Patents

Literature

106results about How to "Increase slippery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

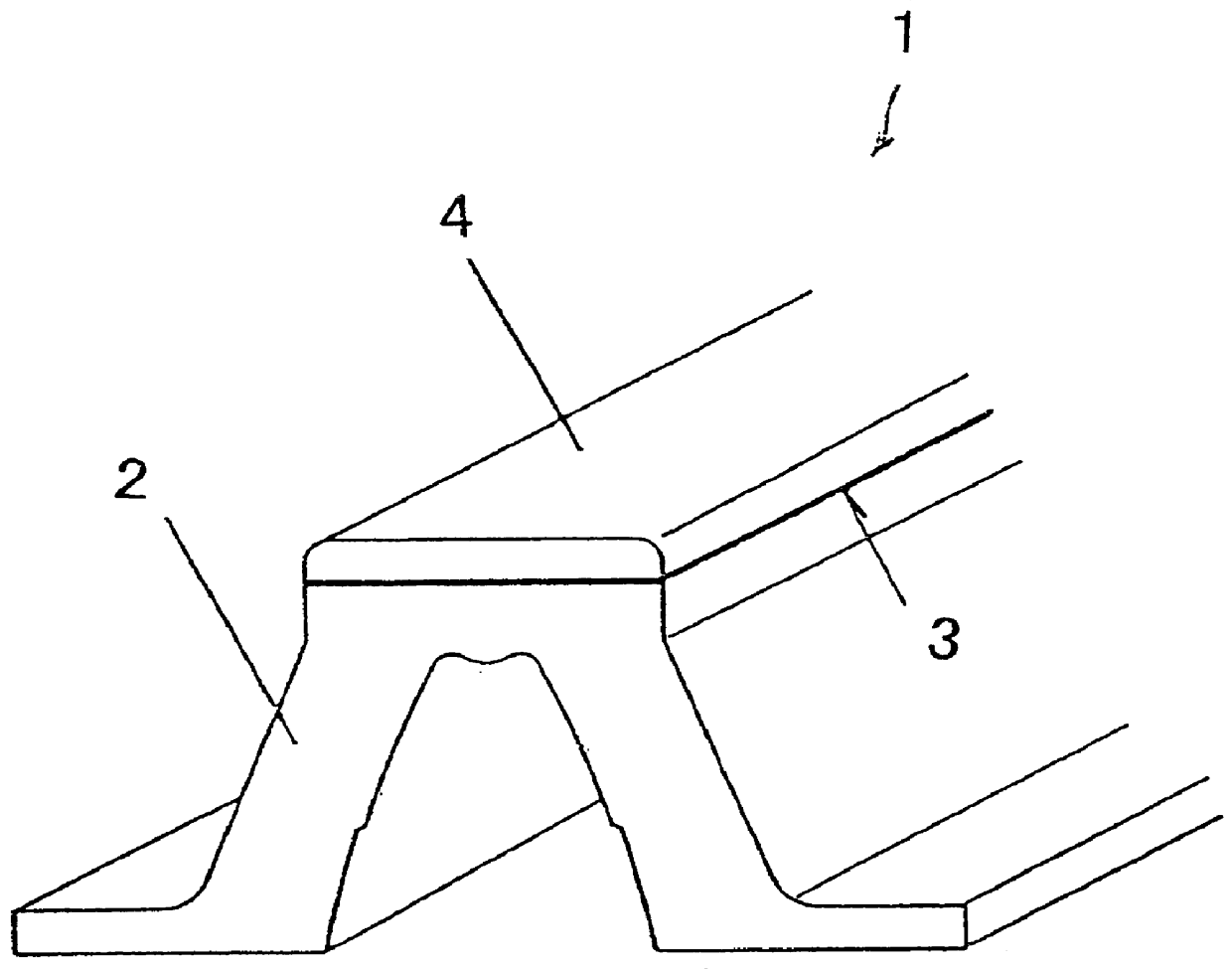

Marine fender

InactiveUS6050211AHigh bonding strengthHigh slip propertyPortable framesVessel cleaningEngineeringBonding strength

Owner:BRIDGESTONE CORP

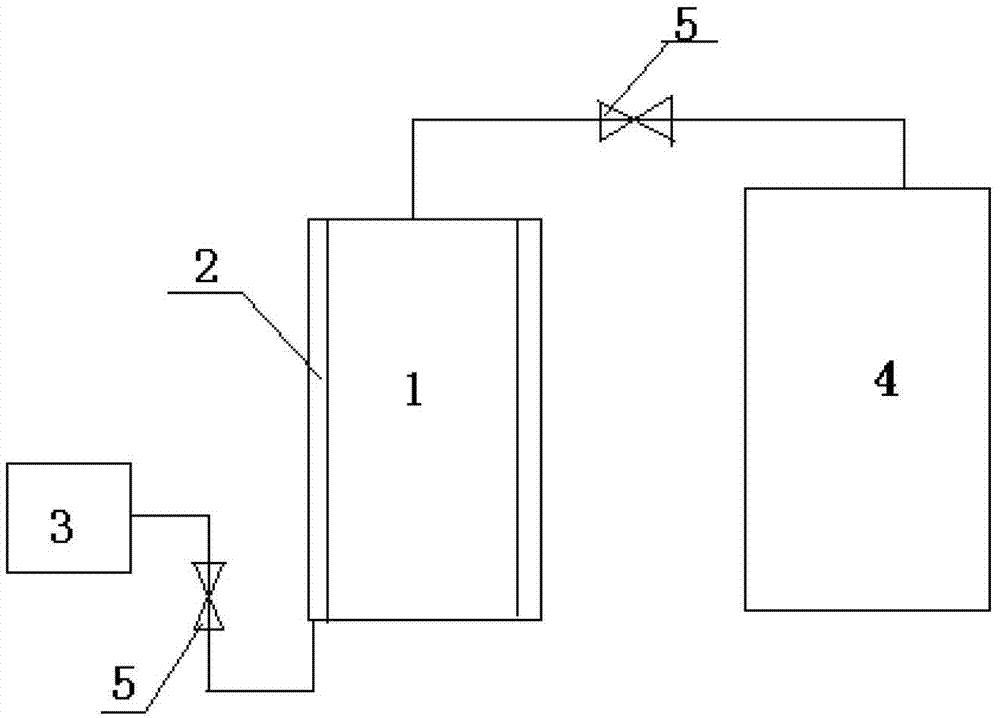

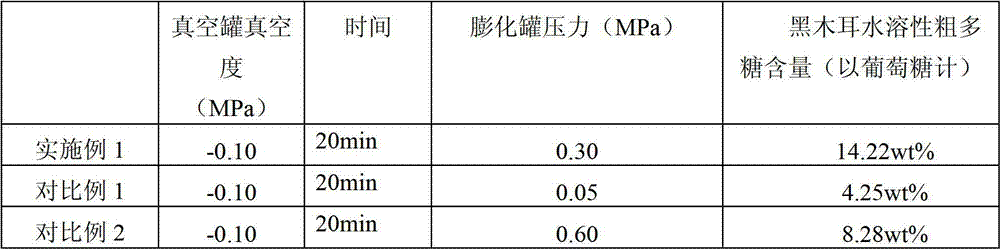

Method for preparing black fungus puffed ultramicro powder

InactiveCN102763817AGood effectThe solution is hard and not suitable for chewingFood preparationFlavorAdditive ingredient

The invention discloses a method for preparing a black fungus puffed ultramicro powder. The method includes selecting black fungus sporophores to serve as a raw material, puffing black funguses by an instantaneous alternating temperature and pressure difference of a puffing tank of a puffing device, maintaining a valve between the puffing tank of the puffing device and a vacuum tank to be in an opening state all the time, subjecting the black funguses in the puffing tank to a vacuum drying, and subjecting the puffed black funguses to a coarse grinding and a superfine grinding to obtain the black fungus puffed ultramicro powder. According to the method, a high pressure gas serves as a carrier, by means of a puffing wall breaking process, a black fungus organization structure is subjected to a cytoclasis to release whole nutritional ingredients and medicinal effect ingredients which are easy to digest and use by human bodies, and problems that the black funguses are hard and not suitable for being chewed, digested and used are solved. Besides, when the black fungus puffed ultramicro powder can be mixed with foods of flours, cakes and the like, the black fungus puffed ultramicro powder has flavor and nutrition of the black funguses, and smoothing taste is increased. The method is low in production cost and suitable for industrialization production, and products are used for foods, health care foods, medicines and raw material extraction.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

Health-care fish balls containing almonds and preparation method of health-care fish balls

The invention discloses health-care fish balls containing almonds. The fish balls are prepared from raw materials in parts by weight as follows: 200-220 parts of fresh silver carp flesh, 6-7 parts of egg white, 4-5 parts of potato starch, 30-33 parts of Chinese yams, 7-8 parts of pork fat, 3-4 parts of honey, 7-8 parts of fresh bayberries, 3-4 parts of sweet almonds, 1-1.2 parts of Lindernia ruellioides, 0.7-0.8 parts of immature orange fruits, 1.1-1.3 parts of Zinnia elegans, 0.8-1.0 part of saccharose, 0.5-0.6 parts of carrageenan, 0.4-0.5 parts of ginger, 4-5 parts of spices and proper amounts of table salt and water. According to the fish balls, adopted auxiliary materials such as the sweet almonds and the like have functions of moistening lung dryness and relaxing bowels, and adopted Chinese herbal medicines such as the Zinnia elegans and the like has functions of clearing heat and realizing diuresis.

Owner:王龙云

Fruity noodles and preparation method thereof

InactiveCN104012870AGreat tasteHigh nutritional valueNatural extract food ingredientsFood ingredient functionsKiwi fruitKiwi

The invention relates to the food field and particularly relates to fruity noodles and a preparation method thereof. The fruity noodles provided by the invention comprise apples, mangos, kiwi fruits, honey, wheat meal, starch, alkaline, salt, coconut juice, edible gum, an emulsifier and transglutaminase. The preparation method for the fruity noodles comprises the four steps. The fruity noodles disclosed by the invention are applicable to a making method for cold noodles with sauce in summer, can blend the fruity taste into the noodles, and is very tasty and refreshing.

Owner:南京麦思德餐饮管理有限公司

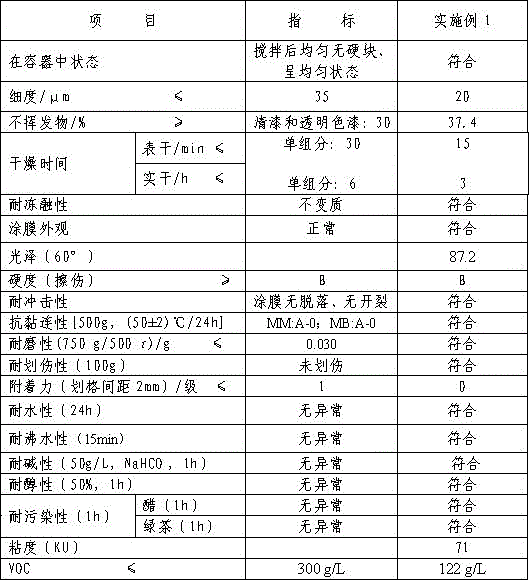

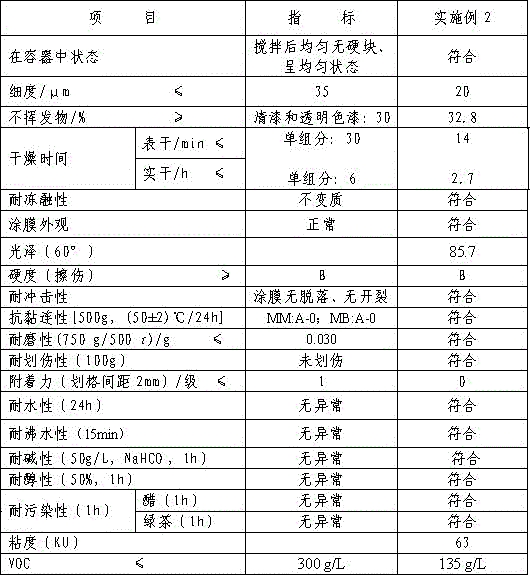

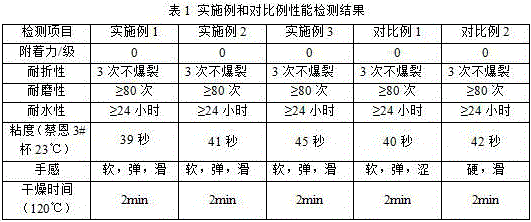

Quick-drying type acrylic acid and polyurethane environment-friendly water-based wood gloss varnish and preparation method thereof

InactiveCN106280812AImprove performanceHigh strengthPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention relates to environment-friendly water-based wood varnish, in particular to water-based wood gloss varnish and discloses quick-drying type acrylic acid and polyurethane environment-friendly water-based wood gloss varnish and a preparation method thereof. The quick-drying type acrylic acid and polyurethane environment-friendly water-based wood gloss varnish is prepared from components in percentage by weight as follows: 30%-50% of a water-based acrylic resin emulsion, 25%-45% of a water-based polyurethane resin emulsion, 3%-8% of a coalescing agent, 0.1%-0.5% of a base material wetting agent, 0.1%-0.3% of an antifoaming agent, 0.5%-1.0% of a thickening agent, 0.1%-0.5% of a leveling agent, 0.1%-0.5% of a slipping and wear-resisting agent and 5%-15% of water. The preparation method of the quick-drying type acrylic acid and polyurethane environment-friendly water-based wood gloss varnish comprises steps as follows: water, the water-based acrylic resin emulsion and the water-based polyurethane resin emulsion are added to a dispersion vat for medium-speed dispersion, the coalescing agent, the thickening agent, the wetting agent, the antifoaming agent and other components are added, after medium-speed dispersion, the fineness and viscosity of a finished product are detected through sampling, and filtration, canning and packaging are performed. The VOCs (volatile organic compounds) of the product can be effectively reduced, the varnish film performance can be remarkably improved, and the varnish has excellent characteristics of quick drying and high strength.

Owner:广东珠江化工涂料有限公司

Aqueous environment-friendly touch-sense printing ink and preparation method of same

The invention provides aqueous environment-friendly touch-sense printing ink and a preparation method of same. The printing ink includes, by weight, 60-70% of aqueous resin, 15-20% of aqueous wax slurry, 2-5% of anhydrous ethanol, 2-5% of deionized water, 0.3-1% of a defoamer, 1-3% of other additives, and 8-12% of aqueous touch-sense powder. The printing ink is free of escape of toxic gas, is environment-friendly and non-pollution, has a milky white color, has strong adhesion force after film forming and is excellent in fold resistance, wear resistance and water resistance.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Eyesight-improvement sesame fish balls and preparation method of eyesight-improvement sesame fish balls

InactiveCN105533499AIncrease the fragranceGreat tasteFood ingredient as taste affecting agentNatural extract food ingredientsSucroseSaccharum

The invention discloses eyesight-improvement sesame fish balls. The eyesight-improvement sesame fish balls are prepared from the following raw materials in parts by weight: 200 to 220 parts of fresh chub meat, 6 to 7 parts of egg white, 4 to 5 parts of potato starch, 30 to 33 parts of rhizome dioscoreae, 7 to 8 parts of pork prime condition, 4 to 5 parts of potherb mustard, 4 to 6 parts of vital gluten, 3 to 5 parts of white sesames, 2.5 to 3 parts of buckwheat leaves, 1 to 1.2 parts of loofah sponge, 1.3 to 1.4 parts of liquorice roots, 0.8 to 1.0 part of sucrose, 0.5 to 0.6 part of carrageenan, 0.4 to 0.5 part of fresh ginger, 4 to 5 parts of spices, proper amount of table salt and proper amount of water. According to the eyesight-improvement sesame fish balls, the auxiliary materials including the white sesames and the like have the functions of replenishing blood and improving eyesight, and dispelling wind and lubricating the intestines; Chinese herbal medicines including the loofah sponge and the like have the effects of clearing away heat and toxic materials and clearing and activating the channels and collaterals.

Owner:王龙云

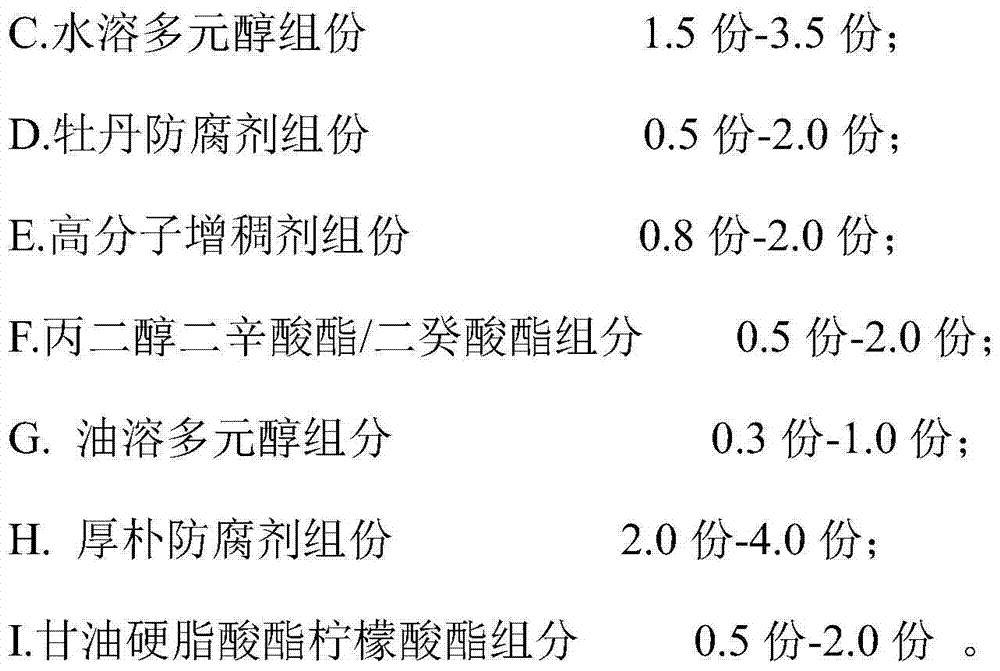

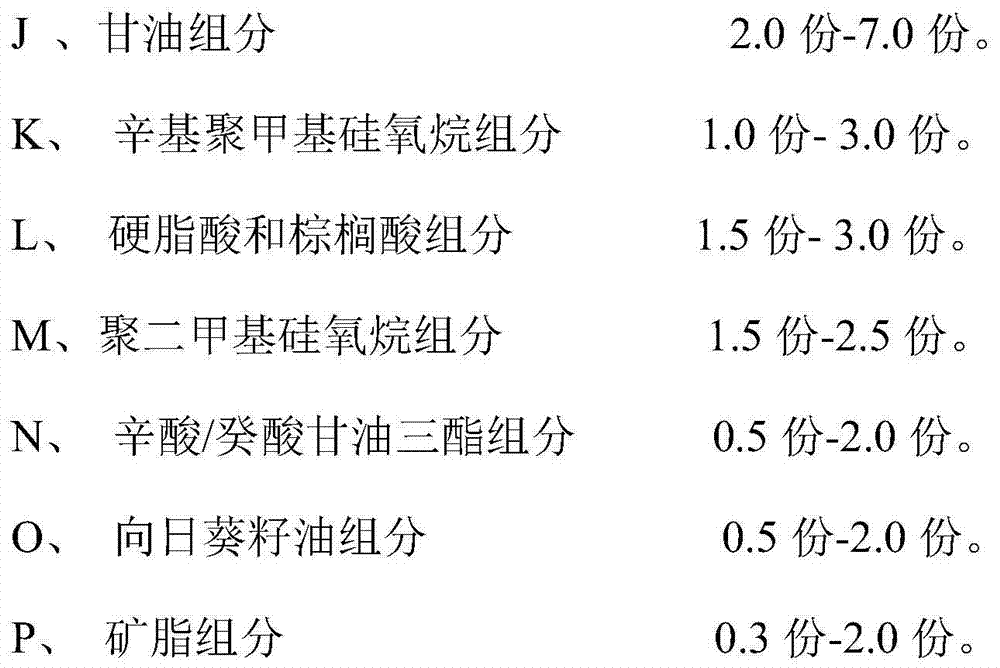

Skin care lotion formula with self corrosion-resistant property

InactiveCN104840400AMoisturizing and film-formingGood spreadabilityCosmetic preparationsAntipyreticLotionMagnolia officinalis

The invention relates to a skin care lotion formula with self corrosion-resistant property. The skin care lotion formula comprises the following components in parts by weight: A. 51.0 to 81.92 parts of water; B. 4.0 to 8.0 parts of urea; C. 1.5 to 3.5 parts of water-soluble polyhydric alcohol; D. 0.5 to 2.0 parts of peony anti-corrosive agent; E. 0.8 to 2.0 parts of polymeric thickener; F. 0.5 to 2.0 parts of propylene glycol dicaprylate / dicaprate; G. 0.3 to 1.0 parts of oil-soluble polyhydric alcohol; H. 2.0 to 4.0 parts of magnolia officinalis; I. 0.5 to 2.0 parts of glyceryl stearate citrate. By adopting the scheme, the skin care lotion formula has the advantages that the components are reasonable, the effects of maintaining moisture, resisting inflammation and nourishing are realized, the self corrosion-resistant property is realized, and the like.

Owner:中山安理汇日用品有限公司

Novel coating for canned luncheon meat inner wall and production method thereof

ActiveCN1990798AStrong adhesion and impact resistanceImprove compactnessLinings/internal coatingsEpoxy resin coatingsSolventChemistry

The invention discloses a method for preparing coating material for luncheon meat cans inner wall. It comprises following steps: synthesing epoxy phenolic resin coatings A with high chemical resistant and mechanical property that meets food sanitary requirement; adding zinc oxide powder into A to mill for slurry B; immersing aluminum into solvent to form C; adding synthetic rap into A to form D after high- speed dispersion; putting A, B, C and D according to a certain proportion into reraction autoclave, stirring for 60 minutes and getting final product. The material A possesses sound chemical and mechanical resistant property, and strong adhesion and anti-impacting property with tinplate; the zinc oxide in B can react with sulfur released from meat, so the coating material can prevent the generation of ferrous sulfide and sulfue spot; the aluminum powder in C can cover the can and intensifies the compactness, and reduces corrison of sulfur to tinplate; the synthetic rap in D can increase the slippery of coating layer and demoulding effect, which enables smooth getting out for meat from can. The invention is characterized by simple and controllable process, lower cost and energy saving, and reduced waste discharge.

Owner:SHANGHAI MEILIN FOODS

Hair conditioner and preparation method thereof

ActiveCN107822927ARelief is not easy to disperseHigh glossCosmetic preparationsHair cosmeticsCombingHair streams

The invention relates to the field of living goods, in particular to a hair conditioner and a preparation method thereof. The hair conditioner is made mainly from various materials, by weight, including 0.5-10 parts of amino silicone oil microemulsion, 2-11 parts of a siloxane polymer, 4.3-14.5 parts of an oil-phase mixture and 95-115 parts of a water-phase mixture. The hair conditioner can avoidthe problem that traditional hair conditioners of pure amino silicone oil are difficult to disperse due to excessively high viscosity and attach to the surface of hair with poor uniformity and smoothness due to too large particle size. The affinity of positive charge, carried by amino functional groups of the amino silicone oil, to keratins can condition hair bundles. The hair conditioner has significant advantages in terms of thermal protection of hair bundles, enhancing hair gloss and smoothness, improving dry combing and wet combing, increasing hair bundle volume and the like.

Owner:HUBEI ENG UNIV

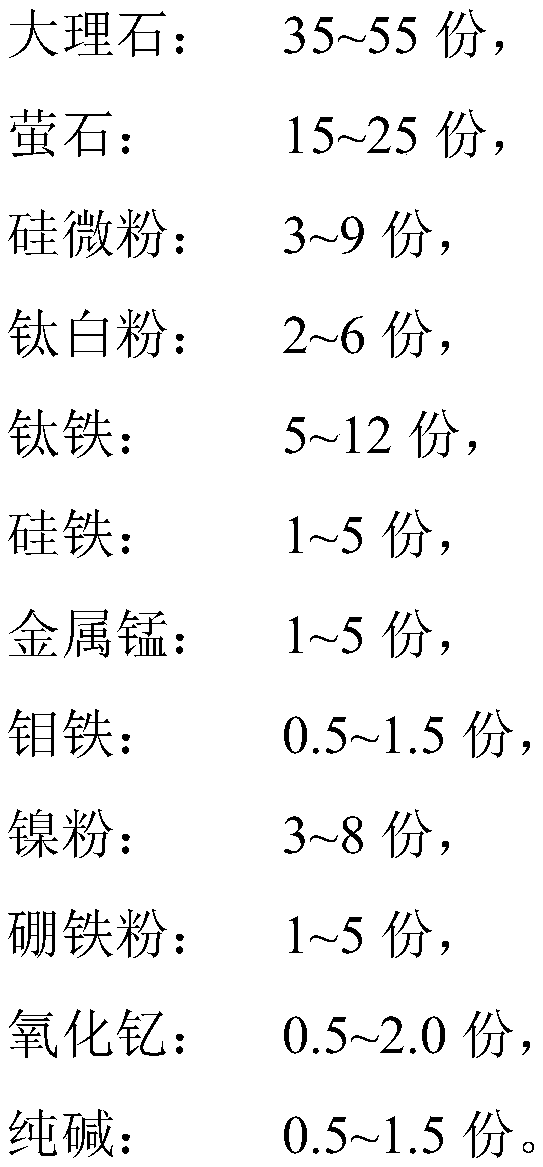

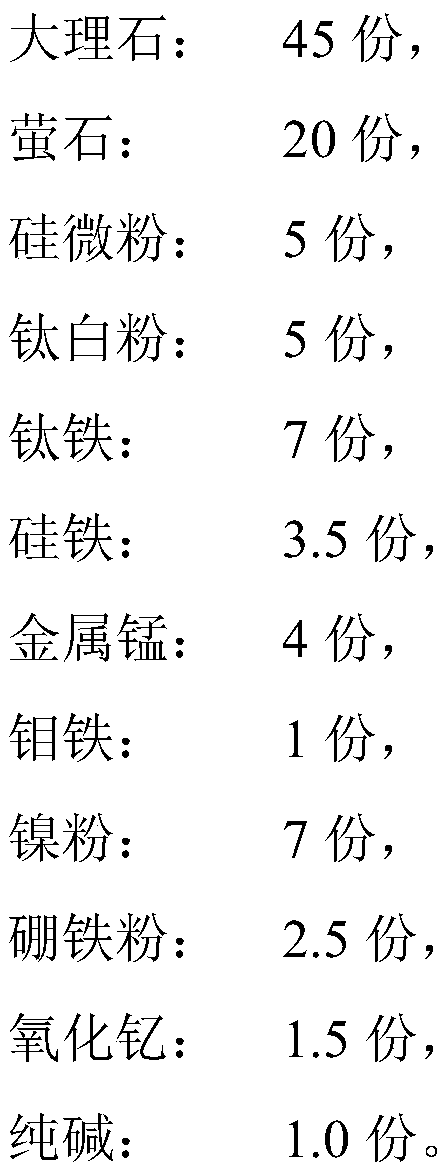

Low-alloy steel electrode with ultra-low hydrogen alkalinity and preparing method thereof

InactiveCN110000489AHigh strengthImprove impact toughnessWelding/cutting media/materialsSoldering mediaSlagYttrium

The invention relates to a low-alloy steel electrode with ultra-low hydrogen alkalinity and a preparing method thereof. The steel electrode comprises a core wire and a coating. The core wire is the H08E core wire, the coating is low-hydrogen design with high alkalinity, and the component comprises marble, fluorite, silica powder, titanium dioxide, ferrotitanium, silicon iron, manganese metal, ferromolybdenum, nickel powder, boron iron powder, yttrium oxide and sodium carbonate. Compared with the prior art, the welding process is excellent, in the welding process, the electric arc is stable, basically, no splashing exists, the slag detachability is good, a molten pool is clear, the welding line forming is attractive, the steel electrode is excellent in operation, and the excellent depositedmetal, impact toughness and the like are achieved.

Owner:POWERCHINA SPEM CO LTD

Production method of preservative natural cellulose membrane

ActiveCN102154812AMild reaction conditionsEasy to controlConjugated cellulose/protein artificial filamentsBleaching apparatusCelluloseChitin formation

The invention discloses a production method of a preservative natural cellulose membrane. The method comprises the following steps: a-(1) soaking, a-(2) squeezing, a-(3) crushing, a-(4) maturing, a-(5) yellowing and a-(6) dissolving the cellulose; b-(1) soaking, b-(2) squeezing, b-(3) crushing, b-(4) yellowing and b-(5) dissolving chitin; c-(1) mixing viscose; c-(2) forming a membrane; and c-(3) desulphurizing, c-(4) bleaching, c-(5) plasticizing and c-(6) drying the membrane. The reaction conditions of the method disclosed by the invention are mild; and the prepared preservative natural cellulose membrane has small space, stable elongation rate and tensile strength, proper stiffness and flexibility, relatively good color and luster and transparency, high hygiene property, antibacterial and bacteriostatic characteristics and the like.

Owner:绍兴柯德新材料股份有限公司

Flower-flavored fish ball and production method thereof

InactiveCN105982248AIncrease the fragranceGreat tasteNatural extract food ingredientsFood ingredient functionsSucroseSaccharum

The invention discloses a flower-flavored fish ball, made from the following materials according to parts by weight: 200-220 parts of fresh sliver carp meat, 6-7 parts of egg white, 4-5 parts of potato starch, 30-33 parts of Rhizoma Dioscoreae, 7-8 parts of fat pork, one muskmelon, 5-8 parts of Osmanthus flower, 4-5 parts of peach blossom, 0.8-1.2 parts of Cortex Albiziae, 1.3-1.4 parts of Cortex Acanthopanacis, 0.3-0.4 part of Fructus Lycii, 0.8-1.0 part of sucrose, 0.5-0.6 part of carrageenan, 0.4-0.5 part of dried ginger, 4-5 parts of spices, suitable edible salt and suitable water. The accessories used herein such as Osmanthus flower have the functions of beautifying skin and soothing throat, and the Chinese herbs used herein such as Cortex Acanthopanacis have the effects of tonifying kidney and liver, strengthening tendons and bones and activating blood and collaterals.

Owner:王龙云

Shower gel formulation and preparation technology thereof

InactiveCN103417407AIncrease slipperyNo dry feelingCosmetic preparationsToilet preparationsShower gelIrritation

The invention discloses a shower gel formulation and a preparation technology thereof. Shower gel comprises, by weight, 10-18% of A-phase materials, 8-12% of B-phase materials, 15-22% of C-phase materials, 26-33% of D-phase materials, 18-25% of E-phase materials, 0.1-1% of F-phase materials, 2-7% of G-phase materials and 1-3% of H-phase materials. The preparation technology of the shower gel includes the steps: firstly, blending the A-phase materials, the B-phase materials, the C-phase materials and the D-phase materials with different containers respectively; secondly, adding the D-phase materials and a stirred B-phase material solution into a stirred C-phase material solution for stirring; thirdly, adding the F-phase materials into a stirred E-phase material solution for stirring; fourthly, putting a stirred solution in the third step, a stirred A-phase material solution, the G-phase materials and the H-phase materials into a solution in the second step for stirring. The shower gel prepared through the formulation and the preparation technology has the advantages of lasting smooth feeling, skin moisturizing and low irritation.

Owner:ZHONGSHAN JIALI DAILY COSMETICS CO LTD

EE cream

ActiveCN105878058AComprehensive nutritionSufficient energyCosmetic preparationsBody powdersAgeingTetrapeptide

The invention aims to provide EE cream. The EE cream comprises cream A and cream B, the cream B is formed by mixing titanium dioxide with the particle size of 80-100 nm and titanium dioxide with the particle size of 280-300 nm by the weight ratio of 2:3, skin flaws can be effectively adjusted, skin brightness is improved, the EE cream has whitening and concealing functions, and the cream is higher in fitness when smeared; acetyl hexapeptide-8 and acetyl tetrapeptide-5 are added by the weight ratio of 3:1, and the EE cream has the effects of improving skin wrinkles, repairing the skin and resisting ageing. Dual-tube design is adopted in the EE cream, and the tube A and the tube B can be mixed by any ratio for use; while having the concealing and face repairing functions, rich nutrient and sufficient energy are provided for the skin, repairing and nourishing are achieved, the defects that traditional foundation make-up and BB cream are low in fitness, and the skin using the cosmetics is dry are overcome, and the skin is made white, glossy, fresh and natural.

Owner:CHENGDU ROLOR COSMETIC

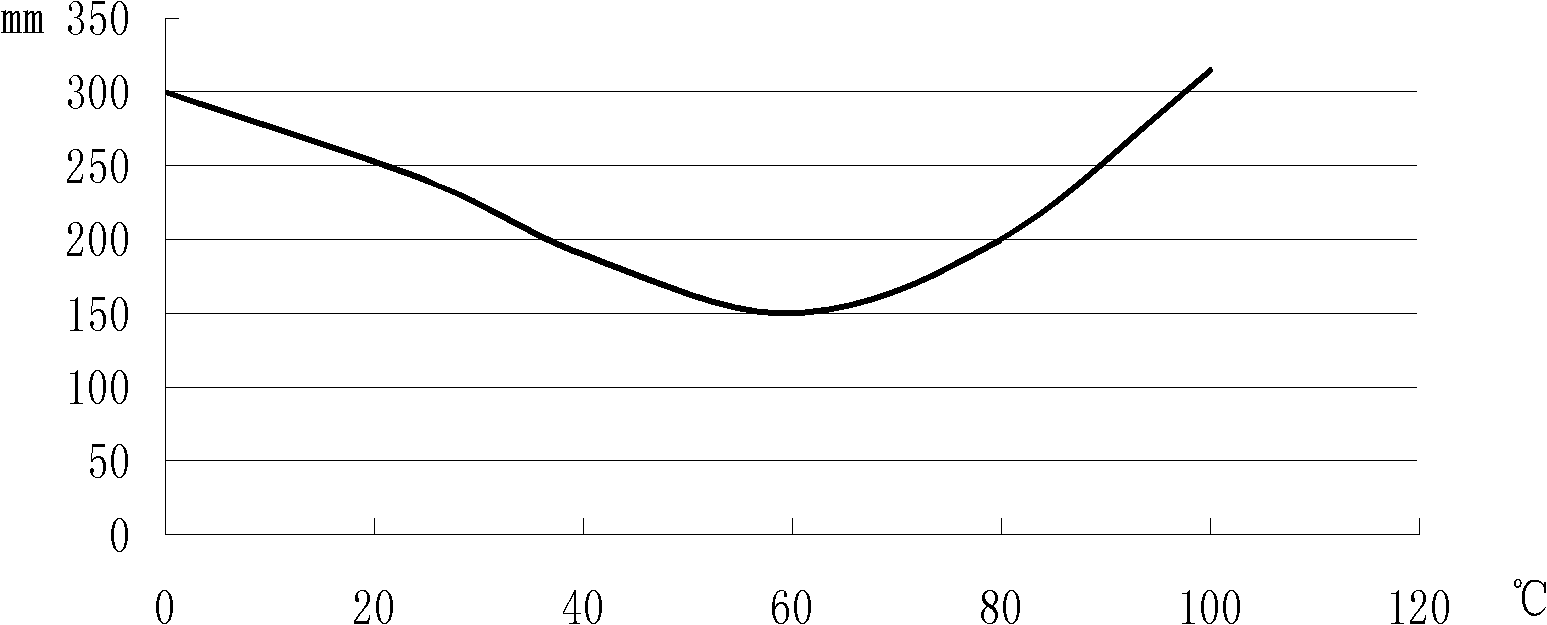

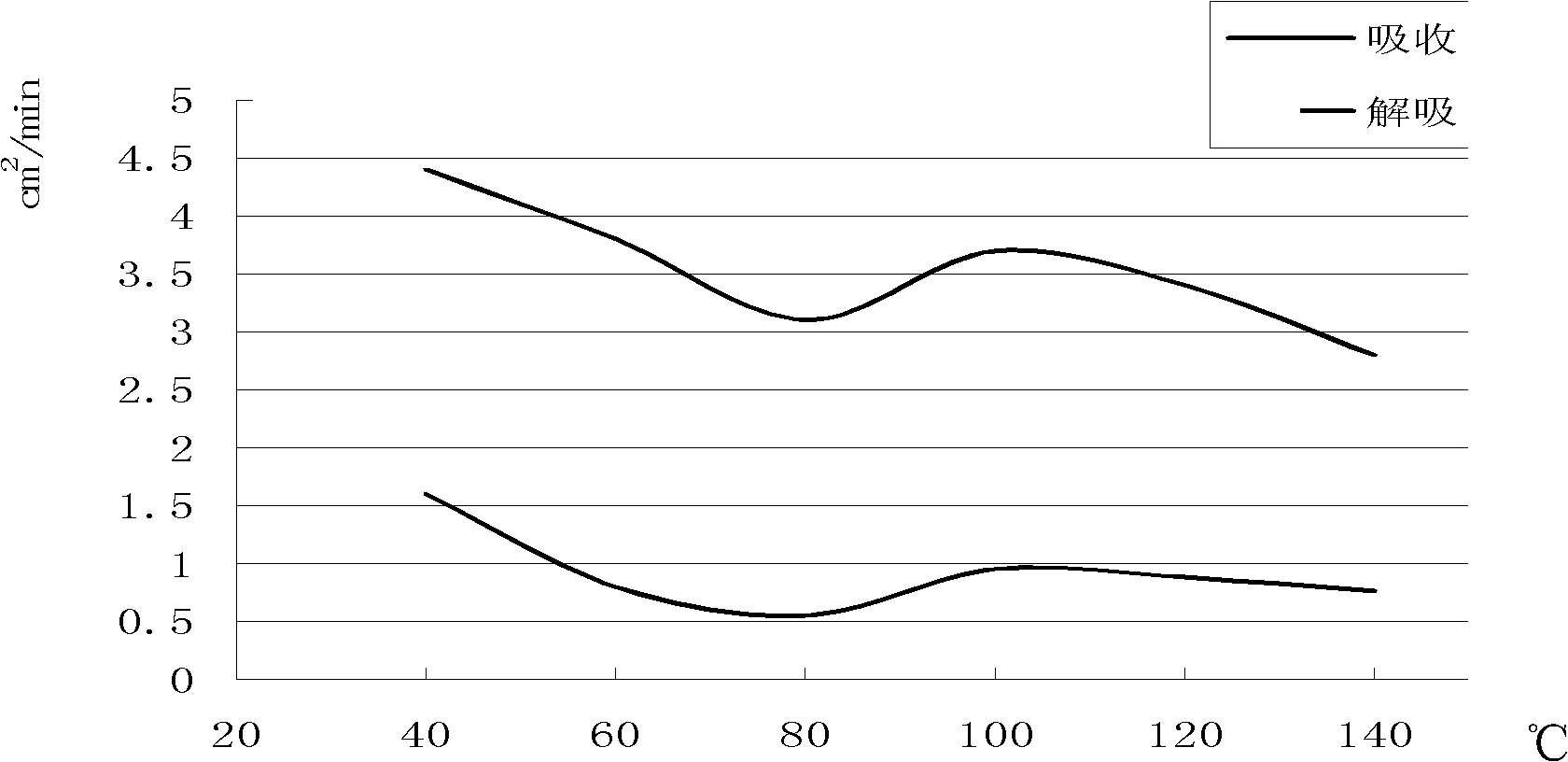

Honeycomb ceramic heat storage body with low adsorption capability and preparation method thereof

The invention discloses a honeycomb ceramic heat storage body with low adsorption capability and a preparation method thereof. The honeycomb ceramic heat storage body with the low adsorption capability is sintered from the following components in parts by weight: 55 to 60 parts of white corundum powder, 8 to 10 parts of mullite, 10 to 15 parts of a-AL2O3 powder, 2 to 3 parts of SiO2 powder, 10 to15 parts of tricalcium phosphate, and 4 to 5 parts of high-temperature adhesive. The honeycomb ceramic heat storage body has high material compacting / low porosity, high high-temperature resistance / high chemical reaction heat, high impermeability, low adsorption capability, high desorption capability, low production cost, high energy-saving rate, low smoke emission temperature, and long service life.

Owner:醴陵友立特种陶瓷有限公司

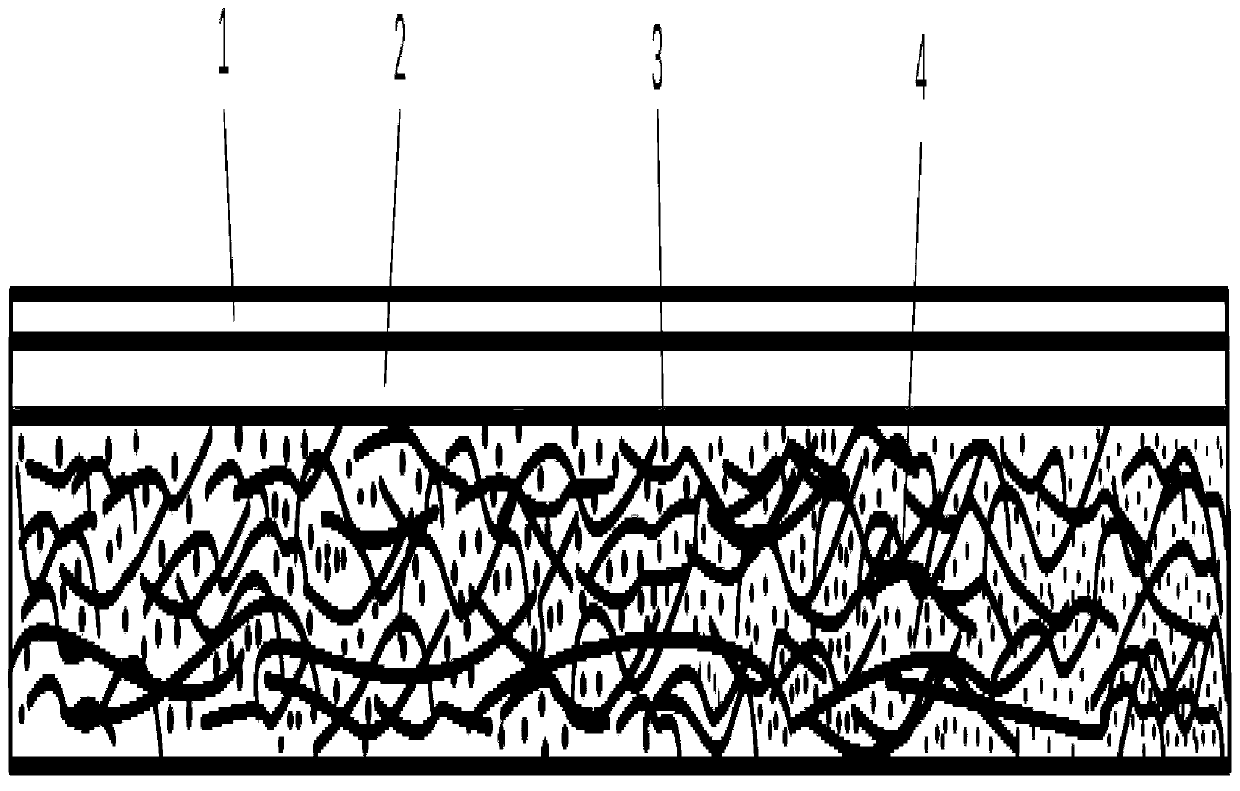

Ultra-soft and fluffy lightweight filament nonwoven composite material and preparation method thereof

ActiveCN108179550AReduce dependenceImprove flexibilityNon-woven fabricsSurgical GownsVolumetric Mass Density

The invention discloses an ultra-soft and fluffy lightweight filament nonwoven composite material with light weight, softness and fluffiness. The structure of the ultra-soft and fluffy lightweight filament nonwoven composite material successively comprises a first concentric hollow filament layer, a core shift hollow filament layer and a second concentric hollow filament layer from bottom to top,wherein the first concentric hollow filament layer, the core shift hollow filament layer and the second concentric hollow filament layer form a stereostructure by hot roll bonding; the areal density of a finished product is controlled between 6 to 100g / m<2> and the stereo thickness of the finished product is controlled between 0.3 to 2.1mm. The invention also provides a preparation method of the ultra-soft and fluffy lightweight filament nonwoven composite material. The ultra-soft and fluffy lightweight filament nonwoven composite material prepared by a preparation method disclosed by the invention, or a laminated body containing the nonwoven composite material can be widely used for medical treatment, civil construction, surgical gowns, packaging sheets, especially for absorbent hygiene products such as diaper and sanitary napkins.

Owner:苏州多瑈新材料科技有限公司

Pearl barley and ormosia fish ball and preparation method thereof

InactiveCN105533500AIncrease the fragranceGreat tasteFood ingredient as taste affecting agentNatural extract food ingredientsCarrageenanSaccharum

The invention discloses a pearl barley and ormosia fish ball which is prepared from the following raw materials in parts by weight: 200-220 parts of fresh silver carp meat, 6-7 parts of egg white, 4-5 parts of potato starch, 30-33 parts of Chinese yam, 7-8 parts of fat pork, 4-5 parts of pearl barley, 2-3 parts of lily bulb, 5-6 parts of ormosia, 1-1.2 parts of fructus amomi, 2-2.3 parts of chrysanthemum flower, 1.3-1.4 parts of bulbus fritillariae cirrhosae, 0.8-1.0 part of saccharose, 0.5-0.6 part of carrageenan, 0.4-0.5 part of fresh ginger, 4-5 parts of spice, a proper amount of table salt and a proper amount of water. The auxiliary materials such as the pearly barley and ormosia adopted for the pear barley and ormosia fish ball have functions of dispelling wind and clearing heat, and moisturizing skin and beautifying; adopted Chinese herbs such as fructus amomi have the efficacies of resolving dampness, promoting appetite, warming the spleen and clearing away the lung-heat.

Owner:王龙云

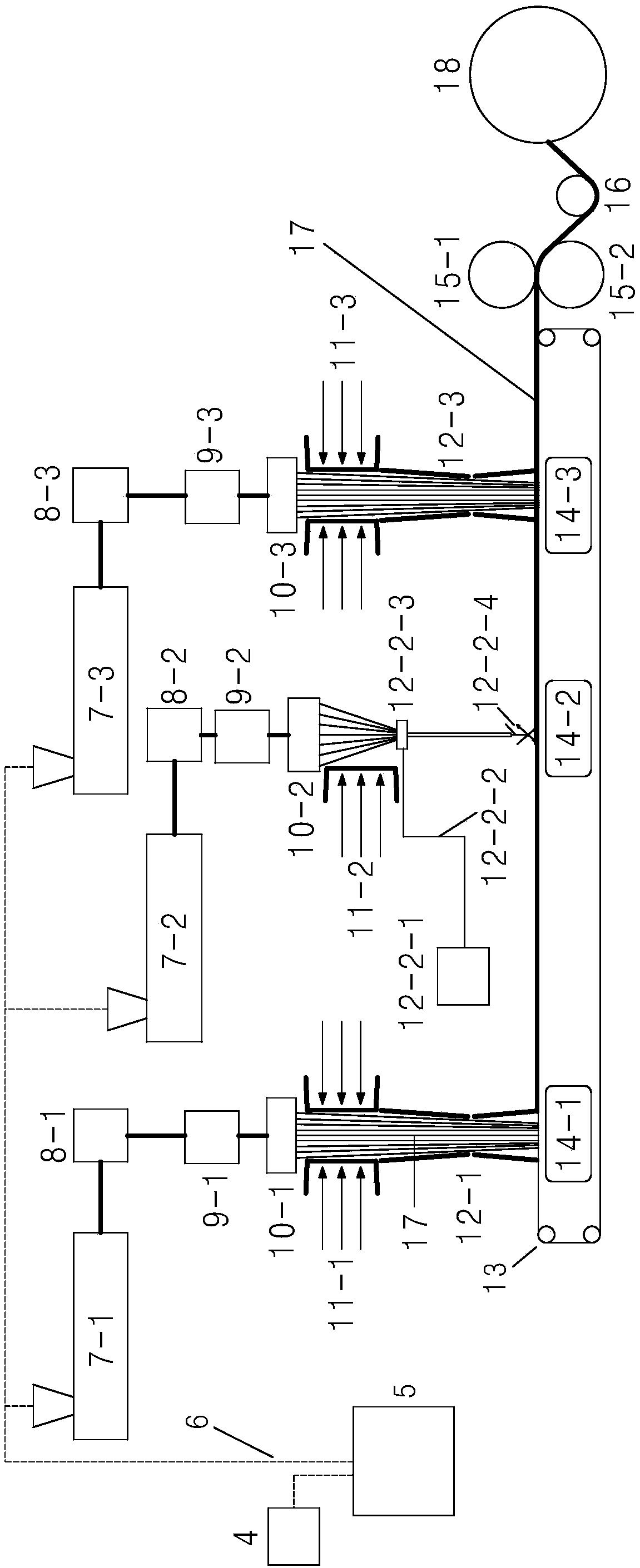

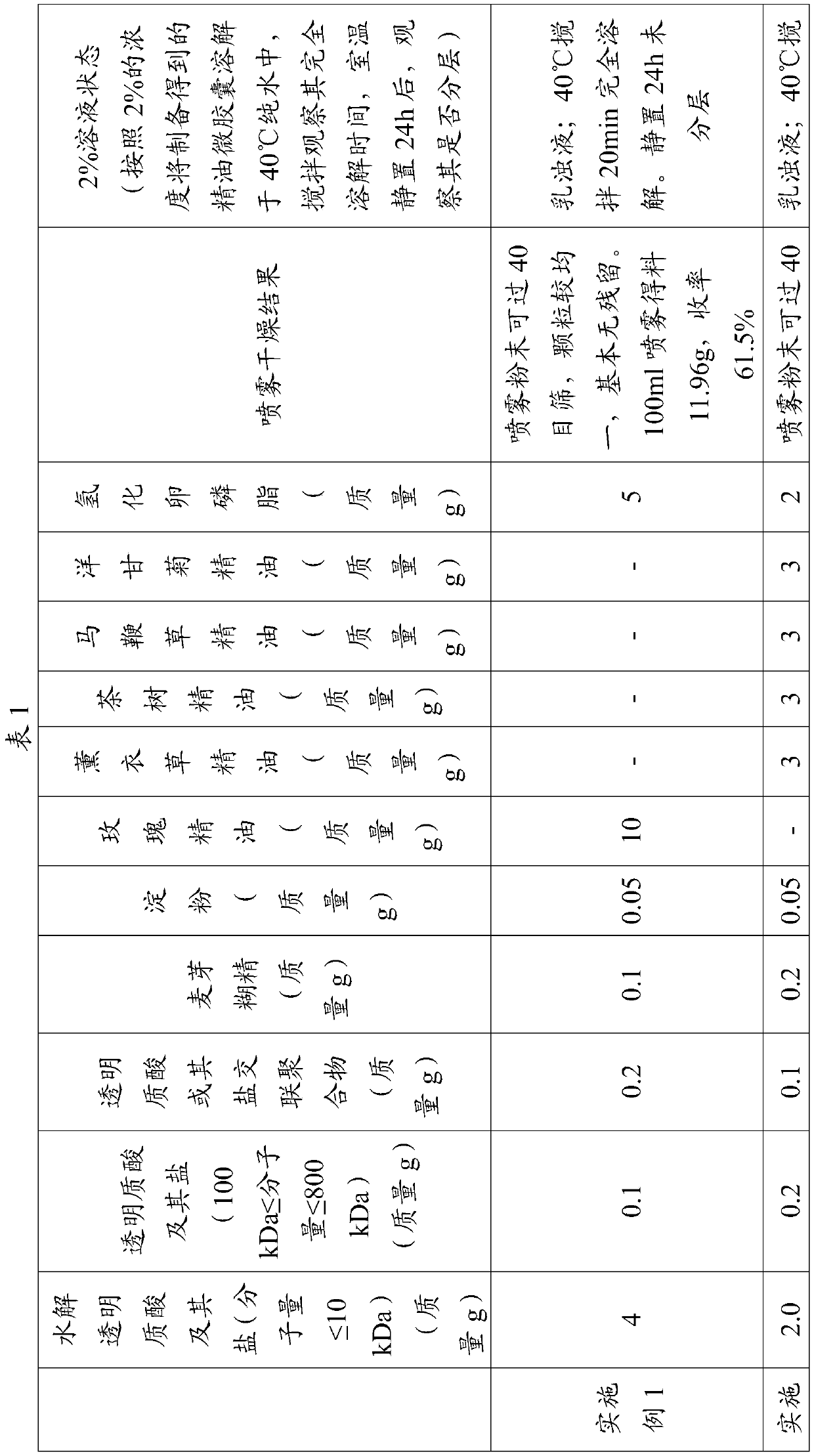

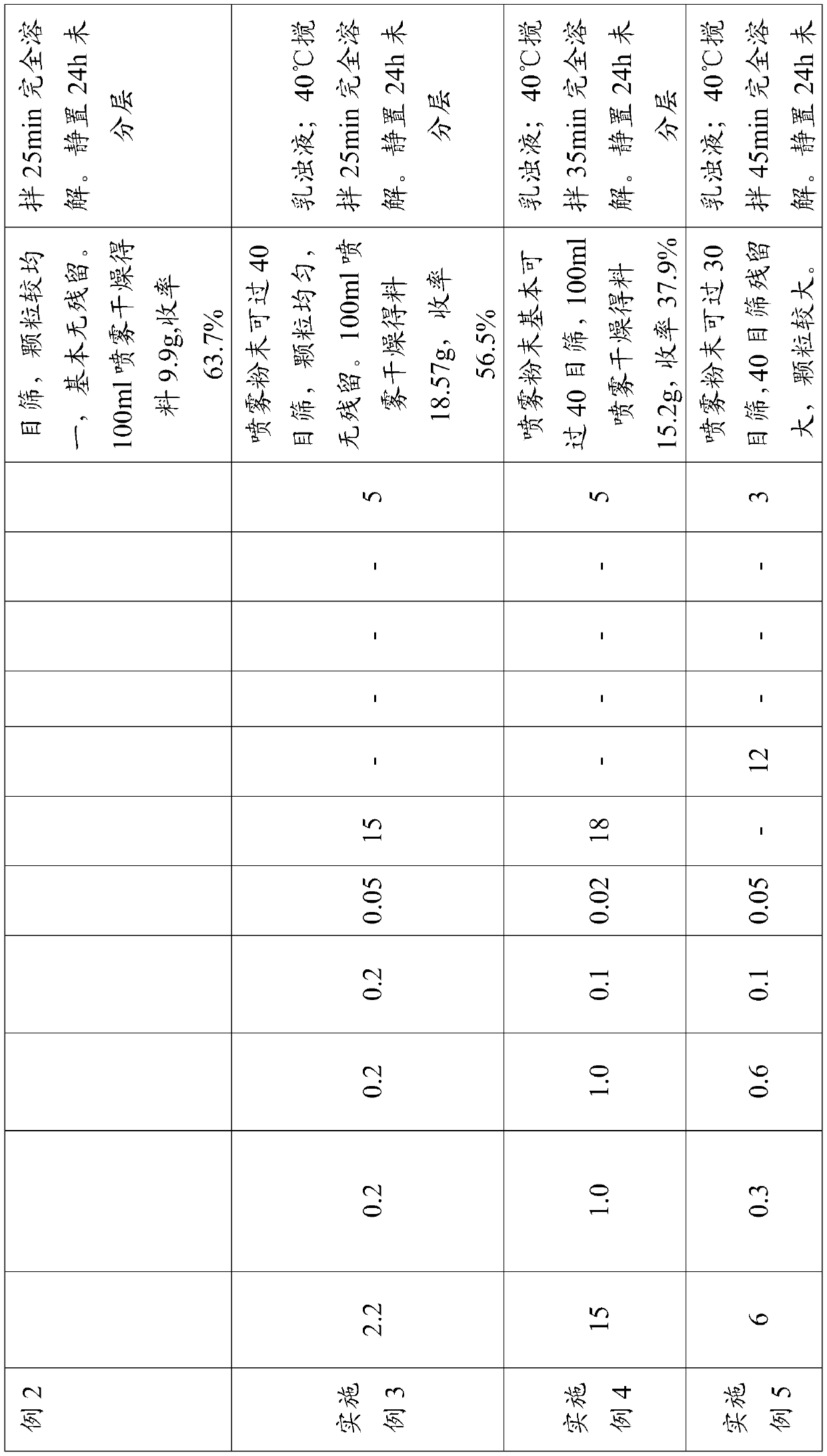

Essential oil microcapsule composition, essential oil microcapsule and preparation method of essential oil microcapsule

ActiveCN110743472AHigh yieldGood stabilityEssential-oils/perfumesMicroballoon preparationHyaluronic acidChemical engineering

The invention discloses an essential oil microcapsule composition. The essential oil microcapsule composition comprises, in percent by weight, 30-80% of a core material, 10-45% of a wall material, 2-35% of an emulsifier and water based on the total dry weight of the essential oil microcapsule composition, the core material is essential oil, and based on the total weight of the wall material, the wall material contains, in percent by weight, 70-100% of hyaluronic acid-based components, wherein the hyaluronic acid-based components include hydrolyzed hyaluronic acids with a molecular weight of not more than 10 kDa and / or salts of the hyaluronic acids, hyaluronic acids with a molecular weight of 100 kDa-800 kDa and / or salts of the hyaluronic acids and hyaluronic acids or salt cross-linked polymers of the hyaluronic acids. The invention also discloses an essential oil microcapsule which is prepared from the essential oil microcapsule composition and a preparation method of the essential oilmicrocapsule. The wall material of the microcapsule composition has good stability, can be added to a water phase directly, and has refreshing, smooth and moist skin feelings, the sticky feeling which is generated by single application of essential oil can be reduced greatly, and the characteristic of long-lasting fragrance is achieved.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

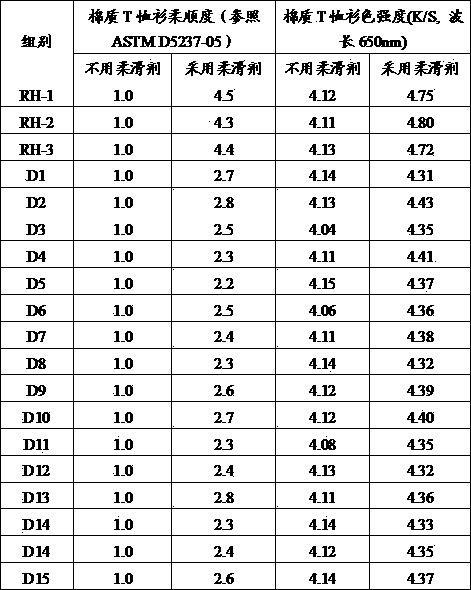

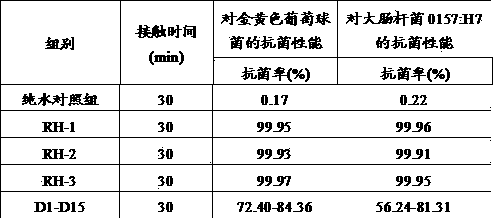

Multiple-effect softening and lubricating agent for textile fabrics as well as preparation method and use thereof

The invention relates to a multiple-effect softening and lubricating agent for textile fabrics as well as a preparation method and a use thereof. The multiple-effect softening and lubricating agent for textile fabrics is prepared from bitallow ethoxycarbonyl hydroxyethyl methyl ammonium methyl sulfate, bipolyethylene polydimethylsiloxane, glycerin monostearate, epoxy chloropropane, polyethylene glycol 2000, mycose, zinc pyrithione, nano-powder, hydroxyl cellulose sodium, pentaerythritol triacrylate, an assistant, an additive and water. The multiple-effect softening and lubricating agent has the advantages of smoothness, fixation, antistatic property, antimicrobial property and the like due to selection of special components and proportion, and has a wide industrialized application prospect in the textile field.

Owner:HEIGHTCHEM FINE CHEM CO LTD

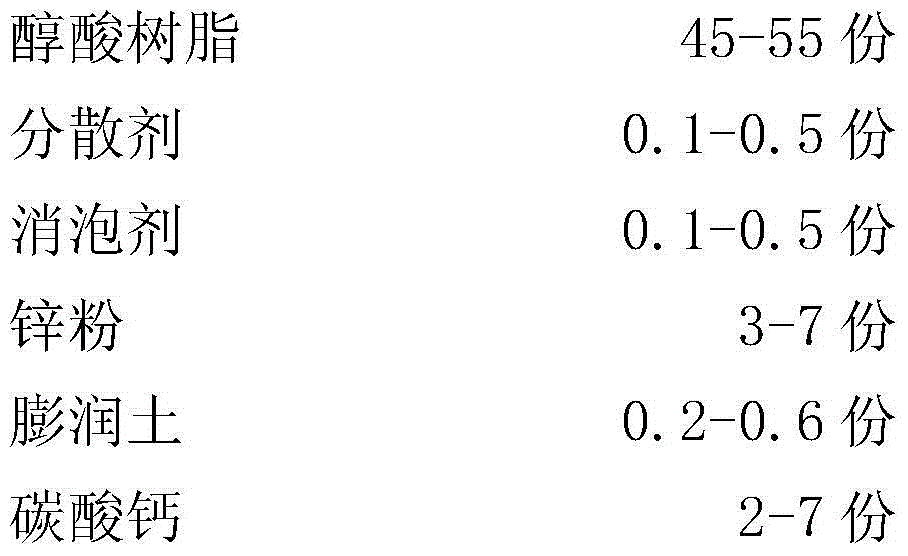

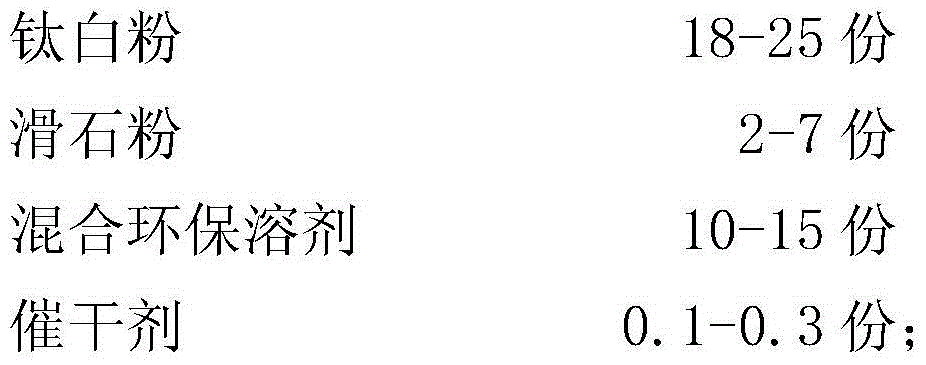

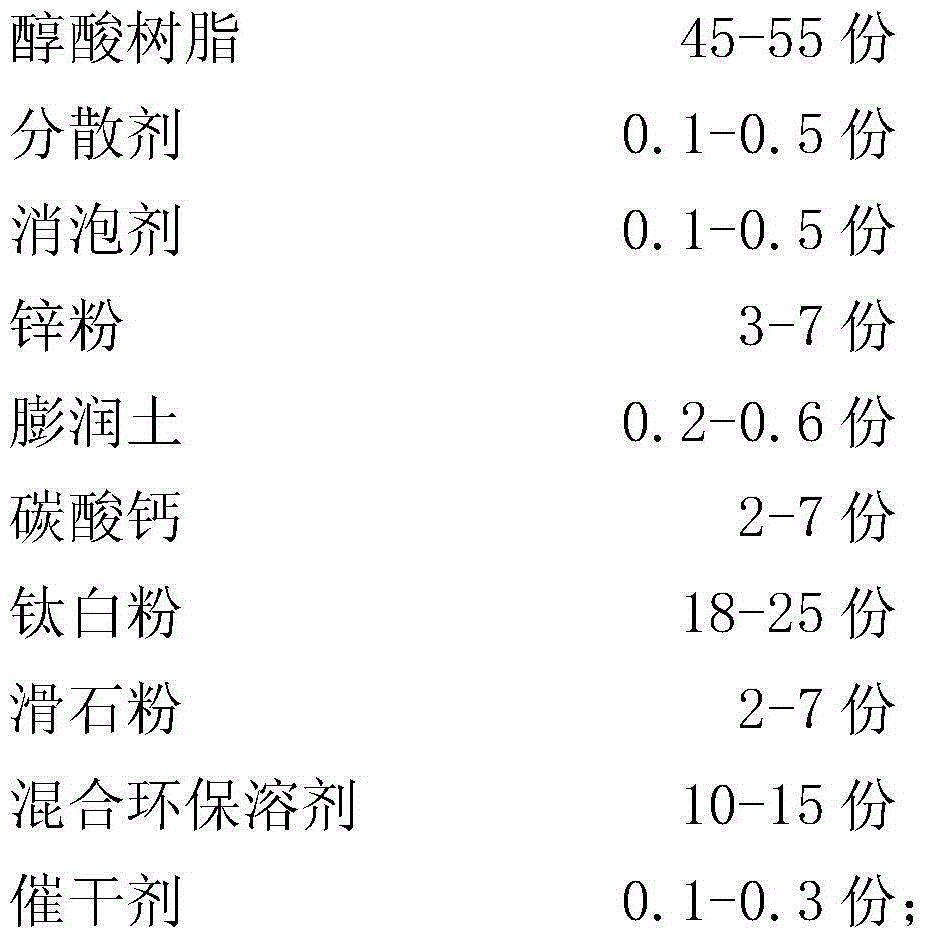

Low-odor polyurethane open white primer and preparation method thereof

InactiveCN104356925AIncrease coverageEnvironmental protection is goodPolyurea/polyurethane coatingsDiluentSolvent

The invention relates to a low-odor polyurethane open white primer and a preparation method thereof. The low-odor polyurethane open white primer is formed by mixing a main agent, a curing agent and a diluent by a mass ratio of (1-1.4):(0.5-0.7):(0.6-1), wherein the main agent, the curing agent and the diluents are respectively prepared from the following components in part by weight: the main agent comprises the following components in part by weight: 45-55 parts of alkyd resin, 0.1-0.5 part of a dispersing agent, 0.1-0.5 part of a defoaming agent, 3-7 parts of zinc powder, 0.2-0.6 part of bentonite, 2-7 parts of calcium carbonate, 18-25 parts of titanium dioxide, 2-7 parts of talcum powder, 10-15 parts of a mixed environment-friendly solvent, and 0.1-0.3 part of a drier. The prepared low-odor polyurethane open white primer has low odor after construction, a primer film can permeate on wood patterns well, and the covering capability and the environment protection property are good.

Owner:SKSHU PAINT

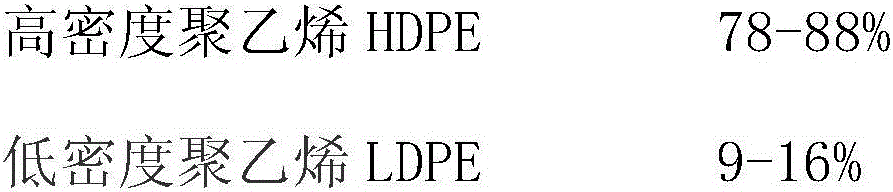

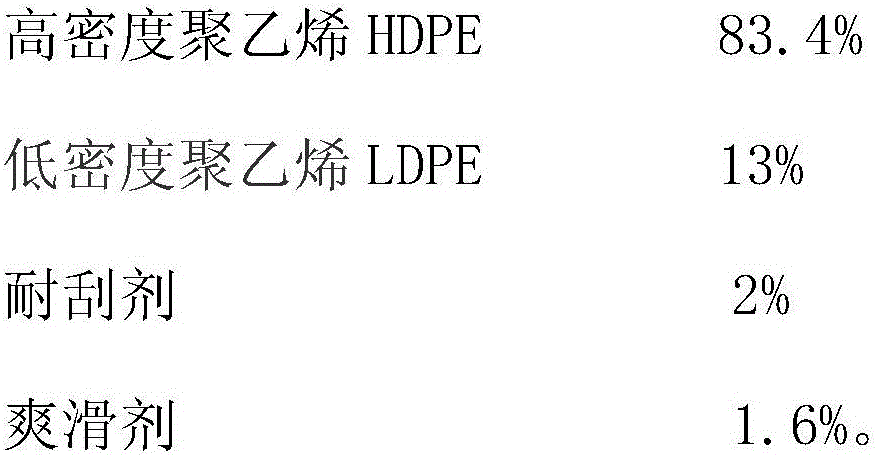

Scraping-resistant PE film packing material and preparing method thereof

The invention relates to a scraping-resistant PE film packing material.The scraping-resistant PE film packing material comprises, by mass, 78%-88% of high density polyethylene (HDPE), 9%-16% of low density polyethylene (LDPE), 1%-3% of scraping-resistant agent and 1.2%-3% of slipping agent.A preparing method of the scraping-resistant PE film packing material includes the following steps that the high density polyethylene (HDPE), the low density polyethylene (LDPE), the scraping-resistant agent and the slipping agent are mixed on a mixing machine according to the mass percent, added into a film blowing unit and heated and extruded through a film-blowing extruding machine, quick cooling is carried out in an air cooling mode during extruding, the product is subjected to the blowing rising process, the drawing process and the rolling process, and the scraping-resistant PE film packing material is obtained.Compared with the prior art, as the specific raw materials are adopted, the transparency of the raw materials is high, the high transparency effect and the scraping-resistant effect of the film can be achieved, and the HAZE can be 10 or below.

Owner:SHANGHAI FUKUSUKE IND

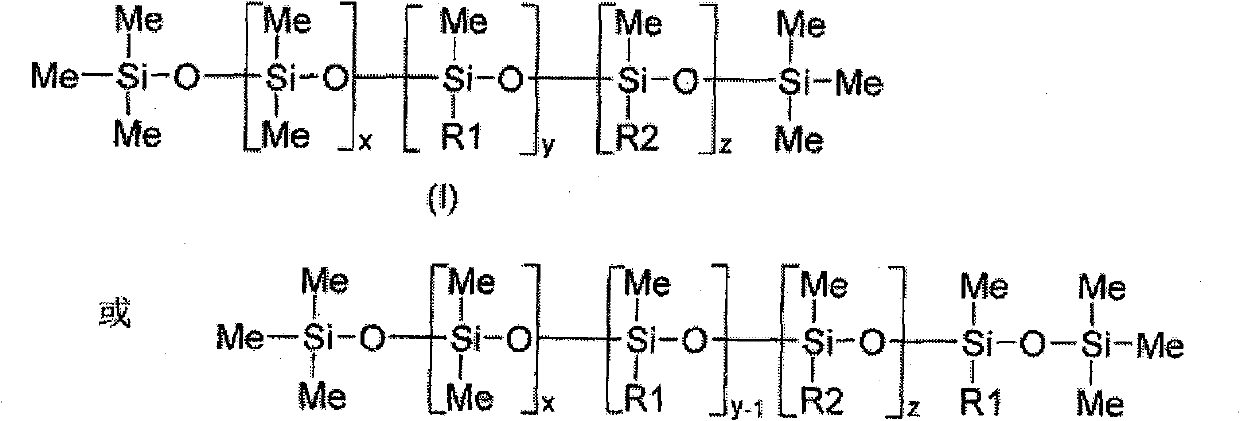

Organosilicon coating levelling agent

Owner:JIAXING UNITED CHEM

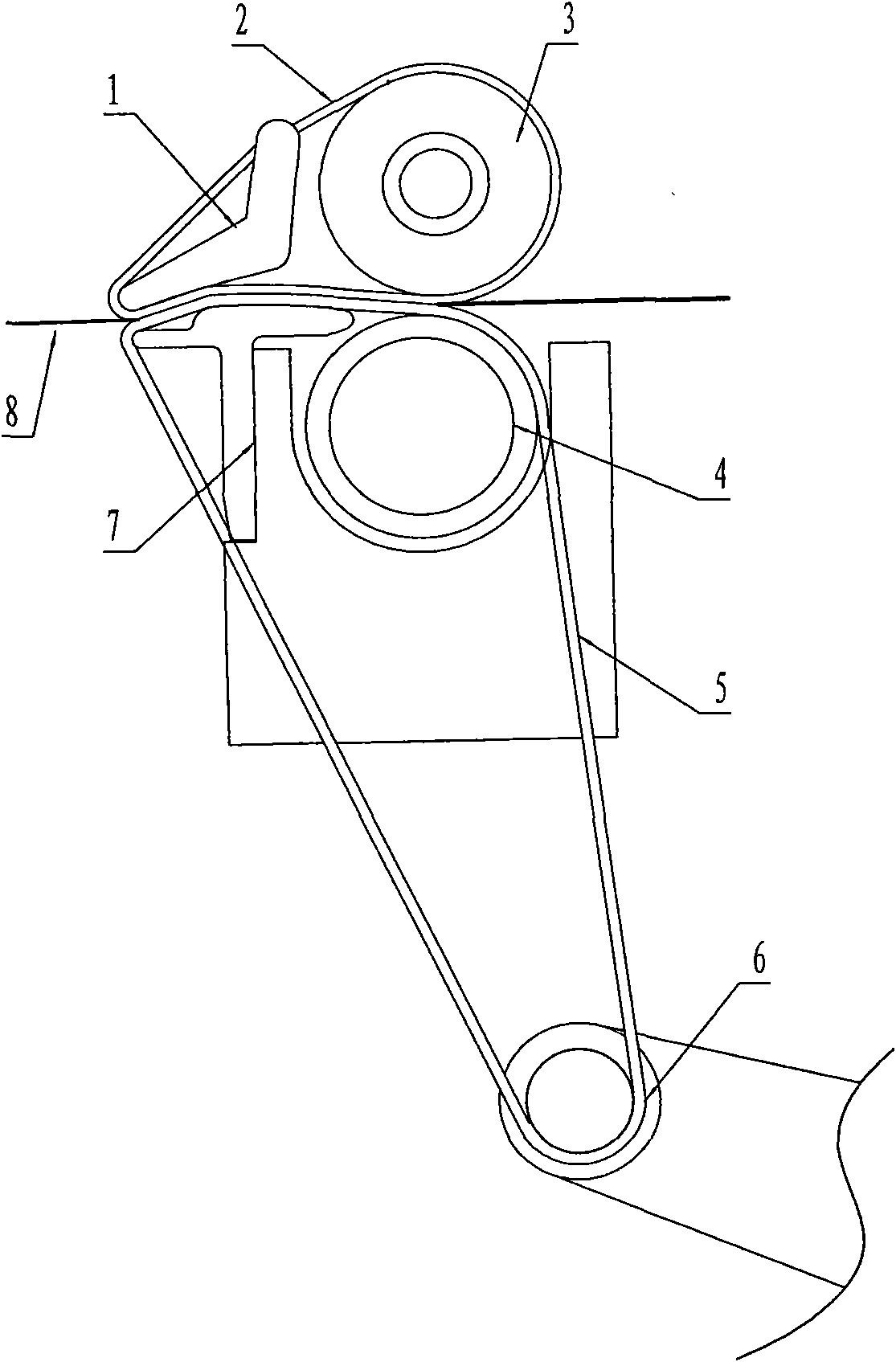

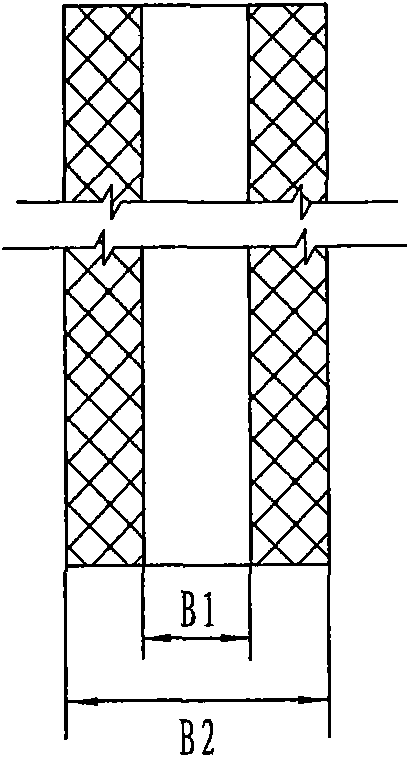

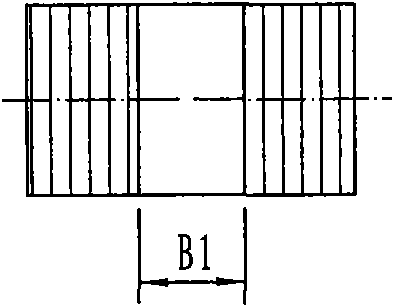

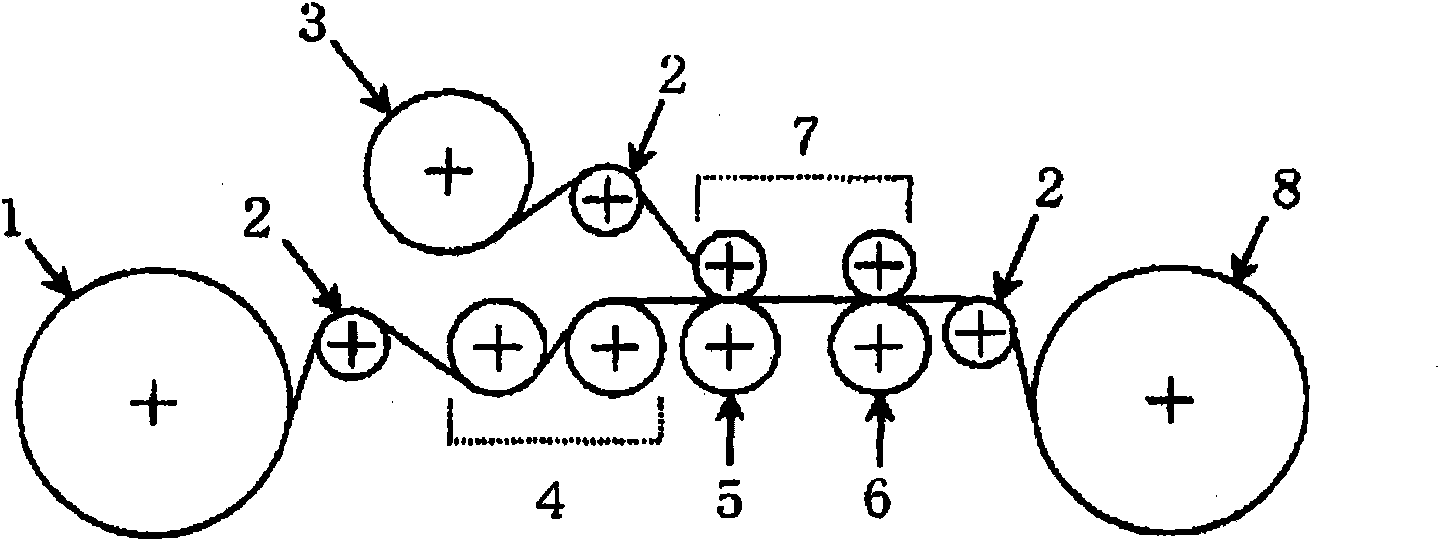

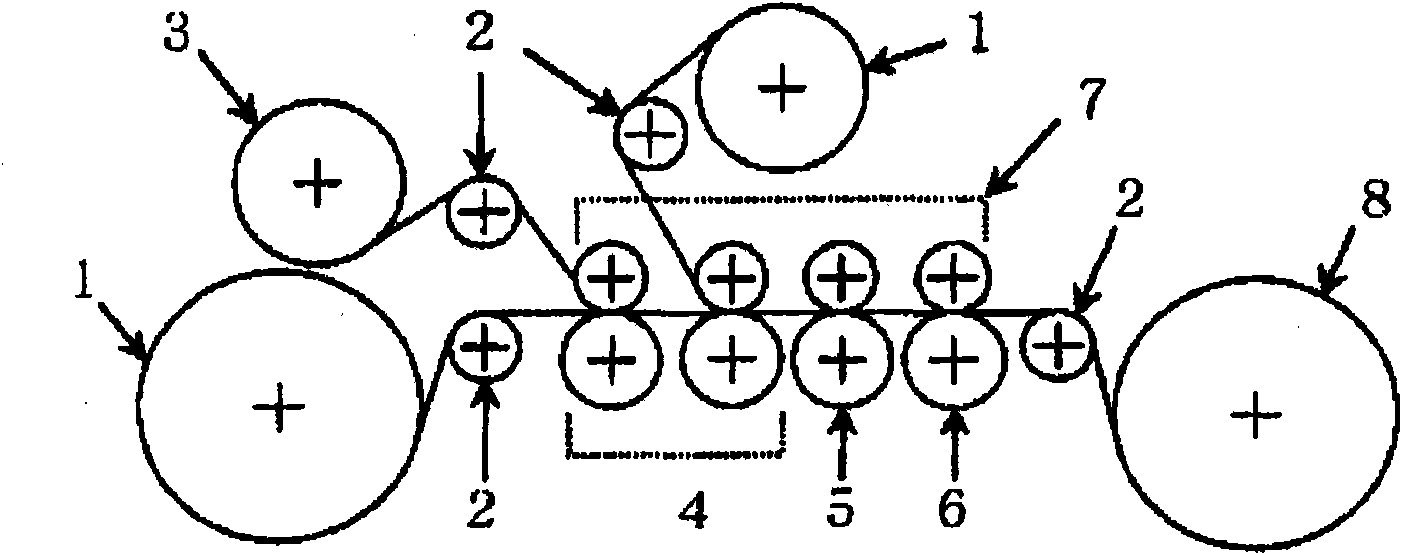

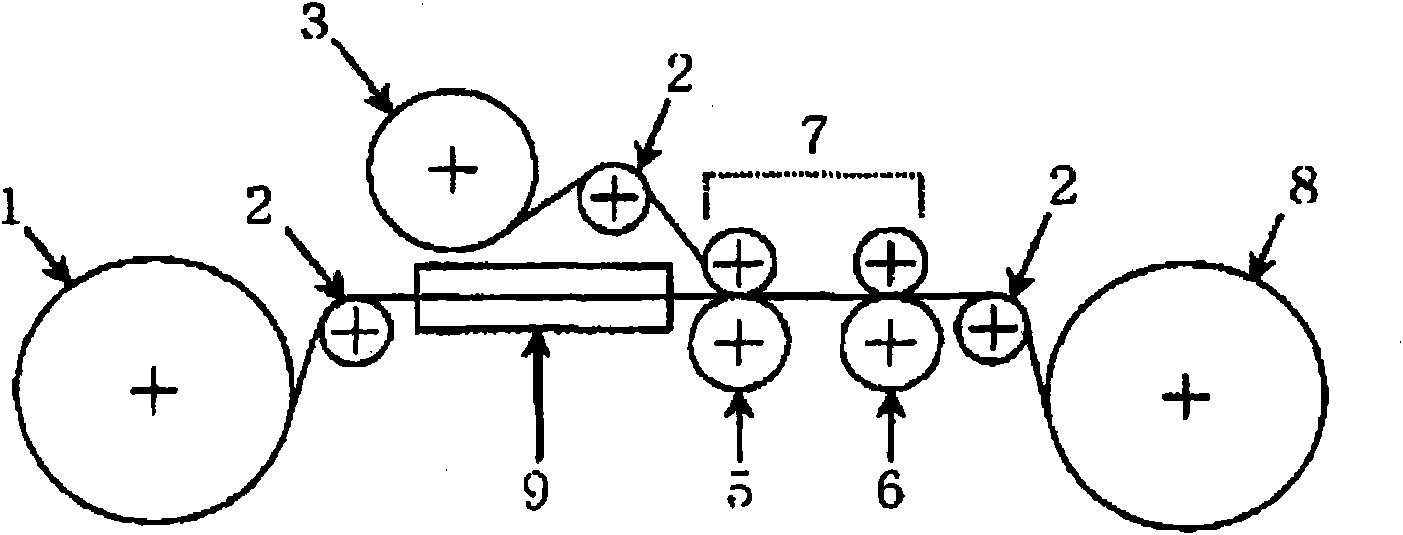

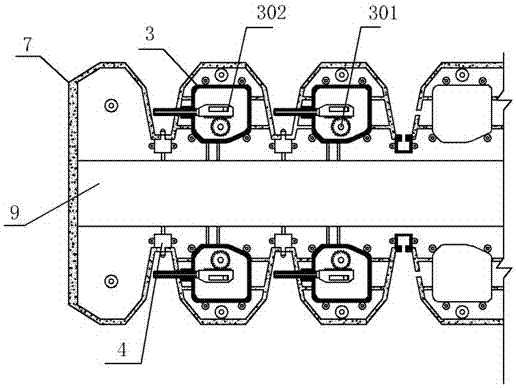

Spinning machine drafting component capable of improving yarn quality

InactiveCN101805947AReduce friction for serious problemsReduce shift point distribution rangeDrafting machinesFiberYarn

A spinning machine drafting component capable of improving yarn quality is used for solving the problem of easy slipping or easy wear of the drafting components. The technical scheme is as follows: the drafting component comprises a top pin, a middle top roller, a top apron surrounding the top pin and the middle top roller, a middle bottom roller, a bottom pin, a tension frame and a bottom apron surrounding the middle bottom roller, the bottom pin and the tension frame; the middle parts of the internal surfaces of the improved top apron and bottom apron are flat and smooth surfaces and the two sides of the improved top apron and bottom apron are pattern surfaces which are symmetrically arranged. The drafting component is designed to utilize flat and smooth surface contact in the fiber strand movement area, thus being conductive to reducing serious friction of the front jaw of the top pin, and to utilize patterns at the two sides, thus solving the problem of easy slipping due to small friction of flat and smooth surface contact between the aprons and the rollers. The drafting component is stable in transmission, greatly reduces slipping, has remarkably increased friction on the same contact area, improves the stability of operation in the main drafting area, is conductive to giving full play to the advantages of fiber control by the aprons and elastic floating jaws, further ensures the uniformity of the yarns and improves the yarn quality.

Owner:张晓方

Flexible printed circuit board, inlet sheet using the same, RFID media, and method for producing the rfid media

InactiveCN101836512ASimplify the manufacturing processEasy to producePrinted circuit aspectsSynthetic resin layered productsElectricityWax

Disclosed is an FPC suitable for use in RFID media. Also disclosed are RFID media improved in production speed, rejection rate, electrical quality and product appearance, and a method for producing such RFID media. Specifically disclosed is a flexible printed circuit board which is produced by etching a laminate that is composed of a biaxially stretched polyester film having a thermal adhesive layer and a base layer formed by co-extrusion and a metal foil bonded to a surface of the biaxially stretched polyester film through the thermal adhesive layer. This flexible printed circuit board is characterized in that the base layer of the biaxially stretched polyester film has a melting point of 200-300 DEG C, and the thermal adhesive layer is made of a polyester resin containing a wax.

Owner:TOYOBO CO LTD

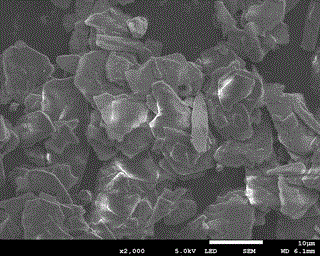

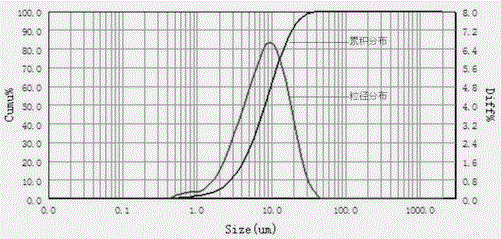

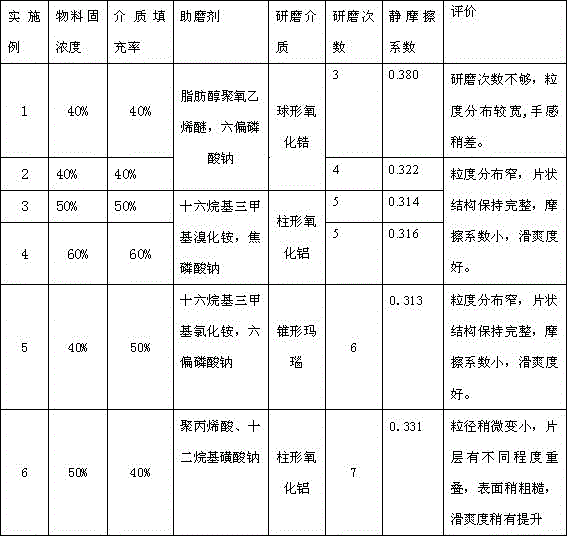

Method for preparing high-smoothness-level talcum powder

ActiveCN105967194AUniform particle sizeComplete sheet structureMagnesium silicatesChemical industryFiltration

The invention discloses a method for preparing a high-smoothness-level talcum powder, wherein a preparation process comprises the following steps: (1) carrying out crushing treatment on a raw material, and smashing the crushed raw material into a fine powder with a continuous crusher; (2) mixing evenly deionized water and an auxiliary agent, to prepare a dispersion liquid; (3) adding the fine powder material to water and a grinding aid, making the material solid concentration be 30%-50%, and stirring evenly; (4) adding a specific-strength grinding medium into a vertical grinding stripping machine, wherein the medium filling rate is 40 vol%-60 vol%; and (5) carrying out circular grinding of the slurry by the vertical grinding stripping machine for 4-5 times, then carrying out conditioning, grading, press filtration, drying, crushing and sieving of the slurry, and thus obtaining the 1250-mesh high-smoothness-level talcum powder. The friction coefficient of the talcum powder is reduced, and the smoothness level of the talcum powder is increased, so that the talcum powder can be better applied in the field of daily chemical industry.

Owner:江西联锴新材料有限公司

Bio-based high gloss vegan leather and manufacturing method thereof

ActiveCN110344276AImprove physical strengthNo pollution in the processPulp beating methodsDryer sectionFiberSlurry

Relating to the technical field of light industry, the invention discloses a bio-based high gloss vegan leather and a manufacturing method thereof. The method includes: subjecting a fiber slurry to pulping by a disc mill, then conveying the slurry to a flow slurry tank, and spraying the slurry to a paper machine net part through the flow slurry tank for dehydration and molding to obtain a vegan leather sheet, and conducting pressing and drying to obtain a vegan leather base; conveying the vegan leather base to a sizing machine for sizing, conducting drying and polishing, conveying the productto a coater for coating, firstly coating a lower coating agent, performing drying and polishing, and then coating an upper coating agent, and conducting drying and polishing to obtain a vegan leatheroriginal base; and conducting calendaring treatment on the vegan leather original base to obtain the bio-based high gloss vegan leather. The vegan leather adopts plant fiber, resin and other bio-basedmaterials as the raw materials, is prepared by wet-process molding, and has the characteristics of green and environmental protection, and high gloss; and with high surface gloss and smooth surface,the vegan leather can be applied to fashion bags, cover binding and other fields, and the products are beautiful and diverse.

Owner:SOUTH CHINA UNIV OF TECH

Special finishing agent for linen rayon fabric

InactiveCN107630350AImprove hydrophilicityGood flexibilityVegetal fibresMontmorilloniteNano zinc oxide

The invention discloses a special finishing agent for linen rayon fabric. The finishing agent is prepared from raw materials in parts by weight as follows: 10-25 parts of polydimethylsiloxane, 3-10 parts of carboxyl silicone oi, 2-10 parts of epoxy silicone oil, 10-25 parts of modified montmorillonite, 0.5-2 parts of nonylphenol polyoxyethylene ether, 1-5 parts of citric acid, 0.5-3 parts of soybean lecithin, 0.5-2.8 parts of sodium tripolyphosphate, 2-8 parts of quinine, 3-13 parts of chitosan, 5-10 parts of flos lonicerae extracts, 3-10 parts of aloe extracts, 2-9 parts of nano-zinc oxide sol, 0.3-1.5 parts of bamboo charcoal powder, 0.4-5 parts of cerium nitrate, 3-7 parts of polyhexamethylene biguanidine, 3-10 parts of a flame retardant and 500 parts of water. The special finishing agent for the linen rayon fabric can endow linen rayon with outstanding flame retardance and bacteria resistance when applied to finishing of the linen rayon, so that the fabric is soft and comfortable to wear.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

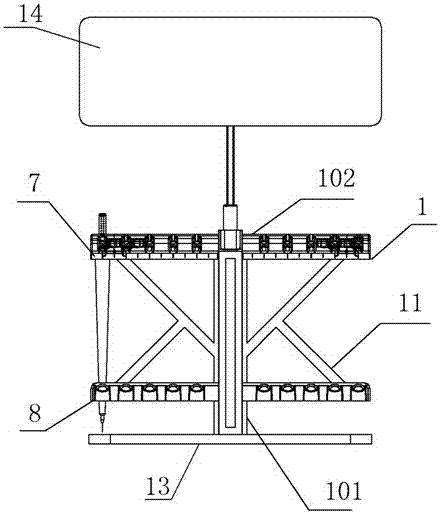

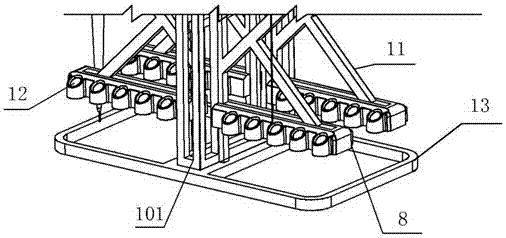

Smart umbrella stand for receiving sharing umbrella

InactiveCN107450399ACompact structureConvenient travelProgramme controlComputer controlActuatorEmbedded system

The invention discloses an intelligent umbrella stand for accommodating shared umbrellas, which includes an umbrella stand for placing umbrellas and a controller for controlling the umbrella stand to lock the umbrellas. The umbrella stand is provided with at least one To lock the umbrella handle of the sunny umbrella and the lock machine connected to the controller, each lock machine on the umbrella frame is provided with a micro switch connected to the controller; the controller is also connected to a communication module. The present invention has a simple and compact structure, and is the executive mechanism of the entire shared umbrella system. By arranging the devices of the present invention in a certain area, and then connecting each device with a remote main server to form a shared umbrella management leasing system, it can be used in a certain area. The rental service of shared umbrellas is provided in the area to facilitate people's travel.

Owner:成都源来来科技有限公司

Rehydrating personal lubricant and method of use

InactiveUS20050158337A1High degreeImprove slipperinessBiocideOrganic active ingredientsMedicineGRAPEFRUIT EXTRACT

A formulation is provided which acts as a rehydrating personal lubricant. A corresponding method of use is also disclosed. The formulation preferably includes guar gum and a water containing solvent. The formulation optionally but preferably additionally includes aloe vera, grapefruit seed extract, and vitamin E, as well as optionally other constituents. The formulation maintains and enhances its slipperiness over time when interacting with bodily fluids secreted by individuals utilizing the formulation during intimate contact such as sexual intercourse, such natural rehydration referred to as native rehydration.

Owner:FLEMING JASON D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com