Low-alloy steel electrode with ultra-low hydrogen alkalinity and preparing method thereof

A low-alloy steel, ultra-low hydrogen technology, applied in welding equipment, metal processing equipment, welding media, etc., can solve the problems of crack growth increase, micro-cracks in the weld of spherical tanks, and reduce the service life of spherical tanks. Achieve the effects of clear molten pool, good electrode operation performance and excellent welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

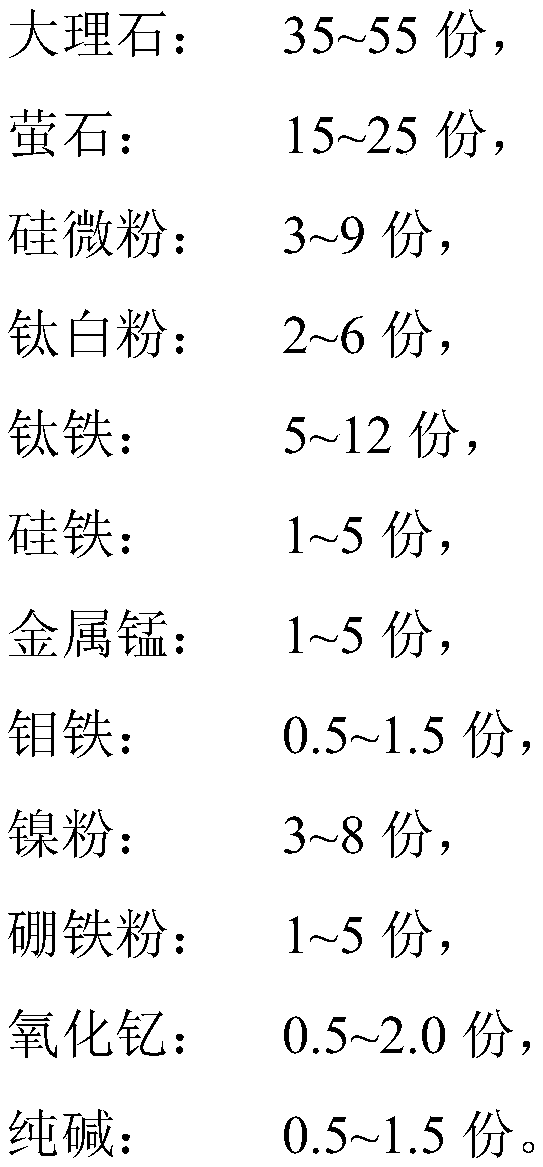

[0038] The mass fractions of each component of the coating are as follows: 40 parts of marble, 17 parts of fluorite, 3 parts of silicon micropowder, 3 parts of titanium dioxide, 5 parts of ferrosilicon, 2 parts of ferrosilicon, 3 parts of manganese metal, 0.7 part of ferromolybdenum, 5 parts 1 part nickel powder, 1.5 part boron iron powder, 0.5 part yttrium oxide, 0.6 part soda ash.

[0039] After mixing the raw materials of the coating in the above embodiment evenly, use a 40-mesh sieve to sieve to below 40 mesh. After the dry powder is stirred evenly, add pure sodium water glass accounting for 20% of the solid component mass content, and after stirring evenly, pass through a conventional electrode The production equipment press-coats it on the H08E welding core to prepare welding rods.

Embodiment 2

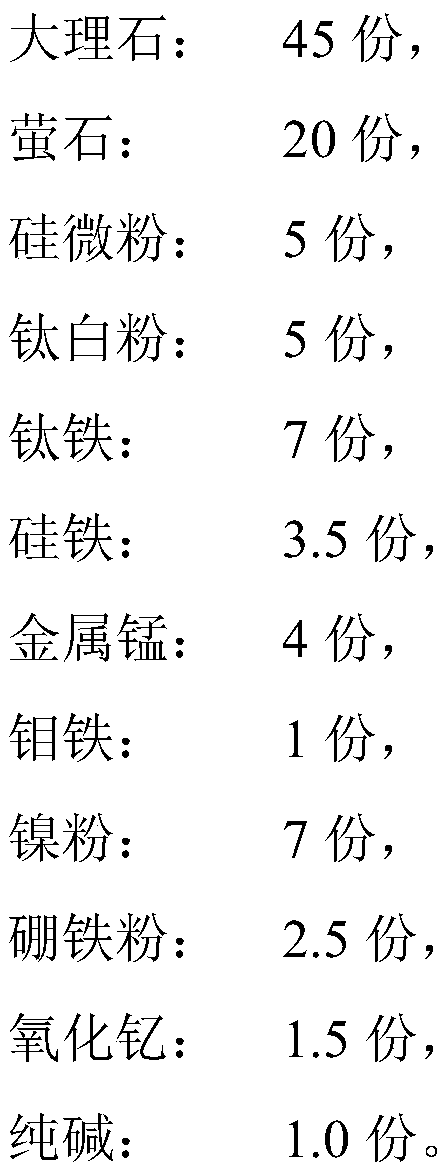

[0041] The mass fractions of each component of the coating are as follows: 45 parts of marble, 20 parts of fluorite, 5 parts of silicon micropowder, 5 parts of titanium dioxide, 7 parts of titanium iron, 3.5 parts of ferrosilicon, 4 parts of manganese metal, 1 part of ferromolybdenum, nickel 7 parts of powder, 2.5 parts of ferroboron powder, 1.5 parts of yttrium oxide, and 1 part of soda ash.

[0042] After mixing the raw materials of the coating in the above embodiment evenly, use a 40-mesh sieve to sieve to below 40 mesh. After the dry powder is stirred evenly, add pure sodium water glass accounting for 20% of the solid component mass content, and after stirring evenly, pass through a conventional electrode The production equipment press-coats it on the above-mentioned welding core to prepare welding rods.

Embodiment 3

[0044] The mass fraction of each component of the coating is as follows: 50 parts of marble, 23 parts of fluorite, 8 parts of silicon micropowder, 6 parts of titanium dioxide, 11 parts of titanium iron, 4.5 parts of ferrosilicon, 5 parts of manganese metal, 1.3 parts of molybdenum iron, nickel 8 parts of powder, 4 parts of ferroboron powder, 2 parts of yttrium oxide, and 1.2 parts of soda ash.

[0045] After mixing the raw materials of the coating in the above embodiment evenly, use a 40-mesh sieve to sieve to below 40 mesh. After the dry powder is stirred evenly, add pure sodium water glass accounting for 20% of the solid component mass content, and after stirring evenly, pass through a conventional electrode The production equipment press-coats it on the H08E welding core to prepare welding rods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com