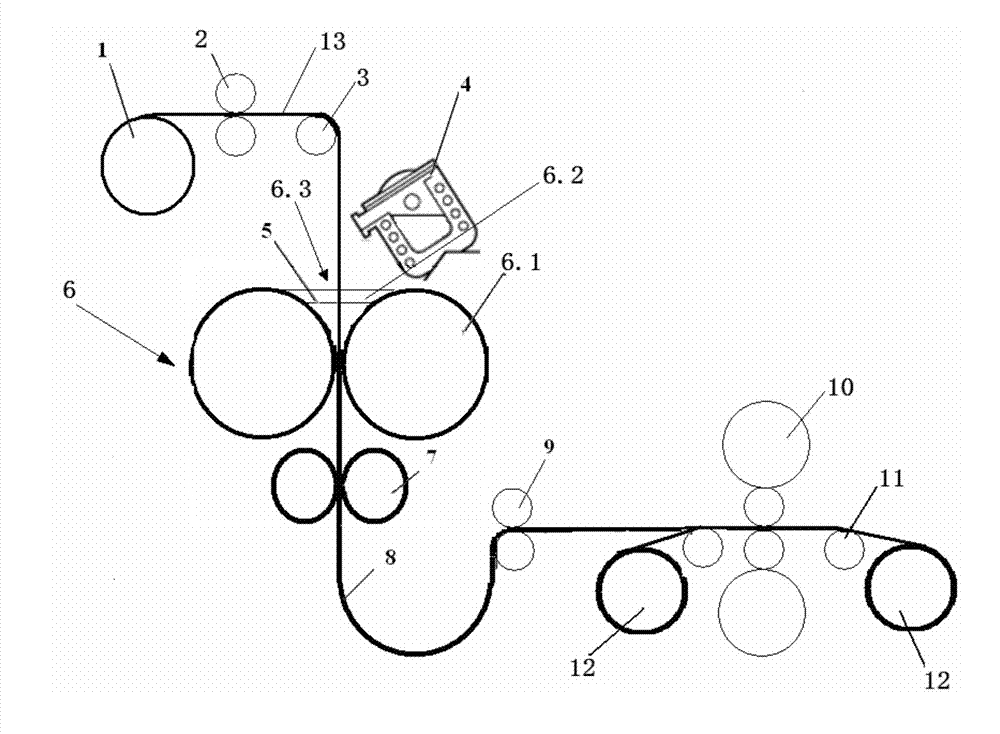

[0050] like figure 1 The casting-rolling compound production device of the metal composite plate shown includes a base metal uncoiler 1, a first pinch roller 2 positioned behind the output end of the base metal uncoiler 1 for conveying the base metal, and a first pinch roll 2 positioned behind the output end of the base metal uncoiler 1. The guide roller 3 at the rear is used to change the conveying direction of the base material, the thin strip continuous casting machine 6 located under the guide roller 3 is used for the composite operation of the base metal, and the thin strip continuous caster 6 located above the thin strip continuous casting machine 6 is used to feed the thin strip continuous casting machine 6 The tundish 4 for conveying the composite layer melt in the center, the secondary cooling leveling roll 7 located under the thin stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com