A nickel-based welding rod

A technology of nickel-based welding rod and welding rod, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve problems such as arc stability and slag coverage, low content of diffusible hydrogen, poor weld formation, etc. , to achieve the effect of good slag removal, excellent operation performance and moderate plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The components of the coating used in the electrode of the present invention and their mass fractions are as follows: rutile: 50%, titanium dioxide: 2%, fluorite: 23%, cryolite 8%, phlogopite: 2%, zircon sand: 3% %, soda ash 1.5%, metal manganese: 5%, ferro-titanium: 3.5%, ferro-niobium: 2%. Among them, Ti in ferro-titanium: 25-35%, and Nb in ferro-niobium: 50-60%.

[0032] The mechanical property requirements of weld core deposited metal are: R P0.2 ≥360MPa, Rm≥550Mpa, A≥27%; the mass percentage of the chemical composition of the welding core deposited metal is: C: 0.017, S: 0.0081, P: 0.005, Si: 0.821, Mn: 5.10, Cr: 15.1, Ni : 68.93, Fe: 7.83, Cu: 0.040, Ti0.142, Nb: 1.37.

[0033] After mixing the raw materials of the drug skin evenly, pulverize the particle size below 40 mesh, add potassium sodium water glass of 43-48Be (20° C.) accounting for 25-30% of the mass content of the solid component, and prepare a paste for the drug skin. Using the deposited metal with ...

Embodiment 2

[0036] The components of the drug skin and their mass parts are as follows: rutile: 36%, titanium dioxide: 7%, fluorite: 30%, cryolite 5%, phlogopite: 4%, zircon sand: 2%, soda ash 1% , Manganese metal: 10%, ferro-titanium: 2%, ferro-niobium: 3%.

[0037] Other conditions are identical with embodiment 1.

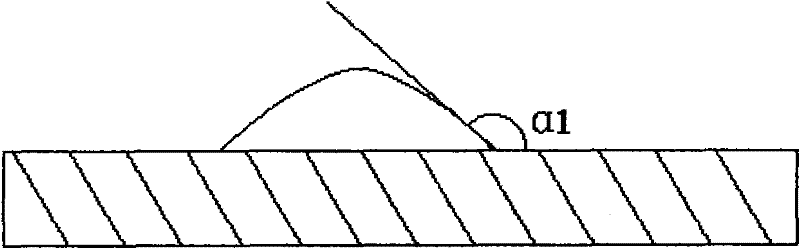

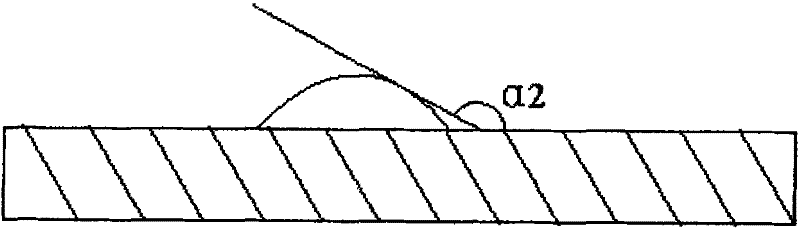

[0038] The electrode produced according to the above process has smooth surface, high yield and stable eccentricity; stable arc during welding, good slag removal, and excellent operating performance of the electrode; beautiful weld shape, moderate bead height, and moderate weld penetration angle; Metal strength and plasticity are moderate.

Embodiment 3

[0040] The components of the coating and their mass parts are as follows: rutile: 45%, titanium dioxide: 6%, fluorite: 20%, cryolite 3%, phlogopite: 3.5%, zircon sand: 4%, soda ash 0.5% , Manganese metal: 10%, ferro-titanium: 4%, ferro-niobium: 4%.

[0041] Other conditions are identical with embodiment 1.

[0042] The electrode produced according to the above process has smooth surface, high yield and stable eccentricity; stable arc during welding, good slag removal, and excellent operating performance of the electrode; beautiful weld shape, moderate bead height, and moderate weld penetration angle; Metal strength and plasticity are moderate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com