Ultra-soft and fluffy lightweight filament nonwoven composite material and preparation method thereof

A composite material and non-woven technology, applied in the directions of non-woven fabrics, textiles and papermaking, can solve the problems of single structure, uniformity, softness and fluffy lines of structure and reinforcement methods, etc., to ensure three-dimensional structure, The effect of reducing friction coefficient and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

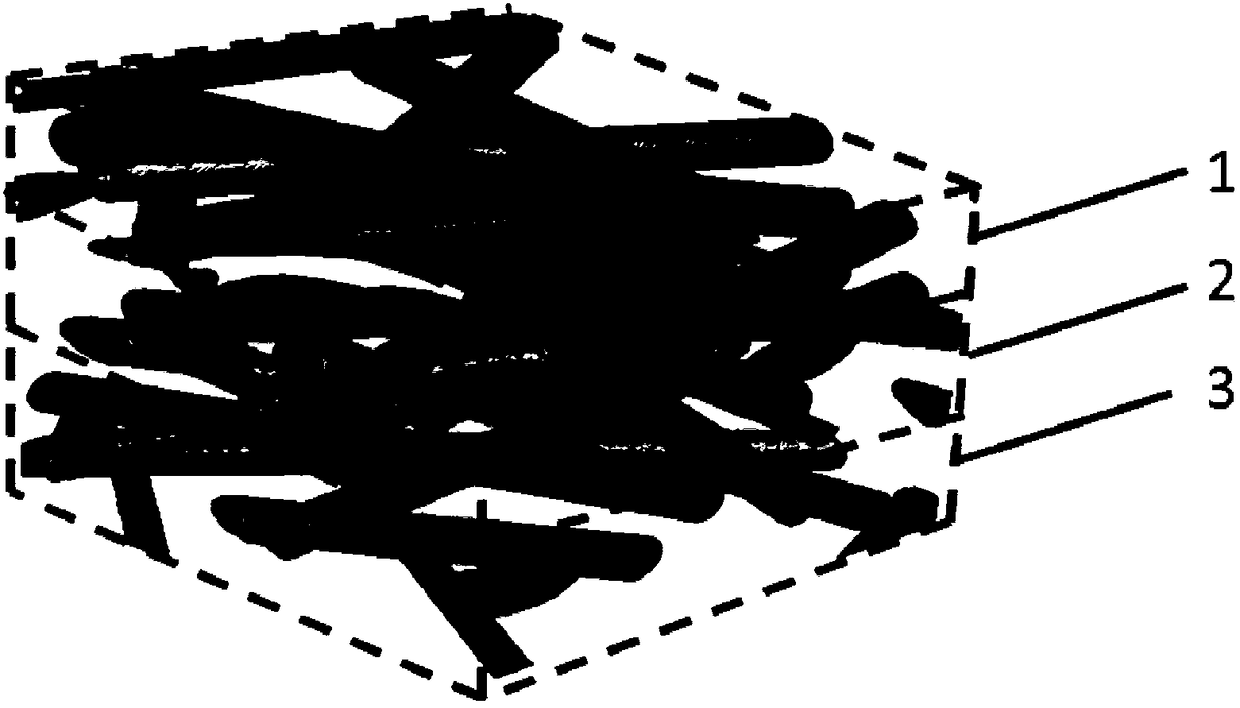

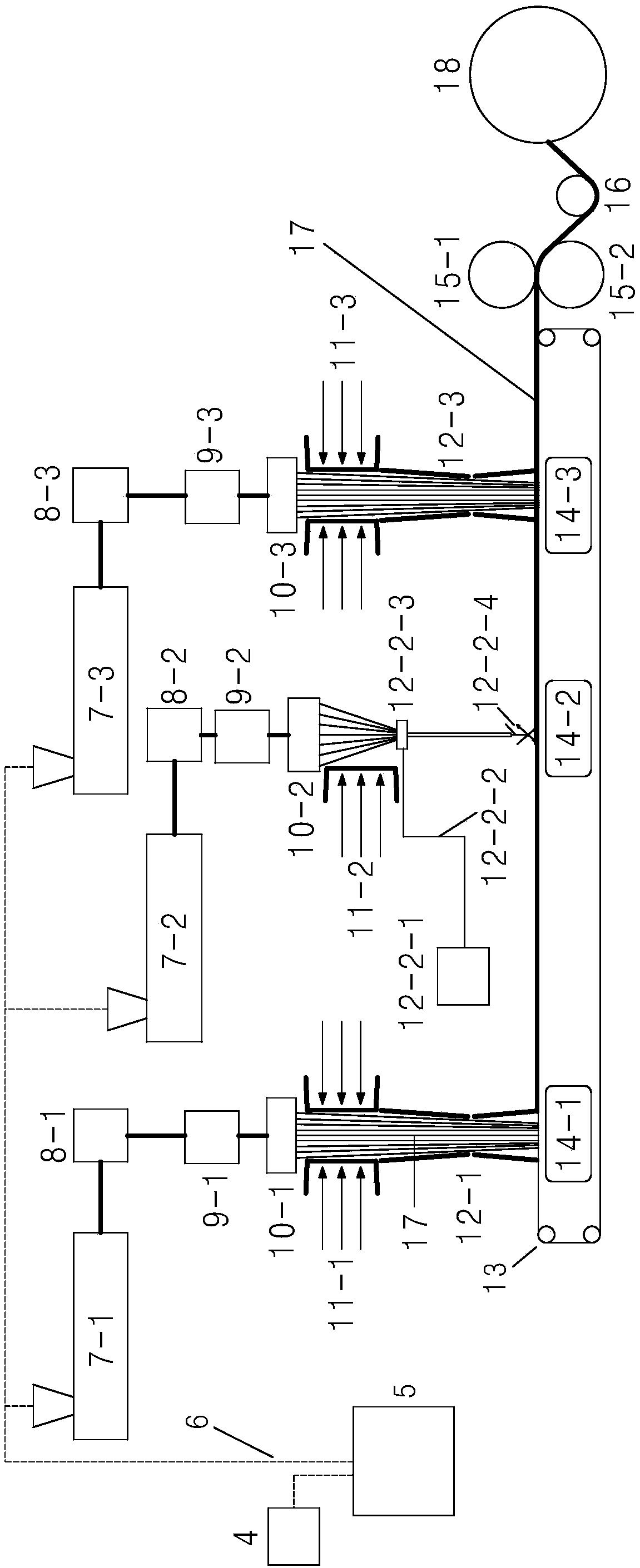

[0036] This example provides figure 1 The supersoft and fluffy lightweight filament nonwoven composite material shown, the nonwoven composite material includes a first concentric hollow filament layer 1, an eccentric hollow filament layer 2 and a second concentric hollow filament layer 3 , the three are shaped together by multiple sets of hot rolling; combined figure 2 ,Specific steps are as follows:

[0037] 1) Blending of raw materials; respectively take 70 parts of polypropylene isotactic copolymer, 15 parts of ultra-high molecular weight polyethylene, 1 part of dimethyl silicone oil, 2 parts of polyethylene wax and 12 parts of metallocene modified polypropylene copolymer, After being sent to the mixer 4 and stirred for 15 minutes, it was introduced into the material pool 5.

[0038] 2) Preparation of the first concentric hollow filament layer; the mixed raw material is fed into the screw extruder 7-1 of the first concentric hollow filament layer through the feeding pipe...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that the ratio of raw materials is different.

[0045] (1) Blending of raw materials; in parts by weight, respectively take 50 parts of polypropylene isotactic copolymer, 15 parts of ultra-high molecular weight polyethylene, 2 parts of dimethyl silicone oil, 3 parts of polyethylene wax and metallocene modified poly 30 parts of propylene copolymers were sent to the mixer 4 and stirred for 20 minutes, and then introduced into the feed tank 5 .

Embodiment 3

[0047] The difference between embodiment 3 and embodiment 2 is that the spinning temperature is different.

[0048] The first concentric hollow filament layer spinning die head 10-1 (setting temperature 245 ° C), the die head 10-2 of eccentric hollow structure (setting temperature 235 ° C), the second concentric hollow filament layer spinning Die 10-3 (setting temperature 245°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com