Propylene material with high modulus and high rigidity for light automobile door panel and preparation method thereof

A high-rigidity, high-modulus technology, applied in high-modulus, high-rigidity light-weight acrylic materials for automobile door panels and its preparation field, can solve the problems of material strength and modulus decline, and achieve improved modulus and rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

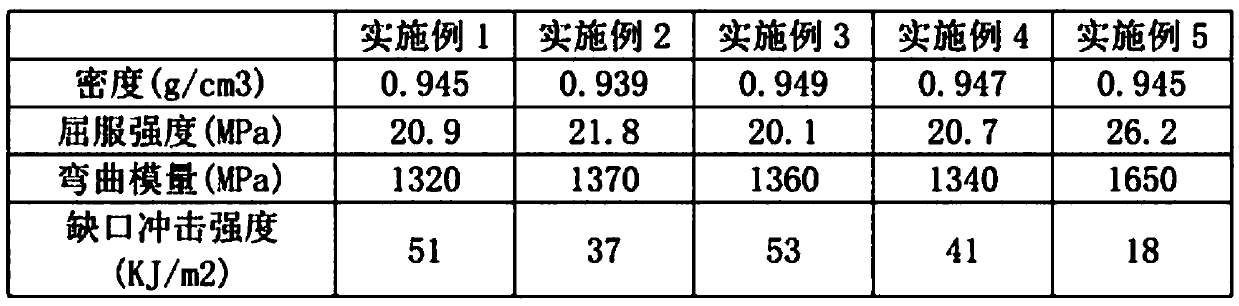

Examples

Embodiment 1

[0041] Taking polypropylene 1 by weight percentage is 36%, polypropylene 2 is 44%, toughening agent 1 is 8%, toughening agent 2 is 4%, superfine inorganic filler 1 is 7%, Irganox 1010 is 0.4%, 5902 is 0.2%, mixed in a high-speed mixer for 3 minutes, and then put into a twin-screw extruder for extrusion and granulation. The temperature of each zone of the screw: 140°C in the first zone, 160°C in the second zone, 190°C in the third zone, and 190°C in the fourth zone. The fifth zone is 200°C, the sixth zone is 200°C, the seventh zone is 200°C, the eighth zone is 210°C, the ninth zone is 210°C, and the machine head is 220°C. Screw host speed: 500 rpm. After the particles are dried, they are put into the injection molding machine for injection molding to prepare samples.

Embodiment 2

[0043] Take by weight polypropylene 1 as 40%, polypropylene 2 as 44%, toughening agent 1 as 8%, ultrafine inorganic filler 1 as 7%, Irganox 1010 as 0.4%, 5902 as 0.2%, mix at high speed Mix in the machine for 3 minutes, and then put it into a twin-screw extruder for extrusion and granulation. The temperature of each zone of the screw: 140°C in the first zone, 160°C in the second zone, 190°C in the third zone, 190°C in the fourth zone, 200°C in the fifth zone, and 200 in the sixth zone. ℃, 200℃ in the seventh zone, 210℃ in the eighth zone, 210℃ in the ninth zone, and 220℃ in the machine head. Screw host speed: 500 rpm. After the particles are dried, they are put into the injection molding machine for injection molding to prepare samples.

Embodiment 3

[0045] Taking polypropylene 1 by weight percentage is 36%, polypropylene 2 is 44%, toughening agent 1 is 8%, toughening agent 2 is 4%, superfine inorganic filler 2 is 7%, Irganox 1010 is 0.4%, 5902 is 0.2%, mixed in a high-speed mixer for 3 minutes, and then put into a twin-screw extruder for extrusion and granulation. The temperature of each zone of the screw: 140°C in the first zone, 160°C in the second zone, 190°C in the third zone, and 190°C in the fourth zone. The fifth zone is 200°C, the sixth zone is 200°C, the seventh zone is 200°C, the eighth zone is 210°C, the ninth zone is 210°C, and the machine head is 220°C. Screw host speed: 500 rpm. After the particles are dried, they are put into the injection molding machine for injection molding to prepare samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com