A kind of preparation method of synthetic fluorine phlogopite

A fluorophlogopite and artificial synthesis technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of small crystals, low pass rate of subsequent processing, and high wafer brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

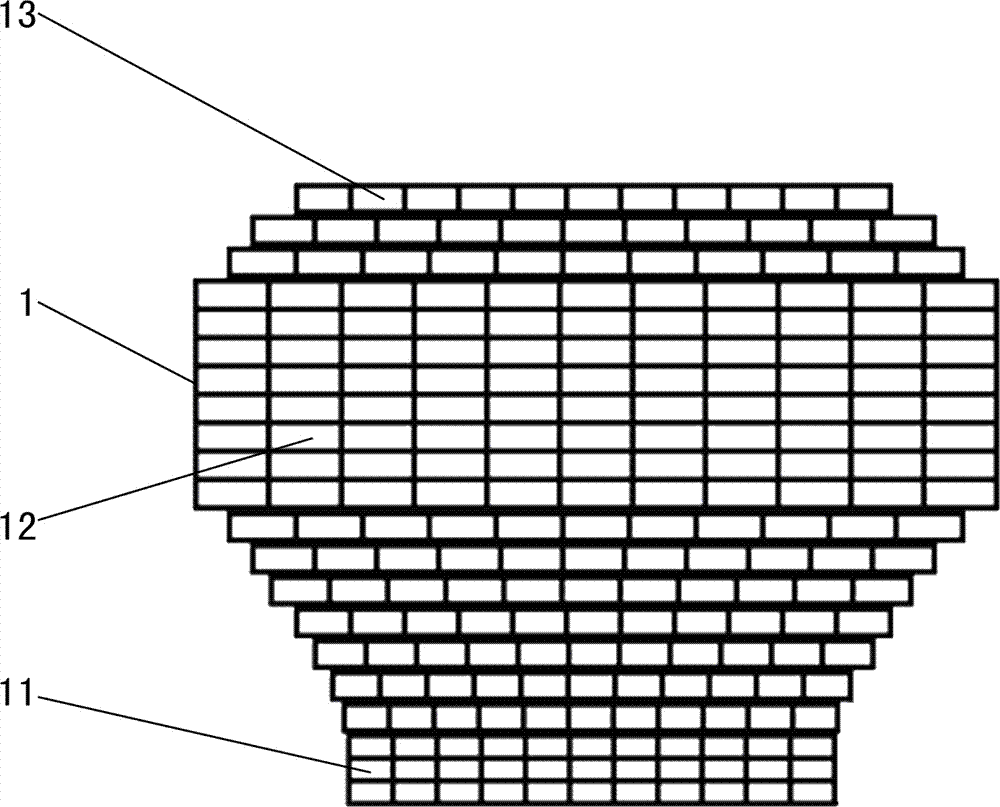

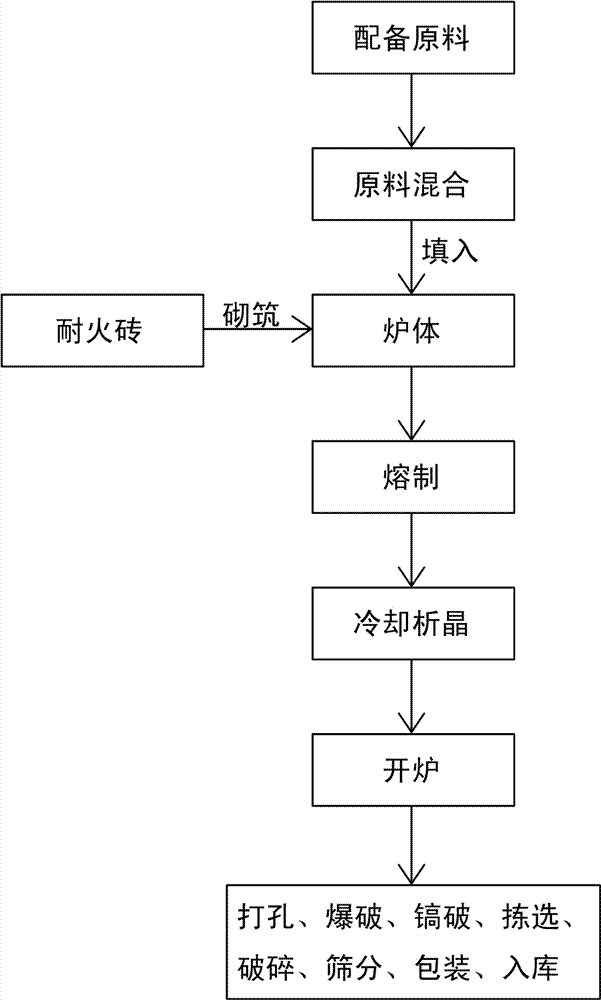

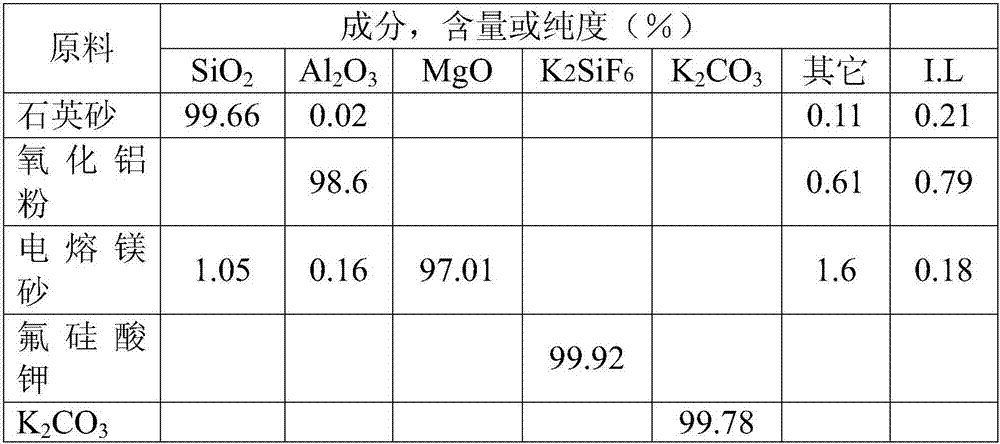

[0041] In this embodiment, in order to prepare artificially synthesized fluorphlogopite, the SiO contained in the raw materials equipped 2 , MgO, Al 2 o 3 、K 2 CO 3 and K 2 SiF 6 The molar ratio is: SiO 2 :MgO:Al 2 o 3 :K 2 CO 3 :K 2 SiF 6 =15.7:18:3:0.7:2.3. According to this molar ratio, calculate the SiO contained in the prepared raw material 2 , MgO, Al 2 o 3 、K 2 CO 3 and K 2 SiF 6 The weight percentage is: SiO 2 36.60%, MgO 28.15%, Al 2 o 3 11.87%, K 2 CO 3 3.75%, K 2 SiF 6 : 19.63%. Use raw materials such as quartz sand, alumina powder, fused magnesia, potassium fluorosilicate and potassium carbonate Content or purity, see Table 1), after calculation, by weight, the proportioning of quartz sand, alumina powder, fused magnesia, potassium fluorosilicate and potassium carbonate is: quartz sand 35.91%, alumina 11.75%, Fused magnesia 29.23%, potassium fluorosilicate 19.44%, potassium carbonate 3.67%.

[0042] refer to figure 2 , preferably, t...

Embodiment 2

[0063] In this embodiment, in order to prepare artificially synthesized fluorphlogopite, the SiO contained in the raw materials equipped 2 , MgO, Al 2 o 3 、K 2 CO 3 and K 2 SiF 6 The molar ratio is: SiO 2 :MgO:Al 2 o 3 :K 2 CO 3 :K 2 SiF 6 =15.9:18:3:0.9:2.1. According to this molar ratio, calculate the SiO contained in the prepared raw material 2 , MgO, Al 2 o 3 、K 2 CO 3 and K 2 SiF 6 The weight percentage is: SiO 2 37.13%, MgO28.20%, Al 2 o 3 11.89%, K 2 CO 3 4.83%, K 2 SiF 6 : 17.95%. Use raw materials such as quartz sand, alumina powder, fused magnesia, potassium fluorosilicate and potassium carbonate Content or purity, see Table 1), after calculation, by weight, the proportioning of quartz sand, alumina powder, fused magnesia, potassium fluorosilicate and potassium carbonate is: quartz sand 36.63%, alumina 11.85%, Fused magnesia 28.84%, potassium fluorosilicate 17.89%, potassium carbonate 4.79%.

[0064] refer to figure 2 , preferably, th...

Embodiment 3

[0085] In this embodiment, in order to prepare artificially synthesized fluorphlogopite, the SiO contained in the raw materials equipped 2 , MgO, Al 2 o 3 、K 2 CO 3 and K 2 SiF 6 The molar ratio is: SiO 2 :MgO:Al 2 o 3 :K 2 CO 3 :K 2 SiF 6 =15.5:18:3:0.5:2.5. According to this molar ratio, calculate the SiO contained in the prepared raw material 2 , MgO, Al 2 o 3 、K 2 CO 3 and K 2 SiF 6 The weight percentage is: SiO 2 36.09%, MgO28.10%, Al 2 o 3 11.85%, K 2 CO 3 2.67%, K 2 SiF 6 : 21.29%. Use raw materials such as quartz sand, alumina powder, fused magnesia, potassium fluorosilicate and potassium carbonate Content or purity, see Table 1), after calculation, by weight, the proportioning of quartz sand, alumina powder, fused magnesia, potassium fluorosilicate and potassium carbonate is: quartz sand 35.66%, aluminum oxide 11.87%, Fused magnesia 28.80%, potassium fluorosilicate 20.96%, potassium carbonate 2.71%.

[0086] refer to figure 2 , preferabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com